Cessna Cardinal RG 1975 Owner's Manual

~

Cessna,

-

-

~-1

"TAKE

YOUR

CES~NA

HOME

fOR

SfRVICf

AT THE

SIGN

OF

THE

CfSSNA

SHIElD'.

CESSNA

AIRCRAFT

COMPANY

~

WICHITA,

k.AN5AS

'

1

'

"

"

I

~

Cessna®

MCRE PEOP.E BUY

AND

Fl'l

CESSNA

AIRPLANES

THAN

ANY

OTHER MAKE

1975

WORLD'S

LARGEST PIIO-

OUCER

OF

GENERAL

AVIATION

AIRCRAFT

SINCE

1956

~~RG

OvVNEH'S

MANUAL

PERFORMANCE

SPECIFICATIONS

GROSS WEIGHT . . . . . . . .

SPEED,

BEST

POWER

MDITURE:

Top

Speed

4:-t

Sea

Levcl

. . .

Cruise,

75'1

Power

at

7000

ft

RANGE,

KXTENDED

RANGE MIXTURE:

Cruise,

75'1

Power

at

7000

ft

60

Gallon;,

No

Reserve

Maximum

P.ange

at

10,

000

ft

.

60

GaUors,

No

Reserve

RATE

OF

CLINB

AT

SEA

LEVEL

SER,'ICE

CEILJNG

TAK:.:<:-OFF:

Ground

Rur_

Total

Distance

OVer

5~-

Foot

Obstacle

LANJING:

Ground Roll . . . . . . . . . . .

i'otal

Distance

Over

5!)-FO<lt

Obstacle

STALL

SPEED:

Flaps

Up,

?ower

Off

• . • ,

Flaps

Dowr.,

Power

Off

. • .

EMPTY

WEIGHT:

(Approtimate)

Cardinal

RG

.

Cardinal

RG

ll

USEFUL

LOAD

Cardinal

RG .

C'arclinal

RG

II

BAGGAGE

...

, •

WING LOADING:

Pounds/Sq

Foot

POWER

LOADl~G:

Pounds/HP

FUEL

CAPACI':'Y:

Total

...

.

OIL

CAPACITY

.......

.

.I'HOPELLER:

Constant

Speed,

Dian_eter

ENGINE:

Lycoming

Fuel

Injectxm

Enbrine

200

rated

HP

at

2700

RPM

*Cardinal

RG

2800

lbs

180

mph

171

mph

945mi

5. 6

hrs

170mph

1210

mi

8.1

hrs

139

mph

925

fpm

17,100ft

890ft

1585

ft

730ft

1350

ft

66

mph

57

mph

1680

lbs

1750

lbs

1120

lbs

1050

lbs

120

lbs

16.1

14.0

61

gal.

9

qts

78

inches

I0-360-A1B6D

*11m

manual

covers

opera~ian

t.~f

lhe

CJ!d1nal

RG

which

is

certificated

as

Modfll l HRG

unde-r

FAA

Type

Gerlihcrte

No.

A20CL

The

manual

also

cove-n

i!Jitlllioo

ot

!he

Reims/Ce>Yla

Cardmal

RG

whkh

IS

mlilicaled

as

MOOel

F177RG

und11

hench

T~pe

Ce1hl1tatiorL

\!Ill

I'J i I

f:l'~-

l'>l)-h

/LJ

I

COPYliGHT e 1!!93

Cessna Aircraft Company

Wichita.

Kansas

USA

CONGRATULATIONS

.....

W~lcome

to

tb~

ranks

of

Cessna

owneraJ

Your

Cesara

has

been

dtsigzred

and

ron-

skuded

W give

you

the

most

in

performance,

econony,

and

comfort,

It

is

our

de-

sire

that

you

v.ill

find

flying

it,

either

fO!"

bu.slness

or

pleasure,

a pleaBa.nt

and

pxofitable

experience,

Tlis

Owner's

Manual haa

bwn

prepared

as

a guide

to

help

you

get

the

most

plawure

aJJd

utility

!ron

your

Card..lllal.

ftG.

U Cmrta!ns

11lfornat1on

about

~our

Cessna'~

equipment,

op~ra.ting

procedures,

and

performance;

1nd

suggestims

fQr

its

se•vic-

Jn~

and

care,

We

urge

you to

read

it

frcm

cover

to

c:Ner,

and

ta

refer

tQ

it

fN-

qvently,

01lr

iuterest

in

your

flying

pleasure

has

tot

ceasE!d wfth

your

_purchase of a

Ces>na.

W:JZld-wlde,

tt_e

Cessna

D&ler

Organizrtion

bll.cked

by

the

Cessna

Service

De(W't-

m~nt

stands

re>.dy

to

&erve

you.

The

following

serviees

are

offend

by n::cst

c~ssna

Dealers:

THE

CE.saiA

WARRANTY--

It

is

designed

to

prwide

you

with

the

most

comprehersive

coverage

possible:

a,

N:.

exdWiions

b.

C:.verage

inchdes

parts

an:llabor

c.

Available

at

Cessna

Dealen

world

wide

d,

Bsst

in

the

industry

Specific

bmE>Hts

and

provisions

-of

tke

warranty

)1us

other

important

benefits

for

you

are

conta.ined

in

your

Customer

Care

Progran

book

supplied

with

your

.airc~t.

Warra&ty

senrice

i,; availablt>

to

you

at

any

authorized

Cessna

Dealer

throughout

the

wor.d

upon

prelimtation

of

your

C1JStomer

Can

Card

which

~stabH<Ihes

~ur

eligibility

under

the

warrarty.

FACTORY

TRAINED PTSRSONNEL t·!

provide

yO\lwith

courtecus

expert

.service.

FACTORY

APPROVED

SERVICE EQUIPMENT tcpr<Wide

you

with

tile

most

effkJent

and

act'Ul'ate

workmar.ship

poasibl<'.

A STOCK OF GENUINE CESSNA SERVICE PARTS

on

hand who'n

you

need

them,

THE

LATEST

AUTHORLTATIVE INFORMATION >OR SERVIC:NG

CEBSNA AIRPLANES,

;ince

Cessna

Dealers

bav<

aU

of

the

Sa-vice

Manuals

aad

P=ts

Cahllogs,

kept

CU'rent

by

ser'l'ice

Letters

and

Berv:ice

News

Letterli,

;rublisbed

by

Cessna

Airciafi

Company.

w~

lll'ge

all

Cessna

owl'll!!rs to

use

the

Cessna

Dealer

OrganiZation

to

tbe

fullest.

A Clll'rent

Cesl:!l:lll

D<oaler

Directory

accOIDpanies

yO'I.li'

new airplaruc. TM-

Directory

is

revised

fre(pently,

and

a

current

CQP)I

can

be

obtained

from

yo.r

Cessna

De-Uer.

Mike

your

Dir~ctory

one

o1

your

cross-wuntry

flight

planning

aids; a warm

we~=me

a11a.its

you

at

rnery

Cessna

Dealer.

'

ti

/

'7111

/

-·

I .

_j..,--6~~---

/ / I ' I

_I~---=?'

--..o---==:::::__

_l__j

·-·7'1'!1AX

'::l

'=-I

~~('--)

=:;;:

~·

::~

11l'-IO"

I

C~

...

~-]

~~1a>mrom

b<lght

of

J;l~ora!t

;,

•+ ru-so

lta<

rlerressed

:>rui

o]j

""""

,~-,d""""

"'""'

pr,~•-">1'

;,.;;,tod,

*•w,r,~

~I'""

cl

;Uooralt -..

!th

,,~\.!<mal

'~

llgUs

,,,<>(l

..

d.

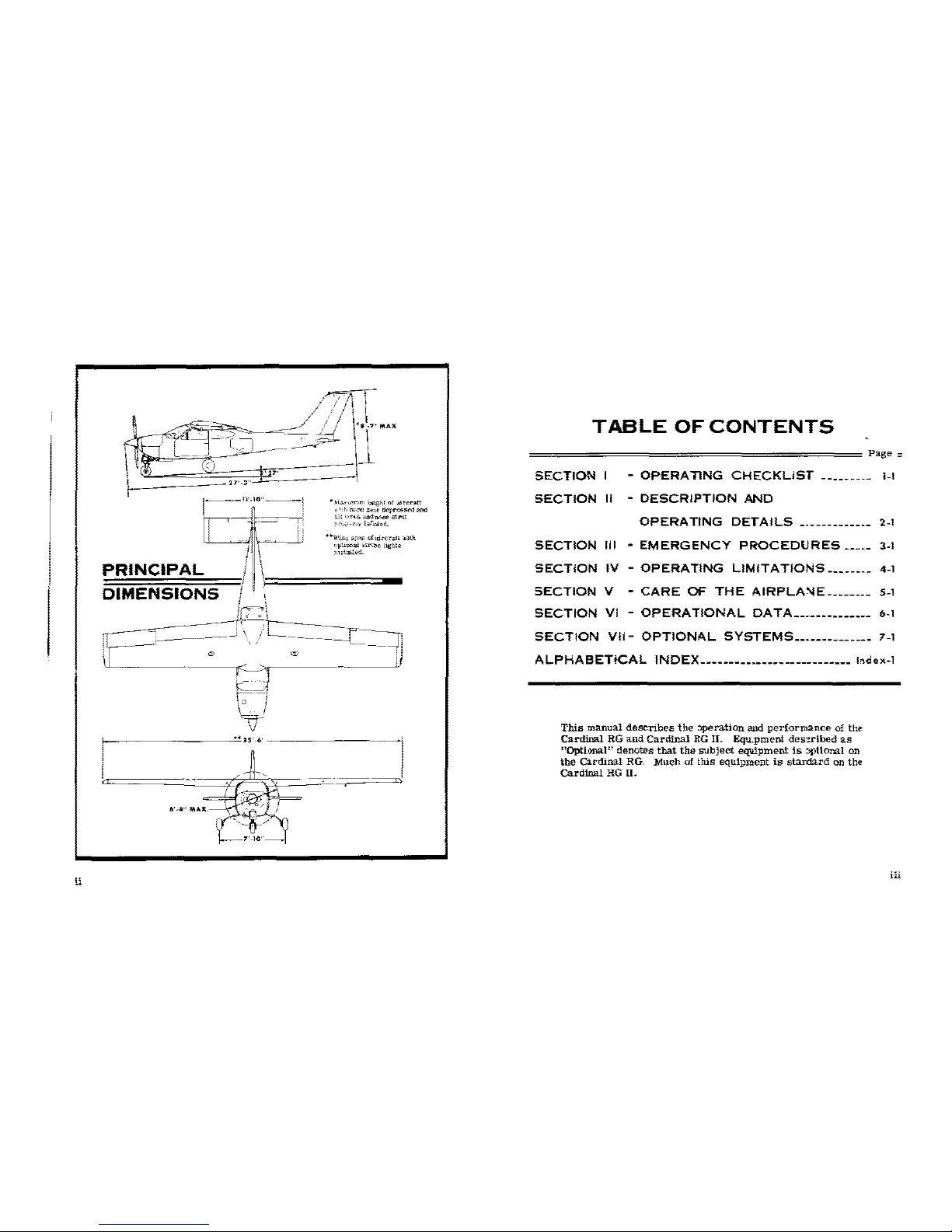

PRINCIPAL

/1\

DIMENSIONS

/

\=,

=====-•

p===?!

