Page 1

Page 2

IT

SERIES

SUBWOOFERS

Attention!

PLEASE READ ALL WARNINGS FOUND IN THIS MANUAL.

THIS

INFORMATION IS HIGHLIGHTED IN BOLD ITALIC TYPE AND IS INCLUDED

TO INFORM YOU OF THE POTENTIAL FOR PERSONAL INJURY OR

DAMAGE TO PROPERTY.

Hearing Damage

CONTINUOUS, EXCESSIVE EXPOSURE TO SOUND PRESSURE

LEVELS IN EXCESS OF 85 dB CAN CAUSE A LOSS OF HEARING. CERWIN-

VEGA IT SERIES COMPONENTS ARE CAPABLE OF PRODUC/NG SOUND

PRESSURE LEVELS GREATER THAN 85 dB.

Volume and Driver Awareness

USE OF INTENSE TECHNOLOGY SERIES SUBWOOFERS CAN IMPAIR

YOUR ABILITY TO HEAR NECESSARY TRAFFIC SOUNDS AND MAY

CONSTITUTE A HAZARD WHILE DRIVING. WE RECOMMEND USING LOW

VOLUME LEVELS WHEN DRIVING YOUR VEH/CLE.

CERWIN-VEGA ACCEPTS NO LIABILITY FOR HEARING LOSS,

BODlLY INJURY, OR PROPERTY DAMAGE AS A RESULT OF USE OR

MISUSE OF THlS PRODUCT.

Installation Warning

USE EXTREME CAUTION WHEN TIGHTENING MOUNTING SCREWS,

AS SCREW HEADS CAN CATCH ON THE SURROUND AND CAUSE

DELAMINATION OF THE SPEAKER ASSEMBLY.

Cerwin-Vega is constantly striving to maintain the highest consumer standards. As a result of these efforts, modifications may

be made from time to time to existing products without prior notice. Specifications and appearance may differ from those listed

or shown in this manual. Cerwin-Vega is a registered trademark of Cerwln-Vega, Inc Dacron and Nomex are registered

trademarks of E.I. Du I’ont De Nemours & Co., Inc.

i

Page 3

I T SERIES SUBWOOFERS

For nearly 50 years, Cerwin-Vega has set the standard for

subwoofer performance worldwide. Established in 1954, CerwinVega was designing subwoofers before most competitors’ engineers

were born. Cerwin-Vega’s goal is to reproduce and even improve the

live musical experience. To this end, we have pioneered a design

philosophy which combines high efficiency with high power

handling, resulting in performance unequaled in dynamic capability.

Dynamics are, first and last, fundamental to the very purpose of

sound reproduction:

“To provide the listener with the highest order

of artistic and subjective resemblance to the condition of a live

rendition.”

Intense TechnologyTkl (IT) competition subwoofers are

designed for optimum performance in small sealed enclosures with

low frequency accuracy without sacrificing output. Each IT

subwoofer utilizes new engineering concepts and technological

innovations such as:

Infused Kevlar and Crystalline Oxide Fiber Cone with

Polypropylene Coating: Extremely rigid and strong with

exceptionally fast transient performance for “tight” natural

sounding bass and low distortion even at high power levels.

Natural Butyl Rubber Surround: Outstanding linearity under

hard drive/high power applications. Long throw with minimum

cone “drift” results in wide dynamic range and low distortion.

Resists ultraviolet radiation.

Nomex’r”’ Spider Material: Vastly stronger than conventional

cloth. Resists tearing or warping under high power conditions

for improved long-term reliability.

Deep-Draw Diecast Frame: More rigid than stamped steel so

frame distortion and resonances are effectively eliminated. Nonmagnetic so all the magnetic energy is used to tightly control the

diaphragm for increased output with prolonged reliability. High

efficiency combines with excellent transient response and

acoustic definition.

Proprietary Integrated Dust Dome: Dust dome is designed as a

7

Page 4

IT

SERIES

SUBWOOFERS

structural member of the cone body for greater cone integrity.

Lower distortion even under extreme loading conditions.

Unitized Magnetic Circuit: Monolithic pole piece/back plate

construction for maximum magnetic efficiency.

