Cessna 182, Skylane Owner's Manual

"

19

5

1

-

5

8

CESSNA

CSSna

ON YOUR TRAVELS,

STOP AT

CESSNA

SERVlCE STATIONS

FOR FAST,

EFFICIENT,

ECONOMICAL

SERVICE.

&£2d

CESSNA

AIRCRAFT COMPANY WICHITA,

KANSAS

Owner

o

Manual

This manual describes

1957

and 1958

Cessna Model

the operation and

182,

and

performance

the

1958 Cessna

of the

Sky-

lane. Equipment described as "Optional" denotes that the

subject equipment is optional on the

equipment is

for minor

identical

performance;

years.

the rudder trim system which

is

model only. The

also described

standard

on the

equipment changes, the

structurally

and operationally, and have the same

therefore,

main difference between

The

1957 model

this

in

manual.

1958

this manual is

has

Model

Cessna

1957

a rudder trim tab

182. Much

Skylane.

and

1958

applícable for

1957

a

is

and 1958

installed on the

of

this

Except

models are

both

model

1958

which

is

D139-13-CES-250-12/73

Ûong

raf uÎahons

. . .

-

You are now the

owner

of a truly

outstand-

ing airplane.

Your Cessna has been engineered

to

give

you the ultimate

in performance,

styling,

durability, flying

comfort,

and

economy

for both

business and

pleasure.

-

We share your

pride

as a Cessna

owner

and

have prepared this

Owner's

Manual as a guide

to acquaint you with

your

airplane and its fine

construction,

equipment, ease of operation and

its care.

-

Every fine

possession is worth

caring for,

and this is

especially

true of your Cessna. This

book is

dedicated to help you

operate

your

air-

plane

to get

the utmost flying

enjoyment and

service with a minimum of care.

i

PRINClPLE

DlMENSIONS

Illllli I

82

- -

/

25' L75"

ii

TABLE

OF

CONTENTS

Page

SECTION I

-

DESCRIPTION . .

1-1

SECTION II

-

OPERATING

CHECK LIST

2-1

SECTION III-OPERATING

DETAILS

3-1

SECTION IV

-

OPERATING

LIMITATIONS

4-1

SECTION

V

-

OPERATIONAL DATA

5-1

SECTION

VI

-

CARE

OF THE

AIRPLANE- 6-1

OWNER'S RESPONSIBILITIES

CROSS

COUNTRY

SERVICE

6-26

ALPHABETICAL

INDEX

A-1

iii

1

2

3

4

5 6

7

8

9

10 11

12

13

14 15

16

17

18

19 28

30 29

24

21

1. Headphone jack 12. Oil Pressure

Gage

22.

Optional

Radio Space

2. Azimuth

Indicator

(Opt. Equip

)

13.

Compass Card Holder

25.

Carburetor

Air Temperature

Gage

3.

Speed

Control

Indicator

(Opt.

Equip.)

14. Manifold Pressure

Gage

(Opt.

Equip.)

4. Clock

(Opt.

Equip.) 15. Oil

Temperature Gage 24.

Cylinder Head Temperature

Gage

5.

Turn

and Bank

Indicator (Opt. Equip.) 16.

Tachometer

(Opt.

Equip.)

6. Airspeed Indicator 17. Right Tank

Fuel

Quantity

Indicator 25.

Control

Panel (See 6gure 2)

7. Altimeter 18. Suction

Gage (Opt. Equip.) 26.

Fuel Strainer Drain Knob

8.

Directional

Gyro

(Opt. Equip.) 19. Glove

Compartment Door

Handle.

27. Optional Radio

9.

Rate-of-Climb

Indicator

(Opt.

Equip.)

20. Glove Compartment

Door 28. Parking

Brake

Handle

10. Gyro Horizon

(Opt.

Equip.) 21. Electrical

System

Control Panel

29.

Optional Instrument

Space

11.

Left Tank

Fuel Quantity

Indicator

(See ngure

5)

30.

Omni Indicator

(Opt. Equip.)

Figure 1. Instrument Panel

description

ONE OF

THE

FIRST STEPS

in obtaining

the

utmost performance,

service,

and

flying

enjoyment from your Cessna is to

familiarize

yourself

with

your

airplane's equipment,

systems, and controls. This

section will

tell

you

where

each

item

is

located,

how

it

operates

and

its

function.

ENGINE

FRICTION LOCKNUT

A

six-cylinder, Continental Model

0-470-L,

230 horsepower

engine

pow-

ers

your airplane. Compact,

depend-

able and

efficient,

the engine

incorpo-

rates

hydraulic

valve-lifters

which

silence valve operation. Built

by a

company whose name has

become a

byword

for

precision-built, perform-

ance-packed aircraft engines, the

Con-

tinental 230 horsepower engine means

top performance for your

airplane at

low

maintenance cost.

THROTTLE CONTROL

THROTTLE.

The throttle

(3,

figure 2) is

cen-

NOTE

trally located

on the

lower

half

of

the

Because

of the

constant

speed

instrument panel

and is

easily

identi-

propeller

mechanism,

standard

fled

by its

large,

round

knob.

