Page 1

VGreen® Motor Automation Adapter Kit

Regal Beloit America, Inc.

1325 Heil Quaker Blvd.

LaVergne, TN 37086

Customer Service: 1-800-262-6484

www.RegalBeloit.com

F O R M

C0048E

Revised

December 2018

Installation Manual and User’s Guide

For use with Century® VGreen variable speed motors

• Read and follow all instructions carefully.

• Disconnect and lock out power before installation and maintenance. Working on or near energized equipment could result in severe

injury or death.

TABLE OF CONTENTS

1.0 KIT CONTENTS ....................................................................................................... 1

2.0 INTRODUCTION ...................................................................................................... 2

3.0 OVERVIEW .............................................................................................................. 2

4.0 CONNECTING TO A VGREEN MOTOR ................................................................... 2

5.0 CONNECTING TO AN ALTERNATE POWER SOURCE ........................................... 5

6.0 CONNECTING TO AN AUTOMATION SYSTEM ..................................................... 5

6.1 Using automation system output connectors .................................................. 5

6.2 Using automation system relays ........................................................................ 5

6.2.1 Connecting to input side of relays ............................................................... 5

6.2.2 Connecting to output side of relays ............................................................ 6

6.2.2.1 Output signal powered by automation adapter .................................. 6

6.2.2.2 Output signal powered by alternate power supply ............................. 6

7.0 OPERATING A VGREEN® MOTOR AUTOMATION ADAPTER ................................ 6

7.1 Adjusting motor speed ......................................................................................... 6

8.0 FAULT STATUS ........................................................................................................ 7

9.0 TROUBLESHOOTING GUIDE ................................................................................. 7

10.0 SPECIFICATIONS ..................................................................................................... 7