.··.

. -

i

~---J\]t-,

---------r==JJ

' G © :

u___--·--we

.~--·

i

~~

~~

;------------~·*

lS'-C.'

-----------']

i

...

6'-ili"

MAX.

TABLE

OF

CONTENTS

================================~~~~~======

Page

=

SECTION

I -

OPERATING

CHECKLIST

--------~

l-1

SECTION

II -

DESCRIPTION

AND

OPERATING

DETAILS-------------

2-1

SECTION

Ill -EMERGENCY

PROCEDURES-----

3-1

SECTION

IV -OPERATING

LIMITATIONS--------

4-l

SECTION

V

-

CARE

OF

THE

AIRPLA\IE

________

5-l

SECTION

VI -OPERATIONAL

DATA

______________

6-1

SECTION

VII-

OPTIONAL

SYSTEMS

______________

7-l

ALPHABETICAL

INDEX---------------------------

l,dex-1

This

manual

describes

the

;)J)eration and

performance

of

the

Cardinal

RG

and

Cardinal

RG

II.

Equ_pment des:!r-ibed

as

"Optional" denotes

that

the

subject

equipment

is

::>ptional

on

the

Cardinal

RG.

Much

of

this

equipment

is

sta:Ildard

on

th~

Cardinal

RG

II.

iii

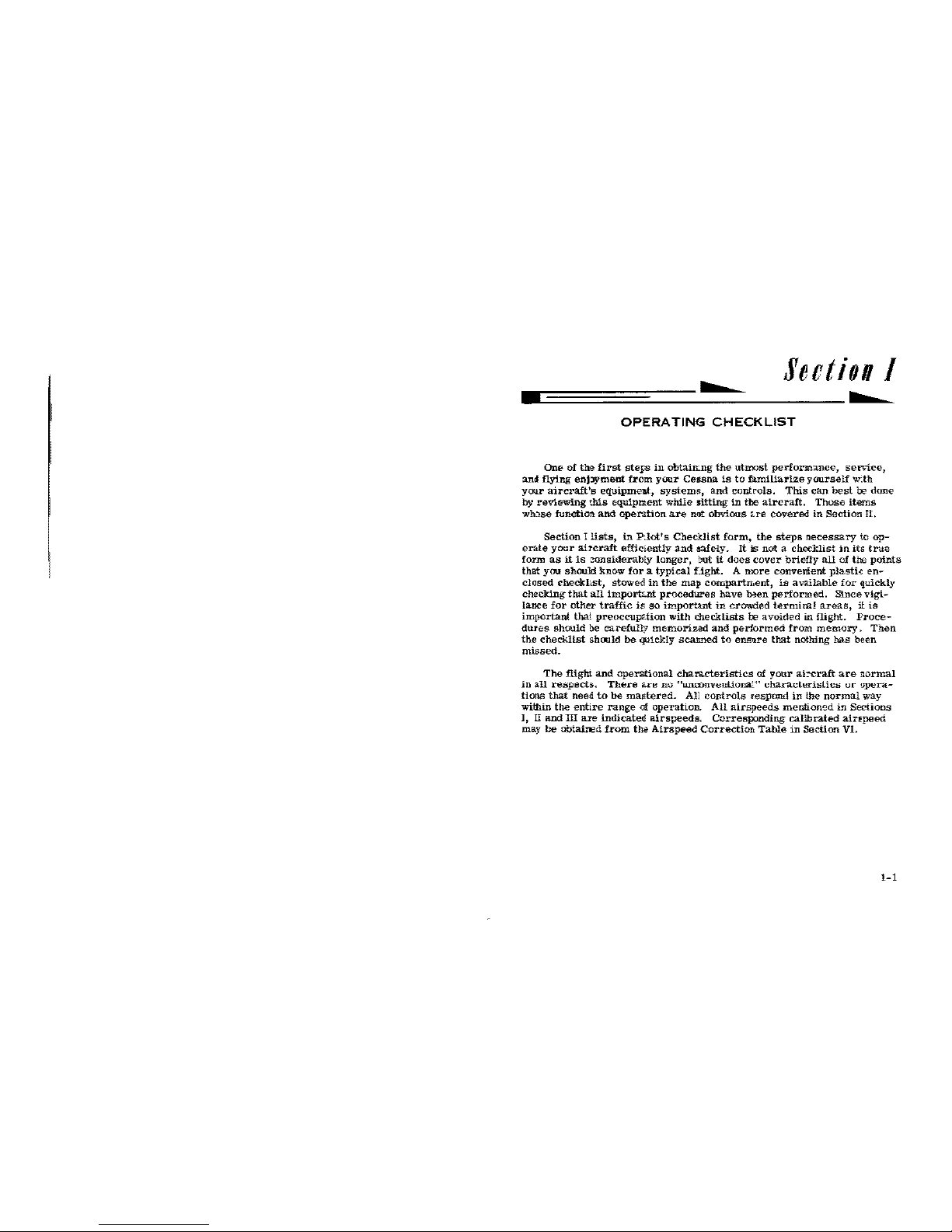

Sution I

~~==-~--

'-=

··--

OPERATING

CHECKLIST

One

of

the

first

steJ'S

in

obtain:.ng

the

utmost

performance,

service,

and

flying

enj:;Jyment from ycrur

Cessna

is

to

familiarize

yourself

w.th

your

aircraft's

equipme1t,

systems,

and

controls.

This

can

best

be

done

by

reviewing

this

equipment

while

sitting

in

tbe

aircraft.

Those

items

whJse

function

and

operation

are

not obvious

::..re

covered

in

Section II.

Section I lists,

in

PJot's

Checklist

form,

the

steps

necessary

to

op-

er.de

your

aircraft

efficiently

and

safely.

It

is

not a

checklist

in

its

true

form

as

it

is

~onsiderably

longer,

but

it

does

cover

briefly

all

of

the

points

that

you

should

know

for a typical

fight.

A

more

convelient

plastic

en-

closed

checkl,st,

stowed

in

the

rna~

compartn,ent,

is

avllilable

for

quickly

checking

that

all

import~

procedures

have

Men

performed.

Since

vigi-

lance

for

other

traffic

is

so

important

in

crowded

termiml

areas,

it

is

important

that preoecupEtion

with

checklists

00

avoided

in

flight.

Proce-

dures

should he carefuU:r

memorized

and

performed

from

memory.

Then

the

checklist

shoold

be

quickly

scanned

to

ellS'lre

tbat

nothing

has

been

missed.

The

flight

and

operational

characteristics

of

your

ai::-craft

are

normal

in

ail

re.specl:;.

There

<.n:l

no

"un.u:mv~uUomL"

characllolristic»

ur

vper<t-

tiOllS

that

need

to

be

mastered.

All

controls

respond

in

the

normal

way

within

the

entire

range

of

operation.

All

airspeeds

mention~d

in

Sectioos

I,

II

and

III

are

indicated

airspeeds.

Corresp:mding

calibrated

ainpeed

may

be

obtaired

from

the

Airspeed

Correctioit

Table

in

Section

VI.

1-1

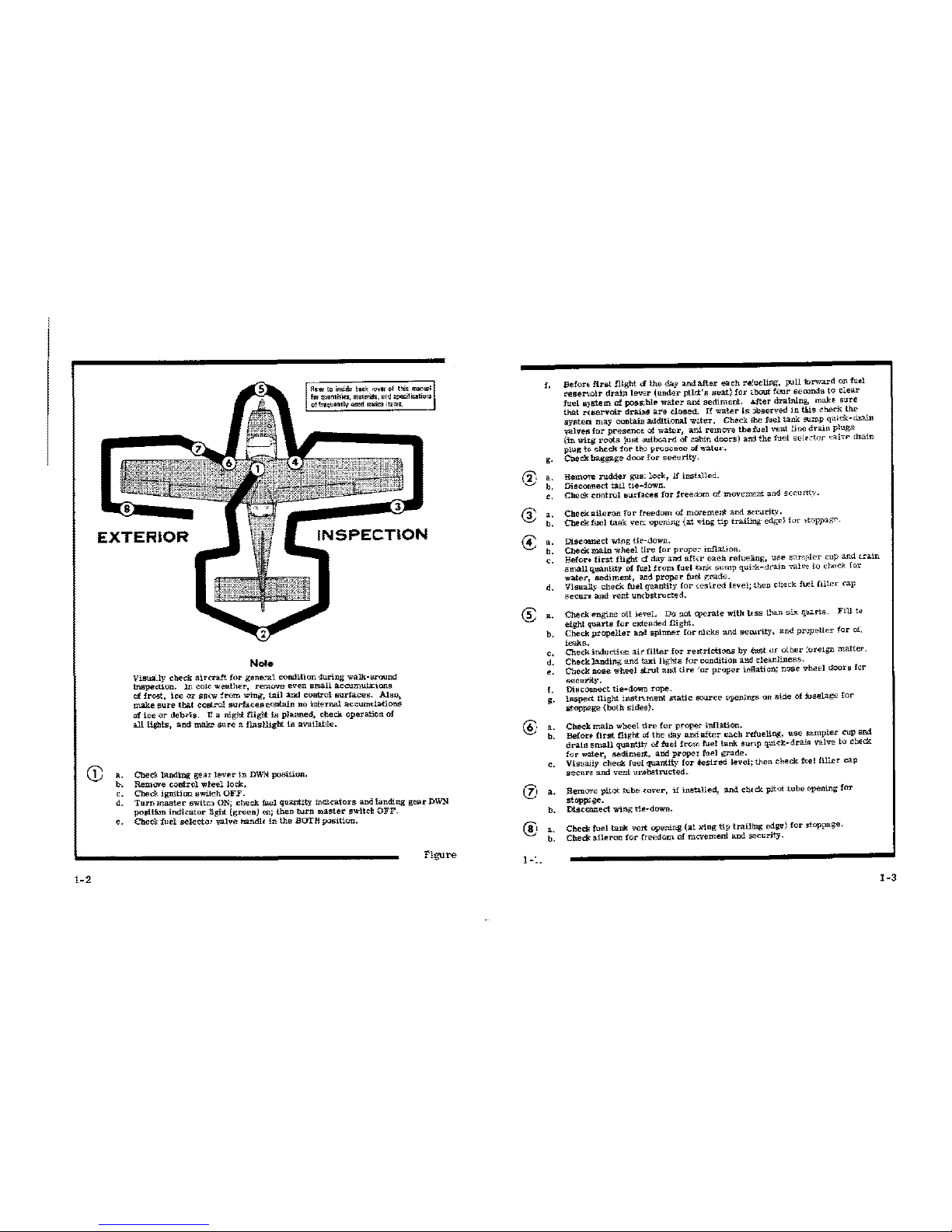

CD

'·

b.

