Cessna SKYMASTER 336 1964 Service Manual

REVISION

MODEL

336

SKYMASTER

1964

SERVICE

D238C2-13

INSERT

PAGES

MANUAL

CHANGE

5

JANUARY

THE

INTO

FOLLOWING

THE

2

2004

BASIC

CHANGED

MANUAL

Cessna

A

Textron

Company

Service

Manual

MODEL

1964

336

FAA

APPROVAL

CHANGE

TEMPORARY

TEMPORARY REVISION 4 DATED

COPYRIGHT © 2004

CESSNA

AIRCRAFT

WICHITA,

D238-2-13

KANSAS,

HAS

BEEN

2

TO THE

CHANGE 2 DATED

COMPANY

USA

OBTAINED

BASIC

ON

MANUAL

23

TECHNICAL

INCORPORATES

MARCH 1978,

17

MARCH 1995.

DATA

Change

IN

THIS

PUBLICATION

TEMPORARY

TEMPORARY

2

SKYMASTER

THAT

AFFECTS AIRPLANE

CHANGE 1 DATED

CHANGE 3 DATED

Member

27 FEBRUARY

1

DECEMBER 1980,

1

APRIL

5

JANUARY

TYPE

DESIGN

of GAMA

1978,

AND

1964

2004

CESSNA

SERVICE

AIRCRAFT

MODEL

336

MANUAL

COMPANY

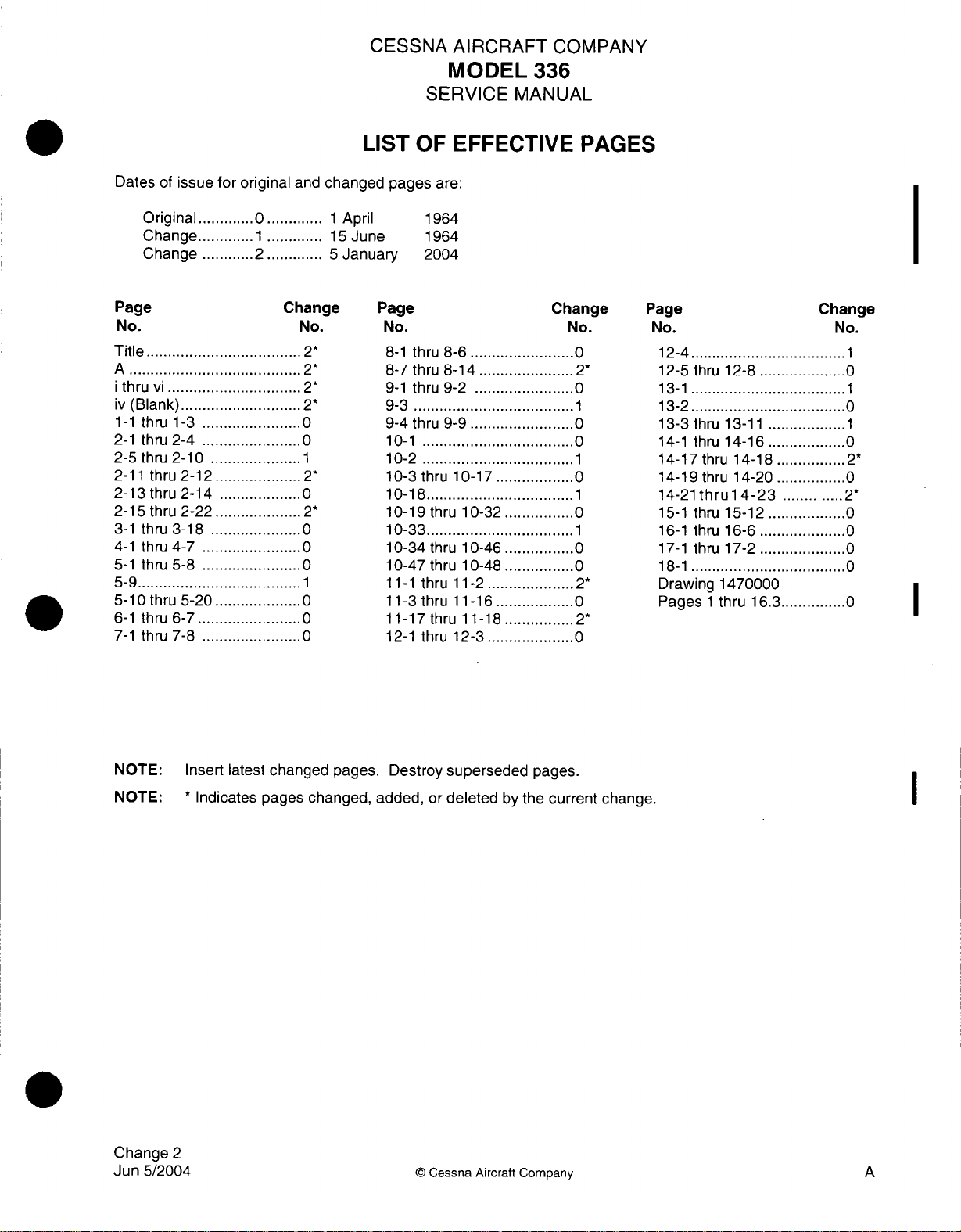

Dates

of

issue

for

original

Original

Change.............1

Change

Page

No.

Title

A

........................................

i

thru

iv

(Blank)

1-1

thru

2-1

thru

2-5

thru

2-11

thru

2-13

thru

2-15

thru

3-1

thru

4-1

thru

5-1

thru

5 -9

......................................

5-10

thru

6-1

thru

7-1

thru

..........

............

.

.......................

vi

...............................

............................

1-3

.......................

2-4

.......................

2-10

2-12

2-14 ...................

2-22

3-18 .....................

4-7

.......................

5-8

.......................

5-20

6-7

........................

7-8

.......................

0.............

2.............5

.....................

....................

.................

....................

and

.............

Change

No.

2*

2

2*

2*

0

0

1

2*

0

2*

0

0

0

1

0

0

0

changed

1

April

15

June

January

*

LIST

OF

EFFECTIVE

pages

are:

1964

1964

2004

Page

No.

8-1

thru

8-6

........................

8-7 thru

9-1

9 -3

9-4

10

10

10-3

10-18..................................1

10-19thru

10-33..................................1

10-34

10-47

11-1

11-3

11-17

12-1

8-14

......................

thru

9-2

.......................

.....................................

thru

9-9

........................

-1

...................................

-2

...................................

thru

10-17

..................

10-32

................

thru

10-46

................

thru

10-48

................

thru

11-2

....................

thru

11-16

..................

thru

11-18

...............

thru

12-3

....................

PAGES

Change

No.

0

2*

0

1

0

0

1

0

0

0

0

2*

0

2*

0

Page

No.

12

-4

....................................

12-5

thru

12-8

1 3 -1

....................................

13

-2

....................................

13-3

thru

13-11

14-1

thru

14-16

14-17thru

14-19

14-21

15-1

16-1

17-1

18-1

Drawing

Pages

14-18 ...............

thru

14-20

thru

14-23

thru

15-12

thru

16-6

thru

17-2

....................................

1470000

1

thru

Change

No.

....................

..................

..................

................

............

..................

....................

....................

16.3...............0

1

0

1

0

1

0

2*

0

2*

0

0

0

0

I

NOTE: Insert

NOTE:

Change

Jun

2

5/2004

*

Indicates

latest

changed

pages

pages. Destroy

changed,

added,

superseded

or

deleted

©

Cessna

by

Aircraft

pages.

the

current

Company

change.

I

A

CESSNA

SERVICE

AIRCRAFT

MODEL

336

MANUAL

COMPANY

SECTION

1

GENERAL DESCRIPTION

2

SERVICING

3

FUSELAGE

4

WINGS,

5

LANDING

6

AILERON

7

FLAP

8

ELEVATOR, TRIM

9

RUDDER

POW

10

11

12

ERPLANTS

FUEL

PROPELLERS

CONTROL

............................................................

.............................................................

BOOMS, AND

GEAR

CONTROL

CONTROL

SYSTEM

................................................ 1-1

EMPENNAGE

........................................................

SYSTEM

SYSTEM

AND

.........................................................

..........................................................

..........................................................

...............................................

INTERCONNECT

SYSTEM

.....................

......................................

.......................................

CONTROL

SYSTEMS

........................

.............

TABLE

OF

.....

CONTENTS

PAGE

2-1

3-1

4-1

5-1

6-1

7-1

8-1

9-1

10-1

11-1

12-1

13

UTILITY

14

INSTRUMENTS

15

ELECTRICAL

16

STRUCTURAL

17

PAINTING

18

WIRING

SYSTEMS

...............................................................

DIAGRAMS

.......................................................

.........................................................

SYSTEMS

REPAIR

..................................................

...................................................

.....................................................

13-1

14-1

15-1

16-1

17-1

18-1

Change

Jan

5/2004

2

©

Cessna

Aircraft

Company

CESSNA

SERVICE

AIRCRAFT

MODEL

MANUAL

COMPANY

336

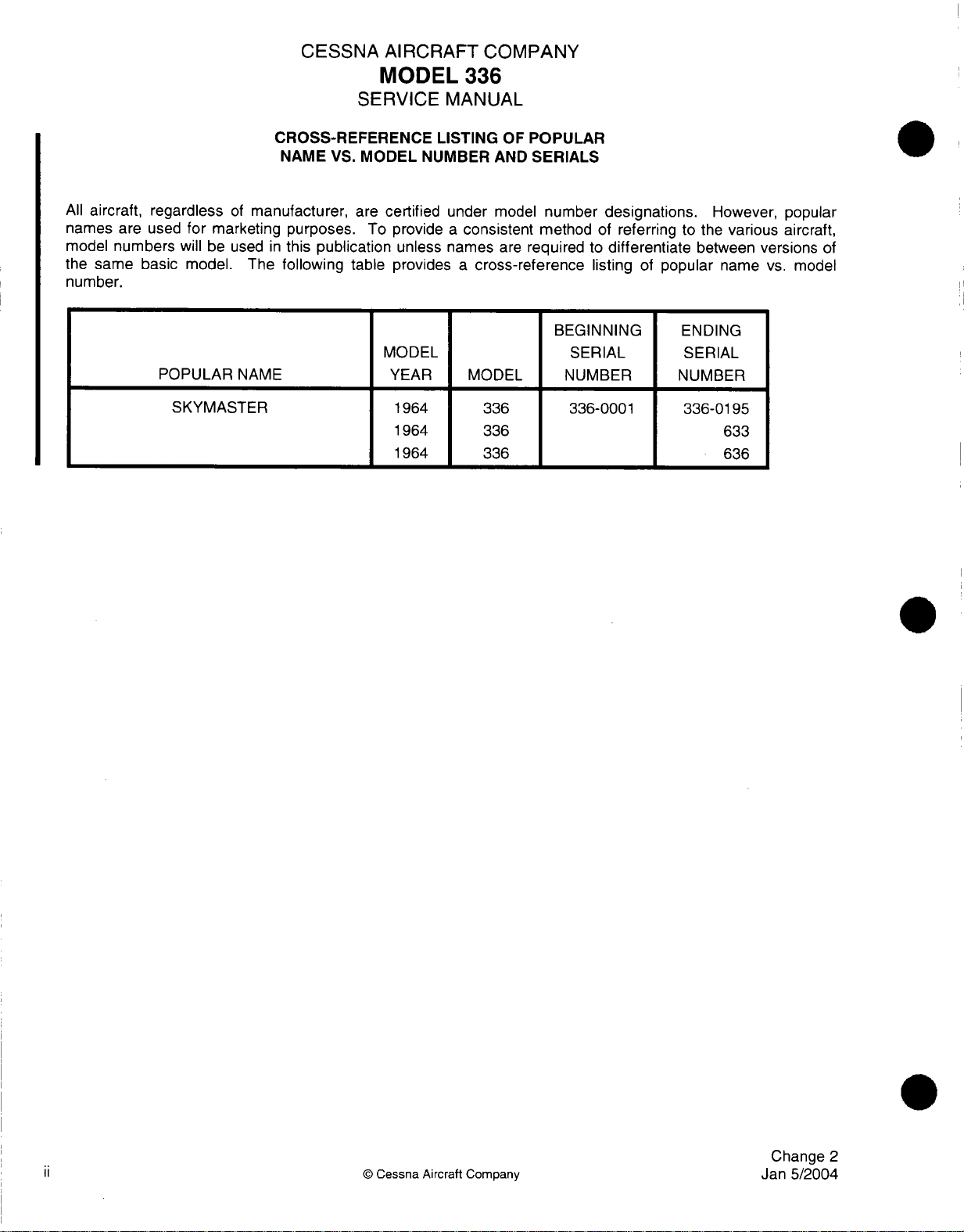

All

aircraft,

names

model

the

same

number.

regardless

are

used

numbers

basic

POPULAR

of

manufacturer,

for

marketing

will

be used

model.

