Century Radikal N640 Instruction Manual

Kit Features: Specifications:

8.58 :1 Main gear ratio

4.5:1 Tail gear ratio

Engineered for OS 55/YS56 motors or compatible

Carbon fiber frames for ultra-rigid and compact design

Push/Pull CCPM control system

Triple bearing supported 10mm hardened main shaft

120 degree dual race ball bearing metal swashplate

Stainless steel damper mounted bearing torque tube for high efficiency

Dual race ball bearing with thrust bearing supported tail blade grips

© 2012 Century Helicopter Products - All rights reserved.

Main Rotor Blade Diameter: 57.3 in /

145.5 cm (640 mm Blades)

Tail Rotor Blade Diameter: 10.25 in /

26.0 cm (92 mm Blades)

Length: 49 in / 124.50 cm

Height: 13.7 in / 34.80 cm

Width: 4.5 in / 11.45 cm

Version 1.00

INTRODUCTION

Radikal N640

Thank You

Thank you for purchasing this new class of helicopters. By incorporating the use of blade sizes up to 640mm allowing 700 class flight

characteristics in a smaller, you’ve made the right choice by going for an economical yet extremely high performance helicopter.

Warning!

This R/C helicopter is not a toy! It is a precision machine requiring proper assembly and setup to avoid accidents. It is the responsibility of

the owner to operate this product in a safe manner as it can inflict serious injury otherwise. It is important for the user/pilot to be responsible for the damage the model is capable of inflicting on one’s self and others around the model during its operation. Century Helicopter

Products, affiliated individuals, and shops/sellers hold no accountability for the operation or use of this model. It is recommended that

if you are in doubt of your abilities; seek assistance from experienced radio control modelers and associations. Although the helicopter

is considered small in size, you must be very cautious during the operation of the model as serious damage, injury, or death can occur.

Flight Checklist

Make sure your transmitter battery is fully charged.

Turn on the transmitter FIRST prior to turning on anything else on the model.

Inspect all parts before each flight to ensure no damage has occurred.

Check all nuts, bolts, and screws to be sure they are securely fastened.

Verify all parts are installed correctly and in proper working condition.

Make sure you have control of the model prior to engaging the motor or engine.

Allow all the components to initialize and test all controls.

Fly the model and be sure the model is capable of a proper hover prior to performing aerobatics.

Land the model and shut off the motor or engine.

Turn off or unplug any battery(ies) on the model BEFORE turning off your transmitter.

General Guidelines

Apply thread lock to all metal to metal thread contact points. Do not apply CA (cyanoacrylate) glue or thread lock to ny-lock nuts (metal

nuts with plastic inserts). Diagrams indicated by bounding boxes for screws, bearings, etc. are illustrated at a 1-to-1 ratio. All other illustrations are not drawn to scale. Throughout this manula, you will find building tips. Please follow the tips and use common sense when

building.

Pre-Assembly Information

Upon opening the kit, all the major component parts are bagged for ease of assembly which correspond to the sections of the manual.

Various assemblies have been pre-assembled however, only as a reference assembly. Final assembly is up to the user. Installation onto

the particular parts, screws and nuts required for each step are packaged in the same bag as the parts. Be careful when opening each

bag as not to lose any hardware. Care has been taken in filling and packing of each bag however mistakes do happen. If there is a parts

shortage or missing hardware, please contact us directly or contact your place of purchase.

Century Helicopter Products

1740-C Junction Ave.

San Jose, CA. 95112

U.S.A.

www.centuryheli.com

Page 2

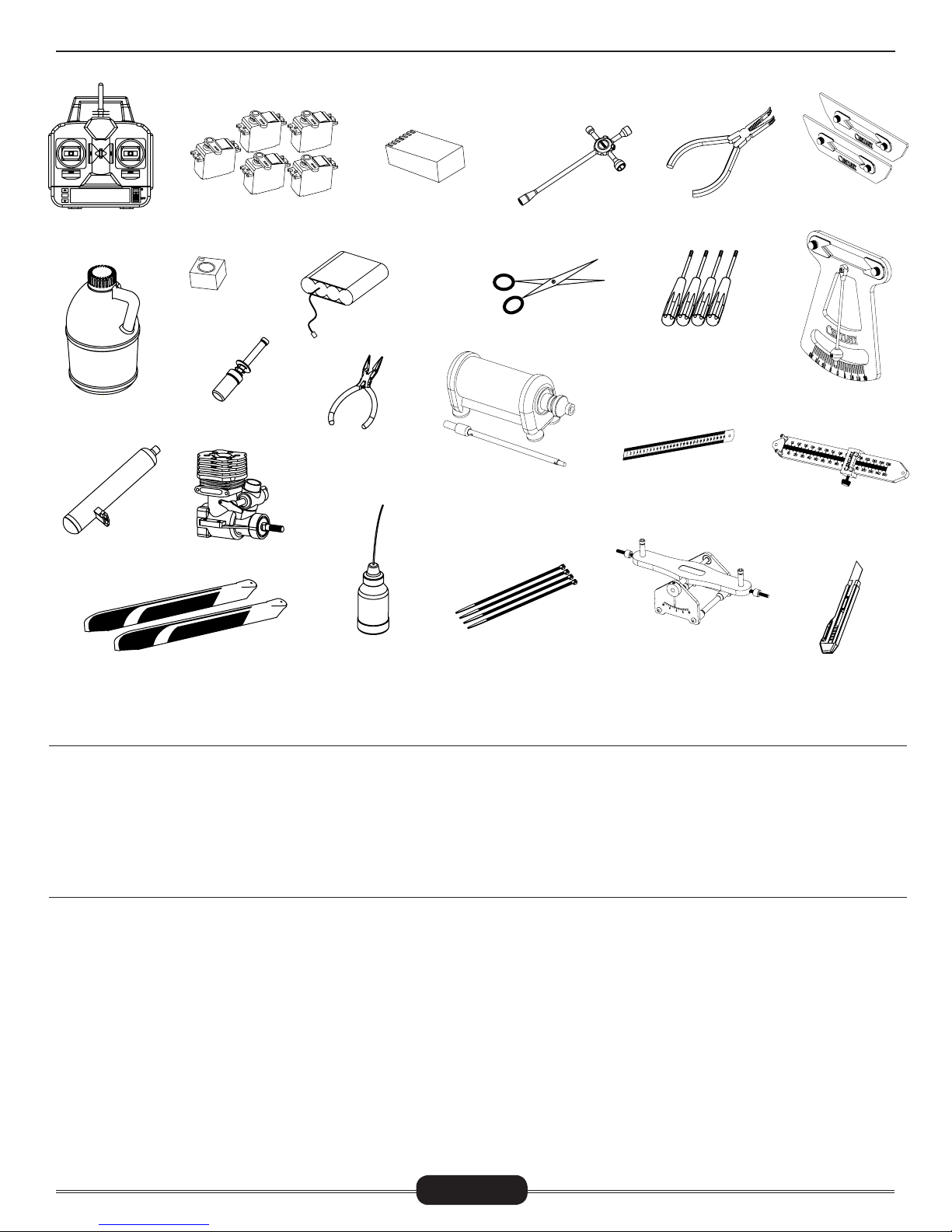

REQUIRED/RECOMMENDED ITEMS

Radikal N640

6 CHANNEL

CCPM TRANSMITTER

(MINIMUM)

