Page 1

TRANSMISSION

TABLE

ASSEMBLY AND OPERATING INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at http://www.harborfreight.com

Copyright © 2004 by Harbor Freight Tools®. All rights reser ved. No por tion of this

manual or any artwork contained herein may be reproduced in any shape or for m

without the express written consent of Harbor F reight T ools .

For technical questions and replacement parts, please call 1-800-444-3353

92409

Page 2

SKU 92409 For technical questions, please call: 1-800-444-335 Page 2

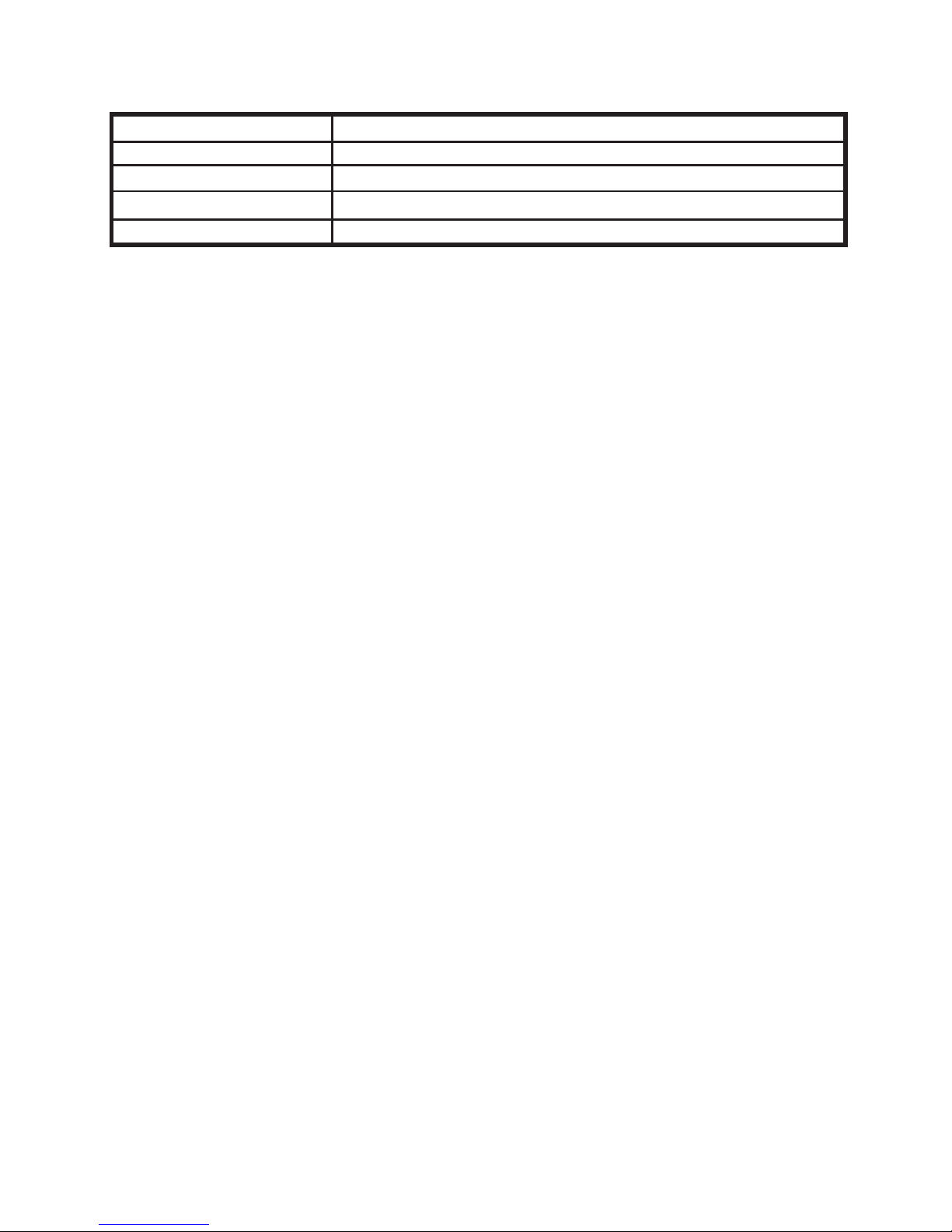

Specifications

Save This Manual

You will need the manual for the safety warnings and precautions, assembly

instructions, operating and maintenance procedures, parts list and diagram. K eep

your inv oice with this man ual. Write the inv oice number on the inside of the front

cover. Keep the manual and inv oice in a safe and dry place for future reference.

