Page 1

7” x 10” Mini Lathe

®

Model 33684

Assembly and Operating Instructions

3491 Mission Oaks Blvd., Camarillo, CA 9301 1

Copyright 2000 by Harbor Freight T ools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight T ools.

For technical questions and replacement parts, please call 1-800-444-33534.

Page 2

Important Safety Instructions

READ ALL INSTRUCTIONS AND WARNINGS BEFORE USING THIS T OOL.

Operator

COMMON SENSE AND CAUTION ARE FACTORS WHICH CANNOT BE BUILT INTO

ANY PRODUCT . THESE F ACTORS MUST BE SUPPLIED BY THE OPERATOR. PLEASE

REMEMBER:

1. When using electric tools, machines or

equipment, basic safety precautions should

always be followed to reduce the risk of fire,

electric shock, and personal injury .

2. Keep work area clean. Cluttered areas

invite injuries.

3. Consider work area conditions. Do not

use machines or power tools in damp, wet,

or poorly lit locations. Do not expose

equipment to rain. Keep work area well lit.

Do not use tools in the presence of flammable gases or liquids.

4. Keep children away. All children should

be kept away from the work area.

5. Guard against electric shock. Prevent

body contact with grounded surfaces such as

pipes, radiators, ranges, and refriderator

enclosures.

6. Stay alert. Never operate equipment if

you are tired.

7. Do not operate the product if under the

influence of alcohol or drugs. Read warning

labels on prescriptions to determine if your

judgment or reflexes might be impaired.

8. Do not wear loose clothing or jewelry as

they can be caught in moving parts.

9. W ear restrictive hair covering to contain

long hair.

10. Use eye and ear protection. Always

wear:

-ANSI approved chemical splash goggles

when working with chemicals.

-ANSI approved impact safety goggles at

other times.

-ANSI approved dust mask or respirator

when working around metal, wood, and

SKU #33684 Page 2

chemical dusts and mists.

-A full face shield if you are producing metal

or wood filings.

11. Keep proper footing and balance at all

times.

12. Do not reach over or across running

machines.

13. Always check that adjusting keys and

wrenches are removed from the tool or

machine work surface before plugging it in.

14. Do not carry any tool with your finger on

either the start button or trigger.

15. When servicing, use only identical replacement parts.

Before Operation

1. Be sure the switch is OFF when not in use

and before plugging in.

2. Do not attempt to use inappropriate

attachments in an attempt to exceed the tool’s

capacity . Approved accessories are available

from Harbor Freight T ools.

3. Check for damaged parts. Before using

any tool, any part that appears damaged

should be carefully checked to determine that

it will operate properly and perform its intended function.

4. Check for alignment and binding of all

moving parts, broken parts or mounting

fixtures and any other condition that may

affect proper operation. Any part that is

damaged should be properly repaired or

replaced by a qualified technician.

5. Do not use the tool if any switch does not

turn off and on properly .

Page 3

Operation

1. Never force the tool or attachment to

do the work of a larger industrial tool. It is

designed to do the job better and more

safely at the rate for which it was intended.

2. Do not carry the tool by its power

cord.

3. Always unplug the cord by the plug.

Never yank the cord out of the wall.

4. Always turn off the machine before

unplugging.

IF THERE IS ANY QUESTION

ABOUT A CONDITION BEING

SAFE OR UNSAFE, DO NOT

OPERA TE THE TOOL!

Check to see if your tool has a two or threeprong plug. If your tool has a two-prong plug,

you may proceed past the next paragraph. If

your tool has a three-prong plug, please continue

reading the following precautions and instructions.

If the tool or machine has a three-prong plug, the

third (round) prong is the ground. Plug this cord

only into a three-prong receptacle. Do not

attempt to defeat the protection the ground wire

provides by cutting off the round prong. Cutting

off the ground will result in a safety hazard and

void the warranty .

Grounding Instructions and

Voltage Warning

Common household current is 110-120 volts.