1.000

NITRO HELICOPTER

FUEL

CN3038A

SILENT POWER

50 MUFFLER

600-640MM ROTOR BLADES

SERVOS X 5

GYRO

GLOW PLUG

IGNITOR

50-56 SIZE NITRO

ENGINE

6 CHANNEL RECEIVER

(MINIMUM)

RECEIVER BATTERY

NEEDLE NOSE

PLIERS

SYNTHETIC

OIL/GREASE

4-WAY WRENCH

HOBBY SCISSORS

CN2057 & CN0426

STARTER

AND STARTER SHAFT

ZIP TIES

CN2034A

BALL LINK PLIERS

CN2017

HEX DRIVERS

1.5, 2.0, 2.5, 3.0 & 4.0

METRIC RULER OR

SIMILAR MEASURING

DEVICE

CN2051

ACCURATECH BLADE BAL-

ANCER V.2

CN2050

PADDLE GAUGE

CN2027

G-FORCE PITCH GAUGE

CN2255

CONTROL ROD

SETUP GAUGE

HOBBY KNIFE

Warranty

Century Helicopter Products assures the purchaser that should a defect in materials or workmanship occur within 30 days from the

date of purchase affecting the original customer (“Purchaser”) under normal use, Century Helicopter Products will assume warranty

replacement or repair as seen fit. In the event the helicopter is assembled by the Purchaser and damage occurs by the Purchaser of the

final product, Century Helicopter Products shall not be liable. The assembled product by the Purchaser shall accept full responsibility and

liability. If the Purchaser is not prepared to accept such liability associated with the assembly or operation of the model, the kit must be

immediately returned in new and unused condition to the original place of purchase.

Warranty Period

This warranty is limited to the original customer (“Purchaser”) and is non-transferable. THE PURCHASER IS RESPONSIBLE FOR TRANSPORTATION CHARGES OF ANY AND ALL REPAIRS OR REPLACEMENTS PROVIDED UNDER THIS WARRANTY. The warranty coverage

will only apply to those products purchased from an authorized Century Helicopter Products dealer or distributor. This warranty can

change or be modified without any prior notice and shall supersede all other warranties expressed or implied. To initiate a warranty claim,

please be sure you have proof of purchase of the product. Century Helicopter Products reserves the right to inspect any and all items

involved in a warranty claim. Century Helicopter Products does not warrant that the operation of the product will be uninterrupted or

error-free. Century Helicopter Products will not be responsible for damage coming from failure to follow instructions relative to the products assembly and usage. This warranty does not apply to damage caused by products other than Century Helicopter Products’, damage caused by accident, abuse, cosmetic damage, negligence, misuse, flood, fire, earthquake other external causes, commercial use, or

modification of or to any part of the Product. This warranty does not cover damage due to improper installation, operation, maintenance,

or attempted repair by anyone other than Century Helicopter Products.

Page 3

AMA RULES & REGULATIONS

Radikal N640

General

1. Model aircraft will not be flown:

(a) In a careless or reckless manner.

(b) At a location where model aircraft activities are prohibited.

2. Model aircraft pilots will:

(a) Yield the right of way to all man carrying aircraft.

(b) See and avoid all aircraft and a spotter must be used when appropriate. (AMA Document #540-D-See and Avoid Guidance.)

(c) Not fly higher than approximately 400 feet above ground level within three (3) miles of an airport, without notifying the airport

operator.

(d) Not interfere with operations and traffic patterns at any airport, heliport or seaplane base except where there is a mixed use

agreement.

(e) Not exceed a takeoff weight, including fuel, of 55 pounds unless in compliance with the AMA Large Model Aircraft program. (AMA

Document 520-A)

(f) Ensure the aircraft is identified with the name and address or AMA number of the owner on the inside or affixed to the outside of

the model aircraft. (This does not apply to model aircraft flown indoors).

(g) Not operate aircraft with metal-blade propellers or with gaseous boosts except for helicopters operated under the provisions of

AMA Document #555.

(h) Not operate model aircraft while under the influence of alcohol or while using any drug which could adversely affect the pilot’s ability

to safely control the model.

(i) Not operate model aircraft carrying pyrotechnic devices which explode or burn, or any device which propels a projectile or drops

any object that creates a hazard to persons or property.

3. Model aircraft will not be flown in AMA sanctioned events, air shows or model demonstrations unless:

(a) The aircraft, control system and pilot skills have successfully demonstrated all maneuvers intended or anticipated prior to the

specific event.

(b) An inexperienced pilot is assisted by an experienced pilot.

4. When and where required by rule, helmets must be properly worn and fastened. They must be OSHA, DOT, ANSI, SNELL or NOCSAE

approved or comply with comparable standards.

Radio Control (RC)

1. All pilots shall avoid flying directly over unprotected people, vessels, vehicles or structures and shall avoid endangerment of life and

property of others.

2. A successful radio equipment ground-range check in accordance with manufacturer’s recommendations will be completed before

the first flight of a new or repaired model aircraft.

3. At all flying sites a safety line(s) must be established in front of which all flying takes place (AMA Document #706-Recommended

Field Layout):

(a) Only personnel associated with flying the model aircraft are allowed at or in front of the safety line.

(b) At air shows or demonstrations, a straight safety line must be established.

(c) An area away from the safety line must be maintained for spectators.

(d) Intentional flying behind the safety line is prohibited.

4. RC model aircraft must use the radio-control frequencies currently allowed by the Federal Communications Commission (FCC). Only

individuals properly licensed by the FCC are authorized to operate equipment on Amateur Band frequencies.

5. RC model aircraft will not operate within three (3) miles of any pre-existing flying site without a frequency-management agreement

(AMA Documents #922- Testing for RF Interference; #923- Frequency Management Agreement)

6. With the exception of events flown under official AMA Competition Regulations, excluding takeoff and landing, no powered model

may be flown outdoors closer than 25 feet to any individual, except for the pilot and the pilot’s helper(s) located at the flight line.

