Page 1

Hobby World Corporation

600

T

gasser conversion

Kit Features:

Lightweight yet extremely strong carbon fiber frames.

Extra large heavy duty clutch system for sustained power transfer.

Plastic injection molded fan cowling for high efficiency engine cooling.

300 mL fuel tank for long engine run time.

5 point engine stabilization system.

Slant gear pinion and main gear provide efficiency and strength.

Heavy duty one-way auto-rotation hub and bearing.

High efficiency push/pull two sided cooling fan.

Heavy duty landing gear.

Exclusively distributed by Century Helicopter Products

© 2011 Hobby World Corporation - All rights reserved.

Version 1.01

Page 2

INTRODUCTION

T600 GASSER CONVERSION

Thank You

Congratulations on the purchase of the newest product that enables the conversion of to gasoline power. This conversion kit will allow

efficient and inexpensive flights with your helicopter.

Warning

This radio controlled model is not a toy! It is a precision machine requiring proper assembly and setup to avoid accidents. It is the

responsibility of the owner to operate this product in a safe manner as it can inflict serious injury otherwise. It is recommended that if

you are in doubt of your abilities, seek assistance from experienced radio control modelers and associations. Keep loose items that can

get entangled in the rotor blades away for the main and tail blades, including loose clothing, hair, or other objects such as pencils and

screwdrivers. Especially keep your hands away from the rotor blades. As manufacturer, we assume no liability for the use of this product.

Flight Guidelines

Please note this checklist is not intended to be a replacement for the content included in this instruction manual. Although it can

be used as a quick start guide, we strongly suggest reading through this manual completely before proceeding.

Always turn the transmitter on first

Allow the gyro, and receiver to arm and initialize properly

Do a pre-flight check making sure all electronics are working and look for any mechanical issues

Fly the model

Land the model

Turn off the engine

Always turn the transmitter off last

General Guidelines

Apply thread lock to all metal to metal thread contact points. Do not apply CA (cyanoacrylate) glue or thread lock to ny-lock nuts (metal nuts

with plastic inserts). Diagrams indicated by bounding boxes for screws, bearings, etc. are illustrated at a 1-to-1 ratio. All other illustrations

are not drawn to scale. Throughout this manual, you will find building tips. Please follow the tips and use common sense when building.

Pre-assembly Information

Various assemblies have been pre-assembled however, only as a reference assembly. Final assembly is up to the user. Installation onto

the particular parts, screws and nuts required for each step are packaged in the same bag as the parts. Be careful when opening each

bag as not to lose any hardware. Care has been taken in filling and packing of each bag however mistakes do happen. If there is a parts

shortage or missing hardware please contact us at:

.launam eht fo snoitces eht ot dnopserroc hcihw ylbmessa fo esae rof deggab era strap tnenopmoc rojam eht lla ,tik eht gninepo nopU

For support, please contact your local dealer/distributor

Page 2

Page 3

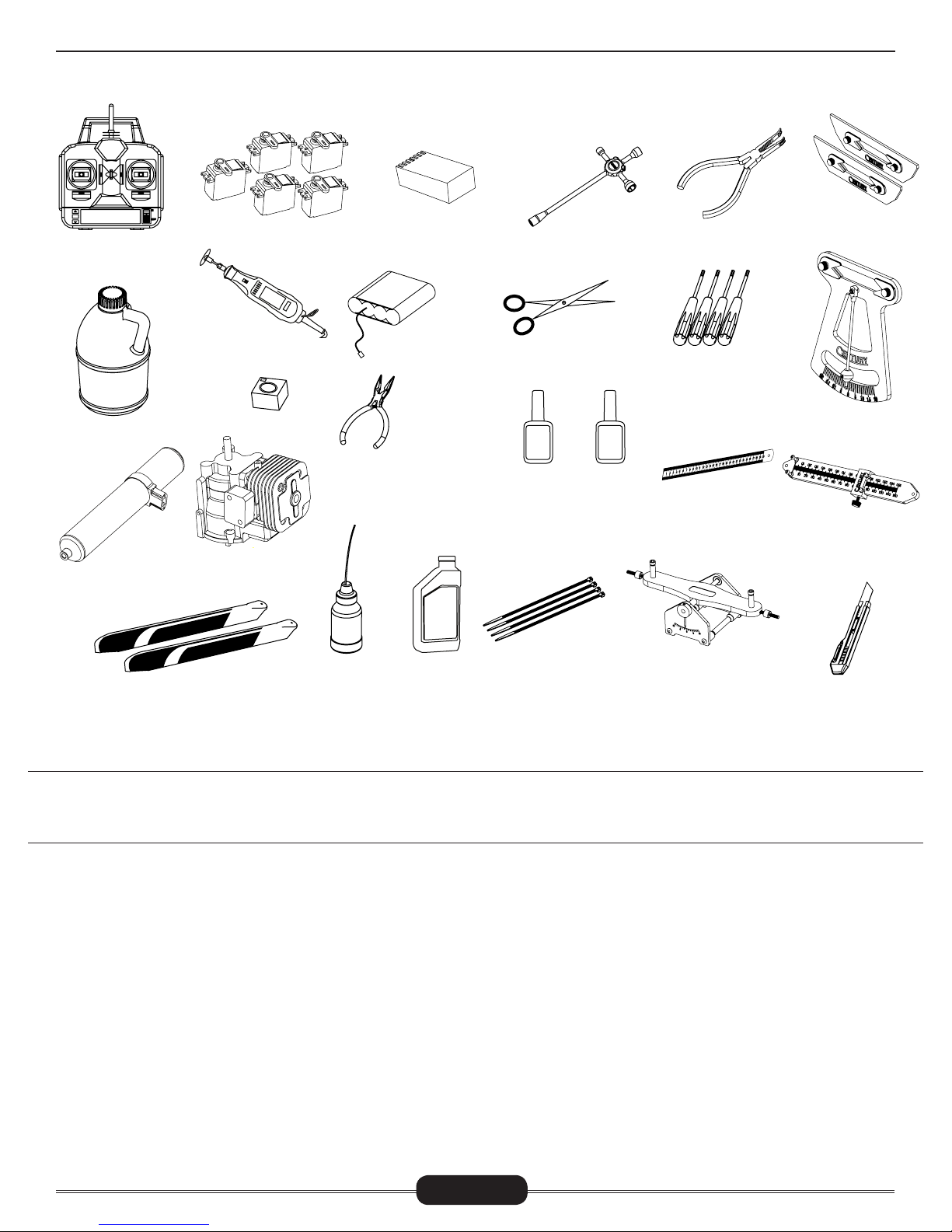

REQUIRED ITEMS

T600 GASSER CONVERSION

6 CHANNEL

CCPM TRANSMITTER

(MINIMUM)