As long as your tool is rated from 110-120V

there will be no complications using this tool

with household receptacles. NEVER try to

plug a 110-120V tool into a 220-240V circuit

(or vice-versa) or serious complications and

possible serious injury to the operator can

occur. The plugs have different shapes to

prevent this.

____________________________________________________________________________

If a three-prong receptacle is not available, you

may use an adapter, but you must then connect

the green ear on the adapter to the outlet.

Unscrew the center screw of the outlet cover

and put the screw through the green ear. Plug

the adapter’s two prongs into the outlet, and

replace the center screw . Now plug the tool or

machine into the adapter.

DO NOT MODIFY THE PLUG IN ANY

W AY . IF YOU HAVE ANY DOUBT , CALL

A QUALIFIED ELECTRICIAN.

Extension Cords

If your tool is double insulated and has a two-prong plug, you may use either a two or three-prong

extension cord. If your tool has a grounded, three-prong plug, you must use a three-prong extension

cord with three-prong receptacles. Only use rounded jacket extension cords listed by the Underwriters Laboratories (UL). If you are using the tool outdoors, use an extension cord rated for

outdoor use (signified by “W A” on the jacket).

The extension cord must have a minimum wire size depending on the amperage of the tool and the

length of the extension cord. The size is determined by its A WG (American Wire Gauge) rating. The

smaller the gauge, the greater the cable’ s capacity. The amount of cords used does not matter. T otal

length determines the minimum A WG rating. Every cord must meet the A WG rating. Use the chart

below to determine what AWG rating is required for your situation. Cord length is rated in feet.

Harbor Freight T ools can supply UL listed and outdoor rated extension cords in multiple A WG

ratings if needed.

AMP T otal Extension Cord Length In Feet

Rating 25’ 50’ 75’ 100’ 125’ 150’ 175’ 200’

0.0 -10.0 18 18 16 16 14 14 12 12

10.1-13.0 16 16 14 14 14 12 12 12

13.1-15.0 14 14 12 12 12 12 12 --

15.1-18.0 14 12 12 12 12 12 -- --

SKU #33684 Page 3

Page 4

Additional Safety Rules for Mini Lathe

1. Before turning on the motor, make sure

that proper lubrication is included (see page

of this manual).

2. Always dismount the chuck and lathe’ s

face plate by hand. Do not use power tools

to perform these tasks.

3. After the chuck is installed, remove the

wrenches and tools to eliminate the possibility of accident when the lathe is turned

on.

4. Never adjust or fix workpieces or any

rotating parts when the lathe is on. Never

use instruments to measure the workpiece

____________________________________________________________________________

Thank you for choosing a Harbor Fr eight T ools product! For future reference, please

complete the owner’s record below:

Model:_______________ Serial Number:_________________ PurchaseDate:__________

when the lathe is on. Never check the

sharpness of the cutter by using your hand.

5. A void accidents resulting from broken

workpieces. Never use an excessively large

tool cutter to do feeding with a large

workpiece.

6.Never change the gear when the lathe is in

operation.

7. Always keep a safe distance from the lathe

to minimize the risk of being struck by a

broken workpiece.

SAVE THE RECEIPT , W ARRANTY AND THESE INSTRUCTIONS. It is important that you

read the entire manual to become familiar with the unit BEFORE you begin assembly .

____________________________________________________________________________

Technical Specifications

Motor: 3/4 Horsepower

Power Source: 110V, Single Phase

Lathe Specifications:

Drive: Gear and Belt

Swing Over Bed: 7”

Distance Between Centers: 10”

Spindle Bore: 3/4”

Quill Travel: 2”

Cross Slide Travel: 2 3/4”

Cross Slide Swing: 4 1/2”

W ork T olerance: .005”

Bed Dimensions: 15 7/8” long, 3 1/4” wide

Saddle Travel: 6 7/8”

Compound Travel: 2 7/8”