Safety Warnings and Precautions

WARNING: When using product, basic safety precautions should always be

followed to reduce the risk of personal injury and damage to equipment.

Read all instructions before using this product!

1. Keep work area c lean . Cluttered areas invite injuries.

2. Observe work area conditions. Do not use machines or po wer tools in

damp or wet locations. Don’t expose to rain. Keep work area well lighted.

3. Keep children away. Children must never be allowed in the work area. Do

not let them handle machines, tools, or extension cords. Do not allow

children to climb on or play on the Transmission Table.

4. When assembling, more than one person is needed for stabilizing par ts

being assembled and for lifting Table to an upright position.

5. Use the right product for the job. There are certain applications for which

this product was designed. Do not modify this product and do not use this

product for a purpose for which it was not intended.

6. Dress properly. Do not wear loose clothing or jew elry as they can be caught

in moving parts.

7. Use eye protection. Always wear ANSI approved impact safety goggles

when assembling this product, and when working with tools and equipment.

Overall Dimensions

Finish

Materials

Weight Capacity

Plastic Drain Tub Capacity

48-1/2” L x 31-1/2” W x 41” Tall

Powder Coated, Rust Resistant-Color Red

Stamped and Formed Sheet Steel Frame-Hard Rubber Casters (4)

880 Lbs.-Evenly Disributed

Holds 2.2 Gallons– 16-1/2” L x 10-3/4” W x 5-3/4” D

Transmission Repair Station has Table Top with Built-in Liquid Drainage Holes.

Page 3

SKU 92409 For technical questions, please call: 1-800-444-335 Page 3

8. Check for damaged par ts. Before using this table, any component that

appears damaged should be carefully checked to determine that it will not

effect the intended function of this product. Replace any broken parts or any

other condition that may affect proper operation. Any part that is damaged

should be properly repaired or replaced by a qualified technician.

9. Replacement parts and accessories. When servicing, use only identical

replacement parts. Use of any other parts will void the warranty.

10. If Keys to the Drawer of the Transmission Table are lost, Harbor Freight

Tools is not responsible. Contact a locksmith for replacement.

11. Place Transmission Table on a flat, level surface. When positioned

correctly, press the Lever on the Swivel Caster w/Locks to prevent

movement. Do not move the Transmission Table while loaded with objects.

12. When working with flammable products like grease, oil, antifreeze,

gasoline, etc., avoid placing table in an area with a pilot light such as in a

waterheater. Be sure the area is well ventilated to avoid a fire.

13. Dispose all hazardous waste products properly. Do not dispose

products in a sewer, stream or ocean. Check with your city government

center for a Hazardous Waste Disposal Plant near you.

14. Once the Transmission Table is Located in it’s desired location, always

lock the Swivel Caster Wheels, that have locks, to prevent unintentional

rolling of the Table.

Warning: The warnings, cautions, and instructions discussed in this instruction manual cannot cover all possible conditions and situations that may occur . It must be understood by the operator that common sense and caution are

factors which cannot be built into this product, but must be supplied by the

operator.

Unpacking

When unpacking, check to make sure all parts are included. See the parts lists on

Page 7. If any parts are missing or broken, please call Harbor Freight Tools at the

number on the cover of this manual.

Page 4

SKU 92409 For technical questions, please call: 1-800-444-335 Page 4

3. Attach the Frame for the Drawer (7) to the underside of the Table Top (6). Be

sure you are installing the Frame (7) in the correct position. Note: The

predrilled holes for the Frame are closer to the front of the Table Top (6).

This will insure the Drawer (8) will be stable. Use Bolts (3), Washers (5), and

Nuts (4). Tighten all hardware.

Refer to the Assembly Drawing on Page 7.

Assembly

1. To protect the finish, set the Table Top (6), face down, on a smooth surface on

the floor. Bolt the Legs (2) into place using Bolts (3), Washers (5), and

Nuts (4).

See Figure 1.

2. Place the Support Braces (11) so that they line up with the predrilled holes

and secure the Support Braces (11) with Bolts (3), Washers (5), and Nuts (4).

See Figure 1.

Figure 1

Leg (2)

Support Braces (11)

Bolts (3)

Washer (5)

Nut (4)

Figure 2

4. Attach the Metal Drawer (8) to the underside of the Table Top (6) where you

have installed the Frame (7). (Note: You need to have the Drawer “out” of

the assembly to install it). Use Bolts (3) in six places. Tighten.

Refer to the

Assembly Drawing on Page 7 and Figure 2.

5. Line the Drawer (8) up with the track in the Metal Drawer assembly (8) by

tilting the front end of the Drawer down, then lifting up the Drawer and sliding

it into place. If it does not fit properly, repeat until you have it on track.

