Center CenterStore Solar Series Servicing Installation And Servicing Instructions

Solar

For latest prices and delivery to your door visit MyTub Ltd - www.mytub.co.uk - info@mytub.co.uk 0844 556 1818

UNVENTED MAINS PRESSURE SOLAR WATER HEATERS

190, 210, 250 and 300 LITRE CAPACITY INDIRECT MODELS

INSTALLATION AND SERVICING INSTRUCTIONS

PACK CONTENTS

The CENTERSTORE Solar unvented solar cylinder water heater incorporating immersion heater(s) and thermal

controls Factory fi tted temperature/pressure relief valve l Cold water combination valve assembly l Expansion

vessel and mounting bracket l Tundish l Motorised valve l Compression nuts and olives l Immersion heater spanner

l Installation instructions

IMPORTANT: PLEASE READ AND UNDERSTAND ALL THESE INSTRUCTIONS

BEFORE COMMENCING INSTALLATION. PLEASE LEAVE THIS MANUAL WITH

THE CUSTOMER FOR FUTURE REFERENCE.

THE BENCHMARK SCHEME

Benchmark places responsibilities on both manufacturers and installers. The purpose is to ensure that customers

are provided with the correct equipment for their needs, that it is installed, commissioned and serviced in

accordance with the manufacturer’s instructions by competent persons and that it meets the requirements of

the appropriate Building Regulations. The Benchmark Checklist can be used to demonstrate compliance with

Building Regulations and should be provided to the customer for future reference.

Installers are required to carry out installation, commissioning and servicing work in accordance with the Benchmark

Code of Practice which is available from the Heating and Hotwater Industry Council who manage and promote

the Scheme. Visit www.centralheating.co.uk for more information.

IMPORTANT NOTE TO USER: PLEASE REFER TO THE USER INSTRUCTIONS SECTION ON PAGES 14 AND 15 FOR

IMPORTANT INFORMATION WITH RESPECT TO THE BENCHMARK SCHEME

INTRODUCTION

The CENTERSTORE Solar cylinder is a purpose designed unvented solar water heater. The unit has a

stainless steel inner vessel, which ensures an excellent

standard of corrosion resistance. The outer casing is a

combination of resilient thermoplastic mouldings and

corrosion proofed steel sheet. All products are insulated with CFC/HCFC free polyurethane foam to meet the

latest European heat loss requirements (see Table 6).

The unit is supplied complete with all the necessary

safety and control devices needed to allow connection

to the cold water mains. All these components are

preset and not adjustable.

This appliance complies with the requirements of the

CE marking directive and is Kiwa approved to show

compliance with Building Regulations (Section G3).

The following instructions are offered as a guide to

installation which must be carried out by a competent

plumbing and electrical installer in accordance with

Building Regulation G3, The Building Standards

(Scotland) Regulations 1990, or The Building Regulations (Northern Ireland).

NOTE: Prior to installation the unit should be stored in

an upright position in an area free from excessive damp

or humidity.

1

1

Contents

For latest prices and delivery to your door visit MyTub Ltd - www.mytub.co.uk - info@mytub.co.uk 0844 556 1818

INTRODUCTION.................................................................1

GENERAL REQUIREMENTS.............................................3

INSTALLATION-GENERAL...............................................4

INSTALLATION - SOLAR PRIMARY...............................9

INSTALLATION - AUXILLARY HEATING COIL...........10

COMMISSIONING.............................................................12

MAINTENANCE..................................................................13

PA GE

USER INSTRUCTIONS.......................................................14

FAULT FINDING AND SERVICING.................................15

OTHER INFORMATION.....................................................17

ENVIRONMENTAL INFORMATION...............................17

COMMISSIONING CHECK LIST......................................18

SERVICE RECORD..............................................................19

GUARANTEE.......................................................................20

TECHNICAL SUPPORT AND SPARES...........................20

2

IMPORTANT: THIS APPLIANCE IS NOT INTENDED

For latest prices and delivery to your door visit MyTub Ltd - www.mytub.co.uk - info@mytub.co.uk 0844 556 1818

FOR THE USE BY PERSONS (INCLUDING CHILDREN)

WITH REDUCED PHYSICAL, SENSORY OR MENTAL

CAPABILITIES, OR LACK OF KNOWLEDGE AND EXPERIENCE, UNLESS THEY HAVE BEEN GIVEN SUPERVISION OR INSTRUCTION CONCERNING THE USE OF

THE APPLIANCE BY A PERSON RESPONSIBLE FOR

THEIR SAFETY. CHILDREN MUST BE SUPERVISED.

