Page 1

CLOSE QUARTERS PLATE

Model

96318

COMPACTOR, 4.5 HP

OPERATING INSTRUCTIONS

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 2007 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any artwork

contained herein may be reproduced in any shape or form without the express written consent of

Harbor Freight Tools. Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein. Tools required for

assembly and service may not be included.

For technical questions or replacement parts, please call 1-800-444-3353.

REV 10i

Page 2

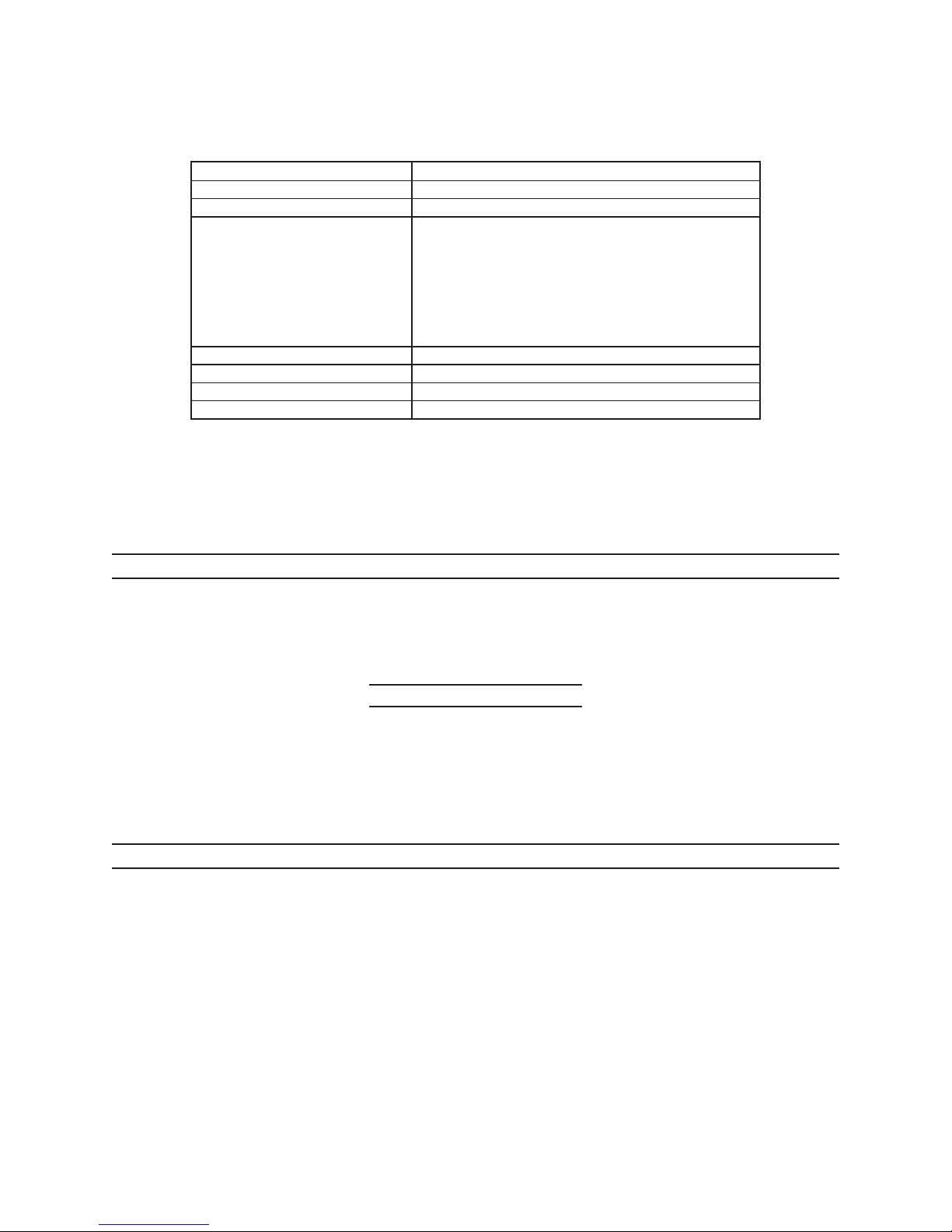

PRODUCT SPECIFICATIONS

Operating Walking Speed 0-82 Feet (0-25 Meters) Per Minute

Maximum Centrifugal Force 2200 Pounds

Vibration Frequency 5,500 Vibrations Per Minute

Engine Type 4.5 HP Robin Subaru Engine

Engine Family: 6FJXS.1271GA

Model Number: EX-13

4 Stroke

Unleaded Gasoline Powered

Engine Approval: 2006 U.S. EPA phase 2 SNRE

2006 California S.L. Sore’s EVH & EVP

Plate Size 13-7/8” W X 20” L

Belts 2 #A838 1/2” Wide V-belts (included)