Engine

equipment

on the

airplane,

power

can be

increased by

pushing

advancing the throttle

will

not

the throttle

in

toward

the instrument

increase

engine

rpm.

It will

panelordecreased by pulling the

con.

increase

the

manifold pressure.

trol

out.

To prevent the throttle

from

With

each

power

increase,

the

creeping, a

knurled, friction-type,

lock

constant

speed

propeller

auto-

nut is incorporated on the

control to matically takes a

larger

"bite",

secureitat

any

desired

setting. enabling

the

engine to run

at

I-1

DESCRIPTION

a

constant

speed at all times.

figure 2)

is located

to

the

left

of the

Engine rpm

can be

changed by

throttle.

The

push-pull

control

operates

adjusting the

propeller

control.

the carburetor air intake

butterfly

Refer

to "PROPELLER PITCH

valve which

proportions the hot and

CONTROL"

paragraph on

cold air

entering

the carburetor.

Pull-

page

1-5

for this procedure. ing

the control out provides

heated air

for the carburetor

while

pushing

the

control

all the way in

provides

only

cold

air

for

the carburetor.

LOCKING

LEVER

The

controL

has

a

center

button

locking device.

To move

the control.

press the lock button in with

the

thumb

and

hold

while

moving

the

control

to

the

desired

position.

Lock

the

control

by releasing

the

thumb

MIXTURE

CONTROL

pressure

on

the button.

Air

pulled into

the heater

muffs

MIXTURE CONTROL.

and

subsequently

into

the engine

does

not

pass through the

air filter. For

The mixture control

(7,

figure

2) is

·

this

reason,

when

taxiing

on

dirty,

the second

knob to the right

of

the

dusty, or sandy fields,

carburetor heat

throttle

in the

lower center

portion

of

should not be

used

until the engine is

the

instrument panel. A

locking

lever

cleared

prior to

take-off.

After

a

full

is

incorporated on

the control to

pre-

stop

landing

under

these

conditions,

vent

its

unintentional

use. To

lean

the

carburetor heat should be

returned

to

mixture,

it is

necessary

to

depress

the

full

cold in order

for the

air filter

to

locking

lever

while

pulling

the

mix-

become fully

effective again.

ture

control

knob

out.

This

operation

Carburetor

ice

can form on the

can

be

accomplished with

one hand

. .

.

by

using

the

thumb

to press the

lock-

ground with

the

engine idling.

There-

. -

fore,

just before

take-off,

when you

ing lever in and

the

index and middle

fingers to

pull

the

mixture control

run-up

the engine and check magnetos,

knob

out.

The

locking

lever

is

effec-

be sure to

put

the carburetor heat in

tive

only

in

the

leaning

operation.

the "ON" position after

the

magneto

Forward movement

of

the mixture

check.

Leave

it in this position

until

control is not affected by

the locking

just

before

you

open the throttle

for

lever. For detailed

operating

instruc

the

take-off

run. Then

move

carburet-

or heat to the

"COLD AIR" osition.

tions

on the use

of

the

mixture

con-

P

trol,

refer to Section III.

This

gives

maximum power

for the

take-off.

Watch

engine for

any

indi-

CARBURETOR AIR HEAT

CONTROL

cations

of

ice

(roughness or

a

drop

in

The

carburetor

air heat control

(1, manifold pressure) during

climb

and

1-2

DESCRIPTION

ALPHABETICALINDEX

Right Tank

Fuel

Quantity

indicator,

iv

Take-Off,

2-3, 3-2,

3-4

5 7

Rudder Control System,

6-10,

6-11

crosswind,

2-3

Ruger

Pedals,

1-13,

1-14

diagram,

5-2

Rudder

Tab,

6-12

minimum

run,

2-3

Rudder Trim

Control

Wheel,

1-14

normal,

2-3

obstacle

clearance,

2-3

'EM

soft

or

rough field,

2-3

k

-O

an3d3-Climb

Chart,

5-3

S

Throttle, 1-1,

1-3

Tie-Down

Procedure,

5-8

Tires,

6-2

m mpener,

6-3

Tu

pressurLnk3Indicator,

iv,

1-17

Speed

Control

Indicator, iv

Stabilizer

Control System,

6-12,

6-13

Stall

Warning

Indicator,

1-17

Stall Warning

Transmitter

Heater,

1-17

Staalling3-7peeds

Chart,

3-7

U

Figure

2.

