Cessna 172, SKYHAWK Ownersmanual

" LOOK FOR

THE

AND

BLUE CESSNA

PENNANTS

FOR THAT EXTRA SERVICE

WHERE

IT

COUNTS WHEN

YOU

NEED IT".

CESSNA AIRCRAFT COMPANY WICHITA, KANSAS

MODEL

7~

AND

SKYHAWK

OWNER'S

MANUAL

PERFORMANCE

and

SPECIFICATIONS

GROSS WEIGHT . . . . .

SPEED:

T

op

Speed

at

Sea Level

.

Cruise,

75%

Po

wer

at

7000

ft

.

RANGE:

Cruise,

75%

Power

at

7000

ft

39

Gal.

No R

eserve

Optimum

Range at

10,

000

ft.

39

Gal

. No

Reserve

RATE

-OF-CLIMB

AT

SEA

LEVEL

. • •

SERVICE

CEILING .

TAKE-OFF

:

Ground

Run

. • • .

••.••

T

otal

Distance

Over

50

Foot

Obstacle

LANDING.

Land

ing

Roll

. . . . . . . . . • .

Total

Dis

tan

ce

Over

50

Foot

Obstacle

EMPTY

WEIGHT

(Approximate)

.

BAGGAGE .

........

. .

WING LOADING:

Pounds/Sq

Foot

POWER

LOADING: Po

unds/HP

FUEL

CAPACITY: T

ota

l

OIL

CAPACITY: To

tal

.

PROPELLER

D~A

METER

PROPELL

ER

TYPE

POWER:

Continental Engine

No.

Horse Power

. . . .

172

2300 l

bs

13

8

mph

130

mp

h

595

miles

4. 6

hours

130

mph

720

miles

7.1

hours

102

mph

645

fpm

13,

100

ft

865

ft

1525

ft

• 520

ft

1250

ft

• •

1260

lbs

• 120

lbs

13.2

15.9

42

gal.

8

qts

76

in.

Fixed

Pitch

0-300-C

*

145

SKYHAWK

2300

lbs

139

mph

131

mph

600

mile

s

4.

6 hou

rs

131 mph

720

mil

es

'l.

1

hour

s

102

mph

645

fpm

1

3,

100

rt

865

fl

1525

ft

520

ft

1250

fl

13

30

l

bs

120

lbs

13 .. 2

1

5.9

42

gal.

8

qt

s

76

in.

Fix

ed

Pit

ch

0-300

-1)

145

•

nie

Model

Fl

72,

which

Is

manufactured

by

Rei.ms A

viation

S.

A.

Re

ims

(Marne) France

1s

identical

to

the

172

except

that

U

is

powered

by

an

0-300-D

engin~

,

manufactured under

iJ~cn.

~

··

by Rolls

Roy

ce,

Crew

e,

England.

All

172

information

in

this

manual

pertains

to

th

e

F172

:is

well.

02()'}.13

(RGl-

10().1/

0l)

COPYRI

GHT e 191M

Cessna Aircraft Company

Wichita, Kansas

USA

CONGRATULATIONS

.....

...

.

Welcome

to

the

ranks

of

Cessna

owners!

Your

Cessna

has

been

designed

and

constructed

to

give

you

the

most

in

performance,

economy,

and

com

-

fort.

It

is

our

desire

that

you

will

find flying

it,

either

for

business

or

pleasure, a pleasant

and

profitable

experience.

This

Owner's

Manual

has

been

prepared

as a guide

to

help you

get

the

most pl

easure

and

utility

from

your

172.

It

contains

information

about

yo

ur

Cessna's equipment, operating procedures, and

performance;

and

suggestions

for

its

servicing

and

care.

We

urge

you

to

read

it

from

cover

to

cover,

and

to

refer

to

it

frequently.

Our

interest

in

your flying

ple

asure has

not

ceased

with

your

purchase

of

a

Cessna. World-wide,

the

Cessna

Deal

er Organization

backed

by

the

Cessna

Service Department

stands ready

to

serve

you.

The

following

services

are

offered

by

most

Cessna

Dealers:

FACTORY TRAINED MECHANICS to

provide

you

with

courteous

expert

service.

FACTORY

APPROVED

SERVICE EQUIPMENT

to

provide

you

wit

h t

he

most

effic

ient

and

accurate

workmanship

possible.

A STOCK

OF

GENUINE CESSNA SERVICE

PARTS

on

hand

when

you

need them

.

THE

LATEST AUTHORITATIVE INFORMATION FOR SER

V-

ICING CESSNA AIRPLANES,

since

Cessna

Dealers

have

all

of

the Serv

ice

Manuals

and

Parts

Catalogs,

kept

current

by

Service

Letters

and

Service

News

Letters

published

by

Cessna

Aircraft

Company.