SKYMASTER

The

NAME

CROSS-REFERENCE

NAME

in

following

VS.

MODEL

are

purposes.

this publication

To provide

table provides

certified

unless

MODEL

YEAR

1964

1964

1964

LISTING

NUMBER

under

a

consistent

names

a

cross-reference

MODEL

OF

AND

model

are

336

336

336

POPULAR

SERIALS

number

method

required

BEGINNING

SERIAL

NUMBER

336-0001

designations.

of

referring

to

differentiate

listing

of

to the

between

popular

ENDING

SERIAL

NUMBER

336-0195

However,

various

versions

name

vs.

633

636

popular

aircraft,

of

model

ii

©

Cessna

Aircraft

Company

Change

Jan 5/2004

2

1.

GENERAL.

CESSNA

SERVICE

AIRCRAFT

MODEL

336

MANUAL

COMPANY

WARNING:

A.

The

information

supplemented,

Information

Changes,

amendments

through

also

have

parts

breakdowns

supplemented,

be

reissued

and

are

subscription

ALL

INSPECTION

METHODS

CESSNA

OVERHAULED

MANUFACTURED,

ENTITIES

MAINTENANCE/SERVICE

APPLICABLE

NON-CESSNA

OVERHAUL

FOR

AND/OR

Letters,

Revisions,

to

the

Cessna

been

by

communicated

services.

OF

ARE

OTHER

SUCH

NON-CESSNA

SELLER

in

this publication

and

automatically

Service

Reissues

this

publication

Propeller

supplied

for some

and

specifically

Cessna.

INTERVALS,

INSPECTION,

SOLELY

CESSNA-APPROVED

REMANUFACTURED,

THAN

AND THE

PARTS.

TIME

LIMITS,

OF SUCH

Bulletins,

and

through

Aircraft

with a group

of

the

amended

Supplier publications

to

the

field

REPLACEMENT

LIFE

LIMITS,

BASED

CESSNA,

PURCHASER

ALL

is

amended

Temporary

various

through Cessna's

ON

THE

THEN

MANUALS

INSPECTION

METHOD

PARTS

NON-CESSNA

based

Service

information

Product

of

supplier

OF

MUST

on

data

by

all

Newsletters,

Revisions.

Support subscription

supplier

by

supplier-issued

reissued

AND

CYCLE

USE

OF

PARTS.

IS

information

publications

equipment

IF

OVERHAULED,

THE

DATA

PARTS

WARNED

INTERVALS,

INSPECTION,

BE

OBTAINED

PARTS.

available

Supplier

Users

available

by

Cessna

Authorized

TIME

LIMITS,

LIMITS,

NEW,

REMANUFACTURED,

PARTS

at

issued

at

which

items.

revisions

ARE DESIGNED,

IN

CESSNA'S

CATALOGS

NOT

TO

REPLACEMENT

LIFE

FROM THE

the

time

in

Service

are

urged

Cessna

services.

provide

Supplier's publications

automatically

Service

OVERHAUL

ETC.,

RECOMMENDED

AND/OR

RELY

LIMITS,

of

Service

Authorized

and

Stations

APPROVED

ARE

NO

LONGER

ON

SUCH

CYCLE

MANUFACTURER

publication

Letters,

Notices,

to

keep

Cessna

disassembly, overhaul,

service

Publication

abreast

Service

information

amend

and/or

TIME

LIMITS,

OR

BY

DATA

TIME

LIMITS,

LIMITS,

and

is

updated,

Service

of

the

Stations

Service

Stations

are

updated,

which

this publication

through

BY

FOR

ETC.,

latest

or

and

may

Cessna's

B.

Inspection,

When

installation

STC.

stresses

airplanes

C.

REVISIONS,

Station or

D.

Information

following

E.

All

Stations

Therefore,

Service

maintenance,

an

STC

installation

must

STC

installations

on

adjacent

with STC

REISSUES

directly

Cessna

Department

P.O. Box

Wichita,

supplemental

Aircraft

7706

Kansas

in

this

range

so

that

it

is

Organization.

and

is

incorporated

be

inspected

can

change

structures

installations.

and

from

Cessna Aircraft

Company

751C

67277-7706

Service

of

serial

numbers;

service

they

recommended

information

have

the latest

parts

requirements

in

accordance

systems

of

the

airplane.

TEMPORARY

Company

Manual

is

applicable

336-0001

concerning

authoritative recommendations

that

Cessna

on

the

airplane,

with

interface,

Cessna

REVISIONS

thru

336-0195,

this

owners

for

STC

installations

those

the

inspection

operating

provided

can be

at the

following address:

to

all

U.S.

manual

utilize

the

portions

program

characteristics

inspection

purchased

Certified

633

and

636.

is

supplied

for

knowledge

are

not

of

the

published

criteria may

from

Model

to

all

servicing

and

included

airplane

and

appropriate

experience

in

this

manual.

affected

by

the

component

not

a

Cessna Service

336

airplanes

these Cessna airplanes.

by

owner

loads

be

valid

within

Cessna

of

the Cessna

of

the

the

or

for

the

Service

Change

Jan

5/2004

2

©

Cessna

Aircraft

Company

iii

2.

CROSS-REFERENCE

A.

All

airplanes, regardless

popular

these airplanes,

to

popular

B.

The

personnel

information

components

C.

Technical

this

systems,

4.

TEMPORARY

A.

Additional

used

operations.

incorporated

names

differentiate

name, model

Cessna

in

Publications

manual.

and

REVISIONS.

information,

to

provide,

LISTING

are

often

the

model

between

Skymaster

servicing

required

or

These

Temporary

into the

repair

may

to

be

without

CESSNA

OF

POPULAR

of

manufacturer,

used

for marketing

number

versions

number,

Series

and

enable

systems.

are

manuals

purchased

which

revisions

maintenance

of the

and

(1964)

maintaining

the

also

available

must

becomes

delay,

AIRCRAFT

MODEL

SERVICE

will be

same

serial

numbers.

Service

Model

mechanic

be

utilized

from

the

available,

new

information,

are

manual

COMPANY

336

MANUAL

NAME

are

used

for

manufacturer.

numbered

at

VERSUS

certified

purposes. To provide

basic

Manual

336

to

service,

the

the

under

in

this

publication

model.

has

airplanes.

various

as

required

may

be

which will

consecutively.

next

revision.

inspect,

components

MODEL

model

unless

The

table

been

prepared

This

manual

troubleshoot,

for

maintenance

provided

assist

NUMBER

number

a

consistent

the

on

page

and

by

temporary

in

Temporary

AND

SERIALS.

designations.

method

popular

ii

provides

to

assist

provides

remove, and

systems

of

maintaining safe

of

name

a

maintenance

the

necessary

that

are

those components

revision. This

revisions

However,

referring

is

necessary

listing

of

replace

not

covered

service

flight/ground

are

to

in

and

is

normally

5.

SERIALIZATION.

A.

All

airplanes

remains

Airplane

of a serial

6.

REVISION FILING

A.

Regular Revision.

(1)

Pages

located

The

number

most recent

Effectivity

NOTE:

B.

Temporary

(1)

File

the

are

issued a serial

with

the

airplane

serial numbers

number

to

at the

first

Beginning

Revision.

temporary

first

in

INSTRUCTIONS.

be

removed

front

number(s)

for

that

section.

date

page

must

pages.

page.

page

Revisions

revisions

of

the

throughout

are

text

or

or

of

this

which

of

page

verify

with

Change 2 to

temporary

number.

used

to

illustration indicates

inserted

manual.

represent

When

two

issue

must

the

active

prior

to

in

the

applicable

revision.

This number

its

service

identify

in

changes

the

maintenance manual

Page

numbers

the

manual

pages

be

inserted

page.

this

service

Change 2 do

section

life.

This serial

within

the

material

are

section

display

the

in

the

manual, a date

not

in

is

assigned

the text

is

listed

number

same two-element

service

have

a

accordance

as

number

or within

applicable

are

determined

in

sequence

are

manual.

will

date

printed

with

airplane

appears

followed

appear

filing

on

an

to

all

airplanes.

by

by a two-element

number,

The

date

on

at

the bottom

instructions

construction

the

airplane

illustration.

the

effectivity

by a dash

the bottom

the

page

column

of

appearing

then

the

begins

data

The

number.

the

with

on

the

of

all

revised

and

plate.

absence

page

A

page

the

revised

on

iv

(2)

The

rescission

or

by a superseding

of a temporary

temporary

revision

revision.

©

Cessna

is

accomplished

Aircraft

Company

by

incorporation

into

the

maintenance

manual

Change

Jan

5/2004

2

7.

IDENTIFYING

A.

Additions

of

B.

When technical

placed

page.

C.

When

revision

D.

For

directing

E.

Changes

the

page

These

extensive

revised

REVISED

or

revisions

and

in

the

pages

bars

or

attention

to wiring

adjacent

changes

outside

technical

will

appear

new

illustrations,

to

diagrams

MATERIAL.

to

text

to

the change.

cause

margin

will

display

changes

the

the

area

CESSNA

SERVICE

in

an

existing

unchanged

adjacent

full

will

are

the

current

are

length

either

indicate

indicated

to

AIRCRAFT

MODEL

section

text

to

the

page

revision

made

to

text

of

text.

a

revision

new

or

by

shaded

COMPANY

336

MANUAL

will

be

appear

number,

date

in

in

an

bar along

revised

areas.

identified

on

a

different

providing

the inside

existing

the

information.

side

section

of

by

a

page(s),

no

other

margin

the

revision

revision

opposite

that

requires

page

or a hand

bar

in

a

revision

of

the

outside

bar

bar

appears

the

page

extensive

indicator

margin

will

be

on

number.

revision,

the

NOTE:

8.

WARNINGS,

A.

Throughout

accomplished

Warnings

WARNING:

CAUTION:

NOTE:

9.

PROPELLER

A. A Cessna

Service

Beginning

revised

Cessna

Department

P.O.

Wichita,

page.

CAUTIONS

the

and

AIRCRAFT

Propeller

Station

Aircraft

Box

7706

Kansas

with

Change

Revisions

text

in

are

utilized.