GENERAL REQUIREMENTS

SITING THE UNIT

The CENTERSTORE Solar must be installed vertically.

Although location is not critical, the following points

should be considered:

• The CENTERSTORE Solar should be sited to ensure minimum dead leg distances, particularly

to the point of most frequent use.

• Avoid siting where extreme cold temperatures

will be experienced. All exposed pipework

should be insulated.

• The discharge pipework from the safety valves

must have minimum fall of 1:200 from the unit

and terminate in a safe and visible position.

• Access to associated controls and immersion

heaters must be available to provide for the

servicing and maintenance of the system.

Where these controls are installed against a wall

a minimum distance of 250mm must be left (see

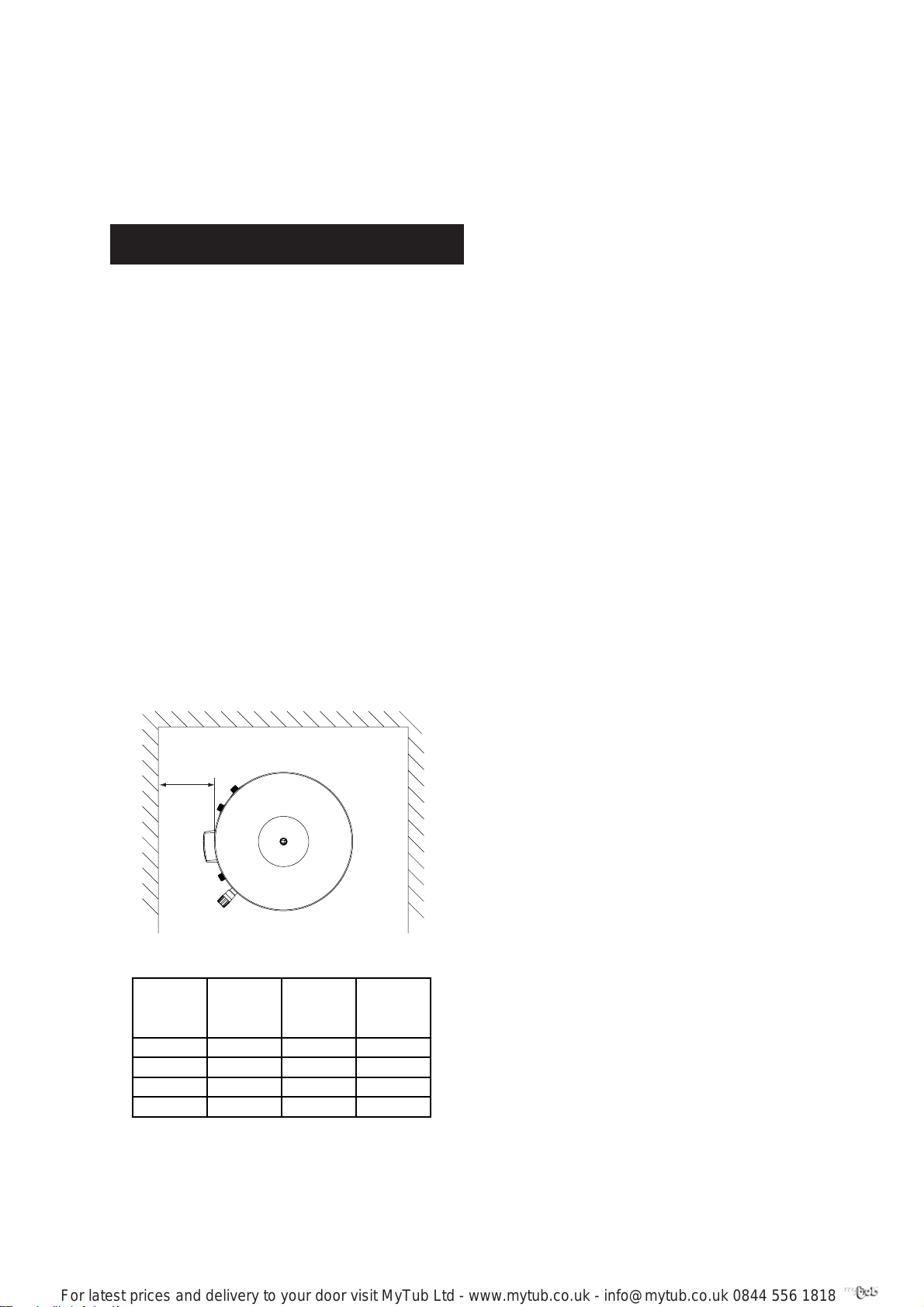

Fig. 1).