We

urge

all

Cessna

owners

to

use

the

Cessna

Dealer

Organization

to

the

fullest.

A

current

Cessna

Dealer

Dire

ctory

accompanies

your

new

airplane. The

Director y

is

revised

frequently,

and a current

copy

can

be

obtained

from

your

Cessna

Dealer

. Make

your

Directory

one

of

your cross-

country

flight

planning

aids; a warm

welcome

awaits

you

at

every

Cessna

Dealer.

ii

so

-20·.o ..

-

------

t-o--

11

' .4

··-

___,

* M

aximum

beighl

of

._irpW>e

"''Ill

nose gear

~pressed

aod an

opc.-

loaal

rotallilg

be;u:on

lnsUlled

.

PRINCIPAL

DIMENSIONS

.

____

q~~

-~

and

Skyhawk

t--

----

-

---

36".1"---

--

- - -

---..1

TABLE

OF

CONTENTS

============================================Pag

e

==

SECTION

I -

OPERATING

CHECK

LIST

..............

1-1

SECTION

II -

DESCRIPTION

AND

OPERATING

DETAILS

...................... 2-1

SECTION

Ill -OPERATING

LIMITATIONS

............. 3-1

SECTION

IV-

CARE

OF

THE

AIRPLANE

............ 4-1

OWNER

FOLLOW-UP

SYSTEM

...........................

4-

s

SECTION

V -

OPERATIONAL

DATA

...................... 5

-1

SECTION

VI -OPTIONAL

SYSTEMS

...................... 6 -1

ALPHABETICAL

INDEX

........................................ l

ndex

-1

ill

CD

a.

Tarn

on

master

switch

a.nd

cltec.k

ft1e-

l

qm.n-

hty

lnclicators,

tbea

turn m11,.ster swit<b.

-

oIT.

00

b.

Ctieck

ignition

switches

,..OFF

."

c. Cllecl<

fuel

selector

vat

...

hmdle

" BOTH

ON_

••

d.

On

f!rsl

rught

et!

day

aod

alter

eaeh

lueli~.

p.tll

out

stn..iner

drain

knob

f

or

:about

4

sec-

onds.

to

clear

fuel

sll'2i

ner

ot

possible

r.tter

and

sediment.

e.

RemOTe

control

..tied

lock.

@

··

(.i\

a.

'\::?/

b.

Check

bag;:age

door

for

sec.wily (left

side

oaly).

Removr

gust

locks

if

lnslalled.

01.sconnect

b:tl

tl~doNtt.

Remove

pst

lock,

If

lnsialled.

Cbeck

main

wheel

tue

for

pl"oper

infiatioo.

Inspect

airspeed

static

source

hole

on

SJde

ol

lusebge

for

stopP3:1:e

(left

stde

only).

No

te

Cbeck.

general

aircn!l

condition

during

walk-arowxl

lnspcctlOll.

U

rught

fllgl!l

is

planned,

cbect

oper-

atioa

ol

all

lights,

and

make

sure

a

fi2Sbliglrt

is

anllallle.

c.

Oisooonect

wlng

Ue-da...n.

16"'

a.

Check

ml

level.

Do

net

"!"'rate

...

tb

less

~

than

six

quan.s.

FUI

for

exiended

llighl.

<i)

b.

Check

propeller

and

spinaer

for

alcks

and

ucur!ty.

c.

Cbeck

nose

wheel

strut

(or

proper

ud'btJoo.

d.

Check

nose

wbeel

tire

for

proper

infla.liort.

e.

DlSCOCllltt.t

Ue-down

rope.,.

r.

.}fake

vtSUa.I

check

to

insare

that

foe!

str.1iner

dn.in

v.llve

is

clOISed a.ner dr.l.inlng ope.r.al1oa.

g.

Check

carburl!'tor

alr

[llter

for

restrtchons

by

dust

or

other

foreJgn matter.

Same

as

@·

®

~b.-

Remove

pilot

tube

coorer tf lnst:all<!d.

Inspect

pilot

tube

opening

for

stoppage.

c.

Check

fuel

lank

<enl

,,._,ing

!or

stoppage.

®

Sameas

@}

Figure

1

-1

iv

I -,

~~iiilP-

One of

the

first

steps

in

obtaining

the

utmost

performance,

service,

and

flying

enjoyment

from

your

Cessna

is

to

familiarize

yourself

with

your

airplane's

equipment, systems,

and

controls.

