Page 1

Kit Features:

Specifications:

Lightweight yet extremely strong G10 or carbon fiber frames.

High gloss large diameter 25mm tail boom with belt drive system.

Blade grips accommodate blades 12mm (LT) to 18mm (HD) blade roots.

300 mL fuel tank for long engine run time.

Convenient and easy access to spark plug.

Triple bearing supported blade grips and tail blade grips.

Machined center dual ball bearing swashplate for 120 degree CCPM.

Adjustable bell-hiller ratio allows tuning for preferred cyclic response (HD)

Tunable flight characteristics for stability or speed.

© 2010 Century Helicopter Products - All rights reserved.

Length: 1366mm

Height: 381mm

Width: 260mm

Main rotor diameter: 1435mm

Tail rotor diameter: 262mm

Main rotor blades: 600mm-640mm

Tail rotor blades: 95mm

Version 1.10

Page 2

INTRODUCTION

Radikal Gasser

Thank You

Congratulations on the purchase of the latest Century Gasser series, the Radikal G20. You’re about to build one of the world’s first fully

functional 3D aerobatic helicopters powered by the Zenoah 20cc gasoline engine. Be sure to read through and follow the instructions

during the build.

Warning

This radio controlled model is not a toy! It is a precision machine requiring proper assembly and setup to avoid accidents. It is the

responsibility of the owner to operate this product in a safe manner as it can inflict serious injury otherwise. It is recommended that if

you are in doubt of your abilities, seek assistance from experienced radio control modelers and associations. Keep loose items that can

get entangled in the rotor blades away for the main and tail blades, including loose clothing, hair, or other objects such as pencils and

screwdrivers. Especially keep your hands away from the rotor blades. As manufacturer, we assume no liability for the use of this product.

Flight Guidelines

Please note this checklist is not intended to be a replacement for the content included in this instruction manual. Although it can

be used as a quick start guide, we strongly suggest reading through this manual completely before proceeding.

Always turn the transmitter on first

Allow the gyro, and receiver to arm and initialize properly

Do a pre-flight check making sure all electronics are working and look for any mechanical issues

Fly the model

Land the model

Turn off the engine

Always turn the transmitter off last

General Guidelines

Apply thread lock to all metal to metal thread contact points. Do not apply CA (cyanoacrylate) glue or thread lock to ny-lock nuts (metal nuts

with plastic inserts). Diagrams indicated by bounding boxes for screws, bearings, etc. are illustrated at a 1-to-1 ratio. All other illustrations

are not drawn to scale. Throughout this manual, you will find building tips. Please follow the tips and use common sense when building.

Pre-assembly Information

Various assemblies have been pre-assembled however, only as a reference assembly. Final assembly is up to the user. Installation onto

the particular parts, screws and nuts required for each step are packaged in the same bag as the parts. Be careful when opening each

bag as not to lose any hardware. Care has been taken in filling and packing of each bag however mistakes do happen. If there is a parts

shortage or missing hardware please contact us at:

.launam eht fo snoitces eht ot dnopserroc hcihw ylbmessa fo esae rof deggab era strap tnenopmoc rojam eht lla ,tik eht gninepo nopU

Century Helicopter Products

1740-C Junction Ave.

San Jose, CA. 95112

www.centuryheli.com

Page 2

Page 3

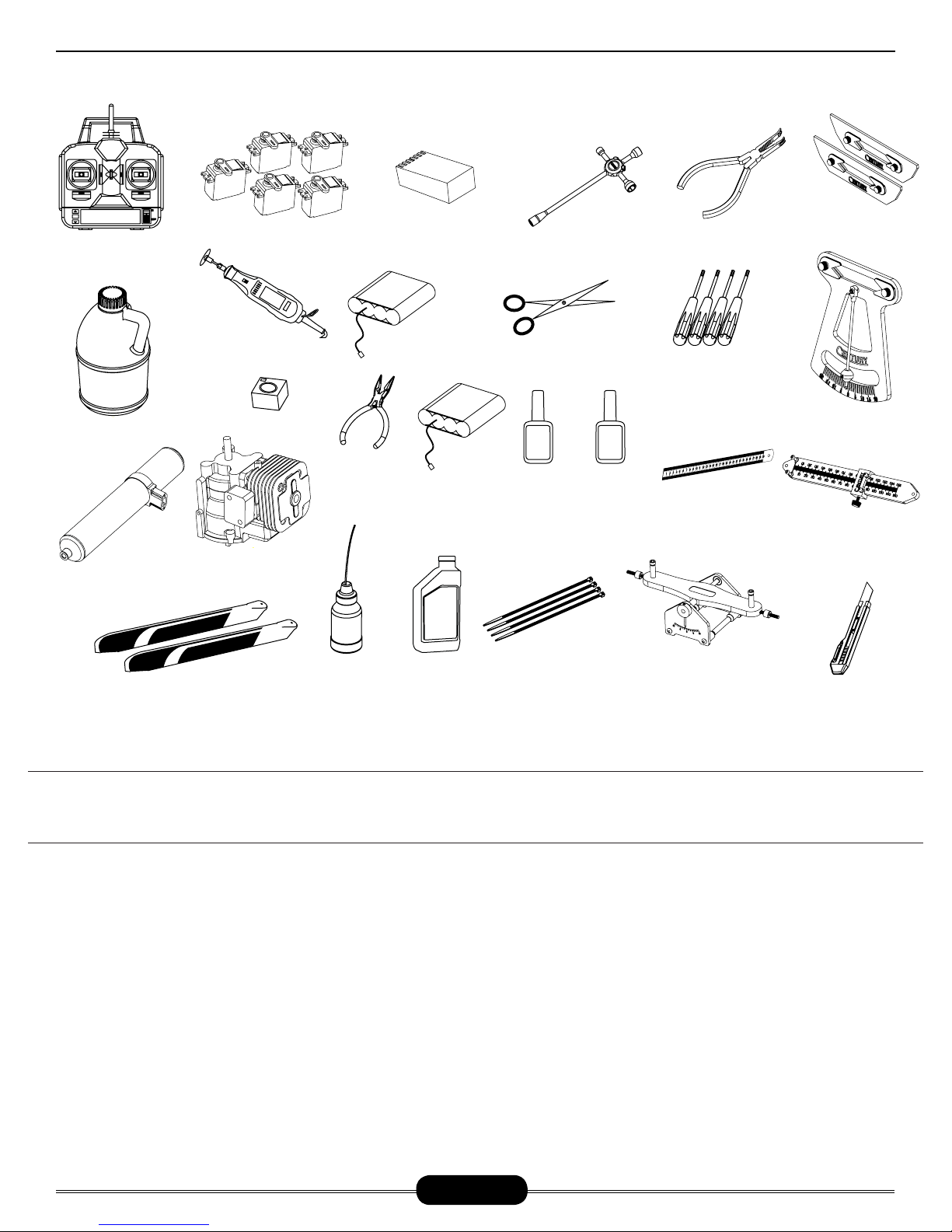

REQUIRED ITEMS

Radikal Gasser

6 CHANNEL

CCPM TRANSMITTER

(MINIMUM)

1.000

87 TO 92 OCTANE

GASOLINE

CN3070

20cc TORPEDO

GASSER TUNED

MUFFLER

600MM TO 660MM

MAIN ROTOR BLADES

DREMEL TOOL

OR SIMILAR

GYRO

1.000

20CC ZENOAH

GASOLINE ENGINE

SERVOS X 5

OIL/GREASE

NEEDLE NOSE

PLIERS

SYNTHETIC

6 CHANNEL RECEIVER

(MINIMUM)

RECEIVER BATTERY

ELECTRONIC

I G N I T I O N

BATTERY

2-STROKE

MOTOR OIL

CN2031

4-WAY WRENCH

HOBBY SCISSORS

SLOW &

Medium CA

GLUE

ZIP TIES

HEX DRIVERS

1.5, 2.0, 2.5, 3.0, 4.0, 5.0

Medium

(Medium)

THREAD-

LOCK

METRIC RULER OR

SIMILAR MEASURING

ACCURATECH BLADE BAL-

ANCER V.2

CN2034A

BALL LINK PLIERS

CN2017

DEVICE

CN2051

CN2050

PADDLE GAUGE

CN2027

G-FORCE PITCH GAUGE

CN2255

CONTROL ROD

SETUP GAUGE

HOBBY KNIFE

Warranty Period

Century Helicopter Products warranties that the Products purchased (the “Product”) will be free from defects in materials and workmanship 30 days from the date of purchase by the Purchaser.

Limited Warranty

(a) This warranty is limited to the original customer (“Purchaser”) and is not transferable. REPAIR OR REPLACEMENT AS PROVIDED

UNDER THIS W ARRANTY I S THE EXCLUSIVE R EMEDY OF T HE PURCHASER. This warranty covers only those P roducts purchased

from an authorized Century Helicopter Products dealer. Third party transactions are not covered by this warranty. Proof of purchase is

required for warranty claims. Further, Century Helicopter Products reserves the right to change or modify this warranty without notice

and disclaims all other warranties, express or implied.

(b) Limitations- CENTURY HELICOPTER PRODUCT MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT NONINFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF THE PRODUCT. THE PURCHASER ACKNOWLEDGES THAT THEY ALONE HAVE DETERMINED THAT THE PRODUCT WILL SUITABLY MEET THE REQUIREMENTS OF THE PURCHASER’S

INTENDED USE.

(c) Purchaser Remedy- Century Helicopter Products’s sole obligation hereunder shall be t hat Century Helicopter Products will, at its

option, (i) repair or (ii) replace, any Product determined by Century Helicopter Products to be defective. In the event of a defect, these

are the Purchaser’s e xclusive remedies. Century Helicopter Products reserves the right to inspect any and a ll equipment involved in

a warranty claim. Repair or replacement decisions are at the sole discretion of Century Helicopter Products. This warranty does not

cover cosmetic damage or damage due to acts of God, accident, misuse, abuse, negligence, commercial use, or modification of or to any

part of the Product. This warranty does not cover damage due to improper installation, operation, maintenance, or attempted repair by

anyone other than Century Helicopter Products. Return of any goods by Purchaser must be approved by Century Helicopter Product s

before shipment.

Page 3

Page 4

AMA RULES & REGULATIONS

Radikal Gasser

General

1) I will not fly my model aircraft in sanctioned events, air shows or model flying demonstrations until it has been proven to be airworthy by having been previously, successfully flight tested.

2) I will not fly my model higher than approximately 400 feet within 3 miles of an airport without notifying the airport operator. I will

give right-of-way and avoid flying in the proximity of full-scale aircraft. Where necessary, an observer shall be utilized to supervise flying

to avoid having models fly in the proximity of full-scale aircraft.

3) Where established, I will abide by the safety rules for the flying site I use, and I will not willfully or deliberately fly my models in a

careless, reckless and/or dangerous manner.

4) The maximum takeoff weight of a model is 55 pounds, except models flown under Experimental Aircraft rules.

5) I will not fly my model unless it is identified with my name and address or AMA number on or in the model. (This does not apply to

models while being flown indoors.)

6) I will not operate models with metal-bladed propellers or with gaseous boosts, in which gases other than air enter their internal

combustion engine(s); nor will I operate models with extremely hazardous fuels such as those containing tetranitromethane or hydrazine.

Radio Control

1) I will have completed a successful radio equipment ground range check before the first flight of a new or repaired model.

2) I will not fly my model aircraft in the presence of spectators until I become a qualified flier, unless assisted by an experienced helper.

3) At all flying sites a straight or curved line(s) must be established in front of which all flying takes place with the other side for

spectators. Only personnel involved with flying the aircraft are allowed at or in front of the flight line. Intentional flying behind the flight

line is prohibited.

4) I will operate my model using only radio control frequencies currently allowed by the Federal Communications Commission. (Only

properly licensed Amateurs are authorized to operate equipment on Amateur Band frequencies.)

5) Flying sites separated by three miles or more are considered safe from site-to site interference, even when both sites use the

same frequencies. Any circumstances under three miles separation require a frequency management arrangement, which may be

either an allocation of specific frequencies for each site or testing to determine that freedom from interference exists. Allocation

plans or interference test reports shall be signed by the parties involved and provided to AMA Headquarters. Documents of agreement and reports may exist between

(1) Two or more AMA Chartered Clubs, (2) AMA clubs and individual AMA members not associated with AMA Clubs, or (3) two or

more individual AMA members.

6) For Combat, distance between combat engagement line and spectator line will be 500 feet per cubic inch of engine displacement.

(Example: .40 engine = 200 feet.); electric motors will be based on equivalent combustion engine size. Additional safety requirements

will be per the RC Combat section of the current Competition Regulations.

7) At air shows or model flying demonstrations, a single straight line must be established, one side of which is for flying, with the

other side for spectators.

8) With the exception of events flown under AMA Competition rules, after launch, except for pilots or helpers being used, no powered

model may be flown closer than 25 feet to any person.

9) Under no circumstances may a pilot or other person touch a powered model in flight.