Oversized Voice Coils: Hand crafted 3” (12/15”) and 2” (S/lo”)

voice coils wound with precision Swiss wire for high power

handling. Consistent and outstanding performance over the

long-term.

High Energy Strontium Ferrite Magnet: Intense flux density with

greater than a 10% increase over conventional strontium ferrite

magnetic materials for high efficiency and greater control with

fast transient response.

Deep Groove Backplate: Extended voice coil excursion capability

for increased mechanical power handling resulting in enhanced

reliability as well as higher output.

Vented Pole: Effectively transfers heat away from voice coil for

improved thermal power handling and reliability.

About This Manual

This manual covers enclosure information for the ITS.O/lO.O/

12.0/15.0 subwoofers. We assume you have a good knowledge of carspeaker installation techniques, including subwoofer box construction.

If not, please consult your authorized Cerwin-Vega mobile audio

dealer for installation options.

Warranty information

Your IT subwoofer is covered by Cerwin-Vega’s limited

one-year warranty. Please read the enclosed warranty card for all

the details.

2

Page 5

IT

SERIES

SUBWOOFERS

Table of Contents

Safety Warnings

introduction

Table of Contents

Applications

IF8.0 SpecificationslThiele-Small Parameters

5

W8.0 Sealed Enclosure Recommendations 6

IrIO. Specificationsflhiele-Small Parameters

7

IWO.0 Sealed Enclosure Recommendations 8

IT-120 Specificationsflhiel-Small Parameters

Irl2.0 Sealed Enclosure Recommendations

IT-15.0 SpecificationslThiele-Small Parameters

/T-15.0 Sealed Enclosure Recommendations

i

f

3

4

9

10

3

Page 6

I T

SERIES

SUBWOOFERS

Applications

The Cerwin-Vega IT Series subwoofers are specifically

designed to be used in small sealed enclosures for optimum

performance with long-term reliability. Thevery low resonance

frequency of each IT subwoofer results in tight, well-controlled bass

where space is limited.

Caution: By definition subwoofers with a low resonantfrequency

designed for small sealed enclosures have a very compliant (soft)

mechanical suspension system. Consequently, high power

application ijz enclosures which are larger than the recommended

volume could result in mechanical damage to the woofer.

For best results, at minimum we recommend lining all inside

box walls with acoustic fiberglass or DacronT” fiberfill of one-inch

thickness. By loosely filling the enclosure (see figures in “enclosure

recommendations”) the enclosure with acoustic fiberglass or

DacronTM fiberfill, the enclosure volume may be reduced by lo-15943

yielding the same results. It is ZW~J importrrvzf that the box have no air

leaks. The more rigid and well-sealed the enclosure, the more

accurate and controlled the bass response. Remember that with small

sealed enclosures, dimension tolerances are highly critical. Please

pay particular attention

that

internal box dimensions match those

recommended in this manual.

The final box shape should be determined by individual space

considerations. Although the shape of the box is not critical to

performance, the length, width, and depth of the box should all be

different dimensions. This prevents common mode resonance that

can occur in the walls of the enclosure. Optimum performance is

achieved when the ratio of the wall dimensions are 1.25 x 1 x 0.8 or

1.66 x 1 x 0.6. These are known as the “golden ratios.” Under no

circumstances should the box be made in a “cube” shape with all

sides equal.

In applications which require multiple woofers, we

recommend a common cavity for each “pair” of woofers. This is

achieved by doubling the recommended enclosure volume. The

woofers should be physically positioned as close together as possible

to create an acoustic “coupling” of the two woofers, which will result

in an increase in output level.