control

Panet

Starter

Button,

1-4,

1-10

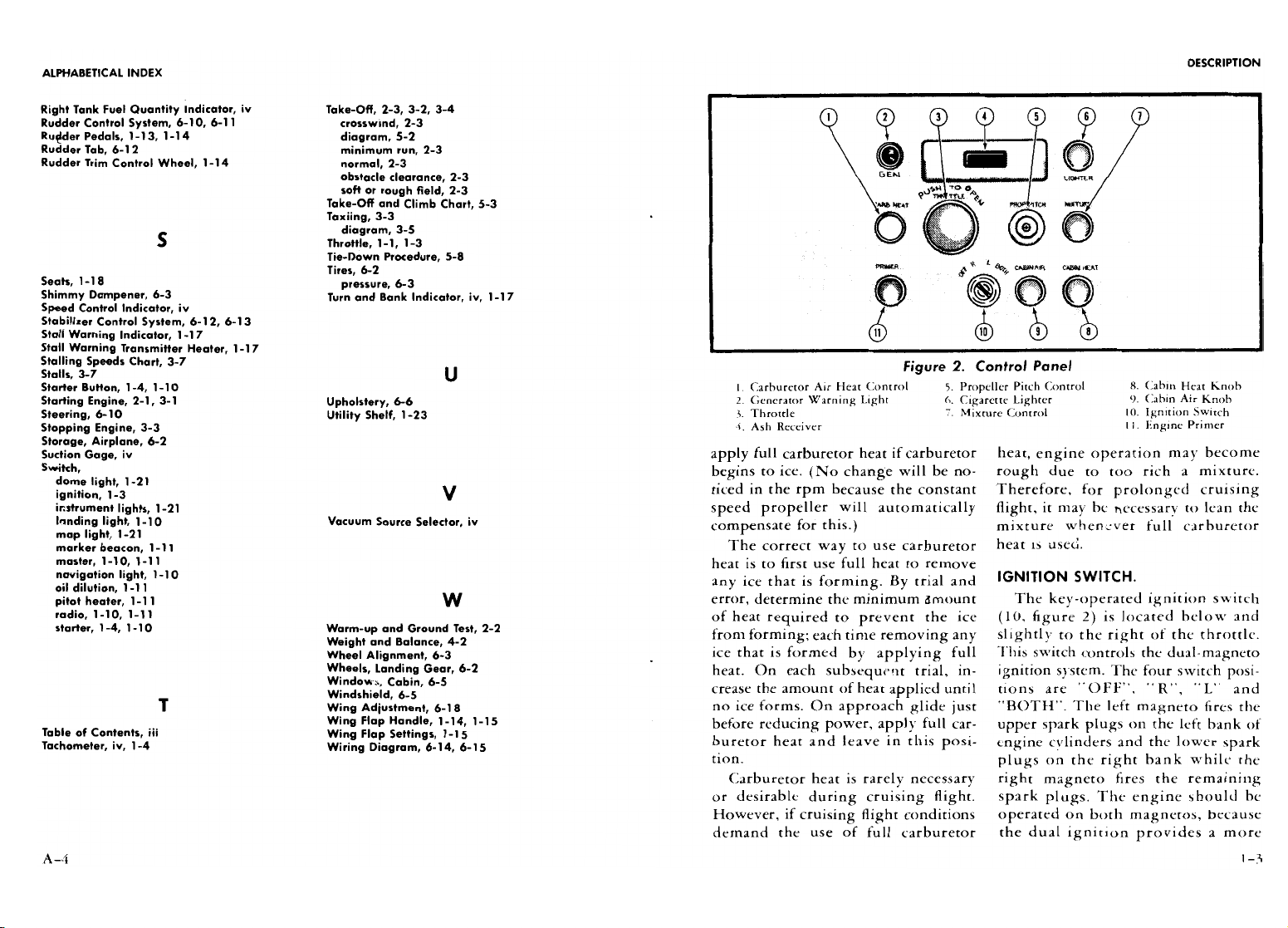

I

Carburetor Air

Heat

Control

5.

Propeller

Pitch

Control 8.

Cabin

Heat Knob

Starting Engine, 2-1,

3-1

Upholstery,

6-6

2.

Generator

Warning

Light

6.

Cigarette

Lighter

9.

Cabin Air

Knob

Steering,

6-10

Utility

Shelf,

1-23

3. Throttle

7.

Mixture

Control

10.

Ignition Switch

Stopping Engine,

3-3 4. Ash

Receiver

i1. Engine Primer

Storage, Airplane,

6-2

Suction

Gage, iv apply

full

carburetor

heat if carburetor heat,

engine oper2tion may become

Switch,

begins to

ice.

(No change

will be

no-

rough

due

to too

rich a

mixture.

dome

light,

1-21

-

ignition,

1-3

ticed in

the rpm

because

the constant

Therefore,

for

prolonged

cruising

instrument lights,

1-21

speed

propeller

will

automatically night,it

may be

necessary

to lean

the

Innding

light,

1-10

Vacuum

Source

Selector,

iv

compensate for this.)

mixture

whenever

full

carburetor

map light,

1-21

marker

beacon,

1-11

The

correct

way

to use carburetor

heat is

used.

master, 1-10,

1-11

heat is to first use full heat to

remove

v

tn light,

1-10

any

ice that is

forming.

By

trial and

IGNITION

SWITCH.

pitot

heater,

1-11

W

error,

determine the minimum amount

The

key-operated

ignition switch

radio,

1-10,

1-11

of heat required

to

prevent

the

ice (10,

figure

2) is located below and

starter,

1-4,

1-10

WWgmht nadnd Ground

Te2st,

2-2

from

forming; each time removing any

slightly to the

right of

the throttle.