Page 4

Page 5

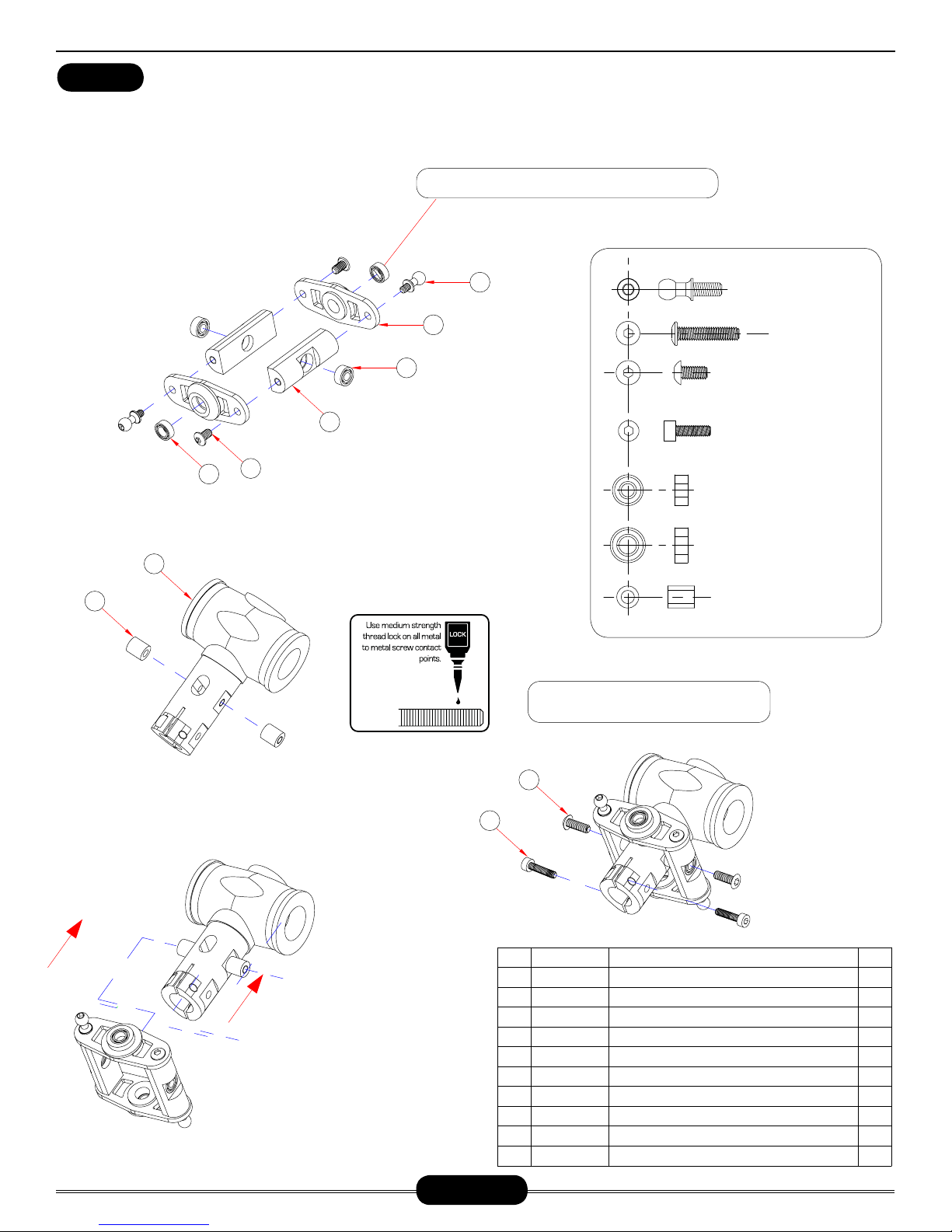

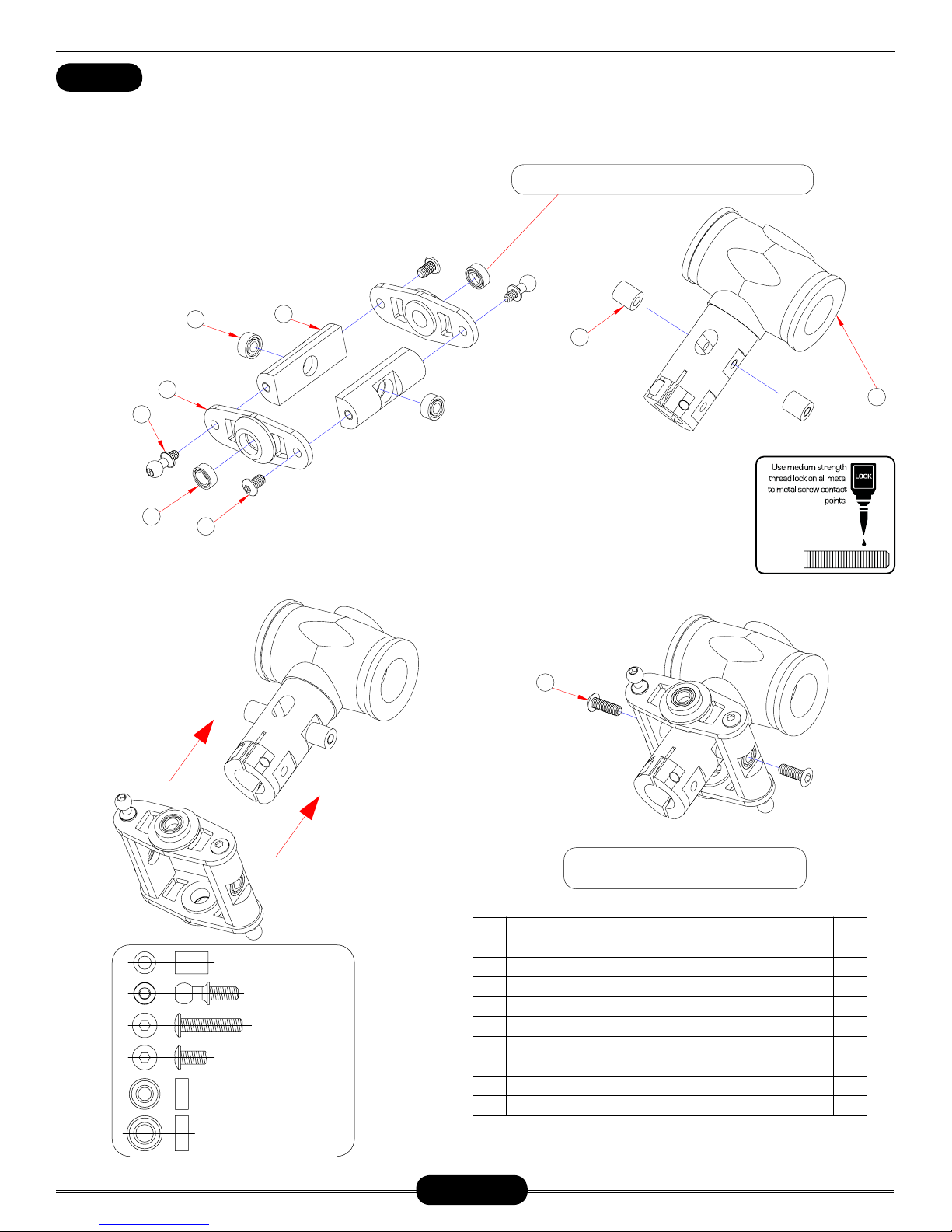

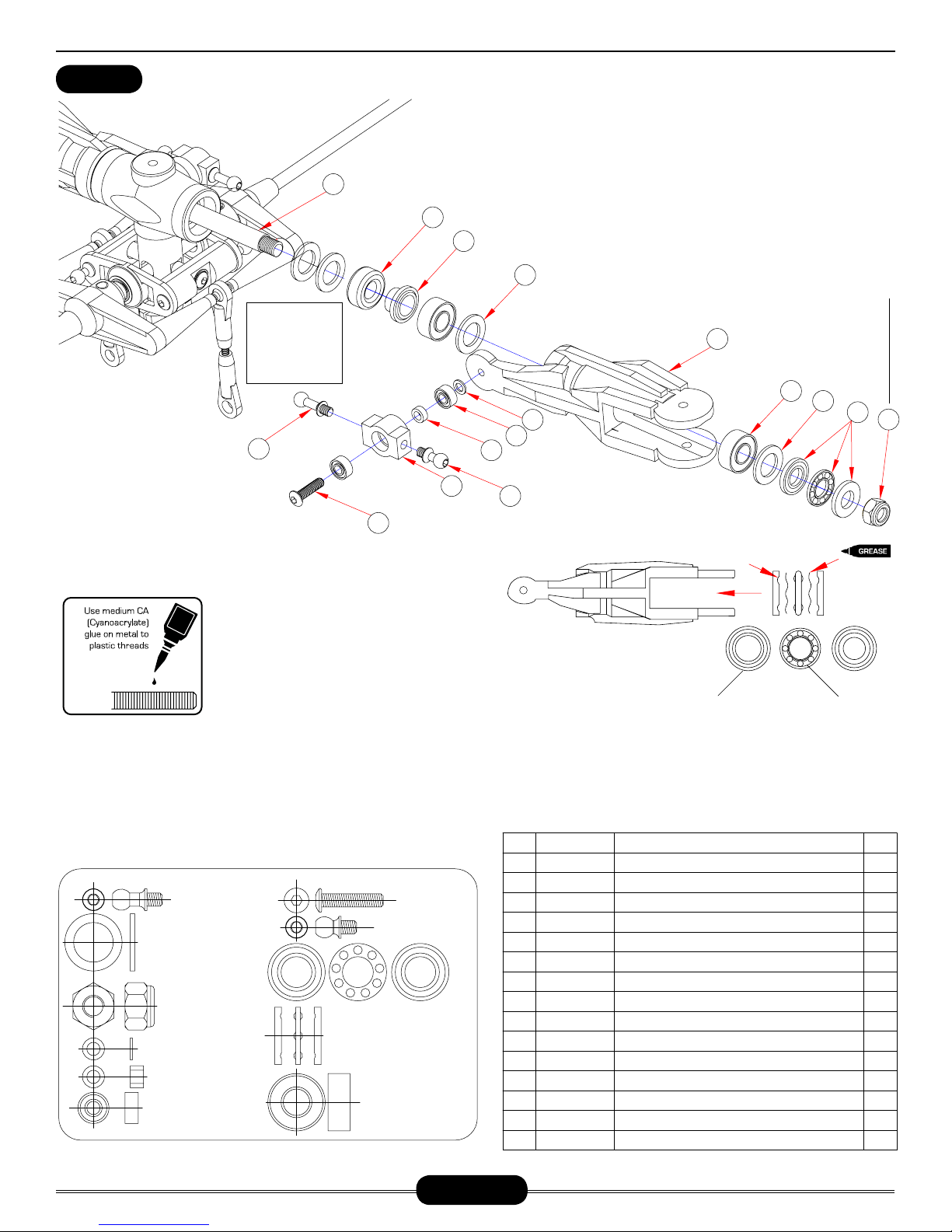

HEAD ASSEMBLY (HD VERSION)

Radikal Gasser

BAG 1

Do not open all the bags prior to starting assembly. Open the bags step by step as you go through the instruction manual. The

components are bagged to make assembly easier. The next few pages will pertain to the assembly of the head. Please follow

the instructions based on the head type you own. Make sure to apply threadlock to any screws going into metal.

Take special care when pressing in these bearings. Do not

Insert one ball bearing into each bearing cup and insert into

the offset plate. Apply one small drop of slow cyanoacrylate

glue (Slow CA) to the joint between the backside of the

bearing cup and the offset plate. Insert one ball

bearing into each tie bar. Using an available

M3 socket cap screw, form threads

into both ends of the tie

bars. Insert one

M3x6 button head

screw through

the right side

hole of the

offset plate

and thread

into one

tie bar.

4

bar bearing, slide one steel spacer

and carefully apply Medium threadlock to

5

6

the exposed threads and insert into the right

side of the head block. Do not overtighten. Repeat

for the second sub-assembly. Once complete apply

a small amount of slow cyanoacrylate glue and insert one

CNLR1020 special long thread ball into each offset plate to com-

plete the assembly.

7

press in on the inner sleeve of the bearing

1

M a k e

t w o

2

i d e n t i c a l

s u b a s s e m -

blies . Note that

3

the bearing cups face

outwards from the head

block. Insert one M3x14 but-

ton head screw through the tie

CNLR1017 L=6.5MM

CNM3X14BHCS

CNM3X6BHCS

CNM2.5X8CS

CNBB0730

CNBB0840

8

Do not secure all the screws until lining up the

components in the following steps.

HI3167G

9

10

No.

1

2

3

4

5

6

7

8

9

10

Part #

CNLR1017

HI3167B

CNBB0730

HI3167G

CNM3X6BHCS

CNBB0840

HI6160A

HI3167G

CNM3X14BHCS

CNM2.5X8CS

Stainless Ball, 3mm Thread, Medium(M3球头螺丝)

Seesaw Offset Plates( 平衡杆固定片)

3x7x3 Ball Bearing( 轴承)

Seesaw Tie Bar Set( 平衡杆控制臂)

M3x6 Button Head Cap Screws( 伞头螺丝)

4x8x3 Ball Bearing( 轴承)

NX Rotor Head Yoke(主旋翼中心座)

3x5x6 Seesaw Tie Bar Set( 铁套)

M3x14 Button Head Cap Screws( 伞头螺丝)

M2.5x8 Cap Screws( 杯头螺丝)

Description

Qty

2

2

2

2

2

2

1

2

2

2

Page 5

Page 6

HEAD ASSEMBLY (LT VERSION)

Radikal Gasser

BAG 1

Do not open all the bags prior to starting assembly. Open the bags step by step as you go through the instruction manual. The

components are bagged to make assembly easier. The next few pages will pertain to the assembly of the head. Please follow

the instructions based on the head type you own. Make sure to apply threadlock to any screws going into metal.

Take special care when pressing in these bearings. Do not

Insert one ball bearing into each bearing cup and insert into

the offset plate. Apply one small drop of slow cyanoacrylate

glue (Slow CA) to the joint between the backside of the

bearing cup and the offset plate. Insert one ball

bearing into each tie bar. Using an available

M3 socket cap screw, form threads

into both ends of the tie

bars. Insert one

M3x6 button head

5

6

screw through

the right side

hole of the

offset plate

and thread

into one

4

3

tie bar.

bearing, slide one steel spacer and care-

fully apply Medium threadlock to the exposed

2

1

threads and insert into the right side of the head

block. Do not overtighten. Repeat for the second

sub-assembly. Once complete apply a small amount of

slow cyanoacrylate glue and insert one CNLR1020 special

long thread ball into each offset plate to complete the assembly.

face outwards from the head

block. Insert one M3x14 but-

ton head screw through the tie bar

press in on the inner sleeve of the bearing

7

Make two identical

subassemblies . Note

that the bearing cups

9

3x5x7.5

CNM3x6BHCS

CNBB37

CNBB48

CNLR1017 L=6.5MM

CNM3x14BHCS

No.

