Central Pneumatic 60637 Owner's Manual & Safety Instructions

Page 2 F o r t e c h n i c a l q u e s t i o n s , p l e a s e c a l l 1 - 8 8 8 - 8 6 6 - 5 7 9 7 . Item 60637

T a b l e o f Co n t e n t s

Safety ......................................................... 2

Setup .......................................................... 6

Specifications ............................................. 6

Operation ................................................... 10

Maintenance .............................................. 12

Parts List and Diagram .............................. 14

Warranty .................................................... 16

W ARNING S Y M B O L S AND D EF INIT IO NS

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Addresses practices not related to personal injury.

S AF ET Y O PERAT IO N M AINT ENANCES ET UP

Page 3F o r t e c h n i c a l q u e s t i o n s , p l e a s e c a l l 1 - 8 8 8 - 8 6 6 - 5 7 9 7 .Item 60637

IM PO RT ANT S AF ET Y INF O RM AT IO N

G e n e r a l S a f e t y W a r n i n g s

W ARNING Re a d a l l s a f e t y w a r n i n g s a n d i n s t r u c t i o n s .

Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

S a v e a l l w a r n i n g s a n d i n s t r u c t i o n s f o r f u t u r e r e f e r e n c e .

The warnings, precautions, and instructions discussed in this instruction manual cannot cover all possible

conditions and situations that may occur. It must be understood by the operator that common sense

and caution are factors which cannot be built into this product, but must be supplied by the operator.

1. W o r k a r e a s a f e t y

a. K e e p w o r k a r e a c l e a n a n d w e l l l i t .

Cluttered or dark areas invite accidents.

b. D o n o t o p e r a t e t h e Co m p r e s s o r i n e x p l o s i v e

a t m o s p h e r e s , s u c h a s i n t h e p r e s e n c e

o f f l a m m a b l e l i q u i d s , g a s e s o r d u s t .

Compressor motors produce sparks

which may ignite the dust or fumes.

c. K e e p c h i l d r e n a n d b y s t a n d e r s a w a y

f r o m a n o p e r a t i n g c o m p r e s s o r .

2. El e c t r i c a l s a f e t y

a. Co m p r e s s o r p l u g s m u s t m a t c h t h e o u t l e t .

Ne v e r m o d i f y t h e p l u g i n a n y w a y .

D o n o t u s e a n y a d a p t e r p l u g s w i t h g r o u n d e d

c o m p r e s s o r s . Standard plugs and matching

outlets will reduce risk of electric shock.

b. D o n o t e x p o s e c o m p r e s s o r t o r a i n o r w e t

c o n d i t i o n s . Water entering a compressor

will increase the risk of electric shock.

c. D o n o t a b u s e t h e c o r d . Ne v e r u s e t h e

c o r d f o r u n p l u g g i n g t h e c o m p r e s s o r .

K e e p c o r d a w a y f r o m h e a t , o i l , s h a r p e d g e s

o r m o v i n g p a r t s . Damaged or entangled

cords increase the risk of electric shock.

3. Pe r s o n a l s a f e t y

a. S t a y a l e r t , w a t c h w h a t y o u a r e d o i n g a n d

u s e c o m m o n s e n s e w h e n o p e r a t i n g t h i s

c o m p r e s s o r . D o n o t u s e t h i s c o m p r e s s o r

w h i l e y o u a r e t i r e d o r u n d e r t h e i n f l u e n c e

o f d r u g s , a l c o h o l o r m e d i c a t i o n . A moment

of inattention while operating a compressor

may result in serious personal injury.

b. Us e p e r s o n a l p r o t e c t i v e e q u i p m e n t .

Al w a y s w e a r ANS I- a p p r o v e d e y e

p r o t e c t i o n d u r i n g s e t u p a n d u s e .

c. Pr e v e n t u n i n t e n t i o n a l s t a r t i n g . En s u r e t h e

s w i t c h i s i n t h e o f f - p o s i t i o n b e f o r e c o n n e c t i n g

t o p o w e r s o u r c e o r m o v i n g t h e c o m p r e s s o r .

