Page 1

WATER PUMP

®

Model 93121 / 94074 / 94075

ASSEMBLY AND OPERATING INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at: http://www.harborfreight.com

TO PREVENT SERIOUS INJURY,

READ AND UNDERSTAND ALL WARNINGS

AND INSTRUCTIONS BEFORE USE.

Copyright© 2005 by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight Tools.

For technical questions, please call 1-800-444-3353.

Page 2

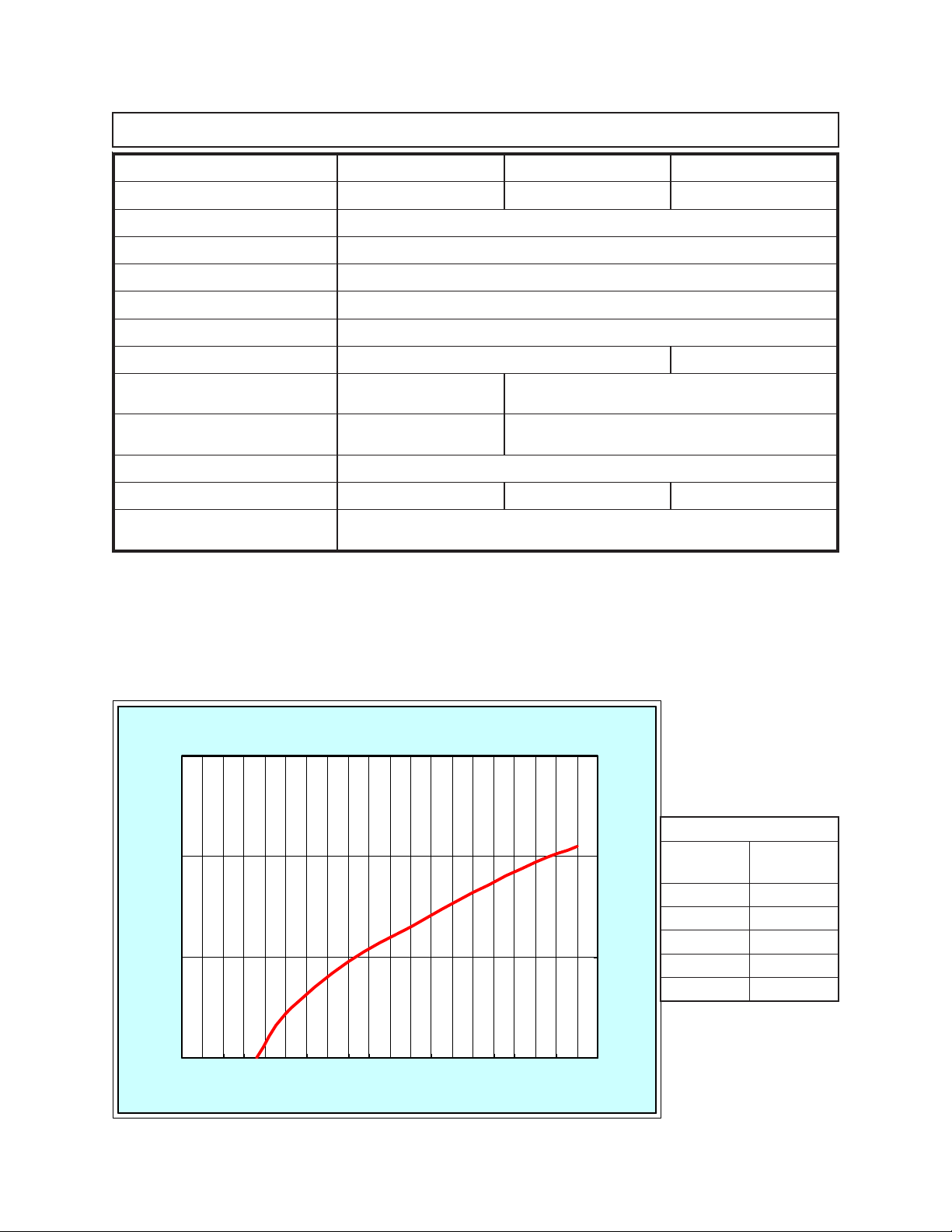

PRODUCT SPECIFICATIONS

ledoM470495704912139

etaRwolFmumixaMMPG731MPG462MPG801

eziSpmuP retemaiDhcnI8

epyTpmuP lagufretneC

deepSpmuPMPR000

,4

gnimirP-fleSoN

noitcuSdaeHmumixaM'72

tfiLdaeHlatoT'401'461

epyTenignE

3

/

epyT/yticapaCleuF

4

,delooCriA,PH5.4

tratSlioceR,ekortS-4

dedaelnU/.laG

enilosaG

,

delooCriA,PH6

tratSlioceR,ekortS-4

enilosaGdedaelnU/.laG1

yticapaCliOenignE.tQ36.

