Page 1

®

®

COMBO RATCHET/IMPACT SET

Assembly and Operating Instructions

3491 Mission Oaks Blvd. / Camarillo, CA 9301 1

Copyright © 1997 by Harbor Freight Tools®. All rights reserved.

No portion of this manual or any artwork contained herein may be reproduced in any

shape or form without the express written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353.

REVISED 12/02 05/04

Page 2

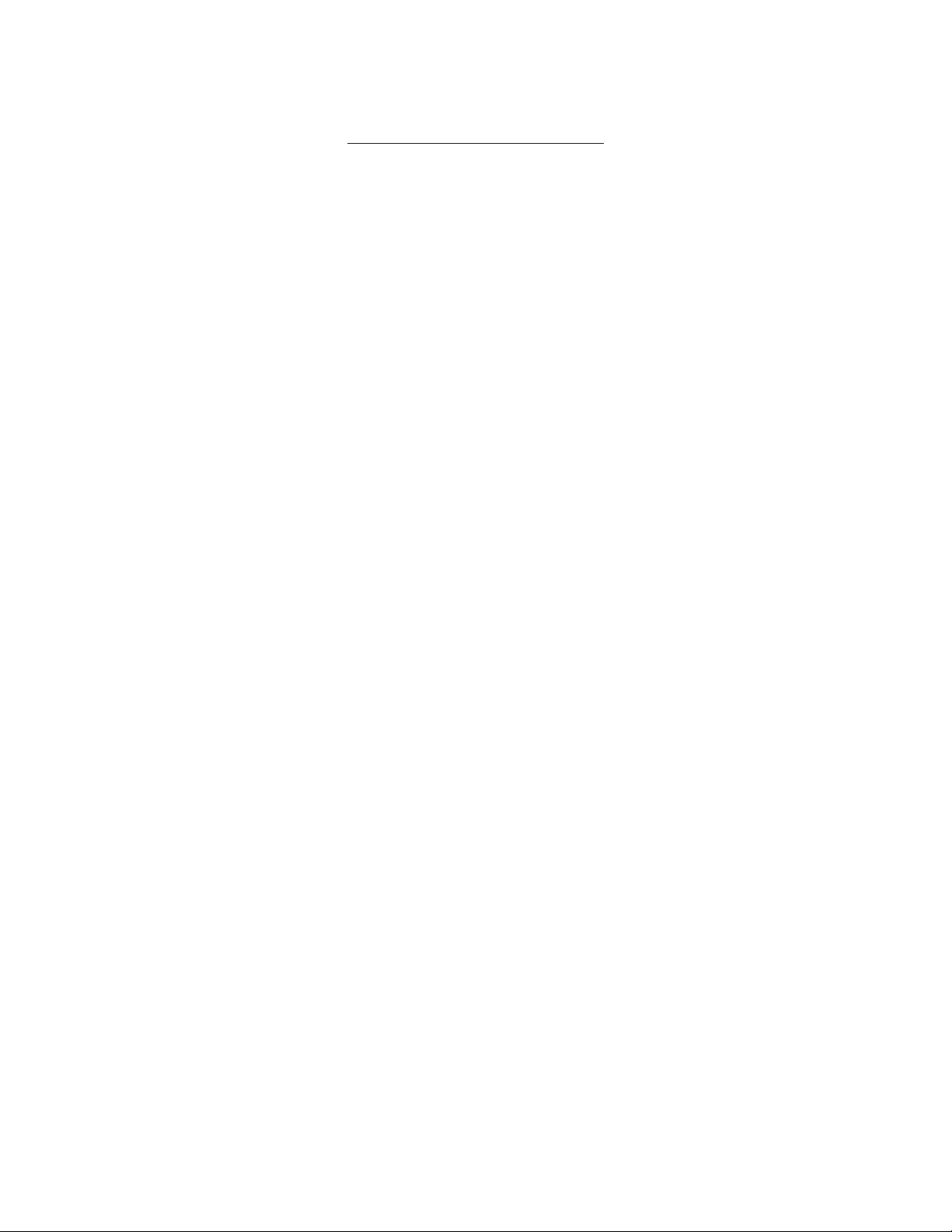

SPECIFICATIONS

RATCHET WRENCH —

Average Air Consumption 4 CFM

Recommended Air Pressure 90 PSI

Air Inlet ¼” NPT

Free Speed 150 RPM

Maximum Torque (ft. lbs.) 45

IMPACT WRENCH —

Bolt Capacity 1/2"

Speed 7000 RPM

Air Inlet ¼” NPT

Sockets 7/16" – 1"

Maximum Torque (ft. lbs.) 230

SA VE THIS MANUAL

You will need the manual for the safety warnings and cautions, assembly instructions, operating

procedures, maintenance procedures, trouble shooting, parts list, and diagram. Keep your

invoice with this manual. Write the invoice number on the inside of the front cover. Keep

both this manual and your invoice in a safe, dry place for future reference.

