Page 1

30” SHEAR BRAKE ROLL

®

Model 05907

Assembly & Operating Instructions

3491 Mission Oaks Blvd. / Camarillo, CA 93011

Copyright 1997 by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form without

the express written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353.

Page 2

SAVE THIS MANUAL

You will need this manual for the safety instructions,

assembly and operating instructions and parts list.

Put it in a safe, dry place for future reference. Keep

your invoice with this manual. Write the invoice

number on the inside front cover.

READ ALL INSTRUCTIONS

BEFORE OPERATING THE

30” SHEAR BRAKE ROLL.

SPECIFICATIONS

Characteristic Value

Measurements 40” x 14 1/2” x 23 1/2”

Weight 297 lb.

Maximum Work Piece Width 30”

Maximum Work Piece Thickness 20 Gauge

SAFETY WARNINGS & CAUTIONS

1. KEEP WORK AREA CLEAN. Cluttered areas invite injuries.

2. KEEP CHILDREN AWAY. All children should be kept away from the work area. Don’t

let them handle the tool.

3. DO NOT OPERATE THE TOOL IF UNDER THE INFLUENCE OF ALCOHOL OR

DRUGS. Read warning labels on prescriptions to determine if your judgment or reflexes

are impaired while taking drugs. If there is any doubt, do not attempt to operate.

4. AVOID MOVING PARTS DURING OPERATION. Keep fingers and hands away from all

moving parts.

5. USE EYE PROTECTION. Wear ANSI approved impact safety goggles. Goggles are

available from Harbor Freight Tools.

6. DRESS SAFELY. Protective, gloves and non-skid footwear or safety shoes are recom-

mended when working with and operating the tool. Don’t wear loose clothing or jewelry.

They can get caught in moving parts. Also, wear a protective hair covering to prevent

long hair from getting caught in the tool.

7. DON’T OVERREACH. Keep proper footing and balance at all times.

8. STAY ALERT. Watch what you are doing. Use common sense. Do not operate any

tool when you are tired.

9. REPLACEMENT PARTS AND ACCESSORIES. When servicing, use only identical

replacement parts. Only use accessories intended for use with this tool. Approved

accessories are available from Harbor Freight Tools.

10. STORE IDLE EQUIPMENT. When not in use, the tool should be stored in “closed”

position and in a dry location to reduce rust. For safety, keep out of reach of children.

Page 2 -- SKU: 05907

Page 3

ADJUSTMENT

Handle Removal and Adjustment

The HANDLE (#18) may be adjusted or moved by removing one of the handle knobs and loosening the wing nut that holds the handle in place. It may then be slid out of the handle socket,

moved to the opposite side of the tool, and tightened in the most convenient position.

Bending Die Adjustment and Removal

The UPPER BRAKING DIE (#12) is segmented and can be used for varying sizes of box and

pan forming. When forming a smaller box or pan, choose the desired size UPPER DIE finger,

center it and remove the others. See below for adjustment instructions.

The SHEAR BRAKE ROLL can be used to bend sheet metal up to 20 gauge. The space

between the UPPER DIE and the MOVING CUTTER PLATE (#11) is adjustable. To adjust the

spacing, perform the following steps:

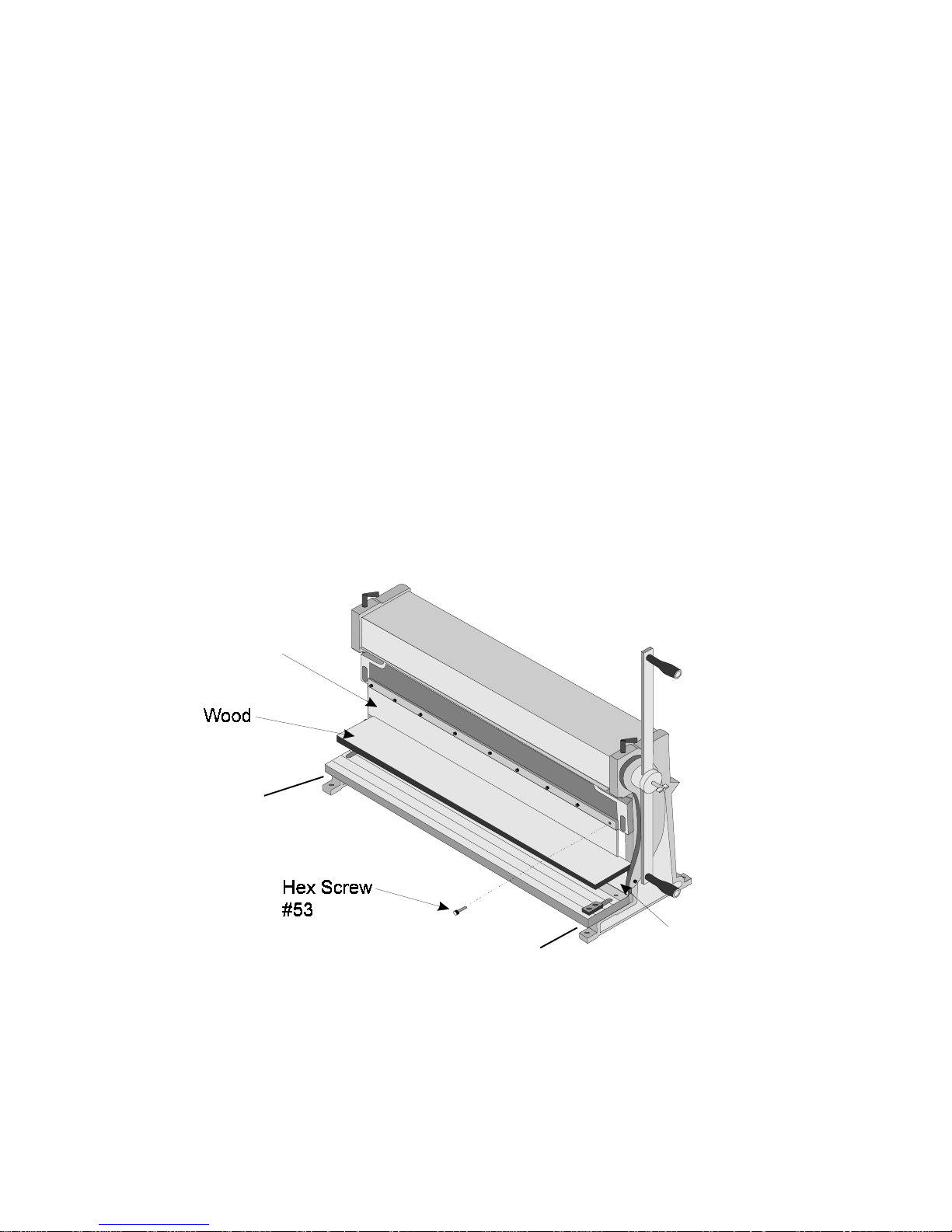

Step 1. Place a flat straight piece of wood between the UPPER BRAKING DIE and MOVING

CUTTER PLATE and raise the MOVING CUTTER PLATE so that the material just

touches the UPPER DIE as shown in Figure 1.

Upper Braking

Die #12

Adjusting Screw #61

Adjusting Screw #61

Moving Cutter Plate #11

Figure 1 — Adjusting the Dies

Step 2. Loosen the HEX SCREWS (#53) holding the UPPER DIE fingers in place. It is not

necessary to remove them.

Page 3 -- SKU: 05907 REV 11/02

Page 4

Step 3: Remove any unneeded UPPER DIE fingers.

Step 4. Raise and lower the MOVING CUTTER PLATE and use the block of wood to adjust the

alignment of the UPPER DIE fingers.

Step 5: Tighten the UPPER DIE HEX SCREWS.