Overall Dimensions 39-49/64” L X 19-11/16” W X 34-5/8” H

Weight 143 Pounds

The Emission Control System for this engine is warranted for standards set by

the U.S. Environmental Protection Agency and by the California Air Resources

Board (also known as CARB). For warranty information, refer to the last pages of

this manual.

UNPACKING

When unpacking, check to make sure all the parts shown on the Parts List are

included. If any parts are missing or broken, please call Harbor Freight Tools at the number

shown on the cover of this manual as soon as possible.

SAVE THIS MANUAL

You will need this manual for the safety warnings and precautions, assembly,

operating, inspection, maintenance and cleaning procedures, parts list and assembly

diagram. Keep your invoice with this manual. Write the invoice number on the inside of the

front cover. Keep this manual and invoice in a safe and dry place for future reference.

GENERAL SAFETY PRECAUTIONS

Failure to follow all instructions listed in the following pages may result in electric

shock, re, and/or serious injury. SAVE THESE INSTRUCTIONS.

1. Do not operate the Plate Compactor in explosive atmospheres, such as in

the presence of ammable liquids, gases, or dust. Power tools create sparks

which can ignite ammable materials.

2. Keep bystanders and children at least six feet away while operating the Plate

Compactor. Distractions can cause you to lose control. Protect others in the work

area from debris such as chips and sparks. Provide barriers and shields as needed.

Never allow children operate or play on or near the Plate Compactor.

SKU 96318 For technical questions, please call 1-800-444-3353. PAGE 2

Page 3

3. The Plate Compactor should only be used in outdoor areas. Carbon monoxide

fumes (from the gasoline engine) are a colorless, odorless gas that, if inhaled, can

cause serious illness or death. If the Plate Compactor is used in enclosed spaces,

the area must be well-ventilated and Engine exhaust fumes must be piped out of

the enclosed space using leak-free, heat-resistant piping. The pipes should not

use any ammable materials, nor should they be installed near the same. Engine

exhaust fumes must be within legal limits.

4. Before performing compacting work near buildings or above pipelines,

check the effect of the vibrations on the buildings and pipelines. If necessary,

immediately stop the compacting work.

PERSONAL SAFETY

1. Stay alert. Watch what you are doing and use common sense when operating

the Plate Compactor. Do not use the Plate Compactor while tired or under the

inuence of drugs, alcohol, or medication. A moment of inattention while operating

this equipment may result in serious personal injury.

2. Do not wear loose clothing or jewelry. Contain long hair. Keep your hair, clothing,

and gloves away from moving parts. Loose clothes, jewelry, or long hair can be

caught in moving parts.

3. Avoid accidental starting. The Gasoline Engine Ignition Switch must be off before

transporting the Plate Compactor or performing any maintenance or service on the

unit. Transporting or performing maintenance or service on equipment with the

Engine Ignition Switch on invites accidents.

4. Remove adjusting keys or wrenches before turning the Plate Compactor on.

A wrench or a key that is left attached to a rotating part of the equipment may result

in personal injury.

5. Do not overreach. Keep proper footing and balance at all times. Proper footing

and balance enables better control of the equipment in unexpected situations.

6. Use safety equipment. Always wear ANSI approved safety goggles underneath a

full face shield, a dust mask or respirator, hearing protection, and heavy-duty work

boots and gloves.

TOOL USE AND CARE

1. Do not force the Plate Compactor. Use the correct equipment for your application.

The correct equipment will do the job better and safer at the rate for which it is

designed.

2. Do not use the Plate Compactor if the Engine Ignition Switch does not turn

it on or off. Any gasoline powered equipment that cannot be controlled with the

Engine Ignition Switch is dangerous and must be repaired.

SKU 96318 For technical questions, please call 1-800-444-3353. PAGE 3

Page 4

3. Disconnect the Engine Spark Plug Wire from the Spark Plug before making any

adjustments, changing accessories, or storing the equipment. Such preventive

safety measures reduce the risk of starting the equipment accidentally.