4. Co m p r e s s o r u s e a n d c a r e

a. D o n o t u s e t h e c o m p r e s s o r i f t h e s w i t c h

d o e s n o t t u r n i t o n a n d o f f . Any compressor

that cannot be controlled with the switch

is dangerous and must be repaired.

b. D i s c o n n e c t t h e p l u g f r o m t h e p o w e r s o u r c e

b e f o r e m a k i n g a n y a d j u s t m e n t s , c h a n g i n g

a c c e s s o r i e s , o r s t o r i n g t h e c o m p r e s s o r .

Such preventive safety measures reduce the

risk of starting the compressor accidentally.

c. S t o r e a n i d l e c o m p r e s s o r o u t o f t h e r e a c h

o f c h i l d r e n a n d d o n o t a l l o w p e r s o n s

u n f a m i l i a r w i t h t h e c o m p r e s s o r o r t h e s e

i n s t r u c t i o n s t o o p e r a t e i t . A compressor is

dangerous in the hands of untrained users.

d. M a i n t a i n t h e c o m p r e s s o r . K e e p t h e

c o m p r e s s o r c l e a n f o r b e t t e r a n d s a f e r

p e r f o r m a n c e . F o l l o w i n s t r u c t i o n s f o r

l u b r i c a t i n g a n d c h a n g i n g a c c e s s o r i e s .

K e e p d r y , c l e a n a n d f r e e f r o m o i l a n d g r e a s e .

Ch e c k f o r m i s a l i g n m e n t o r b i n d i n g o f m o v i n g

p a r t s , b r e a k a g e o f p a r t s a n d a n y o t h e r

c o n d i t i o n t h a t m a y a f f e c t t h e c o m p r e s s o r ’ s

o p e r a t i o n . If d a m a g e d , h a v e t h e c o m p r e s s o r

r e p a i r e d b e f o r e u s e . Many accidents are

caused by a poorly maintained compressor.

e. Us e t h e c o m p r e s s o r i n a c c o r d a n c e w i t h

t h e s e i n s t r u c t i o n s , t a k i n g i n t o a c c o u n t

t h e w o r k i n g c o n d i t i o n s a n d t h e w o r k t o

b e p e r f o r m e d . Use of the compressor for

operations different from those intended

could result in a hazardous situation.

5. S e r v i c e

a. H a v e y o u r c o m p r e s s o r s e r v i c e d b y a

q u a l i f i e d r e p a i r p e r s o n u s i n g o n l y i d e n t i c a l

r e p l a c e m e n t p a r t s . This will ensure that the

safety of the compressor is maintained.

S AF ET YO PERAT IO NM AINT ENANCE S ET UP

Page 4 F o r t e c h n i c a l q u e s t i o n s , p l e a s e c a l l 1 - 8 8 8 - 8 6 6 - 5 7 9 7 . Item 60637

Ai r Co m p r e s s o r S a f e t y W a r n i n g s

1. Ri s k o f f i r e o r e x p l o s i o n - d o n o t s p r a y f l a m m a b l e

l i q u i d i n a c o n f i n e d a r e a o r t o w a r d s a h o t s u r f a c e .

S p r a y a r e a m u s t b e w e l l - v e n t i l a t e d . D o n o t

s m o k e w h i l e s p r a y i n g o r s p r a y w h e r e s p a r k o r

f l a m e i s p r e s e n t . Ar c i n g p a r t s - k e e p c o m p r e s s o r

a t l e a s t 2 0 f e e t a w a y f r o m e x p l o s i v e v a p o r s ,

s u c h a s w h e n s p r a y i n g w i t h a s p r a y g u n .

2. Ri s k o f b u r s t i n g - d o n o t a d j u s t r e g u l a t o r h i g h e r

t h a n m a r k e d m a x i m u m p r e s s u r e o f a t t a c h m e n t .