thgieWlatoT.sbL1.55.sbL8.56.sbL06

seiros

seccA

)1.ytQ(tekcoSgulPkrapS

,)2.ytQ(sgnilpuoCesoH,)3.ytQ(spmalCesoH,)1.ytQ(reniartS

NOTE: This product requires oil and fuel to be added before starting.

Attempting to start the engine without oil WILL ruin the engine and void

the warranty.

Before starting the engine, refer to the engine owner’s manual for

engine maintenance information.

12139

yticapaC

)MPG(

(gal/min)

0246

erusserP

)ISP(

0445

0664

0802

0018

93121 Performance Chart

0 50 100 150

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

200

SKU 93121/94074/94075 For technical questions, please call 1-800-444-3353. PAGE 2

(ft.)

REV 08/05

Page 3

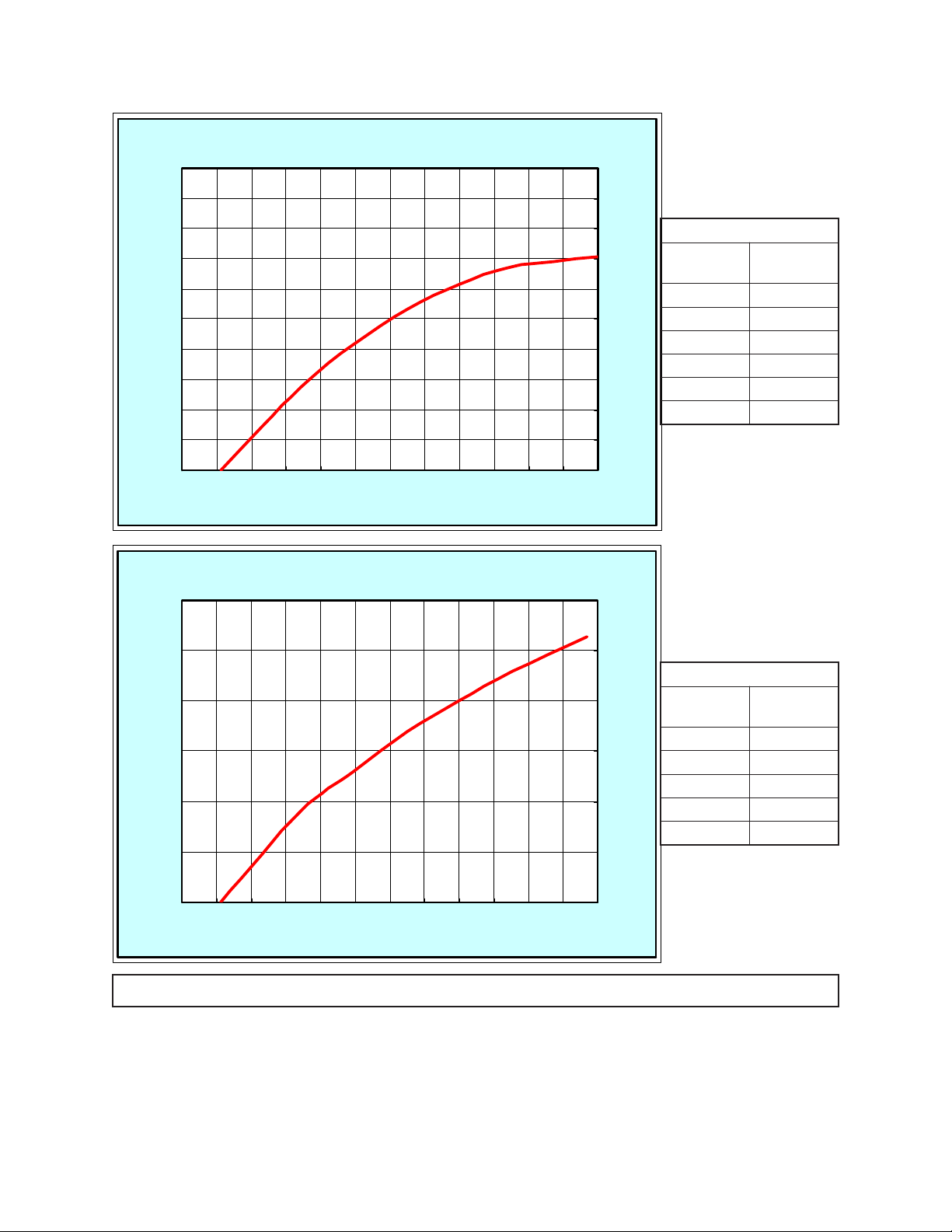

47049

yticapaC

)MPG(

erusserP

)ISP(

0284

(gal/min)

0404

0663

0813

00162

02191

94074 Performance Chart

0 20 40 60 80 100 120 140 160 180 200

0

10

20

30

40

50

60

70

80

90

100

110

120

(ft.)

57049

yticapaC

)MPG(

(gal/min)

0524

erusserP

)ISP(

00173

05182

00271

0528

94075 Performance Chart

0 50 100 150 200 250 300

0

10

20

30

40

50

60

70

80

90

100

110

120

(ft.)

SA VE THIS MANU AL

You will need this manual for the safety warnings and precautions, assembly, operating,

inspection, maintenance and cleaning procedures, parts list and assembly diagram.

Keep your invoice with this manual. Write the invoice number on the inside of the front

cover. Keep this manual and invoice in a safe and dry place for future reference.

REV 08/05

SKU 93121/94074/94075 For technical questions, please call 1-800-444-3353. PAGE 3

Page 4

GENERAL SAFETY RULES

IMPORTANT SAFETY INSTRUCTIONS

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS

Failure to follow all instructions listed below may result in

electric shock, fire, and/or serious injury.

SA VE THESE INSTRUCTIONS

WORK AREA

1. Keep your work area clean and well lit. Cluttered and dark work areas

invite accidents.

2. Do not operate the Water Pump in explosive atmospheres, such as in the

presence of flammable liquids, gases, or dust. Power equipment creates

sparks which may ignite the dust or fumes.

3. Keep bystanders, children, and visitors away while operating the W ater

