Page 1

®

®

AIR CONCRETE VIBRATOR

Model 92804

ASSEMBLY and OPERATING

INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at http://www.harborfreight.com

READ AND UNDERSTAND ALL WARNINGS

AND INSTRUCTIONS BEFORE USE.

Copyright© 2005 by Harbor Freight Tools®. All rights reserved. No portion of

this manual or any artwork contained herein may be reproduced in any shape or

form without the express written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353.

TO PREVENT SERIOUS INJURY,

Page 2

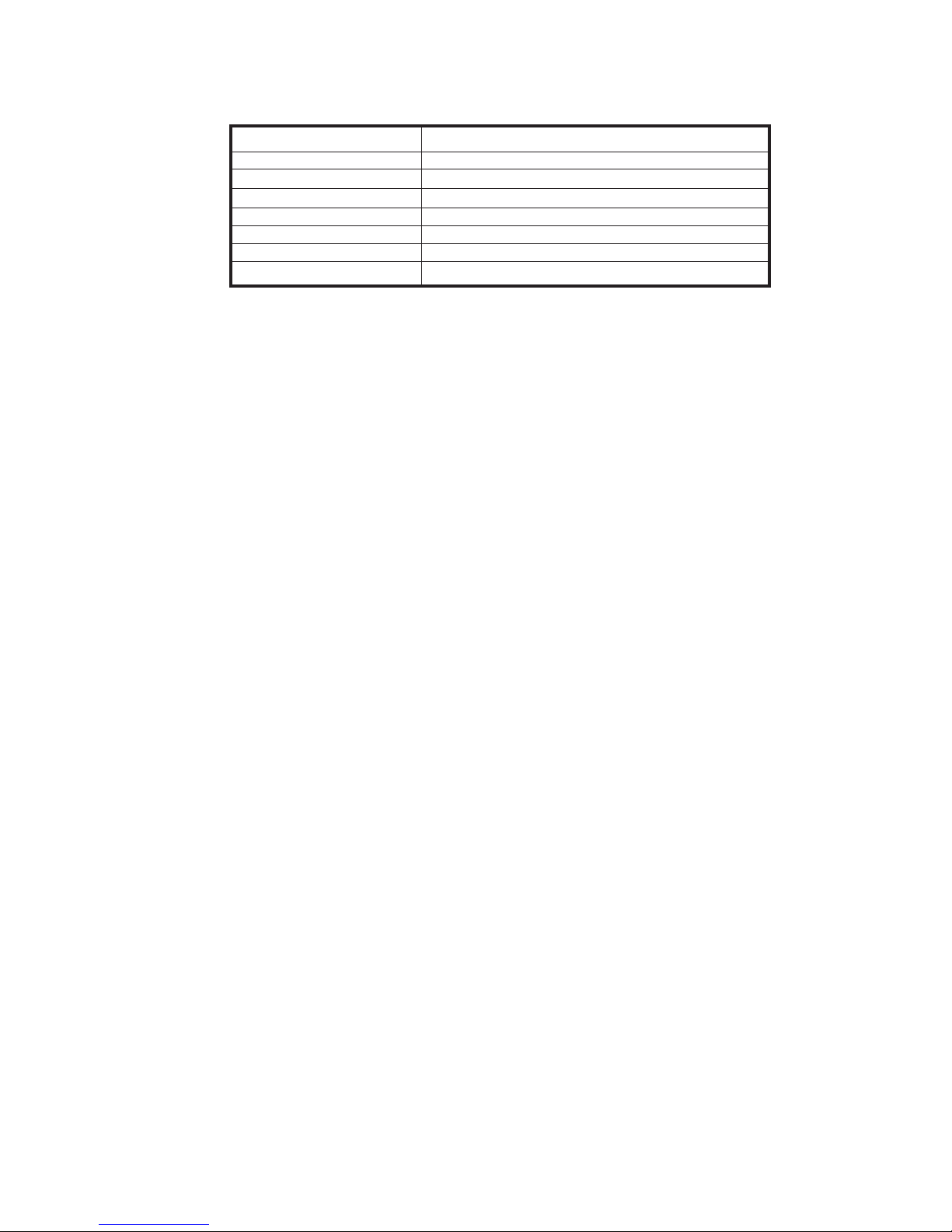

Specifications

Motor 3.6 HP, 3000 RPM (Free Speed 7900 RPM)

