Central Pneumatic 60328 Owner's Manual And Safety Instructions

Page 2 For technical questions, please call 1-800-444-3353. Item 60328

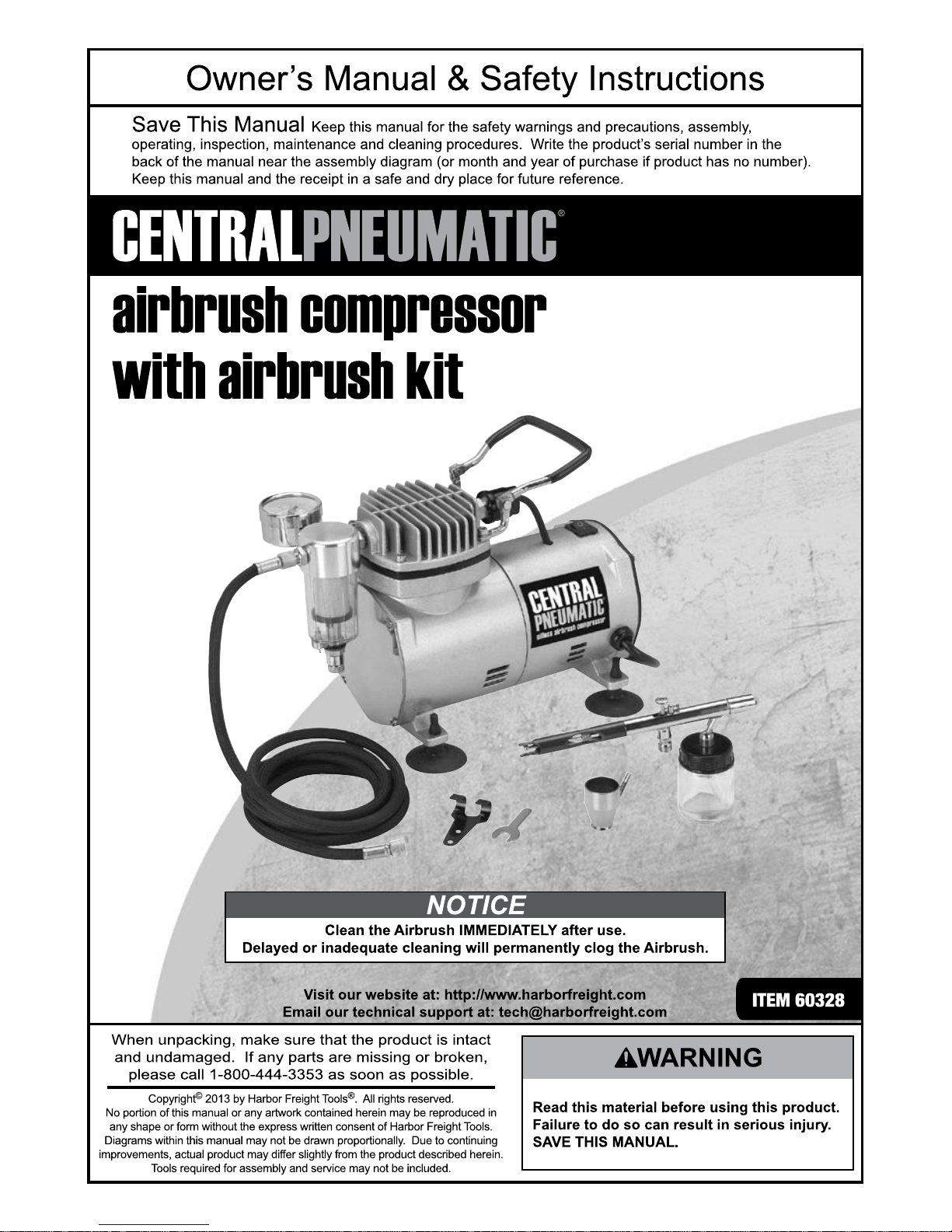

NOTICE

Clean the Airbrush IMMEDIATELY after use.

Delayed or inadequate cleaning will permanently clog the Airbrush.