1.000

87 TO 92 OCTANE

GASOLINE

CN3071

TORPEDO hGASSER

TUNED MUFFLER

600mm - 620mm

MAIN ROTOR BLADES

SERVOS X 5

DREMEL TOOL

OR SIMILAR

GYRO

1.000

23CC ZENOAH

GASOLINE ENGINE

NEEDLE NOSE

PLIERS

SYNTHETIC

OIL/GREASE

6 CHANNEL RECEIVER

(MINIMUM)

RECEIVER BATTERY

2-STROKE

MOTOR OIL

CN2031

4-WAY WRENCH

HOBBY SCISSORS

SLOW &

Medium CA

GLUE

ZIP TIES

HEX DRIVERS

1.5, 2.0, 2.5, 3.0, 4.0, 5.0

Medium

(Medium)

THREAD-

LOCK

METRIC RULER OR

SIMILAR MEASURING

ACCURATECH BLADE BAL-

ANCER V.2

CN2034A

BALL LINK PLIERS

CN2017

DEVICE

CN2051

CN2050

PADDLE GAUGE

CN2027

G-FORCE PITCH GAUGE

CN2255

CONTROL ROD

SETUP GAUGE

HOBBY KNIFE

Warranty Period

Hobby World Corporation

ship 30 days from the date of purchase by the Purchaser.

warranties that the Products purchased (the “Product”) will be free from defects in materials and workman-

Limited Warranty

(a) This warranty is limited to the original customer (“Purchaser”) and is not transferable. REPAIR OR REPLACEMENT AS PROVIDED

UNDER WARRANTY IS THE EXCLUSIVE REMEDY OF THE PURCHASER. This warranty covers only those Products purchased from an

authorized Hobby World Corporation dealer. Third party transactions are not covered by this warranty. Proof of purchase is required

for the warranty claims. Further, Hobby World Corporation reserves the right to change or modify this warranty without notice and

disclaims all other warranties, express or implied.

(b) Limitations – HOBBY WORLD CORPORATION MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR A PARTICULAR PURPOSE OF THE PRODUCT. THE PURCHASER ACKNOLEDGES

THAT THEY ALONE HAVE DETERMINED THAT THE PRODUCT WILL SUITABLY MEET THE REQUIREMENTS OF THE PURCHASER’S

INTENDED USE.

(c) Purchaser Remedy – Hobby World Corporation’s sole obligation hereunder shall be that Hobby World Corporation will, at its option,

(i) repair or (ii) replace, any Products determined by Hobby World Corporation to be defective. In the event of a defect, these are the

Purchaser’s exclusive remedies. Hobby World Corporation reserves the right to inspect any and all equipment involved in a warranty

claim. Repair or replacement decisions are at the sole discretion of Hobby World Corporation. This warranty does not cover damage

due to the improper installation, operation, maintenance, or attempted repair by anyone other than Hobby World Corporation. Return

of any goods by Purchaser must be approved by Hobby World Corporation before shipment.

Page 3

Page 4

AMA RULES & REGULATIONS

T600 GASSER CONVERSION

General

1) I will not fly my model aircraft in sanctioned events, air shows or model flying demonstrations until it has been proven to be airworthy by having been previously, successfully flight tested.

2) I will not fly my model higher than approximately 400 feet within 3 miles of an airport without notifying the airport operator. I will

give right-of-way and avoid flying in the proximity of full-scale aircraft. Where necessary, an observer shall be utilized to supervise flying

to avoid having models fly in the proximity of full-scale aircraft.

3) Where established, I will abide by the safety rules for the flying site I use, and I will not willfully or deliberately fly my models in a

careless, reckless and/or dangerous manner.

4) The maximum takeoff weight of a model is 55 pounds, except models flown under Experimental Aircraft rules.

5) I will not fly my model unless it is identified with my name and address or AMA number on or in the model. (This does not apply to

models while being flown indoors.)

6) I will not operate models with metal-bladed propellers or with gaseous boosts, in which gases other than air enter their internal

combustion engine(s); nor will I operate models with extremely hazardous fuels such as those containing tetranitromethane or hydrazine.

Radio Control

1) I will have completed a successful radio equipment ground range check before the first flight of a new or repaired model.

2) I will not fly my model aircraft in the presence of spectators until I become a qualified flier, unless assisted by an experienced helper.

3) At all flying sites a straight or curved line(s) must be established in front of which all flying takes place with the other side for

spectators. Only personnel involved with flying the aircraft are allowed at or in front of the flight line. Intentional flying behind the flight

line is prohibited.

4) I will operate my model using only radio control frequencies currently allowed by the Federal Communications Commission. (Only

properly licensed Amateurs are authorized to operate equipment on Amateur Band frequencies.)

5) Flying sites separated by three miles or more are considered safe from site-to site interference, even when both sites use the

same frequencies. Any circumstances under three miles separation require a frequency management arrangement, which may be

either an allocation of specific frequencies for each site or testing to determine that freedom from interference exists. Allocation

plans or interference test reports shall be signed by the parties involved and provided to AMA Headquarters. Documents of agreement and reports may exist between

(1) Two or more AMA Chartered Clubs, (2) AMA clubs and individual AMA members not associated with AMA Clubs, or (3) two or

more individual AMA members.

6) For Combat, distance between combat engagement line and spectator line will be 500 feet per cubic inch of engine displacement.

(Example: .40 engine = 200 feet.); electric motors will be based on equivalent combustion engine size. Additional safety requirements

will be per the RC Combat section of the current Competition Regulations.

7) At air shows or model flying demonstrations, a single straight line must be established, one side of which is for flying, with the

other side for spectators.

