Page 1

SC101

Sound level meter

User’s Manual

M_SC101_v0017_20100719_ENG

Page 2

Page 3

SC101

User’s Manual

ENGLISH

CONTENTS

1. GENERAL DESCRIPTION ..................................................................................................5

1.1 Operating modes and functions ......................................................................................5

1.2 Main features of the SC101 ............................................................................................6

1.3 Description of the SC101 ................................................................................................7

1.4 Screen and use of the keypad ........................................................................................9

2. OPERATING THE SC101..................................................................................................12

2.1 First steps .....................................................................................................................12

2.1.1 Equipment and documents .....................................................................................12

2.1.2 SC101 power supply...............................................................................................12

2.1.3 Connecting and disconnecting the preamplifier, using the extension cable and

outdoor kit ........................................................................................................................13

2.2 Starting a measurement................................................................................................15

2.2.1 Starting up the SC101 ............................................................................................15

2.2.2 Main menu of the SC101: Selecting applications and settings...............................16

2.2.3 Checking the SC101...............................................................................................17

2.3 Saturation......................................................................................................................18

2.4 Measuring with the sound level meter application ........................................................18

2.4.1 Starting a measurement .........................................................................................19

2.5 Measuring with the vehicle application..........................................................................20

2.5.1 Starting a measurement .........................................................................................20

2.5.2 Background noise measurement ............................................................................21

2.5.3 L

2.6 Measuring with the leisure and community application (correction by area).................22

2.6.1 Starting a measurement .........................................................................................22

measurement ................................................................................................21

AFmax

2.6.2 Background noise measurement (optional) ............................................................23

2.6.3 L

2.7 Measuring with the leisure and community application (correction by points) ..............25

2.7.1 Starting a measurement .........................................................................................25

2.7.2 Measurement without applying background noise correction.................................26

2.7.3 Measuring with background noise correction .........................................................27

2.8 Measuring with the occupational hazard application.....................................................28

2.8.1 Starting a measurement .........................................................................................28

2.8.2 Projection time ........................................................................................................29

and L’At measurement ........................................................................................24

At

1

Page 4

2.9 Measuring with the machinery application: sound pressure level.................................30

2.9.1 Starting a measurement .........................................................................................30

2.9.2 Background noise measurement ............................................................................31

2.9.3 Obtaining L

2.9.4 K

1A

and K

and L

pA

corrections............................................................................................32

3A

levels.................................................................................31

Cpeak

2.10 Measuring with the machinery application: sound power level ...................................33

2.10.1 Starting a measurement .......................................................................................33

2.10.2 Measuring the sound pressure level at several points..........................................34

2.10.3 Background noise measurement ..........................................................................34

2.10.4 K

1A

and K

corrections Surface area S.................................................................35

2A

2.11 Sensitivity setting ........................................................................................................36

2.12 Contrast setting...........................................................................................................37

2.13 Switching off the SC101.............................................................................................. 37

2.14 Tips and warnings.......................................................................................................37

2.15 Tips for taking measurements.....................................................................................38

3. VIEWING DATA ON A PC.................................................................................................38

4. TECHNICAL SPECIFICATIONS .......................................................................................39

4.1 Measurement range......................................................................................................39

4.2 Detector - Functions LF and LS......................................................................................41

4.3 Peak detector – Lpeak function.....................................................................................41

4.4 Averager – Lt function...................................................................................................41

4.5 Clock features ...............................................................................................................41

4.6 Frequency weighting.....................................................................................................42

4.7 Microphone ...................................................................................................................42

4.8 Directivity ......................................................................................................................44

4.9 Effect of the accessories on the microphone ................................................................44

4.10 Reference conditions ..................................................................................................45

4.11 Preheating time...........................................................................................................46

4.12 Influence of temperature .............................................................................................46

4.13 Influence of humidity ...................................................................................................46

4.14 Electromagnetic compatibility......................................................................................46

4.15 Influence of vibration...................................................................................................47

4.16 Batteries and external power supply...........................................................................47

4.17 Dimensions and weight...............................................................................................47

4.18 Preamplifier connector ................................................................................................47

4.19 Calibration...................................................................................................................48

4.20 Standards....................................................................................................................48

2

Page 5

SC101

User’s Manual

4.21 Notes...........................................................................................................................49

4.22 Accessories.................................................................................................................49

5. ANNEX A: Functions........................................................................................................50

5.1 Function summary chart................................................................................................50

5.1.1 Sound level meter application functions .................................................................50

5.1.2 Vehicle application functions ..................................................................................50

Functions measured............................................................................................................50

Grid functions......................................................................................................................50

5.1.3 Leisure and community application functions (area and points).............................51

Functions measured............................................................................................................51

Grid functions (area) ...........................................................................................................51

Grid functions (points).........................................................................................................51

Settable parameters............................................................................................................52

5.1.4 Occupational hazard application functions ............................................................. 52

Functions measured............................................................................................................52

Grid functions......................................................................................................................52

Settable parameters............................................................................................................52

5.1.5 Machinery application functions: sound pressure level ..........................................53

Functions measured............................................................................................................53

Grid functions......................................................................................................................53

Settable parameters............................................................................................................53

5.1.6 Machinery application functions: sound power level...............................................53

Functions measured............................................................................................................53

Form functions ....................................................................................................................54

Settable parameters............................................................................................................54

5.2 Function definition.........................................................................................................55

5.2.1 Sound pressure level with fast and slow time weighting.........................................55

5.2.2 Peak sound pressure level .....................................................................................55

5.2.3 Equivalent continuous sound pressure level ..........................................................55

5.2.4 Equivalent daily exposure level ..............................................................................56

3

Page 6

6. APPENDIX B: Vehicle noise ............................................................................................57

7. APPENDIX C: Leisure and community...........................................................................60

8. APPENDIX D: Occupational hazards..............................................................................61

9. APPENDIX E: Machinery; sound pressure level ...........................................................63

10. APPENDIX F: Machinery sound power level ...............................................................66

11. APPENDIX G: Grids........................................................................................................71

4

Page 7

SC101

User’s Manual

1. GENERAL DESCRIPTION

The SC101 is more than a mere sound measurement instrument. Not only does it allow the

necessary measurements to be taken, like other devices, it also guides the user through the

measurement process step-by-step. It is an effective and convenient device with

measurement protocols, offering the choice between conventional sound level meter

operation and measurements involving machinery, occupational hazards and others, aimed

at drawing up official reports in compliance with applicable regulations.

The SC101 is a class 1 integrating sound level meter in accordance with international

standard IEC 61672-1, its European counterpart EN 61672-1:2003 and its Spanish

counterpart UNE 61672-1:2005. Furthermore, it complies with standards IEC 60651 and

IEC 60804 type 1, as well as with American standards ANSI S1.4 and S1.43.

1.1 Operating modes and functions

The SC101 is suitable for various applications:

• The CONVENTIONAL SOUND LEVEL METER

application simultaneously measures the

following functions:

LAt, L

L

, L

A1”

Ct

C1”

Equivalent continuous sound pressure level of the measurement time

with A and C frequency weighting

Equivalent continuous sound pressure level, with consecutive integration

time of 1 second and A and C frequency weighting

L

Cpeak

LAF, LAS

Peak sound pressure level with C frequency weighting

Sound pressure level with ‘S’ and ‘F’ time averaging and maximum and

minimum values during measurement time with A frequency weighting.

LCF

* A definition of each of the measured functions can be found in appendix A.

The SC101 also has applications dedicated exclusively to providing a step-by-step guide

through the protocols for the purpose of performing the following acoustic evaluations:

C weighted sound pressure level with ‘F’ time averaging and its

maximum and minimum values during the measurement time.

• VEHICLES

: Determining the sound level (L

) generated by the exhaust system of

AFmax

motor vehicles: cars, public transport vehicles, goods vehicles, motorcycles, mopeds,

three-wheeled vehicles, all-terrain bikes and quads. Test with vehicle stopped in

accordance with Directives 70/157/EEC, 78/1015/EEC and 97/24/EC Chap. 9.

• LEISURE AND COMMUNITY (correction by area)

: Determining the emission and

immission sound levels of businesses and residents in accordance with the various

municipal bylaws in which the specified procedure consists of averaging the background

noise and the activity noise, in order to subsequently apply the background noise

correction.

• LEISURE AND COMMUNITY (correction by points)

: Determining the emission and

immission sound levels of businesses and residents in accordance with the various

municipal bylaws in which the specified procedure consists of measuring the background

noise and the activity noise in each of the points to be assessed, and corrected with its

corresponding background noise.

5

Page 8

• OCCUPATIONAL HAZARDS: Determining the sound levels (L

exposure in the workplace. In accordance with ISO 9612, determination based on tasks,

jobs or working days.

• MACHINERY – SOUND PRESSURE

by machines and equipment at the workplace. In accordance with Directives 2005/88/EC

and 2006/42/EC and ISO 11202.

• MACHINERY – SOUND POWER

sources. In accordance with Directives 2005/88/EC and 2006/42/EC and ISO 3746.

: Determining the noise levels (LpA, L

: Determining the sound power level (LWA) of noise

EX,8h

, L

) of noise

Cpeak

Cpeak

) emitted

1.2 Main features of the SC101

The SC101 is the first sound level meter designed to meet the needs of its users; a userfriendly sound level meter, which can perform acoustic measurements in a quick, convenient

and straightforward manner.

The SC101 includes the following main features:

• The SC101 is a sound level meter with measurement protocols: it includes applications for

guiding the user step-by-step through the measurement protocols (measurements, tests

and calculations) required to obtain the end result on site. It can also be used as a

conventional sound level meter.

• The SC101 has a menu structure with visual, intuitive options

need to configure the language, since the icons are easy to identify and recognise.

• The membrane keypad of the SC101 is designed to be completely flat, to avoid affecting

the excellent acoustic response rate of the device. Moreover, it has a single on/off button

and a simple interface with three soft-key buttons

• The large, high-resolution 3.2” graphic display

according to each application, as well as the partial and final results. Throughout the

measurement process, the values of the measured functions fill in the boxes on the grid

while simultaneously calculating the partial results and the parameters to perform the

tests, ultimately presenting the final results.

• The SC101 has a single measurement range

starting the measurement, and it is therefore independent from the type of sound event to

be measured.

• The SC101 simultaneously

• The SC101 includes the C-130 / C-250 microphone. This microphone

be detached and separated from the SC101 using the CN003, CN010 or CN030

extension cables (according to the length). It can also be used with the TK1000 and

TK200 outdoor kits.

• The SC101 has a USB port for real-time transmission to a PC

guaranteeing its availability in electronic format for use with any application or for postprocessing. It also includes commands for starting and stopping measurements, and it

even offers the possibility of switching the equipment on automatically via the USB port.

This ensures the SC101 is the ideal device for use as a noise measurement terminal. To

implement any of these options, contact an official

• The SC101 has a sensitivity adjustment system with adjustment traceability

. This does away with the

, guaranteeing easy operation.

shows the measurement functions

. No scale adjustments are required before

measures all the functions.

is removable: it can

of all the measured data,

dealer.

.