Cautions

Calls

attention

which

must

Calls

attention

the

airplane

Calls

attention

Aircraft

or

directly

Company

751

C

67277-7706

2

to

this

prior

AND

NOTES.

this manual,

These

precede

be

CUSTOMER

from

adjuncts

the

to

use

followed

to

methods

or

equipment.

to

methods that

Customer

Cessna

service

to

Change

warnings,

text

they

of

materials,

precisely

and

CARE

Care

Aircraft

manual,

2

do

not

cautions

to

the

text

pertain

processes,

to

avoid

procedures

will

make

SUPPLIES

Supplies

Company.

a

revision

have

and

notes

are used

to,

and

injury or

which

the

job

AND

PUBLICATIONS

and

Publications

The

bar

will

a

revision bar

pertaining

to

highlight

Notes

follow

methods,

death

must

easier.

address

appear

procedures,

be

Catalog

to

indicate

to

or

emphasize

the text

to

personnel.

followed

CATALOG.

is:

on

the

the

outside

revised

procedures

they

or

limits

to

avoid

is

available

margin

information.

important

pertain

damage

from

being

to.

a

of the

points.

to

Cessna

10.

CUSTOMER

A.

Change

Jan

5/2004

This

catalog

models

issued

Cessna

This

manual

to

report

wish

to

2

lists

as

well

as

in

paper

and

COMMENTS.

Aircraft

make.

any

Company

can

errors,

all

publications

new

products.

aerofiche

has

be

improved

discrepancies,

and

To

maintain

form.

endeavored

with

your

and

©

Cessna

Customer

this

to

furnish

help.

Please

omissions

Aircraft

Care

catalog

you with

use

in

this

Company

Supplies

in a current

an

the

return

manual

available

accurate,

card

that

as

well

from

status,

useful

is

provided

as

any

Cessna

it

is

revised

and

up-to-date

general

for

prior

yearly

with

your

comments

year

and

manual.

manual

you

v

CESSNA

SERVICE

AIRCRAFT

MODEL

336

MANUAL

COMPANY

I

(THIS

PAGE

INTENTIONALLY

LEFT

BLANK)

Change

©

vi

Cessna

Aircraft

Company

Jan

2

5/2004

SECTION

1

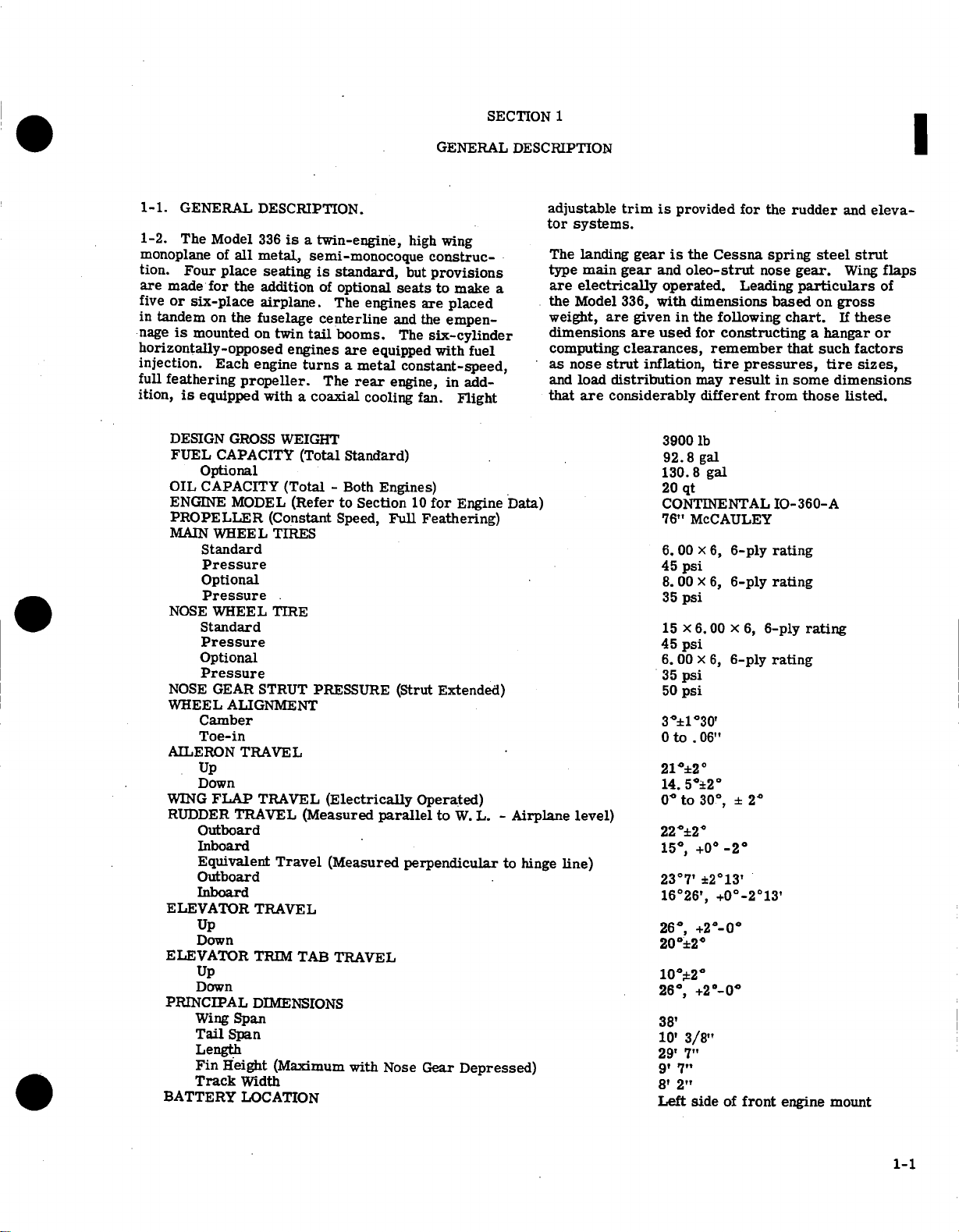

1-1.

GENERAL

1-2.

The

monoplane

tion.

Four

are

made

five

or

six-place

in

tandem

nage

is

mounted

for

Model

of

all

place

the

on

the

DESCRIPTION.

336

metal,

seating

addition

airplane.

fuselage

on

horizontally-opposed

injection.

full

feathering

ition,

Each

is

equipped

DESIGN

FUEL

CAPACITY

engine

propeller.

GROSS

Optional

OIL

CAPACITY

ENGINE

MODEL

PROPELLER

MAIN

WHEEL

Standard

Pressure

Optional

Pressure

NOSE

WHEEL TIRE

Standard

Pressure

Optional

Pressure

NOSE

GEAR

STRUT PRESSURE

WHEEL

ALIGNMENT

Camber

Toe-in

AILERON

TRAVEL

Up

Down

WING

FLAP

RUDDER

TRAVEL

TRAVEL

Outboard

Inboard

Equivalent

Outboard

Inboard

ELEVATOR

Up

TRAVEL

Down

ELEVATOR

Up

TRIM

Down

PRINCIPAL

Wing

Tail

DIMENSIONS

Span

Span

Length

Fin

Height

Track

Width

BATTERY

LOCATION

is

a

twin-engine,

semi-monocoque

is

of

centerline

twin

tail

engines

turns a metal

with

a coaxial

WEIGHT

(Total

(Total -Both

(Refer

(Constant

TIRES

(Measured

Travel

TAB

(Maximum

standard,

optional

The

engines

booms.

are

equipped

The

rear

cooling

Standard)

Engines)

to

Section

Speed,

(Electrically

parallel

(Measured

TRAVEL

with

GENERAL

high

wing

construc-

but

provisions

seats

to

make

are

placed

and

the

empen-

The

six-cylinder

with

fuel

constant-speed,

engine,

Full

in

fan.

Flight

10

for

Engine Data)

Feathering)

add-

(Strut Extended)

Operated)

to

W.

perpendicular

Nose

Gear

Depressed)

DESCRIPTION

a

L. -

Airplane

to

hinge

adjustable

tor

systems.

The

landing

type

main

are

electrically

the

Model

weight,

are

dimensions

computing

as

nose

and

load

that

are

level)

line)

trim

is

provided

gear

is

gear

and

operated.

336,

with

given

in

are

used

clearances,

strut

inflation,

distribution

considerably

3900

92.8

130.8

20 qt

CONTINENTAL

76"

6.00 x 6,

45

8.

35

15 x 6.00 x 6,

45

6.

35

50

3°±1°30'

0

to .06"

21

14.

°

0

220±2"

15°,

23°7'

16°26',

26°,

20°±20

10°*20

26°,

38'

10'

29'

9'

8'

Left

for

the

the

Cessna

oleo-strut

spring

nose

Leading

dimensions

the

following

for

constructing a hangar

based

remember

tire

pressures,

may

result

different

from

lb

gal

gal

McCAULEY

6-ply

rating

psi

00 x 6,

6-ply

psi

6-ply

psi

00 x 6,

6-ply

psi

psi

±2°

50±2

to

30°,

±

2"

+0

-2°

+2013'

+0°-2°13'

0

+2

-00

+2'_-0

3/8"

7"

7"

2"

side

of

front

rudder

gear.

chart.

and

steel

Wing

particulars

on

gross

If

these

eleva-

strut

flaps

of

or

that

such

factors

tire

sizes,

in some dimensions

those

listed.

IO-360-A

rating

rating

rating

engine

mount

1-1

WING

STATIONS

222.00

,

192.00

34.45

0 342.30

27.25

162.00

0

7

60.

135.60

I

107.60

110.50

79.60

138.75

55.50

-e

42.75

AIRPLANE

-30.

00

23.00

19.85

51.50

STA.

70.

00

AT £ OF

1 1

BOOM

TO

FUSELAGE STA.

FUSELAGE

120.00

I

.

I!

I

CORRESPONDS

193.90

STATIONS

_

_

1-2

Figure

1-1.