CNM3x6BHCS

1

CNBB48

2

CNLR1017

3

HI3167B

4

CNBB0730

5

HI3167G

6

HI3167S

7

CNM3x14BHCS

8

HI6160A

9

Part #

8

Do not secure all the screws until lining up the

components in the following steps.

Description

Button Head Screw( 圆头螺丝)M3x6

Bearing(滚珠轴承)4x8x3

Stainless Ball, 3mm Thread, Medium(M3球头螺丝)

Seesaw Offset Plate(平衡杆控制器)

Bearing(滚珠轴承)3x7x3

Seesaw Offset Plate 2(平衡杆控制器2)

3x5x7.5 Seesaw Tie Bar Set(

Button Head Screw( 圆头内六角螺丝)M3x14

Head Block(主旋翼中心座)

铁套)

Qty

2

2

2

2

2

2

2

2

1

Page 6

Page 7

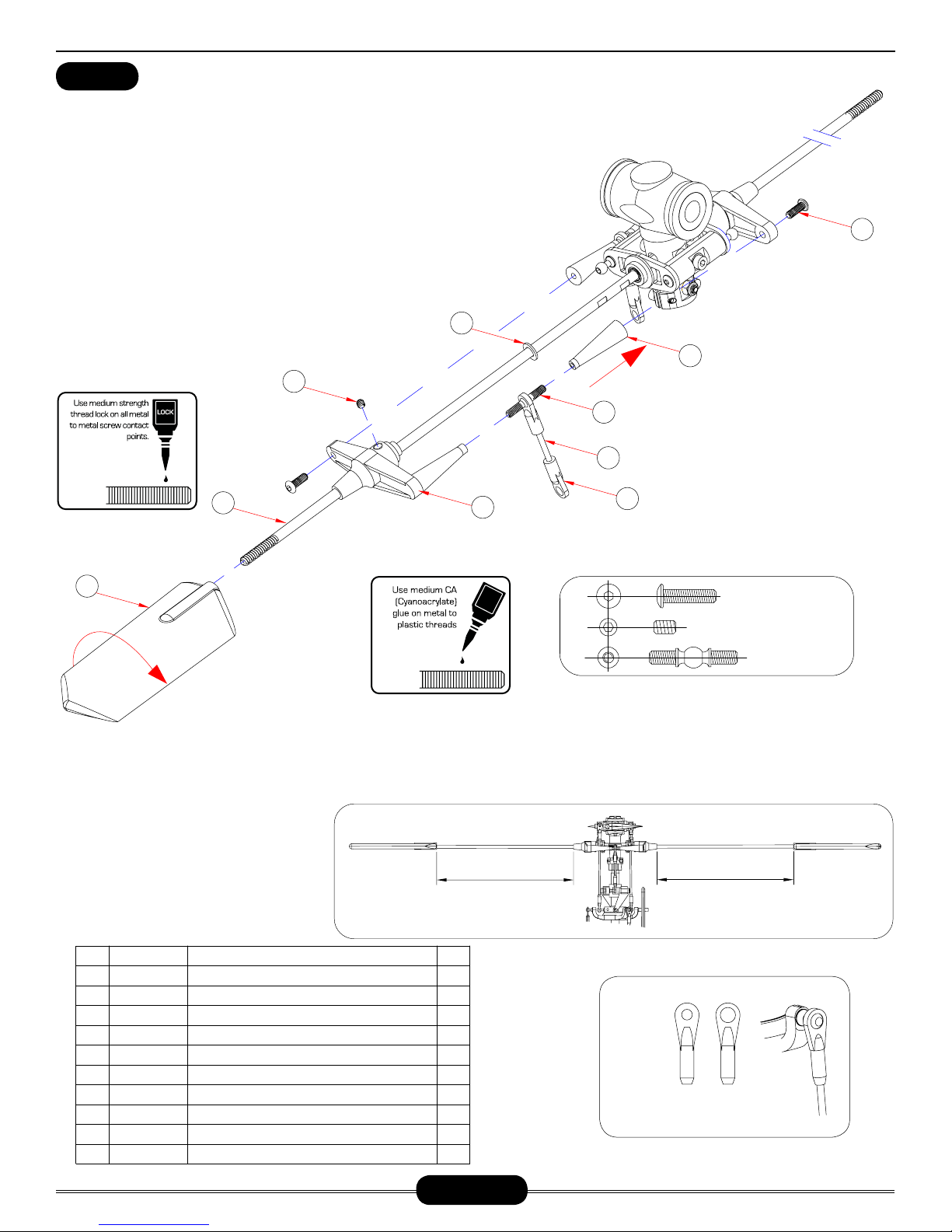

HEAD ASSEMBLY (HD VERSION)

BAG 1

Pushrod assembly (parts 2 through 4) is already assembled but check that the length is

actually 43mm (center to center). As the pushrods are built and installed they should be

checked for tightness. Press one ball link onto each double studded steel ball, making sure

that pressure is applied from the side of the ball link with circle mark. While holding one flybar control arm, apply a small amount of slow cyanoacrylate glue and thread one end of the

double studded steel ball into each standoff. When it becomes difficult to turn with fingers,

apply slow CA to the threads and start screwing in the tapered control arm stand-off on

the other end of the ball. Slide and center the flybar through the head assembly. Carefully look at the flybar control arm assemblies from the previous step and notice

that when installed correctly, the securing set screw is on top. Insert one

M4x6x0.5 micro washer #CNLR1006 against each bearing then slide

the control arm halves onto each side, so that they match together and the set screw remains on top. Insert one M3x12 button head socket screw to secure the opposite standoff.

Hold the tapered standoff using pliers while tightening the screw as the rotor head

rotates clockwise.

9

8

10

1

Radikal Gasser

6

Apply a small amount of cya-

noacrylate glue to the special

5

4

All ball links are molded to be in-

3

stalled in only one direction. Look

carefully at the hole for the ball

as that side is 1mm larger .

2

long thread ball.

7

C

A

CNM3X12BHCS

CNM4X5SS

HW3176C

Loosely tighten the M4x5 set screws into the round aluminum inserts aligned with the flat spots on the flybar. Tighten both set screws, one

at a time using Medium threadlock. Make a pencil mark 5mm past the threads on both ends of the flybar. Thread the flybar paddles onto the

flybar until the mark is reached and align the paddles parallel. Again using the ruler, rotate one paddle or the other to get equal distances while

remembering the leading edge of the paddles turn clockwise.

No.

HI3176C

1

HI6145

2

HW6192

3

4

HI3176C

5

HI3176C

CNM3X12BHCS

6

HI6179B

7

HW3173A

8

CNM4X5SS

9

CNLR1006

10

Part #

Description

Flybar Arms(

Ball Link Set(球头连接头)

Pushrod Set( 拉杆)

Flybar Arms(

Flybar Arms(

M3x12 Button Head Cap Screws( 圆头螺丝)

Flybar Paddles( 平衡翼)

4mm Flybar 500mm(

M4x5 Socket Head Set Screw( 无头内六角螺丝)

M4X6X0.5 Washer( 平面垫片)

平衡翼控制臂)

球头双牙螺丝)

平衡翼控制臂)

平衡杆)

Make sure the distance on

both sides are equal

Qty

2

2

2

2

2

2

2

1

2

2

NOTICE SIZE OF HOLES ON BALL LINKS

THE SIDE WITH THE SMALLER HOLE

SHOULD FACE OUTWARDS

Make sure the distance on

both sides are equal

Page 7

Page 8

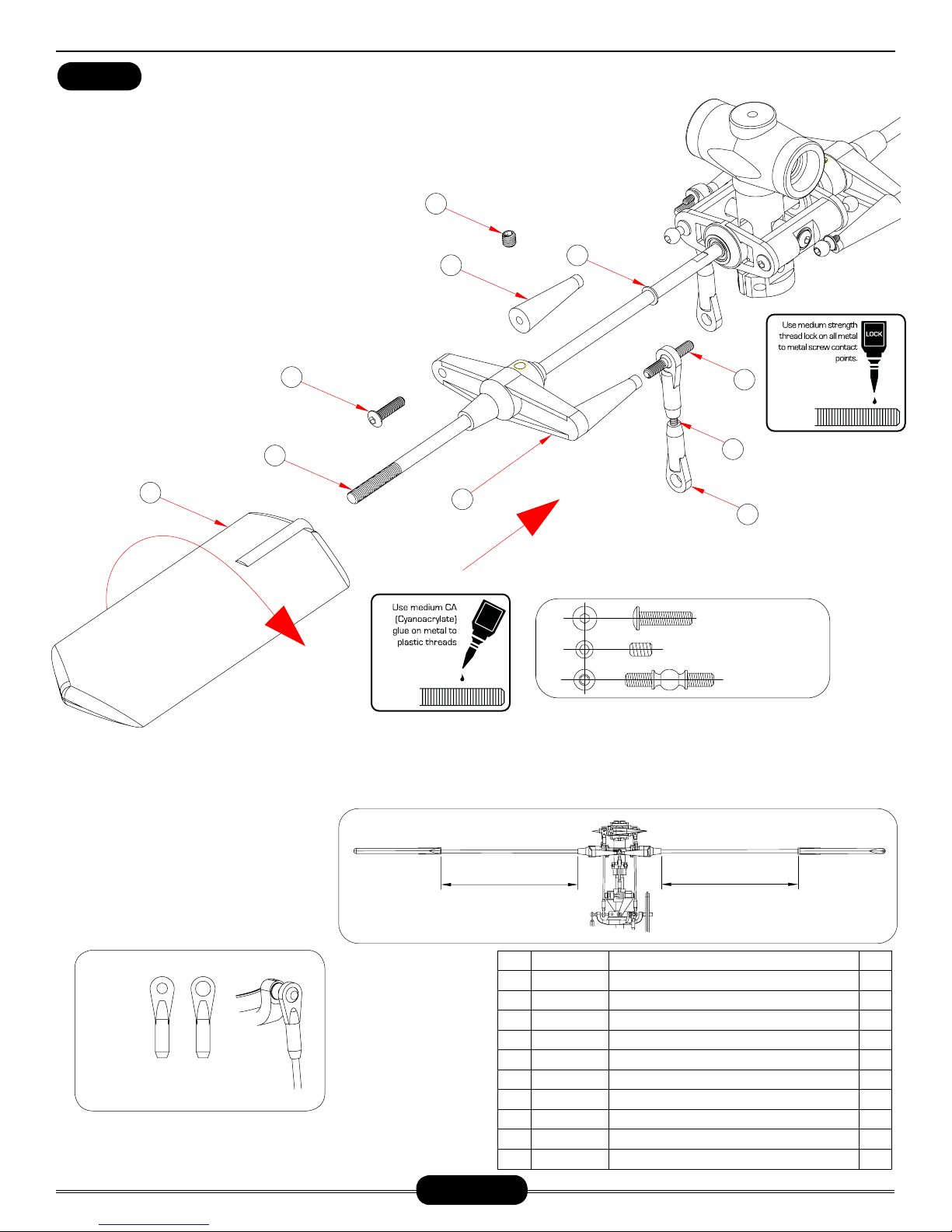

HEAD ASSEMBLY (LT VERSION)

BAG 1

Pushrod assembly (parts 2 through 4) is already assembled but check that the length is

actually 43mm (center to center). As the pushrods are built and installed they should be

checked for tightness. Press one ball link onto each double studded steel ball, making sure

that pressure is applied from the side of the ball link with circle mark. While holding one

flybar control arm, apply a small amount of slow cyanoacrylate glue and thread one end of the double studded steel ball

into each standoff. When it becomes difficult to turn with fingers, apply slow CA to the threads and start screwing in the

tapered control arm stand-off on the other end of the ball.

Slide and center the flybar through the head assembly. Carefully look at the flybar control arm assemblies from the previous step and notice that when installed correctly, the securing set screw is on top. Insert one M4x6x0.5 micro washer

#CNLR1006 against each bearing then slide the control

arm halves onto each side, so that

they match together and the set

screw remains on top. Insert one

M3x12 button head socket screw

8

to secure the opposite standoff.

Hold the tapered standoff using

pliers while tightening the screw

as the rotor head rotates clock-

9

wise.

10

6

7

1

Radikal Gasser

5

4

3

2

C

A

CNM3X12BHCS

CNM4X5SS

HW3176C

Loosely tighten the M4x5 set screws into the round aluminum inserts aligned with the flat spots on the flybar. Tighten both set screws, one

at a time using Medium threadlock. Make a pencil mark 5mm past the threads on both ends of the flybar. Thread the flybar paddles onto the

flybar until the mark is reached and align the paddles parallel. Again using the ruler, rotate one paddle or the other to get equal distances while

remembering the leading edge of the paddles turn clockwise.

NOTICE SIZE OF HOLES ON BALL LINKS

THE SIDE WITH THE SMALLER HOLE

SHOULD FACE OUTWARDS

Make sure the distance on

both sides are equal

No.