3. Ri s k o f i n j u r y - d o n o t d i r e c t a i r

s t r e a m a t p e o p l e o r a n i m a l s .

4. D o n o t u s e t o s u p p l y b r e a t h i n g a i r .

5. D o n o t l e a v e c o m p r e s s o r u n a t t e n d e d

f o r a n e x t e n d e d p e r i o d w h i l e p l u g g e d i n .

Un p l u g c o m p r e s s o r a f t e r w o r k i n g .

6. K e e p c o m p r e s s o r w e l l - v e n t i l a t e d .

D o n o t c o v e r c o m p r e s s o r d u r i n g u s e .

7. Drain Tank daily and after use. Internal rust causes

tank failure and explosion.

8. Do not remove the valve cover or

adjust internal components.

9. Compressor head gets hot during operation.

Do not touch it or allow children nearby during

or immediately following operation.

10. Do not use the air hose to move the compressor.

11. Release the pressure in the

storage tank before moving.

12. The use of accessories or attachments not

recommended by the manufacturer may

result in a risk of injury to persons.

13. All air line components, including hoses, pipe,

connectors, filters, etc., must be rated for a minimum

working pressure of 150 PSI, or 150% of the

maximum system pressure, whichever is greater.

14. USE OF AN EXTENSION CORD IS NOT

RECOMMENDED. If you choose to use an

extension cord, use the following guidelines:

T AB L E A: RECO M M END ED M INIM UM W IRE

G AUG E F O R EX T ENS IO N CO RD S

( 1 2 0 V O L T )

NAM EPL AT E

AM PERES

( a t f u l l l o a d )

EX T ENS IO N CO RD

L ENG T H

25′ 50′ 100′ 150′

0 – 6 18 16 16 14

6.1 – 10 18 16 D o n o t u s e .

10.1 – 12 16 16 D o n o t u s e .

12.1 – 16 14 12 D o n o t u s e .

a. Make sure your extension cord

is in good condition.

b. Be sure to use an extension cord which is heavy

enough to carry the current your product will draw.

An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating.

Table A shows the correct size to use depending

on cord length and nameplate ampere rating.

If in doubt, use the next heavier gauge. The

smaller the gauge number, the heavier the cord.

15. Industrial applications must follow OSHA guidelines.

16. Maintain labels and nameplates on the

compressor. These carry important safety

information. If unreadable or missing, contact

Harbor Freight Tools for a replacement.

17. This product is not a toy.

Keep it out of reach of children.

18. People with pacemakers should consult their

physician(s) before use. Electromagnetic fields in

close proximity to heart pacemaker could cause

pacemaker interference or pacemaker failure.

19. WARNING: The brass components of

this product contain lead, a chemical

known to the State of California to cause

birth defects (or other reproductive harm).

(California Health & Safety code § 25249.5, et seq.)

20. WARNING: Handling the cord on this product will

expose you to lead, a chemical known to the State

of California to cause cancer, and birth defects or

other reproductive harm. Wash hands after handling.

(California Health & Safety Code § 25249.5, et seq.)

S AV E T H ES E INS T RUCT IO NS .

S AF ET Y O PERAT IO N M AINT ENANCES ET UP

Page 5F o r t e c h n i c a l q u e s t i o n s , p l e a s e c a l l 1 - 8 8 8 - 8 6 6 - 5 7 9 7 .Item 60637

G r o u n d i n g

T O PREV ENT EL ECT RIC S H O CK AND D EAT H

F RO M INCO RRECT G RO UND ING W IRE CO NNECT IO N:

Ch e c k w i t h a q u a l i f i e d e l e c t r i c i a n i f y o u a r e i n d o u b t a s t o w h e t h e r t h e o u t l e t i s p r o p e r l y g r o u n d e d .