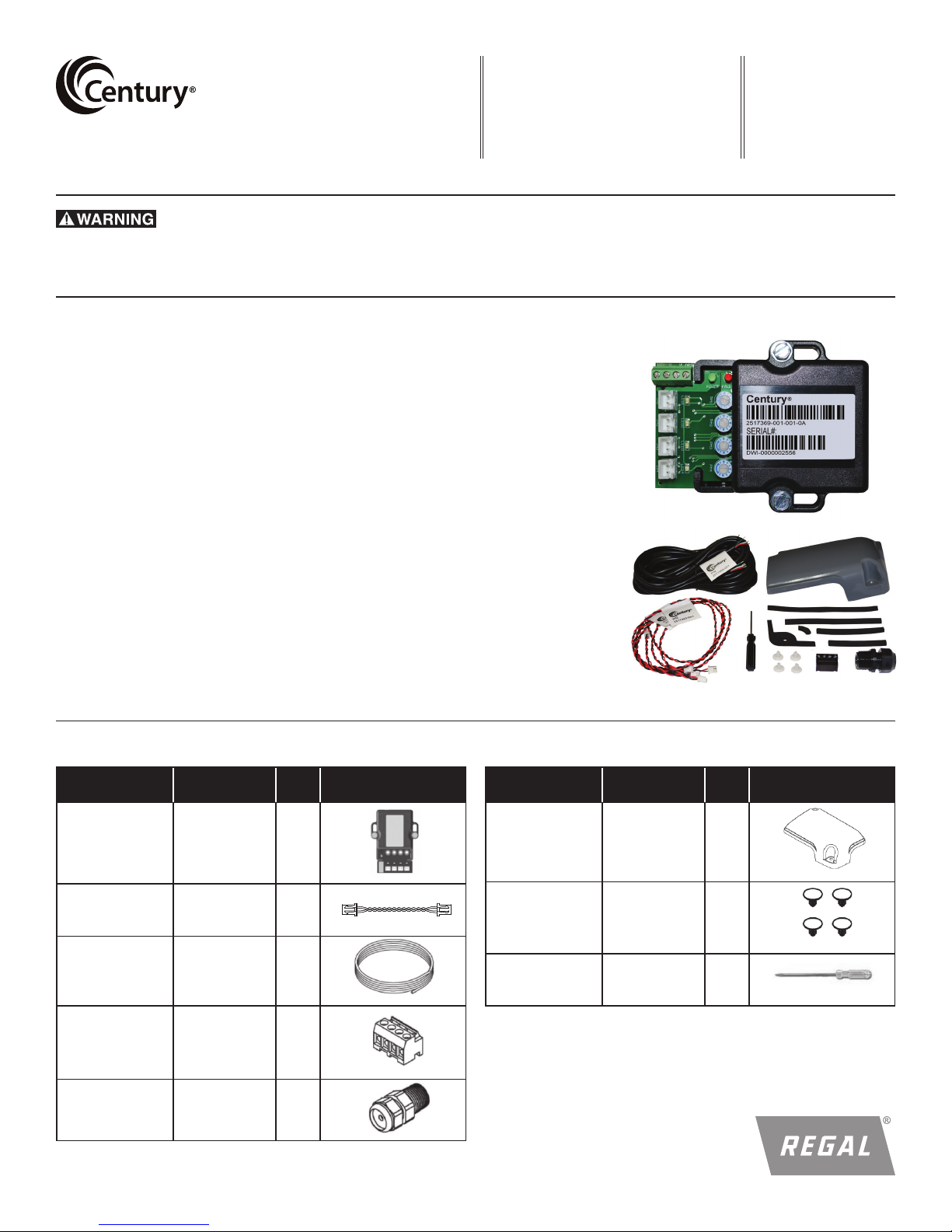

1.0 KIT CONTENTS

PART

Autolmation

Adapter

Digital Input

Cable

Lead Cable 2517465-001 25 FT

RS-485

Connector

Conduit Fitting 2017587-002 1

PART

NUMBER

2517369-001 1

2517463-001 4

2511130-001 1

QTY IMAGE

PART

Terminal Box

Cover Assembly

Plug 2514059-001 4

Screw Driver 2517831-001 1

PART

NUMBER

2513409-001

(Grey)

2513409-002

(Black)

QTY IMAGE

1

1

Page 2

2.0 INTRODUCTION:

The VGreen® Motor Automation Adapter provides the ability to

operate a VGreen motor with a 3rd party automation system such

as the Hayward®* Goldline Pro Logic®*, Pentair®* Easytouch®*,

Jandy®* Aqualink®*, and Intermatic®* controls. This will allow the

user to control and experience the full variable speed capability of

a VGreen product through an existing automation system.

3.0 OVERVIEW:

WARNING! SHOCK HAZARD

Access to the connections referenced in the diagams below

could be in close proximity to mains connections which carry

line voltage capable of causing personal injury or damaging the

equipment if contact is made power should be turned off when

accessing these areas. Failure to take these precautions could

result in serious injury or death.