7. Under no circumstances may a pilot or other person touch a model aircraft in flight while it is still under power, except to divert it

from striking an individual. This does not apply to model aircraft flown indoors.

8. RC night flying requires a lighting system providing the pilot with a clear view of the model’s attitude and orientation at all times.

9. The pilot of a RC model aircraft shall:

(a) Maintain control during the entire flight, maintaining visual contact without enhancement other than by corrective lenses prescribed for the pilot.

(b) Fly using the assistance of a camera or First-Person View (FPV) only in accordance with the procedures outlined in AMA Document

#550.

Free Flight

1. Must be at least 100 feet downwind of spectators and automobile parking when the model aircraft is launched.

2. Launch area must be clear of all individuals except mechanics, officials, and other fliers.

3. An effective device will be used to extinguish any fuse on the model aircraft after the fuse has completed its function.

Page 4

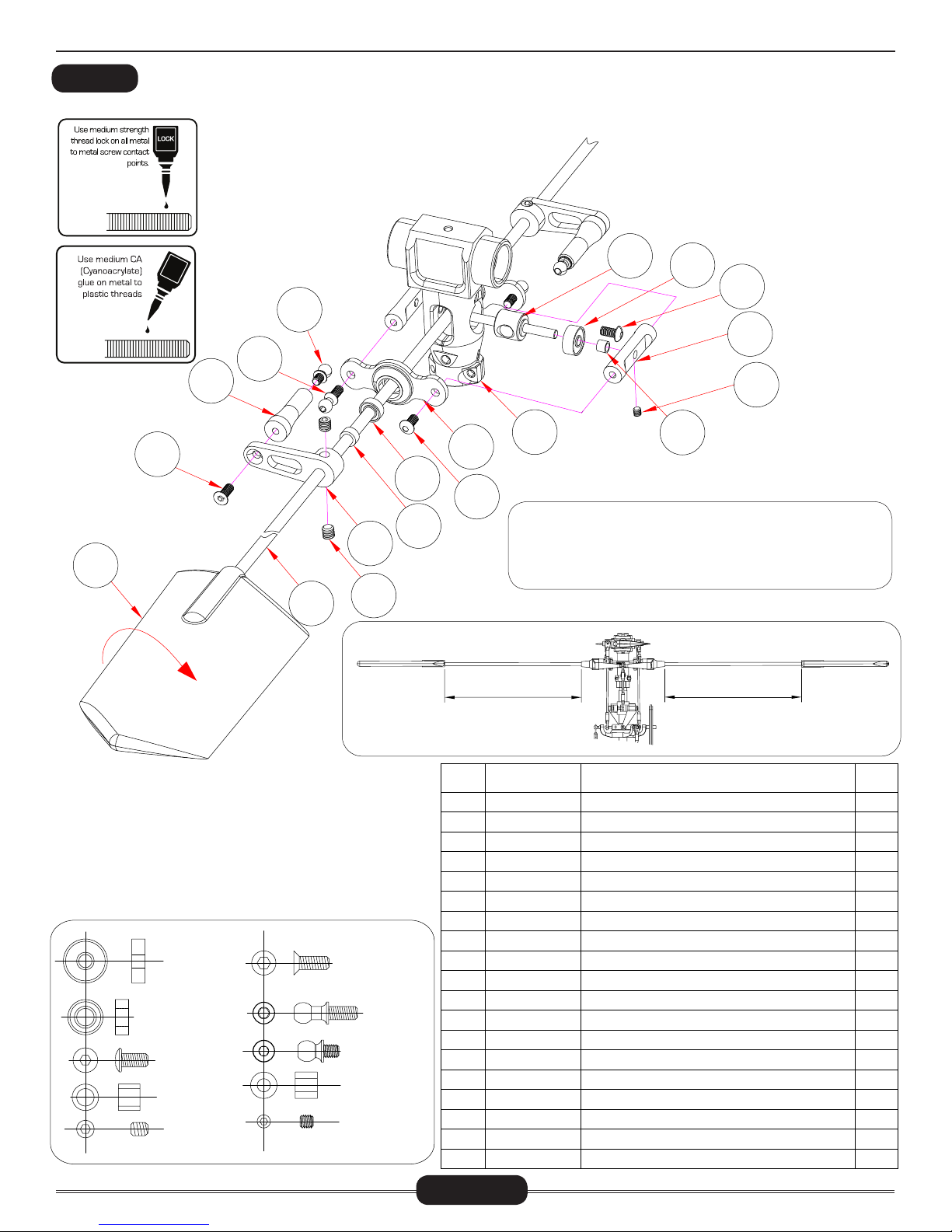

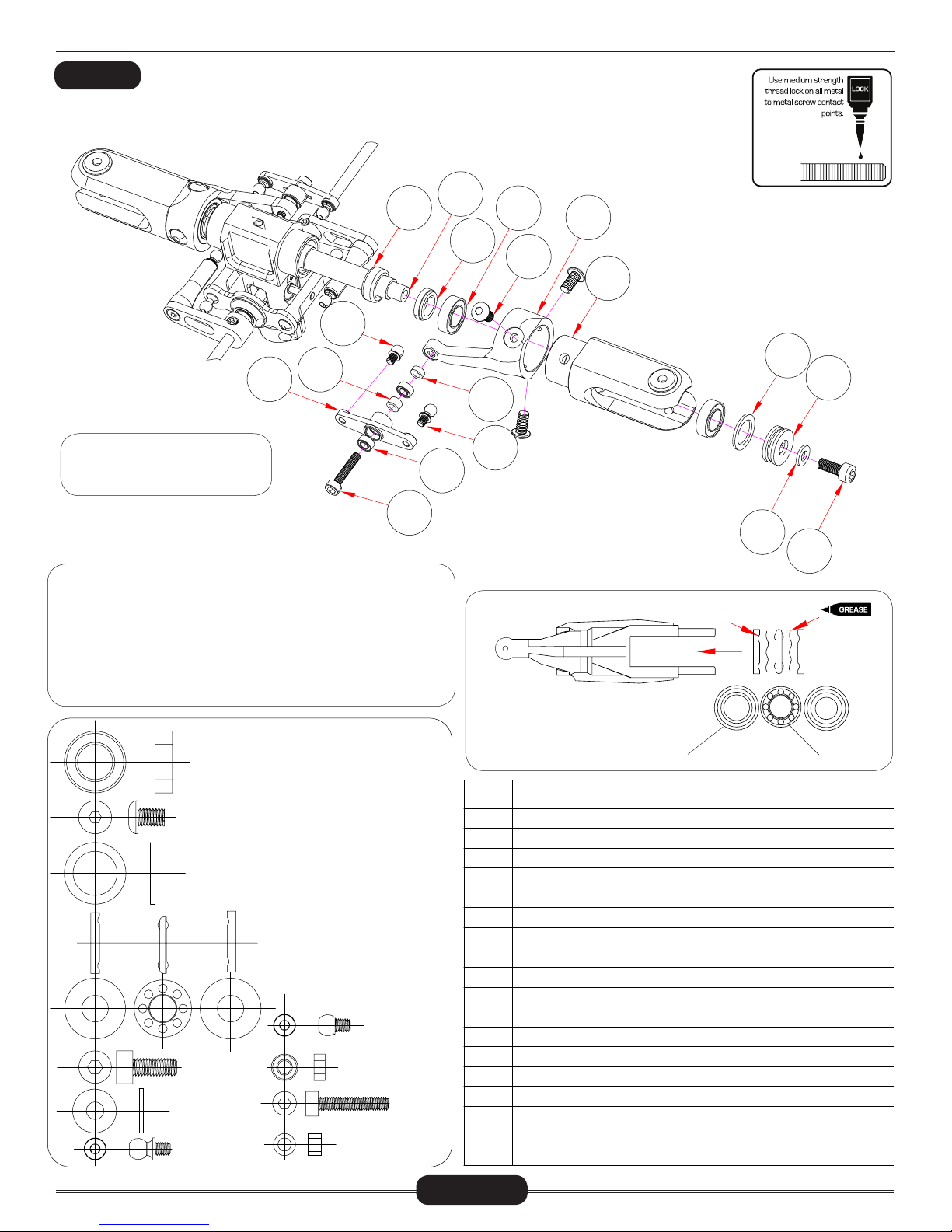

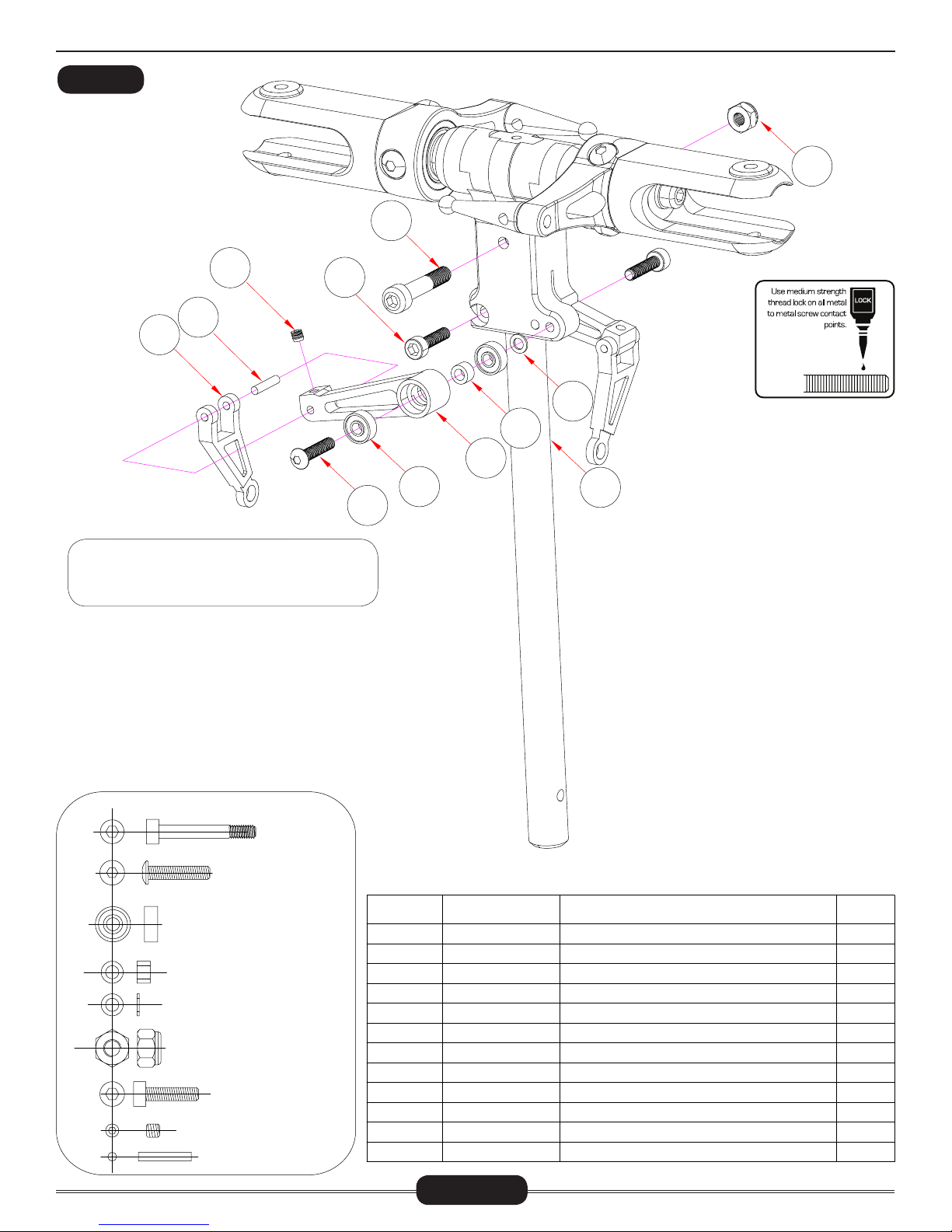

HEAD ASSEMBLY (FLYBAR VERSION)

BAG 1

Do not open all the bags prior to starting assembly. Open the bags step by step as you go through this

instruction manual. The components are bagged to make assembly easier. The next few pages will pertain to the assembly of the head. Please follow the instructions based on the head type you own. Make

sure to apply threadlock to any screws going into metal.

Radikal N640

15

16

C

A

1

2

3

19

4

18

17

7

6

5

8

10

9

The flybar head comes pre-assembled however, it is only assembled as an example of how it should be assembled. The entire

head will need to be taken apart and medium thread lock is

required on all metal to metal parts.