SAFETY W ARNING & CAUTIONS

WARNING: When using pneumatic equipment, basic safety precautions should always be

followed to reduce the risk of personal injury and hazards due to over pressurization. READ ALL

INSTRUCTIONS BEFORE USING THIS TOOL!

1. KEEP WORK AREA CLEAN. Cluttered areas invite injuries.

2. OBSERVE WORK AREA CONDITIONS. Do not use tools in damp, wet, or poorly lit locations. Don’t expose to rain. Keep work area well lit. Do not use electrically powered air

compressors in the presence of flammable gases or liquids.

3. KEEP CHILDREN AWAY. Children must never be allowed in the work area. Do not let them

handle machines, tools, or hoses. Keep others a safe distance from tool while tool is in

operation as accidental actuation may occur , possibly causing injury.

4. STORE IDLE EQUIPMENT. When not in use, tools must be locked up in a dry location to

inhibit rust. Always lock up tools and keep out of reach of children.

5. DO NOT FORCE THE TOOL. It will do the job better and more safely at the rate for which it

was intended. Do not use inappropriate attachments in an attempt to exceed the tool’s

capacities.

For technical questions, please call 1-800-444-3353.

Page #2 -- SKU: 33567 REV 12/02 REV 05/04

Page 3

6. USE THE RIGHT TOOL FOR THE JOB. Do not attempt to force a small tool or attachment

to do the work of a larger industrial tool. Do not use a tool for a purpose for which it was not

intended.

7. DRESS PROPERLY. Do not wear loose clothing or jewelry as they can be caught in moving

parts. Non-skid footwear is recommended. Wear restrictive hair covering to contain long hair .

8. USE EYE AND EAR PROTECTION. Always wear ANSI-approved chemical splash goggles

when working with chemicals. Always wear ANSI-approved impact safety goggles at other

times. Wear a full face shield if you are producing metal filings or wood chips. Wear an

ANSI-approved dust mask or respirator when working around metal, wood, and chemical

dusts and mists. When operating for extended periods of time, use approved ear protection.

Safety goggles and ear protectors are available from Harbor Freight Tools.

9. DO NOT ABUSE THE POWER CORD. Do not yank compressor’s cord to disconnect it

from the receptacle. Do not carry tools by the cord.

10. DO NOT OVERREACH. Keep proper footing and balance at all times. Do not reach over or

across running machines.

11. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for better and safer performance. Follow instructions for lubricating and changing accessories. Inspect compressor’s

cord periodically and, if damaged, have it repaired by an authorized technician. Inspect all

hoses for leaks prior to use. The handles must be kept clean, dry, and free from oil and

grease at all times.

12. REMOVE ADJUSTING KEYS AND WRENCHES. Make it a habit to check that keys and

adjusting wrenches are removed from the tool or machine work surface before plugging it in.

13. AVOID UNINTENTIONAL STARTING. Do not carry any tool with your finger on the trigger,

whether it is connected to the compressor or not.

14. STAY ALERT. Watch what you are doing; use common sense. Do not operate any tool when

you are tired.

15. CHECK DAMAGED PARTS. Before using any tool, any part that appears damaged should

be carefully checked to determine that it will operate properly and perform its intended

function. Check for alignment and binding of moving parts; any broken parts or mounting

fixtures; and any other condition that may affect proper operation. Any part that is damaged

should be properly repaired or replaced by a qualified technician. Do not use the tool if any

switch does not turn on and off properly.

16. REPLACEMENT PARTS AND ACCESSORIES. When servicing, use only identical replacement parts. Use of any other part s will void the warranty. Only use accessories intended for

use with this tool. Approved accessories are available from Harbor Freight Tools.

17. DO NOT OPERATE TOOL IF UNDER THE INFLUENCE OF ALCOHOL OR DRUGS. Read

warning labels on prescriptions to determine if your judgment or reflexes are impaired while

taking drugs. If there is any doubt, do not operate the tool.