Wheel Alignment,

6-3

ice that is formed

by applying

full

This

switch controls

the

dual-magneto

Wheels, Landing

Gear,

6-2

heat. On

each

subsequent

trial,

in-

ignition system.

The four switch

posi-

h

abi5n,

6-5

crease the amount

of

heat

applied

until tions

are

"OFF",

"

R",

"L and

T Wing

Adjustment,

6-18

no ice forms. On approach glide

just "BOTH". The left

magneto

Sres the

Wing Flap

Handle,

1-14,

1-15

before

reducing

power,

apply

full

car-

upper

spark

plugs on

the left bank of

Table

of Contents, m

Wing

Flap Settings,

1-15

-

Tachometer,

iv,

1-4

Wiring Diagram,

6-14,

6-15

buretor heat

and

leave in

this

posi-

engine cylinders and

the

lower spark

tion.

plugs

on the right bank while the

Carburetor heat is rarely

necessary

right

magneto fires

the remaining

or desirable during cruising

night. spark

plugs.

The engine should be

However,

if

cruising

nightconditions operated on both magnetos, because

demand the use of

full

carburetor

the dual ignition provides

a more

DESCRIPTION

ALPHABETICALINDEX

complete

burning

of the

fuel-air

mix-

that

the engine

be turned

over

L O

ture driving the pistons. The

"R"

and

while priming.

It may be

nec-

Landing,

2-5,

3-7

Oil

Dilution

System,

3-9

L"

positions are used for

checking

essary

to continue

priming

crosswind,

2.5

switch,

1-11

purposes only.

until the engine runs

smoothly.

diagram,

5.6

Oil Filler

Cap,

1-6

normal,

2-5 Oli

Level,

1-6

ENGINE PRIMER.

STARTER

BUTTON.

short

field,

2-5

Oil Pressure Gage, iv,

1-8

Landing

Gear, 1-15,

6-2

Oil Specification and

Grade,

1-8

The engine primer (11,

figure 2)

is

A

push-button

switch

(1, figure

5)

Landing

Lights,

1-20

Oil

System,

1-6

a

manual

pump

type

and

is

located

operates

the

electrical starter motor

Left Tank

Fuel

Quantity Indicator,

iv

schematic,

1-7

below

and

slightly

to

the

left of

the

. .

.

Let-down,

2-4,

3-3

Oil Temperature Gage,

iv,

1-8

.

and is located at the

left

sideofthe

in-

Lifting and

Jacking,

6-2

Omm

Indicator,

iv

throttle.

Regardless

of the outside air

Light

Operations

Authorized,

4-1

temperature, use of

the

primer is

nor-

strument panel

dome,

i-2i

optionalRadio space, iv

mally

required

for

starting the

engine.

TACHOMETER.

(*|*

or

ning, 1-io,

1-13

OxcyÃ

dSys m,

3-9

The

primer aids

starting by

supplying

A

recording

engine

tachometer (16,

landing,

1-2o

diagram,

a-il

an

initial

charge of

raw fuel to the

figure 1)

is mounted

above the

en-

map,

1-21

duration

chart,

3-12

navigation,

1-20 face

mask,

3-14

engine

cylinders-

gine

instrument

cluster on the

right

radio dial,

1-21 flow

indicator,

3-14

NOTE

side of

the

instrument panel.

The

Lighting

Eguipment,

1-20

operation,

3-10

Only

five

cylinders are

primed

tachometer indicates engine RPM and

a ra¢ce

sna 182,

i-2a

9pru

scoangn

c couplings,

a-i2

by

the

engine primer. The

right

records

engine operating hours.

Lower

Forward

Section of

Cabin,

1-14

regulator,

3-11

rear

cylinder

(No.

1) provides

MANIFOLD PRESSURE

GAGE.

Lubricartion, b167

schematic,

3-13

the

manifold pressure source

A

manifold pressure gage

(14,

fig-

connection

and is not primed. . .

.

ure

1) is

mounted

immediately to the

To

operate the primer, proceed

as

left of

the

tachometer and above

the

follows:

engine

instrument

cluster on

the

right

M

(1)

First,

unlock

the plunger

by

side of

the

instrument panel.

This

in-

Parking

Brake

Handle, iv,

1-16

turning

the knob

counter-

strument

indicates

the

pressure

of

the

Magnetic Compass,

1-18

Parking

Brake Operation,

1-16

-

Main

Landing Gear,

1-15

Pitot

Heater,

1-17

clockwise until the knob pops

fuel-air

mixture

entering the

engine

Maneuvers,

Pitot-Static System,

1-17

part

way

out-

cylinders andiscalibrated in

inches

normal

category,

4-1

Pressure,

Tire,

6-3

(2) Slowly

pull the

plunger all

of mercury. By

observing

the manifold

Manifold Pressure

Gage, iv,

1-4

Primer, Engine,

1-3,

1-4

Map Light,

1-21

Principle Dimensions,

n

the

way

out and then

push the

pressure gage

and

adjusting the

pro-

Map

Pocket,

1-23

Propeller,

1-5,

6-7

plunger all the

way

in.