HI3167C

1

HI6145

2

Hw6192

3

HI3167C

4

CNLR1006

5

CNM4X5SS

6

HI3167C

7

CNM3X12BHCS

8

HW6173A

9

HI6179B

10

Part #

Seesaw Tie Bars( 稳定翼控制臂)

Ball Link Set(26 Long,4 Short)( 球头连接头)

Pushkod Set(拉杆)

M3 Two-tooth Screw Ball( M3球头双牙螺丝)

Washer 4x6x0.5( 平面垫片)

M4x5 Socket Head Set Screw (无头内六角螺丝)

Seesaw Tie Bars( 平衡杆控制臂)

M3x12 Button Head Cap Screws( 圆头内六角螺丝)

4mm FLYBAR 500mm

Flybar Paddles( 平衡片)

Make sure the distance on

both sides are equal

Description

(平衡杆)

Qty

2

4

2

2

2

2

2

2

1

2

Page 8

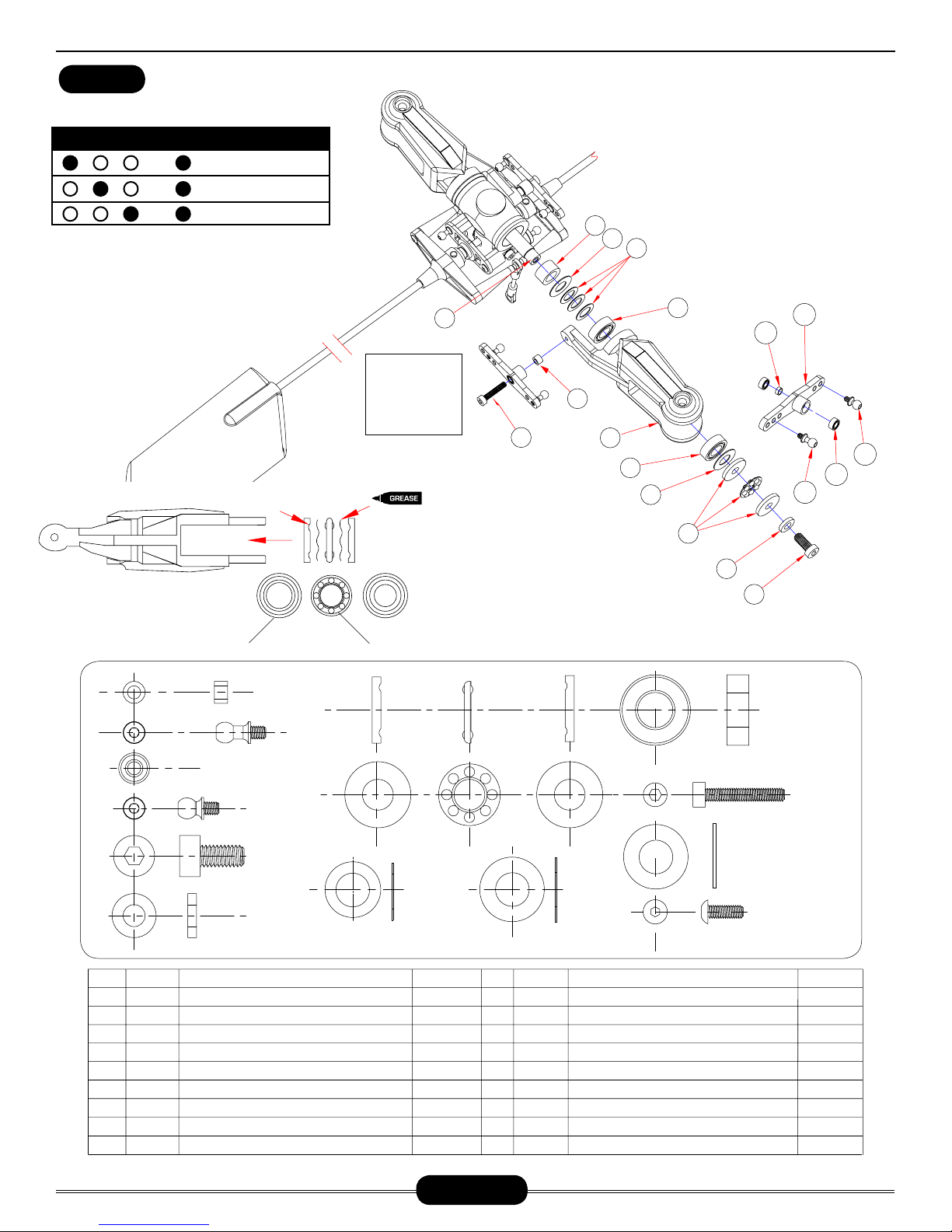

Page 9

HEAD ASSEMBLY (HD VERSION)

BAG 1

BELL MIXER RATIOS STYLE

BELL MIXER RATIOS STYLE

3D1:1.6

1:1.3

1:1

Using an available M3 screw, carefully form the

threads in the blade grip arm. Slide the M3x18

special socket shoulder screw through the bell

mixer arm from the flat side, add one M3x5x3

spacer and apply a drop of Slow Cyanoacrylate

glue or Epoxy glue to the end of the threads

before installing into the blade grip. Tighten the bolt until there is no end to

end movement, but do not

overtighten the bolt as

you can strip out the

hole. Make two assemblies.

THRUST BEARING INSTALLATION GUIDE

SIDE PROFILE - BLADE GRIP

LARGER ID TOWARDS THE GRIP

3D & SPORT

SPORT & FAI

GROOVES INSIDE

RECESSED CREVICE FACES MAIN SHAFT

7

Do not overtighten as you

can strip the

blade grip.

Press one M3x7 flanged ball

bearing into one side followed

by one M3x5 spacer and another

flanged bearing from the opposite side.

If the bearing is tight, lightly sand the bell

mixer and use Red threadlock to bond the

bearing in place. Install the CNLR1014 short

steel ball into the single hole side of the bell mixer

and install the CNLR1020 medium steel ball using

Blue threadlock. Install the medium steel ball according to the table to suit your flying preference. Use the

center hole for sport flying. Make two assemblies.

Radikal Gasser

There are two types of dampeners provided. The hard black plastic dampeners

(HI6520A) should only be used for hard 3D flying. Press in the head dampers

into the rotor head block. Lubricate the inside surface of each damper with light

oil. Press one M8x16 ball bearing into both ends of each main rotor blade grip.

Slide one M14 thrust washer against the bearing closest

to the main rotor blade. Make sure that the bearing and

the thrust washer are properly seated into the deep

end of the blade grip. If necessary use a socket

that matches the outside diameter of the

bearing and press into position. The 8x13

washer/spacer (#15) is used to adjust

tightness of the head. If the head is

binding after tightening the M5

bolt (#6), remove one or more

spacers from each side. Make

two assemblies.

16

1

2

9

8

7

6

3

5

4

13

12

17

14

11

15

10

HW6205

CNLR1020

CNBB0730

CNLR1014

CNM5X10CS

HW6182

8X13

HW6180A

No No.

Part # Part #

1

2

3

4

5

6

7

8

9

HI6189

HW6205

CNLR1020

CNBB0730

CNLR1014

CNM5X10CS

HW6180A

CNBB715T

HW6183

Enhanced Metal Bell Mixer Set

A

M3x5x3 Spacer

Stainless Ball, 3mm Thread, Medium

3x7x3 Ball Bearing

Stainless Ball, 3mm Thread, Short

M5x10 Socket Head Cap Screws

M5x10x1 Feathering Shaft with Center Ball

7x15x5 Blade Grip Thrust Ball Bearing

M5x8x15 Head Shim Set

Descriptio Description n

(垫圈)

(轴承)

(主桨控制臂)

(有头内六角螺丝)

(平面垫片)

(M3球头螺丝)

(M3球头螺丝)

(垫圈)

(止推轴承)

2

2

2

4

2

2

2

2

2

10

11

12

13

14

15

16

17

17

CNBB816

HI6184A

HW6205

CNM3x18CS

HW6182

HW6182

CNBB816

HI6181B

HI6181A

CNBB715T

HW6182

8X15

8x16x5 Bearing

NX Main Rotor Blade Grips

M3x5x3 Spacer

M3x18 Socket Head Cap Screws

8x15 Head Shim Set

8x13 Head Shim Set

8x16x5 Bearing

Hard Head Dampeners Black

Standard Head Dampeners Red

(轴承)

(垫圈)

(轴承)

(主旋翼夹片)

(平面垫片)

(平面垫片)

CNBB816

HW6183

M5X8X15

CNM3X6BHCS

(有头内六角螺丝)

M3X18CS

QtQt yy

4

2

2

2

2

6

4

2

2

Page 9

Page 10

HEAD ASSEMBLY (LT VERSION)

Radikal Gasser

BAG 1

Do not overtighten as you

can strip the

blade grip.

Press one M3x7 ball bearing into one side followed by one

M3x5 spacer and another flanged

bearing from the opposite side. Install the

CNLR1014 short steel ball into one side of the

bell mixer and install the CNLR1020 medium steel

ball on the opposite side. Secure using

rylate glue. Make two assemblies.

15

Slow Cyanoac-

Press in the head dampers into the rotor head block. Lubricate the inside surface

of each damper with light oil. Press one M9X13 flat washer into the end of each

blade grip. If necessary use a socket that matches the diameter of the washer

and press into position. Then press in one M7X13 ball bearing into both ends

of each main rotor blade grip. Slide one M9 thrust washer against the bearing closest to the main rotor blade. Make sure that the bearing and the thrust

washer are properly seated into the deep end of the blade grip. If necessary use

8

a socket that matches the outside diameter of the bearing and press into posi-

tion. Torque down on the M5 locknut (#1) until snug making sure the grip

7

still turns without binding. If you tighten down too much, you will crush

6

the thrust bearings. If this happens, you will need to replace the

thrust bearings. Make two assemblies.

3

Do not apply threadlock to

the nylock nut!

5

4

3

9

2

1

10

11

13

12

14

THRUST BEARING INSTALLATION GUIDE

GROOVES INSIDE

C

M3 CNLR1016A

9x13x1

CNM5LOCK

3x5x0.5

3x5x3

CNBB0730

A

Using an available M3 screw, carefully form the

threads in the blade grip arm. Slide the M3x18

button head cap screw through the bell mixer arm

from the flat side, add one M3x5x0.5 micro washer

and apply a drop of Slow Cyanoacrylate glue to the

end of the threads before installing into the blade

grip. Tighten the bolt until there is no end to end

movement, but do not overtighten the bolt as you

can strip out the hole. Make two assemblies.

CNM3x14BHSC

M3 CNLR1014

CNBB1370T

CNBB1360

SIDE PROFILE - BLADE GRIP

LARGER ID TOWARDS THE GRIP

RECESSED CREVICE FACES MAIN SHAFT

Red dampener is used for normal flight #HI6181A. Black

dampeners are used for 3D flight #HI6181B.

No.

CNM5LOCK

1

CNBB1370T

2

CNM9X13FW

3

CNBB1370

4

HI3184

5

HW6180S

6

HI6181B

7

8

HW6180C

CNLR1003

9

10

CNBB0730

11

HW6205

12

CNLR1014

HI3189A

13

14

CNM3x14BHSC

15

CNLR1016A

Part #

M5 Locknut(M5 防松螺母)

Thrust Ball Bearing( 止推轴承)7x13x4.5

Washer(垫片)9x13x1

Bearing(滚珠轴承)7x13x4

Main Rotor Blade Grip(主桨夹片)

Spacer(铝套)

Dampener Rubber(橡胶圈)

7mm Feathering S haft( 横轴)

Washer(垫片)3x5x0.5

Bearing(滚珠轴承)3x7x3

Spacer(铁套)3x5x3

M3 Linkage Ball(M3 球头螺丝牙长3.5mm)

Bell Mixer Arm( 混控臂)

Buton Head Socket Screw( 圆头内六角螺丝)M3x14

M3 Long Linkage Ball(M3 球头螺丝球头12mm)

Description

Qty

2

2

8

4

2

2

2

1

2

4

2

2

2

2

2

Page 10

Page 11

HEAD ASSEMBLY (HD VERSION)

BAG 1

Slide the washout guide and the rotor head onto

the main shaft. Insert the M4x22 shoulder socket

cap screw through the rotor head hub and main

shaft and secure with one M4 locknut, torque

down the screw. Apply Medium threadlock to the

M2.5x8 socket cap screws and tighten into the

bottom of the rotor head block to clamp against

the main shaft, do not over torque. Position the

washout guide against the collar and align one

hole to the vertical slot in the rotor head. Apply

Medium threadlock to the M3x4 set screws and

evenly tighten set screws in place.

5

6

Radikal Gasser

Do not apply CA or

thread lock to lock nut!

4

M3x4

M4防松螺母

3

2

1

Do not over-tighten!

M2.5x8

M4x22

No.

Part #

1

HI6153

CNM3x4SS

2

3

HW6053A

4

CNM4LOCK

CNM4x22CS

5

CNM2.5x8CS

6

Page 11

Description

Aluminum Washout Guide( 剪型臂导柱)

M3x4 Socket Head Set Screw( 无头内六角螺丝)

10mm Main Shaft( 主轴)

M4 Lock-nut(M4 螺母)

M4x22 Cap Screws( 杯头内六角螺丝)

Cap Screw(杯头内六角螺丝)M2.5x8

Qty

1

2

1

1

1

2

Page 12

HEAD ASSEMBLY (LT VERSION)

BAG 1

Slide the washout guide and the rotor head onto

the main shaft. Insert the M3X18 shoulder

socket cap screw through the rotor head

hub and main shaft and secure with one

M3 locknut, torque down the screw. Apply

Medium threadlock to the M2.5x8 socket cap screws and tighten into the bottom of the rotor head block to clamp

against the main shaft, do not overtorque. Position the washout guide

against the collar and align one

hole to the vertical slot in the rotor

head. Apply Medium threadlock to

the M3x4 set screws and evenly

tighten set screws in place.

3

Do not apply CA or

thread lock to lock nut

Radikal Gasser

1

Do not over-tighten!

2

4

6

5

CNM3x4SS

CNM2.5x8CS

CNM3x18CS

CNM3LOCK

Page 12

No.