SAFETY OPERATION MAINTENANCESETUP

Table of Contents

Safety .................................................2

Specifications .....................................8

Setup ..................................................9

Operation ...........................................11

Maintenance ......................................13

Parts List and Diagram ......................18

Warranty ............................................20

WARNING SYMBOLS AND DEFINITIONS

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Addresses practices not related to personal injury.

IMPORTANT SAFETY INSTRUCTIONS

INSTRUCTIONS PERTAINING TO A RISK OF FIRE,

ELECTRIC SHOCK, OR INJURY TO PERSONS

The warnings and precautions discussed in this manual cannot cover all possible conditions

and situations that may occur. It must be understood by the operator that common sense and

caution are factors which cannot be built into this product, but must be supplied by the operator.

WARNING – When using tools, basic precautions should always be followed, including the following:

Page 3For technical questions, please call 1-800-444-3353.Item 60328

NOTICE

Clean the Airbrush IMMEDIATELY after use.

Delayed or inadequate cleaning will permanently clog the Airbrush.

SAFETYOPERATIONMAINTENANCE SETUP

Work Area

a. Keep the work area clean and well lighted.

Cluttered benches and dark areas

increase the risks of electric shock,

fire, and injury to persons.

b. Do not operate the Compressor in

explosive atmospheres, such as in the

presence of flammable liquids, gases or

dust. Compressor motors produce sparks

which may ignite the dust or fumes.

c. Keep bystanders, children, and

visitors away while operating the tool.

Distractions are able to result in

the loss of control of the tool.

Electrical Safety

a. Compressor plugs must match

the outlet. Never modify the plug

in any way. Do not use any adapter

plugs with grounded Compressors.

Standard plugs and matching outlets

will reduce risk of electric shock.

b. Do not expose Compressor to rain or wet

conditions. Water entering a Compressor

will increase the risk of electric shock.

c. Do not abuse the cord. Never

use the cord for unplugging the

Compressor. Keep cord away from

heat, oil, sharp edges or moving

parts. Damaged or entangled cords

increase the risk of electric shock.

Personal Safety

a. Stay alert. Watch what you are

doing and use common sense when

operating the tool. Do not use the

tool while tired or under the influence

of drugs, alcohol, or medication.

A moment of inattention while operating the

tool increases the risk of injury to persons.

b. Do not overreach. Keep proper

footing and balance at all times.

Proper footing and balance enables better

control of the tool in unexpected situations.

c. Prevent unintentional starting.

Ensure the switch is in the off-position

before connecting to power source

or moving the Compressor.

d.

Use safety equipment. Wear a

NIOSH-approved respirator

during use.

e.

Always wear eye protection.

Wear ANSI-approved

safety goggles.

Compressor Use and Care

a. Do not use the Compressor if the

switch does not turn it on and

off. Any Compressor that cannot

be controlled with the switch is

dangerous and must be repaired.

b. Disconnect the Compressor from

the power source before making any

adjustments, changing accessories,

or storing. Such preventive safety

measures reduce the risk of starting

the Compressor accidentally.

Page 4 For technical questions, please call 1-800-444-3353. Item 60328

NOTICE

Clean the Airbrush IMMEDIATELY after use.

Delayed or inadequate cleaning will permanently clog the Airbrush.

SAFETY OPERATION MAINTENANCESETUP

c. Store an idle Compressor out of the reach

of children and do not allow persons

unfamiliar with the Compressor or these

instructions to operate it. A Compressor is

dangerous in the hands of untrained users.

d. Maintain the Compressor. Keep the

Compressor clean for better and safer

performance. Follow instructions for

lubricating. Keep dry, clean and free

from oil and grease. Many accidents are

caused by a poorly maintained Compressor.

e. Check for misalignment or binding of

moving parts, breakage of parts and

any other condition that may affect the

Compressor’s operation. If damaged,

have the Compressor repaired before

use. If damaged, have the tool serviced

before using. Many accidents are caused

by poorly maintained tools. There is a risk

of bursting if the tool is damaged.

f. Use the Compressor in accordance with

these instructions, taking into account

the working conditions and the work to

be performed. Use of the Compressor for

operations different from those intended

could result in a hazardous situation.