,

6

Page 9

SC101

User’s Manual

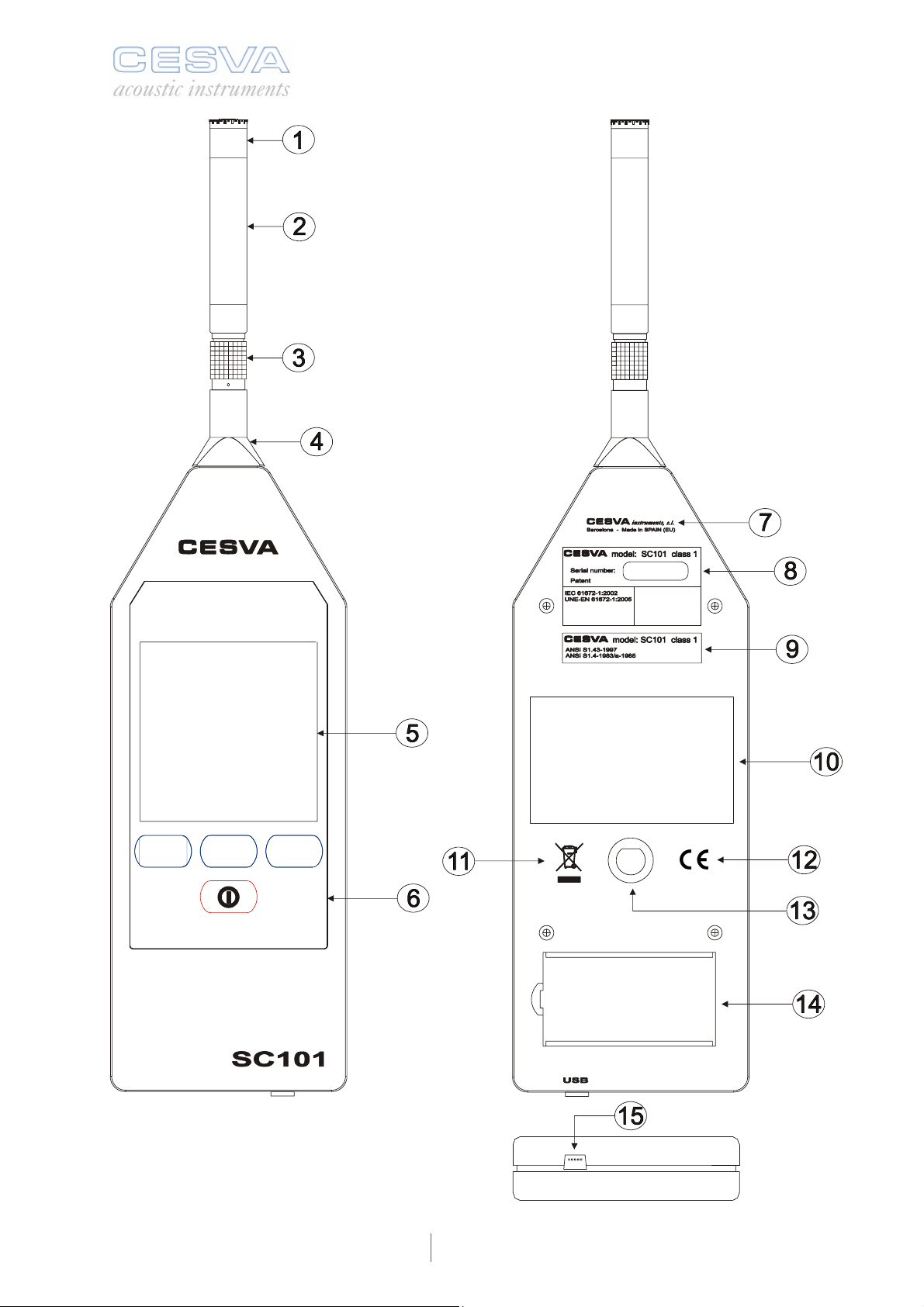

1.3 Description of the SC101

The following figure describes the most important parts of the SC101:

1. ½’’ condenser microphone. The SC101 can operate with microphone model C-130

(polarised to 200 V) + the PA-13 preamplifier or with microphone model C-250 (prepolarised) + the PA-14 preamplifier. Both these models are precision condenser

microphones. The SC101 is a class 1 sound level meter with both microphones.

Preamplifier. The SC101 includes the PA-13 removable preamplifier (for C-130) or

2.

the PA-14 (for C-250), which connects via the LEMO connector (3).

LEMO connector of the preamplifier. Male LEMO connector of the preamplifier.

3.

LEMO connector of the sound level meter. Female LEMO connector of the SC101

4.

sound level meter.

Screen. Graphic LCD screen.

5.

Membrane keypad. Extra-flat keypad designed to reduce the reflections reaching the

6.

microphone from the case of the sound level meter.

Manufacturer’s information.

7.

8. Name plate in accordance with IEC. This area contains details such as make,

model, class and serial number of the sound level meter, as well as all the

international regulations it fulfils as class 1 and its metrology marking.

Name plate in accordance with ANSI.

9.

Space reserved for the periodic inspection label. Space reserved for a label

10.

showing that the sound level meter complies with periodic inspection requirements

(Order ITC/2845/2007).

11. WEEE mark. Symbol indicating separate collection of electrical and electronic

devices.

CE mark. European conformity mark.

12.

Tripod support. Embedded tripod support, with 14” W standard thread. (TR-40 and

13.

TR050).

Battery cover. Cover for the battery compartment, only to be removed when

14.

changing the batteries.

USB connector. USB Mini-B connector for USB 1.1 full-speed bi-directional digital

15.

communication.

7

Page 10

8

Page 11

SC101

User’s Manual

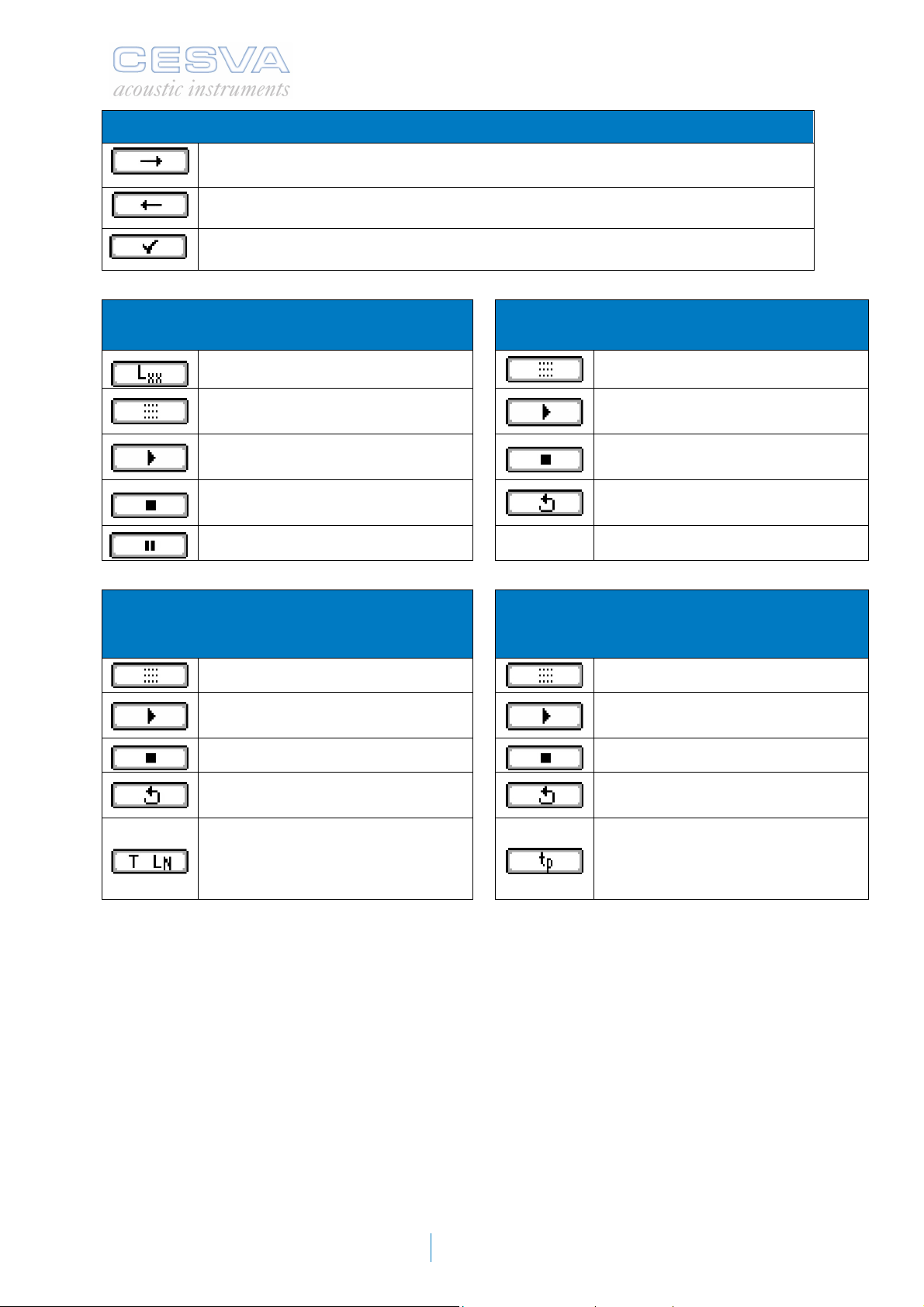

1.4 Screen and use of the keypad

The SC101 has a main menu with icons that provide access to the various applications and

settings of the device.

The top left corner of the screen always shows the active application or setting:

Main menu

Sound level meter application

Vehicle application

Leisure and community application (area)

Leisure and community application (points)

Occupational hazard application

Machinery application: sound pressure

level

Machinery application: sound power level

Sensitivity setting

Contrast setting

Next to the above indications is a battery-shaped

symbol which shows the current charge level of the

batteries (see section 2.1.2).

Inside each application, the top right corner of the

screen shows information on the elapsed

measurement time and its current status:

• Running

• Stopped

• Or paused

The keypad of the SC101 has an on/off button

key buttons. The function of these buttons varies according to the indications at the bottom of

the screen, directly above each of them.

The following tables describe the meaning of the indications used for the buttons of the

SC101 in the various applications:

9

and three flexibly programmable soft-

Page 12

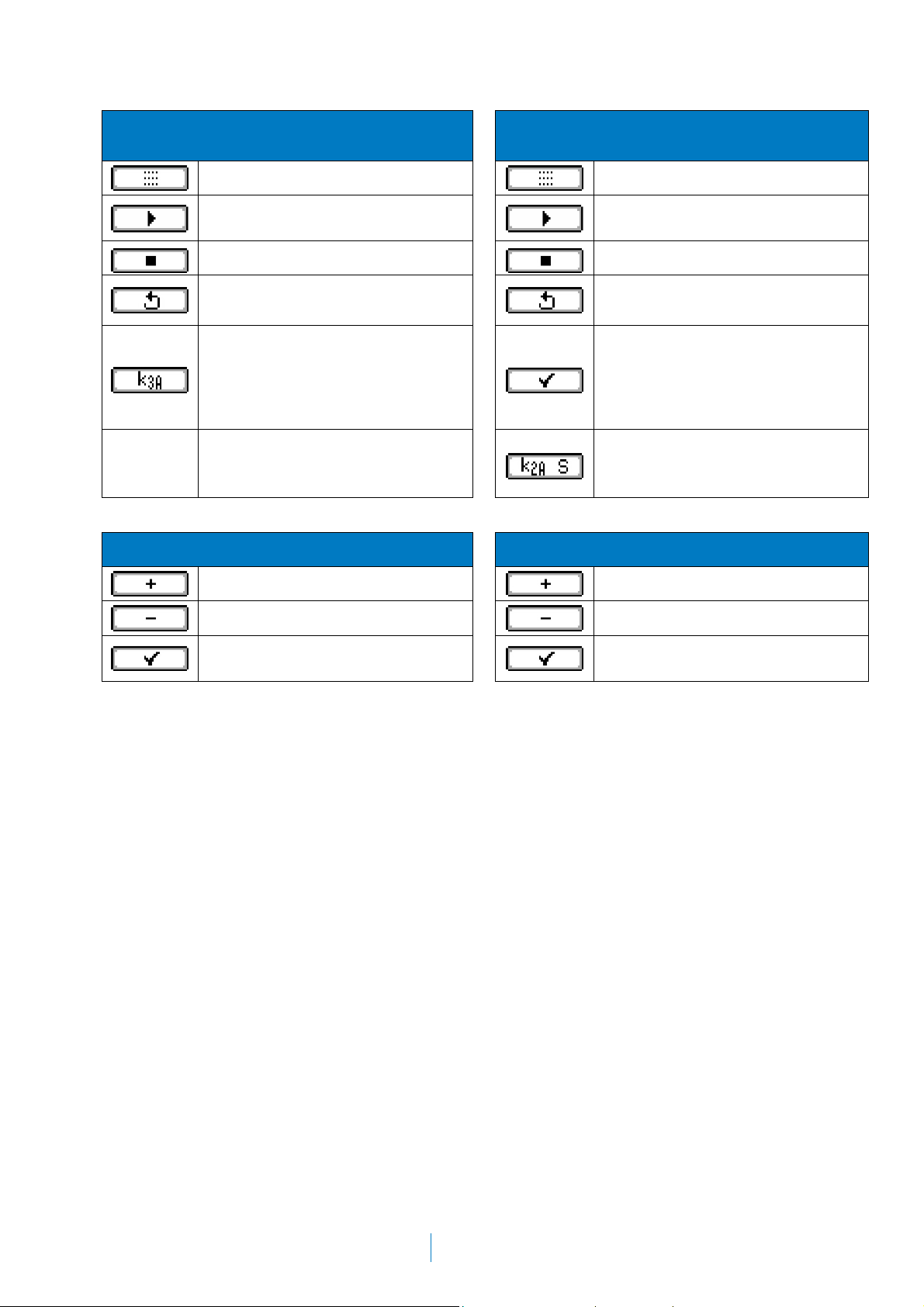

MAIN MENU BUTTONS

Button for moving to the right, next icon, within the menu

Button for moving to the left, previous icon, within the menu

Button for accessing the application or setting corresponding to the selected icon

SOUND LEVEL METER APPLICATION

BUTTONS

Button for changing the functions

viewed on the screen

Button for returning to the main menu

Button for starting or resuming the

measurement

Button for ending the measurement

Button for pausing the measurement

LEISURE AND COMMUNITY APPLICATION

BUTTONS (CORRECTION BY AREA AND BY

POINTS)

Button for returning to the main menu

Button for starting or resuming the

measurement

Button for ending the measurement

Button for cancelling the

measurement

VEHICLE APPLICATION BUTTONS

Button for returning to the main menu

Button for starting or resuming the

measurement

Button for ending the measurement

Button for cancelling the

measurement

OCCUPATIONAL HAZARD APPLICATION

BUTTONS

Button for returning to the main menu

Button for starting or resuming the

measurement

Button for ending the measurement

Button for cancelling the

measurement

Button for entering the measurement

time and indicating whether a

background noise measurement is

required

Button for entering the projection

time

10

Page 13

SC101

User’s Manual

MACHINERY SOUND PRESSURE APPLICATION

BUTTONS

Button for returning to the main menu

Button for starting or resuming the

measurement

Button for ending the measurement

Button for cancelling the

measurement

Button for entering the environmental

correction

SENSITIVITY SETTING BUTTONS

MACHINERY SOUND POWER APPLICATION

BUTTONS

CONTRAST SETTING BUTTONS

Button for returning to the main menu

Button for starting or resuming the

measurement

Button for ending the measurement

Button for cancelling the

measurement

Button for ending the sound pressure

measurements with the machine

switched on and starting the

background noise measurements

with the machine switched off

Button for entering the test acoustic

environment correction and the

measurement surface area

Button for increasing the sensitivity

Button for reducing the sensitivity

Button for confirming the sensitivity

setting

Button for increasing the contrast

Button for reducing the contrast

Button for confirming the contrast

setting

11

Page 14

2. OPERATING THE SC101

This chapter contains all the information required for setting, adjusting and performing

measurements using the SC101.