1

2

3

4

5

6

Part #

CNM2.5x8CS

CNM3x18CS

CNM3LOCK

HW3053B

CNM3x4SS

HI6153

Description

Cap Screw(杯头内六角螺丝)M2.5x8

Cap Screw(杯头内六角螺丝)M3x18

M3 Locknut(防松螺母)

Main Shaft(主旋翼轴)

Set Screw(无头内六角螺丝)M3x4

CNC Washout Guide(剪型臂滑座)

Qty

2

1

1

1

2

1

Page 13

WASHOUT AND SWASHPLATE

Radikal Gasser

BAG 1

1

M3 L=7.8MM CNLR1014

2

3

M3X5X3 HW6205

4

5

7

CNBB0730

6

8

9

10

M10x12x5 HI3152C

M3x5x0.5 CNLR1003

CNM3x16BHCS

M3 L=18MM

Ø2x12

Comes pre-assembled

It is up to you to determine whether this assembly is correct. Please make

sure to check it prior to installation.

No.

HI3152A

1

CNLR1014

2

HW6205

3

CNBB0730

4

HI3152A

5

HI3152A

6

7

HI3152C

CNLR1003

8

9

CNM3x16BHCS

CNLR1014

10

CNLR1021

11

12

HW6146C

Part #

Washout Set (10mm) (

M3 Ball Link(M3球头螺丝)

3x5x3 Bellcrank Spacer(铜套)

3x7x3 Bearing(轴承)

Radius Link w/ Pin(插销)

Radius Link w/ Pin(三角控制臂)

Washout Set (控制臂固定座)

3x5x0.5 Micro Washer(

M3x16 Button Head Cap Screws(

M3 Ball Link(M3球头螺丝)

M3 Ball Link L=18MM(M3球头螺丝)

Radikal Swashplate(十字盘)

Description

摆臂)

)

垫圈

圆头内六角螺丝

Qty

2

2

2

4

2

2

1

2

)

2

4

2

1

Starting with the inside race, apply Medium threadlock to the silver steel balls and attach them across

from each other. The balls need to be started by

hand then tightened with an M2.0 hex key. Insert the

other two steel balls across from each other using

Medium threadlock. Install three long steel balls on

the outer arms using Slow Cyanoacrylate glue.

10

Page 13

11

12

Page 14

WASHOUT AND SWASHPLATE (LT VERSION)

BAG 1

Radikal Gasser

3

4

8

2

1

10

11

12

No.

HI3152A

1

CNLR1014

2

HW6205

3

CNBB0730

4

HI3152A

5

HI3152A

6

7

HI3152C

CNLR1003

8

9

CNM3x16BHCS

CNLR1014

10

CNLR1021

11

12

HW6146C

Part #

5

6

9

Comes pre-assembled

It is up to you to determine whether this assembly is correct. Please make sure to check it

prior to installation.

Starting with the inside race, apply Medium threadlock to the silver steel balls and attach

them across from each other. The balls need to be started by hand then tightened with an

M2.0 hex key. Insert the other two steel balls across from each other using Medium threadlock. Install three long steel balls on the outer arms using Slow Cyanoacrylate glue.

M3 L=7.8MM CNLR1014

M3X5X3 HW6205

Washout Set (10mm) (

M3 Ball Link(M3球头螺丝)

3x5x3 Bellcrank Spacer(铜套)

3x7x3 Bearing(轴承)

Radius Link w/ Pin(插销)

Radius Link w/ Pin(三角控制臂)

Washout Set (控制臂固定座)

3x5x0.5 Micro Washer(

M3x16 Button Head Cap Screws(

M3 Ball Link(M3球头螺丝)

M3 Ball Link L=18MM(M3球头螺丝)

Radikal Swashplate(十字盘)

Description

摆臂)

)

垫圈

圆头内六角螺丝

Qty

2

2

2

4

2

2

1

2

)

2

4

2

1

CNBB0730

M10x12x5 HI3152C

M3x5x0.5 CNLR1003

CNM3x16BHCS

M3 L=18MM

Ø2x12

7

Page 14

Page 15

HEAD PUSHROD LENGTHS (HD VERSION)

BAG 1

Radikal Gasser

A

25.5

14

1

2

3

B

4

C

5

HELPFUL TOOL:

A

PART# CN2219A: BALL LINK

43

25

B

DRAWN TO A SCALE OF

1-TO-1. YOU CAN MATCH

YOUR LINKS UP TO THIS

PAGE FOR PROPER MEASUREMENTS.

EASY DRIVER

NOTICE SIZE OF HOLES ON BALL LINKS

95

75

C

HEL PFUL TOOL

No.

Part #

1

2

3

4

5

HI6145

HW6192A

HI6145

HW6192A

HW6192A

Ball Link Set (26 Long, 4 Short)(

Pushrod Set( 连杆)

Ball Link Set (26 Long, 4 Short)(球头连接杆 )

Pushrod Set( 连杆)

Pushrod Set( 连杆)

THE SIDE WITH THE SMALLER HOLE

SHOULD FACE OUTWARDS

Description

球头连接杆

)

Qty

4

2

8

2

2

PART# CN2255: CONTROL ROD SETUP GAUGE

Page 15

Page 16

HEAD PUSHROD LENGTHS (LT VERSION)

BAG 1

NOTICE SIZE OF HOLES ON BALL LINKS

THE SIDE WITH THE SMALLER HOLE

SHOULD FACE OUTWARDS

25

14

Radikal Gasser

43

5

4

A

HELPFUL TOOL:

PART# CN2219A: BALL LINK

EASY DRIVER

HEL PFUL TOOL

DRAWN TO A SCALE OF

1-TO-1. YOU CAN MATCH

YOUR LINKS UP TO THIS

PAGE FOR PROPER MEASUREMENTS.

25

94

75

C

3

2

1

B

PART# CN2255: CONTROL ROD SETUP GAUGE

Page 16

No.

1

2

3

4

5

Part #

HI6145

HW3192A

HW6192

HI6145

HW6192

Description

Ball Link(塑胶球头连接头)

Pushrod(连杆)L=80MM

Pushrod(连杆)L=25MM

Short Ball Link( 短塑胶球头连接头)

Pushrod(连杆)L=14MM

Qty

8

2

2

4

2

Page 17

SKELETAL SUPPORT BRACES

This bearing is already pressed

6

into the bearing block.

5

Radikal Gasser

BAG 2

4

9

COMES

PRE-ASSEMBLED

3

8

7

10

11

2

1

CNM2.5x6FHCS

CNM3x10FHCS

CNM3x12BHCS

Ø2X24

CNBB1022

Page 17

12

No.

Part #

1

HW6117G20

CNM3x10FHCS

2

HW6119

3

HW6042G

4

5

CNM3x12BHCS

CNBB1022

6

HI6032G

7

HI6032G

8

9

HI6032G

10

CNM2.5x6FHCS

HI6113

11

HW6113S

12

Landing Gear Frame( 引擎座底板)

Flush Head Cap Screws( 斜头内六角螺丝)M3x10

Box Frame Support( 机身加强支架)

Lower Main Shaft Bearing Block(主轴下轴承座)

Button Head Cap Screw( 圆头内六角螺丝)M3x12

Bearing(滚珠轴承

A-Arm Base(A 型控制臂座

Pin(插销)Ø2x24

A-Arm(A型控制臂)

Flush Head Cap Screws( 斜头内六角螺丝

Electronics Plate(电子点火固定板

Aluminum Post( 铝柱)

If you have carbon fiber frames, just add a “C” to the end of the frame

part number.

Description

) 10X22X5

)

Qty

1

2

2

1

2

1

1

1

1

)M2.5x6

)

2

1

1

Page 18

REAR SIDEFRAME (LEFT)

BAG 2

Radikal Gasser

Flanged bearing is already

pressed into frames. Make sure

the flange is facing inwards.

This bearing is already pressed

into the bearing block.

3

4

Dry fit the electronics tray built from

the previous page into the left rear

sideframe prior to mounting onto

the skeletal support frame assembly.

Once done, install the M3x8 button

head cap screws as shown. Apply

medium threadlock to all the screws.

1

5

6

2

CNBB1019

CNM3x8BHCS

No.

1

2

3

4

5

6

Part #

HI6116L

CNM3x8BHCS

CNBB1019

HW6042GU

CNM3x6BHCS

CNBB1019

Main Frames( 左右后侧板)

Button Head Cap Screw( 圆头内六角螺丝)M3x8

Bearing(滚珠轴承)10x19x5

Upper Bearing Block( 主轴上轴承座)

Button Head Cap Screw( 圆头内六角螺丝)M3x6

Bearing(滚珠轴承)10x19x5

Description

If you have carbon fiber frames, just add a “C” to the end of the frame

part number.

Page 18

Qty

2

8

2

1

1

1

Page 19

FUEL TANK

BAG 2

Pay close attention when assembling the fuel tank.

The vent tube must be bent and facing upwards when

installed into the rubber stopper. There are 3 holes

on the rubber stopper but notice only 2 are through

holes. Cut the fuel line and attach the clunk to the

line. Then attach the fuel line to the short brass tube.

When cutting the fuel line, make sure you have enough

slack in the fuel line so the clunk can reach all corners

of the fuel tank. After installing the shorter brass tube

with the fuel line, install the vent tube. Make sure the

vent tube is positioned to point upwards in the fuel

tank. Once you have everything positioned, slowly turn

the M3.5x24 Phillips screw so that you barely grab

the end of the small cap (#4). Once you insert the

fuel tubing assembly into the tank, it will be very difficult to get this small cap out if you happen to drop

it within the fuel tank. Making sure you still have the

small cap (#4) attached to the fuel tubing assembly,

push the fuel tubing assembly into the tank and start

tightening the Phillips screw. This will pull the small

cap (#4) closer to the large cap (#2) and expand the

rubber stopper. Once tightened, gently tug on the assembly to make sure it is properly installed. It should

not come out of the fuel tank.

Bend one of the longer brass tubes into

this shape. This will

be the vent tube.

Radikal Gasser

9

7

8

6

5

4

3

CNM3.5x24ST

No.

1

2

3

4

5

6

7

8

9

Page 19

1

Part #

HI6139

HI6139

HI6139

HI6139

HI6139

HI6139

HI6139

HI6139

HI6139

2

HI6139A: Fuel Tank Fittings Set Only

Description

Tapping Screw( 十字紧固螺丝)M3.5x24

Large Cap(油箱盖)

Rubber Stoper( 油箱塞)

Small Cap(油箱塞固定座)

Long Tube-straight( 长直铜油管)

Pickup Tube-straight(短直铜油管)

Fuel Tubing( 塑胶油管)

Fuel Tank Set( 吸油嘴)

Fuel Tank(油箱)

Qty

1

1

1

1

1

1

1

1

1

Page 20

REAR SIDEFRAME (RIGHT)

BAG 2

12

When installing the elevator bellcrank, make sure to apply medium

CA to the M3x12 button head cap screw.

Radikal Gasser

2

11

8

7

2

3

1

9

5

10

6

Assemble the aileron bellcranks by

4

first pressing in the 3x7x3 bearing

followed by the 3x5x7.5 spacer. Install the remaining bearing along with

the metal balls. It is easier to thread

the M3 linkage balls into the plastic

bell cranks if you use an available M3

screw to make threads. Apply medium CA to the linkage balls. Once

you have the aileron bell cranks built,

install the right rear frame and apply medium threadlock to the M3x8

button head screws and tighten onto

the skeletal support frame. Apply

medium threadlock to the M3x25

button head cap screws and install

the aileron bell cranks onto the aluminum post.

14

13

CNBB812F

3x8x3.5

CNM3x8BHCS

CNLR1014

CNBB0730

CNM3x12BHCS

CNM3x25BHCS

C

A

No.

CNM3x25BHCS

1

CNLR1014

2

CNBB0730

3

4

HI6031G

5

HI6031G

HI6031G

6

HW6125B

7

8

CNBB812F

CNM3x8BHCS

9

10

HI6031S

CNM3x12BHCS

11

12

HI6032GB

HI6139B

13

HI6116R

14

Part #

Button Head Cap Screw( 圆头内六角螺丝)M3x25

M3 Linkage Ball( 球头螺丝

Bearing(滚珠轴承)3x7x3

Bell Crank(左右控制臂)

Bellcrank Spacer( 垫片)3x5x7.5

Bellcrank Spacer( 垫片)3x8x3.5

Canopy Standoff( 机头罩支架)

Elevator Lever Flange Bearing( 带边滚珠轴承)

Button Head Cap Screw( 圆头内六角螺丝)M3x8

Aluminum Post( 铝柱)

Button Head Cap Screw( 圆头内六角螺丝)M3x12

Elevator Bellcrank(

Fuel Tank Isolators(油箱橡胶垫)

Right Rear Frame (

Description

)

控制臂)

左右后侧板

Qty

2

8

4

2

2

2

2

2

10

1

2

1

2

)

1

If you have carbon fiber frames, just add a “C” to the end of the frame

part number.

Page 20

Page 21

CLUTCHBELL ASSEMBLY

BAG 2

Radikal Gasser

1

4

2

CNBB1015

CNM4x4SS

3

CNBB513

6

7

8

9

5

CNBB1524

CNBB511

4

The Radikal uses the regular starting shaft and hex coupler as to align

the clutch to the clutchbell. Clean both the starting shaft and the inside

race of the bearing inside the clutchbell and the inside race of the top

starting shaft bearing. Apply a small amount of Red threadlock positioned just above where the bottom clutchbell bearing will sit on the

starting shaft. Slide the starting shaft up through the bearing blocks.

Apply a small amount of medium threadlock to the top of the starting

shaft and slide the hex coupler in place aligning the flat spot with one of

the holes. Apply medium threadlock to the two M4x4 set screws and

tighten in place.

10

11

Clean the top of the pinion gear and the inside surfaces of both the upper

and lower bearings inside the clutch shaft bearing block using alcohol.

Apply a small amount of Red threadlock to the top edge of the clutch gear

where it will contact the bearing. Press the bearing block in place, firmly

seating the bearing against the top of the pinion gear.