SKU #33684 Page 4

Page 5

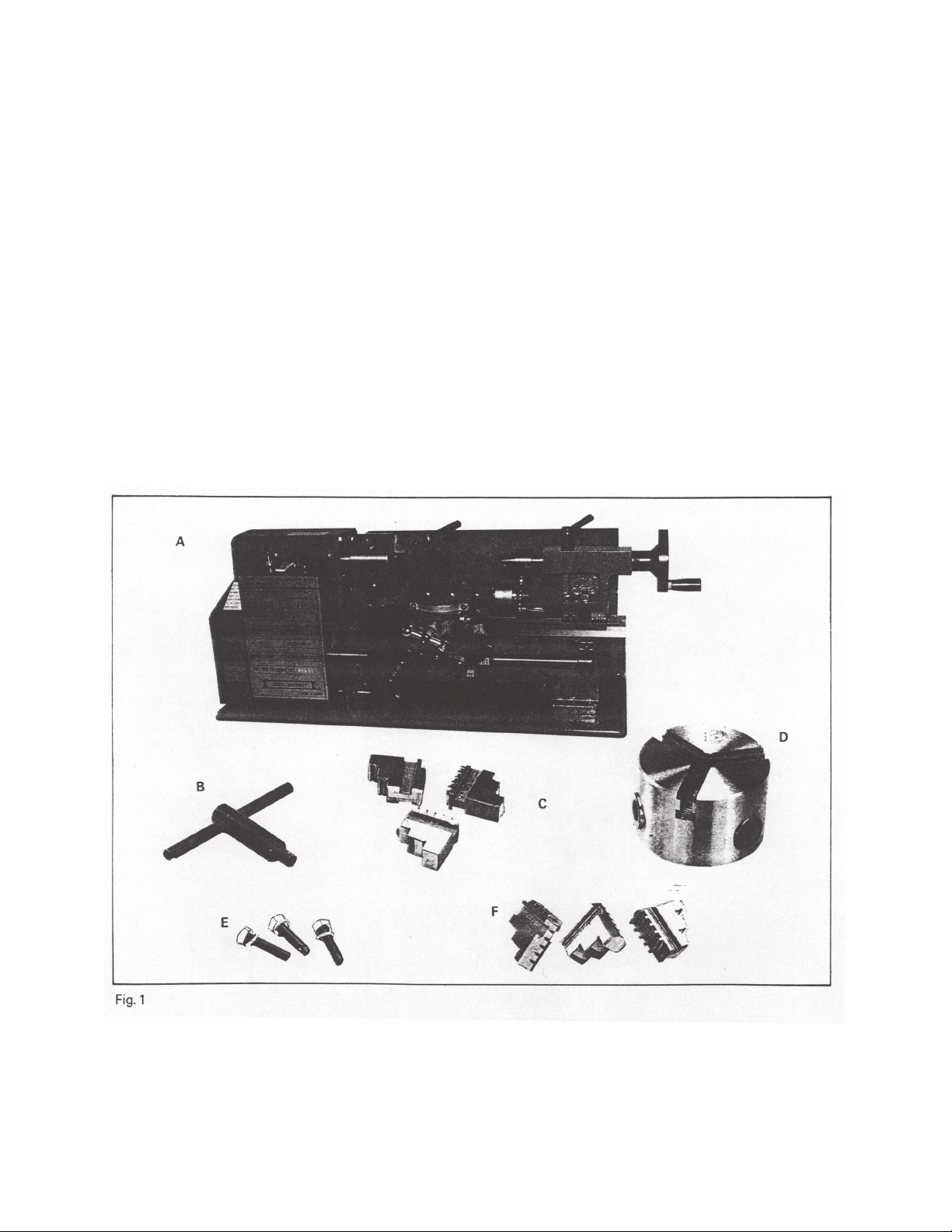

Unpacking

Carefully unpack the Mini Lathe and check all items. Figure 1 below shows all the contents of the

carton. Do not discard any packing material until the Mini Lathe is fully assembled and operational.

If any parts are missing or broken, please call Harbor Freight T ools at 1-800-444-3353. Be sure

you have all parts described in the parts listing on page .