Pump. Distractions can cause you to lose control.

PERSONAL SAFETY

4. Stay alert. Watch what you are doing, and use common sense when

operating a water pump. Do not use a water pump while tired or under the

influence of drugs, alcohol, or medication. A moment of inattention while

operating water pumps may result in serious personal injury.

5. Dress properly. Do not wear loose clothing or jewelry. Contain long hair.

Keep your hair, clothing, and glo ves away from mo ving parts. Loose clothes,

jewelry, or long hair can be caught in moving parts.

6. Do not overreach. Keep proper footing and balance at all times. Proper

footing and balance enables better control of the Water Pump in unexpected

situations.

7. Always wear eye protection. W ear ANSI appro ved safety impact

goggles and nonskid rubber boots. A hardhat must be used for

appropriate conditions.

TOOL USE AND CARE

8. Do not force the Water Pump. Use the correct Water Pump for your

application. The correct Water Pump will do the job better and safer at the rate

for which it is designed.

SKU 93121/94074/94075 For technical questions, please call 1-800-444-3353. PAGE 4

Page 5

9. Do not use the Water Pump if the Power Switch on the Engine does not

turn iton or off. Any Water Pump equipment that cannot be controlled is

dangerous and must be repaired or replaced.

10. Store idle tools and equipment out of reach of children and other untrained

persons. Tools and equipment are dangerous in the hands of untrained users.

11. Maintain the Water Pump with care. Keep the Water Pump clean. A properly

maintained Water Pump is easier to control. Do not use damaged tools and

equipment. Tag damaged tools and equipment “Do not use” until repaired.

12. Check for misalignment or binding of mo ving parts, broken parts, and any

other condition that may affect the Water Pump’s operation. If damaged,

have the Water Pump serviced before using. Many accidents are caused by

poorly maintained tools and equipment.

13. Use only accessories that are recommended by the manufacturer f or your

model. Accessories that may be suitable for one Water Pump may become

hazardous when used on another Water Pump.