4. Store idle equipment out of reach of children and other untrained persons.

Powered equipment is dangerous in the hands of children and untrained users.

Never allow children to play on or near the Plate Compactor.

5. Maintain the Plate Compactor with care. Keep it clean. Do not use if damaged.

Tag damaged equipment “Do not use” until repaired.

6. Check for misalignment or binding of moving parts, cracking or breakage of

parts, and any other condition that may affect the equipment’s operation. If

damaged, have the Plate Compactor serviced before using. Many accidents

are caused by poorly maintained equipment.

SERVICE

1. Service on the Plate Compactor must be performed only by qualied repair

personnel. Service or maintenance performed by unqualied personnel could

result in injury.

2. When servicing the Plate Compactor, use only identical replacement parts.

Follow instructions in the “Inspection, Maintenance, And Cleaning” section of

this manual. Use of unauthorized parts or failure to follow maintenance instructions

may create a risk of injury.

SPECIFIC SAFETY PRECAUTIONS

1. Maintain labels and nameplates on the Plate Compactor. These carry

important information. If illegible or missing, contact Harbor Freight Tools for a

replacement.

2. CAUTION! To avoid injury, keep hands, ngers, and feet away from the Base

Plate (1). Grip the Handle (66) of the Plate Compactor rmly with both hands. If

both hands are holding the Handle and your feet are clear of the Compactor Base,

your hands, ngers, and feet cannot be injured by the Compactor Base. Never

place tools or any other item under the Plate Compactor.

3. Industrial applications must follow OSHA requirements.

4. Keep all spectators at least six feet from the Plate Compactor during operation.

Add barriers (not included) if needed to keep spectators away.

5. Never leave the Plate Compactor unattended while it is running.

6. Stay away from the edges of ditches and avoid actions that may cause the

Plate Compactor to topple over.

SKU 96318 For technical questions, please call 1-800-444-3353. PAGE 4

Page 5

7. Always ascend slopes carefully, in a direct path and in reverse to prevent the

Plate Compactor from toppling over onto the operator.

8. Always park the Plate Compactor on a rm and level surface and shut the

tool off.

9. People with pacemakers should consult their physician(s) before using this

product. Electromagnetic elds in close proximity to a heart pacemaker could

cause interference to, or failure of, the pacemaker.

10. WARNING: Some dust created by power sanding, sawing, grinding, drilling,

and other construction activities, contains chemicals known [to the State of

California] to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

Lead from lead-based paints

Crystalline silica from bricks and cement or other masonry products

Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies, depending on how often you do this type

of work. To reduce your exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such as those dust masks that

are specially designed to lter out microscopic particles. (California Health & Safety

Code § 25249.5, et seq.)

FIRE AND EXPLOSION PRECAUTIONS

1. Gasoline fuel and fumes are ammable, and potentially explosive. Use

proper fuel storage and handling procedures. Always have multiple ABC class re

extinguishers nearby.

2. Keep the Plate Compactor and surrounding area clean at all times.

3. When fuel or oil spills, it must be cleaned up immediately. Dispose of uids and

cleaning materials according to any local, state, or federal codes and regulations.

Store oil rags in an oil-waste approved, covered metal container with a ventilated

bottom.

4. Never store fuel or other ammable materials near the Plate Compactor.

5. Do not smoke, or allow sparks, ames or other sources of ignition around

the Engine and Fuel Tank since they could ignite fumes.

6. Keep grounded conductive objects, such as tools, away from exposed, live

electrical parts and connections to avoid sparking or arcing. These objects

could ignite fumes or vapors.

7. Do not add fuel or oil while the Engine is running or while the Engine is still

hot. Do not operate the Plate Compactor with known leaks in the fuel system.

SKU 96318 For technical questions, please call 1-800-444-3353. PAGE 5

Page 6

8. Excessive buildup of unburned fuel gases in the exhaust system can create

a potentially explosive condition. This buildup can occur after repeated failed

start attempts, valve testing, or hot engine shutdown. If this occurs, open exhaust

system drain plugs, if equipped, and allow the gases to dissipate before attempting

to restart the Engine.

9. Always check the Engine oil level prior to starting the Engine. Read and

understand the Robin Subaru Engine Owner’s Manual for the proper oil level and

oil change schedules.