Identification of Main Components

A. Lathe B. Chuck Key C. External Jaws

D. Chuck E. Chuck Set Screws F . Internal Jaws

SKU #33684 Page 5

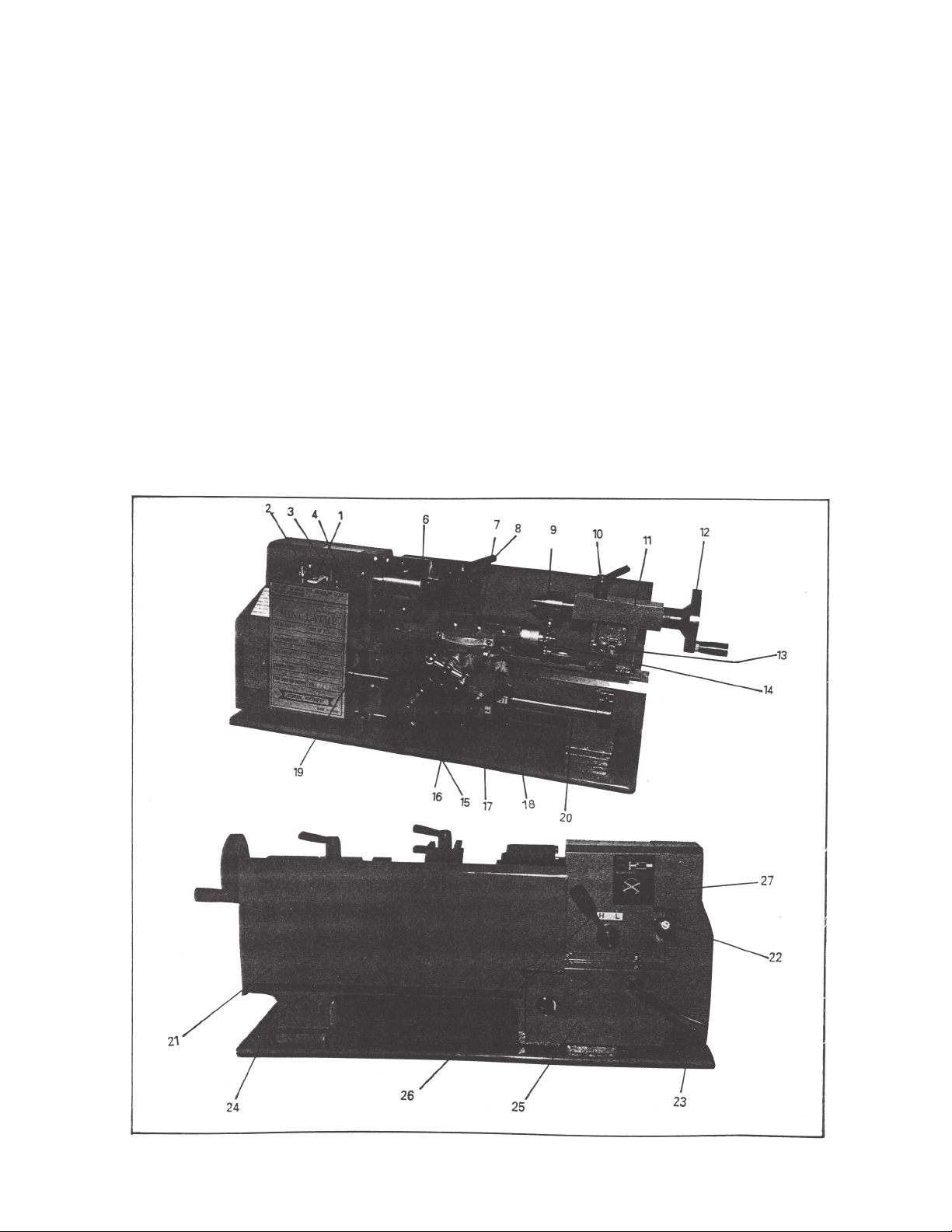

Page 6

Mini Lathe Features

1. Power Switch

2. Power lamp

3. Fuse

4. Speed Control Knob

6. Chuck

7. Compound Rest

8. T ool Post

9. Fixed Center

10.T ailstock Quill Fix Holder

11. Tailstock

12. T ailstock Quill Adjust Handwheel

13. T ailstock Set Screw

14. Compound Rest Crank

1.15. Feeding Control Wheel

16. Cross Feeding Crank

17. Automatic Feeding Handle

18. Thread Dial Indicator

19. Bed Way

20. Lead Screw

21. Rear Splash Guard

22. Feeding Direction Selector

23. Power Cord

24. Chip Tray

25. Motor Cover

26. H/L Gear Shift Lever

27. End Cover

SKU #33684 Page 6

Page 7

Adjusting the Mini Lathe

1. Clean off the protective grease on the Mini Lathe.

2. Check to see that the three set screws on the chuck are tight.

3. Turn the chuck by hand and check that it rotates freely .

4. Move the Feeding Direction Selector (located on the back of lathe) to the middle.

5. Make sure the Switch (#1 in figure 4 below) is at the OFF position.

WARNING: ADJUST THE SPEED CONTROL KNOB (#4) BY TURNING IT TO

ZERO. BEFORE TURNING ON THE MINI LA THE EACH TIME IT IS TO BE USED,

THIS SPEED CONTROL KNOB MUST BE A T ZERO.

6. Plug in the electrical cord and turn the Switch to the ON position and run the lathe for 3 minutes.

When the lathe is on, the Power Lamp (#2) will remain on. Check to see that the lathe operates

normally .

7. Check the Compound Rest Crank and the Cross Feeding Crank to see that they work properly .

If the cranks are too tight or too loose, turn the adjusting screws located at both sides (see figure 5

below).

WARNING: THE MINI LA THE MUST BE COMPLETEL Y STOPPED BEFORE

CHANGING FOR W ARD/REVERSE DIRECTION.

Replacement of Chuck

When replaceing the chuck, place a cloth or a piece of wood on the bedway at the bottom of the

chuck. This step will help avoid damage to the bedway caused by carelessly dropping the chuck.