For technical questions, please call 1-800-444-3353.

Page #3 -- SKU: 33567

Page 4

18. DRAIN COMPRESSOR EVERY DAY. Do not allow moisture to build up inside the compressor. Do not allow compressor to sit pressurized for longer than one hour.

19. MAKE SURE ALL EQUIPMENT IS RATED TO THE APPROPRIATE CAPACITY. Make

sure that the regulator is set at least 10 PSI lower than the lowest rated piece of equipment

you are using.

20. DO NOT USE OXYGEN, COMBUSTIBLE GASES, OR BOTTLED GASES AS A POWER

SOURCE. The tool may explode, possibly causing injury.

21. DO NOT EXCEED the recommended air pressure of 90 PSI.

22. TOOL MUST NOT HOLD PRESSURE WHEN AIR SUPPLY IS DISCONNECTED. If a

wrong fitting is used, the tool can remain charged with air after disconnecting and thus will

be able to cycle after the air line is disconnected possibly causing injury.

23. ALWAYS DISCONNECT AIR SUPPLY: Before making adjustments, when servicing the

tool, when clearing a jam, when tool is not in use, or when moving to a different work area,

as accidental actuation may occur, possibly causing injury.

24. DISCONNECT POWER. Unplug compressor when not in use.

25. OUTDOOR EXTENSIONS CORDS. When the equipment is operated outdoors, use only

extension cords intended for outside use. See chart under “Extension Cords” for the proper

AWG rating depending on the length of the cord(s) being used.

26. DO NOT ABUSE THE POWER CORD. Do not yank it to disconnect it from the receptacle.

Do not carry tools by the cord.

27. GUARD AGAINST ELECTRIC SHOCK. Prevent body contact with grounded surfaces such

as pipes, radiators, ranges, and refrigerator enclosures.

For technical questions, please call 1-800-444-3353.

Page #4 -- SKU: 33567 REV 12/02

Page 5

GROUNDING INSTRUCTIONS

If compressor has a three-prong plug

1. This machine has a three-prong plug. The third prong (round) is the ground. Plug the

machine’s cord only into three-prong receptacles. Never cut off the round prong. Cutting of f

the ground will result in a safety hazard and void the warranty.

2. If a three-prong receptacle is not available, you may use an adapter . Extending from the male

end of the adapter, you will find a ring connector or wire lead with a ring connector where the

ground (round prong) would be. Remove the center screw of the outlet cover and put the

screw through the ring connector and back into the hole of the outlet cover. Do not overtighten or you will crack the outlet cover.

If compressor has a two-prong plug

This machine has a polarized plug. One prong is wider than the other prong. This plug will fit in

polarized outlet only one way. If the plug does not fit fully in the outlet reverse the plug. If it still

does no fit, contact a qualified electrician to install the proper outlet. Do not attempt to modify

the plug in any way. Modifying the plug will result in a safety hazard and void the warranty.

For technical questions, please call 1-800-444-3353.

Page #5 -- SKU: 33567 REV 12/02

Page 6

UNPACKING

When unpacking, check to make sure the following parts are included. All sizes listed below are

approximate. If any parts are missing or broken, please call Harbor Freight Tools at the number

on the cover of this manual.

Item# Description Item# Description

N/A 3/8" Ratchet Wrench N/A Impact Sockets (7/16" – 1")

N/A 1/2" Impact Wrench N/A Oil Pot

N/ A 3/8" to 1/2" Adapter N/ A Air Coupler

N/A 4mm Hex Wrench

ASSEMBLY

Your Air Ratchet comes completely assembled.

Air Connection for Ratchet

Step 1: Remove the plastic cap from the rear of the CONNECTION HEAD (#2).

Step 2: Wrap the threads of the Air Coupler with pipe thread seal tape (not included). Attach

the Air Coupler to the CONNECTION HEAD. Tighten the fitting.

Step 3: Your Air Ratchet is ready for use.

Impact Wrench

This Impact Wrench develops a maximum of 230 ft/lbs. of torque. The amount of torque can be

increased or decreased using the AIR REGULATOR (#11). When the Air Regulator is

completely screwed in it is at it’s lowest setting. Air pressure increases as you loosen the Air

Regulator.

For technical questions, please call 1-800-444-3353.