10. Use only engine manufacturer recommended fuel and oil. Refer to the Engine

Owner’s Manual for further instructions.

MECHANICAL PRECAUTIONS

1. ALWAYS make sure the Engine’s Power Switch is in its “OFF” position before

performing any maintenance on the Plate Compactor. Disconnect the spark plug

wire, and allow the Engine to completely cool before carrying out maintenance.

2. Check for damaged parts. Check for alignment and binding of moving parts, any

broken parts or mounting xtures, and any other condition that may affect proper

operation. Any part that is damaged should be properly repaired or replaced by a

qualied technician.

3. Read and understand all instructions and safety precautions outlined in the

Engine manufacturer’s Owner’s Manual. Do not attempt to operate the Plate

Compactor until you fully understand how to properly operate and maintain the

Engine and how to avoid accidental injuries and/or property damage.

4. Do not alter or adjust any part of the Plate Compactor that is assembled and

supplied by the manufacturer.

5. Always follow and complete scheduled Engine and Plate Compactor main-

tenance.

6. Any adjustments or repairs not covered in this manual must be performed by

a qualied service professional.

BURN AND CHEMICAL PRECAUTIONS

1. Avoid contact with hot fuel, oil, exhaust fumes, and hot solid surfaces.

2. Avoid body contact with fuels, oils, and lubricants used in the Engine. If

swallowed, seek medical treatment immediately. Do not induce vomiting if fuel

is swallowed. For skin contact, immediately wash with soap and water. For eye

contact, immediately ush eyes with clean water, and contact your doctor.

SKU 96318 For technical questions, please call 1-800-444-3353. PAGE 6

Page 7

NOISE PRECAUTIONS

1. Prolonged exposure to noise levels above 85 dBA is hazardous to hearing.

Always wear ANSI approved ear protection when operating or working around the

Plate Compactor when it is running.

INSTALLING THE WHEEL KIT

NOTE: For additional references to the parts listed in the following pages, refer to the

Assembly Diagram.

1. To move the Plate Compactor back and forth, install the Wheel Kit to underneath

the Plate. The Wheel Kit is pre-assembled and only needs to be installed.