2.1 First steps

This section contains the steps to be performed before starting to use the SC101.

2.1.1 Equipment and documents

The first step is to check the equipment and documents supplied with the SC101:

Equipment included:

• SC101 sound level meter

• Protective case

• Windscreen

• Two 1.5 V alkaline batteries

Documents included:

• User’s Manual

• Warranty

If any of these elements are missing, please contact your official

distributor.

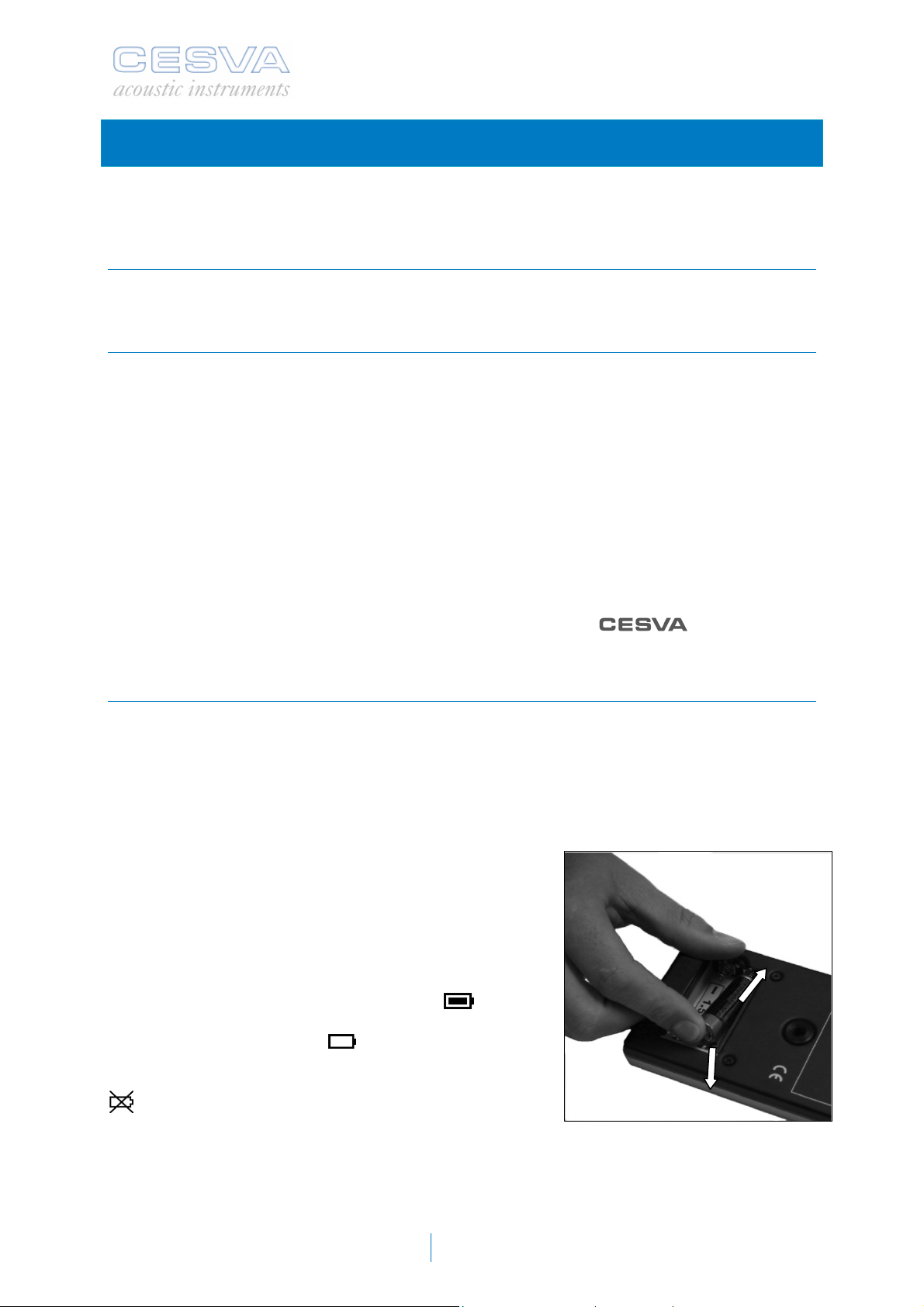

2.1.2 SC101 power supply

The first operation to be performed, before switching on the SC101, is to power it.

The SC101 sound level meter uses two AA (LR6) 1.5 V alkaline batteries, or else can be

powered via the USB port [15]. If both systems are used at the same time (batteries + USB

port), the SC101 chooses whichever one offers the highest voltage.

CESVA PB015 rechargeable batteries can also be used.

To install the batteries, remove the battery compartment

cover [ 14] located on the rear of the SC101. Place the

two batteries as shown in the battery compartment in the

drawing. To do this, press the negative pole of the

battery against the spring and push the battery in so that

the positive pole (raised) presses against the smooth

metal contact.

When the battery is fully charged, the symbol

appears on the screen. The symbol gradually empties as

the battery loses its charge:

of the battery is too low for the SC101 to continue

operating correctly, a crossed-out empty battery symbol

will appear at the centre of the screen for two

seconds, before switching off. The batteries must be

replaced.

1

. When the charge level

2

12

Page 15

SC101

User’s Manual

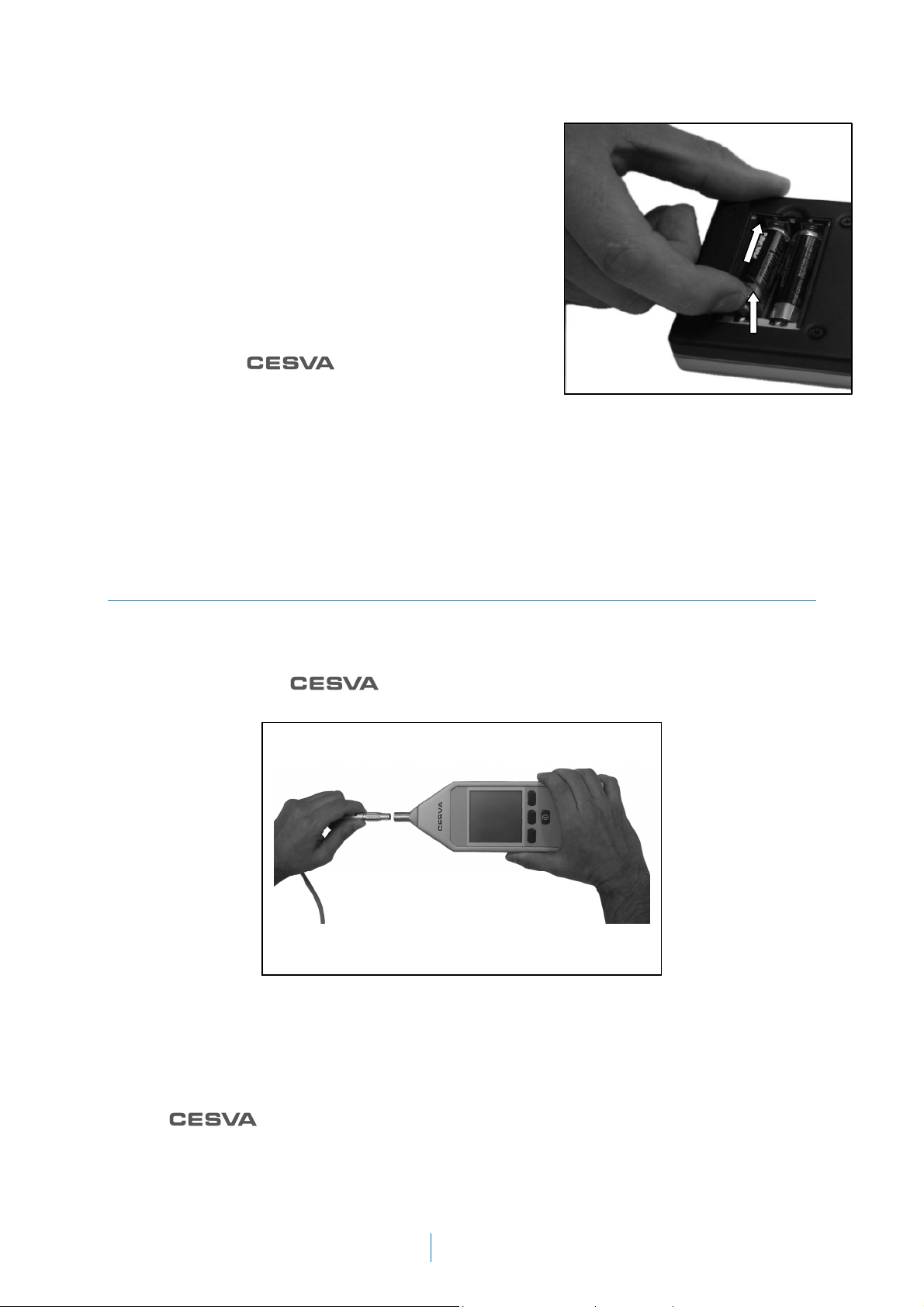

The device must be switched off before replacing the

batteries. To remove the batteries from the SC101, open

the battery compartment and press the battery against

the spring while pulling it outwards, holding the battery

by its positive pole as shown in the figure.

The SC101 can also be powered via the USB Mini-B

port. For this, use the CN1US cable to connect the USB

port of the SC101 [15] to a USB port on a PC. When

connected this way, the screen will show “USB” in place

of the battery symbol.

NOTE: to enable automatic switch-on via USB port,

contact an official

TIPS:

If the SC101 is likely to be unused for an extended period, remove the batteries from the

SC101 to avoid potential damage caused by the batteries leaking.

dealer.

1

1

1

2

2

2

1

2

It is advisable always to carry new spare batteries

.