Reference

Stations

BOLT

(See

SIZE

Note

TORQUE VALUES

FINE

STANDARD

(See

Note

e

1)

2)

TYPE

Alternate

Values

AN310

(See

THREAD

NUTS

Note

IN

POUND-INCHES

SERIES

4)

MS203

AN316

64,

,

AN7502

SHEAR

AN320

TYPE

NUTS

Alternate

Values

AN320

(See

Note

4)

10-32

1/4-28

5/16-24

3/8-24

7/16-20

1/2-20

9/16-18

5/8-18

3/4-16

7/8-14

1-14

1-1/8-12

1-1/4-12

BOLT

(See

Note

8-32

10-24

1/4-20

5/16-18

3/8-16

7/16-14

1/2-13

9/16-12

5/8-11

3/4-10

7/8-9

1-8

1-1/8-8

1-1/4-8

SIZE

TYPE

AN320,

12-19

30-48

60-106

95-170

270-390

290-500

480-750

660-1060

1300-2200

1500-2900

2200-4400

3000-6300

5400-10000

NUTS

AN316

20-25

50-70

100-140

160-190

450-500

480-690

800-1000

1100-1300

2300-2500

2500-3000

3700-5500

5000-7000

9000-11000

STANDARD

1)

Note

(See

12-15

20-25

40-50

80-90

160-185

235-255

400-480

500-700

700-900

1150-1600

2200-3000

3700-5000

5500-6500

6500-8000

TYPE

3)

20-28

50-75

100-150

160-260

450-560

480-730

800-1070

1100-1600

2300-3350

2500-4650

3700-6650

5000-10000

9000-16700

COARSE

NUTS

THREAD

12-15

30-40

60-85

95-110

270-300

290-410

480-600

660-780

1300-1500

1500-1800

2200-3300

3000-4200

5400-6600

SERIES

SHEAR

MS20364,

7-9

12-15

25-30

48-55

95-100

140-155

240-290

300-420

420-540

700-950

1300-1800

2200-3000

3300-4000

4000-5000

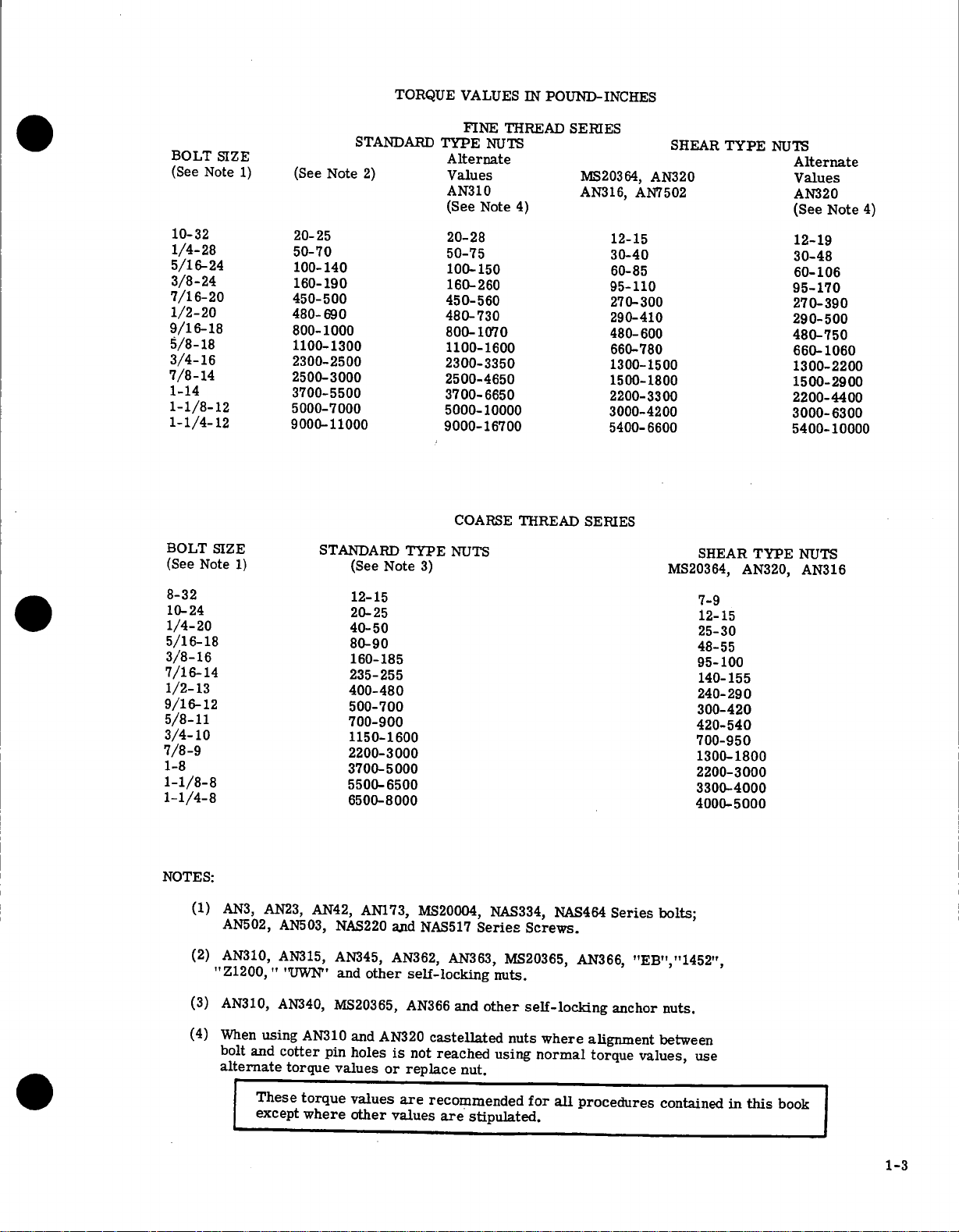

NOTES:

(1)

(2)

(3)

(4)

AN3,

AN23,

AN502,

AN310,

"Z1200, " "UWN"

AN310,

When

using

bolt

and

alternate

These

except

AN42,

AN503,

AN315,

AN340,

AN310

cotter

torque

torque

where

AN173,

NAS220

AN345,

and

other self-locking

MS20365,

and

AN320

pin

holes

values

values

other

and

AN362,

AN366

is

not

or

replace

are

values

MS20004,

NAS517

AN363,

and

castellated

reached using

nut.

recommended

are

stipulated.

NAS334,

Series

MS20365,

nuts.

other

Screws.

self-locking

nuts

where

normal

for

NAS464

AN366,

alignment

torque values,

all

procedures

Series bolts;

"EB","1452",

anchor nuts.

between

contained

use

in

this

book

1-3

TABLE

OF

CONTENTS

GROUND

HANDLING,

SECTION

SERVICING,

Page

2

LUBRICATION,

AND

INSPECTION

I

GROUND

Hangar Storage

Leveling

SERVICING

Fuel

Engine

Engine

Battery

2-1.

2-2.

complished

struts

gear

plane.

ment

2-3.

means

equipment.

336-0058

tional

spars

optional

length

prevent

If

desired, a spreader

vertical

plane

2-4.

wheel

weighted

point is

tered

HANDLING

Towing

Hoisting

Jacking

Parking

Tie-Down

Outside

Extended

Returning

Fuel

When

wheel

center

not

surfaces.

.........

.........

Storage

Tanks ...............

Drains

Oil

Induction

.

GROUND

TOWING.

by

as

push

is

used

The

two

and

is

stowed

towing

more

or

push

HOISTING.

of

hoisting

and on,

hoisting

are

provided

hoisting

of

60

inches

bending

force

use a hoist

JACKING.

of

clear

down

provided

behind

........

........

........

Storage

Airplane

........

........

using

points.

for

the

on

Beginning with

rings

to

the

or

the

............

.............

.............

............

to

Service

... ..........

...............

Air

Filters

HANDLING.

Moving

steering

bar

the

than

nose

control surfaces

provisions

rings

of

the

of

(See

tied

on

nose

the

airplane

the

wing

A

tow

and

is

provided

in

the

baggage

CAUTION

airplane,

39

degrees

gear

will

The

airplane

lugs

which

are

airplane

for

to

the

as

for

the

a

ground,

front

standard

used, a minimum

are

each

cable

eyebolt

jig

may

eyebolts.

minimum

figure

2-1.)

the

down. A permanent

the

bottom

gear,

so

.......

.......

by

struts

or

bar

maneuvering

as

never

either

be

may

equipment.

type

be

When

capacity

tail

of

the

landing

attached

standard

compartment.

turn

side

damaged.

or

empennage

be

lifted

provided

serial

attaching

and

rear

is

required

hoisting

fabricated

hoisting

raise

To

may

be

the

fuselage,

nose

gear

hand

is

to

the

the

equip-

the

nose

of

Do

by

as

optional

number

the

op-

carry-thru

If

cable

to

rings.

to

the

three

of

the

carefully

jack

may

ac-

gear

nose

air-

the

apply

air-

tons.

nose

cen-

2-1

2-1

2-1

2-1

2-4

2-4

2-4

2-4

2-4

2-4

2-5

2-5

2-5

2-5

2-5

2-5

2-5

be

Tires

Nose

Nose

Hydraulic

Oxygen

Oxygen

CLEANING

Windshields

Plastic

Aluminum

Painted

Engine

Upholstery

Propellers

LUBRICATION

INSPECTION

jacked

an

optional

gear

casting

When

ity

to

the

a

wheels

points

To

jack

points.

the

of

front

in

the

screw

sure

after

airplane

the

jack

moving

on

the

be

weighted

used

are

under

is

worked

jacks

and

210

wing

slightly

. .. ...... .

Gear

Gear

Cylinder

Face

Trim

Surfaces

Compartment

if desired.

universal

spring

wing

to

jacking

points

jack

should

jacking

as

a

using

the

of

inboard

slide

jack.

second

and

jacking

simultaneously

is

both

main

These

strut,

wing

spar.

nutplate-provided

install

and

remove

must

are

the

front

engine

when

simultaneously.

tail

the

on

adapter

310

jack

points.

gain

to

Strut

.......

Shimmy

Brake

Systems

.......

Masks

.....

and

Windows

........

Surfaces

and

Interior

....

.....

.....

To

be

point.

.CAUTION

the universal

strut

gear

as

jack

The

operation.

not

recommended.

gears at

points

jack

in

the

A

countersunk

jack

points

jack

operation

be

weighted

used.

engine

engine

and

all

three

the

stand,

should

The

initial

to

jacked

booms

in

Dampener

.....

.....

......

....

jack

one main

jack

point

used.

cause

will

the

wheel

must

with

once

are

bottom

the

for

points

and

is

completed.

is

This

cowl and

mount.

jack

Stands

steady

position.

or

the

be

utilized

may

tail

clearance

.

. .

. .

. . .

gear

which

attaches

Do

not

use

jack

point,

the

main

is

raised,

then

in

accomplished

lowered

be

Jacking

universal

the

use

installed

forward

screw

points.

jack

the

nutplates.

reinstall

The

anytime

down

placing

The

nose

points,

should

airplane

the

The

combination

when

to

have

for

the

is

nose,

at

the

flexibil-

tilting

both

jack

wing

just

flange

installed

screws

nose

by

shot

must

be

placed

before

Model

using

be

lowered

jacks.