8) With the exception of events flown under AMA Competition rules, after launch, except for pilots or helpers being used, no powered

model may be flown closer than 25 feet to any person.

9) Under no circumstances may a pilot or other person touch a powered model in flight.

Page 4

Page 5

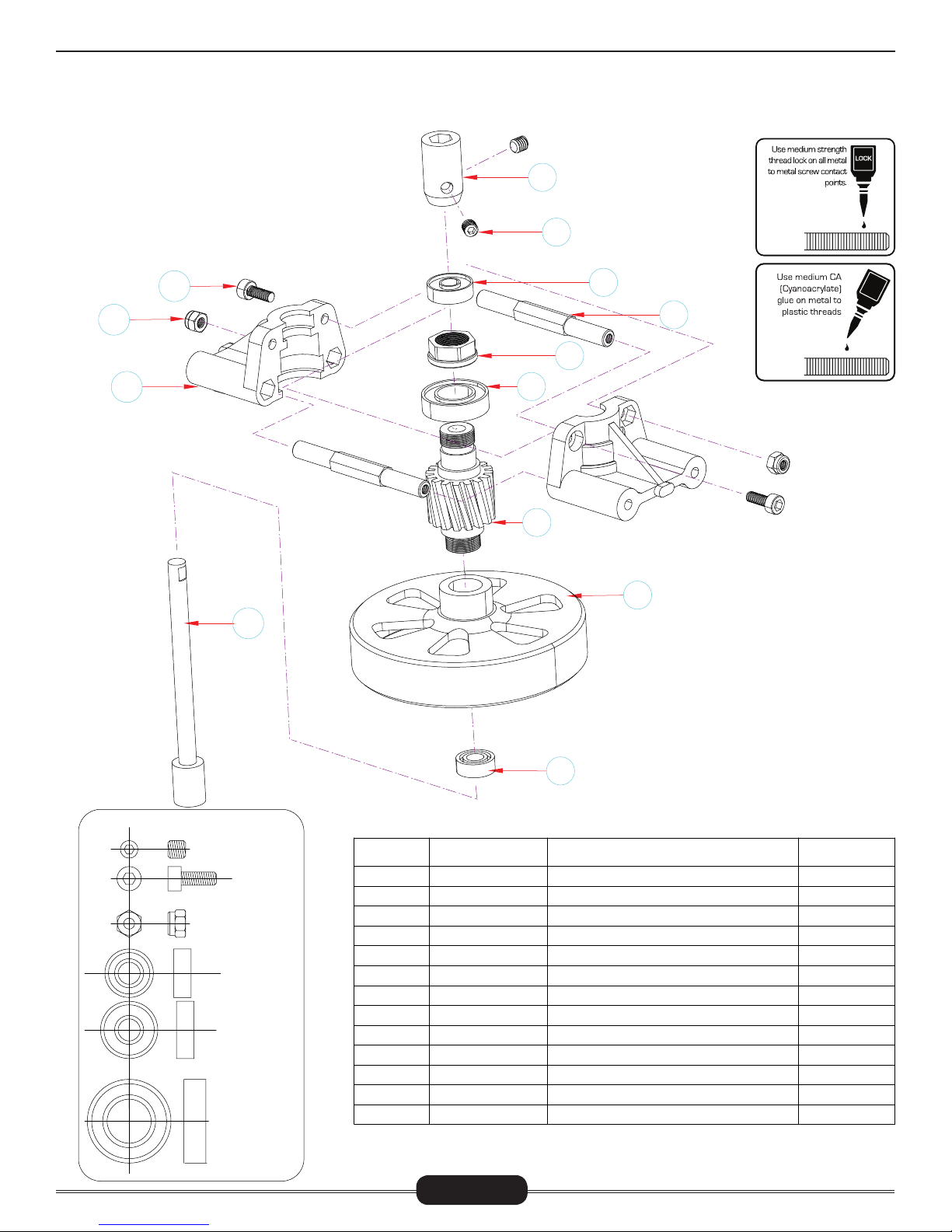

CLUTCH ASSEMBLY

T600 GASSER CONVERSION

Do not open all the bags prior to starting assembly. Open the bags step by step as you go through the instruction manual. The

components are bagged to make assembly easier. The part numbers with an astericks* indicate they are OEM Align part numbers. If you do not have these or similar parts, this conversion kit will not work.

Clean the top of the pinion gear and the inside surfaces of both

the upper and lower bearings inside the clutch shaft bearing

block using alcohol. Apply a small amount of Red threadlock to

the top edge of the clutch gear where it will contact the bearing. Press the bearing block in place, firmly seating the bearing

against the top of the pinion gear.

1

2

12

11

13

10

5

C

A

4

3

6

7

This conversion kit uses the regular starting

shaft and hex coupler to align the clutch to

the clutchbell. Clean both the starting shaft

and the inside race of the bearing inside the

clutchbell and the inside race of the top start-

8

ing shaft bearing. Apply a small amount of

red threadlock positioned just above where

the bottom clutchbell bearing will sit on the

starting shaft. Slide the starting shaft up

through the bearing blocks. Apply a small

amount of medium threadlock to the top of

the starting shaft and slide the hex coupler

in place aligning the flat spot with one of the

holes. Apply medium threadlock to the two

M4x4 set screws and tighten in place.

9

CNM4x4SS

CNM3x8CS

M3 CNM3LOCK

CNBB511

CNBB513

CNBB1019

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

Part #

HW6002

CNM4X4SS

HN6007*

HN6004*

CNBB513

CNBB1019

HW6043B6

HW6013G3

CNBB511

HW6006G3

HN6007*

CNM3LOCK

CNM3X8CS

Page 5

Description

Hex Starter Adapter( 六角启动头)

M4x4 Set Screw( 无头内六角螺丝 )

Clutch Nut(离合器齿轮螺母 )

L=49mm Hex Mounting Bolt( 六角铝柱 )

5X13X4Bearing( 轴承)

10X19X5Bearing( 轴承)

16T Clutch Gear(16 齿离合器齿轮 )

Clutch Bell Assembly 67mm( 离合器罩)

5X11X4Bearing( 轴承)

Start Shaft(启动轴 )

Clutch Bearing Block( 离合器轴承座 )