4

Page 7

IT

SERIES

SUBWOOFERS

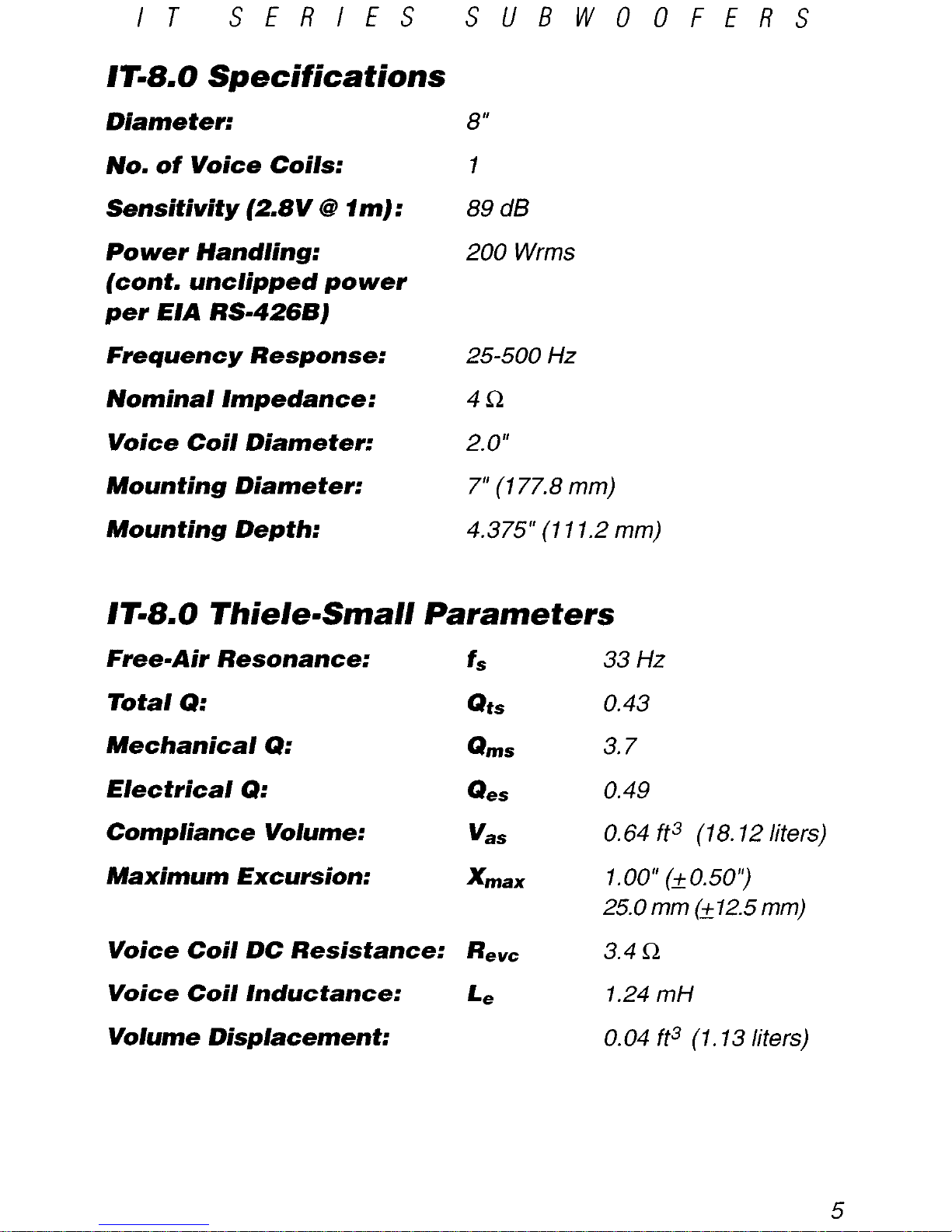

1F8.0 Specifications

Diameter:

No. of Voice Coils:

Sensitivity (2.8V 8 7m) :

Power Handling:

(cont. unclipped power

per HA RS-4266)

Frequency Response:

Nominal Impedance:

Voice Coil Diameter:

Mounting Diameter:

Mounting Depth:

8”

1

89 dB

200 Wrms

25-500 Hz

4fi

2.0”

7” (177.8 mm)

4.375” (111.2 mm)

1F8.0 Thiele-Small Parameters

Free-Air Resonance:

fs

Total 9:

Qts

Mechanical 9:

0

ms

Electrical 9:

Q

es

Compliance Volume:

V

as

Maximum Excursion:

X

max

Voice Coil DC Resistance: Rev=

Voice Coil Inductance:

Le

Volume Displacement:

33 Hz

0.43

3.7

0.49

0.64 ft3 (18.12 liters)