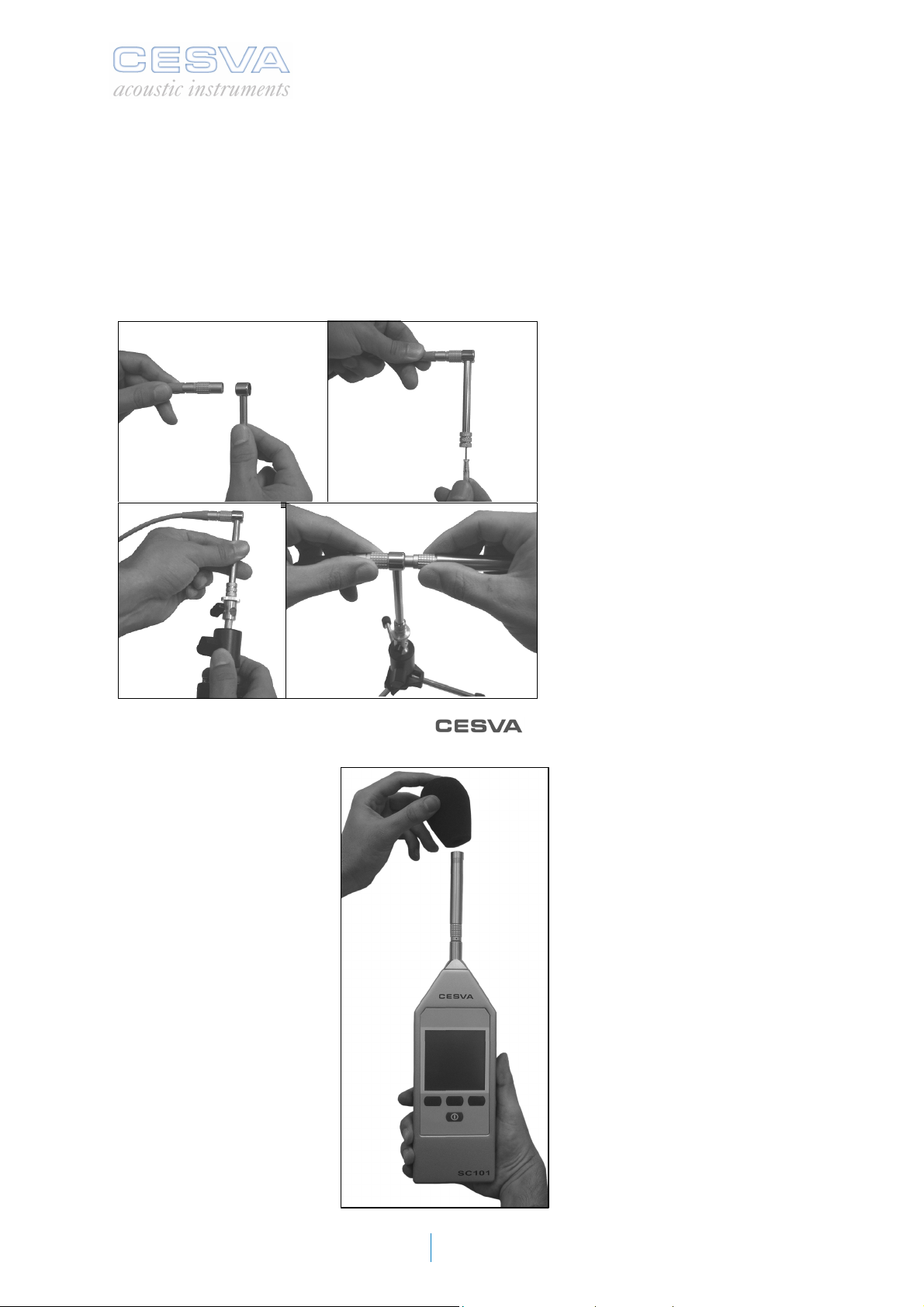

2.1.3 Connecting and disconnecting the preamplifier, using the extension

cable and outdoor kit

The microphone of the SC101 is completely removable. This allows the microphone to be

separated from the sound level meter and the operator. By doing so, the SC101 can be

operated at a distance from the measurement point, avoiding potential interference. To

perform this operation,

metres) or CN030 (30 metres) must be used.

extension cable models CN003 (3 metres), CN010 (10

WARNING! : It is important to make sure the sound level meter is switched off before

attaching or detaching the microphone.

The preamplifier + microphone form an indivisible unit. The microphone is screwed into the

preamplifier. Do not unscrew the microphone from the preamplifier unless strictly necessary;

the microphone might be damaged during handling.

NOTE:

which will be sufficient grounds for voiding the warranty.

To separate the preamplifier from the sound level meter, pull on the preamplifier connector

[

3] as shown in the figure. Do not pull on the preamplifier [ 2].

accepts no responsibility for any operations by unauthorised personnel,

13

Page 16

To reconnect the preamplifier to the sound level meter, reinsert the male LEMO connector of

the preamplifier [

3] into the female LEMO connector of the sound level meter [ 4] by hand,

until they click together. The red dot on the preamplifier connector must be aligned with the

red dot on the sound level meter connector.

WARNING! : Do not attempt to insert or remove the preamplifier by screwing the connector

[

3] as this will damage the sound level meter.

NOTE: The cables do not interfere with the measurement frequency band. It is not necessary

to recalibrate the device when using the extension cables.

With an extension cable, the TR001 adapter can be used to

connect the preamplifier +

microphone to the TR-40 or TR-50

tripod. To do so, follow the steps

below:

1) Insert the female LEMO

1 2

connector of the extension

cable through the TR-001

adapter.

2) Fasten it with the screwdriver.

3) Place the adapter on the

4) Connect the preamplifier.

3 4

To avoid the effects of wind noise, the

attached to the microphone, as shown in the following figure.

windscreen, model PVM-05 can be

tripod.

14

Page 17

SC101

User’s Manual

The measurement equipment can be completed with the outdoor kit, model

TK1000 or TK200, recommended for protecting the preamplifier + microphone unit from

adverse weather phenomena such as moderate rain and wind, birds, insects, humidity, etc.

The outdoor kits include a windscreen, rain protection, bird protection and a dehumidifier.

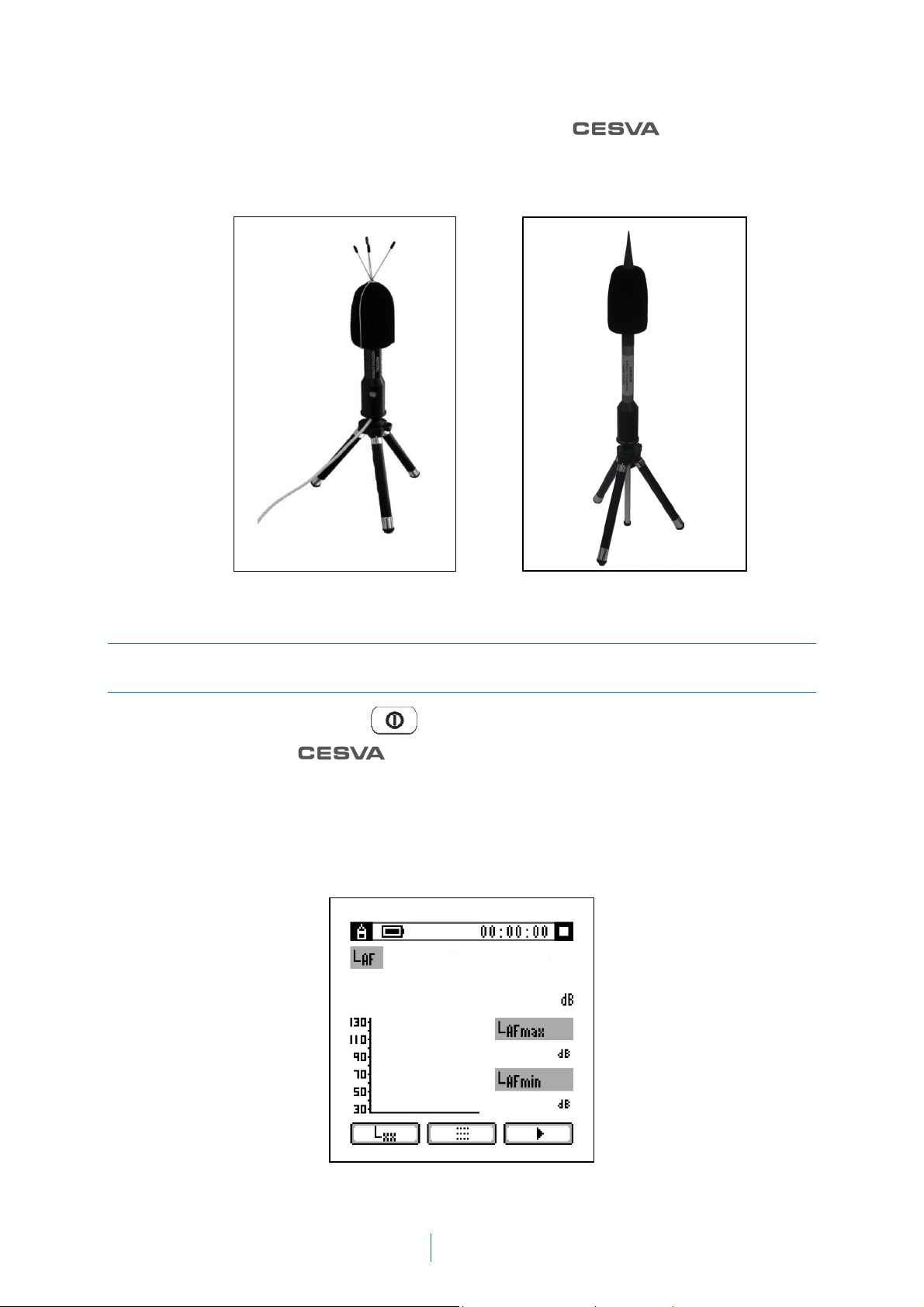

TK1000 TK200

2.2 Starting a measurement

2.2.1 Starting up the SC101

To switch on the SC101 press the button.

The screen shows the logo next to the model number: SC101. After a few

seconds, it displays the screen of the last application used. If the SC101 is being used for the

first time or no applications were active when it was last switched off, the main menu

appears.

is not ready to begin measuring. No measurements can be started until this symbol

disappears (approximately 10 seconds). It is possible, however, during this interval to access

or move around the main menu.

At the same time, an hourglass symbol appears, to show that the sound level meter

If the SC101 does not switch on, check its power supply.

15

Page 18

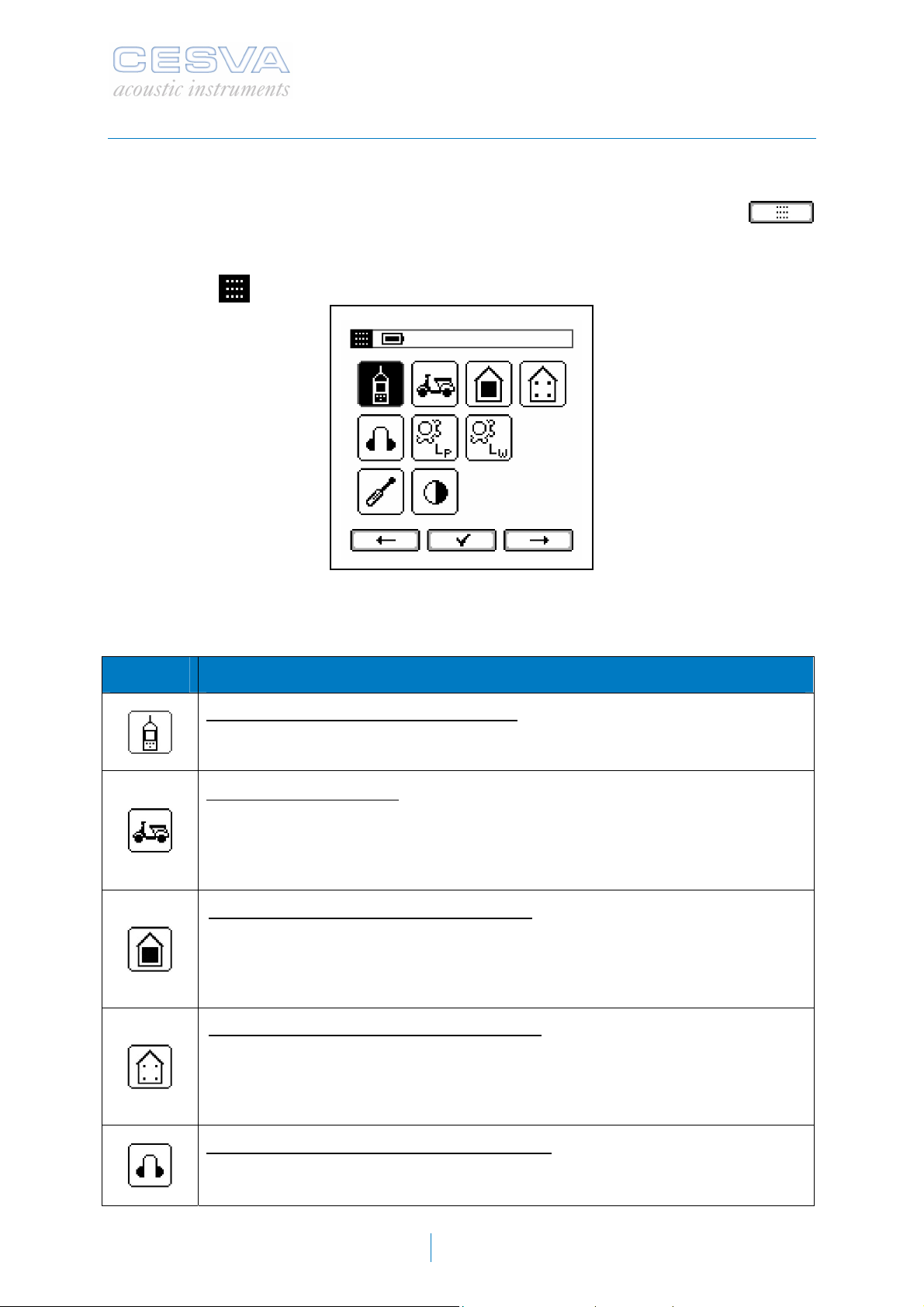

2.2.2 Main menu of the SC101: Selecting applications and settings

Once the sound level meter is switched on, it displays the main menu or the screen of the

last application used.

If the SC101 does not display the main menu, it can be accessed by pressing the

button.

When the SC101 is in the main menu, the following indication appears in the top left corner

of the screen (

).