Make sure the distance on

both sides are equal

14

12

13

11

Make sure the distance on

both sides are equal

CNBB1030

CNBB0840

CNM3x6BHCS

4X6X5

CNM4X4SS

CNM3x8FHCS

CNLR1017

CNLR1014

3X6X5

CNM3x3SS

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Page 5

Part #

CNE518

CNBB1030

CNM3x6BHCS

CNE564S

CNE564S

CNE564S

CNE556-1

HI3167H3

CNM3x6BHCS

CNBB0840

CNE559AS

CNE559AS

CNM4x4SS

HI6179B1

HI3179A

CNM3x8FHCS

CNE559AS

CNLR1017

CNLR1014

Description

Seesaw Shaft( 旋转轴)

3X10X4 Bearing(轴承)

Button Head Cap Screw( 圆头内六角螺丝)

Seesaw Tie Bar Set(平衡杆控制臂)

M3x3 Socket Head Set Screw(无头内六角螺丝)

3x6x5 Spacer( 3x6x5铝套 )

Rotor Head Yoke(主旋翼中心座)

Seesaw Offset Plates(平衡杆固定片)

Button Head Cap Screw(圆头内六角螺丝)

4X8X3 Bearing(轴承)

4X6X5 Spacer(套子)

Flybar Control Arm(平衡翼控制臂)

M4x4 Socket Head Set Screw( 无头内六角螺丝)

4mm Flybar(平衡杆)

Flybar Paddles(平衡翼)

Flush Head Cap Screws(斜头内六角螺丝)M3x8

Flybar Control Arm(平衡翼控制臂)

M3 Ball Link Long(M3球头螺丝)

M3 Ball Link Short(M3 球头螺丝)