1.00” (*0.50’)

25.0 mm (2 12.5 mm)

3.4 R

1.24 mH

0.04 ft3 (1.13 liters)

Page 8

IT

SERIES

SUBWOOFERS

ma0 sealed F

rrequem=YRespovrse

Normalized Amplitude Response (d&SPUHz)

cln

6

0

-6

-12

-18

-24

-30

-36

I I I llllll

I I I

5HZ 10 50 100 500

Total Box Volume*:

0.4 ft3 (11.33 liters)

*Includes driver displacement of 0.04 ft3 (1.33 liters)

Page 9

IT

SERIES

SUBWOOFERS

IT-f 0.0 Specificat ions

Diameter:

No. of Voice Coils:

Sensitivity (2.W 8 lm):

Power Handling:

(cont. unclipped power

per E/A RS-4268)

Frequency Response:

Nominal Impedance;

Voice Coil Diameter:

Mounting Diameter:

Mounting Depth:

10”

1

91 dB

250 Wrms

20-500 Hz

4L2

2.0”

9” (228.6 mm)

5” (117.0 mm)

IT-f 0.0 Thiele-Small Parameters

Free-Air Resonance:

fs

Total Q:

Qts

Mechanical 9:

Q

ms

Electrical Q:

Q

es

Compliance Volume:

V

as

Maximum Excursion:

X

max

Voice Coil DC Resistance: Rev,

Voice Coil Inductance: Le

Volume Displacement:

26 Hz

0.59

4.0

0.69

1.95 ft3 (55.22 liters)

1.34”

(~0.67’)

34.Omm (*17.0mm)

3.4Q

1.4 mH

0.07 ft3 (1.98 liters)

7

Page 10

IT

SERIES

SUBWOOFERS

ITI10.0 Seaki F

-yRes;pourse

Normalized Amplltude Response (dB-SPL/Hz)

d0

6

n

-6

-12

-18

-24

30

-36

1 I

I I1

5w

10

60

100

500

Total Box Vo/ume*:

0.75 fts (2 1.24 liters)

*Includes driver displacement of 0.07 fP (1.98 liters)

IFiO.0 ‘cFilkf’ Sea/&d F

WY Resposrse

Normalized Amplitude

Response (dBSPL/Hr)

dB

6

0

6

-12

-18

Total Box Vo/ume*:

0.6 fp (17.00 liters)

*Includes driver displacement of 0.07 fP (1.98 liters)

8

Page 11

IT SERIES

SUBWOOFERS

lT= f 2.0 Specifications

Diameter:

12”

No. of Voice Coils:

1

Sensitivity (2.W 8 1~~7):

93 dB

Power Handing;

350 Wrms

(cont. unclipped power

per E/A RS-4266)

Frequency Response:

20-500 Hz

Nominal impedance:

4R

Voice Coil Diameter:

3.0”

Mounting Diameter:

11” (279.4 mm)

Mom ting Depth:

5.625” (142.9 mm)

T- 12.0 Thiele-Small Parameters

Free-Air Resonance:

f*

Total 9:

Qts

Mechanical 9:

Q

ms

EIectrical 9:

Q

es

Compliance Volume:

V

as

Maximum Excursion:

X

max

Voice Coil DC Resistance: Rev=

Voice Coil Inductance:

Le

Volume Displacement:

23 Hz

0.44

3.68

0.49

4.43 ft3 (125.44 liters)

1.0” (kO.5’)

25.0 mm b12.5 mm)

3.6R

2.09 mH

0.13 ft3 (3.68 liters)

9

Page 12

IT

SERIES SUBWOOFERS

dB

6

0

-6

-12

-18

-24

-30

36

5HZ

10

50 100

500

Total Box Vo/ume*:

7.00 ft3 (28.32 liters)

*Includes driver displacement of 0.13 ft3 (3.68 liters)

I7V 20 ccFiled’3ealed Fkxpency Response

LIB

6

0

b

12

18

24

30

-38

3n2

IO

100

300

Total Box Volume*:

0.8 fP (22.65 liters)

*Includes driver displacement of 0.13 fp (3.68 liters)