2-14

a

time,

to

brake

wheel

for

jack

outboard

of

the

Remove

Be

of

wing

the

re-

bags

also

wing,

and

310

Models

the

2-6

2-6

2-6

2-6

2-6

2-7

2-7

2-7

2-7

2-7

2-7

2-7

2-7

2-7

2-7

the

it

2-1

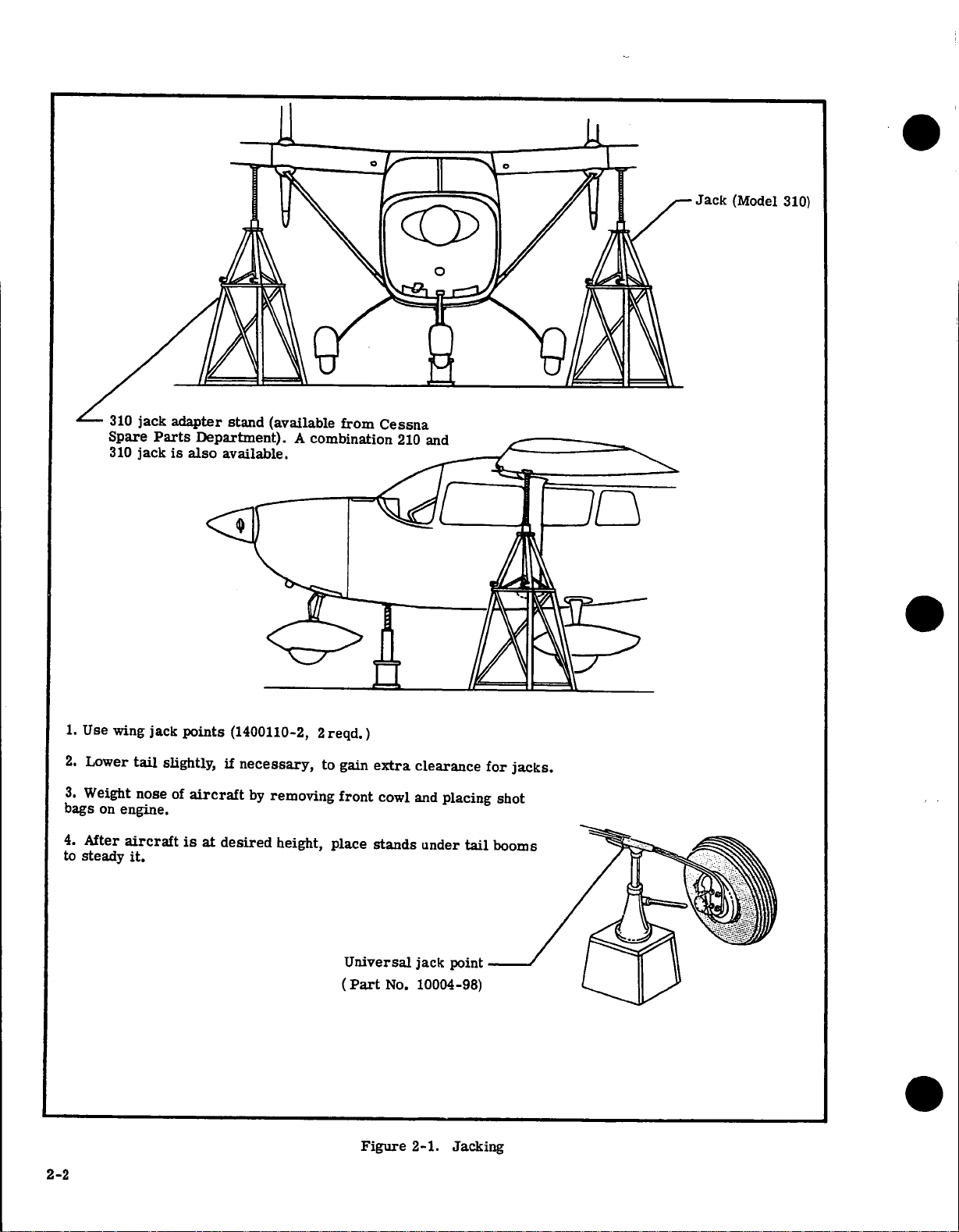

Spare

310

rars

jack

iuepartmeni).

also

is

available.

A

comui

Jack

(Model

310)

2-2

1.

Use

2.

3.

Weight

bags

4.

to

steady

wing

Lower

on

After

jack

tail

nose

engine.

aircraft

it.

points

slightly,

of

aircraft

is

at

(1400110-2,

if

necessary,

by

removing

desired

2

reqd.)

to

gain

front

height, place

Universal

(Part

extra

cowl

stands

No.

Figure

clearance

and

placing

under

jack

point

10004-98)

Jacking

2-1.

tail

for

jacks.

shot

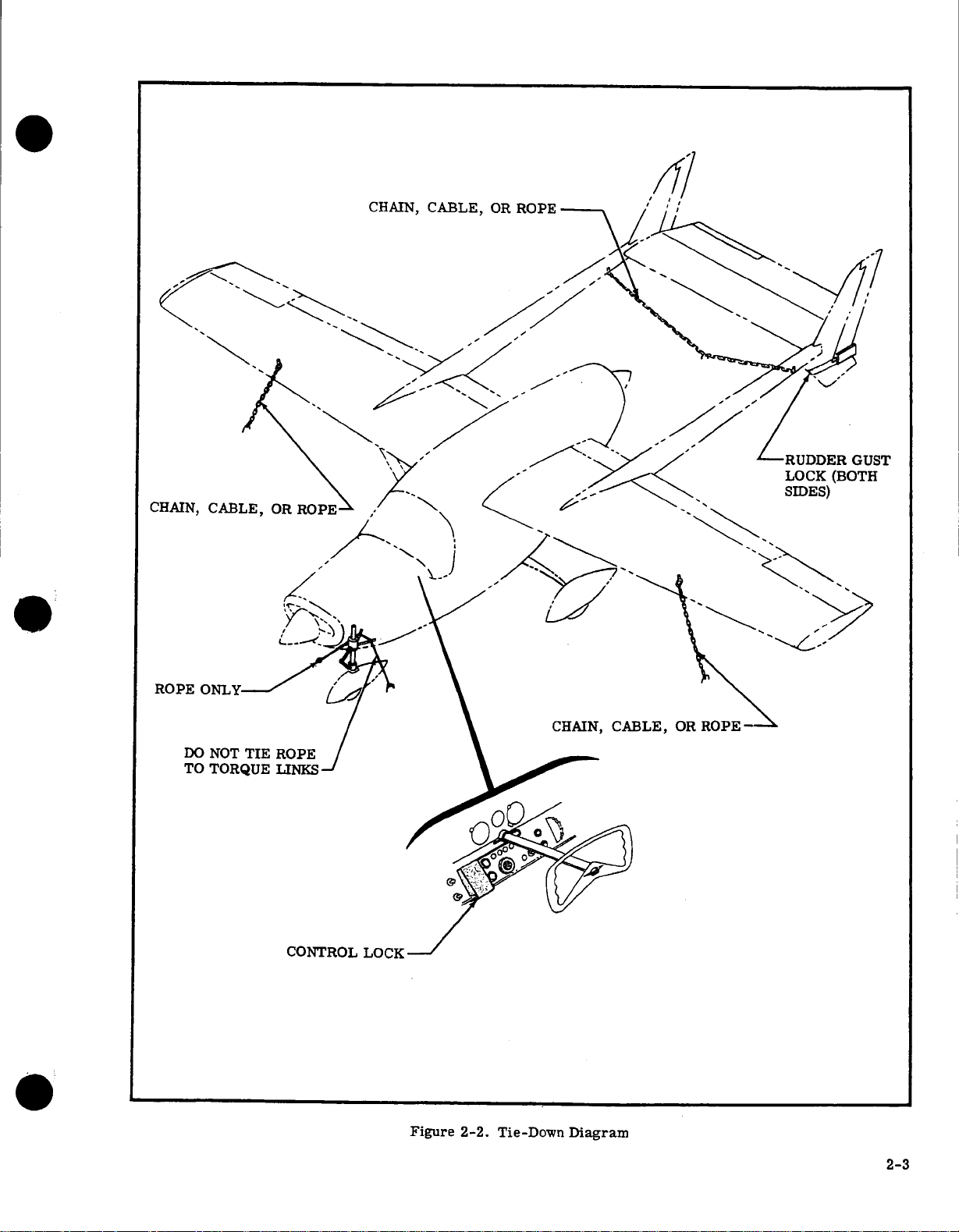

CHAIN,

CABLE,

OR

ROPE

CHAIN,

ROPE

DO

TO

CABLE,

ONL

NOT

TORQUE

TIE

OR

ROPE

ROPE

CONTROL

CHAIN,

CABLE,

OR

ROPE

Figure

2-2.

Tie-Down

Diagram

2-3

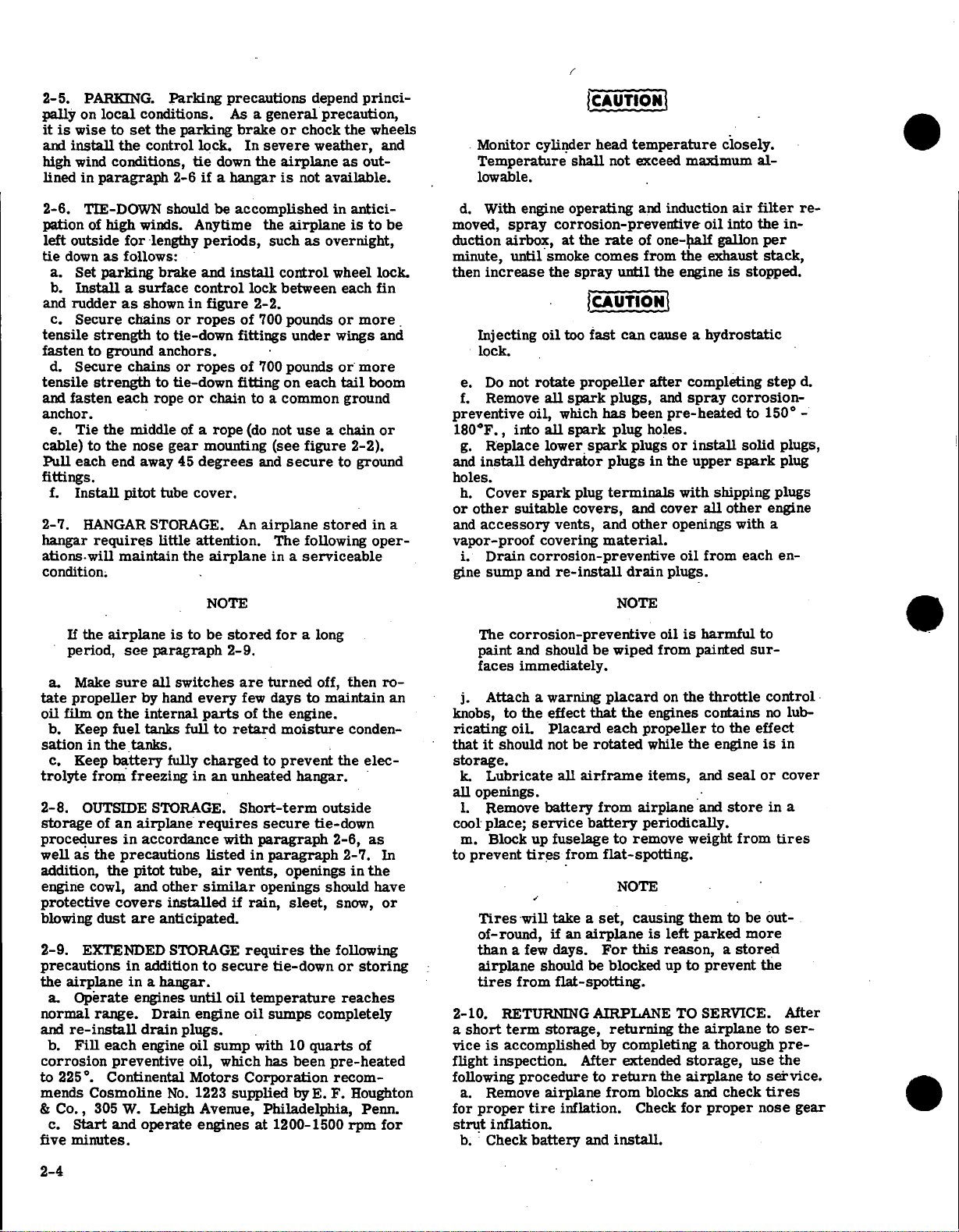

2-5.

PARKING.

pally

on

it

is

wise

and

install

high

wind

lined

in

paragraph

2-6.

TIE-DOWN

pation

of

left

outside

tie

down

a.

Set

b.

Install

and

rudder

c.

Secure

tensile

fasten

tensile

and

d.

strength

to

Secure

strength

fasten

anchor.

e.

Tie the

cable)

to

Pull

each

fittings.

f.

Install

2-7.

HANGAR

hangar

requires

ations-will

condition;

local

conditions.

to

set

the

control

conditions,

high

winds.

for

as

follows:

parking

a

surface

as

shown

chains

ground

chains

each

middle

the

nose

end

away

pitot

STORAGE.

maintain

Parking

the

parking

2-6

should

lengthy

brake

in

or ropes

to

tie-down

anchors.

or

to

tie-down

rope

or

of a rope

gear

45

tube

little

the

precautions

As a general

brake

lock.

tie

down

if

a

hangar

be

accomplished

Anytime

periods,

and

install

control

figure

of

fittings

ropes

of

fitting

chain

mounting

degrees

cover.

