Central Pneumatic 7528 Assembly And Operating Instructions Manual

AIR DRILL- I/2 INCHAIR DRILL- I/2 INCH

AIR DRILL- I/2 INCHAIR DRILL- I/2 INCH

AIR DRILL- I/2 INCH

ASSEMBLY AND OPERATING INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at http://www.harborfreight.com

Copyright © 2004 by Harbor Freight Tools®. All rights reser ved. No por tion of this

manual or any artwork contained herein may be reproduced in any shape or for m

without the express written consent of Harbor F reight T ools .

For technical questions and replacement parts, please call 1-800-444-3353

07528

®

SKU 07528 Page 2

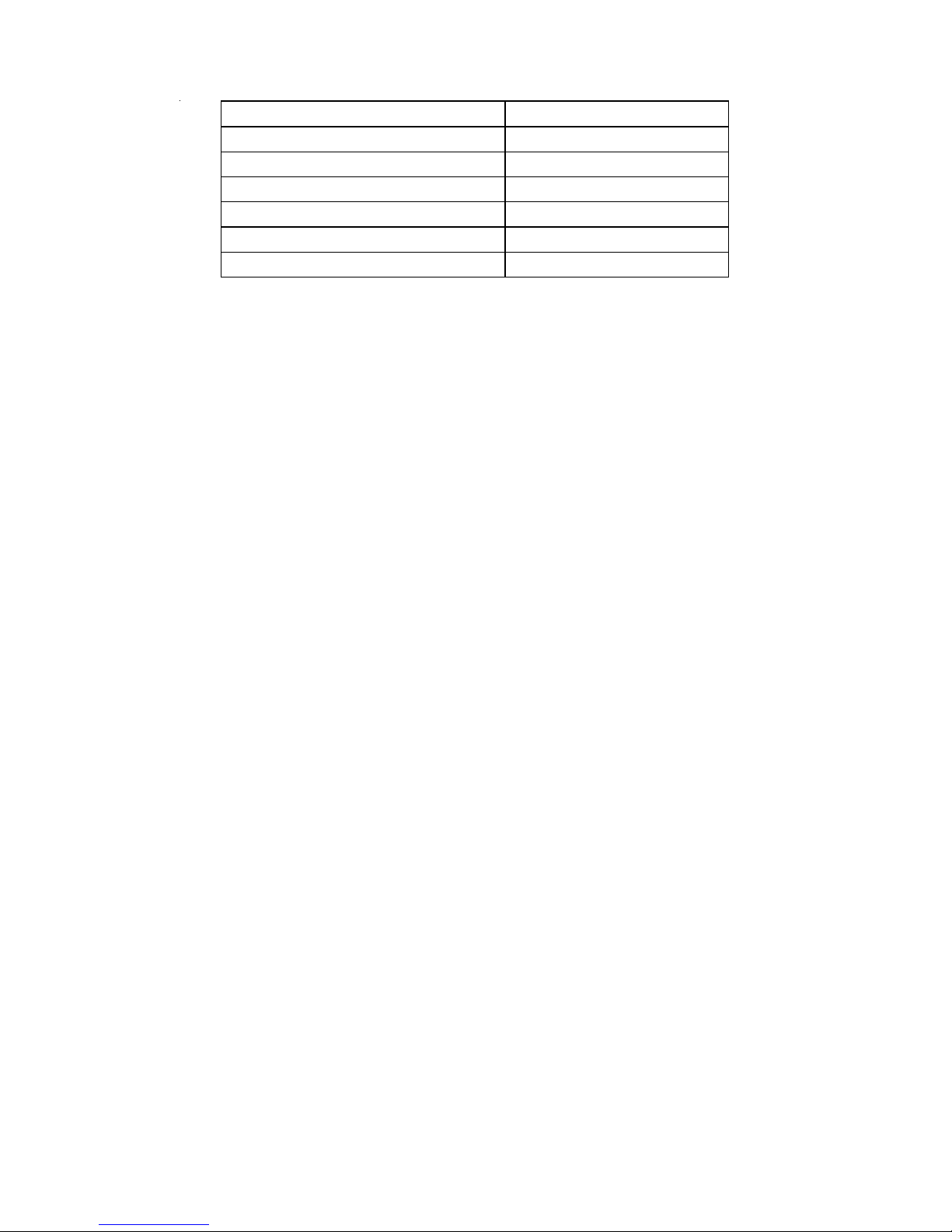

Specifications

Item Description

Chuck ½ inch, Jacobs type

Rated Air Pressure 90 PSI at 4 CFM

Recommended Hose 3/8 inch

Speed 550 RPM

Air Inlet ¼” – 18 NPT

Weight 3.75 lbs.

Save this Manual

You will need the manual for the saf ety warnings and precautions, assembly

instructions, operating and maintenance procedures, parts list and diagram. K eep

your inv oice with this man ual. Write the inv oice number on the inside of the front

cover. Keep the manual and inv oice in a safe and dry place for future reference.

Safety Warnings and Precautions

WARNING: When using tool, basic safety precautions should always be followed to reduce the risk of personal injury and damage to equipment.

Read all instructions before using this tool!

1. Disconnect air before servicing. Do not attempt to disassemble or service

tool with air hose attached.

2. Use only specified operating air pressure. Recommended tool operating air

pressure is 90 PSI.

3. Do not use combustible gases. Do not use combustible gases as a power

source, or use tool in areas where combustib le gases are stored.

4. Av oid possible kic kbac k injury. Hold the tool with both hands during

operation so that your head and body are not injured by possible kickback of

the tool.

5. Use care when transporting tool. Disconnect tool from air supply when

moving tool in the workplace. Carry tool only by the handle without drawing

the trigger.

6. Keep work area c lean . Cluttered areas invite injuries.

7. Observe work area conditions. Do not use machines or po wer tools in

damp or wet locations. Don’t expose to rain. K eep work area well lighted.

SKU 07528 Page 3