T o replace the chuck, loosed the 3 set screws as shown in figure 6 below .

Rev 01/99SKU #33684 Page 7

Page 8

Replacement of Jaws

There are two types of jaws: the internal

jaws and external jaws. Please note that the

number of jaws fit with the number inside the

chuck’s groove. Do not mix them together .

When you are going to mount the jaws,

mount them in ascending order. When they

are taken out, make sure to take them out in

descending order (3-2-1) one by one. After

you finish this procedure, rotate the jaws to

the smallest diameter and check that the three

jaws are well fitted (see figure 7).

If the jaws do not fit well together, you will need to

reassemble them again.

When mounting a workpiece, it is recommended

that all three jaws are loosened at the same time.

This will protectthe threads inside.

Compound Rest Adjustment

T o adjust the compound rest, loosen the two

screws as shown in figure 8 (A). After adjusting

to the required angle, tighten the screws.

Tailstock Rest Adjustment

T o change position or replace the tailstock, loosen the nut as shown in (A) of figure 9.

Replacement of Carbon Brushes

T o replace, remove brush covers on the motor cover (A) in figure 10-A, and the right bottom side of

speed controller as shown in (B) of figure 10-B.

SKU #33684 Page 8

Page 9

Tool Post Adjustment

Loosen the lever shown in (B) of figure 11,

the adjust the tool post position. Once the

adjustment is made, re-tighten the lever. To

replace the work cutter, loosen the screws

(A) with the allen wrench provided.

Automatic Feeding

Adjust the feeding direction selector to the

direction you desire. Press down the handle

(A) in figure 12, and continue with the

automatic feeding procedure. When

feeding, never try to change the feeding

direction.

Threading

Select the feeding direction selector to the

thread direction desired. Then press down

handle (A) in figure 12 by matching the right

calibrations on the thread dial indicator (B)

and continue with the automatic threading

procedure. When threading, never try to

change the direction.