An

attention.

airplane

depend

or

chock

In

severe

the

airplane as

is

not

the

airplane

such

as

control

lock

between

2-2.

700

pounds

under

700

pounds

on

each

to a common

(do

not

use a chain

(see

figure

and

secure

airplane

The

following

in a serviceable

princi-

precaution,

the

weather,

out-

available.

in

anticiis

overnight,

wheel

each

or

more

wings

or

more

tail

ground

2-2).

to

ground

stored

wheels

and

to

be

lock.

fin

and

boom

or

in

a

oper-

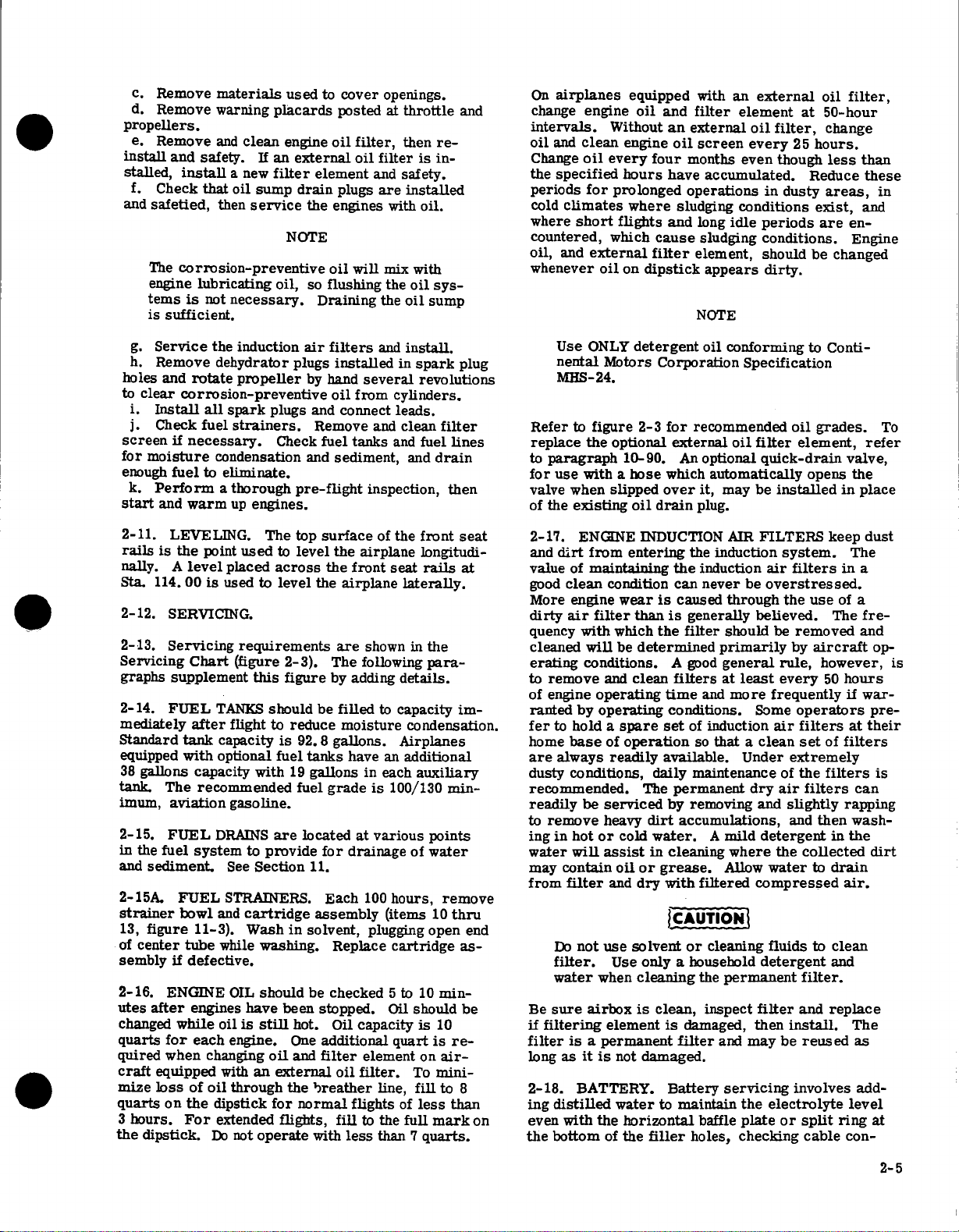

Monitor

Temperature

lowable.

d.

With

moved,

duction

minute,

then

spray

airbox,

until

increase

Injecting

lock.

e.

Do

f.

preventive

180°F.,

g.

and

not

Remove

into

Replace

install

holes.

h.

Cover

or other

and

suitable

accessory

vapor-proof

i.

Drain

gine

sump

CAUTION

cylinder

engine

smoke

head

temperature

shall

not

operating

corrosion-preventive

at

the

rate

comes

the

spray until

CAUTION

oil

too

fast

can

rotate

propeller

all

spark

plugs,

oil,

which

has

been

all

spark

plug

lower

spark

dehydrator

spark

plug

covers,

vents,

covering

corrosion-preventive

and

re-install

plugs

plugs

terminals

and

and

other

material.

drain

exceed

and

induction

of

one-half

from

the

cause

after

and

pre-heated

holes.

or

in

the

cover

openings

plugs.

closely.

maximum

oil

into

gallon

the

exhaust

engine

is

a

hydrostatic

completing

spray

install

upper

with

shipping

all

other

oil

from

al-

air

filter

the

in-

per

stack,

stopped.

step

corrosion-

to

150°

solid

plugs,

spark

plug

plugs

engine

with

a

each en-

re-

d.

-

If

the

period,

a.

Make

tate

propeller

oil

film

b.

sation

c.

trolyte

2-8.

storage

on

Keep

in

Keep

from

OUTSIDE

of

procedures

well

as

the

addition,

engine

cowl,

protective

blowing

2-9.

dust

EXTENDED

precautions

the

airplane

a.

Operate

normal

and

re-install

b.

range.

Fill

corrosion

to

225°.

mends

&

five

Co.,

c.

Cosmoline

305

Start

minutes.

airplane

see

paragraph

sure

all

by

hand

the

internal

fuel

tanks

the

tanks.

battery

fully

freezing

STORAGE.

an

airplane

in

accordance

precautions

the

pitot

and

other

covers

are

in

addition

in

a hangar.

installed

anticipated.

engines

Drain

drain

each

engine

preventive

Continental

No.

W.

Lehigh

and

operate

NOTE

is

to

be

stored

2-9.

switches

every

parts

full

to

charged

in

an

unheated

requires

with

listed

tube,

air

similar

if

STORAGE

to

secure

until

oil

engine

plugs.

oil

sump

oil,

which

Motors

1223

supplied

Avenue,

engines

for

are

turned

few

days to

of

the

retard

moisture

to

prevent

Short-term

secure

paragraph

in

paragraph

vents,

openings

openings

rain,

requires

tie-down

temperature

oil

sumps

with

has

Corporation

Philadelphia,

at

1200-1500

a

long

off,

engine.

hangar.

tie-down

sleet,

the

completely

10

quarts

been

by

E.

then

maintain

conden-

the

elec-

outside

2-6,

as

2-7.

in

the

should

snow,

following

or

storing

reaches

of

pre-heated

recom-

F.

Houghton

Penn.

rpm

ro-

In

have

or

for

an

The

paint

faces

j.

Attach

knobs,

ricating

that

it

should

storage.

k.

Lubricate

all

openings.

1.

Remove

cool

place;

m.

Block

to

prevent

Tires

of-round,

than a few

airplane

tires

2-10.

a

vice

flight

RETURNING

short

is

inspection.

following

a.

Remove

for

proper

strut

inflation.

b.

Check

NOTE

corrosion-preventive

and

should

be

wiped

immediately.

a

to

the

oil.

tires

warning

effect

Placard

not

all

battery

service

up

fuselage

that

be

rotated

airframe

battery

from

placard

each

from

to

flat-spotting.

NOTE

will

take a set,

if

an

airplane is

days.

should

from

For

be blocked

flat-spotting.

AIRPLANE

term

storage,

accomplished

returning

by

After

procedure

tire

battery

airplane

inflation.

and

to

return

from

install.

oil

is

the

propeller

airplane

from

on

the

engines

while

items,

harmful

painted

throttle

contains

to

the

and

and

the

engine

seal or

store

to

sur-

effect

periodically.

remove

causing

this

weight

them

left parked

reason,

up

to

prevent

a

from

to

be

stored

more

the

TO SERVICE.

the airplane

completing a thorough

extended

Check

the

blocks

storage,

airplane

and

check

for proper

use the

to

nose

control

no

lub-

is

in

cover

in

a

tires

out-

After

to

ser-

pre-

service.

tires

gear

2-4

c.

Remove

d.

Remove warning

propellers.

Remove

e.

install

and

stalled,

f.

and

install

Check

safetied,

The

corrosion-preventive

engine

tems

is

is

sufficient.

g.

Service

h.

Remove

holes

to

clear

i.

j.

screen

for

enough

k.

start

2-11.

rails

nally.

Sta.

2-12.

2-13.

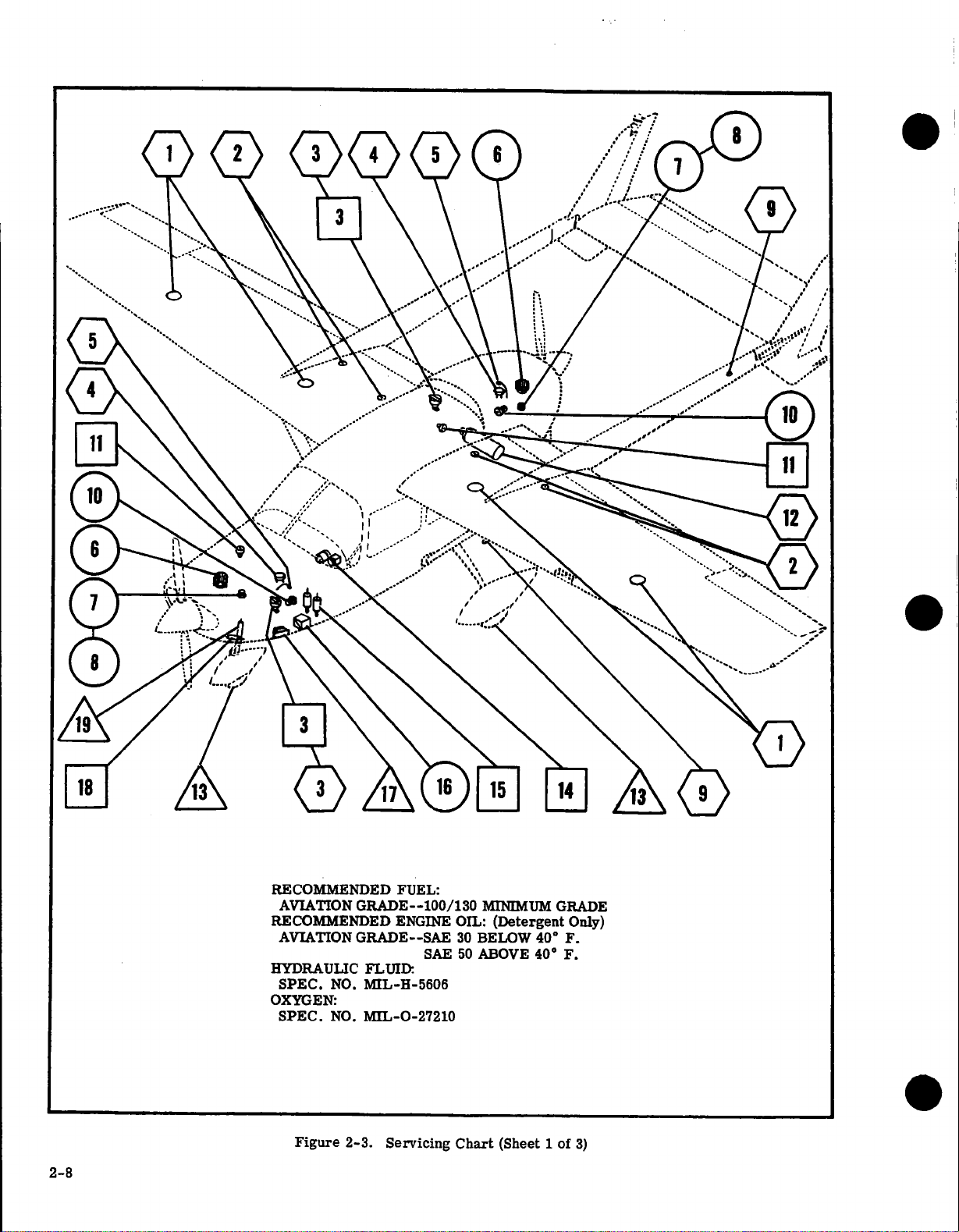

Servicing

graphs

2-14.