• Ensure that the fl oor area for the CENTERSTORE

Solar cylinder is level and capable of perman ently supporting the weight when full of water.

(See Table 1).

Min 250mm

Fig. 1: Siting the Unit

Type

reference

INDIRECT SCS190I 190 240

SCS210I 210 264

SCS250I 250 308

SCS300I 300 367

Table 1: Unit weights

WATER SUPPLY

Bear in mind that the mains water supply to the property

will be supplying both the hot and cold water requirements simultaneously. It is recommended that the

Model

WALL

Nominal

capacity

(litres)

Weight of

unit full

(kg)

maximum water demand is assessed and the water

supply checked to ensure this demand can be satisfactorily met.

Note: A high mains water pressure will not always

guarantee high fl ow rates.

Wherever possible the mains supply pipe should be

22mm. We suggest the minimum supply requirements

should be 1.5 bar pressure and 20 litres per minute fl ow

rate. However, at these values outlet fl ow rates may be

poor if several outlets are used simultaneously. The

higher the available pressure and fl ow rate the better

the system performance.

The CENTERSTORE Solar cylinder has an operating pressure of 3.5 bar which is controlled by the cold water

combination valve assembly. The cold water combination

valve assembly can be connected to a maximum mains

pressure of 16 bar.

OUTLET/TERMINAL FITTINGS (TAPS, ETC.)

The CENTERSTORE Solar cylinder can be used with

most types of terminal fi ttings. It is advantageous in

many mixer showers to have balanced hot and cold

water supplies. In these instances a balanced pressure

cold water connection should be placed between the

2 pieces of the cold water combination valve assembly

(see Fig. 2). Outlets situated higher than the CENTERSTORE Solar cylinder will give outlet pressures lower

than that at the heater, a 10m height difference will

result in a 1 bar pressure reduction at the outlet. All

fi ttings, pipework and connections must have a rated

pressure of at least 6 bar at 80°C.

LIMITATIONS

The CENTERSTORE Solar cylinder should not be used in

association with any of the following:

• Solid fuel boilers or any other boiler in which the

energy input is not under effective thermostatic

control unless additional and appropriate safety

measures are installed.

• Ascending spray type bidets or any other class

1 back syphonage risk requiring that a type A

air gap be employed.

• Steam heating plants unless additional and

appropriate safety devices are installed.

• Situations where maintenance is likely to be

neglected or safety devices tampered with.

• Water supplies that have either inadequate

pressure or where the supply may be intermittent.

• Situations where it is not possible to safely pipe

away any discharge from the safety valves.

• In areas where the water consistently contains a

high proportion of solids, e.g. suspended matter

that could block the strainer, unless adequate

fi ltration can be ensured.

OPERATIONAL SUMMARY

Maximum mains pressure 16 bar

Operating pressure 3.5 bar

Expansion vessel charge pressure 3.5 bar

Expansion relief valve setting 6 bar

T&P relief valve setting 90°C/10

Maximum primary circuit pressure

(auxillary coil) 3 bar

Maximum primary circuit pressure 6 bar

Storage capacity See Table

Weight when full See Table

bar

(solar coil)

1

1

3

3

IMPORTANT NOTE:

For latest prices and delivery to your door visit MyTub Ltd - www.mytub.co.uk - info@mytub.co.uk 0844 556 1818

CENTERSTORE SOLAR MUST BE INCORPORATED

INTO A FULLY PUMPED SOLAR PRIMARY CIRCUIT.

CONTROL OF THE SOLAR PRIMARY IS ACHIEVED BY

THE USE OF EXTERNAL CONTROLS NOT SUPPLIED

WITH THE UNIT. CONTROL MUST BE VIA A PURPOSE

DESIGNED SOLAR HYDRAULIC STATION AND SOLAR

DIFFERENTIAL TEMPERATURE CONTROLLER.