Operation

1. Use the chuck to hold the workpiece

firmly (figure 13 below). Then, use the rolling

center to fix the other end. If you change the

rolling center to drilling chuck you start your

drilling immediately .

SKU #33684 Page 9

2. Use the chuck to hold the workpiece firmly

and cutter to start lathe’s face cutting (figure

14). The edge of the cutter must be at the

same height as the center.

Page 10

3. By changing the tool post angle and adjusting the compound rest, you can do internal cutting

(figure 15).

4. After adjusting the angle of the compound rest, you can do bevel cutting (figure 16).

Set-Up Instructions for Threading Gears

By changing the gear set-up it is possible to cut any thread size. The factory set-up for Mini Lathe

gears is as follows (see illustration below):

A A

Position A= 20T

B

C C B

D

D

T o change the thread size, use the gear box settings shown on the table on the next page.

Position B= 80T

Position C= 20T

Position D= 80T

SKU #33684 Page 10

Page 11

Gear Settings for Various Thread Sizes

Threads Stud Gear Box Threads Stud Gear Box

Per Inch A B C D Per Inch A B C D

12 40 30 38 20 50 60 57

13 40 65 60 30 40 20 50

14 40 35 44 20 55

16 40 40 48 20 60

18 40 45 52 20 65

19 40 50 60 57 56 20 35 30 60

20 40 50 64 20 40 20 40

22 40 55 72 20 45 20 40

24 40 60 76 20 50 30 57

26 40 65 80 20 50 20 40

28 20 35 88 20 55 20 40

32 20 40 96 20 60 20 40

36 20 45 104 20 65 20 40

Example: T o cut 12 threads per inch (see illustration below), use 40T in position A, 30T in

position D, and put any other gear is position B to connect A and D.

A

A

B B

D D

A

B C C B

D D

Example: T o cut 38 threads per inch (see illustration above), use 20T in position

A, 57T in position D, 50T in position B, and 60T in position C.

A

SKU #33684 Page 11

Page 12

SKU #33684 Page 13

Page 13

SKU #33684 Page 14

Page 14

Parts Diagram

SKU #33684 Page 15

Page 15

Additional Set-Up Instructions for Threading Gears

When the lathe is ON and the Spindle is revolving, the threaded bar and the Thread Dial Indicator

will also be revolving (see below).

Thread Dial Indicator

Indicator Housing

T op View

Thread Indicator Housing

Insure that the Alignment Mark is lined up with the

Thread Dial Indicator before operation.

Move the cutting blade to the proper position, and adjust theThread Dial Indicator to the desired

mark. Pull down the Handle and the Mini Lathe starts threading automatically .

Remember: After thread cutting operation is complete, change back to the factory set-up gear

setting:

Position A= 20T

Position B= 80T

Position C= 20T

Position D= 80T

SKU #33684 Page 12

#33684 Page 12

Page 16

SKU #33684 Page 16

Page 17

P ACKING LIST

No. Description Qty Part No.

1 7” x 10” Mini Lathe 1 piece

2 Chuck external jaws 3 piece

3 Chueck Key 1 piece

4 Fuse 5A 1 piece

5 Gear Z: 30, 35, 40, 40, 45, 50, 55, 57, 60, 65 10 pieces

6 Double head wrench 8-10, 14-17 2 pieces

7 Inside six horn wrench S: 3, 4, 5, 6 4 pieces

8 Oil can 1 piece

9 Center MT : 2 1 piece 143

10 Rubber 4 pieces 125

11 Knob 2 pieces 85

12 Instruction Manual 1 copy

13 Wiring Diagram of Control Circuit 1 copy

14 Warranty Document 1 copy

SKU #33684 Page 17

Page 18

SCHEMA TIC DIAGRAM

Fuse

Switch 2

Potentiometer

Switch 1

Motor

110V/60Hz

SKU #33684 Page 18

REV 08/04

Loading...

Loading...