The main menu shows various icons corresponding to applications or settings of the sound

level meter. These icons are as follows:

ICON APPLICATION or SETTING

SOUND LEVEL METER APPLICATION: Generic application for determining

sound levels. It can be adjusted to comply with a large number of regulations. It

measures all the functions simultaneously.

VEHICLE APPLICATION: Application for determining the sound level (L

generated by the exhaust system of motor vehicles: cars, public transport

vehicles, goods vehicles, motorcycles, mopeds, three-wheeled vehicles, allterrain bikes and quads. Test with vehicle stopped in accordance with

Directives 70/157/EEC, 78/1015/EEC and 97/24/EC Chap. 9.

LEISURE AND COMMUNITY (AREA): Determining the emission and

immission sound levels of businesses and residents in accordance with

various municipal bylaws in which the specified procedure consists of

averaging the background noise and the activity noise, in order to

subsequently apply the background noise correction.

LEISURE AND COMMUNITY (POINTS):

immission sound levels of businesses and residents in accordance with the

various municipal bylaws in which the specified procedure consists of

measuring the background noise and the activity noise in each of the points to

be assessed, and corrected with its corresponding background noise.

Determining the emission and

AFmax

)

OCCUPATIONAL HAZARDS APPLICATION: Application for determining the

sound levels (

with ISO 9612, determination based on tasks, jobs or working days.

L

EX,8h

, L

) of noise exposure in the workplace. In accordance

Cpeak

16

Page 19

SC101

User’s Manual

MACHINERY – SOUND PRESSURE APPLICATION: Application for

determining the noise levels (

in the workplace. In accordance with Directives 2005/88/EC and 2006/42/EC

and ISO 11202.

MACHINERY – SOUND POWER APPLICATION: Application for determining

the sound power level (

2005/88/EC and 2006/42/EC and ISO 3746.

SENSITIVITY SETTING: SC101 sensitivity setting.

CONTRAST SETTING: Screen contrast setting.

L

, L

pA

L

) of noise sources. In accordance with Directives

WA

) emitted by machines and equipment

Cpeak

Select the required application or setting using the

and buttons and press

to confirm.

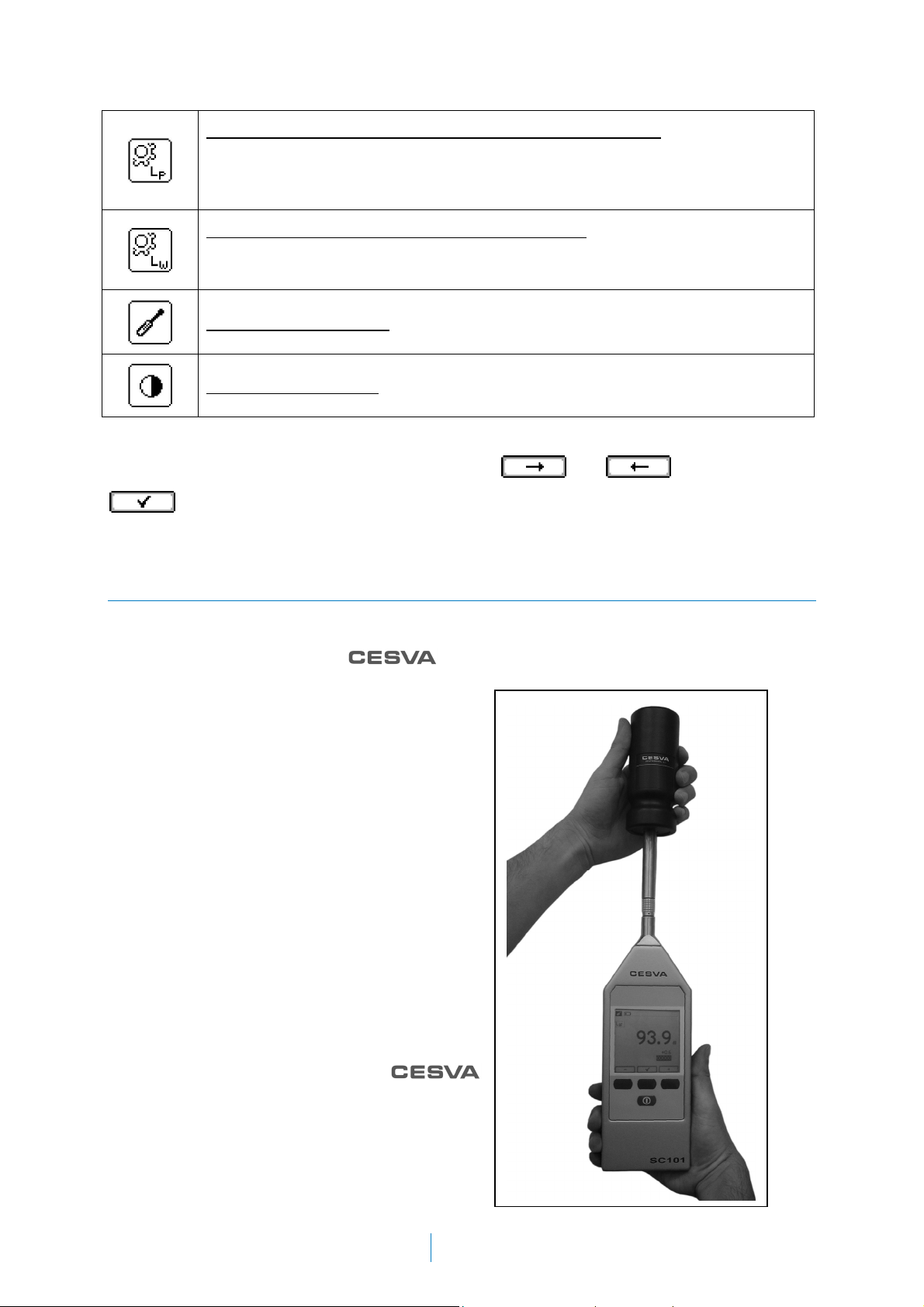

2.2.3 Checking the SC101

It is advisable to check the SC101 before and after taking a measurement.

To check the SC101, use the

steps below:

1) Place the SC101 in the calibrator,

inserting the microphone in the

calibration cavity. Make sure it enters the

cavity fully in a position parallel to the

calibrator axis (see figure). There may be

a certain amount of resistance, since the

calibrator fits onto the sound level meter

tightly. Insert the SC101 gently to avoid

damaging the microphone.

Start up the calibrator and check the

2)

battery status. The LED indicator must

remain lit throughout the entire calibration

process (see the calibrator manual). The

calibrator generates a 94 dB tone at 1

kHz.

sound calibrator, model CB006, and follow the

Apply the free-field pressure corrections

3)

of the microphone at 1 kHz. The free-field

pressure correction of the

C-130 / C-250 microphone at 1 kHz is -

0.1 dB. In other words, the SC101 must

be set to 93.9 dB.

17

Page 20

4) Go to the main menu of the SC101 and use the arrow keys to select the sensitivity

setting icon

5) Check that the value displayed at the centre of the screen (large digits) matches the

value of 94.0 dB, corrected by the relevant corrections (93.9 dB).

If the reading value is more than ± 0.3 dB off the calculated value, the sensitivity of the sound

level meter needs to be adjusted. This adjustment system has a tracing system to keep a

control of the times this adjustment has been made (see section 2.11). If this is not the case,

the sound level meter is measuring correctly and the sensitivity of the SC101 does not need

to be readjusted.

To return to the main menu, press the button.

IMPORTANT NOTE: The sensitivity of the sound level meter should only be adjusted by

authorised, technically competent personnel. Readjusting the sensitivity can lead to a loss of

device calibration traceability.

. Access it using the button.

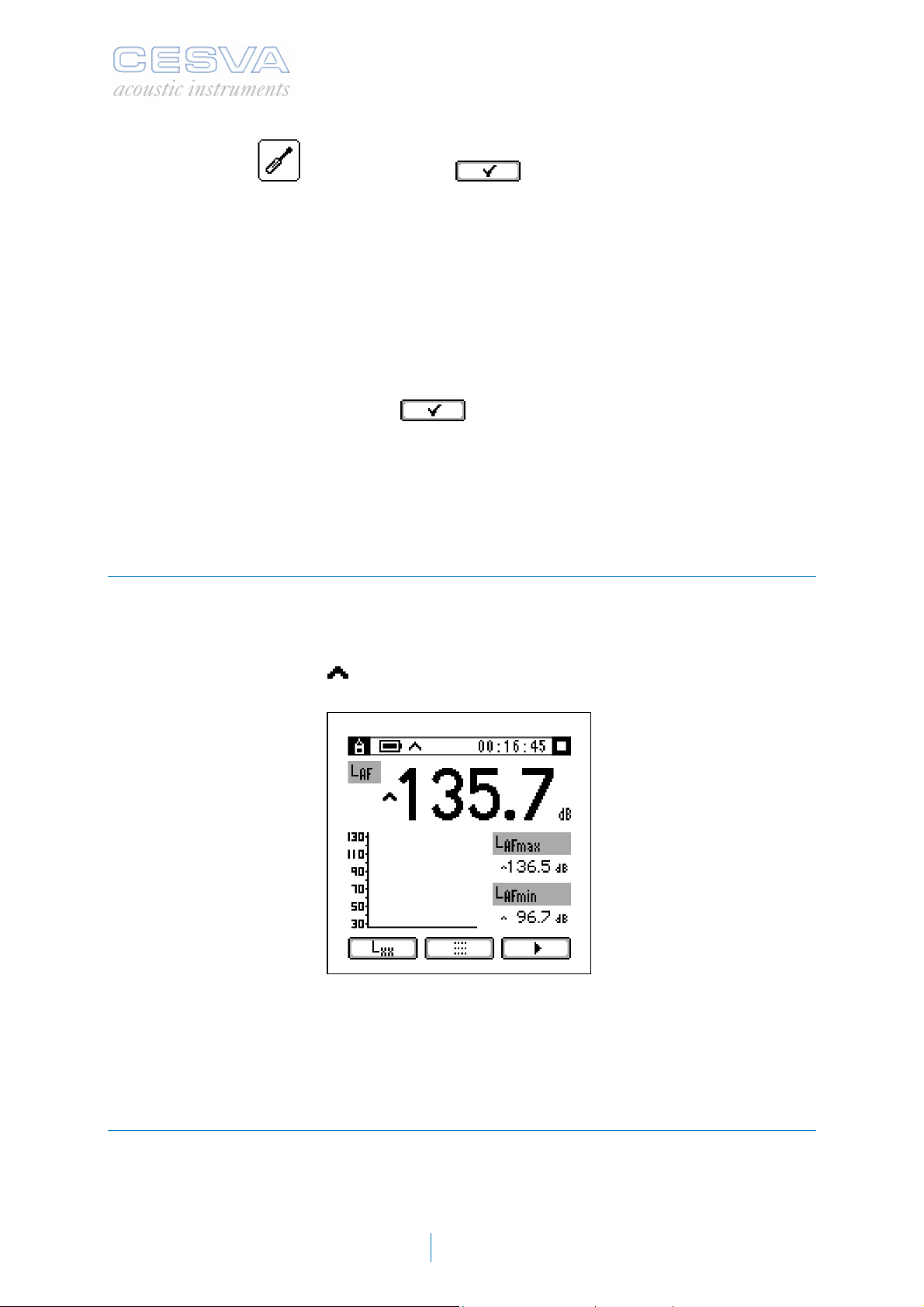

2.3 Saturation

The SC101 has a saturation indicator for each function. If saturation occurs during the

measurement, the ^ sign will be added in front of the value of the function affected.

Whenever a function registers saturation, its measurement is incorrect.

When saturation occurs, the indication appears in the top left corner of the screen.

If the saturation indicator appears during the measurement, the SC101 will not allow the

measured values to be validated and it will not be possible to move on to the next

measurement phase (except in the conventional sound level meter application, which does

not have different measurement phases).

2.4 Measuring with the sound level meter application

This application aims to make the noise measurement process easier for the user. It provides

a graphic and numerical follow-up of the temporal development of the sound event. For the

user’s convenience, three functions are displayed simultaneously, and the functions

displayed can be changed during the measurement process as required.

18

Page 21

SC101

User’s Manual

The sound level meter application is ideal for taking measurements of overall sound pressure

levels, with both instant and averaged values based on integration (equivalent level). The

SC101 measures all the functions at once.

With this application, measurements can be taken to comply with a broad range of

regulations.