'·

d.

'·

1-2

Rortf

tc

iMide

bot<

WYtr

f.)f

!iii<

mamllll

1111

<1l'Ontif...,

matorlik,

•nd

;p!!;~iolllioes

ol l,.quoMiy

"'"d

-'ci

ItaiM.

Note

Visua.ly

cheek

air(ra.ft

for

gene."lll

condition

·iuring

walk-around

lnspecl:ion.

1n

calc

weath;!r,

remove

even

small

accumuta;lons

of

frost,

ice

ax sn(w

from

wing,

tail

and

coutrol

surfaces.

Also,

make

sure

that

eont.rol

surfaces

contain

no

lnlernal

accarmlatlons

of

iee

or

debMs.

U a

night

fliglt

is

planned,

check

operation

of

allliibts,

and

make

sure a flasUigbt

is

availWle.

Checi

landing

gear

leve-r

in

DWN

position.

Remwe

control

w~ecllocl<.

Cheek

ignition

a wile

h.

OFF.

Turn

master

switc~

ON; chec.k

fuel

quantity

i;H1ieatore and

landing

gear

DWN

position

Indicator

light

(green)<£;

then

Nrn

111astet'

swltd

OFF.

Check

fuel

selecta'

valve

hancllE

in

the

BOTE

position.

Figure

@

€

€

<E

®

rz,

@

1-:.

f.

Befan

first

flight d

the

day

and

after

each

re:ueling,

pull

-forward

on

fud

~aenoir

drainlewr

{Ullder

ptld:'s

seat)

for

~bout

four

seronds

to

clear

fuel

a;;sUm

of

poss.bll'

water

am

sediment.

After

draining,

make

sure

that

rE&erv<lir

drahs

are

closed.

If

water

is

)bserved

In

tli.is

check

the

syaten

may

coo.taiD

additional

wrter.

Check

lhe

fuel

tank

rump

quick-dl:ain

valvel!i

for

presence

ilt

water,

al".i

remove

the

fuel

vent

line

drain

plugs

(jn

wir.g l'oots

just

wtboard

of

c:Jbin doo('S)

an:1

the

fuel

sel•ct<Jr

"a!v.-

drain

pl"'g

tc.

check

f!>r

tho

proscn"e

ofwate•··

g.

'·

b.

'·

'·

b.

••

b.

'·

d.

a.

b.

'·

d.

'·

f.

g.

'·

b.

'·

••

b.

'·

b.

Check

baggage

door

for

seeurity.

Remore

ruddeJ"

gus;

loci<,

if

instilled.

Disconnect

tail

tie-·iown.

Check

control

surfaces

for

freeoorn

of

mcvement

and

sccnnty.

Check

aileron

for

freedom

of

morement

and

sel'urity.

Check

fuel

tank

vel".:

open',ng {at

tiug

tip

tr..ilit;g

edge)

for

;toppagr.

Discomect

wtng

tie-down

.

Check

main

wh<:!el

tlre

for

prope:

ir.n.atlon.

Befor•

first

flight

d

day

:and aft.Er

each

refueling,

use

s::tnr•ler cup

and

train

amall

quantity

of

fllill

from

fuel

tmk

sump

qui-:k-drain vall'e

to

dwck

far

water,

sediment,

and

proper

fm:t

rrade.

Viaually

check

fuel

quantity

(or

tesired

level;

theD

check

h.ei

filler

cap

eecun

and

vent

un{bstrueted.

Check

engine

oil

le?@l. Do not

(\~<'rate

with

u-ss

thau

six

qurls.

Fi.U

l<>

eight

quarta

fer

extended

flight.

Check

p.rope.ller

and

spinner

for

nicks

and

sewrity,

and

pr·JPellcr

for

oi.

leaks.

Check

induction

air

filter

for

reatrictions

by

<tw;t

(l.f

other

:or<lign

matter.

Check

landing

and

taxi

lights

for

ccndition

and

~Ieanliness.

Ctlecknose

wheel

strut

and

tire

'or

proper

i.nflaticn;

n<;>Se

\1'heel doorB

fer

-~urity.

DtscOJme<:t tie-dOW'l

rope.

Inspect

flight

instn.ment

static

source

openings

on

side

of

Juselage

for

stopp2ge

{b<;Jth

sides).

Cheek

main

wheel

tire

for

prop"r

l.nfliill.on.

Befou

first

flight

<>1

the

day

and

after

each

rdu.,ling,

use

Ja1'11ple.r

cup

End

drain

small

quantJt:r

of

fuel

from

tuei

tank

sunp

quid:-drain

valve

t<:~

chEck

for

water,

a.edimert,

and

proper

fuel

grade.

Visua;Iy

~heck

fue-l

quantity

for

iesired

level;

then

check

f~el

filler

cap

secure

and

vent

unobstructed.

RemO're

pit<X

t\.lbe

W'ier,

if

inaU.lled, and ch<ck piicl:

tube

opening

fax

stopp<.ge.

Dlscll'lztect

wing

tl.E-dOWD.

Check

fuel

tank

vert

opening

(at

ring

tip

trailing

edge)

for

rtoppage.

Check

ail"ron

for

freedom.

af

mcrement

and

security.

1-3

BEFORE

STARTING ENGINE.

(1)

Exterinr

Preflight--

COMPLETE.

(2)

Seats,

Belts,

Sh011lder

Harnesses--

AJJUST

and

LOCK.

(3)

Fuel

Selector

Valve Handle ·-BOTH.

(4)

Radios.

Autopilot.

Electrical

Equipment --OFF.

(5}

Brakes--

TEST

~nd

SET.

(6) Cowl

Flaps --OPEN

(move

lever

out

of

locking

ht•le to

reposition).

(7}

Landin;;

Gear

Lever --DOWN.

{8)

Circuit

Breakers--

CHECK

IN.

STARTING ENGINE.

{1) MixturS!

--

IDLE

CUT-OFF.

(2)

PropeLer

--

HIGH

RPM.

(3)

Throttle

--

OPEN

1/4

INCH.

(4) :Master

SWitch--

ON.

(5)

Auxiliary

Fuel

Pump --ON.

(6)

Mixture--

ADVA~CE

to

f3

GAL/HR; then RETARD

to

IDLE

CUT-

OFF.

NOTE

If

engine

is

warm,

omit

priming

procedure

above.

(7)

Propeller

Area

--

CLEAR.

(8) IgnitiOJ Sv.·itch --START

(release

when

engine

starts).

(9)

Mixture --RICH

1:ADVANCE

smoothly

when

engine

fires).

NOrE

If

engire

floods,

turn

off

auxiliary

fuel

;rump,

place

mixture

in

idle

cut-off,

open

throttle

1/2,

and

cL"ank

engine.

When

engine

£ires,

advance

mixture

to

full

rieh

and

retard

thrvttle

promptly.

{10)

Oil

Pnssure --CHECK.

(11)

Auxiliary

Fuel

Pump--

OFF.

BEFORE

TAKE-OFF.

1-4

\I)

Parking

Brake

--SET.

(2)

Cabin

Doors--

CLOSED

and

LOCKED.

{3)

Flight

Controls --FREE

and CORRECT.

(4)

stabllator

and

Rudder

Tri:n

--TAKE-OFF.

( 5)

Fuel

Selector

,.alve

Handle --BOTH.

(6)

Throttle --1800

RPM.

a.

Magnetos--

CHECK ;RPM

drop

should not

exceed

15(1

RPM

on

either

magneto

or

50

EPM

differmtial

between

magnetos).

b.

Propeller --CYCLE

from

high

:o low RPM;

return

t{l

high

RP.N:.

e:.

Engine

Ins:ruments

and

AmmetEr --CHECK.

d.

Suction

Ga~e

--

CHECK.

(7)

Fligl\t

Instruments

and

Radios --SET.

(8)

Navigation

Lights,

Flashing

Beac-on,

and

Optimal

Strobe

Lights --ON

{as

r~quired}.

(9)

Throttle

Fricti::m

Lock--

ADJUST.

(10)

Flaps--

0"'

tol0°,

TAKE-OFF.

KORMAl TAKE-Off.

(1)

Wing

Flaps --0"

to

10°

{to"

preferred).

(2)

Power --MAXIMUM (full

throttle

aJtd

2700

RPM).

(3)

Mixture--

RlCH

(lean

for

field

elevation

per

f1:el

flow

placard

above

3COO

feet).

{4)

Aiuraft

Attitude--

LIFT

NOSE

WHEEL

at

65

:M:PH.

{5)

Climb

Speed--

75

to

85

MPH.

{6)

Brakes

--APPLY

momelltarily wha<

airborne.

{7)

Lan:ling

Gear --RETRACT

in

elimt

out.

(8)

Wing

FlapB

--RETRACT

(if

extended).

MAXIMUM

PERFORMANCE

TAtcE-Off.

(1}

Wi~

Flaps--

lDQ.

{2)

Brakes--

APPLY.

{3)

Power--

MAJ\.1MUM

(full

throttle

a.W.

2700 RPM).

(4)

Mixture--

RICH

(lean

for

field

elevation

per

fuel flow

placard

above

3000

feet).

(5}

Brakes--

RELEASE.

(6}

Air:!raft

Attitu:ie --LIF'l' NOSE WHEEL

at

60

MPH.

(7)

Climb

Speed

--

70

MPH

until

aU

obstacles

are

cleared.

(8)

Brakes--

APPLY

rnome:ttarily

when

airborne.

(9} Lar:ding

Gear --RETRACT

after

ol:Etacles

are

cleared.

(10) Wil'g

Flaps

--RETRACT

after

reaching

80

MPH.

1·5

,I

II

'

II

,ll

il

i

II

I

II

NOrE

Do

not

reduce

pov.er

until

landing

gear

and wing

flaps

have been

retracted.

ENROUTE CLIMB.

NORMAl

CLIMB.

(1) Air-speed

--

100 to 120

MPH.

{l)

Power--

25

INCHES Hg.

and

2500

RP.ft'::.

{3)

Mixture--

LEANED

to

13

GAL/HR.

{!)

Cowl

Flaps

--

OPEN

as

required.

MAXiMUM

PEtfORMANCE

CLIMB.