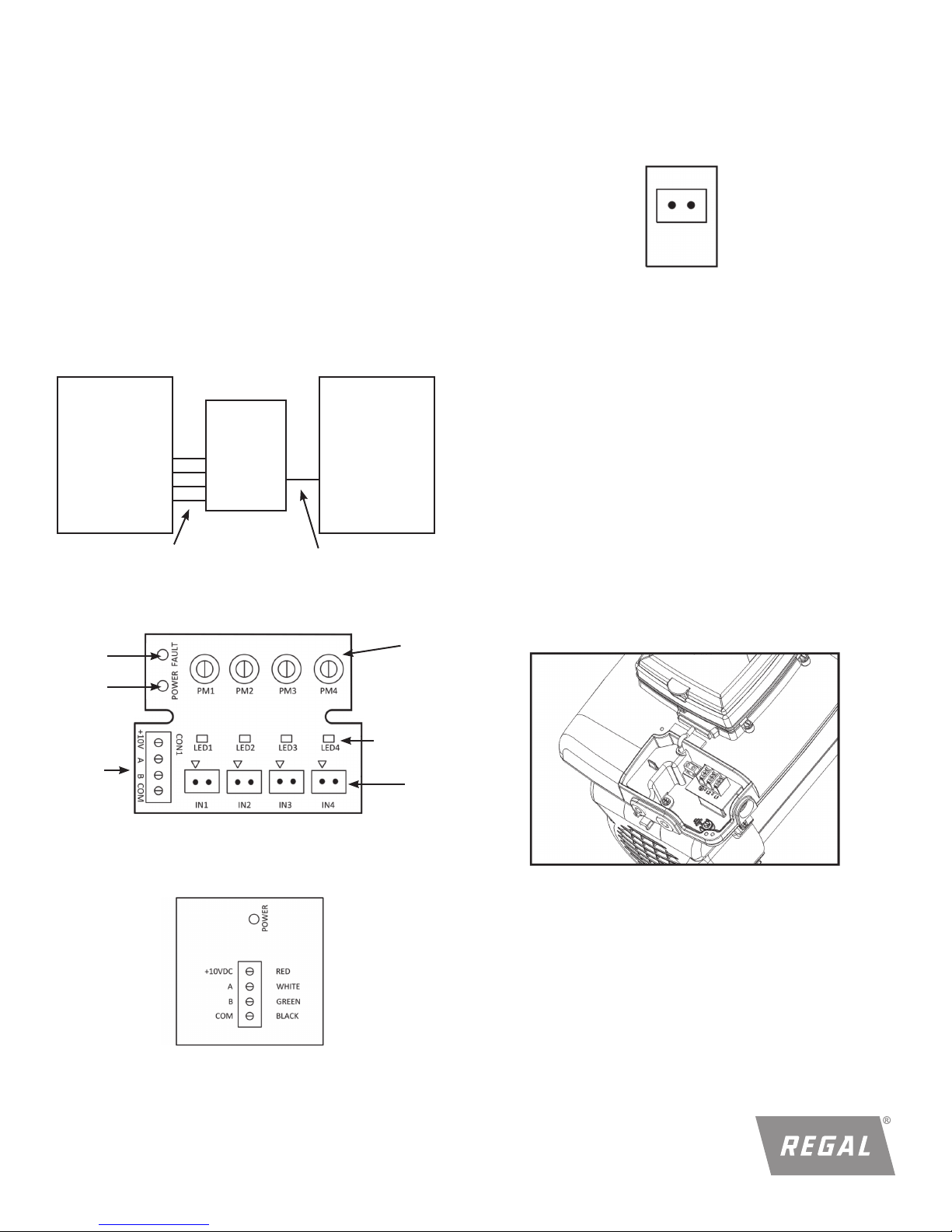

System:

Automation

System

Automation

IN1-IN4

System Outputs J103

2 Conductor Cable

PN: 2517463-001

VGreen

Motor

Adapter

Figure 1

®

CON1

Adapter control board:

4 Conductor Cable

PN: 2517465-001

VGreen

Motor

®

Digital Input:

IN1, IN2, IN3, IN4: 9-30 VAC/VDC (2mA Typical, 22mA MAX)

Connect to relay coil or valve control of automation system.

PWM IN1 Only: 70-125Hz 5-97 % Duty Cycle

Figure 4

4.0 CONNECTING TO A VGREEN® MOTOR

WARNING! SHOCK HAZARD

The automation adapter must be wired according to the locally

adopted version of the NEC. A licensed, qualified electrician

should complete the wiring for this product. Failure to comply

with this could result in death, serious personal injury or property

damage.

NOTE: Refer to manufacturer’s instructions for wiring on all other

products other than the automation adapter.