Page #6 -- SKU: 33567 REV 12/02 REV 05/04

Page 7

OPERATION

Setup

Frequent, but not excessive, lubrication is required for best performance. Oil added through the

airline connection will lubricate internal parts. An automatic airline oiler is recommended but oil

may be added manually before every operation or after about 1 hour of continuous use. Only a

few drops of oil at a time are necessary. Too much oil will collect inside the tool and be blown

out during the exhaust cycle. ONLY USE PNEUMATIC TOOL OIL. Do not use detergent oil or

additives as these lubricants will cause accelerated wear to the seals in the tool.

Dirt and water in the air supply are major causes of pneumatic tool wear. Use a filter/oiler for

better performance and longer life. The filter must have adequate flow capacity for the specific

application. Consult the manufacturer’s instructions for proper maintenance of your filter.

The connector on the tool must not hold pressure when the air supply is disconnected. If the

wrong fitting is used, the tool can remain charged with air after being disconnected and still be

able to drive a fastener. See Figure 1 for the recommended accessories and connection order.

Air

Ratchet

Figure 1 — Airline Oiler Assembly

For technical questions, please call 1-800-444-3353.

Page #7 -- SKU: 33567 REV 12/02

Page 8

Air Ratchet Operation

Step 1: Select the appropriate socket for your needs.

Step 2: Attach the socket to the RATCHET ANVIL (#18) as shown in Figure 2.

Roll Pin

(#5)

Air Inlet

Figure 2 — Attaching the Socket

Step 3: Set the compressor’s pressure regulator to 90 PSI. Do not set the compressor’s outlet

regulator over 90 PSI.

Step 4: Connect the Air Ratchet to the air compressor’s hose. If leaking is detected, discon-

nect the air hose and repair before use.

For technical questions, please call 1-800-444-3353.

Page #8 -- SKU: 33567 REV 12/02

Page 9

Loosening

Step 1: Check the direction of the drive by pressing the TRIGGER (#4) as shown in Figure 3.

Figure 3 — Operating the Air Ratchet

Step 2: If the Air Ratchet is going counterclockwise (the correct direction to loosen), then

proceed to Step 4.

Step 3: To change the direction of the drive to loosen, turn the dial marked “R-F” clockwise as

shown in Figure 4.

Figure 4 — Changing Direction of the Drive

Step 4: Place the socket over the nut to loosen.

Step 5: Grip the Air Ratchet firmly. Press the TRIGGER to begin loosening.

Step 6: If the Air Ratchet cannot loosen the nut, DO NOT raise the outlet pressure of the air

compressor. Do not continue attempts to loosen with the Air Ratchet. Use appropriate

tools and methods to loosen the nut.

Step 7: When the nut is removed, stop the Air Ratchet by releasing the TRIGGER and remove

the Air Ratchet. Remove the nut from the socket if needed.

For technical questions, please call 1-800-444-3353.

Page #9 -- SKU: 33567 REV 12/02

Page 10

Tightening

Step 1: Check the direction of the drive by pressing the TRIGGER (#4) as shown in Figure 3.

Step 2: If the Air Ratchet is going clockwise (the correct direction to tighten), then proceed to

Step 4.

Step 3: To change the direction of the drive in order to tighten, turn the dial marked “R-F”

counterclockwise as shown in Figure 5

Figure 5 — Changing the Direction of the Drive

Step 4: Thread the nut on as far as you can by hand.

Step 5: Place the socket on the nut. To begin tightening the nut, press the TRIGGER.

Step 6: If the Air Ratchet stalls while tightening, do not continue attempts to tighten the nut

with the Air Ratchet. DO NOT raise the outlet pressure of the air compressor. Use the

appropriate tools and methods to tighten the nut.

Step 7: When the nut has been tightened, remove the Air Ratchet and socket.

Step 8: If available, check the recommended torque specification for the nut. You should use a

torque wrench to torque the nut after using the Air Ratchet.

For technical questions, please call 1-800-444-3353.

Page #10 -- SKU: 33567 REV 12/02

Page 11

MAINTENANCE

Your Air Ratchet is best operated with an Airline Oiler. If you are using the Air Tool without an

Airline Oiler, follow the steps below.

Step 1: Disconnect the Air Ratchet from the air hose.

Step 2: Apply a few drops of PNEUMATIC TOOL

OIL through the air inlet before each use,

or every hour if used continuously .

Step 3: Apply a few drops of oil to the V ALVE

(#6), location shown in Figure 6. Work

the TRIGGER a few times to lubricate.