rotate propeller

and

corrosion-preventive

Install

Check

if

necessary.

moisture

fuel

Perform

and

warm

LEVELING.

the

is

A

level

114.00

SERVICING.

Servicing

Chart

supplement

FUEL

mediately

Standard

equipped

38

tank.

imum,

2-15.

in

and

2-15A.

strainer

13,

of

sembly

2-16.

utes

changed

quarts

quired

craft

mize

quarts

3

hours.

the

tank

with

gallons capacity

The recommended

aviation

FUEL

the

fuel

sediment.

FUEL

bowl

figure

center

tube

if defective.

ENGINE

after

while

for

when

equipped

loss

on

the

For

dipstick.

materials

and

clean

safety.

a new

that

oil

then

lubricating

not

necessary.

the

induction

dehydrator

all

spark

fuel

strainers.

condensation

to

eliminate.

a

thorough

up

point

used

placed

is

used to

requirements

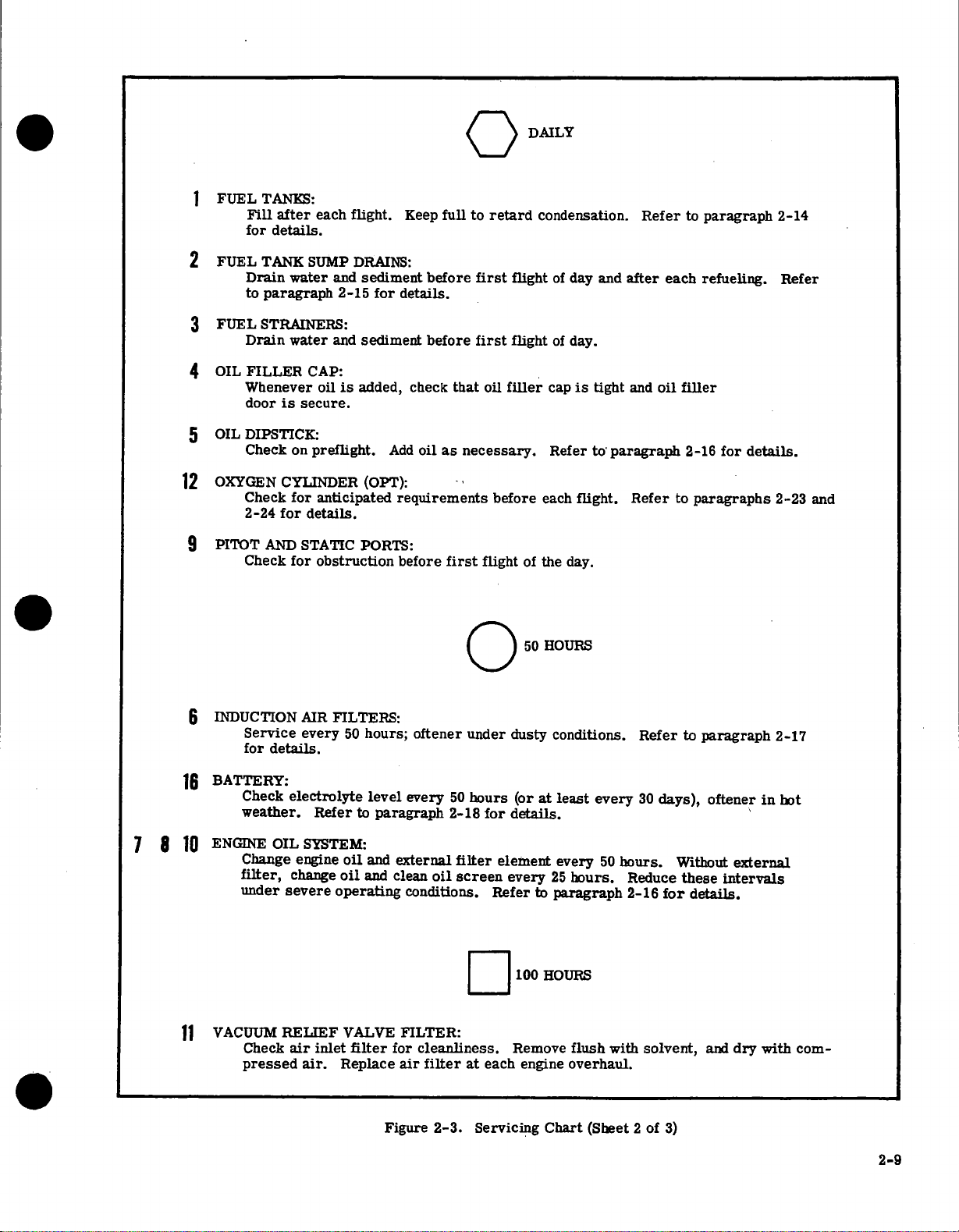

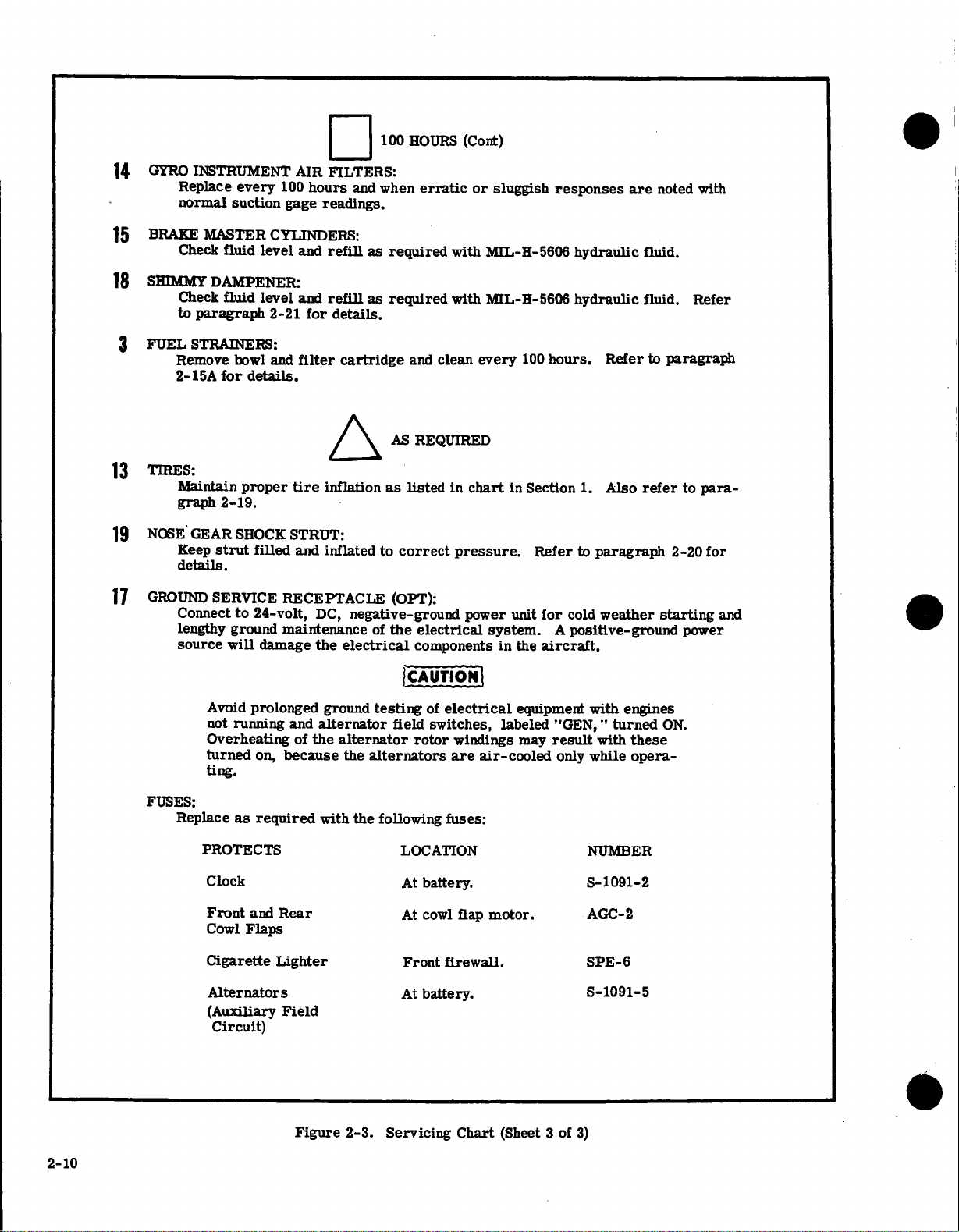

(figure 2-3).

TANKS

after

flight to

capacity

optional

gasoline.

DRAINS

system

See

STRAINERS.

and

11-3).

while

OIL

engines

is

oil

each

engine.

changing

with

through

of

oil

dipstick

extended

Do

not

used

placards

engine

If

an

external

filter

sump

drain

service

NOTE

oil,

air

plugs

plugs

Check

pre-flight

engines.

top

The

to

level

across

level

figure

this

should

reduce

is

92.8

fuel

with

19

fuel

located

are

provide

to

Section

cartridge

in

Wash

washing.

should

have been

hot. Oil

still

One

and

oil

external

an

the

for

normal

flights,

operate

to

cover

openings.

posted

oil

element

plugs

the

engines

oil

so

flushing

Draining

filters

filter,

oil

and

will

at

filter

are

with

mix

the

the

and

installed

hand

by

and

Remove

and

several

oil

from cylinders.

connect

and

fuel

tanks

sediment,

inspection,

surface

the

the

be

the

airplane

front

airplane

are

The

by

adding

filled

of

shown

following

to

moisture

gallons. Airplanes

tanks

have

an

gallons

grade

for

in

each

is

at

various

drainage

11.