SERVICE

14. Water Pump service must be performed only by qualified repair personnel.

Service or maintenance performed by unqualified personnel could result in a risk

of injury.

15. When servicing the Water Pump, use only identical replacement parts.

Follow instructions in the

of this manual. Use of unauthorized parts or failure to follow maintenance

instructions may create a risk of electric shock or injury.

“Inspection, Maintenance, And Cleaning”

section

SPECIFIC SAFETY RULES

General Precautions

1. WARNING! The w arnings, precautions , and instructions discussed in this

manual cannot cover all possible conditions and situations that may occur. The

operator must understand that common sense and caution are factors, which

cannot be built into this product, but must be supplied by the operator.

2. WARNING! People with pacemakers should consult their physician(s)

before using this product. Electromagnetic fields in close proximity to a heart

pacemaker could cause interference or failure of the pacemaker. In addition,

people with pacemakers should adhere to the following: Caution is necessary

when near the magneto and spark plug of a running engine.

3. Industrial applications must follow OSHA requirements.

4. Maintain labels and nameplates on the Water Pump. These carry important

information. If unreadable or missing, contact Harbor Freight Tools for a

replacement.

SKU 93121/94074/94075 For technical questions, please call 1-800-444-3353. PAGE 5

Page 6

Installation Precautions:

1. WARNING! Before using the Water Pump, read and understand the

manufacturer’s

precautions in

Operation, Maintenance, and Parts manual.

this

manual. These should always be followed to reduce the risk of

Also, read the safety

Engine

personal injury and damage to equipment.

2. Use the Water Pump only in well ventilated outdoor areas. Carbon

monoxide is produced during operation, and is a colorless, odorless gas

that, if inhaled, can cause SERIOUS INJURY or DEATH.

3. When using the Water Pump outdoors, it must be weatherproofed and should be

soundproofed.

4. Never lift this equipment using the engine or water pump. Connect lifting

equipment to the Frame of the equipment.

5. Before lifting the Water Pump, ensure the lift rigging and supporting structure are

in good condition, and are rated to lift such a load.

6. Keep all personnel away from the suspended Water Pump during relocating.

7. The supporting floor/ground surface should be level, and strong enough to safely

hold the weight of the Water Pump. If the floor/ground surface is not level, strong

cross members should be placed under the full length of the Water Pump Frame

at its low side.

8. Make sure the intake and discharge hoses (not included) are secured to a

solid surface to ensure the stability of the Water Pump.

9. For trailer installation, the Water Pump should be mounted on the center point of

the trailer, over the wheels.

Fire And Explosion Precautions:

1. Do not pump hazardous materials. Do not pump explosive or flammable

materials such as fuel oil, kerosene, gasoline, etc. Do not pump in close

proximity to flammable or explosive materials. The Water Pump is designed to

move clean or dirty water only. Do not pump water over 104° Fahrenheit.

2. Gasoline fuel and fumes are flammable, and potentially explosive. Use proper

fuel storage and handling procedures. Always have multiple ABC class fire

extinguishers nearby.

3. Keep the Water Pump and surrounding area clean at all times.

4. When spills of fuel or oil occur, they must be cleaned up immediately. Dispose of

fluids and cleaning materials as per any local, state, or federal codes and

regulations. Store oil rags in a covered metal container.

5. Never store fuel or other flammable materials near the Water Pump.

6. Do not smoke, or allow sparks, flames or other sources of ignition around the

Engine and Fuel Tank. Fuel vapors are explosive.

7. Keep grounded conductive objects, such as tools, away from exposed, live elec-

SKU 93121/94074/94075 For technical questions, please call 1-800-444-3353. PAGE 6

Page 7

trical parts and connections to avoid sparking or arcing. These events could

ignite fumes or vapors.

8. Do not refill the Fuel Tank while the Engine is running or while the Engine is still

hot. Do not operate the Water Pump with known leaks in the fuel system.

9. Excessive buildup of unburned fuel gases in the exhaust system can create a

potentially explosive condition. This buildup can occur after repeated failed start

attempts, valve testing, or hot engine shutdown. If this occurs, open exhaust

system drain plugs, if equipped, and allow the gases to dissipate before

attempting to restart the Engine.

10. Use only engine manufacturer recommended fuel and oil.

Mechanical Precautions:

1. ALWAYS make sure the Engine’ s Power Switch is in its “OFF” position.

Disconnect the spark plug wire, and allow the Engine to completely cool before

carrying out maintenance.