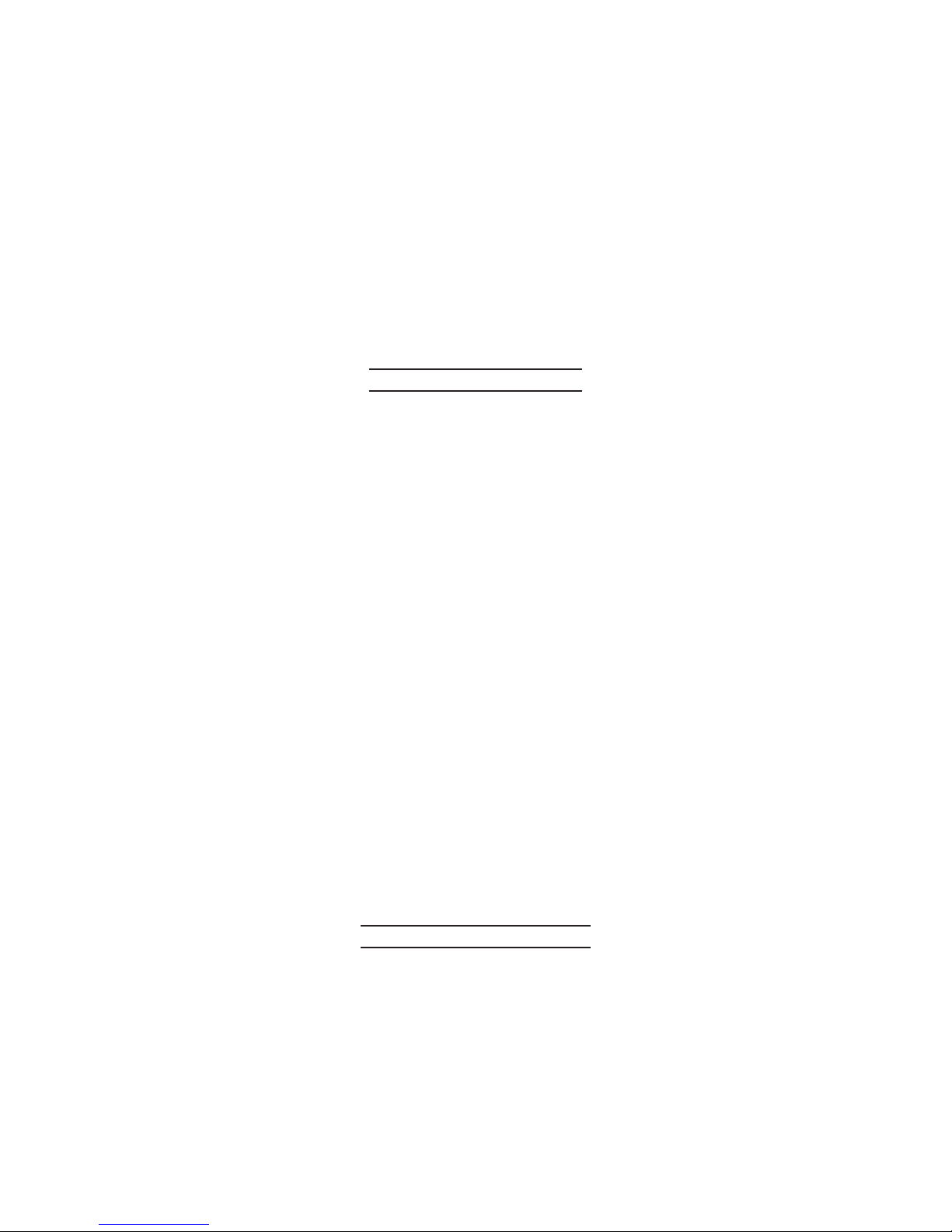

2. Untie the Wheel assembly from the clamp assembly. See photo, below.

Wheel assembly tied

to clamp assembly

3. Use the holes on either side of the frame to mount the Wheel Kit. See photo,

below. Please note: The mounting arms on the Kit will need to be slightly

spread apart to get the ends of the arms into the holes.

Wheel Kit

Mounting

Hole

4. Once the Wheels are mounted, the Plate Compactor can be tilted back and then

moved by the wheels.

REV 07h

SKU 96318 For technical questions, please call 1-800-444-3353. PAGE 7

Page 8

VIBRATION HAZARD

This tool vibrates during use. Repeated or long-term exposure to vibration may

cause temporary or permanent physical injury, particularly to the hands, arms and

shoulders. To reduce the risk of vibration-related injury:

1. Anyone using vibrating tools regularly or for an extended period should rst be

examined by a doctor and then have regular medical check-ups to ensure medical

problems are not being caused or worsened from use. Pregnant women or people

who have impaired blood circulation to the hand, past hand injuries, nervous system

disorders, diabetes, or Raynaud’s Disease should not use this tool. If you feel any

medical or physical symptoms related to vibration (such as tingling, numbness, and

white or blue ngers), seek medical advice as soon as possible.

2. Do not smoke during use. Nicotine reduces the blood supply to the hands and

ngers, increasing the risk of vibration-related injury.

3. Wear suitable gloves to reduce the vibration effects on the user.

4. Use tools with the lowest vibration when there is a choice between different pro-

cesses.

5. Include vibration-free periods each day of work.

6. To reduce vibration, maintain the tool as explained in this manual. If any abnormal

vibration occurs, stop use immediately.

SKU 96318 For technical questions, please call 1-800-444-3353. PAGE 8

REV 07j

Page 9

OPERATING INSTRUCTIONS

NOTE: For additional references to the parts listed in the following pages, refer to the

Assembly Diagram.

Pre-Start Checks:

1. Unfold Handle Assembly (upward) and secure with Locking Grip (61) on each

side.

2. Read and adhere to all safety warnings and instructions presented in the Robin

Subaru Engine Manual. (Model Ex-13)

3. Check to make sure the Engine’s Power Switch is in its “OFF” position.

IMPORTANT! Prior to initial use, the Plate Compactor’s Engine MUST be lled with

approximately 3/4 quart of a high quality SAE 10W-30 grade engine oil.

4. Unscrew and remove the Engine’s Oil Fill Plug located at the bottom of the Engine

Crankcase.

5. Fill the Engine’s Crankcase until the oil level is level with the Oil Fill Hole.

6. Screw the Oil Fill Plug back into the Oil Fill Hole. (For additional information, refer

to the engine manufacturer’s manual.)