This

can

best

be

done

by

reviewing

this

equipment

while

sitting

in

the

airplane.

Those

items

whose function and

operation

are

not

obvious

are

covered

in

Section

II.

Section I lists, in

Pilot's

Check

List

form,

the

steps

necessary

to

operate

your

airplane

efficiently

and

safely

.

It

is

not a

check

list

in

its

true

form

as

it

is

considerab

ly

longer,

but

it

does

cover

briefly

all

of

the

points

that

you would

want

to

or

should

K.now

concerning

the

informati

on

you

need

for a typical

flight.

The

flight

and ope

rational

characteristics

of

your

airplane

are

normal

in

all respec

ts.

There

are

no

"unconventional"

characteristics

or

opera-

tions

that

need

to

be

mastered.

All

controls

respond

in

the

normal

way

within the

entire

range

of

operation. All

airspeeds

mentioned

in

Sections

I

and

II

are

indicated airspeeds. Corresponding

calibrated

airspeed

may

be

obtained

from

the

Airspeed

Correction

Table

in

Secti

on

V.

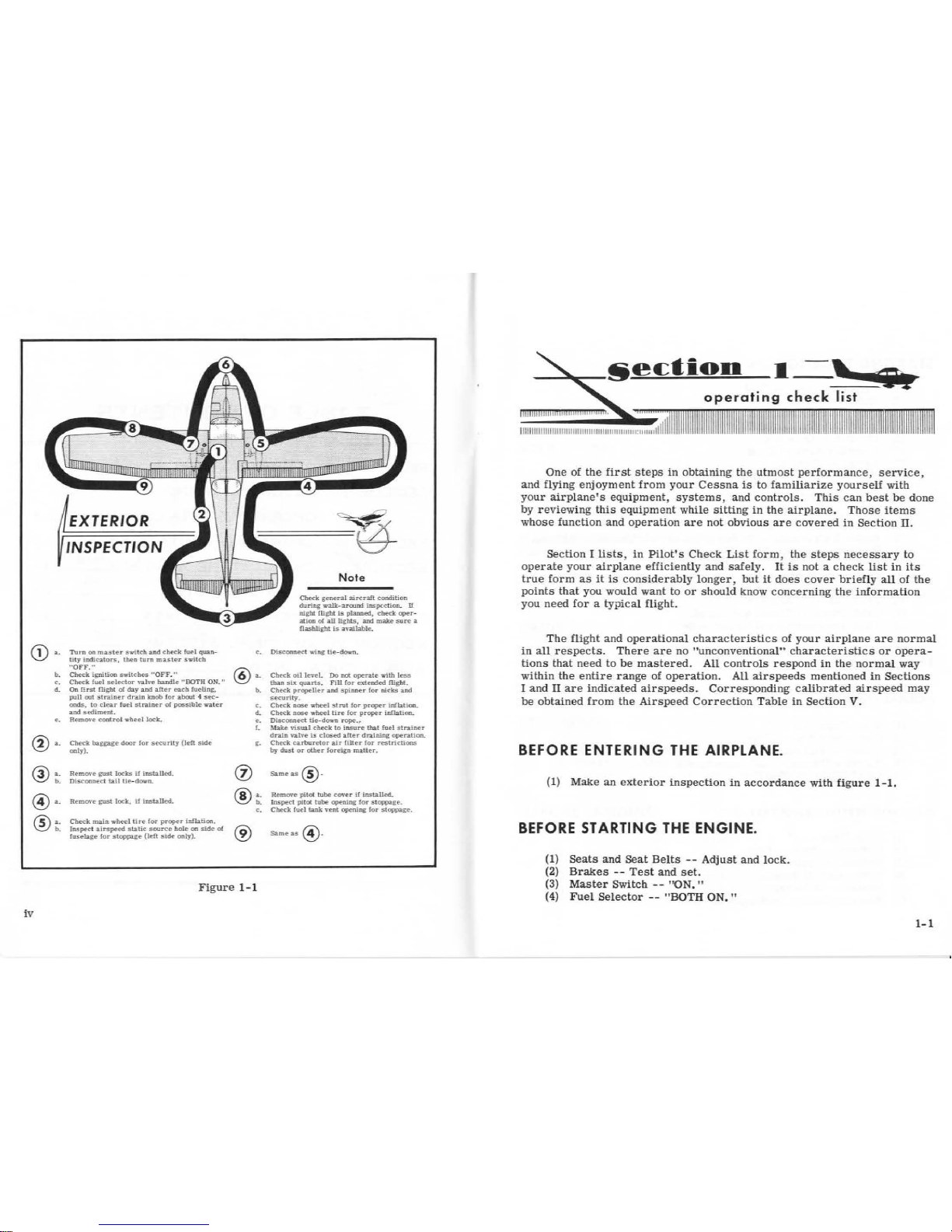

BEFORE

ENTERING

THE

AIRPLANE.