(l)

Airspeed--

95 MPH

at

sea

level

to

-91

MPH

at

10~000

feet.

(l)

Power--

MAXIMUM

(tull

throttle

and

2100

RPM).

(3)

Mixture --LEAN

per

fuel

fltJW

placard.

(4:)

Cowl

F:.aps --FU:.L

OPEN.

CRUISE.

(1)

Power --15 to 25 lNCHEB

Hg.,

2100

to

2500

RPM

(no

more

than

75%).

(:)

Mixture--

LEAN

per

Cessna

Power

Computer

or

Operationa:

Data,

Secticn

VI.

{l)

Cowl

F.lap5 --CLOSED.

LET-DOWN.

1-6

(1)

Power--

AS DESIRED.

NO'IE

Avoid

continuous

operation

Mween

1400

and

1750

RPM

with

less

than

10 inches

Hg.

(2)

Mixture--

ADJUST

for

smooth

operati~"'l.

(3)

Cowl

Flaps

--

CLOSED.

(4}

Wing

Flaps--

AS DESIRED

(O"

to

10"

btlow

150 M?H,

10"

to

30"

below 110

MPH).

(5)

Landing

Gear --AS

DESIRED

(do

not

Wend

above

140 MPH).

BEFORE

LANDING.

{1} Seat3,

Belts,

Harnesses

--

ADJUST

and

LOCK.

(2)

Fuel

Selector

Talve

Handle --BOTH-

{3}

Landing

Gear

--

EXTEND

below

140

MPH.

(4}

Mixklre --RIOI.

{5}

Propeller --HrGH

RPM.

(6)

Airspeed --SO

to

90

MPH

(flaps

UP).

(7) Wing

Flaps --AS

DESIRED (0"

to

10"'

below

15Cl

MPH,

10,

to

30°

below

111)

MPH).

(8)

Airspeed --70 to 80 MPH

{flaps

DOWN).

(9)

Btabilator

and

Rudder

Trirn

--ADJUST,

BALKED LANDING.

(1)

Power--

MAXIMUM

(full

throttle

ani

2700

RPM).

(2) Wmg

Flaps --RETRACT

to

20".

{3)

Airspe€d --75

MPH.

{4) Wing

Flaps--

RETRACT

slowly.

(5)

Cowl

Flaps--

OPEN.

NORMAL

LANDING.

(1}

Touchdown--

MAIN WHEELS

FIRST.

(2)

Landing

Roll--

LOWER

:t-JOSE

WHEEL

GENTLY.

(3)

Braking--

:MIMMUM

REQUIRED.

AFTER

LANDING.

(

1)

Wing

Flaps

--

UP.

(2)

Cow:

Flaps --OPEN.

SECURING AIRCRAFT.

(1)

Parl!ing

Brake--

SET.

(2}

Radios,

Electr1eal

Equipment

--

OFF.

.

(3)

Mixture--

IDLE

ClJT-OFF

(pulled

full

out).

(4)

Ignition

and

Master

Switches--

OFF_

(5)

Control

Lock--

INSTALL.

(6)

Fuel

Selector

Valve Handle --LEFT

or

RIGHT.

l-7

I

I

i

I

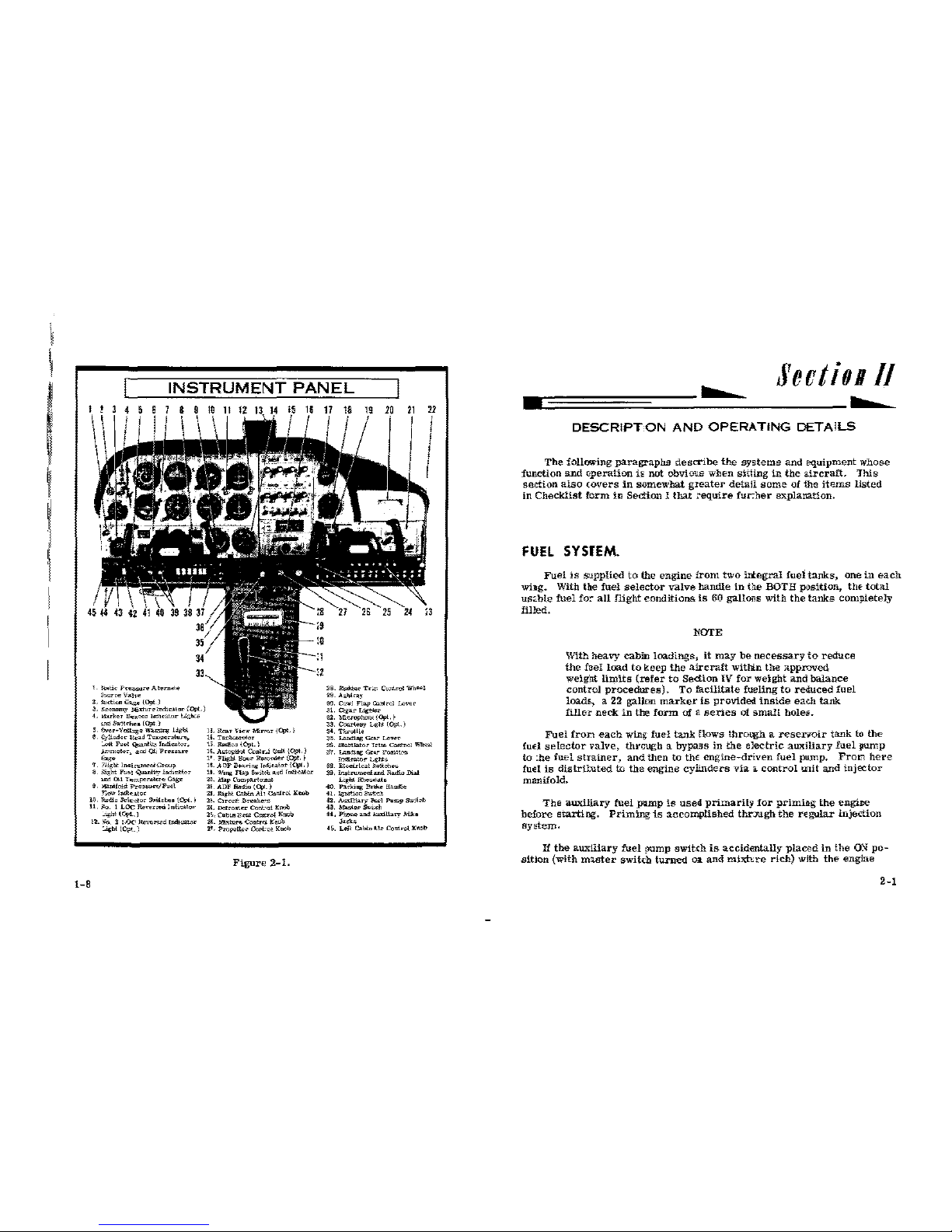

INSTRUMENT

PANEL

I

L

~c

P<~-..c•

Aler.wto

;<-A>"c"

'i«Jve

2,

!actio"

Gag.,

{0¢

J

3.

Eronomy

Mixlunlmheal<>r

iQ>t.

4,

o&ul<ec

S.,ooo

l"'u:at""

Ugk:o

em!

s~·l!<'hes

10¢

)

5. Over-1/<lilag-e

W..mi"!'

IJ;rhl

6.

Cjlind•~

<$<ad

Tl»>;><catu~

_At

Fu<>l

Qtianllt~

IM!ator,

~<m>>el•~.

aod

Ql,

Pco•.an

"""

7.

!Hglot

lnstrnmeclGrou;>

8.

Right

fi~l

QJ:.ctl'y

lod1e>.l<:>c

m<!

Oil

T<>mperalu<>

G"f><'

9.

""-m!ol,;

Pr••""<'</Fuel

;"""" lndk-';to<

lD.

'<;idla

hlt>etar

&ruehes(eyt.)

11,

.<a.

1

LOC

"""'""""

lndi."""'r

__oght

(Q?i_J

1-B

12.

)~,),

2

!.0('

lleve,..,d

tn<liU!!.o<

~ht

((Ft.)

11.

Rea•

V1ew

Mirr<n

{Opl.)

11.

T>~llffi<let"r

t>

Rl>dl~•

{Opt.)

1t.

Autoptl<>l Conlr..J

~nlt

(0;1.)

1'.

l'lighlll""<

Re«J<'<!Or[Opr,)

1!.

AUF

iS~"!;

!rdi<alor

((\It,

1

11.

W~~~&

FtQ

Switet

aod

frnti<#D~

~~.

Map

Corn]>O.rtrno..">t

ll.

ADF

flo&

(q,l.)

2!.

!light

Cohln

All

Conlrcl

K""h

2;.

CirouiC

.&re.U·~

~t.

D.:lros(.,.-

Con\:ol

l::ooi>

l\.,

O.bU!

ll..U

Om><>!

KllCb

~&.

Mixture

<:ootro

K~OO

2'.

Propel!a

Cent·<>~.

Koob

Figure

2-1.

21

~B.

-..,

Tr.m

C\mieul

Whed

211.

A,;!olray

:00.

Cffi>'l

Flap

::mrtrol

Lever

J!.

C.o:u

Llgtlu

:112.

Mtcr<>ph<mo'

!!¥1.)

~-

O:u.>1.-esy

l4;ht

(Ojt..)

$4.

Th-ll•

~0.

LandiJ>g

Ga7

Lev""

:IS.

~lator

Trim

C<lfl!rol

"'~i

;t/.

LltJ>.lJog

Ge.r

PoallW<l

I-<a\or

4;ht•

118.

Eled>-lcall»>ffoh""

11!1.

Inst=mellll..OO

lla<l!o

Thai

L!glll

Rheo.w.ts

-ro.

P>;:-l<:mg -

Ha,!l.<>

tL

JgmUm

h"tdl.

-12.

AuxUl>-r)'

-1

P><-

Swi!oh

4.1.-e<St>ut

44.

P:'l<m<!

aM

"'"il!a<Y

Mlko

- .

H.

Lei!

Cabln

Hr

Co!l!M

Koob

-

Secti011/

-

DESCRIPTON

AND

OPERATING

DETAILS

The

following

paragraphs

describe

the

systems

and

equipment

whose

function

and

operation

is

not

obvious

when

sitling

in

the

aircraft.

This

section

also

<overs

in

somewhat

greater

detail

soma

of1he

items

listed

in

Checklist

form

in

Section I that

require

fur.her

explanation.