M3 Locknut(M3防松螺母 )

M3X8 Cap Screw( 杯头螺丝 )

Qty

1

2

1

2

1

1

1

1

1

1

2

2

2

Page 6

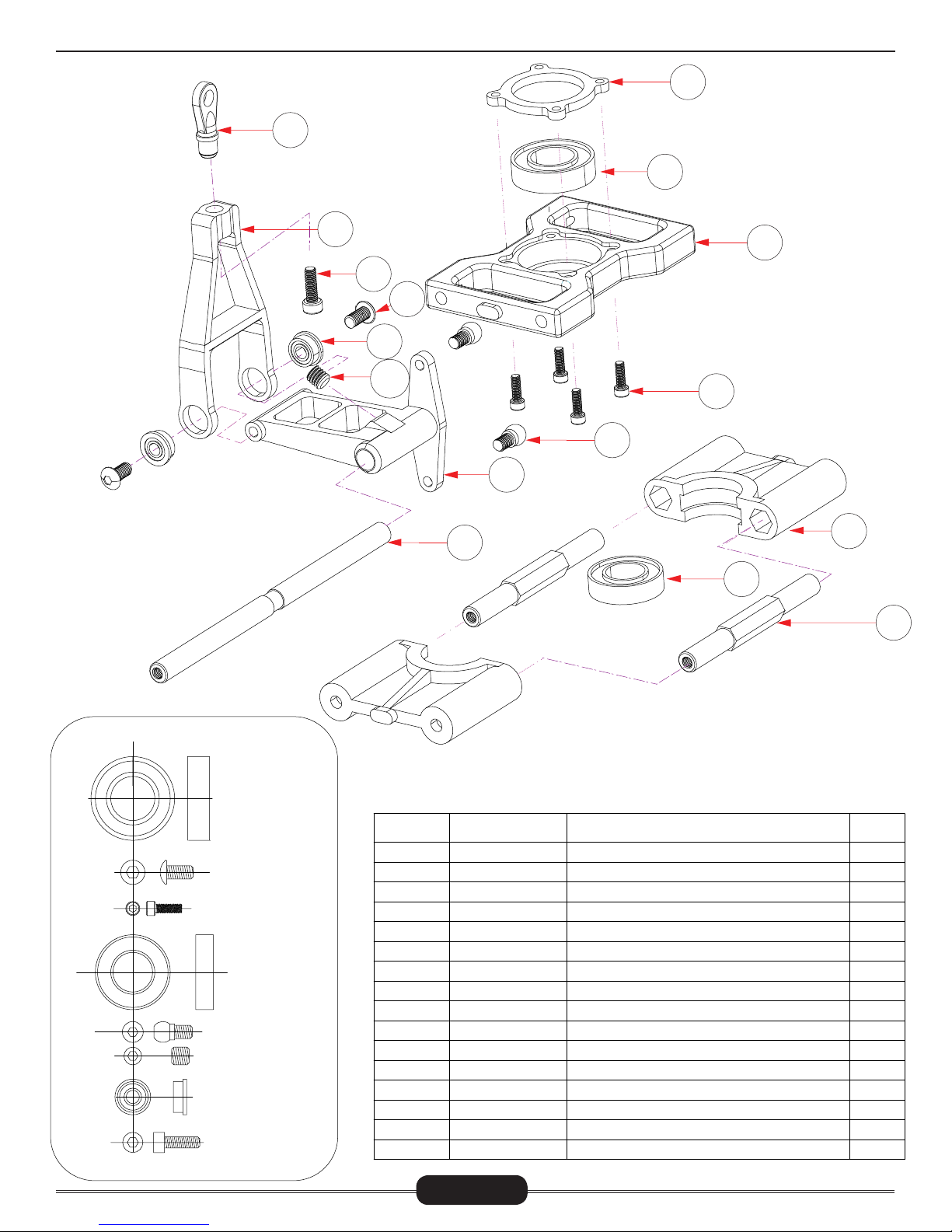

BEARING BLOCKS & ELEVATOR ARM

16

T600 GASSER CONVERSION

1

2

15

14

12

11

13

8

3

4

10

9

5

6

7

CNBB1019

CNM3x6BHCS

CNM2X6CS

CNBB0917

球头Ø4.75X8.68

CNM4x4SS

CNBB37F

CNM2.5x8CS

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Part #

H60154*

CNBB1019

H60154*

CNM2X6CS

HN6011*

CNBB0917

HN6004*

H60220*

H60129*

H60224*

CNM4X4SS

CNBB0730F

CNM3X6BHCS

CNM2.5X8CS

H60128*

H60128*

Page 6

Description

Metal Main Shaft Clamp Ring( 金属主轴固定盖)

10X19X5Bearing( 轴承)

Metal Bearing Block( 金属主轴固定座)

M2X6 Cup Screw( 杯头螺丝)

Plastic Bearing Block( 塑料主轴固定座)

9X17X4 Bearing( 轴承)

L=49mm Hex Mounting Bolt( 六角铝柱)

Control Shaft( 连动秆)

Elevator Lever( 升降连动控制臂)

Linkage Ball A(M3x4)( 球头A(M3X4))Ø4.75X8.68

M4x4 Set Screw( 无头内六角螺丝)

3X7X3 Bearing( 带边轴承)

M3X6 Button Head Screw( 圆头螺丝)

M2.5X8 Cap Screw( 杯头螺丝)

Elevator Arm( 升降控制臂)

Elevator Ball Link( 升降臂连杆头)