(1)

Make

an

exterior

inspection

in acco

rdance

with

figure

1-1.

BEFORE

STARTING

THE

ENGINE.

{l)

Seats

and

Seat

Belts --Adjust

and

lock

.

(2)

Brakes

- -

Test

and

set.

(3)

Master

Switch --''ON. "

(4)

Fuel

Selector --"BO

TH

ON."

1-1

STARTING T

HE

ENGINE.

(1)

Carbureto

r Heat --Co

ld.

(2)

Mixture

- -

Rich.

(3) P

rime

r - - As

required

.

(4)

Ignition

Switch --"BO

TH.

"

(5) T

hrottle --Open

1/8".

(6)

Propeller

Area --Clear.

(7)

Starter --Engage.

BEFORE TAKE-OFF.

(1) T n

rottle

Setting --1600

RPM.

(2) E

ngine

Instruments

- -

Within

green

arc

and

generator light

out.

(3)

Magnetos

- -

Chec

k (75

RPM

maxim

um

differential

between

mag

-

netos)

.

(4)

Carburetor

Heat --Cneck.

(5) Flight

Controls

- -

Cneck.

(6)

Trim

Tab

- - "T

AKE-OFF."

(7)

Cabin

Doors

- -

Closed

and locked

.

(8). F

lightlnstruments

and

Radios

- -

Set.

TAKE-OFF.

NORMAL

T.AKE-OFF

.

(1)

Wing

Flaps --0°

(2)

Carburetor

Heat --Cold.

(3)

Power

- -

Full

thro

ttle (applied

smoothly).

(4)

Elevator

Control

- -

Lift

nosewheel at

60

MPH.

(5)

Climb

Speed

- - 85 MPH.

MAXIMUM

PERFORMANCE TAKE-OFF

.

1-2

(1)

Wing

Flaps --0°

(2)

Carburetor

Heat --Cold.

(3)

Brakes

- -

Apply

.

(4)

Power

- -

Full

throttle.

(5)

Brakes

- -

Release.

(6)

Elevator

Control

- -

Slightly

tail

low.

(7)

Climb

Speed

- - 65

MPH

(with

obstacles

ahead).

CL1MB.

N

ORMAL

CLIMB.

(1}

Airspeed --80

to

90

MPH

.

(2)

Power --Fu

ll

throttle

.

(3)

Mixture

-- Fu

ll

rich

(unless

engine

is

rough)

.

MAXIMUM

PERFORMANCE

CLIMB

.

(1)

Airspeed

- -

80

MPH

at

sea

level to

17

MPH

at

10,

000

feet.

(2)

Power --Full

throttle.

(3)

Mixture --Full

rich

(unless

engine

is

rough.

CRUISING.

(1)

Power --2200

to

2700 RPM.

(2)

Trim

Tab --Adjust.

(3)

Mixture --Lean.

LET-DOWN.

(1)

Mixture --Rich.

(2)

Power --As

desired.

(3)

Carburetor

Heat

--

As

required

to prevent

carburetor icing.

BEFORE

LANDING

.

(1)

Fuel

Selector --"BOTH ON. "

(2)

Mixture

- - Ri

ch.

(3)

Airspeed --70 -80 MPH

(flaps

up).

(4)

Carburetor

Heat --Apply

before

closing

tnrottle.

(5)

Flaps --As

desired

(below

100

MPH).

(6)

Airspeed --65

to

75

MPH

(flaps

down).

1-3

NORMAL

LANDING.

(1) Touchdown - -

Main wheels

first.

(

2)

Landing Roll --Lower nose

wheel gently

.

(3)

Braking

- -

Minimum

required.

AFTER

LANDING.

(1)

Flaps

- - Up.

(2)

Carbure

tor Heat --Cold

.

SECURE

AIRCRAFT.

1-4

{l}

Mixture --Full lean.

(2) All

Switch

es --"O

FF."

(

3)

Brakes --Set.

(4)

Control

Lock --Installed

.

The

following

paragraphs

describe

the

systems

and

equipment

whose

function

and

operation

is

not

obvious

when

sitting

in

the

airplane.

This

section

also

covers

in

somewhat

greater

detail

some

of

the

items

lis

ted

in

Check

List

form

in

Section

I.

Only

those items

of

the

Check

List

re-

quiring

further

exp

lanation

will

be

found

here.