10

Page 13

IT

SERIES

SUBWOOFERS

lT45.0 Specifications

Diameter:

No. of Voice Coils:

Sensitivity (2.W 8 dm):

Power Handling:

(cont. unclipped power

per E/A RS-4266)

Frequency Response:

Nominal Impedance:

Voice Coil Diameter:

Mounting Diameter:

Mounting Depth:

15”

1

95 dB

400 Wrms

20-500 Hz

4Q

3.0”

73.75” (349.25 mm)

6.5 (165.15 mm)

IT-f 5.0 The/e-Small Parameters

Free-Air Resonance:

G

Total 9:

Qts

Mechanical 9:

Q

ms

Electrical Q:

Q

es

Compliance Volume:

V

as

Maximum Excursion:

X

max

Voice Coil DC Resistance: Rev=

Voice Coil Inductance:

Le

Volume Displacement:

23 Hz

0.60

3.50

0.73

9.18 ft3 (260.0 liters)

1.34” (20.67”)

34.0mm (*17.0mm)

3.30

2.0 mH

0.26 ft3 (7.36 liters)

Page 14

IT

SERIES SUBWOOFERS

IT-s.0 Seakf Fkquency Mspmse

Normalized Amplitude Response ~d6SPUHz~

I I

da

6

0

-6

-12

-18

-24

-30

-36

5HZ

10

50 100

500

Total Box Volume*: 2.75 ft3 (77.87 liters)

*Includes driver displacement of 0.26 ft3 (7.36 liters)

Normalized Amplitude Response (dBSPL/Hr~

CJB

6

0

.u

-12

1U

-24

-30

-36

5 Hz 10 50

100

500

Total Box Volume*: 2.25 ft3 (63.71 liters)

*Includes driver displacement of 0.26 fP (7.36 liters)

12

Page 15

Cerwin-Vega, 555 E. Easy Street, Simi Valley, CA 93065

Phone: 805-584-9332, Fax: 805-583-0865

Cerwin-Vega Canada, 1655 Feldspar Court #2, Pickering, Ontario Ll W 3R7

Phone: 905-837-7000, Fax: 905-837-0712

Cerwin-Vega Europe, Dali AlIe 1, DK-9610 Norager, Denmark

Phone: +45-98-551799, Fax: +45-98-551670

wwwzerwin-vega.com

TDMKL1160 0600

Page 16

IT

SERIES

SUBWOOFERS

Attention!

BY NATURE, BASS-REFLEX ENCLOSURES UNLOAD (THE BOX

BECOMES ACOUSTICALLY TRANSPARENT) AT f/2 OCTAVE BELOW THE

TUNlNG FREQUENCY.

THIS CAN RESULT IN OVER-EXCURSION OF THE

WOOFER CONE WH/CH CAN CAUSE MECHANICAL FAILURE.

TO PREVENT

OVER-EXCURSION WHEN USlNG AN IT SERIES WOOFER IN ITS

RECOMMENDED BASS-REFLEX ENCLOSURE, USE A SUBSONIC H/GHPASS FILTER WITH 25-35 HZ CUTOFF 0 12 DB PER OCTAVE.

Excursion Threshold

BassBox 6 Pro

in

0.63

0.55

5 Hz 10

I

50

100 500

Tuning Frequency

Example A: IT-72.0 SVC woofer cone excursion at 350 Watts RMS in

recommended ported enclosure without a subsonic filter.

BassBox 6 Pro

0.65

I !!!!I

I

/

0.47

0.39

I i iii

CL31

0.24

0.15

0.08

I I I Ill

I d I I11111

I

5 Hz

10

I

50

100 500

Tuning Frequency

Example B: IT- 12.0 SVC woofer cone excursion at 350 Watts RMS in

recommended ported enclosure with a subsonic filter.