Qty

2

2

2

8

2

1

2

1

1

2

1

2

2

1

1

1

Page 7

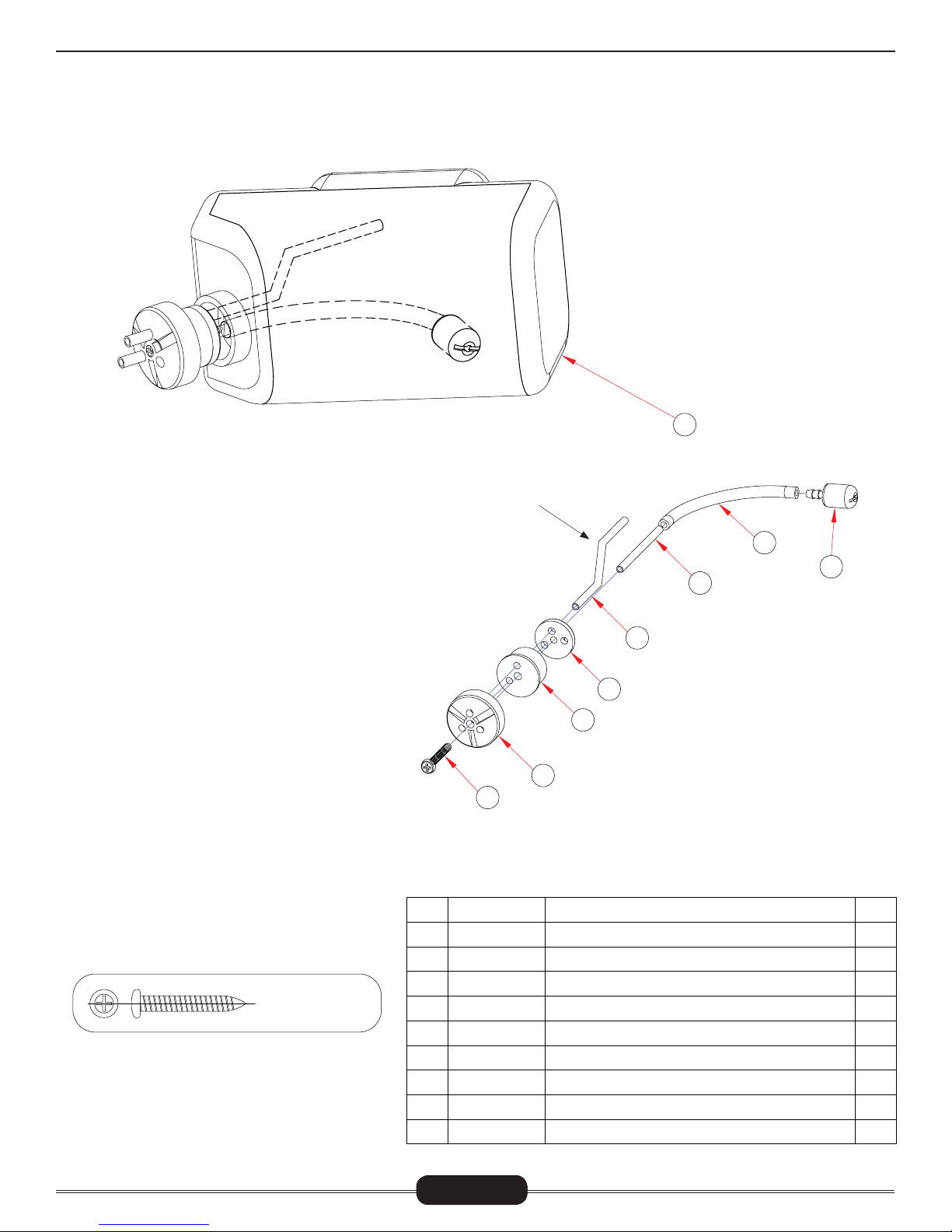

FUEL TANK ASSEMBLY

T600 GASSER CONVERSION

9

Pay close attention when assembling the fuel tank.

The vent tube must be bent and facing upwards when

installed into the rubber stopper. There are 3 holes

on the rubber stopper but notice only 2 are through

holes. Cut the fuel line and attach the clunk to the

line. Then attach the fuel line to the short brass tube.

When cutting the fuel line, make sure you have enough

slack in the fuel line so the clunk can reach all corners

of the fuel tank. After installing the shorter brass tube

with the fuel line, install the vent tube. Make sure the

vent tube is positioned to point upwards in the fuel

tank. Once you have everything positioned, slowly turn

the M3.5x24 Phillips screw so that you barely grab

the end of the small cap (#4). Once you insert the

fuel tubing assembly into the tank, it will be very difficult to get this small cap out if you happen to drop

it within the fuel tank. Making sure you still have the

small cap (#4) attached to the fuel tubing assembly,

push the fuel tubing assembly into the tank and start

tightening the Phillips screw. This will pull the small

cap (#4) closer to the large cap (#2) and expand the

rubber stopper. Once tightened, gently tug on the assembly to make sure it is properly installed. It should

not come out of the fuel tank.

Bend one of the longer

brass tubes into this

shape. This will be the

vent tube.

7

8

6

5

4

3

2

1

CNM3.5x24ST

No.

1

2

3

4

5

6

7

8

9

Part #

HI3138B

HI3138B

HI3138B

HI3138B

HI3138B

HI3138B

HI3138B

HI3138B

HI6139

Page 7

Description

Tapping Screw( 十字紧固螺丝)M3.5x24

Large Cap(油箱盖)

Rubber Stopper( 油箱塞)

Small Cap(油箱塞固定座)

Long Tube-straight( 长直铜油管)

Pickup Tube-straight(短直铜油管)

Plastic Tubing( 塑胶油管)

Fuel Tank Set( 吸油嘴)

Fuel Tank(油箱)

Qty

1

1

1

1

1

1

1

1

1

Page 8

SIDE FRAMES ASSEMBLY

14

10

15

13

12

11

21

17

18

16

8

9

19

20

T600 GASSER CONVERSION

1

2

3

4

5

6

7

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Part #

CNM3X12BHCS

CNM3X4.8FW

H60224*

HN6038*

HN6038*

CNBB0630

HN6019*

HI6116T6

HN6015B*

HI6119

CNBB0510

CNM5X7FW

CNM5X7FW

H6024*

CNBB0950

H60027-1-00*

CNM3X5.5FW

CNM3X6CS

CNM3X8FW

CNM3X8BHCS

HI6139B

Description

M3X12 Button Head Screw( 圆头螺丝)

Ø3xØ4.8x0.3 Flat Washer( 平面垫片)

Linkage Ball A(M3x4)( 球头A(M3X4))Ø4.75X8.68

Ø3xØ4.4x3 Collar( 尾控制臂铝套)

Tail Control Arm( 尾控制臂)

3X6X2.5 Bearing( 轴承)

Frame Mounting Block(机身固定块)

Main Frames (R/L)( 左右主体侧板)