Service

Have your tool serviced by a qualified repair person using only identical replacement parts.

This will ensure that the safety of the tools are maintained.

Specific Safety Instructions

Air Compressor

1. Risk of injury - do not direct air

stream at people or animals.

2. Do not use to supply breathing air.

3. Keep Compressor well-ventilated.

Do not cover Compressor during use.

4. Do not leave Compressor unattended

for an extended period while plugged in.

Unplug Compressor after working.

5. Compressor head gets hot during operation.

Do not touch it or allow children nearby

during or immediately following operation.

6. Do not use the air hose to

move the Compressor.

7. The use of accessories or attachments

not recommended by the manufacturer

may result in a risk of injury to persons.

8. All air line components, including hoses,

pipe, connectors, filters, etc., must be

rated for a minimum working pressure

of 150 PSI, or 150% of the maximum

system pressure, whichever is greater.

9. Air hose fittings may get hot during use.

Allow fittings to cool before disconnecting.

10. Industrial applications must

follow OSHA guidelines.

11. This product is not a toy.

Keep it out of reach of children.

12. Operate unit on level surface.

Airbrush

1. Do not direct spray at people or animals.

2. Do not spray near open flames, pilot lights,

stoves, heaters, the air Compressor, or

any other heat source. Most solvents

and coatings are highly flammable,

particularly when sprayed. Maintain

a distance of at least 25 feet from the

air Compressor. If possible, locate the

air Compressor in a separate room.

Page 5For technical questions, please call 1-800-444-3353.Item 60328

NOTICE

Clean the Airbrush IMMEDIATELY after use.

Delayed or inadequate cleaning will permanently clog the Airbrush.

SAFETYOPERATIONMAINTENANCE SETUP

3. Read all of the information concerning

coating products and cleaning solvents.

Do not use chlorinated solvents

(e.g. 1-1-1 trichloroethylene and

dichloromethane, also known as

methylene chloride) to clean Airbrushes.

Many Airbrushes contain aluminum,

which reacts strongly to chlorinated

solvents. Contact the solvent or coating

manufacturer as needed regarding

potential chemical reactions.

4. Industrial applications must

follow OSHA requirements

5. Spraying hazardous materials may

result in serious injury or death.

Do not spray pesticide, acid, corrosive

material, fertilizer, or toxic chemicals.

6. Paints and solvents may be harmful or fatal if

swallowed or inhaled. Avoid prolonged skin

contact with solvents or paints as they will

irritate skin. After any contact, immediately

wash off exposed area with hot, soapy water.

7. Attach all accessories properly to the

tool before connecting the air supply.

A loose accessory may detach

or break during operation.

8. Install an in-line shutoff valve

to allow immediate control over

the air supply in an emergency,

even if a hose is ruptured.

9. Maintain labels and nameplates on the tool.

These carry important safety information.

If unreadable or missing, contact

Harbor Freight Tools for a replacement.

10. People with pacemakers should

consult their physician(s) before use.

Electromagnetic fields in close proximity to

heart pacemaker could cause pacemaker

interference or pacemaker failure.

11. WARNING: The brass components of

this product contain lead, a chemical

known to the State of California to cause

birth defects (or other reproductive harm).

(California Health & Safety Code

§ 25249.5, et seq.)

12. WARNING: Handling the cord on this product

will expose you to lead, a chemical known

to the State of California to cause cancer,

and birth defects or other reproductive harm.

Wash hands after handling. (California

Health & Safety Code § 25249.5, et seq.)

SAVE THESE INSTRUCTIONS.

Page 6 For technical questions, please call 1-800-444-3353. Item 60328

NOTICE

Clean the Airbrush IMMEDIATELY after use.

Delayed or inadequate cleaning will permanently clog the Airbrush.