This

peller

and

throttle

controls, the

power

Marker

Beacon

Switch,

1-11

Propeller

Pitch Control,

1-3,

1-5

action

is

termed "one

stroke

out ut

of the en

ine

can be adjusted to

Master

Switch,

1-10,

1-11

Miscellaneous

Equipment,

1-22

of the

primer"-

any

power

setting

recommended in the

Mixture control

Knob,

1-2,

1-3

(3)

Normal weather

will require

operating

procedures of Section

II

or

Mooring

Your

Airplane,

6-1

one

or two strokes

of the

performance charts of Section V.

primer,

and very cold

(-20°

F)

weather

may require

three

or

CYLINDER

HEAD

TEMPERATURE

Radio

Dial

Light,

1-21

four

strokes.

GAGE.

(OPTIONAL

EQUIPMENT.)

Radio

Switch,

1-10,

1-11

(4)

Normally,

the

engine

is

start-

A

cylinder

head

temperature

gage

N

ns.c

,b

5a

ed

immediately

after the

prim-

(24, figure

1)

is mounted immediately

Navigation Lights,

1-20

Rear

Seat,

1-18

ing

operation.

In

very cold

below the

engine instrument

cluster

on

nasher,

1-20

Rheostat,

Instrument Lights,

1-21

weather

it is

recommended

the right side of

the

instrument

panel.

Nose

Gear,

1-15

Rheostat,

Radio Dial Light,

1-21

A-3

1-4

ALPHABETICAL

INDEX DESCRIPTION

E

Gyro Horizon,

iv

The

gage

is

calibrated in

degrees

stant speed

feature

enables your

en-

Ground

Service Plug,

1-12,

6-14

Fahrenheit

and

is

electrically

operated. gine to

deliver

uniform

horsepower

Electrical

System,

1-11

However,

its sole

source of power

is

for each

throttle

setting.

control panel,

iv,

1-10,

1-11

schematic,

1-12

a thermocouple mounted

under

the

PROPELLERPITCH

CONTROL.

wiring diagram,

6-14,

6-15

lower

spark

plug of

the

left

rear en

The control

knob

(5,

figure

2)

to

Ele a r

Control

System,

6-12

H

gine cylinder and thus the

instrument

the right

of

the

throttle controls the

before

starting,

2-1,

3-1

Headphone Jack, iv

requires no power from the

electrical

engine speed. With

the

control

full

comraa nn

t

i6ons,

4-2

Heating

System, 1-18,

1-19

system. By

observing

the

gage

read-

forward, the

propeller

is in high

rpm

operating

procedure,

3-1

ings and

adjusting

the power

setting

position. It is moved

through its

com-

primer, 1-3,

1-4

the pilot can keep the engine

temper-

plete range by

pressing in the control

starting,

2-1,

3-1

atures

within

operating

limitations

lock

button in the

center of the

knob

stoppmg,

3-3

warm-up,

2-2,

3-2

PROPELLER.

and

pulling

out

the control

knob

to

Exterior Inspection

Diagram,

1-24

A

constant speed

propeller

is

stand.

its full

out or low

rpm position. For

Ignition

Switch,

1-3

ard

equipment

on

your

airplane, and

sensitive

control,

the

control

knob

,at,°,ia,

¡,

provides

your

airplane

with

maximum

can

be

screwed in

or out by turning

azimuth,

iv

performance

at

take-off,

during

climb,

the knob

with

the thumb

lock

in

its

F

Ieft tank

fuel

quantity,

iv

and

while cruising.

normal

locking position.

g

a u I uantity,

iv

A

propeller with

low

blade

angles

In use,

the

recommended procedure

Flap

BCel

k

Adjustment,6

speed

control,

iv

gives the

best performance

for

take-off

is

to

move

the

control full forward

Flight Control

System, 1-13,

6-7

stall

warning,

1-17

and

climb,

while

a

propeller with

high

(high rpm)

for

taxiing

and

take-off.

Front

Seats,

1-18

Insp

n ann

1 r,

270

blade

angles is more adapted

to

high

After

take-off

and

climb,

screw out

FF

nea

i

ta n u

,

1-10

Inspection Service and inspection

Period,

6-19

speed and

high

altitude

flying.

propeller

control

to the desired

cruis-

Fuel

Quantity

Indicators, iv,

1-11

Instruments,

1-16

A fixed-pitch

propeller

ordinarily

is

ing

rpm. When

changing

rpm

settings

Fuel

Selector Valve,

1-8

'I t a n

,

-2

set

to

obtain

best

performance

while

during cruising flight, it is

recom-

SStrean

at

a n dn

ve 1-80

Instrument

Panel,

iv

the

airplane

is cruising, consequently

mended that

control be moved by

Fuel System,

1-8

Internal

Cabin Measurements,

6-2s

the

take-off

and

climb

characteristics

screwing

in or

out since a small

move-

schematic,

1-9

are not at their best. The constant

ment of the

control

will

cause

a

con-

el

Taankk

Sump

Drain

Plugs,

1-lo

speed

propeller will

permit

low blade

siderable

change in rpm.

angles

for

take-off

and

climb, thereby

Propeller

surging

(rpm

variation up

.!

giving optimum performance.