M3X8 Button Head Collar Screw( 半圆头轴套螺丝)

Frame Bearing( 侧板轴承座)

5X10X4 Bearing( 轴承)

Ø5xØ7x0.2 Flat Washer( 平面垫片)

Ø5xØ7x0.5 Flat Washer( 平面垫片)

Linkage Ball A(M3x4)( 球头A(M3X4))Ø4.75X8.68

5X9X3 Bearing( 轴承)

Metal Aileron Lever( 金属左右控制摇臂)

Ø3xØ5.5x0.3 Flat Washer( 平面垫片)

M3X6 Cup Screw( 杯头螺丝)

Ø3xØ8x2 M3 Specialty Washer( M3特殊垫片)

M3X8 Button Head Screw( 圆头螺丝)

Fuel Tank Guard( 油箱垫圈)

Qty

1

2

2

1

1

2

1

2

16

2

2

2

2

6

4

2

2

2

2

2

2

CNM3x12BHCS

Ø3xØ4.8x0.3

球头Ø4.75X8.68

Ø3xØ4.4x3

CNBB0630

CNM3x8BHCS

CNBB0510

M3X8 Collar Screw

Ø5xØ7x0.2

Ø5xØ7x0.5

CNBB0950

Ø3xØ5.5x0.3

CNM3x6CS

Ø3xØ8x2

Page 8

Page 9

ELECTRONICS TRAYS

T600 GASSER CONVERSION

1

2

10

11

9

8

3

4

C

A

7

5

6

2

CNM3x8BHCS

Ø3xØ8x2

CNM3x14CS

CNM2.5x6FHCS

No.

1

2

3

4

5

6

7

8

9

10

11

Part #

HN6051*

HN6104*

CNM3X8FW

CNM3X8BHCS

HN6016*

HN6016*

CNM3X14CS

CNM2.5x6FHCS

HW6113T6A

HW6113T6

HN6051*

Page 9

Description

Gyro Mount(陀螺仪固定座)

L=54mm Frame Mounting Bolt( 机身铝柱)

Ø3xØ8x2 M3 Specialty Washer( M3特殊垫片)

M3X8 Button Head Screw(圆头螺丝)

Ø3xØ5x7.3 Canopy Support( 机头罩支撑柱)

Canopy Spacer( 机头罩支撑垫圈)

M3X14 Cap Screw( 杯头螺丝)

M2.5x6 Flush Head Cap Screws( 斜头内六角螺丝)

Electronics Plate(电子板)

L=54mm Frame Support Bar(带平面铝柱)

3x8 Phillips Self Tapping Screw

Qty

1

2

6

6

2

2

2

4

1

2

2

Page 10

ENGINE ASSEMBLY

1

T600 GASSER CONVERSION

6.5x13x18 x13x0.5

2

7

18

19

17

4

9

10

5

6

8

3

11

12

13

14

15

CNM6x16CS

6.5x13x1

CNM2.5x8CS

CNM4x10FHCS

CNM3x6FHCS

CNLR1018

CNM3x4SS

CNM2.5x16CS

CNM3x8BHCS

Build the fan by placing Medium threadlock into the threaded holes on the

fan hub (#6). Attach the fan to the hub as shown and install the M3x6

flush head cap screws making sure the screws fall into the beveled hole

on the fan.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Part #

CNBB1014A

HW6011G3

HI6020B

CNM6x16CS

CNM6.5x13FW

HI6012

CNM2.5x8CS

HI6011

CNM3x6FHCS

CNM5x10FHCS

CNLR1018

HW6192B

CNM3x4SS

Z231

CNM2.5x8CS

CNM2.5x16CS

HW6116T6

HW6118H3

CNM3x8BHCS

HW6192

Description

Clutch One Way Bearing (10mm)(单向轴承)

Clutch Shoe 59mm ( 离合器)

Plastic Cooling Shroud( 风扇罩)

Cap Screw(杯头内六角螺丝)M6x16

Washer(垫片)6.5x13x1

Cooling Fan Hub ( 风扇座)

Cap Screw(杯头内六角螺丝)M2.5x8

Two Way Cooling Fan( 风扇)

Flush Head Cap Screws( 斜头内六角螺丝)M3x6

M5X10 Flush Head Cap Screws( 斜头内六角螺丝)

Ultra Short Steel Ball( 球头螺丝)

Carburetor Arm( 化油器控制臂)

Set Screw(无头内六角螺丝)M3X4

Engine(引擎)

Cap Screw(杯头内六角螺丝)M2.5x8

Cap Screw(杯头内六角螺丝)M2.5x16

L=54mm Cooling Shroud Plate Support Bar (铝柱)

Cooling Shroud Mount Plate( 挡风板)

M3x8 Button Head Cap Screw( 圆头内六角螺丝)

8x13x0.5 Spacer

Qty

1

1

1

1

1

1

1

1

5

4

1

1

1

1

2

1

1

1

2

4

When tightening the M6x16 bolt, you can use a piston

locking tool made for gasoline engines or you can remove the spark plug and stuff nylon rope into the piston hole. This will allow you to torque the bolt without

the engine spinning. NEVER grab the bottom of the

crank shaft where the starter attaches and tighten

the bolt holding fan/clutch hub.

16

20

Once you tighten the M3X10 Flush Head Cap Screws (#10), the Cooling

Shroud Mounting Plate (#18) should be snug and not move. If it can

still shift or moves, then install the 8x13x0.5 spacers (#20). The reason

for this is the chamfer depth found on some Zenoah engines are not

consistent with others, therefore some engines will require the spacers

and some will not.

Venturi style intake does not

come with the engine.

Page 10

Page 11

LANDING FRAME STRUCTURE

C

A

13

12

T600 GASSER CONVERSION

When installing the engine assembly to

the frames, do not tighten one side all

the way leaving the other side completely loose. Tighten the M4x20 bolts on

either side of the frames evenly moving

from one side to the other. Make sure

to apply medium threadlock to these

bolts prior to installation. After you have

installed the left and right M4x20 bolts,

install the front engine block making sure

to use medium threadlock on the M4x20

1

Install the landing skids onto the landing struts one

side at a time. After installing the landing skids, position, the landing struts on the skids so that they match

up with the mounting positions on the frames. Place

the washers onto the M3x16 cap screws and then

apply medium threadlock. Install the screws through

3

the landing struts and tighten onto the frames. Turn

the landing skids so that the curve towards the front

is facing straight up. Install the four M3x4 set screws

4

to lock the skids into place. Do not tighten these too

much as you can crack the plastic struts. Lastly, install the landing skid stoppers.