CERWIN-VEGA

Page 17

IT

SERIES

SUBWOOFERS

IT-8.0 SVC/DVC Vented j.34

ft3

total

Enclosure Vol.: VBox =1.25

ft3

(net) + .04 ft3 + .05

ft3

IT-IO.0 SVC/DVC Vented 1.77 ft3 total

Enclosure Vol.: V

BOX=7.60ft3(net)+.07ft3+.70ft3

IT-72.0 SVC/DVC Vented 2.27

ft3

total

Enclosure Vol.: V

Box =2.00

ft3

(net) + .13 ft3 + .08 ft3

IT=i5.0 SVC/DVC Vented 3.93

ft3

total

Enclosure Vol.: V

Box =3.50

ft3

(net) + .26 ft3 + .17 ft3

V aox = vol. net + driver displacement + port displacement

W-8.0

Tuning Frequency:

35 Hz

Port Dimensions:

3.0” dia.

Port Area:

7.07 in2

Number of Ports:

I

Port Length:

10.50”

Port Displacement:

0.05 ft3

Total Box Volume:

1.34 ft3

Frequency Response

snz 10

50 100

- IT-8.0 svc - - - - IT-O.0 DVC

IT-10.0

35 Hz

4.0” dia.

12.57 in2

1

13.25”

0. IO fP

1.77 ft3

IT-12.0

35 Hz

4.0” dia.

12.57 in2

1

10.75”

0.08 ft3

2.21 ft3

mi5.0

35 Hz

4.0” dia.

25.73 in2

2

11.69”

0.17 ft3

3.93 ft3

- IT-IO.0 SVC - - - - IT-IO.0 DVC

- IT-150 SVC - - - - IT-15.0 DVC

TDJKL1163 ll/Oi

Page 18

CERWIN-VEGA!’

Tz Lm?

it

Z,Lqx

Page 19

WELCOME TO THE FAMILY!

First off. you have great taste ill Iouclq)eukt~r~. At (:(,I.\\ iu-\cy;l. 1lt’r11 I)il~ atltl >c,rciamillg >itx~, ure ii \\in or III;..

Xice to know there are a frx p~plt~ oltt there n-ho 41are oitr I)a~~ic~tl for music,. \i,iill IW .c C

crl‘ul to hno\\ Illal Illi. I. s

family cornpan! (has IWPII yincr 10.3). .\nd nc c~ou3itlcr you 11) I)(* I lit IWW~I menil)t~r of the fattlil\. \\c II~IIIC, !g 61

speakers give you yars of c~njoyrlcnt. Of co~~rs~. ill tl~c &II~ of a l)rol,lctn. tlkakt* sure

y,t~

f’atniliarizc~ !oIII..c.II

with this warranty. WP likt> to tllink that while \olirt* yittitrg it1 front of’ \oitr q)~~akt~r~. ~vt;rc stanclitl? I)(4lill(l IIIC.~II

And now a few c-lloice words (71.5. to IW (7~1ct) ?rc,ni our lan.!cl~. (I It>!. &r! Iflltlil! has OW.)

WHO’S COVERED BY THIS WARRANTY?

Cerwin-Vega’s J,imited \Varrarlt!~ 011 r1101,ile atrtlic) y,vaktar+ C.\II~III~

c only to 111~ origirral f~~~rcltaser it, (‘1 ~IJI*II~.I.II

by the original Rill of Sale and onl! to the q)eakc*r\ J~~rcha~tl l’ron~ abtllorizc~tl (Ier\\ ita-\iya (I~l~~r~.

Ten words of advice: retain the oripinal J)ill of zalc ill a ~fc l)la~.e!

WHAT’S COVERED BY THIS WARRANTY?

C&win-Vega warrants that all new mohilc all(lio q,rakt~r~ 41all 1~ I’IW 0. 10,tl clcfcc?+ it1 nratcrial alit1 \~o~~\III~III-~II~~

under normal and JxoJjpr I~W. (&win-Vt ya aprccb to rrpair or rc~J)lac3~

(al

our olbtion) all hii(.li dcl’c~cti\c~ ICII’~- :I!

no charge for labor or matcrial~.

WHAT’S NOT COVERED BY THIS WARRANTY?