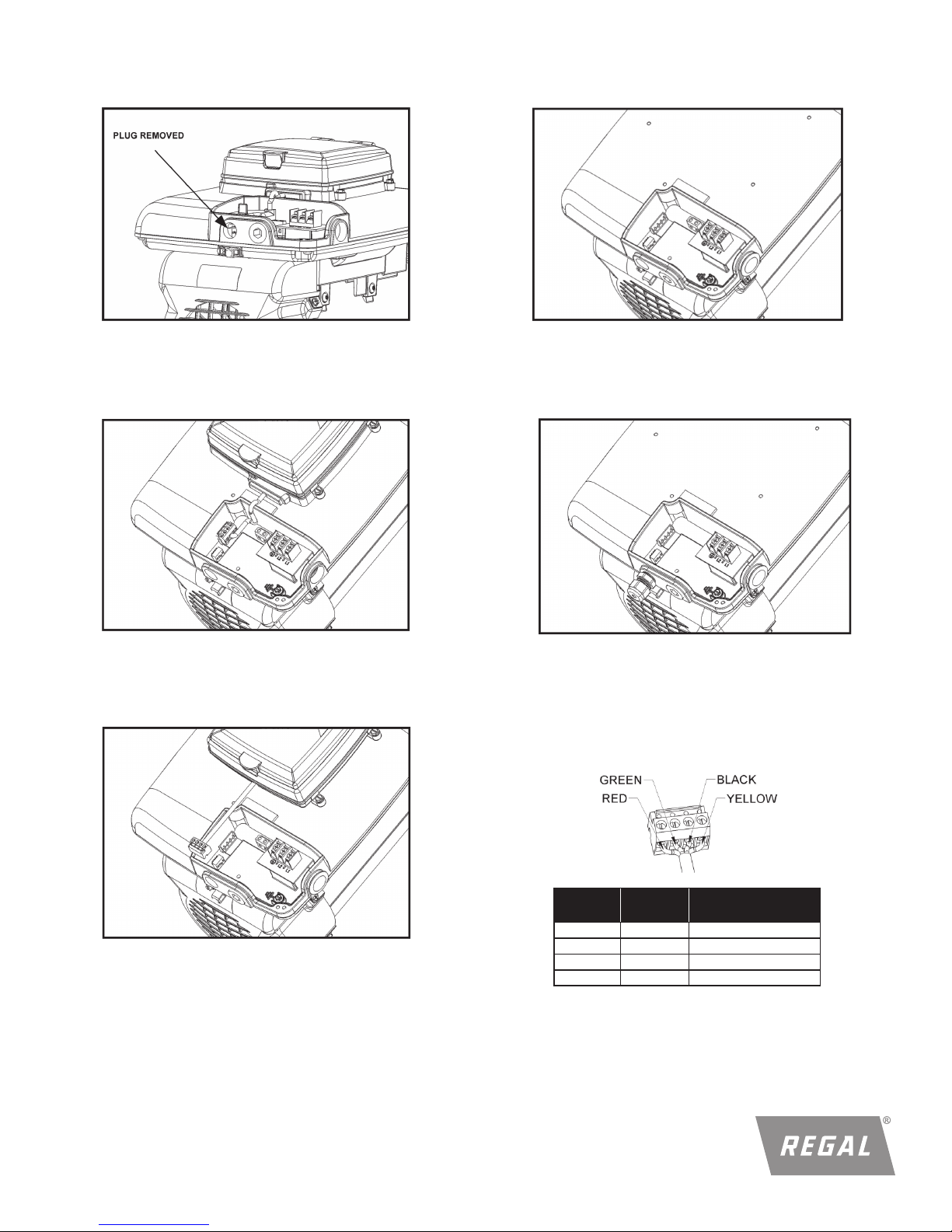

The following steps should be followed to connect the automation

adapter to a VGreen® motor.

1. Disconnect all power sources from the motor and wait five

minutes.

2. Remove the terminal box cover from the controller (two

screws).

Fault

LED

Power

LED

Power and

RS-485

Connector

Power / RS-485 Input:

CON1:

Speed

Adjustment

Potentiometer

(4x)

Active Input

LED’s (4x)

Input

Connector

(4x)

Figure 2

Figure 5: Terminal box cover removed

Figure 3

*The following trademarks or trade names are not owned or controlled by Regal Beloit Corporation:

Hayward and Goldline ProLogic are believed to be the trademarks or trade names of Hayward Industrial Products, Inc.

Pentair and Easytouch are believed to be the trademarks or trade names of Pentair Flow Services, AG.

Jandy and Aqualink are believed to be the trademarks or trade names of Zodiac Pool Systems LLC.

Intermatic is believed to be the trademark or trade name of Intermatic Inc.