5

6

bolt holding the engine’s head in place.

2

CNM3x7FW

CNM2.5x8CS

CNM4x10FW

CNM3x4SS

CNM4x20CS

CNM3x18CS

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

Part #

HW6117G3A

CNM4x20CS

HW6117G30

CNM3x7FW

CNM2.5x8CS

HI6122D

CNM3x4SS

HW3123B

CNM3x7FW

CNM3x18CS

HW3123A

CNM4x20CS

CNM4x10FW

9

10

7

8

Description

Front Engine Mounting Block ( 引擎固定块)

M4X20 Cap Screw( 杯头内六角螺丝)

Landing Gear Frame( 引擎座底板)

3x7x1 Washer( 垫片)

M2.5x8 Cap Screw( 杯头内六角螺丝)

Plastic Struts( 脚架)

M3x4 Set Screw( 无头内六角螺丝)

Aluminum Skids with Caps ( 脚架弯管)

3X7X1 Washer( 垫片)

M3x18 Cap Screw( 杯头内六角螺丝)

Skid End Caps(脚架塞)

M4X20 Cap Screw( 杯头内六角螺丝)

4X10X1 Washer( 垫片)

11

Qty

1

1

1

2

2

2

4

2

4

4

4

2

4

Page 11

Page 12

FRAME REINFORCEMENTS

T600 GASSER CONVERSION

1

2

3

4

5

CNM3x12BHCS

CNM3x10BHCS

Ø3xØ8x2

Ø3xØ5x4

No.

1

2

3

4

5

6

7

8

9

10

7

10

Part #

HI6116TFS

HI6031T6

HI6116TFS

CNM3X8FW

CNM3X10BHCS

CNM3X10BHCS

CNM3X12BHCS

HW6117TS

CNM3X10BHCS

HI6116TRS

8

9

Description

Front Frame Reinforcement Plate (Right) (右机身前侧板补强板)

L=54mm Frame Mounting Bolt( 机身铝柱)

Front Frame Reinforcement Plate (Left) (左机身前侧板补强板)

Ø3xØ8x2 M3 Specialty Washer( M3特殊垫片)

M3X10 Button Head Screw( 圆头螺丝)

M3X10 Button Head Screw( 圆头螺丝)

M3X12 Button Head Screw( 圆头螺丝)

Ø3xØ5x4Aluminum Sleeve( 铝套)

M3X10 Button Head Screw( 圆头螺丝)

Rear Frame Reinforcement Plates (机身后侧板补强板)

6

Qty

1

1

1

8

2

4

2

2

2

2

Page 12

Page 13

RECEIVER & CANOPY MOUNT

T600 GASSER CONVERSION

C

A

10

2

1

3

4

5

2

9

6

7

8

No.

1

2

CNM3x8BHCS

Ø3xØ8x2

CNM2.5x8CS

Ø3xØ5x3

CNM3x10T

CNM3x10BHCS

3

4

5

6

7

8

9

9

Part #

HN6024*

CNM3X8FW

CNM3x10T

CNM3x10T

CNM2.5x8CS

HI6118T6S

HI6118T

HW6205

CNM3X10BHCS

CNM3X8BHCS

Description

Receiver Mount ( 接受机座)

Ø3xØ8x2 M3 Specialty Washer( M3特殊垫片)

M3X10 Socket Button Head Self Tapping Screw(半圆头内六角自攻螺丝)

M3X10 Socket Button Head Self Tapping Screw(半圆头内六角自攻螺丝)

M2.5x8 Cap Screw( 杯头内六角螺丝)

Head Fixed Plate( 机头固定板)

L=54mm Aluminum Column( 带平面铝柱)

3X5X3 Bacer( 铁套)

M3X10 Button Head Screw( 圆头螺丝)

M3X8 Button Head Screw( 圆头螺丝)

Page 13

Qty

1

8

2

2

2

1

1

2

2

2

Page 14

TAIL TRANSMISSION ASSEMBLY

T600 GASSER CONVERSION

3

10

1

2

6

8

4

5

CNBB0490

M3 CNM3LOCK

9

7

No.

1

2

3

4

5

6

7

8

9

10

Part #

HN6030-1*

HN6030-1*

CNBB0490

H60121*

H60121*

H60121*

CNM3LOCK

CNBB1218

HN6090*

CNM3x12CS

Description

Tail Boom Mount(Left) ( 左尾管固定座 )

L=54mm Hexagonal Bolt( 六角铝柱)

4X9X4 Bearing ( 4x9x4轴承 )

Front Drive Gear Assembly( 尾传动导输出轴组)

Tail Boom Mount(Right) ( 右尾管固定座)

Front Umbrella Gear( 前轴传伞齿轮)

M3 Locknut(M3防松螺母)

12X18X4 Bearing (

Tail Boom (尾管

M3x12 Cap Screw( 杯头内六角螺丝)

12x18x4轴承)

)

Qty

1

6

2

1

1

1

4

2

1

4

CNM3x12CS

Page 14

Page 15

TAILBOOM & SUPPORTS

6

T600 GASSER CONVERSION

1

2

Ø3xØ8x2

Ø3xØ5x4

5

4

3

CNM3x18CS

No.

1

2

3

4

5

6

Part #

CNM3x12T

CNM3X8FW

CNM3x18CS

H60052*

H60052*

HN6104*

Description

M3X12 Socket Button Head Self Tapping Screw( 半圆头内六角自攻螺丝)

Ø3xØ8x2 M3 Specialty Washer( M3特殊垫片)

M3x18 Cap Screw( 杯头内六角螺丝)

Tail Boom Brace( 尾管支撑架)

Ø3xØ5x4Aluminum Sleeve( 铝套)

L=54mm Frame Mounting Bolt( 机身铝柱)

Page 15

Qty

6

14

2

2

2

1

Page 16

MAIN GEAR ASSEMBLY

Drop some medium threadlock into the

six holes on the main gear case. Then

use the M3x8 button head cap screws

and install through the main gear case.