Maximum Air Pressure 90 PSI

Air Consumption 120 CFM @ 90 PSI

Starting T orque 5.3 FT/LBS

Stall Torque 8.7 FT/LBS

Air Inlet 1/2” - 14 NPT

Base Dimensions 19-1/4” L x 8-1/4” W x 9-3/4” H

Weight 46.25 LBS

Save This Manual

You will need the manual for the safety warnings and precautions, assembly instructions,

operating and maintenance procedures, parts list and diagram. Keep your invoice with this

manual. Write the invoice number on the inside of the front cover. Keep the manual and

invoice in a safe and dry place for future reference.

Safety Warnings and Precautions

WARNING: When using tool, basic safety precautions should always be followed to

reduce the risk of personal injury and damage to equipment.

Read all instructions before using this tool!

1. Keep work area clean. Cluttered areas invite injuries.

2. Observe work area conditions. Do not use machines or tools in damp or wet

locations. Don’t expose to rain. Keep work area well lit. Do not use electrically

powered compressors in the presence of flammable gases or liquids.

3. Keep children away. Children must never be allowed in the work area. Do not let

them handle machines, tools, extension cords, or air hoses.

4. Store idle equipment. When not in use, tools must be stored in a dry location to

inhibit rust. Always lock up tools and keep out of reach of children.

5. Use the right tool for the job. Do not attempt to force a small tool or attachment to

do the work of a larger industrial tool. There are certain applications for which this

tool was designed. It will do the job better and more safely at the rate for which it was

intended. Do not modify this tool and do not use this tool for a purpose for which it

was not intended.

6. Dress properly. Do not wear loose clothing or jewelry as they can be caught in

moving parts. Protective, electrically nonconductive clothes (including long pants) and

nonskid protective footwear are recommended when working. Wear restrictive hair

covering to contain long hair.

7. Use eye and ear protection. Always wear ANSI approved impact safety goggles and

noise dampening devices (i.e. earmuffs, ear plugs). Wear heavy work gloves.

8. Do not overreach. Keep proper footing and balance at all times. Do not reach over or

across running machines or air hoses.

Page 2SKU 92804 For technical questions, please call 1-800-444-3353

Page 3

9. Maintain tools with care. Keep tools clean for better and safer performance. Follow

instructions for lubricating and changing accessories. Inspect tool cords and air hoses

periodically and, if damaged, have them repaired by an authorized technician. The

handle must be kept clean, dry, and free from oil and grease at all times.

10. Disconnect air supply. Disconnect air hose when not in use.

11. Remove adjusting keys and wrenches. Check that keys and adjusting wrenches

are removed from the tool or machine work surface before plugging it in.

12. Avoid unintentional starting. Be sure the regulator is in the Off position when not in

use and before plugging in.

13. Stay alert. Watch what you are doing, use common sense. Do not operate any tool

when you are tired.

14. Check for damaged parts. Before using any tool, any part that appears damaged

should be carefully checked to determine that it will operate properly and perform its

intended function. Check for alignment and binding of moving parts; any broken parts

or mounting fixtures; and any other condition that may affect proper operation. Any

part that is damaged should be proper ly repaired or replaced by a qualified

technician. Do not use the tool if regulator does not operate properly.

15. Replacement parts and accessories. When servicing, use only identical

replacement parts. Use of any other parts will void the warranty. Only use accessories

intended for use with this tool.

16. Do not operate tool if under the influence of alcohol or drugs. Read warning

labels if taking prescription medicine to determine if your judgement or reflexes are

impaired while taking drugs. If there is any doubt, do not operate the tool.

