Central Pneumatic 93727 Assembly And Operating Instructions Manual

1/4” Air Angle Grinder

93727

ASSEMBLY AND OPERATING INSTRUCTIONS

Due to continuing improvements, actual product may differ slightly from the product described herein.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at http://www.harborfreight.com

Copyright © 2006 by Harbor Freight Tools®. All rights reserved.

No portion of this manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight Tools.

Manual Revised 11h

SKU 93727 For technical questions, please call 1-800-444-3353 Page 1

For technical questions and replacement parts, please call 1-800-444-3353

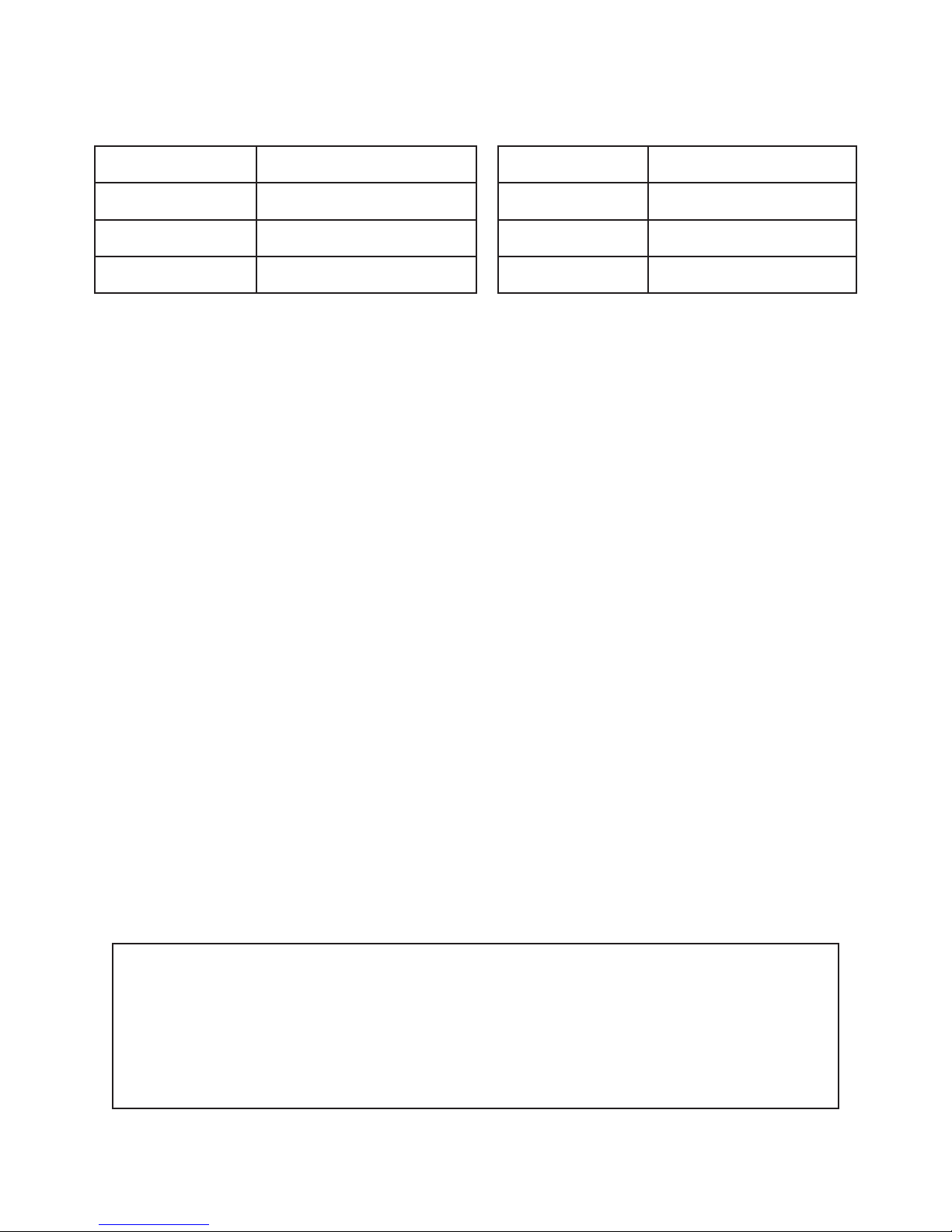

Specications

Construction:

Tool Holder: 1/4” Collet Operating Speed: 16,000 rpm max.

Air Inlet: 1/4” npt Air Inlet Screen: 20 mesh

Overall Dimensions: 6-¼”L x 3”H x 1-½”W Net Weight: 1-¼ lbs.

Cast Aluminum Housing with

Machined Steel Components

Air Consumption:

90 psi operating pressure

3.25 cfm air consumption

Save This Manual

You will need the manual for the safety warnings and precautions, assembly instructions, operating and maintenance procedures, parts list and diagram. Keep your invoice with this manual. Write the

invoice number on the inside of the front cover. Keep the manual and invoice in a safe and dry place for

future reference.