Do not use deterg ent oil or additives as

these lubricants will cause accelerated

wear to the seals in the tool.

CAUTION

Air Inlet

V alve (#6)

(underneath trigger)

Figure 6 — Lubrication Points

For technical questions, please call 1-800-444-3353.

Page #11 -- SKU: 33567 REV 12/02 REV 05/04

Page 12

Impact Wrench Operation

Step 1: Set the compressor’s pressure regulator to a maximum of 90 PSI. 90 PSI is satisfac-

tory without harming this tool.

Step 2: Remove the plastic cap from the rear of the HOSE ADAPTER (#10).

Step 3: Wrap the threads of the Air Coupler with pipe thread seal tape (not included). Attach

the Air Coupler to the HOSE ADAPTER. T ighten the fitting.

Step 4: Determine the socket size necessary for the job you need to do. Att ach the appropriate

1/2” drive socket to the Impact Wrench as shown in Figure 7.

Figure 7 — Attaching the Air Coupler and Socket

Step 5: Connect the Impact Wrench to the air compressor’s hose. If leaking is detected,

disconnect the air hose and repair before use.

For technical questions, please call 1-800-444-3353.

Page #12 -- SKU: 33567 REV 12/02 REV 05/04

Page 13

Step 6: Select the power setting for Loosening by pushing in and turning the AIR REGULATOR

(#11) located on the bottom of the

Impact Wrench as shown in Figure 8.

When the Air Regulator is completely

screwed in it is at it’s lowest setting.

Air pressure increases as you push in

and turn the Air Regulator.

Use the Setting Appropriate for the

Job. Do Not Set the Power Setting

Higher Than Needed. Damage to

Parts Could Result.

CAUTION

Figure 8 — Adjusting the Reverse Power Setting

Step 7: Select the direction of the Wrench (forward or reverse) by pushing the REVERSE

VALVE (#3) located on the handle of the Impact Wrench as shown in Figure 9.

Figure 9 — Selecting Reverse Direction

For technical questions, please call 1-800-444-3353.

Page #13 -- SKU: 33567 REV 12/02 REV 05/04

Page 14

Step 8: Press the TRIGGER (#4) to test the Impact Wrench. The Impact Wrench should spin

freely as shown if Figure 10.

Figure 10 — Pressing Trigger

Loosening

Step 1: Verify that the power level is correct for your needs and that the REVERSE VALVE

(#3) has been shifted (pressed) completely to the right. If not, refer to Steps 6 through

7 under Impact Wrench Operation before proceeding.

Step 2: Place your work in as clear a location as possible. Make sure the air hose will reach as

far as needed without stressing any connections.

Step 3: With the correct socket attached to the Impact Wrench, slide the socket over the nut or

bolt.

Step 4: Grip the Impact Wrench with both hands, especially with higher power settings. Make

sure you are in a stable position and spread your feet shoulder-width apart.

Step 5: Press the TRIGGER (#4) to loosen the bolt.

Step 6: If the bolt will not loosen, and you are on a

low power setting for Loosening, try increas-

ing the power setting and attempt again.

Step 7: If the bolt will not loosen with the Impact

Wrench on a higher power setting, do not repeat attempts to loosen. You may snap

the bolt or strip the threads of the stud or nut. Try another method to loosen the bolt or

nut.

The Impact Wrench May Kick Back

During Operation. If This

Happens, Release the TRIGGER

WARNING

IMMEDIATELY!

For technical questions, please call 1-800-444-3353.

Page #14 -- SKU: 33567 REV 12/02 REV 05/04

Page 15

Tightening

Step 1: Verify that the power level is correct for your needs and that the REVERSE VALVE

(#3) has been shifted (pressed) completely to the left. If not, refer to Steps 6 through 7

under

Step 2: Place your work in as clear a location as possible. Make sure the air hose will reach as

far as needed without stressing any connections.

Step 3: Thread the nut or bolt on as far as possible by hand. This is to prevent cross-thread-

ing.

Step 4: If you have torque specs for the nut or bolt you are working on, refer to them. If a low

torque setting is given, it is recommended that you use a socket wrench or a manual

torque wrench to tighten as the Impact Wrench may provide too much torque, even in

the lowest power setting.

Step 5: Place the socket onto the nut or bolt.

Step 6: Grip the Impact Wrench with both hands, especially with higher power settings. Make

sure you are in a stable position and spread your feet shoulder-width apart.

Impact Wrench Operation before proceeding.