DRAIN TAP

A suitable draining tap should be installed in the

cold water supply to the CENTERSTORE Solar cylinder

unit between the expansion valve (see Fig. 6) and the

heater at as low a level as possible. It is recommended

that the outlet point of the drain pipework be at least

1 metre below the level of the heater (this can be

achieved by attaching a hose to the drain tap outlet

spigot).

INSTALLATION - GENERAL

(FIGS 4 & 6)

PIPE FITTINGS

All pipe fi ttings are made via 22mm compression

fi ttings directly to the unit. The fi ttings are threaded

3/4”BSP male parallel should threaded pipe connections be required.

COLD FEED

A 22mm cold water supply is recommended, however

if a 15mm (1/2”) supply exists which provides suffi cient

fl ow this may be used (although more fl ow noise may

be experienced).

A stopcock or servicing valve should be incorporated

into the cold water supply to enable the CENTERSTORE

Solar cylinder and its associated controls to be isolated

and serviced.

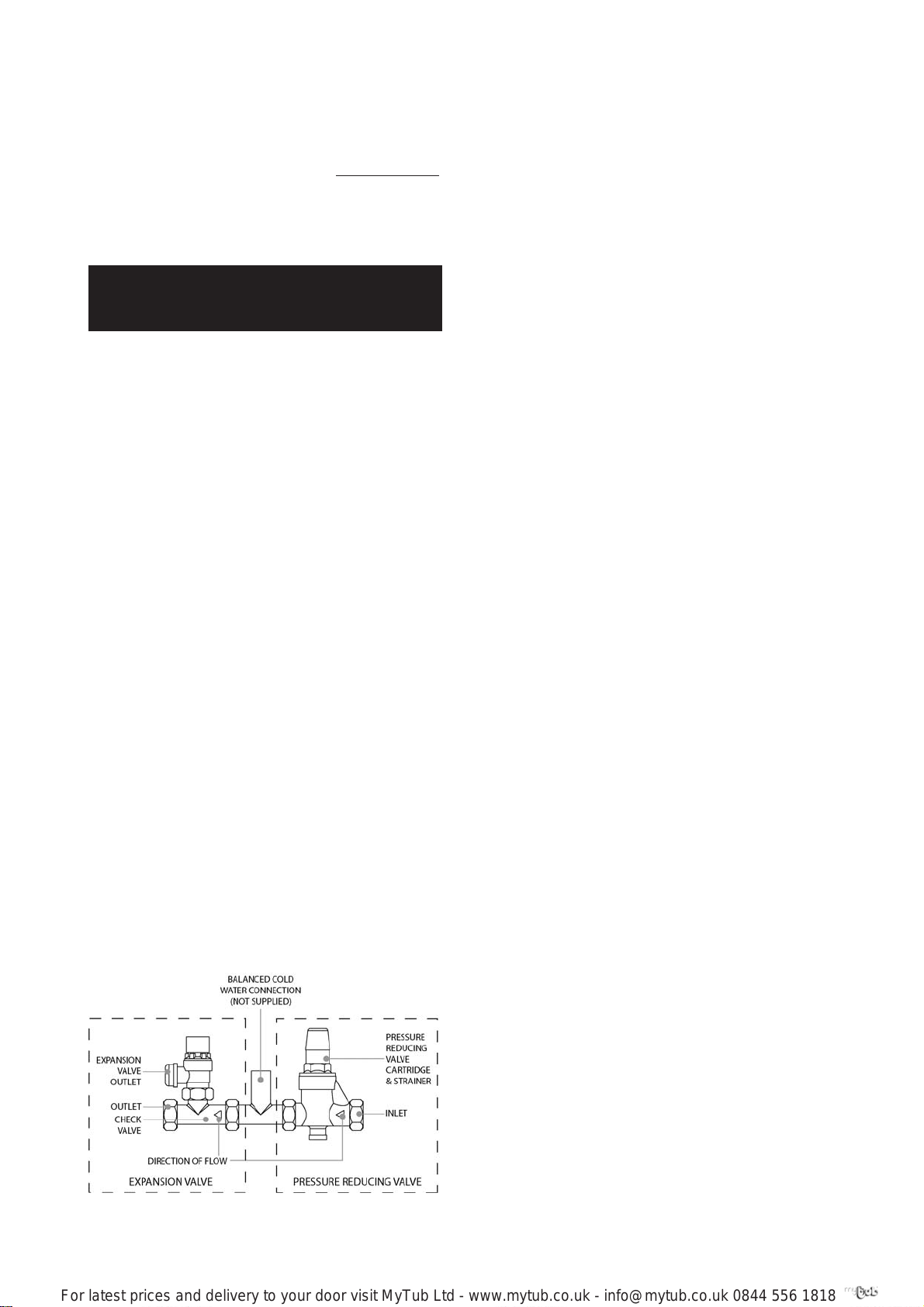

COLD WATER COMBINATION VALVE ASSEMBLY (FIG 2)

The 2-piece cold water combination valve assembly

can be located anywhere on the cold water mains

supply prior to the expansion vessel (see Fig. 6) but the

two pieces do not have to be installed together. The

pressure reducing valve incorporates the pressure

reducer & strainer and the expansion valve incorporates the expansion & check valves. Ensure that the

valves are installed in the correct order and orientation.

No other valves should be placed between the expansion valve and the CENTERSTORE Solar unit. A connection can be made between the expansion and pressure reducing valves to provide a balanced cold water

connection. The expansion valve connection must not