2

Page 3

3. Remove the 3/8” conduit hole plug with a 5/16”

allen wrench.

6. Remove the user interface from the controller (four screws).

Figure 6: 3/8” Conduit hole plug removed

4. Remove the plastic wiring cover inside the terminal box

(one screw).

Figure 7: Internal plastic cover removed

5. Disconnect the 4-pin communication connector (J103)

by pulling up on the connector.

Figure 9: User interface and rubber gasket removed

7. Install the conduit fitting (PN: 2017587-002), turning until

snug.

Figure 10: Conduit fitting installed

8. Route the cable (PN: 2517465-001) through the conduit

fitting, and install to the J103 connector (PN: 2511130-001)

on the cable. See the wiring diagram. Tighten the seal nut

on the conduit fitting until snug.

Figure 8: Communication connector disconnected

3

Pin

Wire

Color

Description

J103-1 Red +10V

J103-2 White RS485-A

J103-3 Green RS485-B

J103-4 Black Isolated ground

Figure 11: Communication connection wiring

Page 4

Figure 12: Cable installed

Dip Switches:

Dip switches one and two of the VGreen® motor need to be on in

order for the automation adapter to function.

REFER TO THE VGREEN MOTOR USER MANUAL FOR DIP

SWITCH POSITIONING.

9. Replace the plastic cover inside the terminal box (one

screw).

11. Assemble the new metal terminal box cover (two

screws). Plug the four user interface mounting holes

with the plastic clips (PN: 2514059-001).

Mounting

Holes

(4X)

Figure 15: Terminal box cover and clips installed

Figure 13: Plastic cover installed in terminal box

10. Attach new gaskets to new terminal box cover.

12. Mount the automation adapter inside of the automation

system control box using double sided mounting tape

supplied on the back of the adapter. Place unit so that the

orientation of the input connectors are downward.

NOTE: Automation adapter wiring is all low voltage; choose a

mounting location away from all high voltage wiring.

Automation

Adapter

Digital

Inputs

Low Voltage

Wire

Figure 14: Gasket placement on new terminal box cover

4

HIgh Voltage

Wire

Figure 16: Automation adapter mounted

Page 5

13. Connect the four wires from the motor to the automation

adapter.

VGreen®

Motor

J103

Figure 17: Motor connected to adapter

5.0 CONNECTING TO AN ALTERNATE POWER

SOURCE:

If you choose not to power the automation adapter from the

®

VGreen

adapter can be powered from any 10-14 VDC alternate power

supply.

motor (J103 low voltage power supply), the automation

Alternate

Power Source

Figure 18:

Automation adapter connected to alternate power source

OUTPUTS

(i.e. AUX1)

VGreen®

Motor

Figure 19:

Automation adapter connected to automation system using

the automation system outputs

6.2 USING AUTOMATION SYSTEM RELAYS

6.21 Connecting to input (i.e. low voltage) side of relays

Connect IN1 to Relay 1 or any relay from the automation

system. Repeat this for IN2, IN3, and IN4 using different

automation system relays for each input.

6.0 CONNECTING TO AN AUTOMATION SYSTEM

WARNING! SHOCK HAZARD

Access to the connections referenced in the diagrams

and instructions below could be in close proximity to main

connections which carry line voltage capable of causing personal

injury or damaging the equipment if contact is made. Power

should be turned off when accessing these areas. Failure to take

these precautions could result in serious injury or death.

NOTE: User may use a minimum of 1 and a maximum of 4 inputs

to the automation adapter.

WARNING! SHOCK HAZARD

Failure to connect the automation adapter to the automation

system wighout using correct polarity may result in damage to

the automation adapter and automation system.

6.1 USING AUTOMATION SYSTEM OUTPUT CONNECTORS

Connect IN1 to AUX1 or any output from the automation

system. Repeat this for IN2, IN3, and IN4 using different

automation system outputs for each input.