Step 7: Press the TRIGGER to tighten the bolt.

Step 8: When the bolt is tight, release the TRIGGER. DO NOT OVER TIGHTEN!

MAINTENANCE

There are no user-serviceable parts in your Impact Wrench. Attempts to repair or make adjustments on your tool are prohibited and will VOID your warranty.

Refer to OPERATIONS Setup for information on maintaining your tool.

Wipe down your tool after every use and store it in a drawer or other safe place.

WARRANTY

Air Tools covered under Central Pneumatic 1 year warranty.

Sockets covered under Pittsburgh Limited Lifetime warranty.

For technical questions, please call 1-800-444-3353.

Page #15 -- SKU: 33567 REV 12/02 REV 04/04

Page 16

PARTS LIST – RATCHET WRENCH

Item# Parts No. Description Item# Parts No. Description

1 HY150-01 Housing 23 HY150-23 Ratchet Y oke

2 HY150-02 Connection Head 24 HY150-24 Cylinder

4 HY150-04 Trigger 25 HY150-25 Rotor

5 HY150-05 Roll Pin 26 HY150-26 Rotor Blade

6 HY150-06 Valve 27 HY150-27 Front Plate

7 HY130-18 O-Ring 28 HY150-28 Front Bearing

8 HY150-08 Spring 29 HY150-29 Rear Plate

9 HY150-09 V alve Plug 30 HY150-30 Rear Bearing

10 HY160-12 O-Ring 31 HY150-31 Cylinder Pin

11 HY150-11 Washer 32 HY150-32 Thrust Washer (3/8")

12 HY150-12 Thread Ring Gear 33 HY150-33 Thrust Washer (1/2")

13 HY150-13 Clamp Nut 34 HY150-34 Spring

14 HY150-14 Idler Gear 35 HY150-35 Lock Pin

15 HY150-15 Idler Gear Pin 36 HY150-36 Ratchet Pawl

16 HY150-16 Idler Gear Plate 37 HY150-37 Pin

17 HY150-17 Crank Shaft 38 HY150-38 Reverse Button

18 HY150-18 Ratchet Anvil 39 HY150-39 Retainer Ring

19 HY150-19 Ratchet Housing 40 HY150-40 Spring

20 HY150-20 Spacer 41 HY150-41 Steel Ball

21 NY150-21 Needle Bearing 42 HY150-42 Washer

22 HY150-22 Drive Bushing

For technical questions, please call 1-800-444-3353.

Page #16 -- SKU: 33567 REV 12/02

Page 17

Exploded View Dia gram - Ratchet Wrench

For technical questions, please call 1-800-444-3353.

Page #17 -- SKU: 33567 REV 12/02

Page 18

PARTS LIST – AIR IMP ACT WRENCH

Item# Parts No. Description Item# Parts No. Description

1 16001 Housing 23 16023 Ball Bearing (X2)

2 16002 V alve Sleeve 24 16024 Cylinder

3 16003 Reverse V alve 25 16025 Rotor

4 16004 Trigger 26 16026 Rotor Blade (X6)

5 16005 Spring Pin 27 16027 Front End Plate

6 16006 Valve Stem 28 16028 Spring Pin

7 16007 Bushing 29 16029 Rear End Plate

8 16008 Steel Ball 30 16030 Spring Pin

9 16009 Spring 31 16031 Oil Seal

10 16010 Hose Adapter 32 16032 Rear Gasket

1 1 16011 Air Regulator 33 16059 O-Ring

12 16012 O-Ring 34 16033 Rear Cover

13 16013 Set Screw 35 16035 Cap Screw (X4)

14 16014 Spring 36 16036 Pin

15 16015 Anvil Bushing 37 16037 Spring

16 16016 Anvil Collar 38 16038 Set Screw

17 16017 O-Ring 39 16039 Exhaust Deflector

18 16018 Anvil 40 16040 Tapping Screw (X2)

19 16019 Hammer Cage 41 16041 Set Screw

20 16020 Hammer Pin 42 16042 Protecting Rubber

21 16021 Hammer Dog 43 16043 Rubber

22 16022 Drive Cam

For technical questions, please call 1-800-444-3353.

Page #18 -- SKU: 33567 REV 12/02

Page 19

Exploded Vie w Diagram -- Air Impact Wrenc h

For technical questions, please call 1-800-444-3353.

Page #19 -- SKU: 33567 REV 12/02

Loading...

Loading...