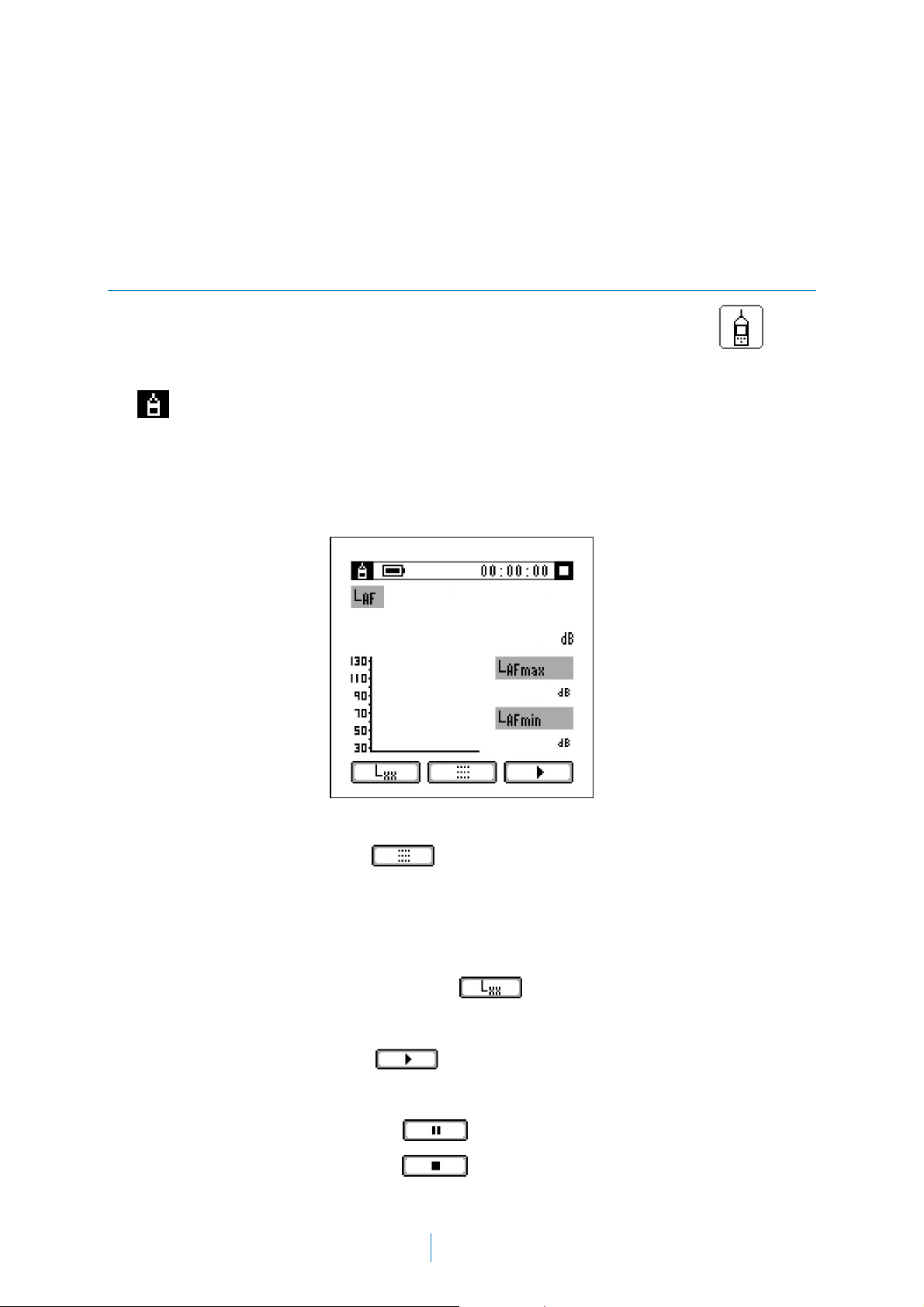

2.4.1 Starting a measurement

From the main menu, the sound level meter application can be accessed via the icon.

The following appears at the top of the screen:

o

o Power indicator (see

o Clock (00:00:00): Counts the measurement time elapsed.

o Measurement status indicator (Stop, Play, Pause).

To return to the main menu, press

: Identifies the application.

2.1.2).

.

The start screen of this application shows three functions in numerical format and the main

function in graphic format.

This screen enables the user to:

o Change the functions displayed, using the

o Perform a measurement.

To start a measurement, press the

Once the measurement has started, it is possible to:

o Pause the measurement using the

o End the measurement by pressing

button.

button.

19

button

Page 22

To resume a paused measurement, press . The clock on the screen stops while the

measurement is paused.

2.5 Measuring with the vehicle application

This application aims to make it easier for the user to take measurements of the sound level

generated by motor vehicle exhaust systems.

The application performs, step-by-step, the measurement process to be followed when

assessing the noise produced by motor vehicles, in accordance with Directives 70/157/EEC,

78/1015/EEC and 97/24/EC Chap. 9. (see APPENDIX B: Vehicle noise).

This is the ideal solution for roadworthiness testing centres. It also checks the values

obtained during the measurement in real time. This feature allows the user to make decisions

on the spot.

2.5.1 Starting a measurement

From the main menu, the vehicle application can be accessed via the icon.

The following appears at the top of the screen:

o

o Power indicator (see

o Clock (00:00:00): Counts the measurement time elapsed.

o Measurement status indicator (Stop, Play, Pause).

To return to the main menu, press

: Identifies the application.

2.1.2).

.

20

Page 23

SC101

User’s Manual

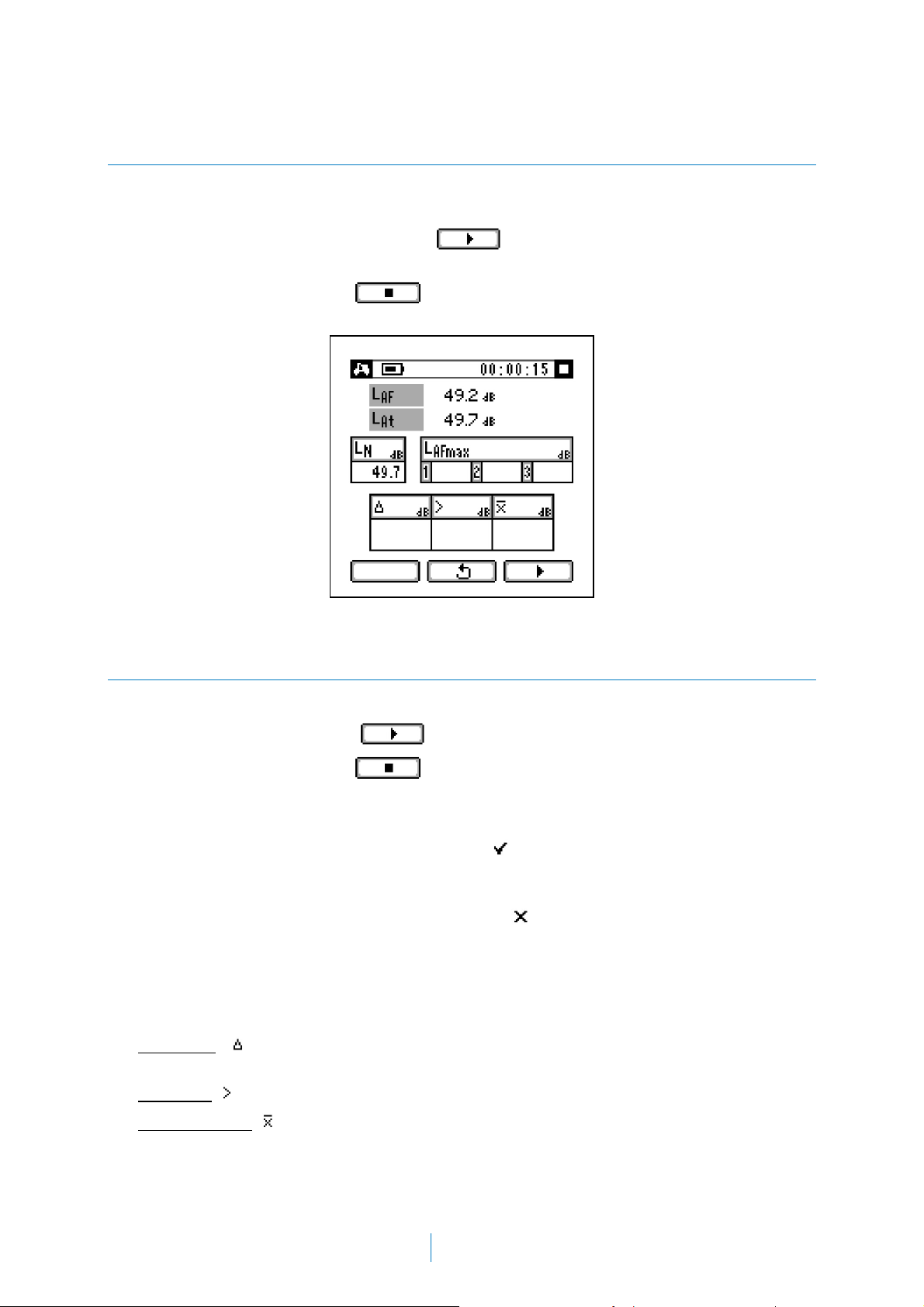

2.5.2 Background noise measurement

Before starting to assess the noise generated by the motor vehicle exhaust system, the

background noise without the vehicle or with its engine turned off must be measured.

To begin the measurement process, press

levels which can be seen at the top of the screen.

To halt the measurement, press

and the value appears automatically in the LN field.

2.5.3 L

AFmax

measurement

. The SC101 will measure the LAF and L

At

Once the background noise has been obtained, the SC101 is ready to measure L

To start the measurement, press

To halt the measurement, press

The device automatically checks whether the value of L

background noise L

o If L

LN + 10, L

AFmax

:

N

will be marked with a at the top of the screen to show that the

AFmax

. The sound level meter measures LAF and L

.

is at least 10 dB higher than the

AFmax

value is correct, and it appears rounded to the nearest integer in the relevant L

AFmax

AFmax

(the first measurement appears in the first box, and so on).

o If L

< LN + 10, L

AFmax

will be marked with an at the top of the screen to show that

AFmax

the value is not correct and will not be taken into account. The measurement must be

repeated.

Whenever the three L

o Difference

( ): the maximum value minus the minimum value of the three L

boxes are filled, the following parameters appear automatically:

AFmax

measurements.

o Maximum

( ): the maximum value of the three L

o Linear average

( ) of the three values rounded to the nearest integer.

measurements.

AFmax

.

AFmax

box

AFmax

.

21

Page 24

Once the three measurements of L

possibility of taking more L

measurements. To continue, press . The latest

AFmax

have been taken, the SC101 offers the user the

AFmax

measurement will replace the oldest one stored and the SC101 will calculate the difference

(

), maximum level ( ) and linear average ( ) fields again using the three values of L

AFmax

shown on the screen.

To cancel a measurement, press

. The SC101 will return to the start screen of the

application, ready for a new measurement, and all previously measured data will be lost.

2.6 Measuring with the leisure and community application (correction by

area)

The leisure and community application aims to help the user with the task of inspecting noise

pollution levels produced by businesses (pubs, bars, shops, etc.) and residents (electrical

appliances, TV, people, etc.). The results of these measurements are later compared with

the emission and immission limit values stipulated in the applicable by laws.

The application performs, step-by-step, the measurement process to be followed for

inspecting noise levels both indoors and outdoors, in accordance with applicable municipal

bylaws in which the specified procedure consists of averaging the background noise and the

activity noise, in order to subsequently apply the background noise correction (see

APPENDIX C: Leisure and community). It is the perfect solution for inspections by police and

city council technicians. It also checks the values obtained during the measurement in real

time. This feature allows the user to make decisions on the spot.

In the process for inspecting emission and immission levels stipulated in the bylaws, several

measurements must be taken, as well as taking other factors into account. With this

application, however, the user only needs to focus on the results obtained, since the device

takes care of checking all the other points.

2.6.1 Starting a measurement

From the main menu, the leisure and community application can be accessed via the

icon.

The following appears at the top of the screen:

o

o Power indicator (see

o Clock (00:00:00): Counter:

: Identifies the application.

2.1.2).

22

Page 25

SC101

User’s Manual

o If the SC101 is working: shows the elapsed measurement time.

o If the SC101 is stopped: shows the time elapsed between the end of one

measurement and the start of the next one.

o Measurement status indicator (Stop, Play, Pause).

To return to the main menu, press

.

Before starting a measurement:

1. Enter the measurement time (this time will be used

for all the measurements made).

2. Specify whether or not background noise

correction will be applied.

To enter the measurement time T (mm:ss):

o Press

o Select the numerical value using

o Confirm with

and

Repeat the process to change the seconds.

The measurement time T (mm:ss) can have the following values:

o 0 to 59 for mm (minutes)

o 0 to 59 for ss (seconds)

Next, specify whether or not a background noise measurement will be taken. Proceed as

follows:

o Use the

o

o

o Confirm the option with

and buttons to select the relevant option:

(background noise correction is not applied)

(background noise correction is applied)

2.6.2 Background noise measurement (optional)

If the background noise correction is to be performed, follow the steps described in this

section. Otherwise, skip to the next section (

To start the measurement, press

Once the time T has elapsed, the measured value of L

entered in the L

box.

N

This application enables as many background noise measurements as necessary to be

made.

2.6.3)

.

appears automatically and is

AT

23

Page 26

To continue with the measurements, press

.

The values will be taken into account when calculating

the final results.