Qty

1

2

2

2

2

2

1

2

2

2

2

2

4

1

2

2

2

2

2

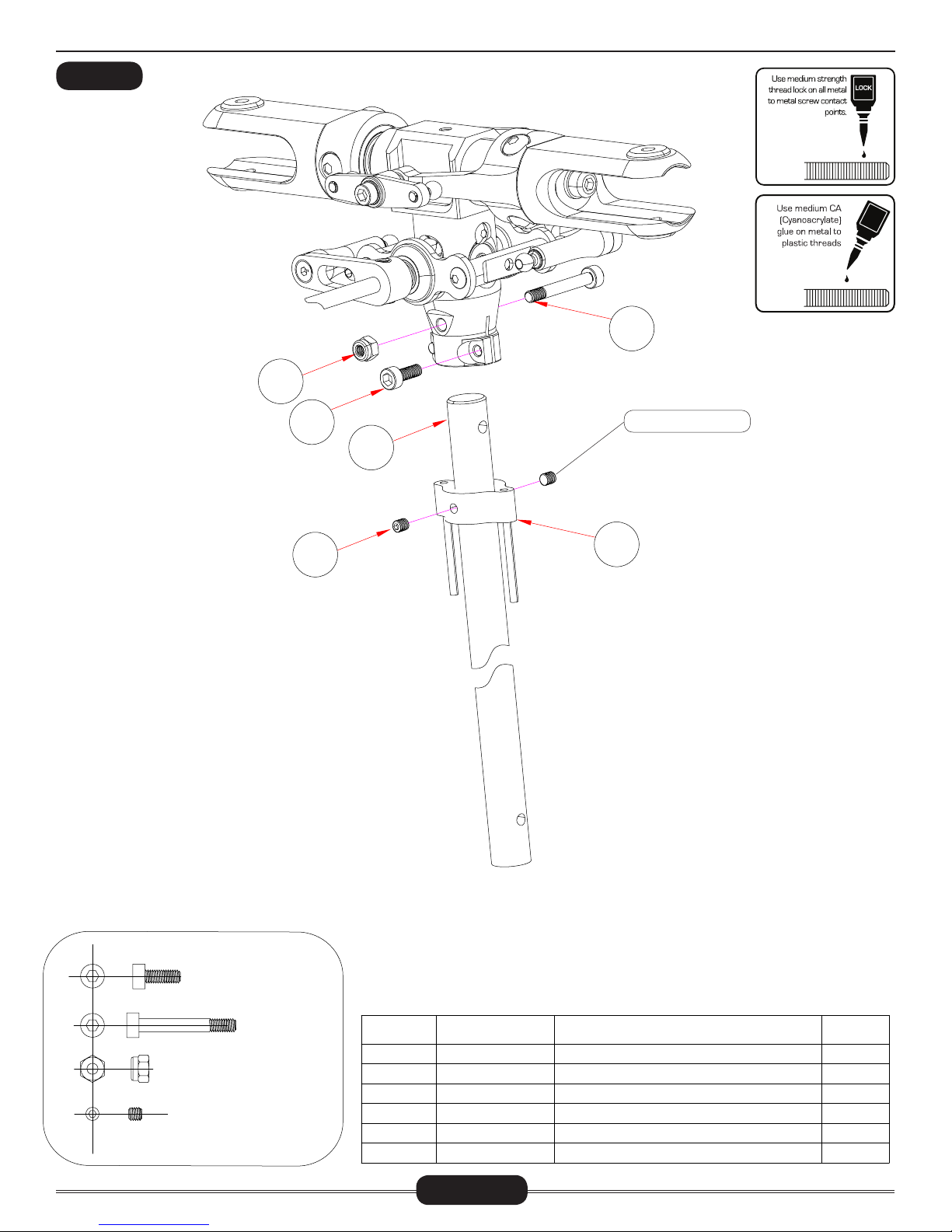

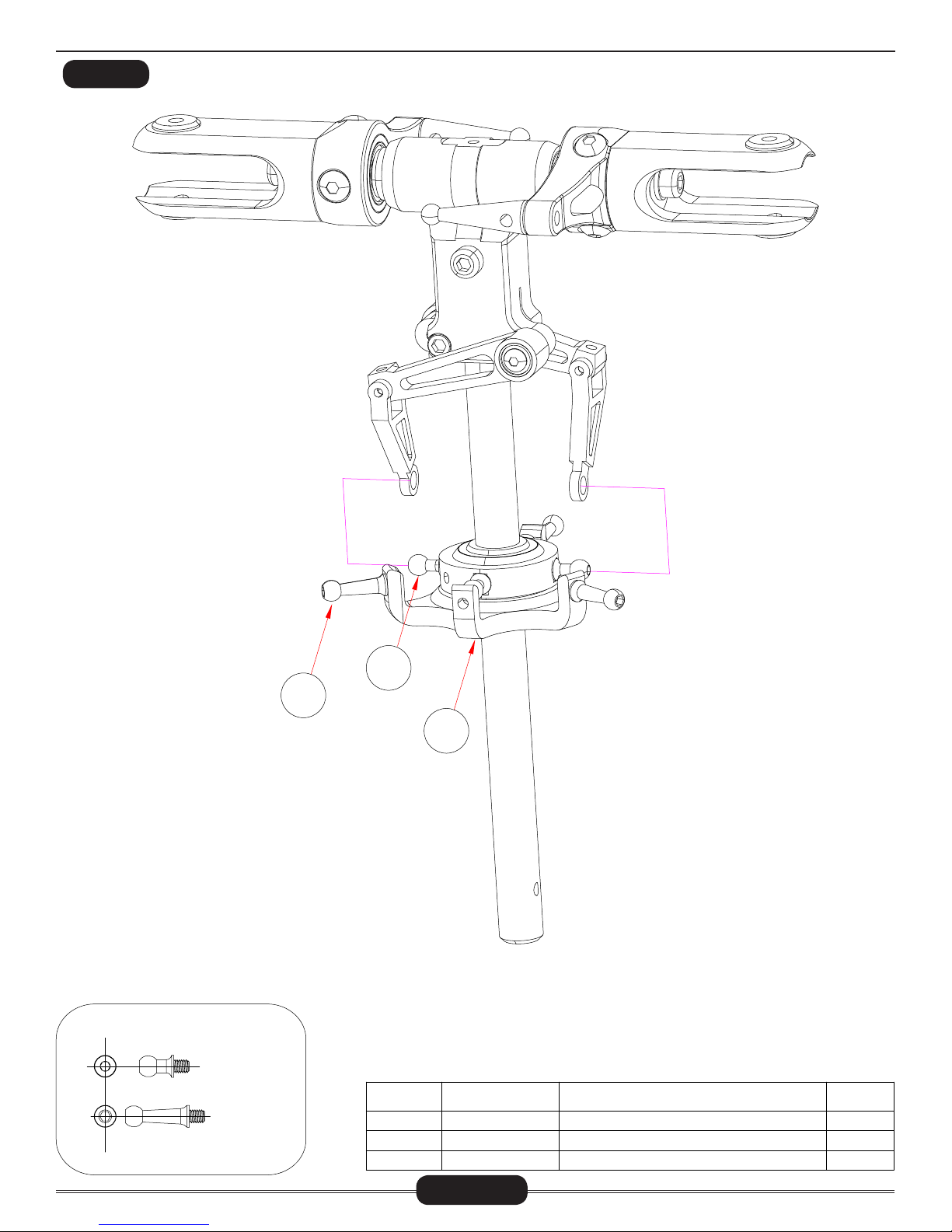

HEAD ASSEMBLY (FLYBAR VERSION)

BAG 1

Radikal N640

1

18

16

Notice the direction of the blade

grips as well as the direction of

the flybar control arm.

Ensure lubricant is applied to the thrust bearings. Be careful when

taking the thrust bearings out of the blade grips. The radial bearings (part #4) should stay within the grips. DO NOT try to remove

these as they have been factory installed. It is best to remove the

grips one side at a time. Before assembly, notice the direction of the

control arm on the grip. It should be assembled as indicated within

this diagram.

17

14

15

2

4

3

5

12

13

THRUST BEARING INSTALLATION GUIDE

SIDE PROFILE - BLADE GRIP

6

7

GROOVES INSIDE

LARGER ID

8

9

11

10

SMALLER ID

CNBB814

CNM4X6BHCS

CNM10X14FW

CNM4x10CS

CNM4X10FW

CNLR1014

CNBB614T

CNLR1023

CNBB364

CNM3X5X3

M3X16CS

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Page 6

LARGER INNER DIAMETER TOWARDS HEAD BLOCK

Part #

HI6181D

CNE521A

CNE522-28

CNBB814

CNM4x6BHCS

CNE557-2

CNE557A-1

CNM10X14FW

CNBB614T

CNM4X10CS

CNM4X10FW

HW6206

CNLR1014

CNBB364

CNM3X16CS

CNE558S

HW6205

CNLR1023

RECESSED CREVICE FACES MAIN SHAFT

Description

Rubber Dampener( 橡皮环)

Feathering Shaft( 横轴)

T=2.8mm, Blade Grip Spacer

8X14X4Bearing( 轴承)

Button Head Cap Screw(圆头内六角螺丝)

Main Rotor Blade Grip Arms(主旋翼夹片臂)

Main Rotor Blade Grips(主旋翼夹片座)

M10x14x1Flat Washer(平面垫片)

6x14x5 Thrust Bearing(止推轴承)

M4x10 Cap Screws( 杯头螺丝)

M4x10x1Flat Washer(平面垫片)

3X5X2 Spacer(固定套)

M3 Ball Link(M3 球头螺丝)

3X6X2.5Bearing( 轴承)

M3x16 Cap Screws(杯头螺丝)

Bell Mixer Arm(混控臂)

3X5X3 Brass Spacer(固定套)

M3 Ball Link(M3 球头螺丝)

( 间隔套)