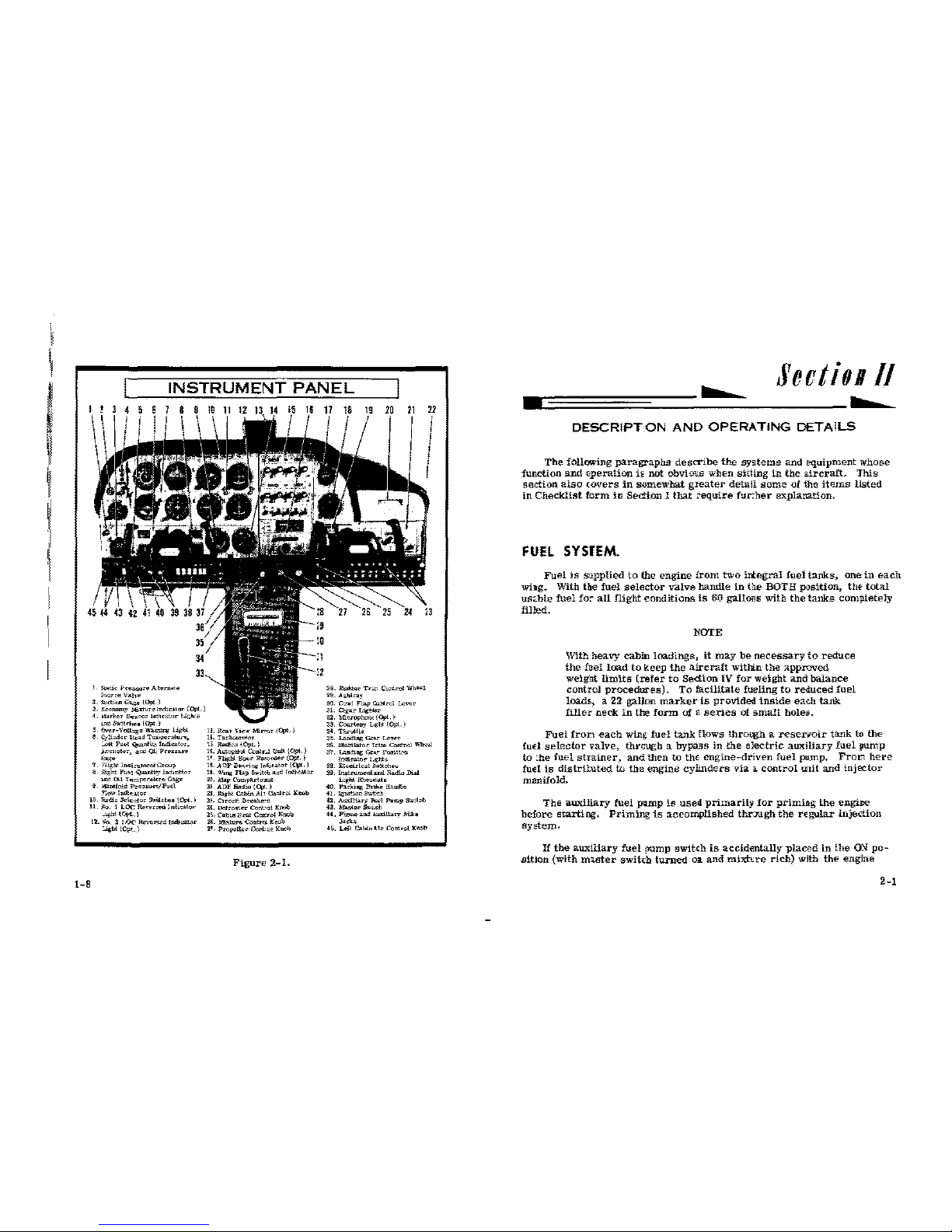

FUEL

SYSJEM.

Fuel

is

S'Jpplied

to

the

engine

from

two

ittegral

fuel

tanks,

one

in

each

wi:ag. With the

fuel

selector

valve

handle

in

be

BOTH

position, thf-

total

us<.ble

fuel

fo:-

all

flight

conditions

is

60

gallons

with

the

tanks

completely

filled.

NOTE

With

heavy

cabin

loadings,

it

may

be

necessary

to

reduce

the

fuel

load

to

keep

the

aircraft

witbin

the

approved

weight

limits

(refer-

to

Section

IV

for

weight

and

balance

control

procedures).

To

facilitate

fueling

to

reduced

fuel

loadf., a 22 gallon

marker

is

provided.

inside

each

tank

filler

neck

in

the

form

of

a

series

of

small

holes.

Fuel

fron

each

wing

fuel

tank

tlows throq.;h a

reserroir

tank

to

the

fud

selector

valve,

thrcugh

a bypa:;s

in

the

electric

auxiliary

fuel

pump

to

:he

fuel

strainer,

and

then

to

the

engine-driven

fuel

pump.

From

here

fuel

is

distriluted

to

the

engine

cylinders

via a control

UJiit and

injector

manifold.

The

auxiliary

fu-el

_plUllp

is

used

primarily

for

primiDg

th-e

engine

before

starting.

Priming

is

accomplished

thr:JU.gb

the

regular

injection

system.

lf

the

auxiliary

fuel

fl'Um_p

switch

is

accidentally

plactld

in

the

00

po-

sition

(with

master

switch

turned

01.

and

mixhre

rich)

with

the

engine

2-1

I

I

i

I

INSTRUMENT

PANEL

I

L

~c

P<~-..c•

Aler.wto

;<-A>"c"

'i«Jve

2,

!actio"

Gag.,

{0¢

J

3.

Eronomy

Mixlunlmheal<>r

iQ>t.

4,

o&ul<ec

S.,ooo

l"'u:at""

Ugk:o

em!

s~·l!<'hes

10¢

)

5. Over-1/<lilag-e

W..mi"!'

IJ;rhl

6.

Cjlind•~

<$<ad

Tl»>;><catu~

_At

Fu<>l

Qtianllt~

IM!ator,

~<m>>el•~.

aod

Ql,

Pco•.an

"""

7.

!Hglot

lnstrnmeclGrou;>

8.

Right

fi~l

QJ:.ctl'y

lod1e>.l<:>c

m<!

Oil

T<>mperalu<>

G"f><'

9.

""-m!ol,;

Pr••""<'</Fuel

;"""" lndk-';to<

lD.

'<;idla

hlt>etar

&ruehes(eyt.)

11,

.<a.

1

LOC

"""'""""

lndi."""'r

__oght

(Q?i_J

1-B

12.

)~,),

2

!.0('

lleve,..,d

tn<liU!!.o<

~ht

((Ft.)

11.

Rea•

V1ew

Mirr<n

{Opl.)

11.

T>~llffi<let"r

t>

Rl>dl~•

{Opt.)

1t.

Autoptl<>l Conlr..J

~nlt

(0;1.)

1'.

l'lighlll""<

Re«J<'<!Or[Opr,)

1!.

AUF

iS~"!;

!rdi<alor

((\It,

1

11.

W~~~&

FtQ

Switet

aod

frnti<#D~

~~.

Map

Corn]>O.rtrno..">t

ll.

ADF

flo&

(q,l.)

2!.

!light

Cohln

All

Conlrcl

K""h

2;.

CirouiC

.&re.U·~

~t.

D.:lros(.,.-

Con\:ol

l::ooi>

l\.,

O.bU!

ll..U

Om><>!

KllCb

~&.

Mixture

<:ootro

K~OO

2'.

Propel!a

Cent·<>~.

Koob

Figure

2-1.

21

~B.

-..,

Tr.m

C\mieul

Whed

211.

A,;!olray

:00.

Cffi>'l

Flap

::mrtrol

Lever

J!.

C.o:u

Llgtlu

:112.

Mtcr<>ph<mo'

!!¥1.)

~-

O:u.>1.-esy

l4;ht

(Ojt..)

$4.

Th-ll•

~0.

LandiJ>g

Ga7

Lev""

:IS.

~lator

Trim

C<lfl!rol

"'~i

;t/.

LltJ>.lJog

Ge.r

PoallW<l

I-<a\or

4;ht•

118.

Eled>-lcall»>ffoh""

11!1.

Inst=mellll..OO

lla<l!o

Thai

L!glll

Rheo.w.ts

-ro.

P>;:-l<:mg -

Ha,!l.<>

tL

JgmUm

h"tdl.

-12.

AuxUl>-r)'

-1

P><-

Swi!oh

4.1.-e<St>ut

44.

P:'l<m<!

aM

"'"il!a<Y

Mlko

- .

H.

Lei!

Cabln

Hr

Co!l!M

Koob

-

Secti011/

-

DESCRIPTON

AND

OPERATING

DETAILS

The

following

paragraphs

describe

the

systems

and

equipment

whose

function

and

operation

is

not

obvious

when

sitling

in

the

aircraft.

This

section

also

<overs

in

somewhat

greater

detail

soma

of1he

items

listed

in

Checklist

form

in

Section I that

require

fur.her

explanation.

FUEL

SYSJEM.

Fuel

is

S'Jpplied

to

the

engine

from

two

ittegral

fuel

tanks,

one

in

each

wi:ag. With the

fuel

selector

valve

handle

in

be

BOTH

position, thf-

total

us<.ble

fuel

fo:-

all

flight

conditions

is

60

gallons

with

the

tanks

completely

filled.

NOTE

With

heavy

cabin

loadings,

it

may

be

necessary

to

reduce

the

fuel

load

to

keep

the

aircraft

witbin

the

approved

weight

limits

(refer-

to

Section

IV

for

weight

and

balance

control

procedures).

To

facilitate

fueling

to

reduced

fuel

loadf., a 22 gallon

marker

is

provided.

inside

each

tank

filler

neck

in

the

form

of

a

series

of

small

holes.

Fuel

fron

each

wing

fuel

tank

tlows throq.;h a

reserroir

tank

to

the

fud

selector

valve,

thrcugh

a bypa:;s

in

the

electric

auxiliary

fuel

pump

to

:he

fuel

strainer,

and

then

to

the

engine-driven

fuel

pump.

From

here

fuel

is

distriluted

to

the

engine

cylinders

via a control

UJiit and

injector

manifold.

The

auxiliary

fu-el

_plUllp

is

used

primarily

for

primiDg

th-e

engine

before

starting.

Priming

is

accomplished

thr:JU.gb

the

regular

injection

system.

lf

the

auxiliary

fuel

fl'Um_p

switch

is

accidentally

plactld

in

the

00

po-

sition

(with

master

switch

turned

01.

and

mixhre

rich)

with

the

engine

2-1

I!

I.

I!!'

2-2

FUEL

SYSTEM

SCHEMATIC

T•"""''"""""'"'"'''"""-'f>oill.ruo"--,

....

"""·-

..

~.-...,.n<p=~~,..,..-~.,,.

·~"'<

~

,,.

........ ~ ,..,.

..........

'""'"~·

--"'"""_'_""''"""""""'

- ................... .,

......

,_

..

,,...c

..........

-..,.,.

....

~

......

,.

....

....,

..