Page 21

No.

1

2

3

4

5

6

7

7

8

9

10

11

Part #

CNM4x4SS

HW6002

CNBB513

HW6007G

HW6007GS

CNBB1015

HW6043A

HW6043B

CNBB1524

HW6013G

CNBB511

HW6006

Description

Set Screw(无头内六角螺丝)M4x4

6mm Hex Coupler(

Bearing(滚珠轴承)5x13x4

Bearing Block( 轴承座)

Long Hex Spacers( 六角铝柱)L=52MM

Bearing(滚珠轴承)10x15x4

Alloy Drive Gear 14T For LT Version(合金传动齿轮)

Alloy Drive Gear 16T For HD Version(合金传动齿轮)

Bearing(滚珠轴承)15x24x5

Clutch Bell Assembly( 离合器罩)

Bearing(滚珠轴承)5x11x4

Starting Shaft( 启动轴)

六角启动头)

Qty

2

1

1

2

4

1

1

1

1

1

1

1

Page 22

ZENOAH 20CC ENGINE PREPARATION

Radikal Gasser

It is not so apparent how the propeller hub is attached to the engine.

A 13mm lock nut is supplied in the kit to aid in the removal of the

propeller hub.

Install the supplied 13mm locknut and tighten down onto the shaft. Tighten down on the top lock nut while applying opposite force (un-

First undo the nut and remove the propeller washer. Screw down

the original nut onto the stud followed by the locknut.

screwing) to the second nut using the Zenoah supplied wrench.

This will allow you to lock the nuts together.

Because you have no use for the propeller hub, you can use a wrench

or vice to grab onto the hub while trying to undo the stud. Grabbing

onto this aluminum hub may damage the hub but it’s of no use in this

build. Once this stud is loosened, you can remove the propeller hub.

Remove the stud and hand tighten it a few threads into the crank.

With the propeller hub still in the vice, gently tap on the head of the

stud with a hammer while supporting the engine with your other

hand. This will loosen the hub from the crank shaft.

MAKE SURE NOT TO LOSE THIS KEY! It is very important to retain this

key for the following steps. Without this key, you cannot mount your fan

and clutch assembly. After you have removed the hub, remove the bottom plate and flush head cap screws. Set these aside as you will not be

needing them for the rest of the build.

Page 22

Page 23

CLUTCHSHOE AND FAN ASSEMBLY

BAG 3

Radikal Gasser

1

Bearing is pre-installed

2

7

Install the clutch temporarily and do a dry

fitment into your clutch bell that is mounted

to your frames. If your clutch shoe is sitting

outside the clutch bell when your engine is

mounted to your frames, you will most likely

need 2 clutch shims.

15

16

13

17

Do not overtighten

3

8

4

5

6

9

10

11

The hex starting system is a regular replacement part and will wear due to normal use. The pull start option is a better alternative to starting the helicopter.

12

You can use a pull start for the first start

of the day. Afterwards using a heavy

duty electric starter is possible.

Do not overtighten

14

6.5x13x1

CNM2.5x8CS

CNM4x10FHCS

CNM3x6FHCS

6.5x13x1

CNM6x16CS

CNLR1018

CNM3x4SS

Lay the cooling fan shroud mount plate onto

the face of the engine with the straight edge

towards the cylinder head and the access

hole on the muffler side.

No.

Part #

HI6020G

1

CN2263K

2

HW6011G

3

HW6011GS

4

CNM6x16CS

5

CNM6.5X13FW

6

HI6009GBKH

7

8

HI6009GBK

9

HI6009GM

10

CNM3x6FHCS

11

HW6118W

12

CNM2.5x8CS

13

CNM4x10FHCS

14

ZENE20EIN OT INCLUDED

15

HW6192B

16

CNM3x4SS

17

CNLR1018

Plastic Cooling Shroud( 风扇罩)

Auto Hub Assembly(8mm)( 单向轴承)

Clutch Shoe(离合器)

Clutch Shim(垫片 )20x22x0.5

Cap Screw(杯头内六角螺丝)M6x16

Washer(垫片)6.5x13x1

Cooling Fan Hub(风扇座)

Cooling Fan(风扇)

Magnet(磁铁)

Flush Head Cap Screws( 斜头内六角螺丝)M3x6

Cooling Shroud Mount Plate( 挡风板)

Cap Screw(杯头内六角螺丝)M2.5x8

Flush Head Cap Screws( 斜头内六角螺丝)M4x10

Engine(引擎)

Carburetor Arm( 化油器控制臂)

Set Screw(无头内六角螺丝)M3X4

Ultra Short Steel Ball( 球头螺丝)

Description

Qty

1

1

1

1

1

1

1

1

2

4

1

3

4

1

1

1

1

Page 23

Page 24

EFI PICK UP

BAG 2

Radikal Gasser

3

4

5

1

Mount the plate onto the engine first and

tighten the M4x10 Flush Head Cap Screws.

After you have installed the plate, then install

the sensor. The sensor can be adjusted

slightly to advance or retard timing.

2

6

CNM4x10FHCS

CNM2.5x8CS

2.5x4x4

Page 24

No.

1

HI6010

Not Included

2

CNM4x10FHCS

3

4

HI6010

5

CNLR1003

6

CNM2.5x8CS

Part #

Description

Sensor Adaptor Board(

Sensor(感应器)

Flush Head Cap Screws( 斜头内六角螺丝)M4x10

Copper Sleeve( 铜套)2.5x4x4

Washer(垫片)3x5x0.5

Cap Screw(杯头内六角螺丝)M2.5x8

感应器固定板)

Qty

1

1

2

2

2

2

Page 25

ELECTRONICS TRAYS

BAG 3

Radikal Gasser

5

1

2

4

3

Start by installing the four M2.5x6 flush head cap screws into

the lower electronics tray by using medium threadlock. Use

the M3x30 Phillips tapping screws to mount the canopy hook.

6

Do not overtighten this as you can strip the plastic.

Next apply medium threadlock to the remaining four M2.5x6

flush head cap screws and install them into the upper electronics tray. Tighten to the frame support bars.

7

No.

CNM2.5x6FHCS

1

HW6113A

2

HW6113AS

3

4

HI6113B

5

CNM3x30ST

6

HI3129

HI3129

7

Part #

Flush Head Cap Screws( 斜头内六角螺丝)M2.5x6

Upper Electronics Tray( 变速器固定板)

Frame Support Bar( 铝柱)

Lower Electronics Tray( 接收机固定板)

M3x30 Phillips Tapping Screws( 自攻螺丝)

Canopy Mount Spacer ( 机头罩扣座)

Canopy Mount Hook( 机头罩扣)

Description

If you have carbon fiber frames, just add a “C” to the end of the frame

part number.

CNM2.5x6FHCS

CNM3x30ST

Qty

8

1

4

1

2

1

1

Page 25

Page 26

FRONT SIDE FRAMES

BAG 3

1

2

Radikal Gasser

Make sure when fitting the electronics trays that you have a complete mating with the upper side frames. If the keys do not fit into

the slots on the upper side frames and you tighten down on the

screws, your frame will be crooked.

Apply medium threadlock to the eight M3x8 button head cap

screws and tighten down.

CNM3x8BHCS

No.

1

2

Part #

HI6115GL

CNM3x8BHCS

Front Frames ( 前侧板)

Button Head Cap Screw( 圆头内六角螺丝)M3x8

Description

If you have carbon fiber frames, just add a “C” to the end of the frame

part number.

Page 26

Qty

2

8

Page 27

MOUNTING MOTOR

BAG 2

Radikal Gasser

1

Loosely fit the CNM4X10 cap screws that hold the

engine on the plate. Then line up the bearing assembly

in the upper portion of the frames. Keep this loose for

2

now until you are ready to mesh the pinion gear with

the main gear.

CNM3x8BHCS

1

Page 27

No.

1

2

Part #

CNM3x8BHCS

CNM4x10CS

CNM4x10CS

Description

Button Head Cap Screw( 圆头内六角螺丝)M3x8

Cap Screw(杯头内六角螺丝)M4x10

Qty

6

4

Page 28

ATTACHING FRONT FRAME ASSEMBLY

BAG 2

Radikal Gasser

When mounting the front frames to the rear frames,

make sure the keyed split matches up properly

prior to tightening the eight M3x8 button head cap

screws. This is very important as you can warp the

frames if it’s not set in place when tightening down.

Prior to installing the eight M3x8 button head cap

screws, be sure to use medium threadlock.

1

CNM3x8BHCS

Page 28

No.

CNM3x8BHCS

1

Part #

Description

Button Head Cap Screw( 圆头内六角螺丝)M3x8

Qty

8

Page 29

LANDING GEAR

LANDING GEAR PACKAGE

Radikal Gasser

3x8x1

CNM3x4SS

CNM3x16CS

1

4

3

5

2

6

Install the landing skids onto the landing struts one

side at a time. After installing the landing skids,

position, the landing struts on the skids so that

they match up with the mounting positions on the

frames. Place the washers onto the M3x16 cap

screws and then apply medium threadlock. Install

the screws through the landing struts and tighten

onto the frames. Turn the landing skids so that the

curve towards the front is facing straight up. Make

sure you have approximately 28mm of skid showing

out the back. Install the four M3x4 set screws to

lock the skids into place. Do not tighten these too

much as you can crack the plastic struts. Lastly,

install the landing skid stoppers.

Page 29

No.

1

2

3

4

5

6

Part #

HI3122A

HW3123A

CNM3x16CS

CNM3x8FW

CNM3x4SS

HW3123A

Description

Plastic Struts( 脚架)

Aluminum Skids( 脚架弯管)

Cap Screw(杯头内六角螺丝)M3x16

M3x8x1 Flat Washers( 垫片)

Set Screw(无头内六角螺丝)M3x4

Landing Skids Stopper(脚架塞)

Qty

2

2

4

4

4

4

Page 30

MAIN GEAR ASSEMBLY

BAG 3

Radikal Gasser

Apply medium threadlock to the four

M3x6 flush head cap screws and install

through the tail drive gear tightening

onto the driven tail hub. Apply medium

threadlock to the six M3x8 flush head

cap screws and install onto the main

gear with the auto-rotation one way

1

bearing. Make sure the flush head cap

screws are installed onto the concave

beveled side of the screw holes on the

main gear.

2

3

Be sure to clean the inside and outside of the main shaft

sleeve with alcohol prior to installation.

4

5

6

For the roller bearings, we recommend a very light oil. The oil MUSTNOT attack/break down plastic as

this could damage the cage in the

one-way bearing. Prior to applying oil,

7

make sure to clean the roller bearings with a cotton swab making sure

there is no debris in the bearings.

CNM3x6FHCS

CNM3x8FHCS

Page 30

No.

1

2

3

4

5

6

7

Part #

HW6057A

HI6057

CNM3x6FHCS

HW6057C

CNM3x8FHCS

HI6057C

HW6057D

Description

Driven Tail Hub( 传动主齿轮座)

Tail Drive Gear(传动主齿轮)

Flush Head Cap Screws( 斜头内六角螺丝)M3x6

Main Shaft Sleeve(主齿轮铁套

Flush Head Cap Screws( 斜头内六角螺丝

Main Gear 90T

One-way Bearing( 单向轴承座

(斜齿轮

)

)M3x8

)

)

Qty

1

1

4

1

6

1

1

Page 31

ATTACHING HEAD AND MAIN GEAR

Radikal Gasser

BAG 3

1

CNM4x4SS

CNM2.5x8CS

10x18x1

Ø3x23.7

3

2

4

6

5

4

Apply grease to the thrust bearing. Place the Main Gear assembly into

the frames. Insert the main shaft with head assembly through the bearing blocks while lining up the thrust bearing, and mast stopper while going through the Main Gear assembly. Line up the whole in the Main Shaft

with the hole on the Driven Tail Hub. With the help of needle nose pliers

or hemostats, place the Pin (#5) through while making sure you have it

going through the Main Shaft. Install the 2 M4x4 set screws making

sure you have them evenly threaded on both sides. When installing the

Mast Stopper (#3), make sure it is pushed up to the top prior to tightening the M2.5x8 Cap Screw.

CNBB1018T

No.

1

2

3

4

5

6

Page 31

Material No.