D o n o t m o d i f y t h e p o w e r c o r d p l u g p r o v i d e d w i t h t h e c o m p r e s s o r .

Ne v e r r e m o v e t h e g r o u n d i n g p r o n g f r o m t h e p l u g . D o n o t u s e t h e c o m p r e s s o r i f t h e p o w e r c o r d o r p l u g i s

d a m a g e d . If d a m a g e d , h a v e i t r e p a i r e d b y a s e r v i c e f a c i l i t y b e f o r e u s e . If t h e p l u g w i l l n o t f i t t h e o u t l e t , h a v e a

p r o p e r o u t l e t i n s t a l l e d b y a q u a l i f i e d e l e c t r i c i a n .

1 1 0 - 1 2 0 V AC G r o u n d e d Co m p r e s s o r s : Co m p r e s s o r s w i t h T h r e e Pr o n g Pl u g s

1. In the event of a malfunction or breakdown,

grounding provides a path of least resistance for

electric current to reduce the risk of electric shock.

This compressor is equipped with an electric

cord having an equipment-grounding conductor

and a grounding plug. The plug must be

plugged into a matching outlet that is properly

installed and grounded in accordance

with all local codes and ordinances.

2. Do not modify the plug provided –

if it will not fit the outlet, have the proper

outlet installed by a qualified electrician.

3. Improper connection of the equipment-grounding

conductor can result in a risk of electric shock.

The conductor with insulation having an outer

surface that is green with or without yellow

stripes is the equipment-grounding conductor.

If repair or replacement of the electric cord or

plug is necessary, do not connect the equipmentgrounding conductor to a live terminal.

4. Check with a qualified electrician or service

personnel if the grounding instructions are

not completely understood, or if in doubt as to

whether the compressor is properly grounded.

5. Use only 3-wire extension cords that have

3-prong grounding plugs and 3-pole receptacles

that accept the compressor’s plug.

6. Repair or replace damaged or worn cord immediately.

1 2 5 V AC 3 - Pr o n g Pl u g a n d O u t l e t

( f o r u p t o 1 2 5 V AC a n d u p t o 1 5 A)

G r o u n d i n g

Pi n

7. This compressor is intended for use on a

circuit that has an outlet that looks like the one

illustrated above in 1 2 5 V AC 3 - Pr o n g Pl u g

a n d O u t l e t . The compressor has a grounding

plug that looks like the plug illustrated above

in 1 2 5 V AC 3 - Pr o n g Pl u g a n d O u t l e t .

8. The outlet must be properly installed and grounded

in accordance with all codes and ordinances.

9. Do not use an adapter to connect this

compressor to a different outlet.

S y m b o l o g y

PS I

Pounds per square inch of pressure

CF M

Cubic Feet per Minute flow

S CF M

Cubic Feet per Minute flow

at standard conditions

NPT

National pipe thread, tapered

NPS

National pipe thread, straight

Double Insulated

Canadian Standards Association

Underwriters Laboratories, Inc.

V AC

Volts Alternating Current

A

Amperes

S AF ET YO PERAT IO NM AINT ENANCE S ET UP

Page 6 F o r t e c h n i c a l q u e s t i o n s , p l e a s e c a l l 1 - 8 8 8 - 8 6 6 - 5 7 9 7 . Item 60637

S p e c i f i c a t i o n s

Electrical Rating 120VAC / 60Hz / 2.6 A

Air Outlet Size

1

/4″ -18 NPT

Air Pressure

Shut-off 100 PSI

Restart 85 PSI

Air Tank Capacity 3 Gallons

Air Flow Capacity

0.6 SCFM @ 90 PSI

1 SCFM @ 40 PSI

Fuse Size 3A ( r e p l a c e o n l y w i t h s a m e s i ze a n d t y p e )

2 2 7 8 4 7

In s t r u c t i o n s f o r p u t t i n g i n t o u s e

Re a d t h e ENT IRE IM PO RT ANT S AF ET Y INF O RM AT IO N s e c t i o n a t t h e b e g i n n i n g o f t h i s

m a n u a l i n c l u d i n g a l l t e x t u n d e r s u b h e a d i n g s t h e r e i n b e f o r e s e t u p o r u s e o f t h i s p r o d u c t .