7. Before rst use, remove the Engine’s Fuel Tank Cap and ll the Fuel Tank with

unleaded gasoline. Replace the Fuel Tank Cap. Thereafter, check the Fuel Tank

for the amount of unleaded gasoline before each use. Rell the Fuel Tank only

with unleaded gasoline.

To Start And Operate The Plate Compactor:

1. Open the Fuel Valve on the Engine and the Throttle (65) on the Handle (66).

2. Turn the Choke Lever on the Engine to its “CHOKE” position.

3. Set the Speed Control Lever to its “LOW” position.

4. Turn the Engine’s Power Switch to its “ON” position.

5. Grip the Start Handle of the Engine loosely and pull it slowly several times to allow

the gasoline to ow into the Engine’s carburetor. Pull gently on the cord until

pressure is felt. Release the cord to retract. Hold the handle and pull hard and fast

to start the engine. Pull the cord all the way out, using two hands if necessary. If

necessary, pull the cord several times until the Engine starts.

SKU 96318 For technical questions, please call 1-800-444-3353. PAGE 9

Page 10

5.

6. Allow the Engine to run for several seconds. Then, turn the Choke Lever to its

“RUN” position. Adjust the Throttle to appropriate speed.

7. Grip the Upper Handle (66) rmly with both hands. To avoid injury, keep hands,

ngers, and feet away from the Compactor base. Grip the Handle of the Compactor

rmly with both hands. If both hands are holding the Handle and your feet are clear

of the Compactor Base, your hands, ngers, and feet cannot be injured by the Base

Plate (1).

8. Adjust the Speed Control Lever between its “LOW” to “HIGH” position, depending

on the desired vibration speed.

9. Slowly guide the Plate Compactor in the desired direction.

10. Always keep a safe distance away from the edge of ditches and avoid any actions

that may cause the Plate Compactor to topple over.

11. Always ascend slopes carefully in a direct path and back up slopes to prevent the

Plate Compactor from toppling back onto the operator.

12. To Stop The Plate Compactor: Turn the Speed Control Lever to its “LOW” position,

and turn the Engine’s Power Switch to its “OFF” position.

13. Close the Fuel Valve on the Engine.

INSPECTION, MAINTENANCE, AND CLEANING

1. CAUTION! Always make sure the Engine’s Power Switch is in the “OFF” position

when performing inspection, maintenance, or cleaning. Disconnect the spark plug

wire from the engine. Allow sufcient time for the Engine to completely cool before

performing any inspection, maintenance, or cleaning on the Plate Compactor and/or

Engine.

2. Before each use, inspect the general condition of the Plate Compactor. Check for

loose screws, misalignment or binding of moving parts, cracked or broken parts, and

any other condition that may affect its safe operation. If an Engine problem occurs,

always have the Engine immediately checked out by a qualied service technician

before further use. Do not use damaged equipment.

3. Before each use, check to make sure the engine’s oil level is full. If necessary, add

oil until the level is even with the Oil Fill Hole.

4. Before each use, remove all debris from the Plate Compactor with a soft brush,

vacuum, or compressed air. Then use a premium quality lightweight machine oil

to lubricate all moving parts.

SKU 96318 For technical questions, please call 1-800-444-3353. PAGE 10

Page 11

5. Every 25 hours of use, drain the old Engine oil and replace with approximately 3/4

(0.6) quart of a high quality SAE 10W-30 grade engine oil. Make sure to contact a

local environmental or recycling center for proper disposal of old oil.

6. Follow all directions for maintenance and upkeep listed in the Robin Subaru Engine

manual.

7. Every 300 hours of use, have a qualied, certied technician perform thorough

maintenance on the Plate Compactor and Engine.

8. The Grease Bearing (45) must be greased through the grease port after every 120

hours of use.

9. To lube the Eccentric Shaft (11), use the two grease ttings on the top of the

Cover (8). See photo, below.

10. When the Plate Compactor is operated frequently and/or under heavy-duty use, the

Eccentric Shaft (11) should be checked and lubed before each use. The grease

(not included) should be comparable to Mobilux EP 3.

SKU 96318 For technical questions, please call 1-800-444-3353. PAGE 11

REV 07h, 10i

Page 12

LIMITED 1 YEAR WARRANTY

Harbor Freight Tools Co. makes every effort to assure that its products meet high

quality and durability standards, and warrants to the original purchaser that this product is

free from defects in materials and workmanship for the period of one year from the date

of purchase (90 days if used by a professional contractor or if used as rental equipment).