~

·-·"'-"'""

..

.

FUEL

RISERVOHI

v:a:n·

FUEL

SELECTOR VAL'lE

.....................

_.;.,

.........

"""·"""

o.

t..1

~"'-'"'

«~••

'•"""•

,..~·.c-...orr

_.,

....

,

.......

"

....

......,.

DRAIN

LEVER

A/

(UNDER

ff..DT'S

SEATlV

AllX!LlAFY

A1JX!LIAHY

FtELPUMP

"""!TCH

MlJ<"rJRt

CO!o.'!ROL

THR01T"c,£

'm

INJECTION

~'~

E?«JINJ;;-IIRWEN

FUEL

PUMP

,----I

J

FUEL

C('NTBOL l-'NI'l'

'

..

I

CJDE----,

~

FUEL

:SUPPLY

c::::=l

VENT

~

---

MEC!fl,l,"JCAL

UJ>."KAGi

~EL<;;CT:ttcAL

FUEL

FLOW

INDICA TOR I

CONNE:TION

I

(l<lg!ot

hal!

o1

<hotl

in~tr-t)

Figure

2-2.

sbpped,

the

intake

manifolds

will

be

flooded.

The

auxlliary

fuel

Jl1llllP

is

also

used

for

vapor

suppression

in

hot

weather.

Nnrmally,

momentary

U>e

will

be

sufficient

br

vapor

suppres-

sion; however, continucus

operation

is

permlssible

if

required.

'Iurning

or.

the

auxiliary

fuel

pump

with a normally

orerating

engine

pump

vill

re-

sult

in

only a

very

minrr

enrichment

of

the

nrlxture.

It

is

not

necessary

to

have

the

auxiliary

fuel

pump

operating

dlring

normal

take-off

and

lanling,

since

gravity

ami

the

engine-driven

pump

Wlll

supply

adequate

fuel flow

to

the fuel

inje:tor

Wlit.

In

the

event

of

failill"e

of

the

engine-driven

pump,

lEe of the

auxiliary

fuel pump

will

provide

3ufficient fuel to

mailtain

flight at

maximum

con-

ti:ruous power-.

The

fueJ

selector

'alve

handle

should

be

in

the

BOTH

position

for

take-off,

lar.ding,

and

power-on

naneuvers

ihat

involve

prolonged

slips

or

skids.

Illring

prolonged

clim1:

or

cruise

with

the

fuel

selector

in

BOTH position, unequal

fuel

flow

from

each

:ank

may

occur

if

the

air-

craft

is

out of

trim

directionally

(;lip

indicator

ball

not

centered)

or

if

the

fuel

tank

caps

are

r.ot

sealing

properly.

The

resulting

heaviness

can

be

alleviatei

gradually

by

turning

the

selectcr

valve

to

:he

tank

in

the

heavy

wing.

To

ensure a prompt

engine

n:start

after

rmming

a fuel tank

dry,

switch

the

ft.el

selector

to

the

opposite

tank at

the

first

indication

::d

fuel

flow

fluctuation

or

power

loss.

Then

turn

or.

the

auxiliary

fuel

pump

and

advance

the

mixture

ccotrol

to

full

rich.

Afler

power

and

steady

:fuel

flow

are

restored,

turn

off

the

aw:itiary

fuel

pump

and

lean

the

mixture,

if

desirable.

Prior

to

landing, the

fuel

seleetor

should

be

returned

to

the BOTH

position.

NOTE

With low

fuel

(!/16th

tanl

or

less) a prolonged

powered

steep

descent

:1000

feet

or

more)

sllould

be

avoided

witll

more

than

10~

flaps

to

prevent

the

possibility

of

fuel

starvation

resulting

:rom

un~overing

the

fuel

tank

outlets. H starvation

shoo.ld

occur 1 leveling

tie

nose

and

turning

on

the

auxiliary

fuel

punp

should

restore

engine

power

within

30

seconds.

For

fuel

system

servicing

inf:.rmation,

refer

to

Servicing

Require-

ments

on

thE

inside

back

cover.

2-3

FUEL

TANK

SUMP

QUICK-DRAIN

VALVES.

Each

fttel

ta*

sump

is

equipped

Vlith a iuel

quick-drain

valve

to

f>.-cili-

tate

draining

and/or

examination

of:

fuel

for

conttmination

and

grade.

The

valve

extends

through

the

l<twer

surface

of

the

wing

just

out:>eard of

tiE

cabin

door. A sampler

cup

stored

in

the

aircraft

is

m~ed

to

examine

ne

fuel.

Insert

the

probe

in

the

sampler

et.tp

into

the

center

of

the

quick-

drain

valve

and

push.

Fuel

will

drain

fl'om

the

tank

S\lmp

i'lto

the

sam-

pler

cup

until

pressure

on tfl€ valw<

is

released.

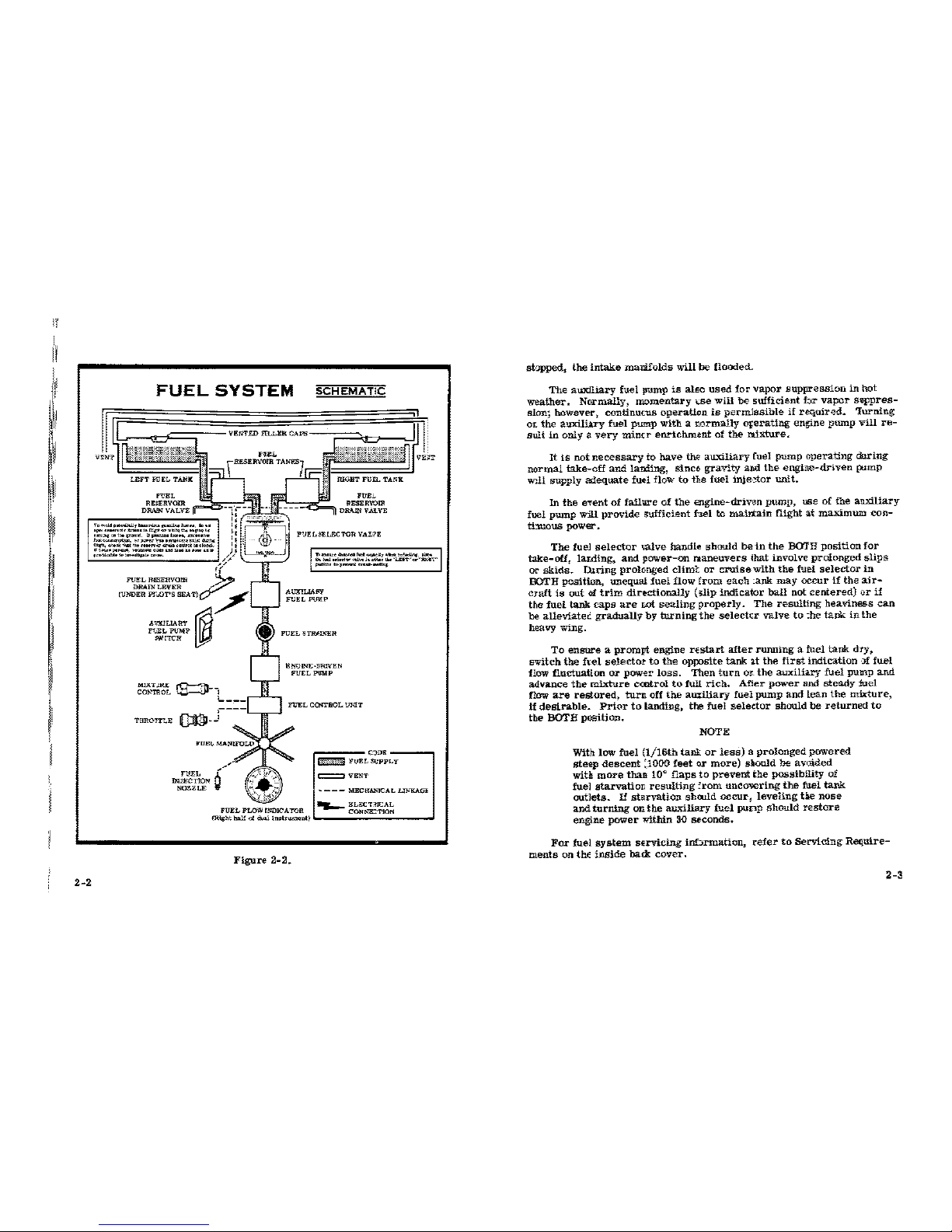

ELECTRICAL

SYSTEM.

ELectrical

energy

is

$Upplied

by a 14-volt,

direct-current

system

powered

by

an

er.gi_ne-driven

alternator

(see

figure

2.-3). The 12-v{llt

battery

is

located

aft

of

the

rear

cabin

Wall.

Power

is

supplied

to

aU

electrical

circuits

through

a

split

bus

bar,

one sJde cQfrt.aining

electronic

system

circuits

:md

the

other

side

having

general

electrical

system

ci:-

cuits.

Both

sides

of

the

bus

are

on

at

all

times

except whet:

either

an

ex-

ternal

power

source

is

connected

or

tbe

starter

switch

is

turned

on; then a

power

contactor

is

automatlcally

activated

to

open

the

circuit

to

the

elec-

tronic

bus.

Isolating

the

electronic

clt>euits

in

this

manner

prevents:

harmhl

transien::

voltages

:lrom damaging

the

transistors

ir. the

eleetr:mic

equipnent.

MASlER SWITCH.

The

master

switch

is a split-rocker

type

swftch

labele£

MASTEn,

and

is

ON

in

the

·1p

position

and

OFF

b

the

down

position.

The

right

half

o:l

the

switci:,

labeled

BAT,

contrala

all

electrical

power

to

the

air-

plane.

The

left

half,

labeled

ALT

.•

controls

the

alter.nat{lr.

N:~rmally,

b:th

sides

0::

the

mast€l"

switch

sllould

be

us~d

simulta-

neously; however, the

BAT

side

nf

the

switch

could

be

turned

ON

sepa-

rately

to

Check

equipment

while

on

the

gl"aund. The

ALT

side

of

the

switch,

when

pla~

in

the

OFF

position,

removes

the

altenator

frorn

the

electrical

system.

Witlt

this

switch

in

the

OFF

positioa

the

entire

e1ectr~ea1

load

is

placed

on

the

battery,

ContinuOO

operation

with

the

alternator

switcll

OFF

Will

reduce

battery

power

low enough

to

open

the

batter1

contactor,

remove

power

from

the

alternator

field.

and prevEnt

alternator

restart.

2-4

ELECTRICAL

SYSTEM

SCHIIUTIC

TO

..._.,

"EL"

L_l----<o~<:w

~

.......

....,,..