T O PREV ENT S ERIO US INJ URY F RO M ACCID ENT AL O PERAT IO N:

T u r n t h e Po w e r S w i t c h “O F F ” a n d u n p l u g t h e Ai r Co m p r e s s o r f r o m i t s e l e c t r i c a l

o u t l e t b e f o r e a s s e m b l i n g o r m a k i n g a n y a d j u s t m e n t s t o t h e c o m p r e s s o r .

No t e : For additional information regarding the parts listed in the following pages,

refer to the Assembly Diagram near the end of this manual.

F u n c t i o n s

F u s e

H o l d e r

O u t p u t Ai r

Pr e s s u r e

G a u g e

S w i t c h

T a n k Ai r

Pr e s s u r e

G a u g e

S a f e t y

V a l v e

Re g u l a t o r

K n o b

Ai r

O u t l e t

S AF ET Y O PERAT IO N M AINT ENANCES ET UP

Page 7F o r t e c h n i c a l q u e s t i o n s , p l e a s e c a l l 1 - 8 8 8 - 8 6 6 - 5 7 9 7 .Item 60637

As s e m b l y / M o u n t i n g

1. Break in the new Air Compressor as follows:

a. Turn the Power Switch off and unplug the unit.

Insert a male coupler (sold separately)

into the female Quick Coupler and fully

open all regulators and valves.

b. Plug in the Power Cord.

c. Turn the Power Switch ON.

d. Let the unit run for 30 minutes.

Air will expel freely through the Coupler.

e. Turn the Power Switch OFF.

f. Unplug the Power Cord and

remove the male coupler.

2. Connect a regulator valve, an inline shut off valve

and a 1/4″ NPT air hose to the Quick Coupler

(all sold separately). The air hose must be long

enough to reach the work area with enough extra

length to allow free movement while working.

No t e : An i n - l i n e s h u t o f f b a l l v a l v e i s a n i m p o r t a n t

s a f e t y d e v i c e b e c a u s e i t c o n t r o l s t h e a i r s u p p l y e v e n

i f t h e a i r h o s e i s r u p t u r e d . T h e s h u t o f f v a l v e s h o u l d

b e a b a l l v a l v e b e c a u s e i t c a n b e c l o s e d q u i c k l y .

3. Depending on the tool which you will be

using with this compressor, you may need to

incorporate additional components, such as an

in-line oiler, a filter, or a dryer (all sold separately),

as shown on Figure A on page 8 and

Figure B on page 9. Consult your air

tool’s manual for needed accessories.

S AF ET YO PERAT IO NM AINT ENANCE S ET UP

Page 8 F o r t e c h n i c a l q u e s t i o n s , p l e a s e c a l l 1 - 8 8 8 - 8 6 6 - 5 7 9 7 . Item 60637