2. Use the right product for the job. There are certain applications for which this

product was designed. Do not use small equipment, tools, or attachments to do

the work of larger industrial equipment, tools, or attachments. Do not use this

product for a purpose for which it was not intended.

3. In cold weather, when the Water Pump is not in use, protect the interior of

the Pump from freezing by draining the liquid and pumping a permanent

type automobile antifreeze containing a rust inhibitor through the system. A

50% mixture with water is recommended. Be sure to flush the system with a

neutralizing liquid prior to reuse of the unit. NOTE: Antifreeze is poisonous and

could cause serious personal injury if ingested. ALWAYS dispose of antifreeze properly.

4. Prior to use, and periodically thereafter, check to make sure all connections

are tight and secure.

5. Check for damaged parts. Before using the Water Pump, any part that appears

damaged should be carefully checked to determine that it will operate properly

and perform its intended function. Check for alignment and binding of moving

parts, any broken parts or mounting fixtures, and any other condition that may

affect proper operation. Any part that is damaged should be properly repaired or

replaced by a qualified technician.

6. The Water Pump is designed with guards for protection from moving parts.

In any case, care must still be taken to protect personnel and equipment from

other mechanical hazards when working around the Water Pump.

7. Do not operate the Water Pump with safety guards removed.

8. The Water Pump must never be run dry. Always make sure to completely fill

the Pump Casing (1) with water prior to operating the unit. Not doing so may

damage the inner seals which depend on the water for lubrication.

SKU 93121/94074/94075 For technical questions, please call 1-800-444-3353. PAGE 7

Page 8

9. Always f ollow and complete scheduled Engine and W ater Pump maintenance.

Chemical Precautions:

1. Avoid contact with hot fuel, oil, exhaust fumes, and solid surfaces.

2. Avoid body contact with fuels, oils, and lubricants used in the Engine. If

swallowed, seek medical treatment immediately. Do not induce vomiting if fuel is

swallowed. For skin contact, immediately wash with soap and water. For eye

contact, immediately flush eyes with clean water.

Noise Precautions:

Prolonged exposure to noise levels above 85 dBA is hazardous to hearing.

Always wear ANSI approved ear protection when operating or working around the

Water Pump when it is running.

UNPACKING

When unpacking, check to mak e sure all the parts shown on the Parts Lists on pages 15

and 16 are included. If any parts are missing or broken, please call Harbor F reight Tools at

the number shown on the cov er of this manual as soon as possible.

GENERAL LOCATION

1. It is recommended to locate and install the Water Pump outdoors where cooling

air is readily available.

2. Install the Water Pump so that the engine air inlets and outlets are not blocked by

obstructions such as bushes, trees, or snow drifts. Locating it in the path of

heavy winds or snowdrifts may require the placement of a barrier f or protection.

The air inlet, in normal weather conditions, should face the pre vailing wind

direction.

3. Install the Water Pump on a concrete slab or other area where rain drainage or

flood waters can not reach it.

4. Water Pump placement should allo w four feet of access to all sides f or maintenance.

5. Place the Water Pump as close as possible to the water that will be pumped to

reduce the length of hoses.

WATER PUMP SUPPORT AND MOUNTING

For permanent or semi-permanent installation: Mount the Water Pump on a

concrete slab capable of supporting the weight of the unit. The slab must extend

on all sides beyond the Frame (33) by at least one foot. Contact a cement contractor for slab specifications if necessary. Attach the Frame to the concrete slab

using 3/8” diameter expansion anchor bolts (not supplied).

SKU 93121/94074/94075 For technical questions, please call 1-800-444-3353. PAGE 8

Page 9

ASSEMBLY INSTRUCTIONS

NOTE: For additional information regarding the parts listed in the following pages, refer

to the Assembly Diagrams on pages 15 and 16.

WARNING! Always turn off the Power Switch to the Engine and remove its

spark plug

any adjustments to the Pump. Once finished, reinstall the spark plug.

To Assemble The Intake Hose And Discharge Hose:

1. NOTE: The sizes of Hose Couplings (18, 28) on the three Water Pump models

discussed in this manual are as follows:

Model 93121 = 2”

Model 94074 = 2”

Model 94075 = 3”

Intake and Discharge Hoses (not included) with a diameter corresponding to

model (93121, 94074, or 94075)

enlarge the discharge size below or above your Water Pump model as this will

affect Pump flow and performance. (See Figure A, next page.)

prior

to assembling the Water Pump, unclogging the Pump, or making

must

be used. Do not attempt to reduce or

your

2. Assemble the

(17), one Hose Coupling (18), two Hose Bands (31), and one Strainer (32).