8. Keep children awa y. Children must nev er be allowed in the work area. Do

not let them handle machines, tools, or extension cords.

9. Store idle equipment. When not in use , tools must be stored in a dry

location to inhibit rust. Alw a ys loc k up tools and k eep out of reach of children.

10. Do not force tool. It will do the job better and more safely at the rate for

which it was intended. Do not use inappropriate attachments in an attempt to

exceed the tool capacity.

11. Use the right tool for the job. Do not attempt to force a small tool or

attachment to do the work of a larger industrial tool. There are certain

applications for which this tool was designed. Do not modify this tool and do

not use this tool for a purpose for which it was not intended.

12. Dress properly. Do not wear loose clothing or jewelry as they can be caught

in moving parts. Protectiv e , electrically nonconductiv e clothes and nonskid

footwear are recommended when w orking. Wear restrictive hair co v ering to

contain long hair .

13. Use eye and ear protection. Always wear ANSI approved impact saf ety

goggles. W ear an ANSI approved dust mask or respirator when working

around metal, wood, and chemical dusts and mists. W ear ear plugs .

14. Do not overreach. Keep proper footing and balance at all times. Do not

reach over or across running machines.

15. Maintain tools with care. Keep tools sharp and clean for better and safer

performance. F ollow instructions f or lubricating and changing accessories.

Inspect tool periodically and, if damaged, have them repaired b y an

authorized technician. The handles must be kept clean, dry, and free from oil

and grease at all times.

16. Remove adjusting keys and wrenches. Check that k e ys and adjusting

wrenches are removed from the tool or machine w ork surface before

plugging it in.

17. Stay alert. Watch what y ou are doing, use common sense. Do not operate

any tool when you are tired.

18. Replacement parts and accessories. When servicing, use only identical

replacement parts. Use of any other parts will void the warranty. Only use

accessories intended for use with this tool. Approved accessories are

availab le from Harbor F reight Tools.

19. Maintenance. F or your safety, service and maintenance should be

performed regularly by a qualified technician.

Loading...

Loading...