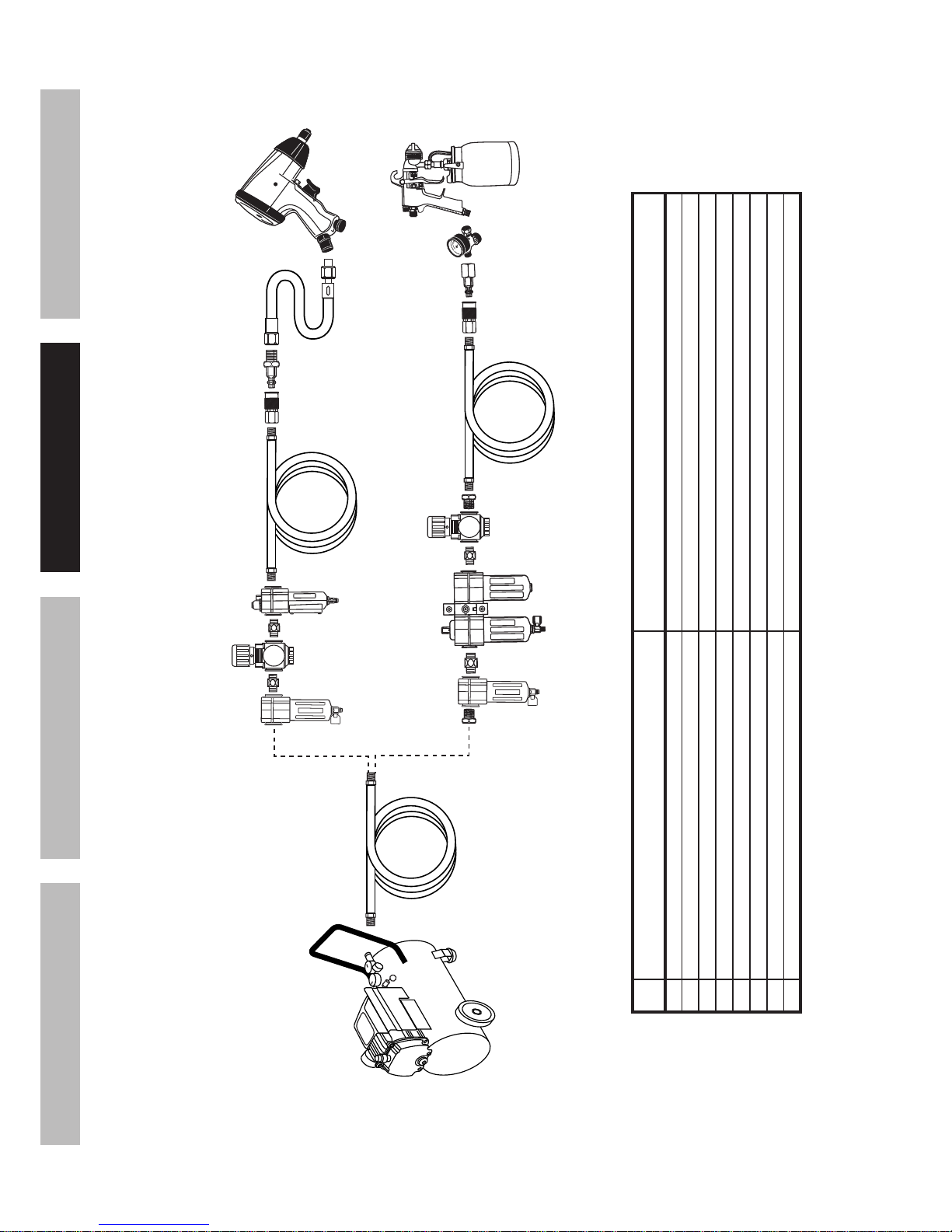

F i g u r e A: Po r t a b l e Ai r S u p p l y S e t u p

G

A

E

E H

F

B

Non-lubricated

Tools

Lubricated

Tools

A

B

C

C

D

A

D e s c r i p t i o n F u n c t i o n

A Air Hose Connects air to tool

B Filter Prevents dirt and condensation from damaging tool or workpiece

C Regulator Adjusts air pressure to tool

D Lubricator (optional) For air tool lubrication

E Coupler and Plug Provides quick connection and release

F Leader Hose (optional) Increases coupler life

G Air Cleaner / Dryer (optional) Prevents water vapor from damaging workpiece

H Air Adjusting Valve (optional) For fine tuning airflow at tool

S AF ET Y O PERAT IO N M AINT ENANCES ET UP

Page 9F o r t e c h n i c a l q u e s t i o n s , p l e a s e c a l l 1 - 8 8 8 - 8 6 6 - 5 7 9 7 .Item 60637