(See Figure A.)

3. Assemble the

(27), one Hose Coupling (28), and one Hose Band (31). (See Figure A.)

COUPLING

PACKING

(17)

HOSE

COUPLING

(18)

Intake

Hose, using one Hose Joint (16), one Coupling Packing

Discharge

HOSE

JOINT

HOSE

(16)

BAND

(31)

Hose, using one Hose Joint (26), one Coupling Packing

INTAKE HOSE

(NOT INCLUDED)

HOSE

BAND

(31)

DISCHARGE HOSE

(NOT INCLUDED)

(26)

HOSE

BAND

(31)

FIGURE A

HOSE

COUPLING

COUPLING

PACKING

(27)

SKU 93121/94074/94075 For technical questions, please call 1-800-444-3353. PAGE 9

(28)

HOSE

JOINT

Page 10

To Attach The Intake Hose And Discharge Hose To The Water Pump:

1. Intake hose must be designed for suction so that it does not collapse. To

attach the

Intake

Hose to the Water Pump, position the Hose Coupling (18)

against the threaded/intake opening in the Casing (1). Then, firmly screw the

Hose Joint (16) onto the opening. (See Figures A and B.)

2. To attach the

Discharge

Hose to the Water Pump, position the Hose Coupling

(28) against the threaded/discharge opening in the Bend (19). Then, firmly screw

the Hose Joint (26) onto the opening. (See Figures A and B.)

DISCHARGE

OPENING

INTAKE

OPENING

BEND

(19)

CASING

(1)

FIGURE B

3. Route the Discharge Hose as needed to direct the discharge to the desired

location. The Discharge Hose should be kept as short as possible with a

minimum number of turns.

4. Make sure the area where the Strainer (32) on the Intake Hose is located is free

from accumulated debris, rocks, and other objects that may damage the Pump.

OPERATING INSTRUCTIONS

NOTE:

For additional references to the parts discussed in the following pages,

refer to the Assembly Diagrams on pages 15 and 16 of this manual.

Engine Pre-Start Checks:

1. Before operation, it will be necessary to refer to the

Operation, Maintenance, and Parts manual

(included) for detailed information

about starting, running, and stopping the Engine.

2. IMPORTANT! Engine oil MUST be added to the Engine’s crankcase prior to

starting and running the Engine. Failure to add oil, according to the Engine

manufacturer’s recommendations, will damage the Engine and void its warranty.

(See

Engine

SKU 93121/94074/94075 For technical questions, please call 1-800-444-3353. PAGE 10

manufacturer’s manual.)

Engine manufacturer’s

Page 11

3. Check to make sure the Engine’s “ON/OFF” Switch is in its “OFF” position.

(See

Engine

manufacturer’s manual.)

4.

Unscrew

and remove one of the Engine’s Oil Dipsticks located on either side at

the bottom of the Engine Crankcase. Fill the Engine’ s crankcase with the proper

type

and

amount

Then, replace the Oil Dipstick. (See

of engine oil as recommended by the Engine manufacturer.

Engine

manufacturer’s manual.)

5. Before the first use, remove the Engine’s Fuel Tank Cap and fill the Fuel Tank with

unleaded

Tank for the amount of

gasoline. Then, replace the Fuel Tank Cap. Thereafter, check the Fuel

unleaded

gasoline in the Fuel Tank. If necessary, refill the

Fuel Tank with unleaded gasoline.

(See

Engine

manufacturer’ s man ual.)

Water Pump Pre-Start Checks:

1. IMPORTANT ! The Water Pump MUST be primed with water prior to each

use of the unit. The Water Pump must never be run dry. Always make sure to

completely fill the Pump Casing (1) with water prior to operating the unit. Not

doing so may damage the inner seals which depend on the water for lubrication.

To fill the Pump Casing, unscrew and remove the Plug (22) located at the top of

the Bend (19). Fill the Pump Casing completely with water. Then, replace the

Plug. (See Figure C.)