17. Use proper size and type extension cord. If an extension cord is required for the air

compressor, it must be of the proper size and type to supply the correct current to the

compressor without heating up. Otherwise, the extension cord could melt and catch

fire, or cause electrical damage to the compressor. Check your air compressor’s

manual for the appropriate size cord.

18. Maintenance. For your safety, maintenance should be performed regularly by a

qualified technician.

19. Compressed air only. Never use combustible gas as a power source.

20. WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities, contains chemicals kno wn [to the State of California] to cause

cancer, birth defects or other reproductive harm. Some examples of these chemicals

are:

- Lead from lead-based paints

- Crystalline silica from bricks and cement or other masonry products

- Arsenic and chromium from chemicall y treated lumber

Your risk from these exposures varies, depending on how often y ou do this type of

work. To reduce your exposure to these chemicals: work in a well ventilated area, and

work with approved safety equipment, such as those dust masks that are specially

designed to filter out microscopic particles.

(California Health & Safety Code § 25249.5,

et seq.

)

Page 3SKU 92804 For technical questions, please call 1-800-444-3353

Page 4

21. This item creates powerful vibrations in both the workpiece and in the

operator’s body. Prolonged use could lead to personal injury.

22. Only use the Concrete Vibrator to vibrate and smooth wet concrete. Do not use

it on hard surfaces or you will damage the unit or cause personal injury.

Note: Performance of the compressor (if powered by line voltage) may vary depending on

variations in local line voltage. Extension cord usage may also affect tool performance.

Warning: The warnings, cautions, and instructions discussed in this instruction manual

cannot cover all possible conditions and situations that may occur. It must be understood by the operator that common sense and caution are factors which cannot be

built into this product, but must be supplied by the operator.

Unpacking

When unpacking, check to mak e sure that the product is intact and undamaged. If an y

parts are missing or broken, please call Harbor Freight Tools at the number on the cover of

this manual as soon as possible.

Connecting the Air Supply

Concrete

Vibrator

For best service you should incorporate an oiler, regulator, and inline filter, as shown in the

diagram above. Hoses, couplers, oilers, regulators, and filters are all available at Harbor

Freight Tools.

1. You will need to prepare an air connector (not included) to connect to the Air Inlet on

the Regulator (21), on the Concrete Vibrator. First, wrap the air connector with pipe

thread seal tape before threading it into the Air Inlet (see FIGURE 2 on page 5) on the

Regulator (21). Connect the air source hose to a quick connect coupler, and then to

the Concrete Vibr ator . The air source hose m ust be a sufficient size to provide enough

air volume to operate this tool.

Note: If y ou are not using an automatic oiler system, before operation, add a fe w drops

of Pneumatic Tool Oil to the airline connection. Add a fe w drops more after each hour

of continual use.

2 . Set the air pressure on the regulator to 90 PSI. Do not exceed the recommended air

pressure of 90 PSI.

3. Check the air connection for leaks. Disconnect from the air source.

Page 4SKU 92804 For technical questions, please call 1-800-444-3353

Page 5

Operation

WARNING! This Concrete Vibrator produces significant torque and vibration.

The elderly, infirm, and pregnant women should not use this device.

W ARNING! THE BASE UNIT OF THE CONCRETE VIBRA T OR MUST BE SECUREL Y

STRAPPED DOWN BEFORE USE.

Refer to cover photo and the assembly diagrams.

WARNING: Only use the Concrete Vibrator to vibrate and smooth wet concrete. Do

not use it on hard surfaces or you will damage the unit or cause personal injury.

Connecting the Vibrating Head to the Base Unit

1. Insert the Rod on the center of the Cylindrical Connector (A16) into the center hole in

the end of the Base Unit. Align the notches on the bottom of the Cylindrical Connector

(A16) with the handle on the Base Unit. Tur n the Handle to lock the Cylindrical Con-

nector (A16) into place. See FIGURE 1.