This Limited Wbxmty does not

q)pl~-

to tlef~c.tivr equipme~~t that:

II;I~

IWCI~

al~~~rc-tl

or rt*l~airc~cI I)! o~II(.I. tf1;11!

factory approl-ed procedures: ha3 I~~rn sul)jectc~(l to nrpligenc~c~. miiuhfb or ac~c~itlcnt: Ita+ 11~11 cla~nap~l In ittll)t~~lti 1’

line voltage; had its serial numh~r or

am

Jbart of it altered. tl&~cetl. or rtlino\etl: has I)cen u~tl for ot ticsr ll~iit~

home entertainment purpobc~: or INI, IIWII uhcd iii a n-ay that I ‘7 c’olltrar\- to (.+ra.ili-b

p's v.rittcrl ill+lrllc.tioti-.

Except as provided by statute. thi- I>imitc(l Warranty does not (‘over lo&. c.orl~c.cl~~t’t~ti~ll or 0thc.r~ ibct. lx,\1111 iI,,

from the improper use of. or inal,ilit!- to oprratt~. any (Zerwill-Ciya Ixo(1uc.t.

HOW LONO DOES THE WARRANTY EXTEND?

Cerwin-Vegas Limited Warrant\- rstrndi for a period of one ( 1) \-ear for all s~cm spcakcr c~o~rr~,onc*nt~.

(‘1~0111 (IillC

of purchase as shon-n on the original Bill of Sale. If a defect exih;k within the. \varrantv J)eriocl. IIW \\:II’WIII! M ill

not expire until the defect has been fixed. The warrantv period will &o 1~. extended if t11e warra~~t\ 1.cl)ait.y II;I\c’

not been performed due to tlrlays caused b>- circmmstanrrs bt,yoncl the control of the original l~~r~~l&~r. 01’ il’ tl~(.

R-arranty repairs did not remedy the defect and the original purchaser

trot

ifies (:ttr\\ in-\1 ‘apa or t 111. ori,gillitl ~lc;tl~~r

or an Authorized Cerwin-Vega Srrvicc Crntc~r of the faihlre of the repairs \vithin :30 tl+h aftr~r IIW! \\(‘I’(’ I.(IIII~~~.I(.I~.

HOW DO YOU GET WARRANTY SERVICE?

In order to obtain warrant! srrvirr. c.ontac’t your original tlt.aler or tlistributor. or a11 .\uthori/c~~l ( :(.I,\\ it{-\(:;;I

Service Center. If. for

sorue

rca+cm. ?ou havr ‘trouble locatinp it her\ ic,e rt’lll.(.,t’iitiiti\(L.

~v~illit~~l ( i*n+

ilti-\t.zii.

(:ustomer Service DPpartltiPnt for aA5taricc:

CERWIN-VEGA! ~‘/r.s/o///c~/~ .s’cwi/~c~ /h/,/.

5% I!% st Eu.Y,\ St

wrt

Si/,/i ldlq,: (’

I o:M,.r

III 5ome cases. the Customc~r 517 ict* Dqtart mcnt (xii sc~lvc a

.cr\ iota l~rol~l~~1t1 Lx it

hot11

ikrl\ r(‘l11171 14

(~llliil)llll,tlt

to &win-&pa. therebv avoitlirrg transit &la\ s. Plron~:

805-S84-5300 Iin: 80’5-S26-3653

NOW, WHAT IF THE PRODUCT MUST BE RETURNED?

If the Customer Service JIcf);trtlttcllt ~ktcwuinrs that the r~cJ~liJ)rltctrt IIN~-I IW II~IIII~~II~<~ IO (:~br\\ itti-\(‘,za lip ,<‘I I it.1,.

a Return .i\uthorization will Ibts ia,llf’tl t)y mail. ant1 IIIC (Iv~‘(v.I ivf* rnc’rr~ll;till~li~t~

IIIU!

IN& l Ililq)t~~l tlirt*(.tl\ to 1111, ~IIIO\I.

address freight prepaid. alon

g with

ii

cop\- of both 11~.

Heli~rtl

\utl~ori7atioll ;IINI tllc oripiilill Ilill of lialc. ‘I 1111 11roduct will be repaired or replac~rtl (at our ootiolt) UIMI rt‘tur.lrc.cl 10 ttrc, oripimtl INII~I’~I~WI’. OnI\ IIW t’(‘tt1r11 oo*t;t:l’

will be paid bp (:erwin-Vega. ( Ierwi n-G

ga will riot IN’ r~~y)o~iGtA~ for ~la~tli~y o(.(.llrrittg iI1 9ll’il)lll(~rlt ~I~IIII 1111,

,2~‘i,g-

nal purchaser or due to improper Jjackin,

0 rnatcrial~. Kt’ttIcItIhcr

10 IKI,,~,

alI (‘(lilil)ltlcIit ~.ilrcF~~ll! iill~l io

1111.