--~-

owa-c:~

J •

·~~

"'

MT

HlO

+--

~

~"OJ'

·-

"

<<KI>•

"'""

""""' • .,

.....

,

•

'""

ill-"'""'

"""""""o'

~~

"'"""''

"""'

"''"'

a@

'~<c.;,,

..

.,

......

,""

Figure

2-3.

''""~'

OWO-ro<T...C.. W......,t<;:J.

"""''

",...u

I"'H

$TR<l&i

i10HT!;

)mTf

~

>0

<N<>I~~

•N$Ut1W~T

CW5UO

<0

NQ;o

<><AO

V.fHY

s-.n;;~

<DO

;;tAO

CONT'tO\

O!l.d

uu.o

,..

,,...,c..,;o~

,~

)--ro

UNti

..

O

<>a•

..

OT<:)t

WtN<

nM

S<S!f

..

COtm.H/DOM<

HQ"r>

,.,N,-..o,.

swnc><

~U'-'-'""~

·~··

"""''

CUj.M

liGH!

..

(W{C10CW

0<01

~

;o

'~""'

coo•o""~'O>t

c•

~luO

...

AI<OM<N<

INN<-~T¢l(OMI

TO

SU..tl

W~ONINO

'y'""

~

ro

"""'""""'""

..

~lOUDI£>)0Pll

~

!0

U"'O

(Ofl)

U~Q

)Ofll

h-'»---to

uno

10"'

~lOUOC>IOPlJ

·-·

'

)!I

I'

I

~I

'~I

~

111

1:'

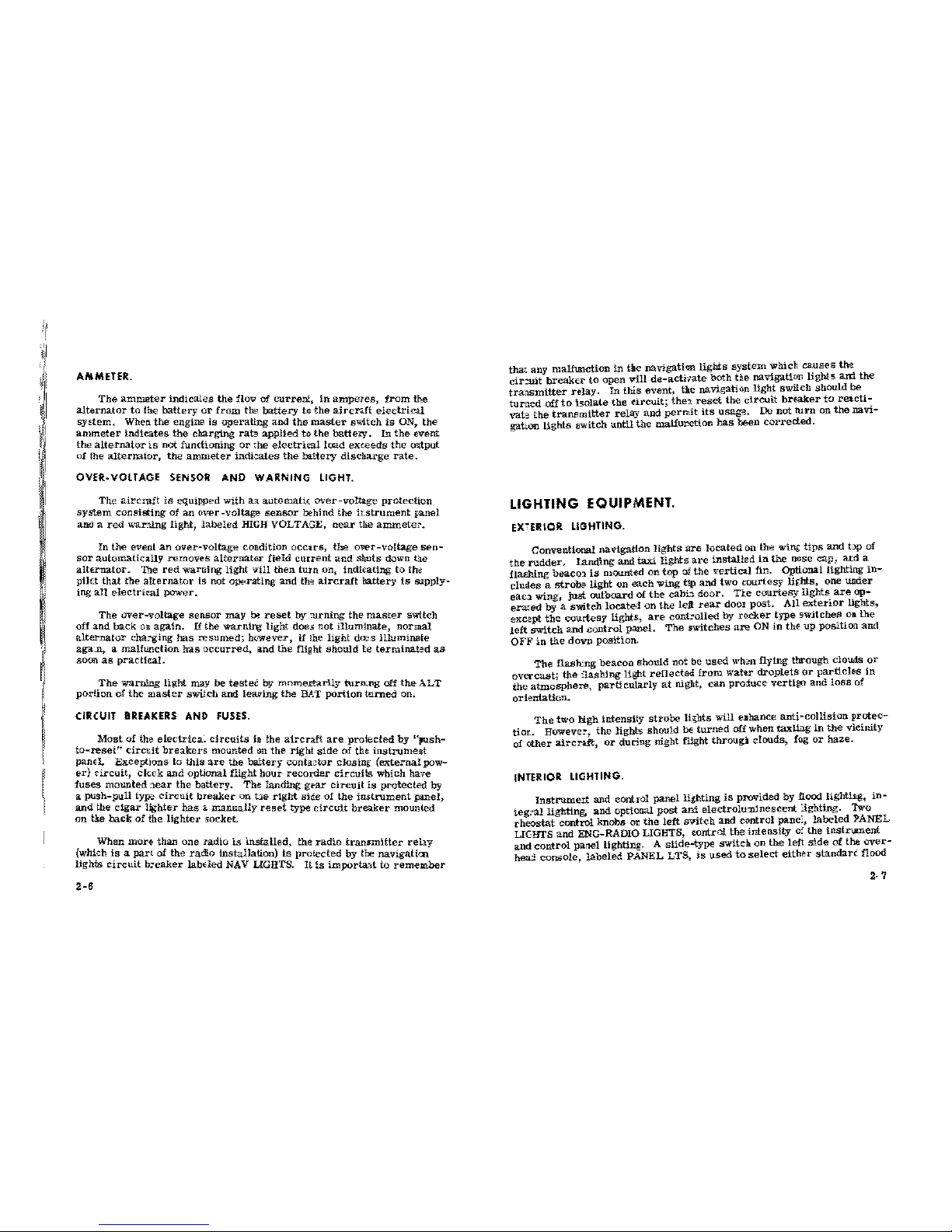

AMMETER.

The

ammeter

indicates

the

flov

of

current,

in

amperes,

from

the

alternator

to

lhe

battery

or

from

th:J

battery

to

the

aircrJt

electrical

sy~tem.

When

the

engine

is

operating

and

the

master

switch

is

ON,

the

ammeter

indicates

the

charging

rat=-

applied

to

the

battery,

In

the

event

the

alternator

is

not

functioning

or

:he

electrh:alload

exceeds

the

output

of

lbe

alternator,

the

ammeter

indi::ates

the

battery

discharge

rate.

OVER·VOLTAGE

SENSOR

AND

WARNING

LIGHT.

The

aircraft

is

equipped

with

a:t

automati<

over-voltage

protection

system

consi!?ting

of

an

over-voltage

sensor

behind the ir_strument

pwel

arui a

red

waning

light,

labeled

HIGH VOLTAGE,

near

the

ammete:-.

In

the

event

an

over-voltage

condition

occ~trs,

the

over-voltage

sen-

sor

automatically

removes

alternatar

field

current

and

shuts

down

tle

alternator.

The

red

wartling

light

will

then

turn

on,

indicating

to

the

pikt

that

the

alternator

is:

not ope>rating

and

tha

aircraft

battery

is

supply-

ing

all

electrical

pow-er.

The

over-voltage

sensor

may ~ reset

by

:urning

the

master

switch

off

and

back

on

again.

If

the

warn~

light

does

not

illuminate,

normal

alternator

cha:-ging

has

resumed;

however,

if

the

light

dres

illuminate

aga~n,_

a

malfunction

has

occurred.

and

the

flight

should

te

terminat:!d

as

soon

as

practieal.

The

warning

light

may

be

testeC

by

momertarily

turn.ng

off

the

ALT

portion

of

the

master

switch

and

leaving

the

BJ!.T

portion

turned

on.

CIRCUIT

BREAKERS

AND

FUSES.

Most

of

the

electr-ica~

circuits

in

the

aircraft

are

proJected

by

"push-

to-reset"

ciret.it

breakers

mounted

on

the

right

side

of

the

instrument

paneL

Exceptions

to

this

are

the

battery

conta:;tor

closing

(external

pow-

er}

circuit,

clcck

and

optional

flight

hour

recorder

circuits

which have

fuses:

mounted

:;ear

the

battery.

The

landing

g~ar

circuit

is

protected

by

a

push-pull

tne

circuit

b:reaker

on

lle

right

side of

the

instrument

panel,

and

the

c1gar

lighter

has a manually

r€set

type

circuit

breaker

mounted

on

t:ie

back

of

the

lighter

.wcket

When

mort

than

one

radio

is

installed,

the

radio

transmitter

relay

(which

is a part

of the

radio

installation)

is

protected

by

tEe

navigatioo

lights

circuit

b:-eaker labiOled

NAV

UGHTS.

It

is

importa~t

to

remember

2-6

tha:

any

malfunction

in

tke navigatioo

lights

system

which

causes

the

cir~t

break€r

to

open

vill

de-acth•ate

both

the

navigation

lights

ani

the

traasmitter

relay.

In

this

event,

tke navigati<m

light

switch

should

be

turned

off

to

isolate

the

eircuit;

the:t

reset

the

circuit

breaker

to

racti-

yah

the

transmitter

relay

and

permit

its

usage.

Do

not

turn

on

the

navi-

gatlon

lights

switch

until

the

malfur.ction

has

been

corrected.

LIGHTING EQUIPMENT.

EX~ERlOR.

LIGHTING.

Conventional nav-igation

lights

are

located

on

the

wine;

tips

and

bp

of

the

rudder,

landing

and

taxi

lights

are

installed

in

the

nose

cap,

at:d a

flashing

beaco1

is

mmmted

on

top

o1

the

vertical

fin.

Optional

lighting

in-

cludes

a

strobe

light

on

each

wing

tip

and

two

courtesy

li!ihts,

one

under

eaC3 wing,

just

outboard

of

the

cabb

door.

Tte

courtesy

lights

are

op-

era:::ed

by

a

switch

loeated

on

the

left

rear

doo1

post.

All

exterior

lights,

except

the

courtesy

lights,

are

cont-olled

by

rocker

type

switcbes

oa

the

left

switch

and

control

panel.

The

switches

are

ON

in

thE

up

position

and

OFF

in

the

down

position,

The

llash:ng

beacon

should

not

be

used

wh~n

flying through

douds

or

overcast;

the

ilashing

light

reflected

from

water

droplets

or

particles

in

the

atmosphere,

particularly

at

night,

can

proluce-

vertigo

and

loss

of

orientation.

The

two

bigh

intensily

strobe

li~hts

will

e.hance

anti

-collision

protec-

tior:. Howeve:-,

the

lights

should

bE

turned

off

when

taxlhg

in

the

vicinity

of

other

aircraft,

or

during

night flight

througk

clouds,

fog

or

haze.

INTERIOR LIGHTING.

Instrumert

and

conhol

panel lighting

is

provided

by flood lighting,

in-

teg:-a.Illghting.

and

optional

post

an:i eleclrolu:n1nesC£nt

Jghting.

Two

rheostat

control

knobs m the

left

svitch

and

control

pane:,

labeled

:PANEL

LKHTS

and

ENG-RADIO LIGHTS,

control

the

intensity

o:

the

instrument

and

control

patJellighting. A slide-type

switch

on

the

left

side

of

the

over-

heaj

console,

labeled

PANEL

LTS,

is

used

to

select

either

standarc

flood

2·7

~I

lighting

in

the

FLOOD

position,

optional

post

li_Jhting

in

the

POST

position,

or

a combination of

post

and

flood

lighting

in

the

BOTH

position.