FIGURE 1

Cylindrical Connector (A16)

Rod

Base Unit

Notches

Operating the Unit

Handle

2. After making sure the Base Unit is strapped securely in place using the metal

Support Bracket (20) surrounding it, attach the air hose source and turn on the air

compressor. We recommend having a second person to adjust the Regulator (21) for

power. DO NOT LET GO OF THE CONCRETE VIBRATOR TUBE HEAD WHEN THE

UNIT IS ON. To adjust the Regulator (21), loosen the Lock Nut and adjust the air flow

using the Knob. After achieving the correct air flow, use a wrench to gently tighten the

lock nut. See FIGURE 2.

FIGURE 2

Support Bracket (20) of

Base Unit

Regulator (21)

Knob

Lock Nut

Air Inlet

Page 5SKU 92804 For technical questions, please call 1-800-444-3353

Page 6

Operation (continued)

Note: Grip the Vibrating Tube Head just above where the Flex Tube (A13) connects with the

Casing (A4).

3. If necessary , shake the Vibrator head to start the vibration. K eeping 3/4 of the Vibrating

Head inside the concrete, slowly mov e it within the area you desire to settle. Do not pull

the Vibrating Head out of the wet concrete with the unit on or wet concrete will vibrate

off the head covering the operator and the surrounding area. When you are finished,

have your partner turn off the air compressor and disconnect the air supply.

4. Loosening the Handle on the Base Unit (see FIGURE 1), remove the Vibrating Head

from the Base Unit.

5. Clean the concrete off of the unit and surrounding area before it dries.

Maintenance

Warning! Disconnect the Concrete Vibrator from the air source hose before attempting

any maintenance.

1. Clean the Vibrating Head immediately after each use, before any concrete dries on it.

Do not submerge the Base unit in water . Use a wet cloth to remove concrete from the

Vibrating Head. Do not use any harsh detergents or solvents to clean the Concrete

Vibrator .

2. Dry the Base Unit with a lint free cloth.

Page 6SKU 92804 For technical questions, please call 1-800-444-3353

Page 7

Motor Parts List

Part No. Description Qty.

1 Cylinder 1

2 Front End Plate 1

3 Rear End Plate 1

4 Rotor 1

4A Drive Key 1

5 Vane 4

6* Vane Spring 2

7* Vane Pin 4

8 Front Rotor Bearing 1

9 Rear Rotor Bearing 1

10 Rotor Shaft Seal 1

11 End Plate Gasket 2

12 Front End Cap 1

12A Front/Rear End Cap Screw 6

13 Front End Cap Seal 1

14 Rear End Cap 1

15 Rear End Cap Gasket 1

16 Muffler 1

17 Front/Rear End Plate Screw 12

18* Mounting Foot 4

19* Mounting Flange 4

20* Support Bracket 1

21* Regulator 1

* Not shown on the diagram.

Motor Assembly Diagram

NOTE: Some par ts are listed and shown for illustration purposes only and are not available

individually as replacement parts.

Page 7SKU 92804 For technical questions, please call 1-800-444-3353

Page 8

Vibrating Head Parts List

Part No. Description

A1 Cone

A2 Spacer

A3 Raceway

A4 Casing

A5 Rolling Body

A6 Oil Seal Ring

A7 Oil Seal Housing

A8 Oil Seal

A9 Bearing

A10 Pipe Adapter

A11 Shaft Adapter

A12 Flexible Shaft

A13 Flexible Pipe

A14 Cylindrical Plug

A15 Conical Sleeve

A16 Cylindrical Connector

Vibrating Head Assembly Diagram

THE MANUF ACTURER AND/OR DISTRIBUT OR HAS PRO VIDED THE PARTS DIA GRAM IN THIS

MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR MAKES ANY REPRESENTA TION OR W ARRANTY OF ANY KIND T O THE B UYER THAT HE

OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS

QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER

AND/OR DISTRIBUTOR EXPRESSLY ST A TES T HA T ALL REP AIRS AND PARTS REPLACEMENTS

SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS AND NO T BY THE

BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER

REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PA RTS THERET O , OR ARISING

OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

PLEASE READ THE FOLLOWING CAREFULLY

Page 8SKU 92804 For technical questions, please call 1-800-444-3353

Loading...

Loading...