be used for any other purpose.

EXPANSION VESSEL

The expansion vessel accommodates expansion that

results from heating the water inside the unit. The

expansion vessel is pre-charged at 3.5 bar. The expansion vessel must be connected between the expansion valve (see Fig. 2) and the CENTERSTORE Solar

cylinder (see Fig. 6). The location of the expansion

vessel should allow access to recharge the pressure as

and when necessary, this can be done using a normal

car foot pump. It is recommended that the expansion

vessel is adequately supported. An expansion vessel

wall mounting bracket is supplied for this purpose and

should be fi tted.

NOTE: DO NOT USE THE POTABLE WATER EXPANSION VESSEL SUPPLIED WITH THE CENTERSTORE

SOLAR CYLINDER FOR ANY OTHER PURPOSE. IT

IS NOT SUITABLE FOR USE ON A SOLAR PRIMARY

CIRCUIT.

SECONDARY CIRCULATION

If secondary circulation is required it is recommended

that it be connected to the CENTERSTORE Solar cylinder

as shown in Fig. 3. The secondary return pipe should be

in 15mm pipe and incorporate a check valve to prevent

backfl ow. A suitable WRAS approved bronze circulation

pump will be required. On large systems, due to the increase in system water content, it may be necessary to fi t

an additional expansion vessel to the secondary circuit.

This should be done if the capacity of the secondary

circuit exceeds 10 litres.

Pipe capacity (copper)

15mm O.D = 0.13 l/m (10 litres = 77m)

22mm O.D = 0.38 l/m (10 litres = 26m)

28mm O.D = 0.55 l/m (10 litres = 18m)

OUTLET

The hot water outlet is a 22mm compression fi tting

located at the top of the cylinder. Hot water distribution pipework should be 22mm pipe with short runs

of 15mm pipe to terminal fi ttings such as sinks and

basins. Pipe sizes may vary due to system design.