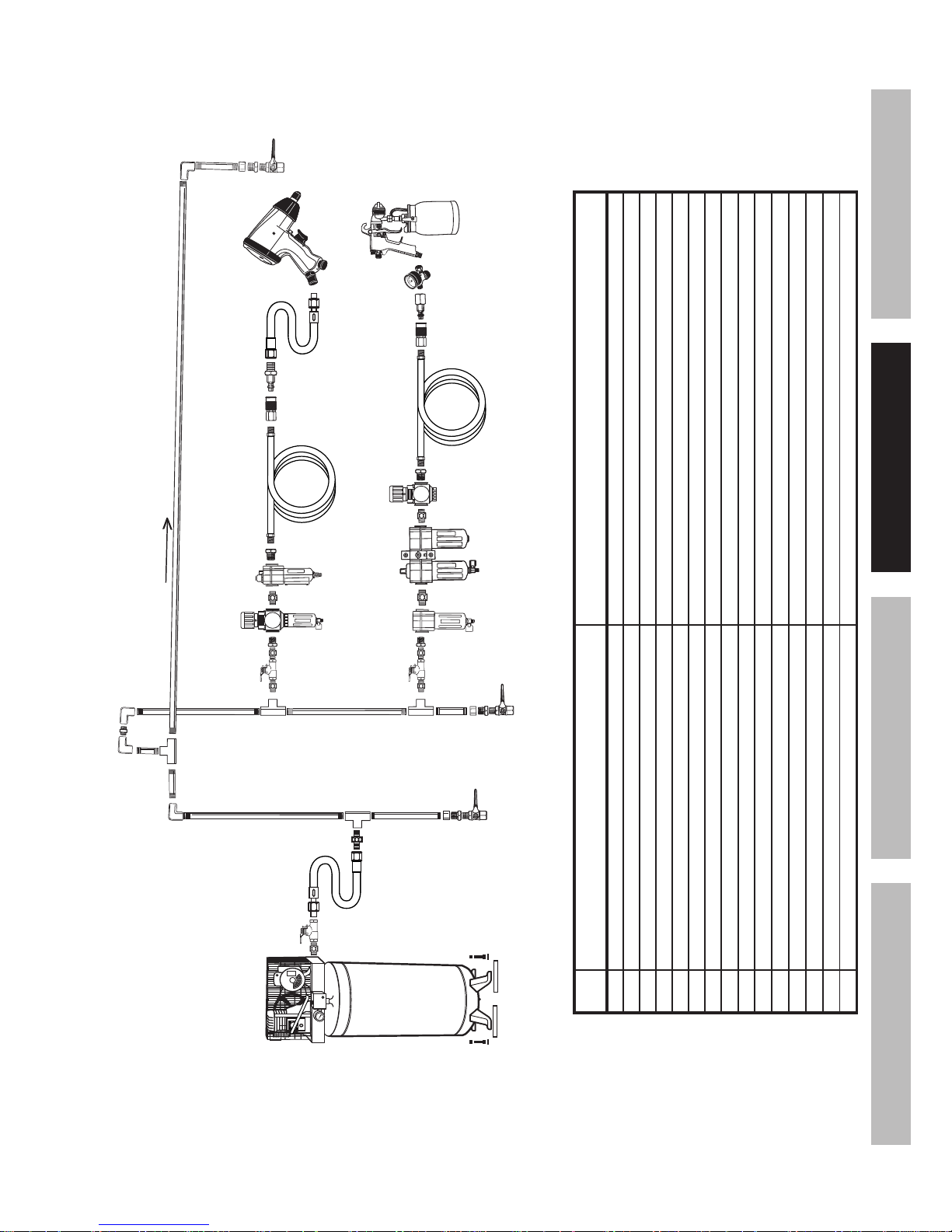

F i g u r e B : S t a t i o n a r y Ai r S u p p l y S e t u p

N

L

L O

M

C

C

Non-lubricated

Tools

Lubricated

Tools

H

I

I

J

J

K

H

F

G

E

S lop e

F

F

B B

A

C

D

D e s c r i p t i o n F u n c t i o n

A Vibration Pads For noise and vibration reduction

B Anchor Bolts Secures air compressor in place

C Ball Valve Isolates sections of system for maintenance

D Isolation Hose For vibration reduction

E Main Air Line - 3/4″ minimum recommended Distributes air to branch lines

F Ball Valve To drain moisture from system

G Branch Air Line -1/2″ minimum recommended Brings air to point of use

H Air Hose Connects air to tool

I Filter Prevents dirt and condensation from damaging tool or workpiece

J Regulator Adjusts air pressure to tool

K Lubricator (optional) For air tool lubrication

L Coupler and Plug Provides quick connection and release

M Leader Hose (optional) Increases coupler life

N Air Cleaner / Dryer (optional) Prevents water vapor from damaging workpiece

O Air Adjusting Valve (optional) For fine tuning airflow at tool

S AF ET YO PERAT IO NM AINT ENANCE S ET UP

Page 10 F o r t e c h n i c a l q u e s t i o n s , p l e a s e c a l l 1 - 8 8 8 - 8 6 6 - 5 7 9 7 . Item 60637

O p e r a t i n g In s t r u c t i o n s

Re a d t h e ENT IRE IM PO RT ANT S AF ET Y INF O RM AT IO N s e c t i o n a t t h e b e g i n n i n g o f t h i s

m a n u a l i n c l u d i n g a l l t e x t u n d e r s u b h e a d i n g s t h e r e i n b e f o r e s e t u p o r u s e o f t h i s p r o d u c t .

Co m p r e s s o r Ar e a S e t Up

1. Designate a work area that is clean and well-lit.

The work area must not allow access by

children or pets to prevent injury.

2. Locate the Compressor on a flat level surface to

ensure proper pump lubrication and to prevent

damage to the unit. Keep at least 12″ of space

around the unit to allow air circulation.

3. Route the power cord from the compressor