Qty

2

1

2

4

6

2

2

2

2

2

2

2

2

4

2

2

2

2

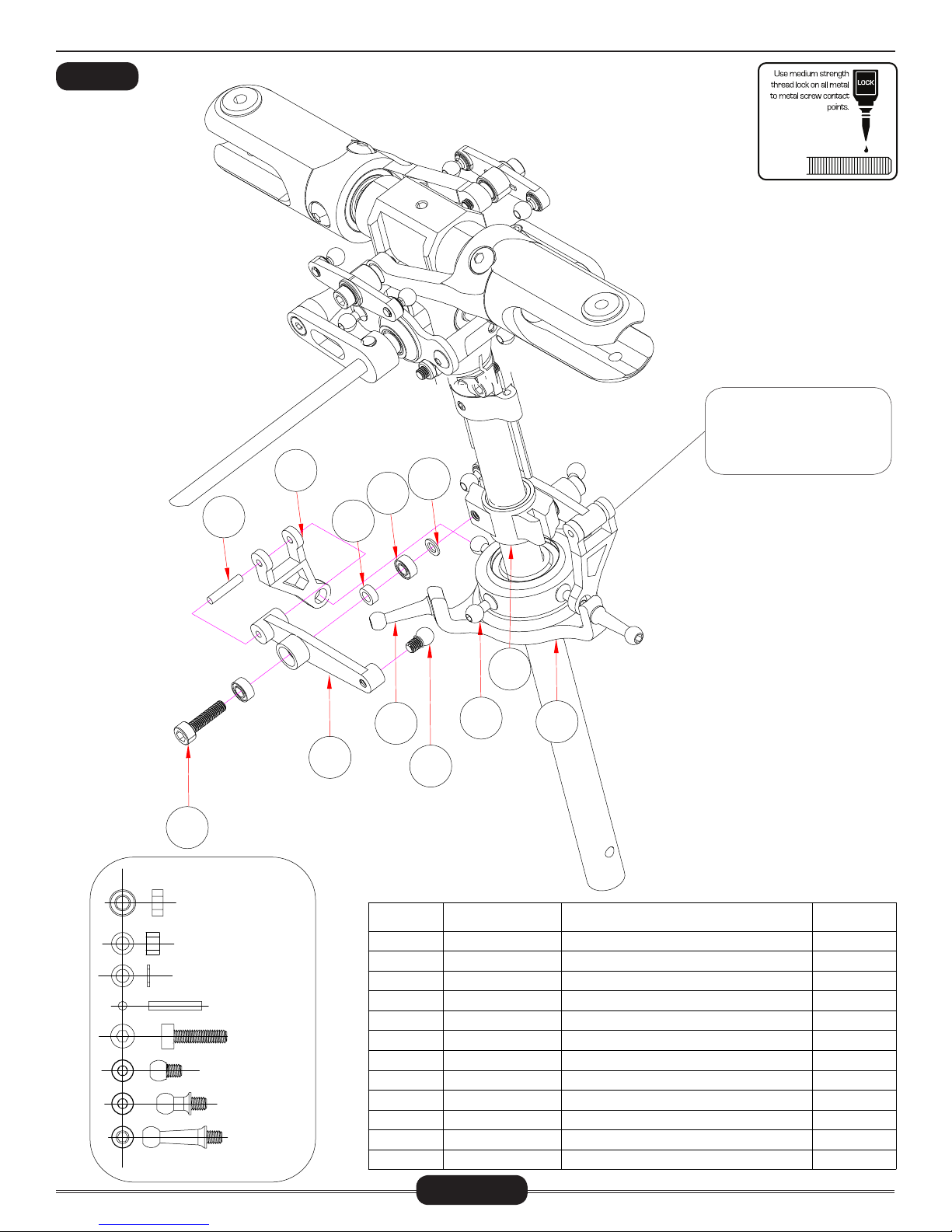

HEAD ASSEMBLY (FLYBAR VERSION)

BAG 1

1

6

Radikal N640

C

A

2

4

Do not over-tighten!

3

5

M3X8CS

CNM3X22SCS

M3 CNM3LOCK

CNM3x3S S

No.

1

2

3

4

5

6

Part #

CNM3LOCK

CNM3X8CS

HW5053

CNM3x3SS

CNE556-2

CNM3X22SCS

Page 7

Description

M3 Locknut(M3螺母)

M3x8 Cap Screws(杯头螺丝)

10mm Main Shaft(主轴)

M3x3 Socket Head Set Screw(无头内六角螺丝)

Aluminum Washout Guide(剪型臂导柱

M3x22 Cap Screws(杯头螺丝)

)

Qty

1

2

1

2

1

1

HEAD ASSEMBLY (FLYBAR VERSION)

BAG 1

4

1

2

5

3

Radikal N640

Hint: To ensure this pin does

not pop out, periodically

check it between flights. You

also can apply a tiny drop of

CA to either side of the pin.

6

CNBB36

CNM3X5X3

M3x5x0.5 CNLR1003

Ø2x12

M3X12CS

CNLR1023

CNLR1020

M3 L=18MM

7

8

No.

1

2

3

4

5

6

7

8

9

10

11

12

9

CNLR1003

CNBB36

HW6205

CNE516B

CNE516B

CNM3X12CS

CNE560S

CNLR1021

CNLR1023

CNLR1011

CNE594

HW5146N

10

Part #

11

12

Description

3X5X0.5 Flat Washer(平面垫片)

3X6X2.5 Bearing(轴承)

3X5X3 Brass Spacer(固定套)

Radius Link w/ Pin( 三角控制臂)

Radius Link w/ Pin( 插销)

M3x12 Cap Screws( 杯头螺丝)

Washout Arm(摆臂)

M3 Ball Link L=18MM(M3 球头螺丝)

M3 Ball Link(M3 球头螺丝)

M3 Ball Link(M3 球头螺丝)

Washout Hub (控制臂固定座)

NX Dual Ball Bearing Swashplate(

十字盘)

Qty

2

4

2

2

2

2

2

2

2

4

1

1

Page 8

LINKAGE RODS (FLYBAR VERSION)

BAG 1

1

A

2

Radikal N640

NOTICE SIZE OF HOLES ON BALL LINKS

THE SIDE WITH THE SMALLER HOLE

SHOULD FACE OUTWARDS

D

9

8

7

3

B

4

5

C

6

A

B

C

D

25

14

51,5

30

54,5

35

97

80

The linkage rods come pre-built. Even

though they are pre-built, you will need

to verify their lengths. The diagram

with lengths are drawn at a true to

life scale, therefore you can lay your

linkages on the diagram to find the

correct measurements.

No.

Part #

1

HI6145

2

HW5192

3

HI6145

4

HW5192

5

HI6145

6

HW5192

7

HI6145

8

HW5192

9

CNLR1022SP

Page 9

HEL PFUL TOOL

PART# CN2255: CONTROL ROD SETUP GAUGE

Description

Ball Link Set (26 Long, 4 Short)(球头连接杆)

Pushrod Set( 连杆)

Ball Link Set (26 Long, 4 Short)(球头连接杆)

Pushrod Set( 连杆)

Ball Link Set (26 Long, 4 Short)(球头连接杆)

Pushrod Set( 连杆)

Ball Link Set (26 Long, 4 Short)(球头连接杆)

Pushrod Set( 连杆)

Special Ball Link (M3 十字盘特殊球头螺丝)