FIGURE C

PLUG

(22)

SKU 93121/94074/94075 For technical questions, please call 1-800-444-3353. PAGE 11

Page 12

OPERATING INSTRUCTIONS

REFER TO ENGINE MANUFACTURER’S DOCUMENTATION FOR DETAILED

ENGINE OPERATION INSTRUCTIONS AND PRECAUTIONS.

To Start The Water Pump:

1. Check the Engine oil level. Before checking the Engine oil level, make sure the

Engine is not running and is placed on a level surf ace.

2. Check the Engine Fuel level in the gasoline Tank. Do not overfill the Tank. Do not

fill the fuel Tank when the Engine is running.

3. Check the Intake and Discharge Hoses for weak or worn conditions before each

use. Check to make sure all connections are tight and secure.

4. Check to make sure the Water Pump is primed.

5. Make sure the Engine and Water Pump turns freely by hand. If it cannot be

turned over by pulling on the recoil starter rope, have a qualified service

technician open the Casing (1) of the Water Pump to remove obstructions lodged

in the unit.

6. Turn on the Engine’s power switch, and start the Engine by pulling the recoil

starter rope out quickly and forcefully. Repeat pulling until the Engine starts.

7. Idle the Engine for 3-5 minutes to allow it to warm up. Then, open the throttle

lever and allow the Engine to run faster.

8. As the Water Pump begins operating, it will cause an increased load upon the

Engine. Open the Engine throttle lever further to increase the Engine speed

adequately for the pumping operation.

To Stop The Water Pump:

1. To stop the Water Pump for a short period of time, run the Engine throttled all the

way down and turn the Engine power switch to its “OFF” position.

2. To stop the Water Pump for a long period of time, turn the Engine fuel lever to its

“OFF” position instead of turning the Engine power switch off. Allow the Engine

to idle for 2-3 minutes until the fuel in the Engine carburetor is depleted and the

Engine stops. Then, turn the Engine power switch to its “OFF” position. Drain all

the Engine fuel from the fuel tank and fuel lines. NOTE: Throughout this

process, check to make sure there is water in the Water Pump’s priming

chamber.

3. After use, if the pump is to remain idle for a period, drain all water from pump and

hoses.

SKU 93121/94074/94075 For technical questions, please call 1-800-444-3353. PAGE 12

Page 13

INSPECTION, MAINTENANCE, AND CLEANING

1. WARNING! Always make sure the Engine’s power switch is turned off and

prior

to performing any inspection, maintenance, or cleaning of the Water Pump.

2. Before each use, inspect the general condition of the Water Pump. Check for

clogs throughout the system, misalignment or binding of moving parts, damaged or

loose intake and discharge hoses, and an y other condition that ma y aff ect the safe

operation of the Water Pump. If abnormal noise or vibration occurs, have the problem corrected before further use. Do not use damaged equipment.

3. Periodically, check to mak e sure the area where the W ater Pump’ s Strainer (32) is

located is free from accumulated debris, rocks, and other objects that ma y damage

the Pump.

4. When cleaning, spray the exterior and Strainer (32) of the Water Pump with a

garden hose. Do not introduce water or an y other liquid into the intake and e xhaust

ports of the Engine.

5. In cold weather, when the Water Pump is not in use, protect the interior of the

Pump from freezing by draining the water and pumping a permanent type automobile

antifreeze containing a rust inhibitor through the system. A 50% mixture with water

is recommended. Be sure to flush the system with a neutralizing liquid prior to

reuse of the unit. NOTE: Antifreeze is poisonous and could cause serious

personal injury if ingested. ALWAYS dispose of anti-freeze properly.

6. T o drain the W ater Pump, unscre w and remove the Plug (22) located at the bottom

of the Casing (1). Replace the Plug and securely tighten. (See Figure D.)

7. W ARNING! All maintenance, service, or repairs not listed in this manual should

only be performed by a qualified service technician.

FIGURE D

PLUG

(22)

SKU 93121/94074/94075 For technical questions, please call 1-800-444-3353. PAGE 13

Page 14

TROUBLESHOOTING

1. Engine does not start.

A. Make sure the Engine’s power switch is in its “ON” position.

B. Make sure the Engine’s fuel lever is open.

C. Make sure the Engine’s throttle lever is open.

D. Make sure the Engine has adequate fuel and oil.

E. Make sure the Engine’s spark plug and spark plug wire are firmly connected.

F. Check the Engine manufacturer’s manual for further instructions.

2. Water Pump runs, but does not discharge water.

A. Make sure the Water Pump has been primed.

B. Discharge hose may be frozen or blocked. Check to see if discharge hose

passes through cold areas or is blocked or kinked.