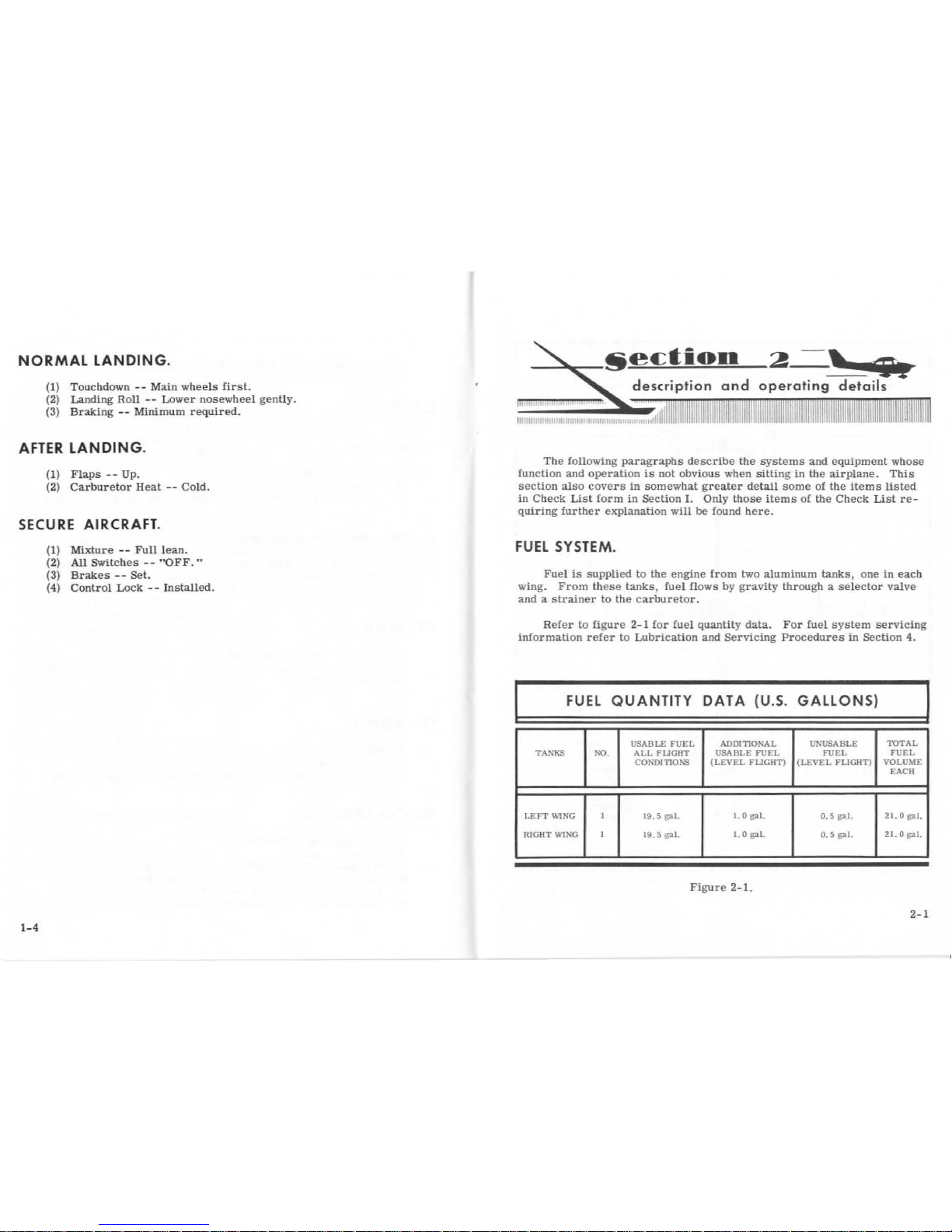

FUEL

SYSTEM

.

Fuel

is

supplied

to

the

engine

from

two

aluminum

tanks,

one

in

each

wing.

From these

tanks,

fuel

flows

by gravity

through a selector

valve

and a strainer

to

the

carburetor.

Refer

to

figure 2-1

for fuel

quantity

data.

For

fuel

system

servicing

information

refer

lo

Lubrication

and

Servi

cing

Procedures

in

Section

4.

FUEL

QUANTITY

DATA

(U.S.

GALLONSt

I

USABLE

FUEL

ADDITIONAL UNUSABLE

TOTAL

TAXKS

00.

ALL

FLIGHT

USABLE

FUEL

FUEL

FUEL

CO?>"D

ITIO!\S

(LEVEL

FLIGHT)

(LEVEL

FLIGHT)

VOLUME

EACH

LEFT

WING

I

19.