VGreen®

Motor

Figure 20:

Automation adapter connected to automation system using

the automation system relays

5

Page 6

6.2.2 Connecting to input (i.e. high voltage) side of relays

6.2.2.1 Output signal powered by automation adapter

From the 10V connection of the automation adapter board

(CON1), run a wire to the input on desired relays. Run

the output of the relay to the right pin of an input on the

automation board (IN1-IN4). Connect IN1-IN4 left pin with

COM on CON1 of the automation adapter.

7.0 OPERATING A VGREEN® MOTOR

AUTOMATION ADAPTER

Figure 23: Automation adapter board

7.1 ADJUSTING MOTOR SPEED

The motor speed for each input can be set independently. To do

this, using the screw driver provided, turn the potentiometer

clockwise or counterclockwise. Clockwise increases the speed

and counterclockwise decreases the speed. The speed ranges

from 600-3450 RPM. Do this for each input.

VGreen®

Motor

Figure 21:

Automation adapter connected to automation system using

the automation system relays

6.2.2.2 Output signal powered by alternate source from

an alternate power supply (9-30 VAC/VDC), run a wire from

the positive side of the power source (DC+) to the input on

the desired relays. Run the output of the relay to the right

pin of an input on the automation board (IN1-IN4). Connect

IN1-IN4 left pin with the common (DC-) of the alternate

power source.

When applying a PWM signal to IN1, the speed is based on

the duty cycle. A 97% duty cycle is 3450 RPM and a 5% duty

cycle is 600 RPM. Intermittent speeds can be set by raising or

lowering the duty cycle of the PWM signal.

NOTE: When using a PWM signal as an input for IN1, if the duty

cycle is less than 5%, the automation adapter will not accept

this input. It will be treated as if there is no input being applied.

If the duty cycle is greater than 97%, the automation adapter

will accept this input as a DC voltage or normal input. In this

case the speed of the motor is controlled by the corresponding

potentiometer.

NOTE: If more than one digital input is present, then the

automation adapter will give priority to the highest number digital

input. Therefore IN4 has highest priority followed by IN3, then

IN2, then IN1. To show this, the highest priority input LED is the

only input LED illuminated when two or more inputs are present.

NOTE: When communication between the adapter and the

motor is interrupted or lost, the motor will continue to operate for

approximately 1 minute before stopping.

VGreen®

Motor

Figure 22:

Automation adapter connected to automation system using

the automation system relays

6

Page 7

8.0 FAULT STATUS

Fault LED

Behavior

OFF No error N/A

Flash 1 time No response

Flash 2 times Data error

Flash 3 times CRC error

Flash 4 times Low input voltage

Flash 5 times Motor fault

Flash 6 times Command error

Definition

Check communication

connections (RS-485)

Check power connection and

verify that there is a 10 VDC

input

Refer to your VGreen

motor user manual

9.0 TROUBLESHOOTING GUIDE

Symptom

Power is applied

to the motor, but

power LED is not

illuminated on

the automation

adapter

Possible

Causes

Power supply cables

are loose at the RS-485

connector

Power supply cables are

loose at CON 1 of the

adapter

Motor dip switches1 and

2 are not on

Potential

Solutions

®

Potential

Solutions

Check/tighten the

connections

Check/tighten the

connections

Turn motor dip switches 1

and 2 on

Automation adapter is

damaged

Automation

adapter is presenting a digital

input, but motor

is not running

Fault LED blinked Check fault table

Possible connection loss Check/tighten connections

Automation adapter is

damaged

Replace automation

adapter

Replace automation

adapter

10.0 SPECIFICATIONS

OVERALL RATINGS

Input (CON1) 10-14 VDC (30mA Typical)

Aux inputs (IN1 - IN4) 9-30 VAC/VDC (2mA Typical, 22mA MAX)

- PWM input (IN1 Only) 70-125Hz 5-97 % duty cycle

Ambient conditions

Storage -30°C to 80°C (-22°F to 176°F)

Operating 0°C to 50°C (32°F to 122°F)

Humidity 0-85% Non-condensing

Regal, Century and VGreen are trademarks of Regal Beloit Corporation or one of its affiliated companies.

©2013, 2018 Regal Beloit Corporation, All Rights Reserved. MCIM18021E • Form# C0048E

7

Loading...

Loading...