CNBB1018T

CNM2.5X8CS

HW6054

CNM4x4SS

HW6057AS

HW6057DS

Description

Thrust Bearing( 止推轴承)10x18x5.5

Cap Screw(杯头内六角螺丝)M2.5x8

Mast Stopper( 主轴限位块)

Set Screw(无头内六角螺丝)M4x4

Pin(

插销)Ø3x23.7

Copper Washer( 铜垫片)10x18x1

Qty

1

1

1

2

1

1

Page 32

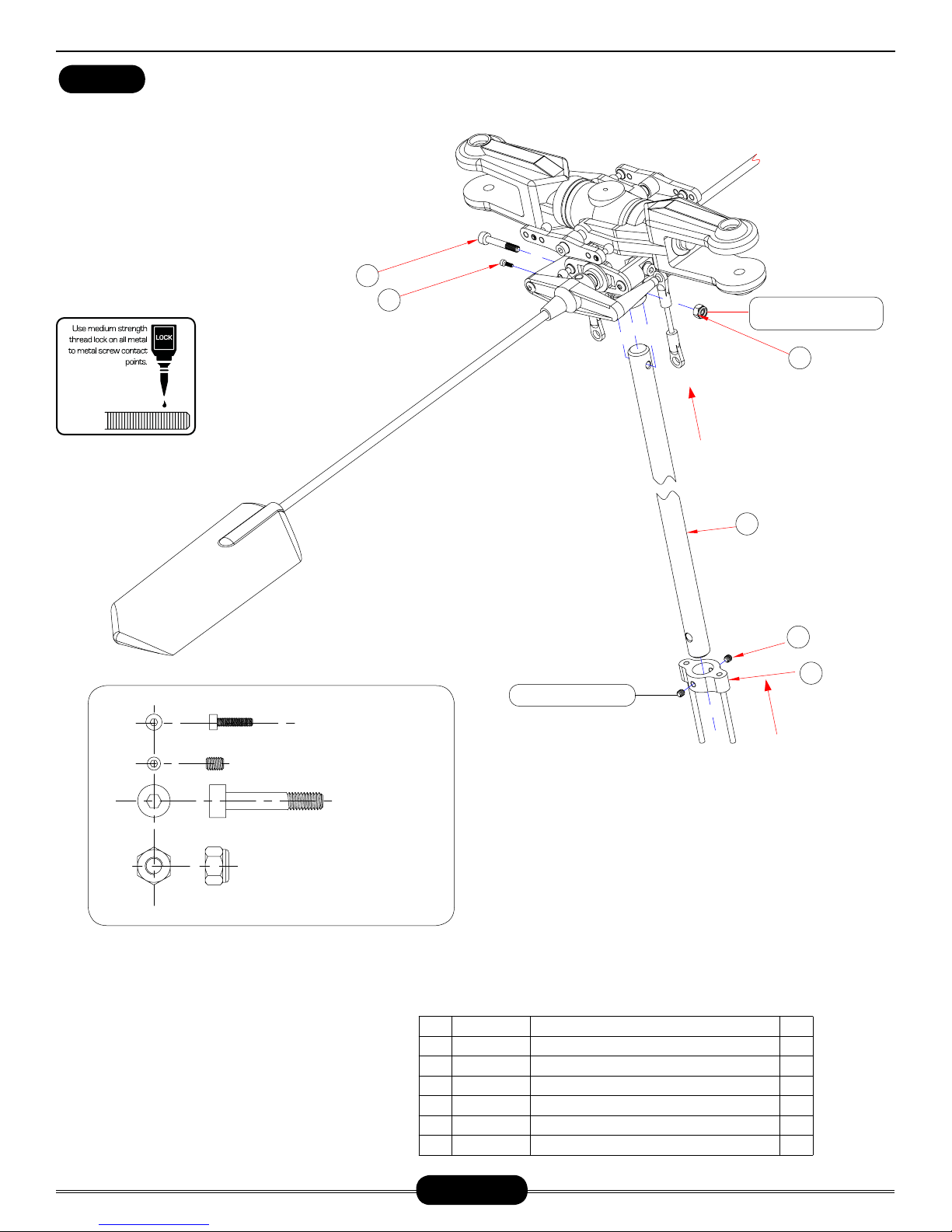

TAIL BOOM COMPONENTS

BAG 4

Radikal Gasser

20

When installing all the hardware onto the boom, make

sure you do so prior to installing the tail gearbox. Otherwise you will not be able to once your tail gearbox is

mounted. Do not apply the zip ties until the very

end when you are sure of the positions of

the tail control rod guides. When build-

17

ing the tail control rod, make sure

to place the control rod through the

guides prior to installing the ends.

Do not install the horizontal fin until

you have tightened the tail boom supports and horizontal fin mount. It is

best to install the horizontal fin to-

16

wards the end of your build.

1

18

19

14

21

13

11

12

10

9

15

CNM3x10CS

CNLR1013

M2 CNLR1018

CNM2x8PH

CNM3x8ST

CNM3x8BHCS

M3 CNM3LOCK

INCLUDED

CNM2.3x12ST

CNM3x14BHCS

8

2

3

4

5

6

7

No.

HI6080B

1

CNM3x10CS

2

NOT INCLUDED

3

NOT INCLUDED

4

NOT INCLUDED

5

6

HI3205A

CNM2.3x12ST

7

8

CNLR1013

CNLR1018

9

HI6106B

10

11

HI6068A

12

CNM3x14BHCS

CNE543

13

CNM2x8PH

14

CNE543

15

16

HW3202C

17

CNM3x8ST

HI6106B

18

19

CNM3LOCK

CNM3x8BHCS

20

HI6067GH

21

Part #

Tail Servo Mount( 尾翼伺服机座)

Cap Screw(杯头内六角螺丝)M3x10

Servo(伺服机)

Copper Rivet(铜铆钉)

Anti-Vibration Pad(防震胶垫)

Servo Mounting Plate( 伺服机固定板)

Self Tapping Screws( 尖尾自攻螺丝)M2.3x12

Steel Ball 2mm Thread(m2 球头螺丝)

M2 Hex Nuts(m2 六角螺母)

Adjustable Tail Guides( 尾拉杆固定座)

Horizontal Fin Mount( 水平翼固定座)

Button Head Screw( 圆头内六角螺丝)M3x14

Tail Boom Support Strut End( 连杆头)

Phillips Screw( 圆头十字螺丝)M2x8

Tail Control Rod( 尾舵控制连杆)

Tail Boom Support Struts( 尾支撑杆)

Self Tapping Screws( 尖尾自攻螺丝)M3x8

Zip Tie( 扎带)

M3 Lockmut(M3 螺母)

Button Head Screw( 圆头内六角螺丝)M3x8

Horizontal Fin( 水平翼)

Description

Qty

2

2

2

2

2

2

4

1

2

1

1

1

2

2

1

2

2

1

1

2

1

If you have carbon fiber frames, just add a “C” to the end of the frame

part number.

Page 32

Page 33

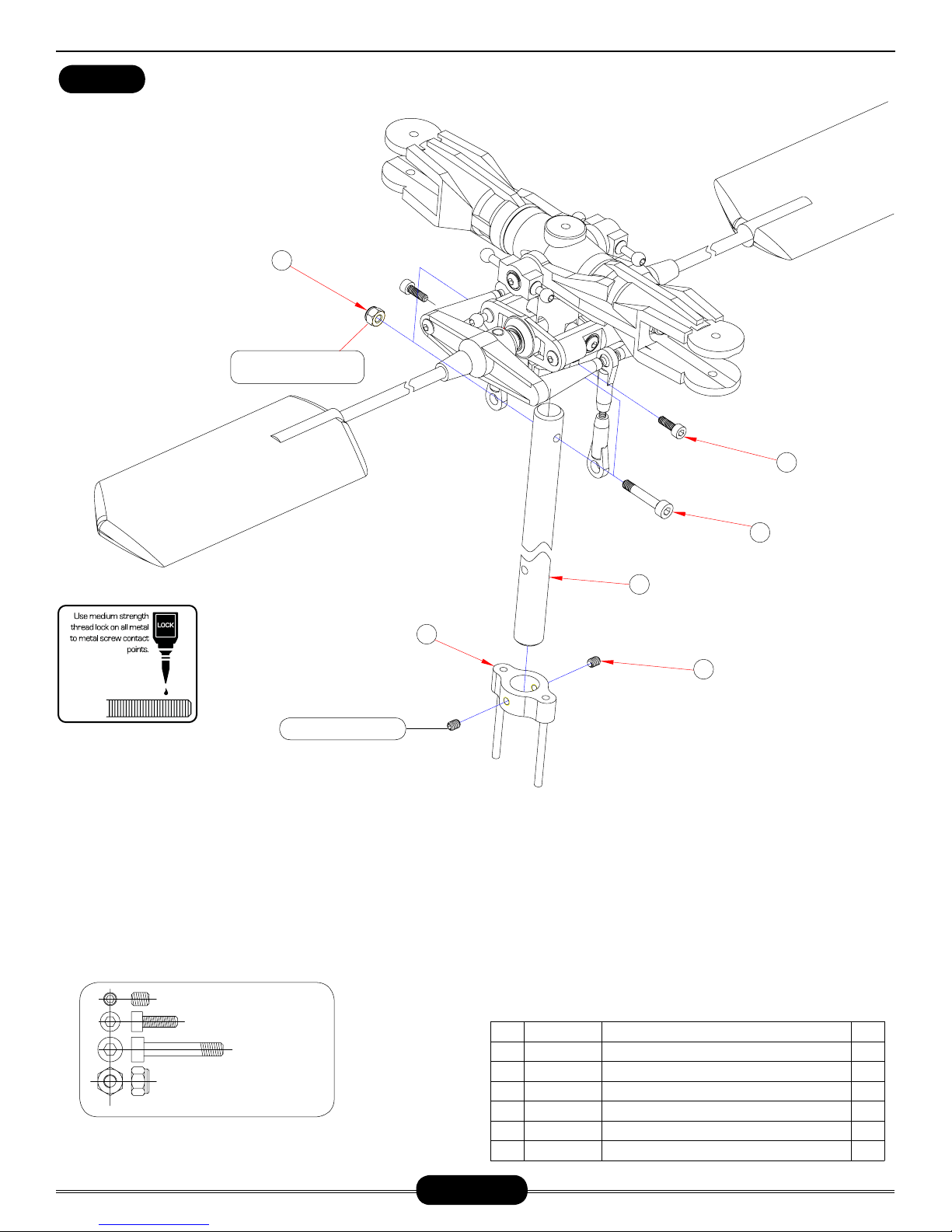

TAIL GEARBOX

BAG 4

15

Make sure to install

this first before

clamping the tail

gearbox together.

16

19

20

The taller lip should

face outwards.

14

21

17

13

12

22

Radikal Gasser

When pressing the bearing retainers into the tail gear box

plate, make sure you are pressing it into the correct side. The

left and right side are different. If you do not do this, it will be

difficult to remove this pieces once it’s pressed in.

11

10

9

8

7

6

5

24

4

When clamping the tail gearbox to the boom, make sure

the tail boom retainers are

properly keyed to the slots on

the tail boom. After clamping,

approximately 3mm of the tail

boom should be visible.

CNM3x6BHCS

CNM3x8BHCS

CNM2.5x8CS

5x7x3.5

5x7x6.5

M3 CNM3LOCK

Ø2x12

CNBB1350

L=26MM

Ø5x27

18

CNM3x40CS

5x7x12

CNBB38

CNM3x4SS

3

23

2

1

No.

HI6067GV

1

2

3

CNM2.5x8CS

4

HI6078H

5

6

CNBB1350

7

CNE529

8

CNE529

9

10

11

HW6078TP

12

HW6073B

13

14

15

CNM3LOCK

16

17

18

19

CNM3x6BHCS

HI6078P

20

HI6078P

21

22

HI6078P

HI6631

23

CNM3x4SS

24

Part #

CNM3x8BHCS

CNM3x40CS

HW6073B

HW6073B

HI6078H

HW6078TP

HI6078B

HI6078B

HI6078B

Vertical Fin(垂直翼)

Button Head Screw( 圆头内六角螺丝)M3x8

Cap Screw(杯头内六角螺丝)M3x40

Cap Screw(杯头内六角螺丝)M2.5x8

Bearing Units( 轴承套)

Bearing(滚珠轴承)5x13x4

Spacer Units(铝套)M5x7x6.5

Lock Pin(插销)Ø2x12

Tail Gear(尾皮带轮)

Tail Output Shaft(尾翼轴)

Threaded Spacer( 铝柱)Ø5x27

Spacer Units(铝套)5x7x3.5

Tail Gearbox Bearing Retainer(双轴承套)

Tail Gear Box Plate-Right(尾齿轮箱夹片)

M3 Locknut(M3螺母)

Tail Pitch Bellcrank "L" Arm(L臂)

Tail Gear Box( 尾齿轮箱)

Short Threaded Hex Spacer( 六角铝柱)L=26mm

Button Head Screw( 圆头内六角螺丝)M3x6

Spacer ( 铝套)3x5x12

Bearing(滚珠轴承)3x8x3

Tail Belt Tensioner Pulley( 皮带压轮)

Tail Belt(皮带)

Set Screw(无头内六角螺丝)M3x4

Description

Qty

1

8

1

1

1

3

1

1

1

1

1

1

1

1

1

1

2

4

1

2

1

1

1

1

If you have carbon fiber frames, just add a “C” to the end of the frame

part number.

Page 33

Page 34

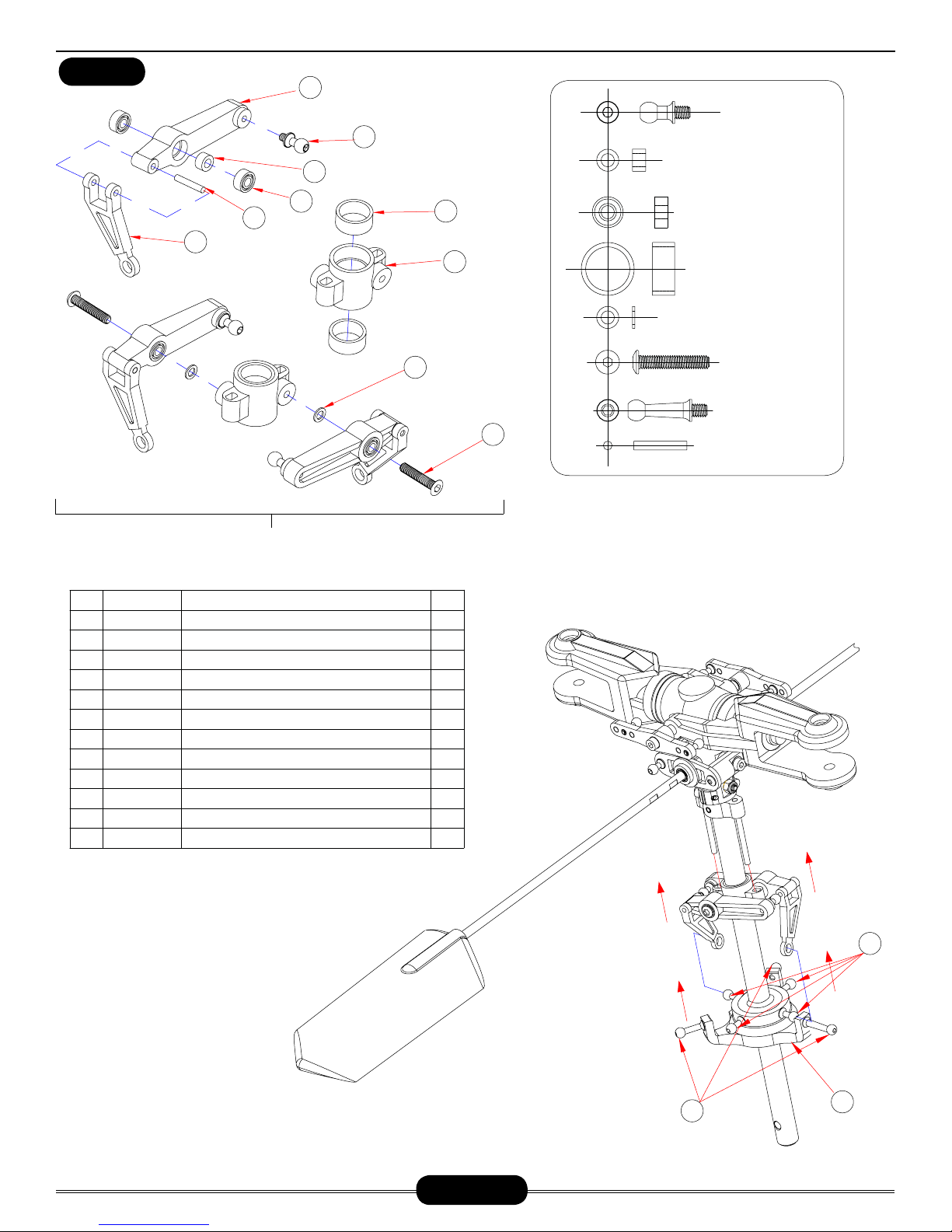

TAIL ROTOR ASSEMBLY

BAG 4

Radikal Gasser

Comes pre-assembled.