5

gal.

1. 0

gal.

0.

5

gal.

21.0gal.

RIGHT

WING

I

19.5

gal.

1.

0

g;a.I.

0. 5 gal.

21.0gal.

Figure 2-1.

2-1

2-2

LEFT

FUEL

TANK

FUEL

SYSTEM

····SCHEMATIC····

FUEL

STRAINER

RIGHT

FUEL

TANK

THROTTLE

CARBURETOR ".,,-

.,,,-

,,'=K)

...__...,.,,,.....---

'',,,

~

TO

-gr.,"G

IN

E

.....

Figure 2-2

MIXTURE

CONT

ROL

KNOB

FUEL

STRAINER DRAIN

KNOB

.

Refer

to

fuel

strainer

servicing

procedures, Section

4.

ELECTRICAL

SYSTEM.

Electrical

energy

is

supplied

by

a

14-

volt,

direct-current

system

powered

by

an

engine-driven

§8R8Pll:!M'

. A

12-volt

storage

battery

is

located

on

the

left-hand

forward

portion

of

the

firewall.

At.-~~

~Q,.

CIRCUIT BREAKERS .

All

electrical

circuits

in

the

airplane,

except

the

clock circuit, are

protected

by

circuit

breakers.

The

clock

has a separate

fuse

mounted

adjacent

to

the

battery.

The

stall

warning

unit,

Oap

position

indicator,

turn

-and-

bank

indicator

and

the

optional

gyro

horizon

test

lights

circuits

are

protected

by a single

automatically

resetting

circuit

breaker

mounted

behind

the

instrument

panel.

The

cigar

light.er.

is

protected

by

a

manually

-

reset

type

circuit

breaker

mounted

directly

on

the

back

of

the

lighter

be-

hind

the

instrument

panel. The

remaining

circuits

are

protected-by

"push

-

to-reset"

breakers

on

the

instrument

panel.

GENERATOR

WARNING

LIGHT.

The

red

generator warning

light

indicates

generator

output.

The

light

remains

off

as

long

as

the

generator

functions

properly.

If a

mal

-

function

interrupts

generator

output,

the

light

will

illuminate.

It

also

will

illuminat

e when

the

battePy

or

external

power

is

on,

before

starting

the

engine,

and

whenever

engine

speed

is

insufficient

to

produce

gen-

erator

output.

The

light

does

not

show

battery

drain

.

LANDING

LIGHTS.

A

three-position,

push-pull

switch

controls

the

optional

landing

lights.

To

turn

one

lamp

on

for

taxiing,

pull

the

switch

out

to

the

filist

stop.

To

turn

both l

amps

on

for

landing,

pull

the

switch

out

to

the

sec-

ond

stop.

2-3

CABIN

HEATING

AND

VENTILATION

SYSTEM .

For

cabin

ventilation,

pull the "CABIN AIR" knob

out.

To

raise

the

air

temperature,

pull

the

"CABIN

HT"

knob

out

approximately 1/4"

to

1/ 2"

for a small

amount

of

cabin

beat.

Additional

heat

is

available

by

pulling

the knob

out

farther;

maximum

heat

is

available

with the "CABIN

HT"

knob

pulled

full

out

and the "CABIN AIR" knob

pushed

full

in. When

no h

eat

is

desired

in

the

cabin, the

"CABIN

HT"

knob

is

pushed

full in.

STARTING ENGINE.

Ordinarily

the

engine

starts

easily

with bne

or

two

strokes

of

the

primer

in

warm

temperatures

to

six

strokes

in

cold

weather,

with the

throttle

open

approximately

1/ 8

inch.

In

extremely

cold

temperatures,

it

may

be

necessary

to

continue

priming

while

cranking

.

Weak

intermittent

exp

losions

followed by puffs

of

black

smoke

from

the

exhaust

stack

indicates

overpriming

or

flooding.

Excess

fuel

can

be

cleaned

from

the

comb

ustion

chambers

by

the foll

owing

procedure:

Set

the

mixture

control

full l

ean

and

the

throttle

full

open;

then

crank

the

engine

through

several revol

uti

ons

with

the

starter.

Repeat

the

starting

procedure

without

any

additional

priming.

H the

engine

is

underprimed

(most

like

ly

in cold

weather

with a cold

engine)

it

will

not

fire

at

all,

and

additional

priming

will

be

necessary

.

As

soon

as

the

cylinders

begin

to

fire

, open the

throttle

sli

ghtly

to keep

it

running.

Aft

er

starting

,

if

the

oil

gage

does

nol

begin

to

show p

ressure within

30

seconds

in

the

summertime

and

about

twice

tha

t long

in

very

cold

weather, stop

engine

and

investigate.