Each

100

assembly

solvent,

(items

plugging

Replace

be

checked 5 to

stopped.

capacity

additional

element

filter

oil

filter.

breather

line,

flights

fill

to

the

less

with

than 7 quarts.

throttle

re-

then

is

in-

safety.

installed

oil.

with

oil

sys-

oil

sump

install.

in

spark

revolutions

leads.

clean

filter

and

fuel

and

drain

then

the

front

longitudi-

seat

rails

laterally.

in

the

para-

details.

capacity

condensation.

additional

auxiliary

100/130

points

of

water

hours,

remove

10

open

cartridge

min-

10

Oil

should

10

is

quart

is

on

air-

To

mini-

fill

to 8

less

of

full

mark

and

plug

lines

seat

at

im-

min-

thru

as-

be

re-

than

end

on

On

airplanes

change

intervals.

oil

Change

the

periods

cold

where

engine

and

clean

oil

specified

for

climates

short

Without

every

countered,

and

Use

nental

external

oil

ONLY

Motors

oil,

whenever

MHS-24.

to

Refer

replace

to

for

valve

of

2-17.

and

value

good

More

dirty

quency

cleaned

erating

to

of engine

ranted

fer

home

are

dusty

figure

the

paragraph

with

use

when

the

existing

ENGINE

dirt

from

maintaining

of

clean

engine

air

filter

with

will

conditions.

remove

operating

by

operating

to

hold

base

always

conditions,

condition

and

a

of

recommended.

be

or

hot

will

contain

filter

not

serviced

heavy

assist

use

readily

to

remove

in

ing

water

may

from

Do

filter.

when

water

sure

filtering

is

it

as

BATTERY.

distilled

with

bottom

airbox

a

permanent

is

the

of

Be

if

filter

long

2-18.

ing

even

the

equipped

oil

and

engine

four

hours

prolonged

where

flights

which

cause

filter

on

dipstick

detergent

Corporation Specification

2-3

optional

10-90.

a hose

oil

over

drain

slipped

INDUCTION

entering

is

wear

than

the

which

determined

be

clean

spare

operation

readily

daily

The

dirt

water.

cold

in cleaning

grease.

or

oil

and

dry

solvent

Use

only

cleaning

clean,

is

element

not

damaged.

water

to

horizontal

filler

the

an

with

filter

an

external

screen

oil

months

have

accumulated.

operations

sludging

and

long

idle

sludging

element,

appears

NOTE

oil

conforming

for

recommended

external

An

which

oil

optional

automatically

may

it,

plug.

AIR

the

induction

induction

the

can

never

caused

is

through

generally

should

filter

primarily

good

and

general

at

more

A

filters

time

conditions.

induction

of

set

so

that

available.

maintenance

permanent

by removing

accumulations,

mild

A

where

Allow

filtered

with

ICAUTION

cleaning

or

a

household

permanent

the

inspect

is

damaged,

and

filter

Battery

servicing

maintain

baffle

holes,

external

element

oil

filter,

every

25

even

though

in

dusty

conditions

periods

conditions.

should

dirty.

oil

filter

quick-drain

installed

be

FILTERS

system.

filters

air

be

overstressed.

the

believed.

be

by

rule,

least

every

frequently

Some

air

a clean

extremely

Under

of

dry

air

and

slightly

and

detergent

the

water

compressed

fluids

detergent

filter

install.

then

be

may

electrolyte

the

or

plate

checking

oil

at

50-hour

change

hours.

less

Reduce

areas,

exist,

are

be changed

to

Conti-

grades.

element,

opens

in

keep

use

of

The

removed

aircraft

however,

50

operators

filters

of

set

filters

the

filters

then

in

collected

to

drain

to

clean

and

filter.

and

replace

reused

involves

split

cable

filter,

than

these

and

en-

Engine

refer

valve,

the

place

dust

The

in

a

a

fre-

and

hours

if

war-

pre-

their

at

filters

can

rapping

wash-

the

air.

The

as

add-

level

ring

con-

in

To

op-

is

is

dirt

at

2-5

nections,

electrolyte

(baking

lyte

with

to

enter

can

and

coat

the

days),

water,

trolyte level

and

2-19.

sure

ing

bruises,

and

soda)

or

corrosion.

clean

battery

permanently

terminal

with

petroleum

battery

oftener

not

clean,

This

aircraft

a

negative

polarity.

electrical

TIRES

specified

tire

pressure,

and

neutralizing

corrosion.

or

and

water.

as

damage

connections

every

in hot

or

acid

in

the

remove

ground

Reverse

components.

should

in

slippage.

and

Use

water

clean

Follow

Do

it

50

"rejuvenators,"

battery.

any

is

the

examine

with

not

allow

will

neutralize

battery.

with

jelly

before

hours

(or

weather.

evidence

CAUTION

equipped

system.

polarity

be maintained

of

chart

tire

NOTE

cleaning

bicarbonate

to

neutralize

a

thorough

bicarbonate

Brighten

a

wire

connecting.

at

least

only

Add

to

Inspect

of

corrosion.

with

alternators

Observe

will

at

Section

for

wear,

off

any

of

electro-

flushing

of

electrolyte

cable

brush,

every

distilled

maintain

the

battery

proper

damage

the

air

1.

When

cuts,

spilled

soda

soda

then

Check

30

elec-

and

pres-

check-

and

box

To

stalled

that

the

or

fill

Remove

a.

Using

b.

places

filler

Fill

c.

Install

d.

To

fill

airplane,

Remove

a.

Submerge

b.

and

fluid

remove

of

filling

Reinstall

c.

hydraulic

Keep

exposed

off

which

rel

fluid,

dust

add

airplane:

on

tow-bar,

a

the

plug.

with

and

shimmy

proceed

work

entrapped

any

cylinder.

fluid.

the

portions

a

with

may

not

Do

since

grit.

and

fluid

filler

MIL-H-5606

filler

plug

shimmy

clean

shimmy

to

plug

turn

dampener

filler

safety

dampener

as

follows:

plug

dampener

dampener

before

dampener,

of

cloth

the

cut

the

wipe

this

tends

air

seals

dampener.

from

nose

piston

hydraulic

plug.

when

dampener.

from

MIL-H-5606

in

piston

and

removing

NOTE

the

dampener

remove

to

in

shaft

to

collect

dampener

in

gear

the

at

fluid.

removed

it

is

shaft in

ascertain

dampener

especially

dust

the

dampener

hydraulic

with

even

while

the

end

hydraulic

and

complete

shaft,

and

in-

direction

opposite

from

out

from

the

wiped

grit

bar-

more

to

Recommended

tained.

ber

that

a

inside

pressure.

2-20.

requires

is

MIL-H-5606)

sure.

as

zero.

fill

lic

several

nose

to

2-21.

shimmy

100

with

NOSE

periodic

filled

with

When

follows:

Remove valve

a.

b.

Remove

c.

Telescope

to

bottom

fluid.

Lift

of

Install

50

psi

Keep

the

off

grit

rel

since

grit.

hours.

fluid,

nose

times

airplane

with

the

exposed

with

which

Do

NOSE

dampener

d.

e.

this

free

Especially

any

drop

tire

GEAR

hydraulic

and

servicing

valve

gear

of

filler

of

to

valve

nose

nose

portion

a

clean

may

not

wipe

tends

GEAR

The

of

in

cold

in temperature

causes a corresponding

STRUT.

checking

inflated

is

cap

housing

airplane,

expel

and

housing

wheel

gear

dry

cut

to

SHIMMY

should

dampener

entrapped

to

fluid

the

nose

reduce

and

assembly.

strut

to

with MIL-H-5606

hole

extend

entrapped

any

repeat

assembly

off

NOTE

shock

of

the

cloth

the

seals

the

strut

collect

be

must

pressure

tire

should

weather,

of

The

nose

ascertain

(Federal

to

its

step

ground

strut,

strut

to

with

even

DAMPENER.

serviced

air,

the

correct

gear

air

shortest

and

"c."

piston,

remove

in

the

hydraulic

more

be

to

Specification

strut

compress

air,

and

(strut

especially

at

filled

serve its

be

main-

remem-

the

air

drop

strut

gear

the

that

air

proceed

pressure

length

hydrau-

then

inflate

extended).

wiped

dust

and

strut

bar-

dust

The

least every

completely

in

strut

pres-

to

and

strut

lower

strut

fluid,

and

purpose.

the

of

is

70°F.

The

valve

removing

cylinder

oxygen

be

Remove

a.

Do

near

oxygen

operation.

ing

Close

b.

Disconnect

c.

Loosen

d.

brake

100

accomplished.

HYDRAULIC

entrapped

OXYGEN

not

2-22.

checked

every

at

tem

response

2-23.

equipped

cylinder

sure

cylinder

at

clockwise.

cylinder.

for

the

hours.

the

to

with

should

below

contains

oxygen

so

supplier,

permit

airplane

system,

master

cylinder

BRAKE

correct

Add

master

the

is

access

cylinders.

whenever

air

brake

CYLINDER.

an

optional

refilled

be

psi.

300

cubic

48

system

system

oxygen

the

be

refilled

to

the

panel

WARNING

smoking

while

or

Guard

switch

shut-off

oxygen

clamps

securing

SYSTEMS

amount

MIL-H-5606

pedals.

When

NOTE

is

may

cylinder.

following

work

when

against

on.

lines

of

there

Some

oxygen

when

fully

of

feet

equipped

be

by

right

on

open

or

is

the

inadvertently

valve

from

cylinder

should

at

fluid

hydraulic

the

Bleed

oxygen

refilled

a

performed

system

a

is

airplanes

system.

system

charged

oxygen

a

with

without

the

If

commercial

procedure

rear

flame

is

turning

by

cylinder.

and

least

brake

spongy

The

the

at

1800

filler

oxygen

of

fuselage.

or

in

on

in

turn-

remove

be

fluid

sys-

are

oxygen

pres-

oxygen

psi

may

full

2-6

e.

Refill

(MIL-O-27210).

This

moisture

age

temperature,

f.

inder.

Oil,

with

such

compound

used

to

vent

2-24.

face

the

map

should

masks,

the

supply

2-25.

2-26.

sides

cleaning

makes

2-27.

shields

fresh

feel

and

soft

cloth,

means

clean,

build

dust

particles.

rubbing

then

washing

with

water

Do

carbon

de-ice

cleaning

and

2-28.

ped

with

wheels

soap

graph

airplane.

cylinder

oxygen

to

the

Reverse

grease,

oxygen

contact

safely

first

three

thread

OXYGEN

masks

compartment.

include

hoses

of

CLEANING.

Keeping

maintaining

reduces

inspection

WINDSHIELDS

and

water

dislodge

or

of

carrying

damp

up

an

electrostatic

lightly

and

not

use

tetrachloride,

fluid,

craze

PLASTIC

plastic

and

other

and

water.

when

cleaning

with

is

specially

which

could

system

the

or

and

render

preceding

WARNING

or

other

create a

must

approved

are

checking

and

masks

the

windows

and

chamois

chamois.

with

the

soap.

gasoline,

spray. These

the

be

on

oxygen

threads

seizure.

FACE

normally

fittings,

as

airplane

the

trim

the

possibility

and

maintenance

AND

should

soap,

using

any

caked

may

water

Oil

and

a

kerosene-moistened

kerosene

CAUTION

lacquer

plastic.

TRIM.

control

plastic

Observe

the

aviator's

NOTE

dried

cause

which

the

steps

lubricants

serious

avoided.

under

MIL-T-5542

systems.

of

male

MASKS.

stowed

Oxygen

the

condition

and

required.

clean

appearance

WINDOWS.

be

the

dirt

be

to

the

Rubbing

charge

grease

residue

alcohol,

fire

extinguisher

thinner,