Ibrigill;ll

carton if possible. ~idditional charges may be a(l~lc~l il’ IMW oacAilr,c rtl;lrc,ri;tl-

itw rt~(lliirt~(l Ior

wl11r11

.llifbttl~.lll.

SAVE YOUR ORIGINAL P;M:KIX M.~TTERIJ.S!

OTHER RCMEDIES UNDER THE LAW

The exercise of any of the pro&ion5 under the I .illlitc’ll \\;II.~~IIII!

(lot.

+ 1101 afl;v~l

tll(s

~)I~II(Y’I

ioIl> or r4.ltl4.lli4.. 01’

the original purchaser under other Ia~vs. If ~011 ha\c, utklit ional (III~~~I ioll

_I :I bcbut wrt i1.t.. \\

rilf, 01’

(,itll 111~ ( ‘IIY~OIIN~I.

I

Service Department. This I,imited Warrant! appli

t+ to all Itlol~ilr iill(lic, y~~~ak(~r+. alItI QIIH.~W(II.~ all lhr(‘\ iota. \\a~‘-

rant? statements. Cerain-%:?a reserves the right to 1tlakc3 4,hallzc,* itI

~woO1~~1 tleigu

at~tl q)t~c~iI’i(~;ll iolly al it~b\ I illi(..

EXCEPT AS PROVIDED HEREIN AND RI APPLICABLE LAW, CERWIN-VEGA MAKES NO ADDITIONAL REPRESENTATION OR WARRANTY OF ANY

NATURE WHATSOEVER, EXPRESSED OR IMPLIED, AS TO THE EQUIPMENT, INCLUDING BUT NOT LIMITED TO, THE MERCHANTARlllTY. FITNESS

1011 A PARTICULAR PURPOSE, DESIGN CONDITION

OR

WORKMANSHIP OF THE EQUIPMENT, OR THE QUALITY OF THE MATERIAL lNCLUDED

THEREIN, THIS LIMITED WARRANTY CONSTITUTES THE SOLE AND ENTIRE AGREEMENT BETWEEN CERWIN-VEGA AND THE ORlGlNAL PURCHASER

Page 20

PLETE AND RETURN WITHIN 10 DAYS OF PURCFlASE

PLEASE SEND ME FREE INFORMATION ON OT#ER CERWIN-VEGA PRODUCTS

H:~ ;

‘.I I)IO I 01 I)bI’I.\hl 114 ~~

MI l.I’t\II I)1 \ IOI 11.1’1 \hl I:- .~~~-

I.

b

bill \I,

IlO\I I

I Ill \I I / lOI I)>I’I\hl-I<*.-

I ‘.\ :t ’ I I I 0’ -01 \ h I I:-

_ MOHII I, \I I)IO t 01 l)*l’l \hl I(-

__. ~~~.

PliO! i

. -IO\ ?I I’I \\ I<\( h

_ PI<0

501 \I) REl\

Cl I:\;1 \ I ‘.\ ~llII<I* II\1-

I’()\ I

I I:+

& 1.: \Hl’l.I c:> l~‘Oli

I/ I/,,/ !,i/lC,‘.\ *,I ,,,l,S.il f/C, ,WMI liL.c~.- .~

/I I,<,/ / ,:lii u/ I,,,,,,,~ ~/l/r/;,, s, “,,‘,I, ,I,. I jr,, lI<ll I,.’

/I /;,,I I, ,. ,:I ,,/ ,,,, ,lU/,~ *,//<I;0 ,~,X,, I,, (10 ,\‘O,I l/rrrY,.-

()I%( I\II \ I

I’ll I

\ 1; I ,, I I 1% () I: * _. .__

Page 21

i,,” V,‘, ,.,, ill,,!

Loading...

Loading...