Lack

of oil

pressure

can

cause

serious

engine

damage.

After

starting,

avoid

the

use

of

carburetor

heat

unless

icing

conditions

prevail.

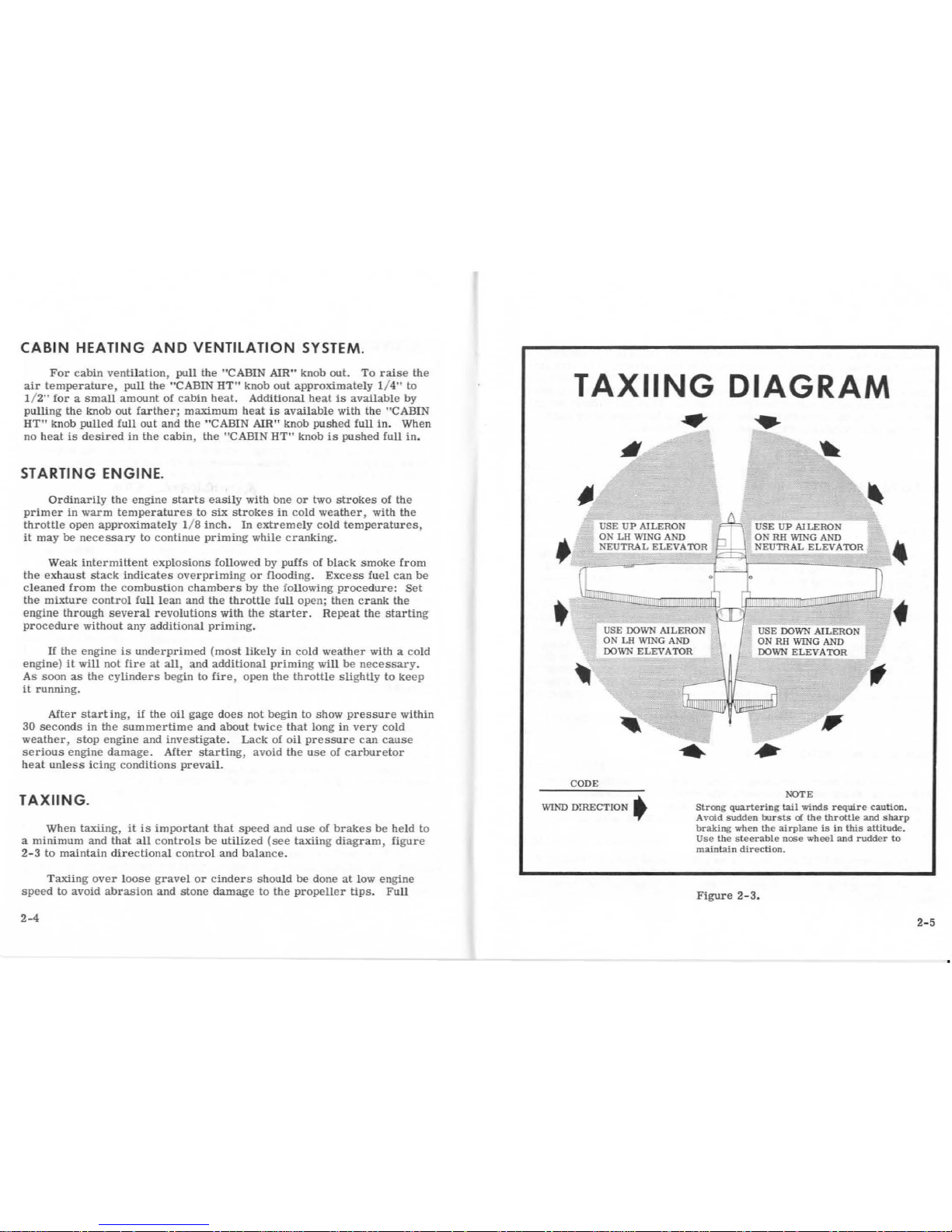

TAXIING

.

When

taxiing, it

is

important

that

speed

and

use

of

brakes

be

held

to

a

minimum

and

that

all

controls

be

utilized

(see

taxiing

diagram,

figure

2-3

to

maintain

directional

control

and

balance.

Taxiing over

loose

gravel

or

cinders

should

be

done

at

low

engine

speed

to

avoid

abrasion

and

stone

damage

to

the

propeller

tips.

Full

2-4

TAXIING

DIAGRAM

•

USE

UP

AILERON

USE

UP

AILERON

ON

LH WING

AND

.KEUTRAL

ELEVATOR

ON

RH

WING

AND

NEUTRAL

ELEV A TOR

.