After

CONTROL

LOCK BUTTON

Jacking and Lifting,

6-2

the

airplane

has

reached

its

proper

altitude

and has

leveled

off,

the

pro-

G

peller

can be

changed

to

a

higher

Gage,

blade

angle

and thus provide

the

de-

carburetor air temperature, iv

sired

cruising

performance.

cylinder head temperature, iv,

1-4

The propeller is controlled

by

a

manifold

pressure,

iv,

1-4

.

oil

pressure,

iv,

1-8

Knob

governor

which

automatically changes

'

LOW RPM

HIGH RPM

oil

temperature,

iv,

1-8

cabin

air,

1-3

the

pitch

of

the propeller

to

counter-

suction,

iv

cabin

heat,

1-3

act

any

tendency

of the engine

to vary

Generator

Warning

Light, 1-3,

1-10,

1-13

carburetor

air heat

control, 1-2,

1-3

Glove Compartment,

iv,

1-23

fuel strainer

drain, iv,

1-lo

from

the

rpm

setting established

by

PROPELLER

PITCH CONTROL

Ground Handling,

6-1

mixture

control,

1-2,

1-3

the propeller

pitch control.

This

con-

A-2

I-5

DESCRIPTION

and down several times

before

engine

opening the

2ccess

door

on

the

left

ALPHABETICAL INDEX

smooths out and becomes steady) can side of

the engine

cowl

and

re2ding

be prevented

by smooth throttle

and

the oil

level

on the

dipstick, located

propeller

control

operation.

Do not

just

aft of the left rear

engine cylinder.

change

throttle and propeller

controlset-

The

dip

stick

incorporates

2

spring

cessnaService

Publications,

6-26

rings with

jerky

and rapid

motions.

lock which prevents

it

from

working

cigarette

Lighter,

1-3,

1-22

loose in

flight.

The dip

stick

can

be

Adjustable

Stabilizer

Control Wheel,

1-13

Circuit

Breakers, 1-11,

1-13

NOTE

removed

by rotating it

until

the spring

After

Landing,

2-5

Check

List,

2-1

If

the

engine power

and rpm

lock is

disengaged and

pulling

the dip

AAil

o

rran

de

6

-6

9

Clea

nn

um

surfaces,

6-5

are to be increased,

increase

the

stick

up

and

out.

When

replacing

the

Airplane

File,

6-18

battery,

6-4

propeller

control

first

and

then

dip

stick,

m2ke

sure

th2t

the spring

Airspeed Correction

Table,

5-1

carburetor air

filter,

6-6

the

throttle.

If

power and rpm

lock

is engaged.

AArspeedd

Ln

taa't

ns

4-1

enDgine compartment,

6-6

are

to be decreased,

reduce

the

To obtain

correct

oil

level

readings, Altimeter,

iv

tires,

6-3

throttle first

and

then

the

pro-

it is import2nt

that

the

engine

be

shut

Aluminum

Surfaces,

6-5

upholstery,

6-6

peller

control. In this

manner,

down

at least

5

to 10

minutes prior

to

g¡,

Sce ers,

1-3,

1-23

dh

d

65-5

excessive

cylinder

pressures

the oil check.

This

permits

the

engine

Assist

straps,

1-22

clearingthe Propeller,

3-1

will be

avoided.

oil to drain out

of the

engine oil

pas-

Azimuth Indicator,

iv

Climkb,

2-4 -62,

3-4

s2ges

into

the

oil sump

giving

a

more

coatHanger Hook,

1-23

OIL SYSTEM.

2ccur2te

oil

level

reading.

Cold Weather Operation,

3-8

Compass Card Holder, iv

The Continental

0-470-L

engine

has

NOTE control,

a

wet

sump

oil

system which

utilizes

Oil should

be

2dded

if

below

ad ta rle

stabilizer,

1-13

the engine

pan

as

an oil tank. Other

nine

quarts

and

should

be

full

saggage

compartment,

1-23

cabin heater,

1-3

major components of the

system

are

if

an extended

flight

is planned.

Battery,

6-4

carburetar air

heat,

1-2,

1-3

an

engine-driven

oil

pump

2nd an oil

.

.

.

Befav Entering

Airplane,

2-1

mixture,

1-2,

1-3

- The

oil

filler

cap

is

made accessible

Before Landin

2-4

panel,

1-3

cooler

mtegrally mounted on the

en-

s'

rk brak

by opening the access door

on

the

Befo;e

starting

Engine,

2-1,

3-1

pa ing e,

iv

gin

1

temperature is regulated

auto-

top of the engine

cowl. In repl2cing

Bef

te ke-Off,

2-3

propdell pitc1h,

14-3

.