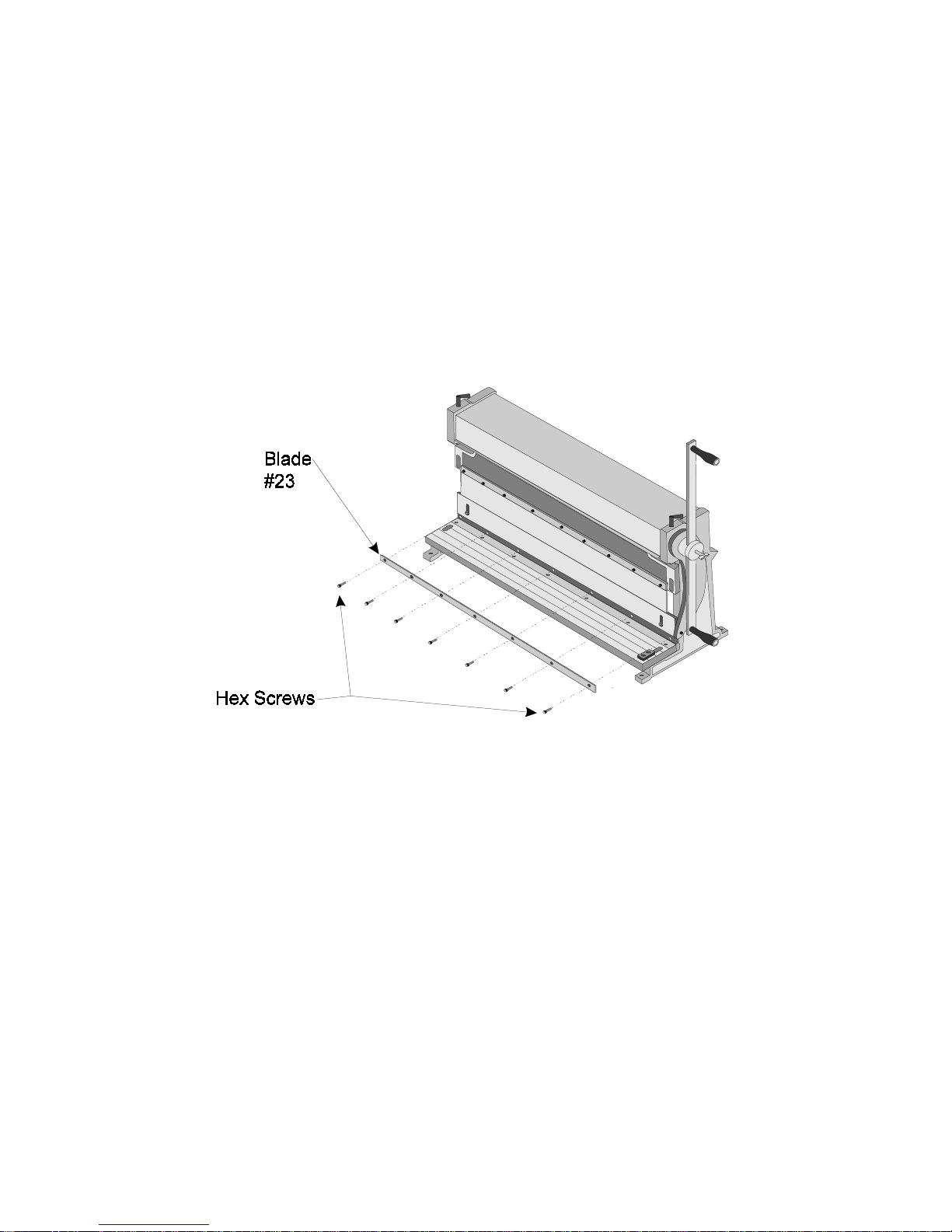

Removal and Installation of Upper Cutting Blade

Step 1: Remove the HEX SCREWS (#56) from the upper cutting BLADE (#23) as shown in

Figure 2.

#56

Figure 2 — Upper Blade Removal

Step 2: Remove the upper cutting BLADE.

Step 3: Align the upper cutting BLADE so that it is flush with the MOVING CUTTER PLATE

(#11) and secure with its SCREWS.

Adjustment of Upper Blade

Step 1: Place a 30” piece of thin cardboard or paper between the UPPER and LOWER

BLADES (#23).

Step 2: Rotate the HANDLE (#18) and cut the material.

Step 3: Use a straightedge to determine the straightness of the cut and if the BLADE is in need

of adjustment.