See Figure 3.

Metal Drawer (8)

With Drawer

Removed

Drawer (8) at a Tilt

Figure 3

Track

Page 5

SKU 92409 For technical questions, please call: 1-800-444-335 Page 5

Installing the Plastic Tub

1. There are two rails that act as tracks for the

Plastic Tub (9). These rails are installed under

the drainage holes at one end of the

Transmission Table Top (6).

See Figures 6 & 8.

2. Slide the Plastic Tub (9) into the track on the

underside of the Table Top (6). Be sure it is

positioned under the drain holes before

working on machinery to insure catching any

liquids.

See Figures 6 & 8.

3. After sliding the Plastic Tub (9) into place,

screw in the two Bolts (12) into the holes on

the track. This will prevent the Plastic Tub from

sliding too far forward. Remove the Bolts to

empty fluids caught in the Tub.

Follow the

disposal of Hazardous Waste instruction on

Page 3. See Figure 7.

Plastic

Tub (9)

Figure 6

Figure 7

Bolt 12

Track

Plastic

Tub (9)

Figure 4

Figure 5

Key and

Lock (13)

Plastic

Drawer

Stop

7. Use the Keys and Lock (13) to secure objects

when not in use.

Figure 5.

6. Once the Drawer (8) is in place on the track,

install the Locks (13) at the back of the Drawer.

Push the Button on each side into the predrilled

holes to secure Drawer (8). This will prevent the

Drawer from being pulled out too far and

spilling the contents on the floor. To remove the

Drawer, reverse the step.

See Figure 4.

Figure 8

Drainage

Holes

Page 6

SKU 92409 For technical questions, please call: 1-800-444-335 Page 6

Installing the Casters

1. Attach two Swivel Casters (1) on one side of

the Table Legs (2), using Bolts (3), Washers

(5), and Nuts (4). Attach the two Swivel

Castors with Locks (10) to the opposite Legs

(2), using Bolts (3), Washers (5), and Nuts (4).

(Note: To lock and unlock, use your foot to

press or release lever).

2. Once assembly is complete, set the

Transmission Table upright. Roll the Table and

check that it is assembled correctly. Check that

the Transmission Table is level. Tighten all

hardware. Caution: At all times, the Table Top

should be emptied of any load that is on top

before moving. Lock the Swivel Casters (1)

and distribute the weight evenly when working

on any machinery.

See Figures 9 & 10.

Bolt (3)

Washer (5)

Nut (4)

Figure 10

Lock

Lever

Swivel Lock

Caster (10)

Lever

Swivel

Castor with

Lock (10)

Maintenence

1. To remove dust, use a damp cloth. To remove grease or oil, use a detergent

based cleaning solvent, rinse with damp cloth, and dry.

2. This product should be assembled and stored in a dry area.

Figure 9

Note: Never exceed the maximum load capacity as described on page 2.

Page 7

SKU 92409 For technical questions, please call: 1-800-444-335 Page 7

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUF ACTURER AND/OR DISTRIB UTOR HAS PR O VIDED THE PARTS DIAGRAM IN

THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR

DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE

BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT OR

THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE PR ODUCT. IN FACT,

THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY STATES THat ALL REPAIRS

AND P AR TS REPLACEMENTS SHOULD BE UNDER T AKEN BY CER TIFIED AND LICENSED

TECHNICIANS AND NOT BY THE B UYER. THE BUYER ASSUMES ALL RISK AND LIABILITY

ARISING OUT OF HIS OR HER REP AIRS TO THE ORIGINAL PRODUCT OR REPLA CEMENT

PARTS THERET O , OR ARISING OUT OF HIS OR HER INSTALLA TION OF REPLACEMENT

P ARTS THERET O.

Parts List

Part # Description Qty.

2

2

48

44

44

1

1

1

1

2

2

2

1

Swivel Caster

Leg

Bolt (M8 x 15)

Nut (M8)

Washer

Top of Table

Frame for the Drawer

Metal Drawer (Assmebly)

Plastic Tub

Swivel Caster with Lock

Support Brace

Bolt (M8 x 30)

Lock and Keys Set

1

2

3

4

5

6

7

8

9

10

11

12

13

Part 1

Part 2

Part 4

Part 3

Part 5

Assembly Drawing

Part 6

Part 7

Part 8

Part 9

Part 10

Part 11

Part 12

Part 13

NOTE: Some parts are listed and shown for illustration purposes only and are not available

individually as replacement parts.

Loading...

Loading...