. the

oil

filler

cap, make

sure that it

is

Brake Pedais,

1-16

wheels,

1-13

matically

in this

system

by a

thermo-

on

firmly

and

turned

clockwise

2s

far

Brake System,

1-16

Cross Country Service,

6-26

statically

controlled oil cooler. The Cruise,

3-2,

3-6

as it will

go

to prevent loss of oil thru

Cruisin

,

2-4

thermostat shuts

off the passage of

oil

9

. the

filler

neck.

cylinder

Head Temperature

Gage,

iv,

1-4

through

the

cooler whenever the oil

temperatures

are below

150°

F.

Ordi-

OIL SPECIFICATION AND GRADE.

narily, the

oil

cooler is

adequate to

Aviation grade

oil is recommended

keep

oil

temperatures well

within the

for your airplane and

should be

Cabin

Air Knob,

1-3

normal operating

range

as indicated

changed

every

25 hours of oper2tion

cabinAir

Temperature

Control

System,

1-18

D

by

the green

arc

on the

oil

tempera.

When

adding

or changing

oil, use

the

diagram,

1-19

ture

indicator.

gr2des

in

the

following

table:

cabin

Doors,

1-22

Dip

Stick,

1-6

Cabin

Heat

Knob,

1-3

Directional

Gyro,

iv

OIL LEVEL.

Average Outside

Recommended

cabinVentilators,

1-20

Dome

Light,

1-21

The oil c2pacity

of the

Continent21

Temperature OH

Grade

r Hec

2Co

ol,

1-2,

1-3

Drain Plu

,sump,

1-10

0-470-L

engine

is twelve quarts. The

Below

40°

F. SAE

30

carburetor

Air

Temperature

Gage,

iv

fuel

line,

1-10

quantity

can

be

checked

e2sily by

Above

40°

F. SAE

50

center

of

Gravity

Envelope,

4-3

oil

sump,

1-7

1-6

A--I

CARE-RESPONSIBILITIES

DESCRIPTION

THERMOSTAT

Sales a Seruite

PROPELLER

CONTROL

.

OIL

COOLER

PHOPELLER

(THERMOSTAT

OPEN)

CROSS

COUNTRY

SERVICE

'*,

THERMOSTAT

On

your cross

country

travels

makeita point to

stop at a

Cessna

*-

°1HLEC

service

station

for your service

requirements.

Your Dealer will be

PROPELLER

CLOSED)

glad to

supply

you with

a copyofa

current

service station list, or if

GOVERNOR

you wish,

you

may write to the Service Department, Cessna Aircraft

Company,

Wichita, Kansas,

asking

for it and

it

will

be

promptly

mailed

to you.

°'LLE

CAP

CESSNA SERVICE

PUBLICATIONS

I

a

The

Cessna

Aircraft

Company

publishes

and

revises,

as necessarv.

1.

O

OIL

OIL

PRESSURE

TEMPERATURE

Manuals,

Parts

Catalogs,

Service Letters

and Service News LetterS. GAGE

GAGE

This

material

goes to all

authorized

Cessna

Service

Stations so that

they

have the

latest

authoritative information

for

servicing

your

Cessna.

Your Cessna

Dealer

has

an owner

follow-up

system

to

notify

you

sue

on

when he

receives

information that applies

to

your Cessna.

In

addi

SCREEN

- -

-

OIL DIP

STICK

tion. if you wish, you

may

choose

to

receive

similar

not16cation

directly

from

the Cessna

Service

Department. A subscation card

DR

LIN

UG

is supplied

to

you in

your

airplane file for your

use,

should

you

FUEL

LINE

eboose to request

this service. Your

Cessna

Dealer will

be

glad to

',"°uMOOINL

OISLCRFIELENER

wpply you

with

details

concerning these follow-up

programs,

and

SOLENOID

stands

ready

through

his

Service

Department

to

supply you with

fast,

efficient,

low

cost service.

ENGINE

SUMP

ENGINE

PRESSURE

-

OIL

PUMP

RELIEF VALVE

ENGINE

OIL

Figure3.Oil

System Schematic

6-26

1--7

DESCRIPTION

CARE

-

RESPONSIBILITIES

NOTE

ing air

by a

filter screen located in the

During

oil

changes, remove and

air scoop. Proper

cleaning

and

servic-

clean oil filter screen

located

ing

of

this air filter is important to

Cabin (floor) Lengths:

.

. .

increase life

and maintain

top

efTi-

ynow

to

NOTE

on

the right sideofthe

engine

.

Measurements

are with

accessory

section.

ciency of

the

engine. The

filter

should .

. .

. . -

43 in

co-pilot seat,

rear

seat,

be

serviced every

25

hours

(during

- - -

21 in

and

baggage

compartment

OIL

TEMPERATURE GAGE-

regular oil

change)

or oftener

when

mh

o

abl

A capillary

type,

oil temperature

operating

in

dusty

conditions.

Under

27 in-

and

saving 40

lbs

on

emp-

gage (15, figure

1) is

mounted

within

extremely

dusty

conditions,

daily

the

engine instrument

cluster on

the maintenance

of

the

air filter

is

recom-

right

side of the

instrument

panel.