13

12

10

Face flat side of

tail hub towards

the gear box.

Starting with the tail rotor assembly, press the

4x10x4 (#11) bearing into the tail blade grip. Grease

the thrust bearings prior to installation. Making sure

the open ball end is facing the tail hub, place the thrust

bearing assembly into the tail blade grip followed by

the 3x5x0.5 micro washer. Install the 3x9x2.5 (#4)

bearing and then tighten the assembly with the M3

locknut.

No.

Part #

1

HI6099A

HW6204

2

CNM3LOCK

3

4

CNBB0930

CNLR1003

5

6

CNBB49T

7

CNM3x16BHCS

8

CNM3x18CS

HI6096A

9

10

CNLR1013

11

CNBB410

12

HW3098A

13

CNM3x4SS

14

HI3087B

CNLR1019

15

16

CNBB37F

17

18

HI6102

HI6102

Tail Rotor Blades(尾旋翼)

Micro Washer( 垫片)3x10x1.5

M3 Locknut(M3 螺母)

Bearing(滚珠轴承)3x9x2.5

Micro Washer( 垫片)3x5x0.5

Thrust Ball(止推轴承)d4xD9x4

Button Head Screw( 圆头内六角螺丝)M3x16

Cap Screw(杯头内六角螺丝)M3x18

Tail Rotor Grip( 尾旋翼夹片)

Steel ball 2mm Thread(m2 球头螺丝)

Bearing(滚珠轴承)4x10x4

Steel Tail Rotor( 尾旋翼中心座)

Set Screw(无头内六角螺丝)M3x4

Tail Pitch Plate(尾翼控制臂组)

M3 Linkage Ball( 球头螺丝) L=13MM

Flange Bearing( 带边滚珠轴承)3x7x3

Bellcrank Spacer( 铁套)3x5x2

Tail Bellcrank Lever( 尾控制臂)

9

Description

14

11

3

16

18

8

15

17

7

6

5

4

another spacer and secure using one M3

locknut from the molded recess on the outside.

When correctly installed, the leading edge of the

tail rotor blades will rotate into the down wash

from the main rotor blades.

Tail blade tension should be set tight enough

that the rotor blade will stay straight on its

3

2

Qty

2

4

3

2

3

2

2

2

2

2

2

1

1

1

1

2

1

1

1

M3 CNM3LOCK

CNBB0930

3x5x0.5

CNBB49T

CNM3x12BHCS

CNM3x18CS

CNLR1013

Slide one M3x18 special socket

cap screw from the inside of the

tail rotor grip and position the first

M3x10x1.5 spacer, insert the tail blade,

own, but will pivot easily when the blade

tip is moved.

After flying the model, if a vibration

is noticed on the vertical fin, the

complete tail rotor assembly

can be removed with the hub

and further balanced using

a High Point balancer.

CNBB410

CNM3x4SS

Ø2x7

CNBB610

HI3087B

CNLR1019

CNBB37F

3x5x2

3x10x1.5

Page 34

Page 35

TRANSMISSION CASE

Radikal Gasser

BAG 4

When orienting the belt the front transmission pulley as viewed from the top

should be turning counter-clockwise.

When the belt is twisted as shown below,

the rear tail pulley should turn counter

clockwise when viewed directly on from

the right side of the helicopter.

9

1

2

10

11

You may notice the boom and the

tail transmission case is scuffed.

This is done during the manufacturing process to ensure a

proper grip.

13

8

To adjust belt tension, pull forward on the front transmission

box and tighten the screws.

12

The belt should be tight enough

that it should not travel past the

half way point when pressed

down from the back. If it is too

tight, you will cause excessive

drag.

3

6

5

7

4

HELICOPTER NOSETAIL OUTPUT SHAFT

4x6x0.5 CNLR1006

CNBB410

CNM3x4SS

CNM3x12CS

M3 CNM3LOCK

CNM3x8FHCS

Ø4x30 CNE533

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

Part #

CNLR1006

CNBB410

CNE538

CNE533

HI6060B

CNM3x4SS

CNM3x12CS

HW6007GS

CNM3LOCK

HI6117A

CNM3x8FHCS

HI6631

HW6062G

Micro Washer( 垫片)4x6x0.5

Bearing(滚珠轴承)4x10x4

Transmission Gear( 皮带输入齿轮)

Lock Pin(插销)M4x30

Upper Transmission Case( 尾管夹片)

Set Screw(无头内六角螺丝)M3x4

Button Head Cap Screw

Long Hex Spacers( 长六角铝柱)L=52MM

M3 Locknut(M3螺母)

Head Lock Gyro Plate( 陀螺仪板)

Flush Head Cap Screws( 斜头内六角螺丝)M3x8

Tail Belt Drive( 皮带)

Tailboom(尾管)

Description

杯头内六角螺丝)M3x12

(

Qty

2

2

1

1

2

2

4

2

4

1

2

1

1

If you have carbon fiber frames, just add a “C” to the end of the frame

part number.

Page 35

Page 36

ATTACHING TAIL TO MAIN FRAME

BAG 4

3

Radikal Gasser

2

1

Install the tail assembly onto the main frames by using threadlock on eight

the M3x8 button head cap screws. Make sure to install two screws opposite of each other on either side and tighten down making sure the transmission gear is properly meshed with the tail drive gear. If you are unsure about

proper gear mesh, use a strip of paper slightly taller than the tail drive gear

and pass it between the gears as you spin the tail drive gear. As the paper

passes through from one side of the frames to the other, a nice zig-zagged

pattern should develop. If it is a very faint zig-zag pattern or no pattern appears, the gear mesh is too loose. If the paper comes through crushed, the

gear mesh is too tight. After the tail assembly is installed on the main frame,

install the tail boom braces using the two M3x25 cap screws and boom

support posts making sure to apply medium threadlock.

CNM3x25CS

CNM3x8BHCS

No.

1

2

3

CNM3x25CS

HW6202BS

CNM3x8BHCS

Part #

Description

Cap Screw(杯头内六角螺丝)M3x25

Boom Support Posts(铝柱)

Button Head Cap Screw( 圆头内六角螺丝)M3x8

Qty

2

2

8

Page 36

Page 37

INSTALLING SERVOS

3

2

Radikal Gasser

BOLTS BAG

To secure the servo mounting tabs, the

best thing to use is a set of hemostats

or needle nose pliers to hold the tab in

place while tightening the servo mounting screws. Be sure to use a large

enough Phillips screw drive so as to

not strip the head of the Phillips tapping

screws.

1

5

4

9

10

A servo arm of approximately

12mm is recommend for the

throttle servo.

CNM2x8PH

CNLR1014

6

8

CNM2.3x12ST

CNLR1013

7

NOT

INCLUDED

No.

CNM2x6PH

1

HW6192C

2

CNLR1014

3

4

CNM2.3x12ST

HI3205A

5

NOT INCLUDED

6

NOT INCLUDED

7

8

NOT INCLUDED

CN2288

9

CNLR1013

10

HI3205B

11

Part #

11

Description

Phillips Screw( 十字螺丝)M2x6

Pitch Compensators(伺服机控制臂)

M3 Linkage Ball(

Self Tapping Screws( 尖尾自攻螺丝

Servo Mounting Plate(

Servo(

Copper Rivet(铜铆钉)

Anti-Vibration Pad(防震胶垫)

Metal Servo Arm(

Steel Ball 2mm Thread(M2

Servo Mount Tabs(

球头螺丝)

伺服机固定板)

伺服机)

金属伺服机控制臂)

球头螺丝)

伺服机固定座)

)M2.3x12

Qty

10

3

6

16

8

4

16

8

1

1

8

Page 37

Page 38

ADJUSTING PUSHROD LENGTHS

Radikal Gasser

BOLTS BAG

HELPFUL TOOL:

PART# CN2219A: BALL LINK

EASY DRIVER

72.2

4

55

25

47.8

3

85

105~106

2

1

5

NOTICE SIZE OF HOLES ON BALL LINKS

THE SIDE WITH THE SMALLER HOLE

SHOULD FACE OUTWARDS

93.6

76.4

Page 38

No.

1

2

3

4

5

Part #

HI6145

HW6192D

HW6192D

HW6192D

HW6192D

HEL PFUL TOOL

PART# CN2255: CONTROL ROD SETUP GAUGE

Description

Ball Link(塑胶球头连接头)

Pushrod(连杆)L=85MM

Pushrod(连杆)L=25MM

Pushrod(连杆)L=55MM

Pushrod(连杆)L=80MM

Qty

18

4

2

2

1

Page 39

ATTACHING MUFFLER

Shown is the optional Torpedo Slim Tuned Gasser Muffler. This is not included in your kit.

When installing the bolts to hold the muffler, automotive Goop® can be used as a threadlocking

adhesive. This will keep the bolts in place. Another suggestion is to bring the engine to operating

temperatures and then re-torque the M5 bolts

holding the muffler in place.

Radikal Gasser

YES

CNM5x20CS

NO!

2

If you purchased a Zenoah G20 engine, the engine package should include the stock black box muffler.

This muffler can be used however, if

installed without any modifications, it is

VERY DANGEROUS as the muffler tip

is pointed directly at the fuel tank. DO

NOT USE IT THIS WAY! If you choose

to use the stock muffler, you will need

to deflect the muffler tip downwards

and away from any components that

can be affected by heat. It is highly

recommended to purchase a muffler

such as the Torpedo Slim (CN3070)

or equivalent.

No.

Part #

1

2

CNM5x20CS

CN3071

Cap Screw(杯头内六角螺丝)M5x20

Torpedo Slim Gas Muffler(排气管)

Description

INCLUDED

(Comes With Muffler)

(Optional)

1

Qty

2

1

Page 39

Page 40

INSTALLING ELECTRONICS

INCLUDED

4

3

1

2

Radikal Gasser

INCLUDED

6

2

INCLUDED

5

The electronics configuration is shown as an example of how

to mount the electronics. It is not necessary to mount your

electronics this way.

No.

NOT INCLUDED

1

NOT INCLUDED

2

3

NOT INCLUDED

4

NOT INCLUDED

5

NOT INCLUDED

6

NOT INCLUDED

Part #

Description

Receiver(接收机)

Receiver Battery( 电池)

Gyro Isolation Foam( 防震垫片)

Gyro(佗螺仪)

On/Off Switch( 开关)

Electronic Ignition( 电子点火)

Qty

1

2

1

1

1

1

Page 40

Page 41

CANOPY

Radikal Gasser

1

2

It will be necessary to cut the windshield out from the mold.

It is recommended to use curved hobby scissors for this pro-

3

cess. If the lines are not smooth, you can use 200 grit sandpaper to sand the edges.

4

Prior to making the holes for the canopy chin

mount, you should mount your canopy to the

mechanics making sure any linkages, servos,

etc...are not touching the canopy. It may be necessary to cut the canopy to avoid binding these

linkages. Also, make sure your muffler is not

touching the canopy as the canopy will melt.

CNM3x6ST

CNM2x5ST

When drilling the holes into

the canopy for the grommets,

do not oversize these holes. If

you do this, the grommets will

not stay in place. If you have

6

a hard time mounting the

grommets onto the canopy

standoffs, you can use a dab

of oil.

5

Apply the decals as shown. If you need a better reference,

the box cover is also a good image to follow.

Page 41

No.

1

2

3

4

5

6

7

Part #

HI6133G

CNM2x5ST

HI6130G

CN2210A

CNM3x6ST

HI3129C

HI6131G

Description

Tinted Windshield( 透明罩)

Screw(螺丝)

Canopy( 机头)

Canopy Grommets( 橡皮环)

M3x6 Phillips Tapping Screws( 尖尾螺丝)

Canopy Mount(机头固定座)

Decal Sheet

Qty

1

6

1

2

2

1

1

Page 42

MOUNTING MAIN BLADES

Radikal Gasser

1

3

2

INCLUDED

If using wood blades, make sure

the blade roots are glued with a

medium CA or epoxy. Make sure

you’re glueing onto the wooden part

of the blade and not directly onto

plastic covering of the blades. If the