CODE

WIND

D!RECTION

t

NOTE

Strong

quartering

tail

winds

require

caution.

Avoid

sudden

bursts

of

the

throttle

and

sharp

braking

when

the

airplane

is

in

this

attitude.

Use

the

steerab

l e

nose

wheel

and

rudder

to

maintain

direction.

Figure

2-3.

2-5

throttle

run-ups

over

loose

gravel

are

especially

harmful

to

propeller

tips.

When

take-offs

must

be

made

over a gravel

surface,

it

is

very

im-

portant

that

the

throttle

be

advanced

slowly.

This

allows

the

airplane

to

start

rolling

before

high

RPM

is

developed,

and

the

gravel

will

be

blown

back

of

the

propeller

rather

than

pulled

into

it.

Wben unavoidable

small

dents

appear

in

the

propeller

blades, they

should

be

immediately

cor-

rected

as

described

in

Section 4 under

propeller

care.

BEFORE

TAKE-OFF.

WARM

UP.

Since

the

engine

is

closely

cowled

for

efficient in-fli

ght

engine

cool-

ing

,

precautions

should

be

taken

to

avoid

overheating

during

prolonged

engine

operation

on

the

ground

.

MAGNETO

CHECK.

The

magneto

check

should

be

made

at

1600

RPM

as

follows: Move

the

ignition

switch

first

to

"R"

position,

and

note

RPM.

Next move

the

switch

back

to

"BOTH"

position

to

clear

the

other

set

of

plugs. Then

move

the

switch

to

the

"L"

position

and

note

RPM. The

difference

be-

tween

the

two

magnetos

operated

indi.vidually

should

not

be

more

than

75

RPM.

HIGH RPM MAGNETO CHECKS.

If

there

is

a doubt

concerning

the

operation

of

the

ignition

system

,

RPM

checks

at

higher

engine

speeds

will

usually

confirm

whether a de-

ficiency

exists.

If

a full

thro~le

run-up

is

necessary

the engine should

run

smoothly

and

turn

approximately

2230

to

2330

RPM

with the

car-

buretor

heat

off.

An

absence

of

RPM

drop

may

be

an

indication

of

faulty grounding

of

one

side

of

the

ignition

system

or

should

be

cause

for

suspicion

that

the

magneto

timing

has

been

"bumped-up"

and

is

set

in

advance

of

the

set-

ting specified

.

2-6

TAKE-OFF.

POWER CHECK.

Since the

use

of

full

throttle is

not

recommended

in

the

static

run-up,

it

is

important

to

check

full-throttle

engine

operation

early

in

the

take-off

run.

Any sig

ns

of rough

engine

operation

or

sluggish

engine

acceleration

is

good

cause

for

discontinuing

the

take-off.

If

this occurs,

you

are

j

ustifi

ed

in

ma.king a thorough

full-throttle, static

run-up

before

another

take-off

is

attempted.

Prior

to

take-off

from

fields

above

5000

ft.

elevation, the

mixture

should

be leaned

to give

maximum

RPM

in

a

full-throttle, static

run

-up.

WING

FLAP

SETTINGS

.

Normal

and

obstacle

clearance

take-offs

are

performed

with

wing

flaps up.

The

use

of 10 °

flaps

will

shorten

the

ground

run

approximately

10%,

but

this

advantage

is lost

in

the

climb

to

a 50-foot

obstacle.

There-

fore

the use

of

10°

flap

is

reserved

for

minimum

ground

runs

or

for

take-

off

from

soft

or

rough

fields

with

no

obstacles

ahead

.

If

10° of

flaps

are

used

in

ground

runs

,

it

is

preferable

to

leave

them

extended

rath

er

than

retract

them

in

the

climb

to

the

obstacle.

The

ex-

ception

to

this

rule

would

be

in

a high

altitude

take-off

in

hot

weather

where

climb

would

be

marginal

with

flaps

10° (1

st

notch).

Flap

deflections

of

30 °

to 40°

are

not

recommended

at

any

time

for

take-off.

PERFORMANCE CHARTS.

Consult

the

take-off

chart

in

Section

5,

for

take-off

distances

under

various

gross

weight,

altitude,

and

headwind

conditions.

CROSSWIND

TAKE-OFFS.

Take-offs

into

strong

crosswinds

normally

are

performed

with

the

minimum

flap

setting

necessary

for

the

field

length,

to

minimize

the

drift

angle

immediately after

take-off.

The

airplane

is

accelerated

to

2

-7

Loading...

Loading...