Page 4 -- SKU: 05907 REV 11/02

Page 5

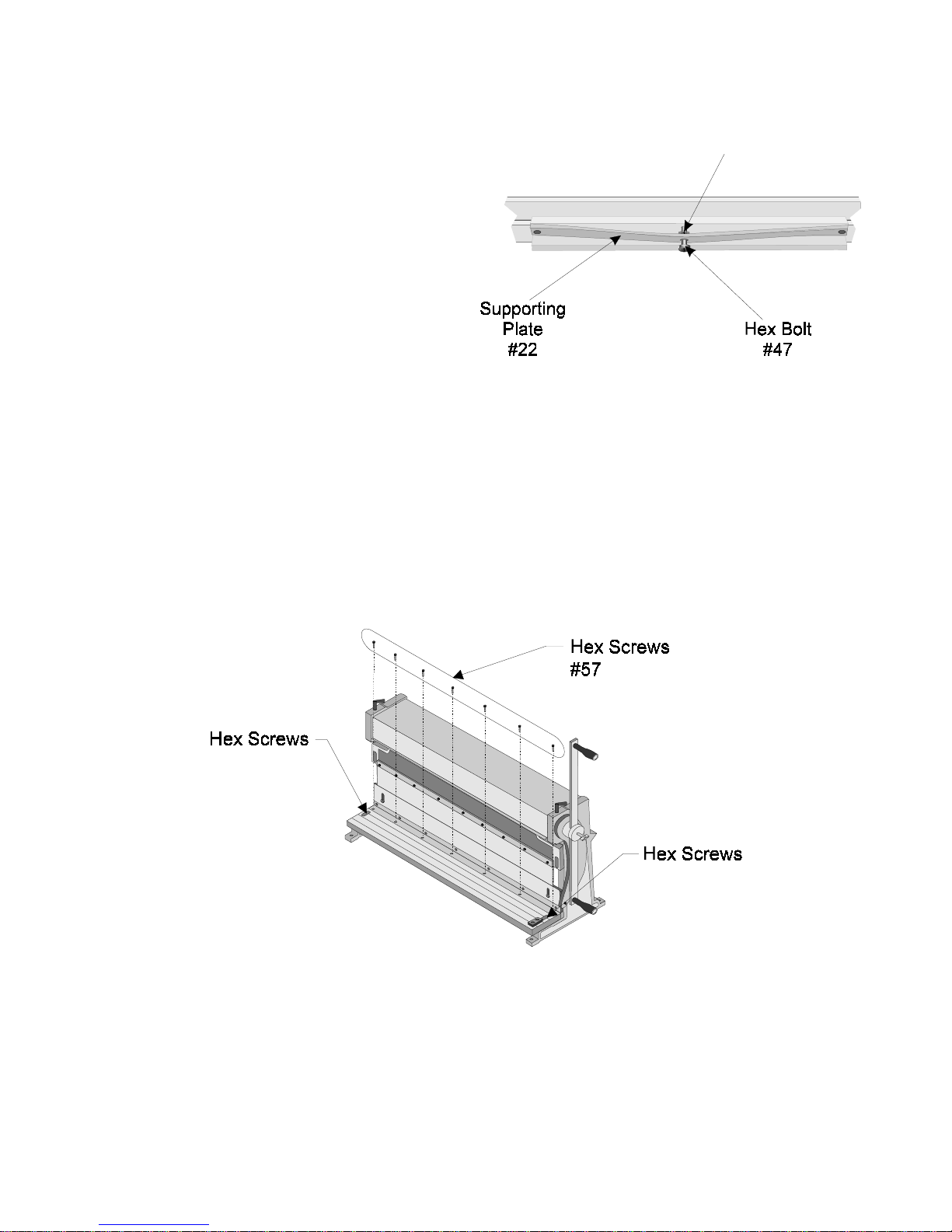

Step 4: If the BLADE is bowed out, away

from the front of the tool, turn the

Nut

#49

adjustment NUT (#49) counterclockwise (see Figure 3). This will tighten

the SUPPORTING PLATE (#22) and

push the middle of the UPPER

BLADE (#23) out while pulling its

ends in.