Once the measurements have been made, they must be

validated by pressing

To cancel a measurement, press

.

. The SC101

will return to the start screen of the application, ready for

a new measurement, and all previously measured data

will be lost.

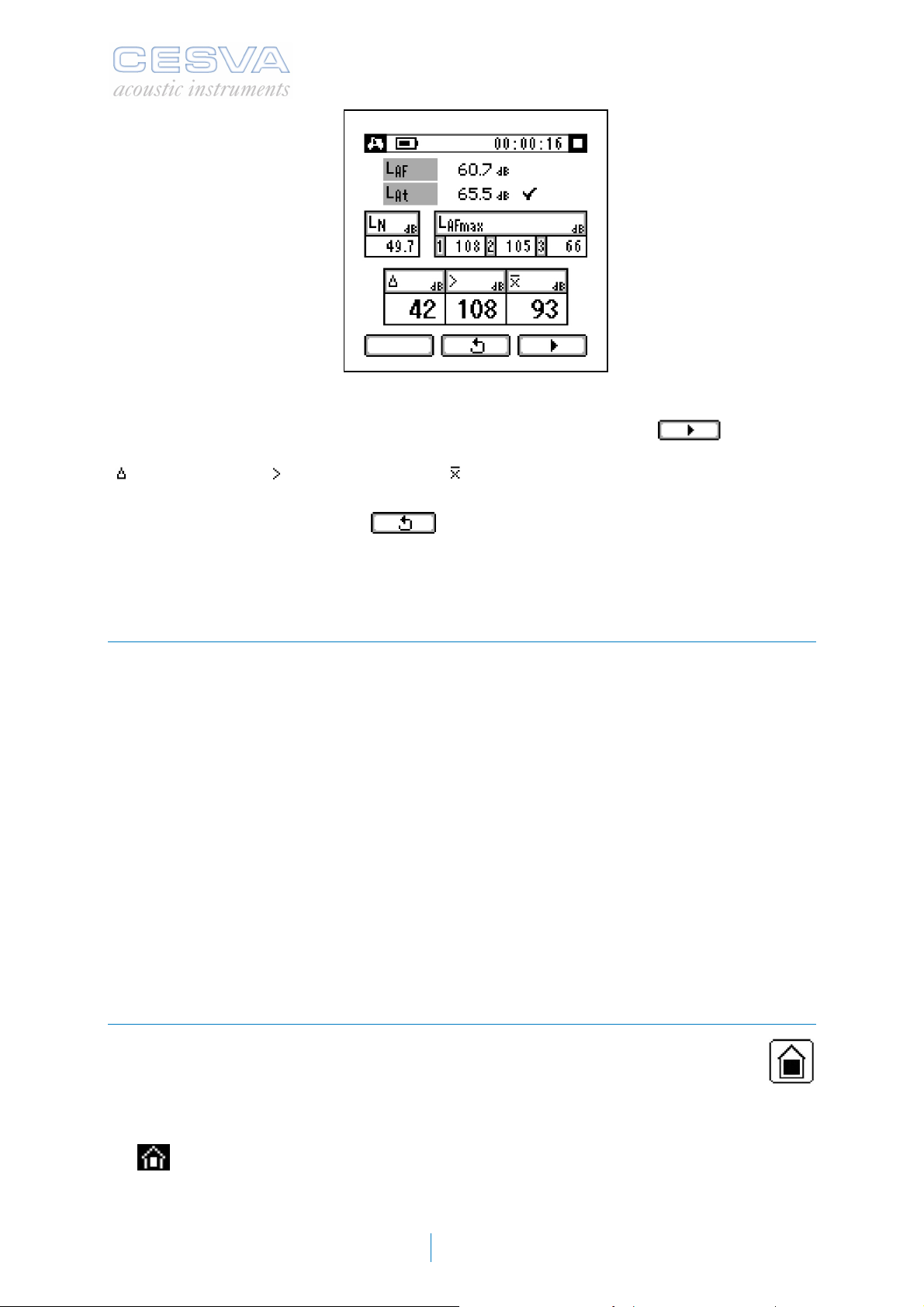

2.6.3 L

and L’At measurement

At

To start the measurement, press .

As with the background noise measurement, the measurement will stop automatically once

the time T has elapsed, and the measured value for the L

function will appear. The

AT

following data will appear at the same time:

number of measurements taken to calculate LAt.

o N:

Difference between the maximum and minimum value of the measured LAT values.

o :

o L

o L:

: Average energy of the measured LAt values.

At

Difference between LAt and LN.

o If L < 3, L will be marked with the

symbol to show that it is not correct

and that the last measurement needs to be repeated, since it cannot be taken

as valid.

o L’

: Value of LAt corrected for background noise.

At

o If you chose not to measure the background noise or L 10: L

o If 3 L >10, the SC101 applies the background noise correction.

The SC101 offers the possibility of performing more L

To continue with the measurements, press

measurements.

AT

. The values will be taken into account

when calculating the final results.

If

is pressed before the time T has elapsed, a

new measurement is started, without taking into account

the result of the previous L

for calculating the end

AT

results.

= L’At

At

To cancel a measurement, press . The SC101

will return to the start screen of the application, ready for a

new measurement and all previously measured data will

be lost.

24

Page 27

SC101

User’s Manual

2.7 Measuring with the leisure and community application (correction by

points)

The leisure and community application aims to help the user with the task of inspecting noise

pollution levels produced by businesses (pubs, bars, shops, etc.) and residents (electrical

appliances, TV, people, etc.). The results of these measurements are later compared with

the emission and immission limit values stipulated in the applicable bylaws.

The application performs, step-by-step, the measurement process to be followed for

inspecting noise levels both indoors and outdoors, in accordance with applicable municipal

bylaws in which the specified procedure consists of measuring the background noise and the

activity noise in each of the points to be assessed, and corrected with its corresponding

background noise (see APPENDIX C: Leisure and community). It is the perfect solution for

inspections by police and city council technicians. It also checks the values obtained during

the measurement in real time. This feature allows the user to make decisions on the spot.

In the process for inspecting emission and immission levels stipulated in the bylaws, several

measurements must be taken, as well as taking other factors into account. With this

application, however, the user only needs to focus on the results obtained, since the device

takes care of checking all the other points.

2.7.1 Starting a measurement

From the main menu, the leisure and community application can be accessed via the

icon.

The following appears at the top of the screen:

o

o Power indicator (see

o Clock (00:00:00): Counter:

o Measurement status indicator (Stop, Play, Pause).

: Identifies the application.

2.1.2).

o If the SC101 is working: shows the elapsed measurement time.

o If the SC101 is stopped: shows the time elapsed between the end of one

measurement and the start of the next one.

25

Page 28

To return to the main menu, press .

Before starting a measurement:

1. Enter the measurement time (this time will be used for all the measurements made).

2. Specify whether or not background noise correction will be applied.

To enter the measurement time T (mm:ss):

o Press

o Select the numerical value using

o Confirm with

and

Repeat the process to change the seconds.

The measurement time T (mm:ss) can have the following values:

o 0 to 59 for mm (minutes)

o 0 to 59 for ss (seconds)

Next, specify whether or not a background noise measurement will be taken. Proceed as

follows:

o Use the

o

o

o Confirm the option with

and buttons to select the relevant option:

(background noise correction is not applied)

(background noise correction is applied)

2.7.2 Measurement without applying background noise correction

If the option not to apply background noise correction has been chosen, follow the steps

shown below.

Click on

and the values of the L

appear:

: Maximum L

o

o L’

: as background noise correction is not

AT

applied, this value will always be the same as L

: Number of measurements carried out to

o N

calulate L’

Difference between the maximum and minimum

o :

values of the L’

: Maximum L’AT value of all those measured.

o

o L’

: average of all the L’

At

. Once the T, interval has passed the measurement will stop automatically,

and L

AT

value of all those measured.

AFmax

.

At

measured.

AT

measured.

AT

functions will appear. The following data will also

AFmax

.

AT

26

Page 29

SC101

User’s Manual

With this application as many measurements of the activity as required can be taken.

To continue taking measurements click on

. These values will be taken into account

in the above results.

To cancel a measurement click on

.

To restart the process click on ; the SC101 will return to the starting screen of the

application, ready to start a new measurement, and data of any measurements taken so far

will be lost. To return to the main menu click on

.

2.7.3 Measuring with background noise correction

If the option to apply background noise correction has been chosen, follow the steps shown

below.

Click on

and the values of the L

appear. At the same time the background noise box (L

. Once the T, interval has passed the measurement will stop automatically,

and L

AT

functions pertaining to the background noise will

AFmax

) will be filled in with the value of LAT.

N

The sound level meter offers the option of restarting the measurement process

moving on to measure the noise level of the activity

. By clicking on once

the T interval has passed, the following data will appear:

o L:

Difference between LAT and LN.

o If L < 3 ; L will be marked with the

symbol indicating that it is incorrect

and the last measurement must be repeated as it cannot be taken as valid.

o L’

: Value of L

AT

o If L 10 ; L

corrected for background noise.

AT

= L’AT

AT

o If 3 L <10 ; the SC101 will apply the

background noise correction.

or

: Number of measurements carried out for the

o N

calculation of L’

Difference between the maximum and minimum

o :

values of the L’

: Maximum value of L’AT of all those measured.

o

o L’

: average of all the L’

At

.

At

measured.

AT

measured.

AT

27

Page 30

This application allows an unlimited number of measurements to be taken.

To continue taking measurements click on

in the above results.

To cancel a measurement click on

To restart the process click on , the SC101 will return to the starting screen of the

application, ready to start a new measurement, and data of any measurements taken so far

will be lost. To return to the main menu click on

.

. These values will be taken into account

.

2.8 Measuring with the occupational hazard application

The occupational hazard application is designed to help the user assess the levels perceived

by a worker during his/her working day. It allows the assessment to be made according to

working days, jobs and tasks. The data obtained can then be used to assess the PPE used

by workers according to the HML and SNR methods.

The application performs, step-by-step, the measurement process to be applied when

assessing hazards associated with the exposure of workers to noise, in accordance with the

Technical Guide for the assessment and prevention of hazards associated with exposure of

workers to noise, (see APPENDIX D: Occupational hazards). It is the perfect solution for

companies in terms of occupational hazard prevention services, both internally and

externally. It also checks the values obtained during the measurement in real time. This

feature allows the user to make decisions on the spot.

In the process for assessing occupational hazards, several measurements must be taken, in

addition to checking other factors. With this application, however, the user only needs to

focus on the results obtained, since the device takes care of checking all the other points.

2.8.1 Starting a measurement

From the main menu, the occupational hazard application can be accessed via the

icon.

The following appears at the top of the screen:

o

o Power indicator (see

o Clock (00:00:00): Counts the measurement time

o Measurement status indicator (Stop, Play, Pause).

To return to the main menu, press

: Identifies the application.

2.1.2).

elapsed.

.

To start the measurement, press

LAt, LCt and L

Cpeak

.

. The SC101 measures and displays the functions

28

Page 31

SC101

User’s Manual

To end a measurement, press . The SC101 performs the calculations automatically

and presents the results of the following parameters, per screen:

: average energy of the measured LAt values

o

o

: average energy of the measured LCt values

: maximum L

o

: number of measurements taken

o

: difference between the maximum and minimum value of the measured LAT values

o

o L

: projected equivalent daily exposure level, with A frequency weighting.

EX,8hp

value of all the measured values

Cpeak

The application allows all the required measurements to be performed.

To take another measurement, press

.

These measurements will be taken into account when calculating the parameters above.

To cancel a measurement, press . The SC101 will return to the start screen of the

application, ready for a new measurement, and all previously measured data will be lost.

To change the projection time, the measurement process must be stopped

(see 2.8.2).

2.8.2 Projection time

To assess noise exposure for measurement times shorter than the exposure times, the

projected parameters must be calculated.

This application can be used to obtain the projected daily sound exposure level L

determines the sound exposure that would be obtained if the measurement time was equal

to the projection time. For this reason, only the projection time

(tp) corresponding to the

expected time of exposure to noise should be entered.

By default, the SC101 assigns 8 hours to the projection time, but this value can be edited.

To modify the value of tp:

o Make sure the measurement process is halted

o Press the

button.

.

EX,8hp

, which

29

Page 32

o Select the numerical value using and

o Confirm with

Repeat the process to change the minutes.

The projection time tp (hh:mm) can have the following

values:

o 0 to 24 for hh (hours)

o 0 to 59 for mm (minutes)

2.9 Measuring with the machinery application: sound pressure level

The machinery application (sound pressure level) aims to help the user with the task of

performing measurements to assess the sound pressure level generated by machines and

equipment in the workplace.

In this application, the sound level meter guides the user, in an intuitive, sequential manner,

through the steps of the measurement process described in Directives 2005/88/EC and

2006/42/EC and the ISO 11202 standard (see APPENDIX E: Machinery; sound pressure

level). It also checks the values obtained during the measurement in real time, allowing the

user to make decisions on the spot.