See engine manufacturer’s warranty which covers engine. This warranty does not apply

to damage due directly or indirectly, to misuse, abuse, negligence or accidents, repairs or

alterations outside our facilities, normal wear and tear, or to lack of maintenance. We shall

in no event be liable for death, injuries to persons or property, or for incidental, contingent,

special or consequential damages arising from the use of our product. Some states do

not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation of exclusion may not apply to you. THIS WARRANTY IS EXPRESSLY IN LIEU

OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with

transportation charges prepaid. Proof of purchase date and an explanation of the com-

plaint must accompany the merchandise. If our inspection veries the defect, we will either

repair or replace the product at our election or we may elect to refund the purchase price

if we cannot readily and quickly provide you with a replacement. We will return repaired

products at our expense, but if we determine there is no defect, or that the defect resulted

from causes not within the scope of our warranty, then you must bear the cost of returning

the product.

This warranty gives you specic legal rights and you may also have other rights

which vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY DIAGRAM

IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR DISTRIBUTOR MAKES

ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED

TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS

OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY STATES THAT

ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED

TECHNICIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING

OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR

ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

SKU 96318 For technical questions, please call 1-800-444-3353. PAGE 12

Page 13

PARTS LIST

Part Description Qty

1 Base Plate 1

2 Bolt M12x30 1

3 Spring Washer 12 1

4 Washer 1

5 Driven Pulley 1

6 Inner Hex Screw M6x20 6

7 Spring Washer 6 6

8 Cover 1

9 Bearing 6308 2

10 Flat Key 10x30 1

11 Eccentric Shaft 1

12 Inner Hex Screw M16x40 2

13 Spring Washer 16 4

14 Inner Hex Screw M16x120 2

15 Spring Washer 6 6

16 Inner Hex Screw M6x20 6

17 End Cap 1

18 Shaft Sleeve 1

19 Lifting Knob 1

20 Bolt M10x20 2

21 Spring Washer 10 2

22 Rubber Bumper 4

23 Spring Washer 12 4

24 Nut M12 4

25 Shaft Circlip 16 2

26 Flat Washer 16 4

27 Wheel 2

28 Axle 1

29 Cover Plate 1

30 Bolt M8x60 1

31 Nut M8 1

32 Axle Locking Buckle 1

33 Washer 8 1

34 Dishing Nut M8 1

Part Description Qty

35 Belt Cover Plate 1

36 Engine Fixing Plate 2

37 Spring Washer 8 4

38 Nut M8 4

39 Engine 1

40 Spacer 1

41 Flat Key 5x50 1

42 Bolt 5/16”-24 4

43 Shaft Circlip 30 1

44 Hole Circlip 55 1

45 Bearing 6006 2

46 V-Belt 2

47 Driving Pulley 1

48 Clutch Wheel Shield Plate 1

49 Spring 1

50 Idle Block 6

51 Impeller 1

52 Washer 8 1

53 Bolt 5/16”-24 1

54 Belt Cover 1

55 Inner Hex Screw M8x65 2

56 Inner Hex Screw M8x15 1

57 Bolt M12x60 2

58 Spring Washer 12 2

59 Nut M12 2

60 Supplemental Grip 1

61 Locking Grip 2

62 Bolt M10x60 2

63 Rivet 2

64 Fixing Screw 3

65 Throttle 1

66 Handle 1

Record Product’s Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only, and are not available

individually as replacement parts.

SKU 96318 For technical questions, please call 1-800-444-3353. PAGE 13

Page 14

ASSEMBLY DIAGRAM

Note: Drawing is not to scale

SKU 96318 For technical questions, please call 1-800-444-3353. PAGE 14

Page 15

Emission Control System Warranty

The California Air Resources Board (herein CARB), the United States Environmental Protection Agency (herein EPA), and Harbor Freight

Tools® (herein HFT) are pleased to explain the emission control system warranty on your 1995 and later Small Off-Road Engine (herein

engine). In California, the engine must be designed, built and equipped to meet the State’s stringent anti-smog standards. Elsewhere

within the United States, new off-road, spark-ignition engines certied for model year 1997 and later, must meet similar standards set

forth by the EPA. HFT must warrant the emission control system on your engine for the periods of time described below, provided

there has been no abuse, neglect or improper maintenance of your engine.

Your emission control system may include parts such as the carburetor or fuel-injection system, and the ignition system. Also included

may be hoses, belts, connectors and other emission-related assemblies.