Step 5: If the BLADE is bowed in, towards

the back of the tool, turn the adjustment NUT clockwise (see Figure 3).

This will loosen the SUPPORTING

PLATE and pull the middle of the

UPPER BLADE in while pushing

Figure 3 — Upper Blade Alignment

its ends out.

Removal and Installation of Lower Blade

Step 1: Remove the HEX SCREWS (#59) from the lower cutting BLADE (#23) as shown in

Figure 4.

#59

#59

Figure 4 — Removal and Installation of Lower Blade

Step 2: Remove the lower cutting BLADE (#23).

Step 3: Replace the lower cutting BLADE and secure using its HEX SCREWS.

Page 5 -- SKU: 05907 REV 11/02

Page 6

Adjustment of Lower Cutting Blade

Step 1: Lower the upper BLADE (#23) to its lowest position.

Step 2: Loosen the two inset HEX SCREWS (#59) located on top of the WORK TABLE (#2) as

shown in Figure 4.

Step 3: Adjust the lower cutting BLADE by turning its ADJUSTMENT SCREWS (#61) as

shown in the Parts Diagram on page 13. The distance between the lower cutting

BLADE and the upper cutting BLADE should be 5 to 8 percent of the thickness of the

workpiece.

Step 4: Tighten the two inset HEX SCREWS (#59) located on top of the cutting blade.

Page 6 -- SKU: 05907 REV 11/02

Page 7

OPERATION

Shearing

Step 1: Scribe the cutting mark on the material.

Step 2: Slide the material between the upper BLADE (#23) and the lower BLADE (#23) so that

the upper BLADE is positioned directly above the mark and the right hand side of the

material rests against the GUIDE (#16) as shown in Figure 5.

Step 3: While holding the material steady, rotate the HANDLE until the material has been cut.

Page 7 -- SKU: 05907

Figure 5 — Shearing

Page 8

Angle Bending

Step 1. Mark the work piece where you want to bend the material.

Step 2. Place material above the MOVING CUTTER PLATE (#11) as shown in Figure 6.

Upper Braking

Die #12

Moving Cutter

Pate #11

Figure 6 — Angle Bending

Step 3. Align the bending mark with the front edge of the UPPER DIE.

Step 4. Rotate the HANDLE (#18) until the desired angle has been formed. Use a protractor or

other measuring tool to ensure accuracy.

Page 8 -- SKU: 05907 REV 11/02

Page 9

Radius Bending

Radius bending is most commonly used to make cylinders and cones, as shown in Figure 7.

Both shapes are formed by making a series of small, closely spaced bends in the work piece.

Work

Bench

Figure 7 — Radius Bending

For cylinders, the bends are evenly spaced, i.e. every bend is identical.

For Cones, simply move one side of your stock out further than the other every time you make a

bend.

Pan Forming

The Hand Brake Roll can be used to make various sizes of pans. The maximum lip (side) height

supported by this tool is 1”.

To form a pan:

Step 1. Pre-measure and cut your material before bending. Notch the corners according to the

desired lip height as shown in Figure 8.

Step 2. Insert material between the UPPER BRAKING DIE (#12) and the MOVING CUTTER

PLATE (#11). Bend the material until as 90 degree angle has been formed.

Step 3. Rotate the material 90º counterclockwise. Allow the completed side to extend just

beyond the dies. Bend the second side.

Step 4. Repeat Step 3 for the third side.

Step 5. Rotate to the final side, and insert work piece between the dies. Your formed sides will

be on the outside of the dies.

Step 6. Before bending, tap one corner nearer to the middle of the machine. This will allow the

material to clear the UPPER BRAKING DIE when raised.

Page 9 -- SKU: 05907 REV 11/02REV 07/02

Page 10

Step 7. Bend the fourth side.

Step 8. Using a block or piece of wood, tap the corner of material back into place.

Step 2: Bend Second Side

plaplace.

Figure 8 — Pan Forming

Rolling

Step 1:Move the COVER (#33) back and out of the way.

Step 2:Drop the BACK PRESSING ROLL (#24) by loosening the SCREW (#25).