Switches

a.'"ld

controls

on

the

lower

part

of

the instrurr.ent

panel

may

be

lighted

by

optional

eledroluminescent

panels

which

do

not

require

light

bulbs

for

illum:nation.

T:>

operate

t:Us

lighting.

turn

on

the

NAV

LIGHTS

switch

and

adjust

light

intensity

with

the

contra:.

knob

labeled

PANEL

LIGHTS-

Electroh1mines~nt

lighting

is

not

affected

by

the

selection

of

post

or

flood

lighting.

Instrument

and

control

panel

flood

lighting

oonsists

of

four

red

flood

lights

on

the

un:ierside

of

the

anti-glare

shield,

and a singl.e

red

flood

light

in

the

forward

part

of

the

overh:md

console.

To

use

:Iood

lighthg.

place

the

PANEL

LTS

sehdor

switcb.

in

the

FlOOD

position

and

adjust

light

intensity

'irith

the

PANEL

LIGHTS

rheostat

control

koob.

The

instrulllent

panel

may

be

eq_Upped

with

optional

post

lights

which

are :nounted

at

the

edge

of

each

instrument

or

ronl:rol

and

provide

direct

lightng.

The

Lghts

are

cr;>erated

by

placing

the

PANEL

Lt"S

selectOJ

switch

in

the

POST

positioo

and

adjurting

light

intensity

with

the

PANEL

LIGHTS

rhoostat

control

knob.

By

p:.acing

the

PANEL

LT.S

selector

switch

in

the

BOTH positia.n..

the

post

lights

can

be

used

in

comb.imtion

with

the

standard

flood

ligiling.

The

engine

instrument

cluster,

radio

equip:nent,

and

magnetic

com-

pass

have

integ.:-alligbting

and

operate

independently

of

post

or

flood light-

ing.

The

light

:ntensity

of

these

iten:s

is

controlled

by

the

ENG-RADIO

LIGETS

rheostat

control

knob.

A

cabin

dome

light

is

located

in

lhe

aft

part

of

the overhead console,

and

is

operated

by

a

switch

adjacent

io

the

light.

To

turn

the

light

on,

mOVli:

the

switcl:

to

the

right.

The

inatrunent

panel

eontrol pedestal.

may

·Je

equipped

with

an

option-

al

co.lrtesy

ligb::,

mounted

at

its

base,

which

illuminates

the

forward

cabin

floor

area.

This

light

is

controlled

by

the

courtesy

light

svttch

on

the

left

rear

door

post.

An

optional

map

light :nay be mounted on

the

bottom

of

the

pilot's

con-

trol

vheel.

The

light

illuminates

the

lower

portion

of

the

cabin

just

for-

ward

of

the

pilot

and

is

helpful when theck:ing maps

and

other

flight

data

during

night

operations.

To

operate

the

light,

first

turn

or.

the

NA

V

LrGHI'S

switch;

then

adjust

the

map

light's

intemtty

with the

knurled

diak

type

::-heostat

control

located

at

the

bcttom

of

thE

control

wlteel.

·-·

LANDING GEAR

SYSTEM.

The

retractable

tric!cle

landing

gear

is

extended and

retracted

by

hy-

draulic

actuators

powered

by

an

eledrically-driven

hydraulic

power

pack.

The

power

pack

assemblJ

is

located

aft

of

the

:-ear baggage

compartment

wan.

Mechanically-actuated wheel

well

doors

are

provided

for

the

nose

gear.

They

are

open

when

the

nose

gear

is

down

and

closed when

it

is

ret:

acted.

An

over-center

mechanical

linkage

provides

a positiYe

mechankal

up

and down lock

for

the

no~e

wheel. The

main

gear-

utilizes

hydraulic

se-

quence valve Cownloeks

and

hydraul:.c

pressur~

for

positive

uplock.

:Main

gear

uploek

pressure

.is

maintained

automatically

by

the

·power

pack

as-

sembly.

If

pressure

drlf,ls below

tlat

neeessa:y

to

retail:

uplock

pres-

sure

on

the

main

gear,

tll€

power

~ck

will

automatically

compensate.

Two

position-indicator

lights,

mounted

to

the

left

of

the

stabilator

trim

control

"'hef!I, indicate

that

the

gear

is

either

up

or

down

and

lGcked.

Both

the

gear

UP

(amber}

and

gear

DWN

{gree:t)

lights

are

the

press-to-

test

type,

inccrporating

4i.mming

stutters

for

:light

operation.

As

an

ad-

ditional

rerninier

that

the

gear

is

~racted,

a

warning

horn

sounds

inter-

mittently

wher.ever

the

tt.rottle

is

retarded

below

approxi:nately

12

inches

manifold

pressure

(master

switch

oo.)

with

the

gear

up

or

not down and

loeied.

LANDING

GEAR

LEVElL

The

gear

[ever,

mmnted

to

the

left

of

the

engine

con:rols,

has

:wo

positions

(up

f:lr

gear

up,

and

down

for

gear

down) which give a

mechan-

ical indication

of

landing

gear

position.

From

either

position,

the

l~ver

must be

pullet

out

sllghtly

to

clear

a.

detent

be:ore

it

can

be

repositioned;

operaUon of tl:e

landing

gear

system

will

not begin until

t:1e

lever

has

be-en

repositioned.

After

the

lever

has

baen repositioned, hydraulic

pressure

is

cirected

wi!hin

the

sy.Etem

to

achtate

the

ge<.r

to

the

selected

position.

Til£

gear

lever

will

remain

in

whict.ever position

bas

bee:t

selected.

During

a

normal

cycle,

the

gear

locks

up

:ll'

down and

the

position

in-

dicator

light

c:nnes

on

injicating

completion

oi

the

cycle.

Landing

gear

extension

can

be

detectee

by

illumiration

of

the

gear

DW1f

indicator

light

(green),

a.bser.ce of a

gear

warning

~orn

with

be

throttle

retarded

Mlow

approximately

12

inches

manifold

pressure,

alld

visual

inspection

of

the

m.Un

gear

position. Indication

of

gear

retracton

is

prov.ded

by

illumin-

aticn

of

the

gear

UP (amber) light. Shoold a

gear

indieabr

light

faL

to

2-9

II

illurrinate,

the

light

should

be

checlu:d

for a bumed-out

bulb

by

pressing

to

test.

A burne<i-out

bulb

can

be

replaced

in

flight

with

tt.e

bulb

fron

the

r-emaining

indicator

light.

A

safety

switch,

actu.ated

by

the

Mse

gear,

electrica.I.y

prevents

inad\<!rtent

rehaction

whenever

the

r.ose

gear

strut

is

corr.pressed

by

the

weight

of

the

ai:craft.

Also, a switch

type

eirruit

breaker

is

provickd

as a maintenance

safety

feature.

With

the

switth

pulled

rn..t,

landing

gear

operation

is

prEvented.

After

maintmance

is

campleted,

and

prior

t')

flight,

the

switch

should

bF

placed

in

the

on

poS:tion

{push~d

in).

EMERGENCY

l-AND

PUMP.

':'he

landing

gear

emezgency

hanC

pump

is

located

on

the

floor

between

the

fmnt

seats

<:nd

is

used

to

manually

extend

the

gear

in

the

event

of

hy-

draulic

pump

failure.

Whm

not

in

use,

the

pump

handle

is

retracted

and

stowEd

beneath

a.

hinged

cover

marked

with

a

placard

outlir.ing

emergency

operation

procedures.

Re:er

to

Section

ill

for

emergency

operation

oE

the

hand

pump.

CABIN

HEATING,

VENTILATING

AND

DEFROSTING

SYSTEM.

The

temperature

and volume

of

a:.rflow

into

the

cabin

can

be

regu:.ated

to

any

degree

d€sired

by

adjustment

d a

single

CABIN HEAT

knob

and

two

CABIN

AIR

knol::s.

When

r;artial

eabi:l

heat

is

desired,

ble:liiing

warm

and

cold

<dr

will

reSJJ.t

in

improved

ventilation

and

reat

distribrl:ion

thrrn;;hout

the

cabin.

I'ront

cabin

heat

and

v:ntilating

air

from

tlw

main

heat

and

ventila-

ting

system

is

nuted

throt:gh two mallifolds

located

forward

of

the

rudder

pedals

to

directionally-adjustable,

on-off

ventilaturs

on

the

front

cabb

sidewalls.

Rear

cabin

hea:

and

ail'

is

supplied

ty

ducts

from

both

fro1.t

cabin

ventilators,

one

exte:uling down

each

side

of

the

cabin

to

the

for.vard

doo~st:,

then

along

the

lo·.ver

edge

o:'

the

cabin

door

to

an

outlet

near

the

aft

eCge

of

the

{bor.

Airfbw

from

each

outlet

rnay

be

dire)ted

through

either

of

two

lowered

operlngs

by

rotating

a kncb Dn

top

of

the

Dutlet.

For

maxill'lum

rear

cabin

heating,

close

tnth

front

cabin

ventilators.

2-10

Windshield

defrost

air

is

supplied

from

the

left

cabin

manifold; t:.1ere-

fore,

the

temperature

of

the

defrosting

air

is

the

same

as

heated

cabin

air, A push-pllll

control

knob labelEd DEFROSTER

regulates

the

volume

of

air

to

the

wbdshield.

Pttll

the

kmb

out

as

necessary

for

defrosting.

Four

sepal'ately

adJustable

over1ead

ventihtor-s

supply

individual

air-;

two

are

mounted

in a console

ab:we

the

pil(lt

and

co-p-Jot,

and

two

opti(lnal

individual

ventila:ors

may

00

mounted

.n

the

rear

cabin

eeiling.

Additional

ground

and

flight

ventilation

is

available

through

an

open-

able

vent

windcw

in

each

cabin

door.

These

wi:ldows

can

'3e

opened

<.-t

speeds

up

to

HO

MPH

by

rotating

the

crank

located

below

the

window.

SHOULDER

HARNESSES.

Shoulder

larness:es

are

provided

as

standard

equipment

for

the

pilot

and

front

seat

passenger,

and

as

optional

for

tre

rear

sea:

passengers.

Seat

belts

are

standard

~ipment

for

all

passe:1gers.

E;;.ch

front

seat

harmss

is

attached

to a rear

door

post

just

above

wim:ow

line

and

is

stowed

behind

a stowage

sheath

mounte:i

above

the

cabin

door.

When stowing

the

harness,

fold

it

and

place

it

behind

the

sheath.

The

optional

rea:-

seat

shoulder

harnesses

are

attached

ad-

jace:d

to

the

lover

corners

of

the

rear

window.

Each

rea.-

seat

harn~ss

is

stowed

behh.d a stowage

sheath

located