C. Intake hose may be frozen, b loc ked, damaged, or has a loose connection.

Thoroughly clean the Strainer (32) on the intake hose and check for any loose

connections. Check to see if intake hose passes through cold areas or is

blocked or kinked. Intake hose must be designed for suction so that it does

not collapse.

D. Vertical lift is beyond the Water Pump’s capability. Check the

Specifications”

section (page #2) for your Water Pump model’s maximum lift

“Product

capability. If necessary, reduce height of vertical lift.

E. Impeller of the Water Pump is jammed. Clean the Impeller. If necessary,

have a qualified service technician inspect the Impeller.

3. Pump Motor runs, but delivers small amount of water.

A. Vertical lift is approaching Water Pump’s maximum lift capability. Check the

“Product Specifications”

section (page #2) for your Water Pump model’s

maximum lift capability. If necessary, reduce height of vertical lift.

B. Strainer (32) is partially blocked. Check to make sure Strainer is clear of

debris.

C. Intake and/or discharge hose is partially blocked. Check hoses for blockage.

Intake hose must be designed for suction so that it does not collapse.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY DIAGRAM IN

THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR DISTRIBUTOR MAKES ANY

REPRESENT ATION OR WARRANTY OF ANY KIND T O THE BUYER THAT HE OR SHE IS QUALIFIED T O MAKE ANY

REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT.

IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS

REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE

BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE

ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION

OF REPLACEMENT PARTS THERETO.

SKU 93121/94074/94075 For technical questions, please call 1-800-444-3353. PAGE 14

Page 15

PARTS LIST AND ASSEMBLY DIAGRAM - MODEL 93121

#

#

#

Part

1 Casing 14 Bolt (W/S.W.) 26 Hose Joint

2 Casing Packing 15 Check Valve 27 Coupling Packing

4 Casing Cover 16 Hose Joint 28 Hose Coupling

5 Bolt 17 Coupling Packing 29 Bolt (W/S.W.)

6 Seal Packing 18 Hose Coupling 30 Flange Nut

7 Spring Washer 19 Bend 31 Hose Band

8 Plain Washer 20 Bend Packing 32 Strainer

9 Impeller 21 Bolt (W/S.W.) 33 Frame

10 Mechanical Seal 22 Plug 50 Special Bolt (W/S.W.)

11 Inner Casing 23 Plug Packing 51 Spanner

12 Inner Casing Packing24 Plug 52 Hook

13 Valve Case 25 Plug Packing

NOTE: When ordering parts, make sure to specify your Water Pump model number.

Description Part

Description Part

Description

50: SPECIAL BOLT (W/S.W.) NOT SHOWN.

51: SPANNER NOT SHOWN.

52: HOOK NOT SHOWN.

Some parts are listed and shown for illustration purposes only,

and are not available individually as replacement parts.

NOTE:

SKU 93121/94074/94075 For technical questions, please call 1-800-444-3353. PAGE 15

Page 16

PARTS LIST AND ASSEMBLY DIAGRAM

MODEL 94074 & MODEL 94075

Part # Description Part # Description Part # Description

1 Casing 12 Inner Casing Packing 23 Plug Packing

2 Casing Packing 13 Valve Case 24 Plug

3 Bolt (W/S.W.) 14 Bolt (W/S.W.) 25 Plug Packing

4 Casing Cover 15 Check Valve 26 Hose Joint

5 Bolt 16 Hose Joint 27 Coupling Packing

6 Seal Packing 17 Coupling Packing 28 Hose Coupling

7 Spring Washer 18 Hose Coupling 29 Bolt (W/S.W.)

8 Plain Washer 19 Bend 30 Flange Nut

9 Impeller 20 Bend Packing 31 Hose Band

10 Mechanical Seal 21 Bolt (W/S.W.) 32 Strainer

11 Inner Casing 22 Plug 33 Frame

NOTE: When ordering parts, make sure to specify your Water Pump model number.

NOTE:

Some parts are listed and shown for illustration purposes only,

and are not available individually as replacement parts.

SKU 93121/94074/94075 For technical questions, please call 1-800-444-3353. PAGE 16

Loading...

Loading...