Step 3:Insert just the leading edge of your workpiece between the UPPER PRESSING ROLL

(#32) and LOWER PRESSING ROLL (#31), and tighten the roll bar gap ADJUSTABLE

BOLT (#27) until the ROLL BARS are barely snug against the workpiece.

Step 4:Advance the SCREW (#25) as much as desired depending upon the tightness of the roll

to be accomplish. (The tighter the roll, the more the knobs must be advanced.)

Step 5:Crank the HANDLE ASSEMBLY (#18 & 26) until the proper roll has been achieved. The

material should feed itself through the rollers as you crank the HANDLE ASSEMBLY.

Page 10 -- SKU: 05907 REV 11/02

Page 11

Wire Rolling

Step 1:Use the proper groove in the UPPER PRESSING ROLL (#32) depending upon the

gauge of the wire being rolled.

Step 2: Follow the procedures as listed above in “Rolling”.

Pressing

Step 1:Slide the PRESS PLATE BRACKETs (#8) of the Press Plate Assembly into the receiver

holes of the MOVING CUTTER PLATE (#11). Note that the PRESSING PLATE (#10)

should be facing down.

Step 2:Place the workpiece so that it is centered under the PRESS PLATE.

Step 3:Rotate the HANDLE (#18) to press the workpiece.

Page 11 -- SKU: 05907 REV 11/02

Page 12

PARTS LIST

PART # DESCRIPTION Qty PART # DESCRIPTION Qty

1 Left Wall 1 32 Upper Pressing Roll 1

2 Work Bench 1 33 Cover 1

3 Crossbeam 1 34 Pressing Roll Lock 1

4 Crank Arm 2 35 Eccentric Shaft 2

5 Right Wall 1 36 Jacket 2

6 Bear Frame 1 37 Roll Key 4

7 Cover 2 38 Hex Bolt 4

8 Press Plate Bracket 2 39 Hex Screw 2

9 Spring 2 40 Hex Bolt 2

10 Pressing Plate 1 41 Hex Bolt 1

11 Moving Cutter Plate 1 42 Hex Bolt 2

12 Upper Braking Die 1 43 Hex Screw 2

13 Pressing Plate 1 44 Hex Screw 2

14 Screw 2 45 Washer 2

15 Rolling Wheel 2 46 Hex Bolt 1

16 Guide 1 47 Hex Bolt 2

17 Adjustable Bolt 2 48 Washer 2

18 Handle 2 49 Hex Nut 1

19 Positioning Bar 2 50 Hex Srew 2

20 Positioner 2 51 Hex Screw 2

21 Positioning Plate 1 52 Hex Screw 7

22 Support Plate 1 53 Hex Screw 4

23 Blades 2 54 Washer 2

24 Back Pressing Roll 1 55 Hex Bolt 2

25 Screw 2 56 Hex Screw 7

26 Handle Knob 2 57 Hex Screw 2

27 Adjustable Screw 2 58 Hex Screw 7

28 Roll Bushings 4 59 Hex Screw 2

29 Washer 2 60 Clamp Screws 2

30 Gear 2 61 Adjusting Screws 2

31 Lower Pressing Roll 1

Page 12 -- SKU: 05907 REV 11/02

Page 13

Parts Diagram

#5907 30” Shear Brake Roll

61

61

Page 13 -- SKU: 05907 REV 11/02

Page 14

27

32

IN

24

31

26

SKU 05907

SHEET METAL & WIRE FORMING

Remove the cover (#33) from the machine. The roller gears (#30) should have a coating

of general purpose grease for smooth operation. Clean any dirt or excess grease from

the rolls.

The following steps apply to both wire and sheet metal bending.

Adjust screws (#27) to the thickness of the stock. It should feed between rollers (#31) and

(#32) without slipping or binding when the handle (#18) is turned. The material is fed into

the rollers from the front of the machine.

Back Pressing Roll (#24) forms the radius in the material. The closer it is to the feed

rollers, the smaller the radius will be. Handle Knobs (#26) adjusts the spacing of the back

roller.

Metals will have different bending characteristics. Some are very pliable, while others

have considerable spring or memory. Practice before beginning an important project.

Page 14 -- SKU: 05907

REV 11/02

Loading...

Loading...