A

mended. Refer to

the

servicing

in-

green arc on

the

gage dial indicates

structions stamped

on

the

carburetor

'

the

normal operating range of

oil

air filter for the servicing

procedure

temperatures. Refer to

Section

IV

for

to

be used.

instrument markings.

OIL

PRESSURE

GAGE.

FUEL

SYSTEM.

An

oil

pressure gage

(12, figure

1)

Fuelissupplied

to the engine

from

is

mounted within

the engine

instru-

two

rubberized,

bladder-type

fuel

ment cluster on

the right side of the

cells,

one located in each wing.

From

instrument panel. The gage is

cali-

these tanks, fuel is

gravity-fed

through

cabin(floor)

Widths:

brated

in pounds per

square inch.

a

fuel

selector valve and fuel

strainer

Refer to Section

IV

for

instrument

to

the

engine carburetor.

(i)

/

Cabin

Volume:

.

Point

Tunnel

to

Side Wall

.

.

-

15

1/2 in.

55 Cubic

feet

markmgs

unobstructed.

FUELSPECIFICATION

AND

GRADE•

Rear

Lineofpilot's

AIR INDUCTION

SYSTEM.

Aviation grade

fuel

should

always

Seat-Wall

to

Wall. .

.

.

. .36 tn.

Air is

ducted to the

carburetor from

be used except

under emergency

con- (Ï)^ft

Door Post Bulkhead .

.

. 31 in.

an air

scoop

located on the bottom of ditions.

The recommended

fuel is

80

(i)

Aft

Section Bulkhead

. . . . .30

in.

D

00

R WID

I

HS

the engine

cowl.

Dirt and

other

for-

octane

minimum

rating.

Highly

lead-

(i)

Rear

wan-or

saggage

eign matter is

filtered from the

incom-

ed

fuels are not recommended.

Compartment

-

-

30

in.

Cabin

Heights:

40 36

nwho

FUEL

QUANTITY DATA

(U.

S. GALLONS).

^2

-

.48

inches

i

n

uw)ws

.

. .

. . .

46

inches

ADDITIONAL

TOTAL

-

-

45 inches

TANKS

NO

UASLALFLLE

FUHEL

UFSOARBLLEE

LEL

UNFUUSEABLE

V

ME

. . .

. .

40 inches

CONDITIONS

FLIGHTONLY EACH

.

. . .

. -

21

inches

LEFT

WING l

27.5

gal.

3.5

gal.

1.5

gal.

32.5

RIGHT

WING 1

27.5

gal.

3.5

gal. 1.5 gal.

32.5

---

INTERNAL

CABIN

ME

ASUREMENT

1-8

6-25

CARE

-

RESPONSIBILITIES

DESCRIPTION

fuselage

attachment. If

necessary,

tighten

landing

gear

bolts

and

wedges. With airplane

in normal

position on

the

floor

visually

inspect

FUEL

QUANTITY

INDICATORS

landing

gear

spring leaf for

cracks.

(Remove

landing

gear wheels and

pack with grease at

first

100

hours and

every

500 hours

thereafter

un-

LEFT

RIGHT

less otherwise

designated

by

owner.)

2. Operate brakes and feel

for

sponginess. Bleed,

and

refill

brake system

if necessary.

Check brake

linings

for wear within permisssible

limitS.

LEFT WING TANK

RIGHT WING

TANK

3. Set

parking brake and

check exposed

lines and hoses for deterioration

and evidence of leakage of

hydraulic fluid.

4.

Examine tires

for

proper

inflation, wear,

cuts and blisters. Uneven or

excessive wear

may

indicate need

for

re-alignment of

wheels.

IX. Electrical System.

1. Check

electrical

system by

operating

the lights,

starter,

and

all

acces-

sories which

are incorporated

in the

electrical system.

SUMP

TA SUMP

X.

Visual Check for Exterior

Surfaces.

1. Clean exposed surfaces

FUEL SELECTOR

2. Check:

VALVE

a. Condition

of

exposed

aluminum surfaces.

b,

Airspeed static source

holes

on each

side

of

fuselage

for stoppage

ENGINE PRIMER

FUEL LINE

c.

Evidence of

leaking

fuel or oil-determine

cause.

DRAIN PLUG

d.

Condition of

decorative

paint

and

all

markings.

XI.

Recowl the engine and

install propeller spinner.

Replace all inspection

plates,

fairings and

seats.

FUEL STRAINER

XII.

Run

engine as in

preliminary run-up

to

check for ignition

drop,

gener-

É

cTO

EN ES

ator

charging rate, oil pressure,

smoothness,

and general operation

of

en-

gine,

propeller,

controls,

and indicatorS. FUEL

STRAINER

DRAIN VALVE

CARBURETOR

i

ggggg i

co en

THROTTLE

VENT

TO

ENGINE

FUEL

CYLINDERS

-FUEL

SYSTEM

g

Figure

4.

6-24

I-9

Loading...

Loading...