Where a warrantable condition exists, HFT will repair your engine at no cost to you including diagnosis, parts and labor.

Manufacturer’s Warranty Coverage

California and United States Emission Control Defects Warranty Statement

The 1995 and later engines are warranted for two (2) years. If any emission-related part on your engine is defective, the part will be

repaired or replaced by HFT.

Harbor Freight Tools Emission Control Defects Warranty Coverage

Engines are warranted for a period of two (2) years relative to emission control parts defects, subject to the provisions set forth below.

If any emission related part on your engine is defective, the part will be repaired or replaced by HFT.

Owner’s Warranty Responsibilities

- As the engine owner, you are responsible for the performance of the required maintenance listed in your Owner’s Manual. HFT

recommends that you retain all receipts covering maintenance on your engine, but HFT cannot deny warranty solely for the lack

of receipts or for your failure to ensure the performance of all scheduled maintenance.

- As the engine owner, you should, however, be aware that HFT may deny you warranty coverage if your engine or a part has failed

due to abuse, neglect, improper maintenance, or unapproved modications.

- You are responsible for shipping your engine to a HFT warranty station as soon as a problem exists. Contact the HFT Customer

Service department at the number below to make shipping arrangements. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and responsibilities, you should contact the Harbor Freight Tools Customer

Service Department at 1-800-444-3353.

Harbor Freight Tools Emission Control Defects Warranty Provisions

1. Length of Coverage

HFT warrants to a rst retail purchaser and each subsequent purchaser that the engine is free from defects in materials and

workmanship that cause the failure of warranted parts for a period of two (2) years after the date of delivery to the rst retail

purchaser.

2. No Charge Repair or Replacement

Repair or replacement of any warranted part will be performed at no charge to the owner if the work is performed through a warranty

station authorized by HFT. For emissions warranty service, contact the HFT Customer Service Department at 1-800-444-3353.

3. Consequential Damages Coverage

Coverage under this warranty shall also extend to the failure of any engine components caused by the failure of any warranted

part while it is still covered under this warranty.

4. Coverage Exclusions

Warranty claims shall be led in accordance with the provisions of the HFT warranty policy explained in the box at the top of the

previous page. HFT shall not be liable for any loss of use of the engine, for any alternative usage, for any damage to goods, loss

of time, or inconvenience. Warranty coverage shall also be excluded for any part which fails, malfunctions, or is damaged due to

failure to follow the maintenance and operating instructions set forth in the Owner’s Manual including, but not limited to:

(a) use of parts which are not authorized by HFT

(b) improper installation, adjustment or repair of the engine or of any warranted part unless performed by an authorized warranty

center

(c) failure to follow recommendations on fuel use contained in the Owner ’s Manual

(d) improper or inadequate maintenance of any warranted parts

(e) repairs performed outside of the authorized warranty service dealers

SKU 96318 For technical questions, please call 1-800-444-3353. PAGE 15

Page 16

(f) alterations by changing, adding to or removing parts from the engine.

5. Service and Maintenance

Component parts which are not scheduled for replacement as required maintenance or are scheduled only for regular inspection

to the effect of “repair or replace as necessary” are warranted for the warranty period. Any warranted part which is scheduled

for replacement as required maintenance is warranted for the period of time up to the rst scheduled replacement point for that

part. Any replacement part, provided it is equivalent in durability and performance, may be used in performance of maintenance

or repairs. The owner is responsible for commissioning a qualied technician/mechanic to perform all required maintenance, as

outlined in the Inspection, Cleaning, and Maintenance section on page 9 and 10 of this manual.

6. Warranted Parts

1) Fuel Metering System

i) Carburetor and its internal parts.

ii) Fuel pump (if so equipped).

iii) Cold start enrichment system.

2) Air Induction System

i) Intake pipe/manifold.

ii) Air cleaner.

3) Ignition System

i) Spark plug.

ii) Magneto ignition system.

4) Catalyst System (if so equipped)

i) Exhaust pipe stud.

ii) Mufer.

iii) Catalytic converter (if so equipped).

5) Miscellaneous items Used in Above Systems

i) Vacuum, temperature and time sensitive valves and switches.

ii) Hoses, belts, connectors, and assemblies.

SKU 96318 For technical questions, please call 1-800-444-3353. PAGE 16

REV 07h

Loading...

Loading...