Make sure to use threadlock sparingly

as to not get excess threadlock onto

the plastic gear.

If in the future your one-way bearing or

sleeve is worn or damaged, it is highly

recommended to replace the sleeve and

one-way bearing hub at the same time.

T600 GASSER CONVERSION

1

2

DIRECTION OF

FREE SPIN

3

For the roller bearings, we recommend a very light oil. The oil MUSTNOT attack/break down plastic as

this could damage the cage in the

one-way bearing. Prior to applying oil,

make sure to clean the roller bearings with a cotton swab making sure

there is no debris in the bearings.

CNM3x8BHCS

18x24x16

4

Shorter side of protrusion on one-way hub

should be facing up going into the gear.

5

6

7

15x24x2

No.

1

HW6057T6

CNM3X8BHCS

2

3

HI6057T6

4

CNBB1824A

5

HW6057T6H

CNM15X24FW

6

7

H60020A*

Page 16

Part #

Description

Main Shaft Auto Sleeve( 主齿轮铁套)

M3X8 Button Head Screw( 圆头螺丝)

103T Main Gear( 103齿齿轮)

18x24x16 One-way Bearing( 单向轴承)

Main Gear Case( 主齿中心座)

15x24x2 Flat Washer( 铜平面垫片)

Tail Drive Gear (副齿轮)

Qty

1

6

1

1

1

1

1

Page 17

MAIN SHAFT TO MAIN GEAR ASSEMBLY

T600 GASSER CONVERSION

6

5

4

3

10x13x4

CNM4x4SS

M3 CNM3LOCK

CNM3x20CS

1

2

No.

1

2

3

4

5

6

Part #

CNM3x20CS

CNM3LOCK

HW6057T6S1

H60159*

H60159*

CNM4X4SS

Description

M3x20 Cap Screw( 杯头内六角螺丝)

M3 Locknut(M3防松螺母)

10x13x4 Brass Sleeve( 铜套)

Main Shaft(主轴 )

Lock Collar( 主轴固定块)

M4x4 Set Screw( 无头内六角螺丝)

Qty

1

1

1

1

1

2

Page 17

Page 18

SERVO INSTALLATION

T600 GASSER CONVERSION

1

2

3

4

5

6

10

7

9

8

CNM2NUT

CNM3x6ST

CNM2.3x12ST

CNM2x8PH

No.

1

2

3

4

5

6

7

8

9

10

Part #

CNM2NUT

CNM3x6ST

CNM2.3x12ST

HI3205A

H60089*

NOT INCLUDED

CNM2x8PH

HI6205B

NOT INCLUDED

NOT INCLUDED

Description

M2 Nut(M2螺母)

M3x6 Self Tapping Screw(尖尾自攻螺丝)

M2.3x12 Self Tapping Screw( 尖尾自攻螺丝)

Servo Mounting Plate(伺服机固定板)

Linkage Ball A(M2x3.5)(球头A)Ø4.75X8.18

Servo(伺服机)

Phillips Screw(十字螺丝)M2x8

Servo Mount 3 Hole Tabs (伺服机固定座)

Short Servo Arm( 短伺服机摆臂)

Long Servo Arm( 长伺服机摆臂)

Qty

8

5

10

5

8

5

10

10

2

3

Page 18

Page 19

PUSHROD MEASUREMENTS

T600 GASSER CONVERSION

HEL PFUL TOOL

4

1

2

3

5

6

PART# CN2255: CONTROL ROD SETUP GAUGE

21

32

50

31,5

39,5

60,5

51

61

80

80

90

109

3

4

1

No.

1

2

3

4

5

6

6

Part #

HN6099*

HN6052*

HN6099*

HN6099*

HN6099*

HN6099*

Description

L=61mm Linkage Rod(连杆)

Ball Link(连杆头)

L=32mm Linkage Rod(连杆)

L=39.5mm Linkage Rod( 连杆)

L=197mm Linkage Rod( 连杆)

L=90mm Linkage Rod(连杆)

Qty

4

20

2

2

1

1

5

187

197

216

Page 19

Page 20

MUFFLER & ESSENTIALS

T600 GASSER CONVERSION

The muffler is not an included item. It is an optional item that

offers better performance but the stock can muffler from the

engine can be used.

9

8

1

7

10

6

2

3

4

5

CNM5x20CS

CNM3x4SS

No.

1

2

3

4

5

6

7

8

9

10

Page 20

Part #

CN3071

CN3071

CN3071

CNM3x4SS

NOT INCLUDED

NOT INCLUDED

NOT INCLUDED

NOT INCLUDED

NOT INCLUDED

NOT INCLUDED

Description

M5X20 Cap Screw(杯头内六角螺丝)

M5x8 Spring Washer

Torpedo Slim V2 Muffler( 排气管 )

M3x4 Set Screw( 无头内六角螺丝)

Battery(电池)

Receiver( 接受机)

Hook & Loop Strap(束带 )

Anti-vibration Pad (防震垫 )

Gyro (陀螺仪)

Tubing( 油管)

(弹簧垫片

)

Qty

2

2

1

2

1

1

2

1

1

2

Page 21

MOUNTING CANOPY

1

T600 GASSER CONVERSION

3

2

5

4

Congratulations on finishing the build of the gasser conversion for your T600. Please follow your instruction

manual on setting up your transmitter and gyro systems. Also it is very important that you follow the instructions included with the Zenoah G23 engine for the break in process and finally tuning the engine. If the steps

are not followed your engine will not perform at it’s optimum levels.

CNM3x8BHCS

No.

1

2

3

4

5

Part #

H60092*

CNM3X8BHCS

CN2210A

ORIGINAL ITEM

HN6088

Page 21

Description

Canopy Standoff( 机头固定铝柱)

M3X8 Button Head Screw( 圆头螺丝)

Canopy Grommets(橡皮环)

Canopy(机头)

Canopy Mount( 机头固定座)

Qty

2

2

2

1

1

Page 22

PERSONAL BUILD NOTES

T600 GASSER CONVERSION

Page 22

Loading...

Loading...