Safety Warnings and Precautions

WARNING: When using tool, basic safety precautions should always be followed to reduce the risk

of personal injury and damage to equipment. Read all instructions before using this tool!

1. Keep work area clean. Cluttered areas invite injuries.

2. Observe work area conditions. Do not use machines or power tools in damp or wet locations.

Don’t expose to rain. Keep work area well lit. Do not use electrically powered tools such as an air

compressor in the presence of ammable gases or liquids.

3. Keep children away. Children must never be allowed in the work area. Do not let them handle

machines, tools, or extension cords.

4. Store idle equipment. When not in use, tools must be stored in a dry location to inhibit rust.

Always lock up tools and keep out of reach of children.

5. Use the right tool for the job. Do not attempt to force a small tool or attachment to do the work of a

larger industrial tool. There are certain applications for which this tool was designed. It will do the job

better and more safely at the rate for which it was intended. Do not modify this tool and do not use

this tool for a purpose for which it was not intended.

6. Dress properly while working. Do not wear loose clothing or jewelry as they can be caught

in moving parts. Protective, electrically non-conductive clothes and non-skid footwear are

recommended when working. Wear restrictive hair covering to contain long hair.

7. Use eye and ear protection. Always wear ANSI approved impact safety goggles. Wear a full

face shield if you are producing metal lings or wood chips. Wear an ANSI approved dust mask or

respirator when working around metal, wood, and chemical dusts and mists.

WARNING! Some dust created by power sanding, sawing, grinding, drilling, and other construction

activities, contain chemicals known (to the State of California) to cause cancer, birth defects or

other reproductive harm. Some examples of these chemicals are: lead from lead-based paints,

crystalline silica from bricks and cement or other masonry products, arsenic and chromium from

chemically treated lumber. Your risk from these exposures varies, depending on how often you do

this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and

work with approved safety equipment, such as those dust masks that are specially designed to lter

out microscopic particles. (California Health & Safety Code § 25249.5, et seq.)

SKU 93727 For technical questions, please call 1-800-444-3353 Page 2

8. Do not overreach. Keep proper footing and balance at all times. Do not reach over or across

running machines.

9. Maintain tools with care. Keep tools clean and in good condition for better and safer performance.

Follow instructions for lubricating and changing accessories. Inspect tool ttings and hoses

periodically and, if damaged, have them repaired by an authorized technician. The handles must be

kept clean, dry, and free from oil and grease at all times.

10. Stay alert. Watch what you are doing, and use common sense when operating a power tool.

Do not use a power tool while tired or under the inuence of drugs, alcohol, or medication. A

moment of inattention while operating power tools may result in serious personal injury.

11. Avoid accidental starting. Be sure the Throttle Lever is in the OFF position before attaching

the air pressure hose. Carrying power tools with your nger on the throttle lever invites accidents.

12. Remove adjusting keys or wrenches before turning the power tool on. A wrench or a key that

is left attached to a rotating part of the power tool may result in personal injury.

13. Do not overreach. Keep proper footing and balance at all times. Proper footing and balance

enables better control of the power tool in unexpected situations.

14. Use clamps (not included) or other practical ways to secure and support the work piece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to loss of control.

15. Do not use the power tool if the Power Switch does not turn it on or off. Any tool that cannot be

controlled with the Power Switch is dangerous and must be replaced.

16. Disconnect the air hose from the tool before making any adjustments, changing accessories,

or storing the tool. Such preventive safety measures reduce the risk of starting the tool accidentally.

17. Check for misalignment or binding of moving parts, breakage of parts, and any other

condition that may affect the tool’s operation. If damaged, have the tool serviced before

using. Many accidents are caused by poorly maintained tools.

18. Tool service must be performed only by qualied repair personnel. Service or maintenance

performed by unqualied personnel could result in a risk of injury.

19. When servicing a tool, use only identical replacement parts. Use of unauthorized parts or failure

to follow maintenance instructions may create a risk of electric shock or injury.

20. Maintain labels and nameplates on the tool. These carry important information. If unreadable or

missing, contact Harbor Freight Tools for a replacement.

21. When starting a hand-held power tool, always maintain a rm grip on the tool with both

hands to resist starting torque.

22. Always keep the air pressure hose away from moving parts on the tool.

23. Hold tool by insulated gripping surfaces when performing an operation where the tool may

contact hidden wiring. Contact with a “live” wire will make exposed metal parts of the tool

“live” and shock the operator.

24. Never lay the tool down until the motor has come to a complete stop. The tool may create

unforeseen risk while the motor cycles down.

Warning: The warnings, cautions, and instructions discussed in this instruction manual can-

not cover all possible conditions and situations that may occur. It must be understood by the

operator that common sense and caution are factors which cannot be built into this product,

but must be supplied by the operator.

SKU 93727 For technical questions, please call 1-800-444-3353 Page 3

Loading...

Loading...