Fig. 2: Cold water combination valve assembly

4

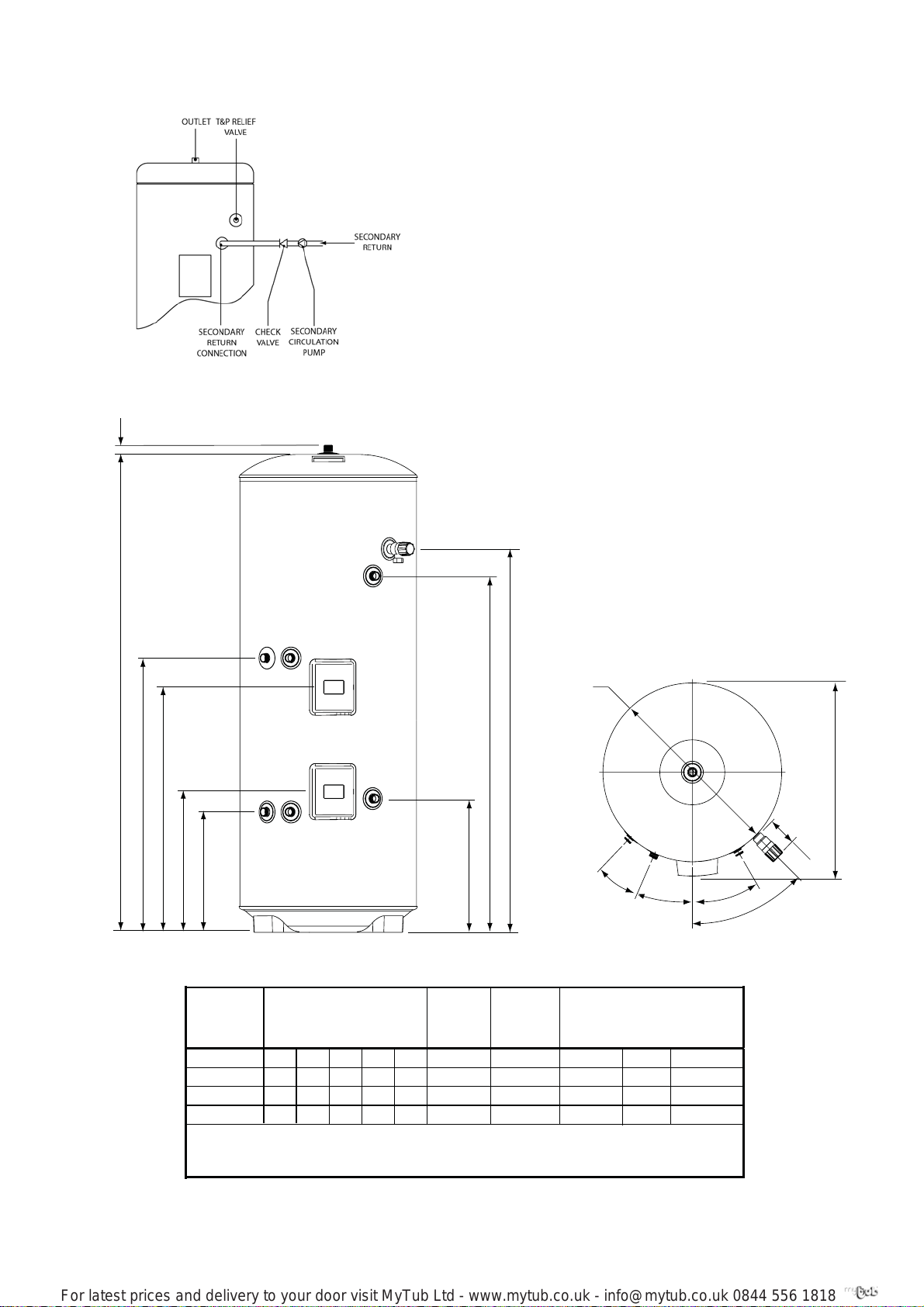

Fig. 3: Secondary circulation connection

For latest prices and delivery to your door visit MyTub Ltd - www.mytub.co.uk - info@mytub.co.uk 0844 556 1818

29

A

C

B

370

433

Fig. 4: General dimensions

NOMINAL

CAPACITY

(litres)

190

250

300

1372 803 923732 1019

210

1473 925 1095

1731 1072 12581160 1391 1.1

2038 1243 15731438 1715 1.1

NOTES:

1. Recovery time based on heating 70% of auxillary volume through 45°C

2. Direct heating times assume use of lower element only and auxillary cylinder volume being heated.

DIMENSIONS (mm)

ABCDE

1009

1184 1.1

412

SOLAR

SURFACE

AREA (m)

1.1

E

D

AUXILLARY

VOLUME

(litres)

120

120

145

175

Ø

550

20°

SURFACE

AREA

(m

)

0.61

0.68 18.3 17

0.79 20.0

0.79

AUXILLARY COIL

RATING

(kW)

11.9

20.0

25°

594

81

30°

45°

RECOVERY

(mins)

22

19

22

Table 2: Dimensions and performance

5

5

DISCHARGE PIPEWORK

For latest prices and delivery to your door visit MyTub Ltd - www.mytub.co.uk - info@mytub.co.uk 0844 556 1818

It is a requirement of Building Regulation G3 that any

discharge from an unvented system is conveyed to

where it is visible, but will not cause danger to persons

in or about the building. The tundish and discharge

pipes should be fi tted in accordance with the requirements and guidance notes of Building Regulation G3.