SAFETY OPERATION MAINTENANCESETUP

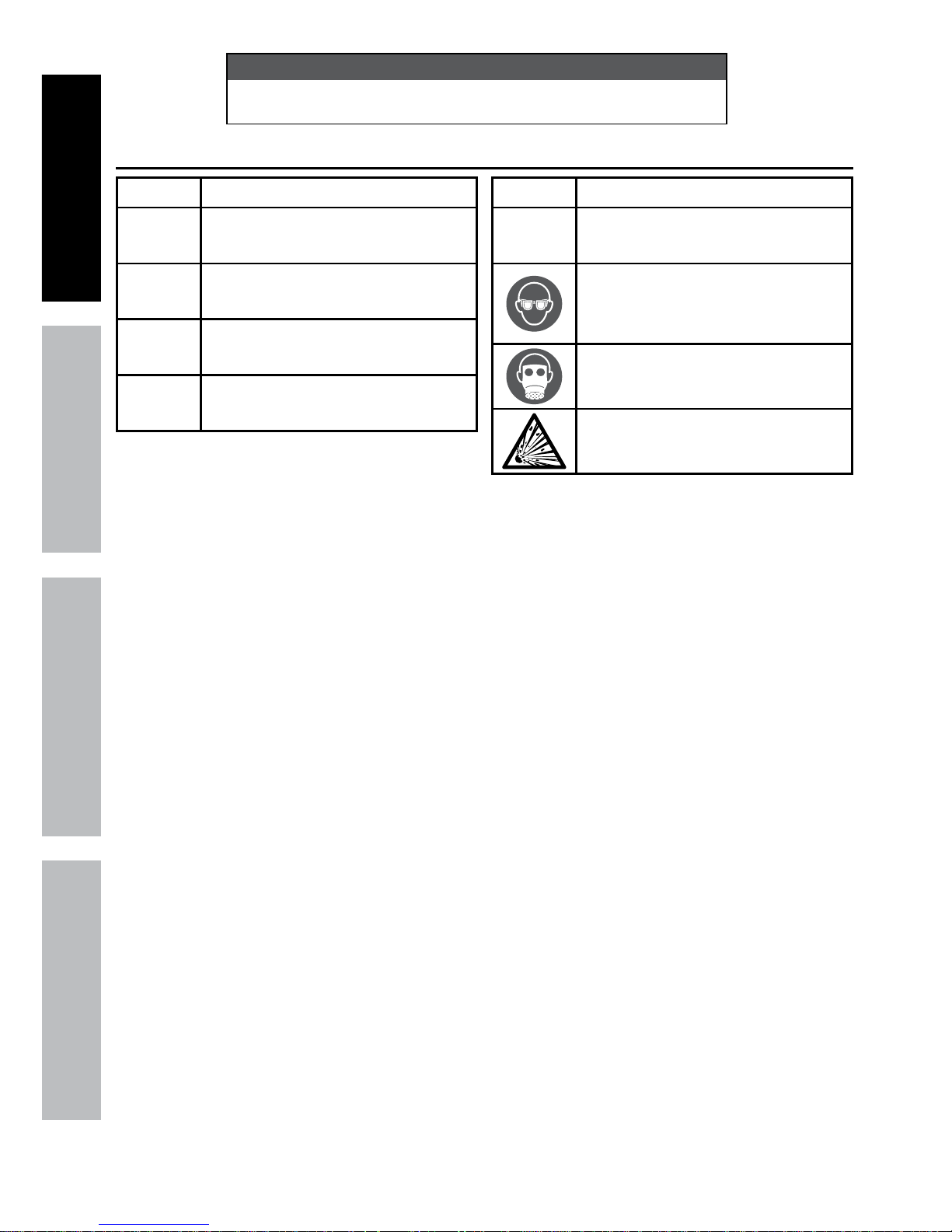

Symbol Definitions

Symbol Property or Statement

PSI

Pounds per square

inch of pressure

CFM

Cubic Feet per Minute flow

SCFM

Cubic Feet per Minute flow

at standard conditions

NPT

National pipe thread, tapered

Symbol Property or Statement

NPS

National pipe thread, straight

WARNING marking concerning

Risk of Eye Injury.

Wear ANSI-approved

eye protection.

WARNING marking concerning

Risk of Respiratory Injury.

Wear NIOSH-approved respirator.

WARNING marking concerning

Risk of Explosion.

Loading...

Loading...