Qty

4

2

4

2

4

2

4

2

1

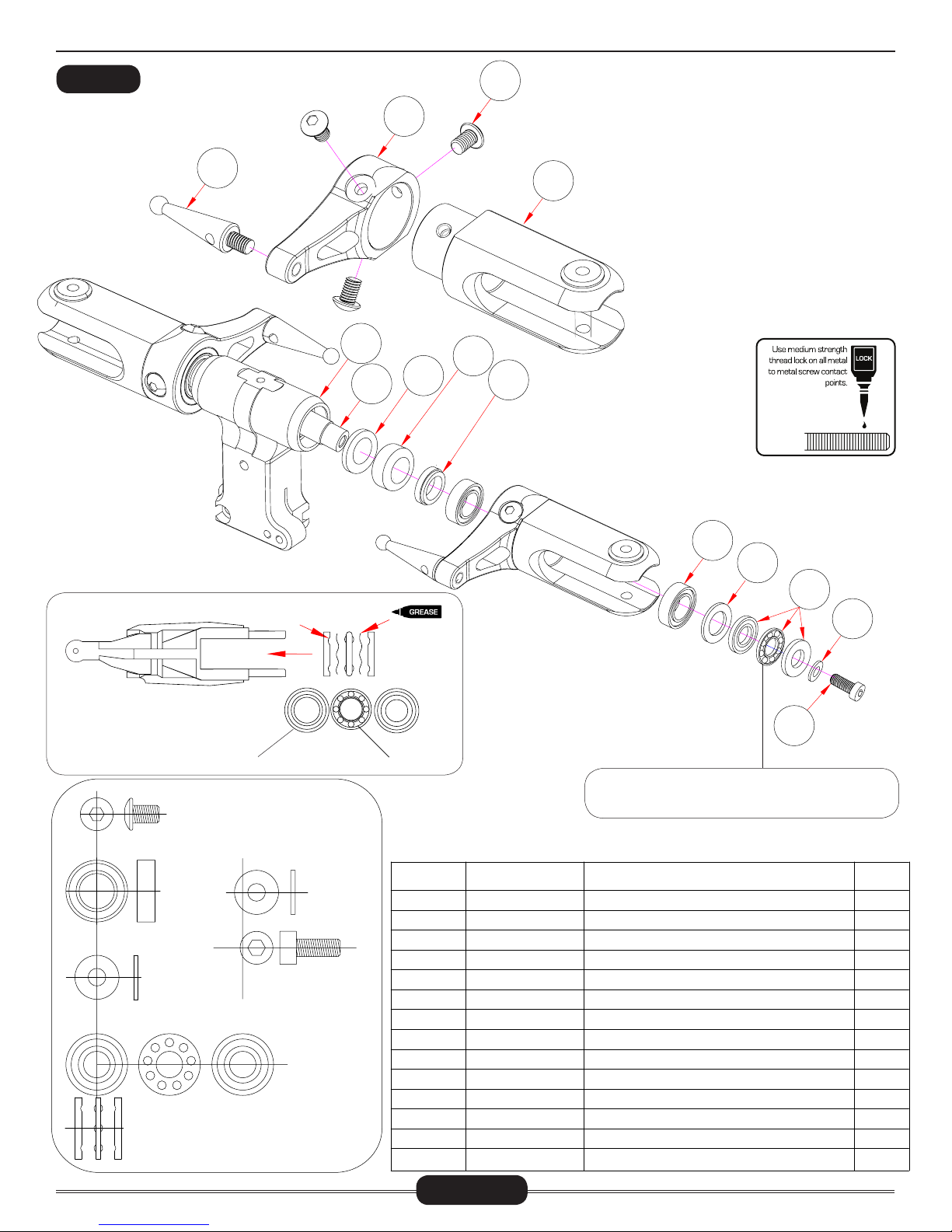

HEAD ASSEMBLY (FLYBARLESS)

Radikal N640

BAG 1

1

5

6

2

7

8

3

9

4

The flybarless head comes pre-assembled

however, it is only assembled as an example of how it should be assembled. The

entire head will need to be taken apart and

medium thread lock is required on all metal

to metal parts. Ensure lubricant is applied

to the thrust bearings. Be careful when

taking the thrust bearings out of the blade

grips. The radial bearings (part #9) should

stay within the grips. DO NOT try to remove

these as they have been factory installed.

It is best to remove the grips one side at a

time. Before assembly, notice the direction

of the control arm on the grip. It should be

assembled as indicated within this diagram.

THRUST BEARING INSTALLATION GUIDE

SIDE PROFILE - BLADE GRIP

LARGER INNER DIAMETER TOWARDS HEAD BLOCK

CNM4x6BHCS

CNBB814

4x10x1

CNBB614T

Parts diagrams are drawn on a 1-to-1 scale.

GROOVES INSIDE

LARGER ID

M4X10X1

CNM4X10CS

SMALLER ID

RECESSED CREVICE FACES MAIN SHAFT

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Page 10

Part #

CN2517A-1

CN2517A-1

CNM4x6BHCS

CN2517A-1

CN2517A-2

CNE521A

CN2517A-6

HI6181D

CN2517A-25

CNBB814

CNM10X14FW

CNBB614T

CNM4X10FW

CNM4X10CS

10

11

12

13

14

Make sure the open ball side of the thrust bearing

is facing towards the rotor head.

Description

Flybarless Arm Ball(摆臂)

Flybarless Arm(摆臂座)

Button Head Screw( 圆头螺丝)M4x6

Main Rotor Blade Grip(主桨夹片)

Head Block(主旋翼中心座)

Feathering Shaft( 横轴)

Head Damper Spacers(塑料圈)

Rubber Dampener( 橡皮环)

T=2.50mm Spacer

8x14x4 Bearing( 轴承)

Flat Washer(垫片)10x14x1

Thrust Ball Bearing( 止推轴承)6x14x5

M4x10x1 Spacer( 垫圈)

M4x10 Cap Screws(杯头螺丝)

( 铝套)

Qty

2

2

6

2

1

1

2

2

2

4

2

2

2

2

HEAD ASSEMBLY (FLYBARLESS)

BAG 1

1

Radikal N640

12

3

2

4

5

6

The follower arms already come pre-assembled.

DO NOT try to remove the bearings as they are

factory installed.

7

11

9

8

10

CNM3X22SCS

CNM3x16BHCS

CNBB0830

M3x5x3 HW6205

M3x5x0.5 CNLR1003

CNM3LOCK

CNM3x12CS

CNM3X3SS

Ø2x12

No.

1

2

3

4

5

6

7

8

9

10

11

12

Part #

CNM3X22SCS

CNM3X12CS

CNM3X3SS

CN2517A-5

CN2517A-5

CNM3x16BHCS

CNBB0384

CN2517A-5

HW6205

HW5053A

CNLR1003

CNM3LOCK

Page 11

Description

M3x22 Cap Screws(杯头螺丝)

M3x12 Cap Screws(杯头螺丝)

M3x3 Socket Head Set Screw

Radius Link w/ Pin(插销)

Radius Link w/ Pin( 三角控制臂)

Button Head Cap Screw( 圆头内六角螺丝)M3x16

Bearing(滚珠轴承)3x8x3

Washout Control Arm( 剪型臂)

Spacer(铁套)3x5x3

10mm Main Shaft(主轴)

3x5x0.5 Micro Washer( 垫圈)

M3 Locknut (M3

防松螺母)

(无头内六角螺丝)

Qty

1

2

2

2

2

2

4

2

2

1

2

1

HEAD ASSEMBLY (FLYBARLESS)

BAG 1

Radikal N640

CNLR1020

M3 L=18MM

1

2

No.

1

2

3

3

Part #

CNLR1021

CNLR1020

HW5146N

Description

M3 Ball Link L=18MM(M3 球头螺丝)

M3 Ball Link(M3 球头螺丝)

NX Dual Ball Bearing Swashplate(十字盘)

Qty

3

4

1

Page 12

Loading...

Loading...