The G3 Requirements and Guidance section 3.9 are

reproduced in the following sections of this manual.

Information Sheet No. 33 available from the British

Board of Agrément gives further advice on discharge

pipe installation. For discharge pipe arrangements not

covered by G3 Guidance or BBA Info Sheet No.33

advice should be sought from your local Building

Control Offi cer.

Any discharge pipe connected to the pressure relief

devices (Expansion Valve and Temperature/Pressure Relief Valve) must be installed in a continuously

downward direction and in a frost free environment.

The water may drip from the discharge pipe of the

pressure relief device. This pipe must be left open to

the atmosphere. The pressure relief device is to be operated regularly to remove lime deposits and to verify

that it is not blocked.

G3 REQUIREMENT

“...there shall be precautions...to ensure that

the hot water discharged from safety devices is

safely conveyed to where it is visible but will not

cause danger to persons in or about the building.”

G3 GUIDANCE SECTION 3.9

The discharge pipe (D1) [see fi g. 5 in this instruc-

tion book] from the vessel up to and including

the tundish is generally supplied by the manufacturer of the hot water storage system. Where

otherwise, the installation should include the

discharge pipe(s) (D1) from the safety device(s).

In either case the tundish should be vertical,

located in the same space as the unvented hot

water storage system and be fi tted as close as

possible and within 500mm of the safety device

e.g. the temperature relief valve.

The discharge pipe (D2) from the tundish should

terminate in a safe place where there is no risk

to persons in the vicinity of the discharge, preferably be of metal and:

a. be at least one pipe size larger than the

nominal outlet size of the safety device unless its

total equivalent hydraulic resistance exceeds that

of a straight pipe 9m long i.e. discharge pipes

between 9m and 18m equivalent resistance

length should be at least two sizes larger than

the nominal outlet size of the safety device,

between 18 and 27m at least 3 sizes larger ,

and so on. Bends must be taken into account

in calculating the fl ow resistance. Refer to Table

3, Table 1 and the worked example [see Table 3

and Fig. 5 in this instruction book].

use within buildings and their curtilages, Appendix E, section E2 and table 21.

b. have a vertical section of pipe at least 300mm

long, below

bends in the pipework.

c. be installed with a continuous fall and in a

frost free environment.

d. have discharges visible at both the tundish

and the fi nal point of discharge but where this

is not possible or is practically diffi cult there

should be clear visibility at one or other of these

locations. Examples of acceptable discharge

arrangements are:

Worked example of discharge pipe sizing

Fig. 5 is for a G1/2 temperature relief valve with a discharge pipe (D2) having 4 No. elbows and length of 7m

from the tundish to the point of discharge.

the tundish before any elbows or

i. ideally below a fi xed grating and above the

water seal in a trapped gully.

ii. downward discharges at low level; i.e. up

to 100mm above external surfaces such as

car parks, hard standings, grassed areas etc.

are acceptable providing that where children

may play or otherwise come into contact with

discharges a wire cage or similar guard is positioned to prevent contact, whilst maintaining

visibility.

iii. discharges at high level; e.g. into a metal

hopper and metal down pipe with the end

of the discharge pipe clearly visible (tundish

visible or not) or onto a roof capable of

withstanding high temperature discharges

of water and 3m from any plastics guttering

system that would collect such discharges

(tundish visible).

iv. where a single pipe serves a number of

discharges, such as in blocks of flats, the

number served should be limited to not

more than 6 systems so that any installation

discharging can be traced reasonably easily.

The single common discharge pipe should be

at least one pipe size larger than the largest

individual discharge pipe (D2) to be connected. If unvented hot water storage systems

are installed where discharges from safety

devices may not be apparent i.e. in dwellings

occupied by blind, infi rm or disabled people,

consideration should be given to the installation of an electronically operated device to

warn when discharge takes place.

Note: The discharge will consist of scalding

water and steam. Asphalt, roofi ng felt and

non-metallic rainwater goods may be

damaged by such discharges.

An alternative approach for sizing discharge

pipes would be to follow BS 6700:1987 Specifi cation for design installation, testing and maintenance of services supplying water for domestic

From Table 3:

Maximum resistance allowed for a straight length of

22mm copper discharge pipe (D2) from a G1/2 temperature relief valve is 9.0m.

6

Loading...

Loading...