In the process for assessing the sound pressure level of machines, various types of

measurements need to be taken, in addition to checking other factors. With this application

however, the device stores the values in order to perform all the checks, leaving the user free

to focus on the results obtained.

2.9.1 Starting a measurement

From the main menu, the machinery application: sound pressure level can be accessed via

the

The following appears at the top of the screen:

o

o Power indicator (see

o Clock (00:00:00): Counts the elapsed measurement

o Measurement status indicator (Stop, Play, Pause).

icon.

: Identifies the application.

2.1.2).

time.

To return to the main menu, press

.

30

Page 33

SC101

User’s Manual

2.9.2 Background noise measurement

Before starting to determine the noise levels (LpA, L

) emitted by machines and

Cpeak

equipment in the workplace, the background noise must be measured without any machines

or equipment, or with them switched off.

To begin the measurement process, press

displays L

and L

At

Cpeak.

. This performs the measurement and

To end the measurement, press . The background noise value is displayed in the

L’’

box.

pA

2.9.3 Obtaining L

pA

and L

Cpeak

levels

Once the background noise has been measured, the SC101 is ready to obtain LpA and L

To perform a measurement, press

To halt the measurement, press

: LAt points measured and used to calculate L’pA.

o N

o L’

o L

: Average energy of all the measured LAt values.

pA

: Difference between values L’pA and L’’pA.

o If L < 3, L will be marked with the

. The sound level meter measures LAt and L

. The following values appear automatically:

symbol to show that it is not correct

and that the last measurement needs to be repeated, since it cannot be taken

as valid.

Cpeak

Cpeak

.

.

31

Page 34

o K

: Background noise correction.

1A

o If L 10, K

= 0.0

1A

o If 3 L >10, the SC101 calculates the background noise correction

o K

o L

o L

: Environmental correction (see 2.9.4)

3A

: L’pA level corrected by K1A and K3A. The value is rounded to the nearest integer.

pA

: Maximum L

Cpeak

level measured. The value is rounded to the nearest integer.

Cpeak

NOTE: If L < 3, the values of fields k

cannot be calculated.

, k3A, LpA and L

1A

will not be displayed, since they

Cpeak

An LAt will be measured for every evaluation point. To measure another point, simply repeat

the procedure above. These measurements will be taken into account when calculating the

final results.

To cancel a measurement, press

. The SC101 will return to the start screen of the

application, ready for a new measurement, and all previously measured data will be lost.

2.9.4 K

The SC101 automatically calculates the K

and K

1A

corrections

3A

background noise correction.

1A

However, it is up to the user to enter the environmental correction value K3A (for more

information, see APPENDIX E: Machinery; sound pressure level).

To enter the environmental correction K

o Press the K

button.

3A

o Select the value using the

:

3A

and

buttons

o Confirm the value by pressing the

button

As of this time, the SC101 will take the new K

into account for calculating the end noise level (

value

3A

L

emitted by machines and equipment in the workplace.

32

pA

)

Page 35

SC101

User’s Manual

2.10 Measuring with the machinery application: sound power level

The machinery application (sound power level) aims to help the user with the task of

performing measurements to assess the sound power level generated by noise emissions

(machines).

In this application, the sound level meter guides the user, in an intuitive, sequential manner,

through the steps of the measurement process described in Directives 2005/88/EC and

2006/42/EC and the ISO 3746 standard (see APPENDIX F: Machinery sound power level). It

is the ideal solution for machinery manufacturers.

It also checks the values obtained during the measurement in real time. This feature allows

the user to make decisions on the spot.

In the process for assessing the sound power level of machines, various types of

measurements need to be taken, in addition to checking other factors. With this application

however, the device stores the values in order to perform all the checks, leaving the user free

to focus on the results obtained.

2.10.1 Starting a measurement

From the main menu, the machinery application: sound power level can be accessed via the

icon.

The following appears at the top of the screen:

o

o Power indicator (see

: Identifies the application.

2.1.2).

o Clock (00:00:00): Counts the measurement time

elapsed.

o Measurement status indicator (Stop, Play, Pause).

To return to the main menu, press

.

33

Page 36

2.10.2 Measuring the sound pressure level at several points

The first step in this application consists of measuring the sound pressure level at several

points with the noise emission switched on.

To perform a measurement, press

To end the measurement, press

. The LAt value is measured.

.

The following values appear automatically:

: LAt points measured and used to calculate L’pA.

o N

o L’

o

: Average energy of all the measured LAt values.

pA

: Difference between the maximum and minimum

value of L’

pA

.

o If 2·N, L will be marked with the

symbol to show that it is not correct.

This application can perform as many measurements as required, with the noise emission

switched on.

To continue taking more measurements with the noise emission switched on, press

These values will be considered in the above results.

Once these measurements are complete, they must be confirmed.

To confirm them, press

.

.

To cancel a measurement, press

. The SC101 will return to the start screen of the

application, ready for a new measurement, and all previously measured data will be lost.

2.10.3 Background noise measurement

Background noise is measured with the noise emission switched off.

NOTE: Perform the same number of background noise measurements as performed to

calculate L’

To perform background noise measurements, press

measure L

.

At

To end the measurement, press

The following values appear automatically:

: LAt points measured and used to calculate L’’pA.

o N

o L’’

o L

: Average energy of all the measured LAt values.

pA

: Difference between values L’pA and L’’pA.

pA

.

. The sound level meter will

.

o If L < 3, L will be marked with the

symbol to show that it is not correct

and that the last measurement needs to be repeated, since it cannot be taken

as valid.

34

Page 37

SC101

User’s Manual

o K

: Background noise correction.

1A

o If L 10, K

= 0.0

1A

o If 3 L >10, the SC101 calculates the background noise correction

o K

o L

o S m

o L

: Environmental correction (see 2.10.4).

2A

: L’pA level corrected by K1A and K2A.

pfA

2

: Surface area being assessed (see 2.10.4).

: Sound power level, calculated using the L

WA

value obtained and the S entered. The

pfA

value is rounded to the nearest integer.

To cancel a measurement, press

. The SC101 will return to the start screen of the

application, ready for a new measurement, and all previously measured data will be lost.

2.10.4 K

The SC101 automatically calculates the K

However, it is up to the user to enter the environmental correction value K2A (for more

information, see APPENDIX F: Machinery sound power level) as well as the value in m

and K

1A

corrections Surface area S

2A

background noise correction.

1A

2

of

the surface area S being assessed.

To enter the environmental correction K

o Press the

button

o Select the value using the

:

2A

and

buttons

o Confirm the value by pressing the

button

Repeat the last two steps to enter the surface area S.

35

Page 38

As of this time, the SC101 will take into account the new K2A and S values to calculate the

L

definitive sound power level (

) generated by machines.

WA

2.11 Sensitivity setting

IMPORTANT NOTE: The sensitivity of the sound level meter should only be adjusted by

authorised, technically competent personnel. Readjusting the sensitivity can lead to a loss of

device calibration traceability.

1) Go to the main menu of the SC101 and use the arrow keys to select the sensitivity

setting icon;

. Access it using the button.

2) Check that the value displayed at the centre of the screen (large digits) matches the

value of 94.0 dB, corrected by the relevant corrections (93.9 dB).

If the difference between the reading and the calculated value is less than ± 0.3 dB,

the sound level meter is working correctly.

Otherwise, the sensitivity of the sound level meter needs to be adjusted.

The procedure for adjusting the sensitivity is described below:

1) The SC101 allows the level to be adjusted using the and buttons.

Remember that any changes made to the sensitivity setting will be recorded. The sensitivity

adjustment screen shows the variation in dB, with a

counter showing the number of times this sensitivity

setting has been changed.

NOTE: This feature enables the user to keep control

of the number of times the sensitivity setting

has been changed.

2) To confirm the setting and return to the main

menu, press the

button.

36

Page 39

SC101

User’s Manual

2.12 Contrast setting

1) Go to the main menu of the SC101 and use the arrow keys to select the contrast

setting icon;

button.

2) The screen shows the contrast level in numbers,

as well as a sample of the four colours the

device can display, to be used as reference

when selecting the contrast level.

3) To change the contrast setting, press the

and buttons.

4) To confirm the setting and return to the main

menu, press the

. Access it using the

button.

2.13 Switching off the SC101

To switch off the SC101, check that no measurements are in progress ( ) and press:

2.14 Tips and warnings

When attaching and detaching the microphone, use only the hands, no tools. Do not do

this while the SC101 is switched on.

The microphone should never be dismantled, since this can cause permanent damage.

Keep the microphone away from dust and sharp objects.

Avoid excess moisture and sudden temperature changes that can cause condensation on

the microphone.

Do not remove the protective grid of the microphone unless strictly necessary. Never

touch the diaphragm. If the diaphragm is very dirty, remove the dust carefully using a very

fine camelhair brush.

diaphragm

Any impact on the SC101 will be picked up by the microphone and may affect the

measurement value.

When the SC101 is exposed to vibrations, it is advisable to insulate it. This can normally

be achieved using pads of foam rubber or similar materials.

When the measurements are taken outdoors, the supplied windscreen must be placed on

the microphone, since the wind can produce a very loud noise.

37

Page 40

When holding the SC101 by hand to take measurements, keep arm outstretched. To

avoid interference, we recommend using the TR-40 or TR050 tripod and the CN003,

CN010 or CN030 microphone extension cable. Remember that the microphone can only

be detached with the SC101 switched off.

It is advisable to check the SC101 before and after each measurement. Use the

CB006 acoustic calibrator. See section 2.2.3.

Remove the batteries if you will not be using the SC101 for an extended period.

The

for a long time. If any malfunction cannot be corrected by changing the battery or checking

the manual, send the SC101 to an official

have it repaired by unauthorised personnel.

This device will only work with the accessories listed in the Accessories section. If any

different accessories are used and this causes a failure in the device, will

assume no responsibility for this fault and the warranty will be void.

SC101 sound level meter is designed to provide reliable measurements

after-sales centre. Never attempt to

2.15 Tips for taking measurements

To prevent the operator from influencing the measurements (shielding effect) it is advisable

to take acoustic measurements with the sound level meter away from the body (without

making it difficult to read). For increased reliability, we recommend using the tripod. The axis

of the microphone should be pointed towards the noise source.

For indoor measurements, it is advisable to keep the sound level meter away from reflecting

surfaces (walls, objects, floors, etc.) to avoid adding the reflected noise to the noise being

measured.

For outdoor sound measurements, the sound level meter microphone should be protected

with the windscreen, and it is advisable to check the weather conditions (temperature,

humidity, atmospheric pressure).

When performing long-term outdoor measurements, it is advisable to use the TK1000 or

TK200 outdoor kit to protect the equipment against environmental agents (wind, rain,

moisture).

When measuring sound fields with very low levels, remember the measurement range

specifications. If a measure a level below the specified lower measurement limit is to be

made, the noise characteristics of the actual device must be taken into account.

3. VIEWING DATA ON A PC

The SC101 sound level meter has a USB port for communicating with a PC, via the CN1US

cable (see 4.22).

This port allows real-time transmission of the data measured by the SC101 to a computer,

with a high transfer rate.

If this communication is to be performed, contact an official after-sales centre.

38

Page 41

SC101

A

User’s Manual

4. TECHNICAL SPECIFICATIONS

4.1 Measurement range

Functions LF, LS and L

Starting point for the linearity tests 94 dB

t

For C-130 + PA-13

Electrical measurement range (with nominal microphone

sensitivity) at 1kHz:

Upper limit

Upper limit for crest factor 3:

Lower limit

Linear measurement range at 31.5 Hz:

Upper limit

Lower limit

Linear measurement range at 4 kHz:

Upper limit

Lower limit

Linear measurement range at 8 kHz:

Upper limit

Lower limit

Linear measurement range at 12.5 kHz

:

Upper limit

Lower limit

Electrical noise (with nominal microphone sensitivity without

preamplifier):

Maximum

Typical

Total noise at 20 °C (electrical + thermal of the microphone):

Maximum

Typical

FREQUENCY

WEIGHTING

C

137.0

130.0

24.8

97.6

24.8

138.0

24.8

135.9

24.8

132.7

24.8

15.7

15.0

21.2

20.6

137.0

130.0

25.8

134.0

25.8

136.2

25.8

134.0

25.8

130.8

25.8

17.1

16.3

22.0

21.8

Note: the intrinsic noise is measured with equivalent levels, with integration time of more

than 30 seconds.

39

Page 42

A

For C-250 + PA-14

Electrical measurement range (with nominal microphone

sensitivity) at 1kHz:

Upper limit

Upper limit for crest factor 3

Lower limit

Linear measurement range at 31.5 Hz:

Upper limit

Lower limit

Linear measurement range at 4 kHz:

Upper limit

Lower limit

Linear measurement range at 8 kHz:

Upper limit

Lower limit

Linear measurement range at 12.5 kHz:

Upper limit

Lower limit

Electrical noise (with nominal microphone sensitivity without