to the grounded wall outlet, along a safe path

without creating a tripping hazard or exposing

the power cord to possible damage.

G e n e r a l O p e r a t i o n

1. Turn red regulator knob counterclockwise completely.

2. Close the Drain Valve.

3. Plug the Air Compressor Power Cord into

a grounded 120 VAC electrical outlet.

4. Turn the Switch ON.

5. Allow the Air Compressor to build

up pressure until it cycles off.

No t e : At the beginning of the day’s first use of the

Air Compressor, check for air leaks by applying soapy

water to connections while the Air Compressor is

pumping and after pressure cut-out. Look for air bubbles.

If air bubbles are present at connections, tighten

connections. Do not use the Air Compressor

unless all connections are air tight, the extra air

leaking out will cause the compressor to operate

too often, increasing wear on the compressor.

No t e : As long as the Power Switch is ON, the operation

of the Air Compressor is automatic, controlled by an

internal pressure switch. The Compressor will turn on

automatically when the air pressure drops to 85 PSI,

and will turn off automatically when the

air pressure reaches 100 PSI.

W ARNING ! T O PREV ENT S ERIO US

INJ URY AND D EAT H F RO M EX PL O S IO N:

D o n o t a d j u s t t h e i n t e r n a l

p r e s s u r e s w i t c h . Any change to the

automatic pressure levels may cause

excess pressure to accumulate,

causing a hazardous situation.

6.

AF T ER the Compressor builds up enough

pressure and shuts off, adjust the Air Compressor’s

Regulator Knob so that the air output is enough

to properly power the tool, but the output will

not exceed the tool’s maximum air pressure at

any time. Turn the knob clockwise to increase

the pressure and counter-clockwise to decrease

pressure. Adjust the pressure gradually, while

checking the air output gauge to set the pressure.

S AF ET Y O PERAT IO N M AINT ENANCES ET UP

Loading...

Loading...