Page 1

N9745 Bracket/Harnesses Assembly Kit

for N1611 Alternator

Replacement Instructions

To replace the bracket assembly on the

N1611 anti-drive end (ADE) housing:

1. See N1607/N1611 Service Manual SM0030A:

Follow steps 3 and 4 to uncover ADE rectifier/

housing assembly.

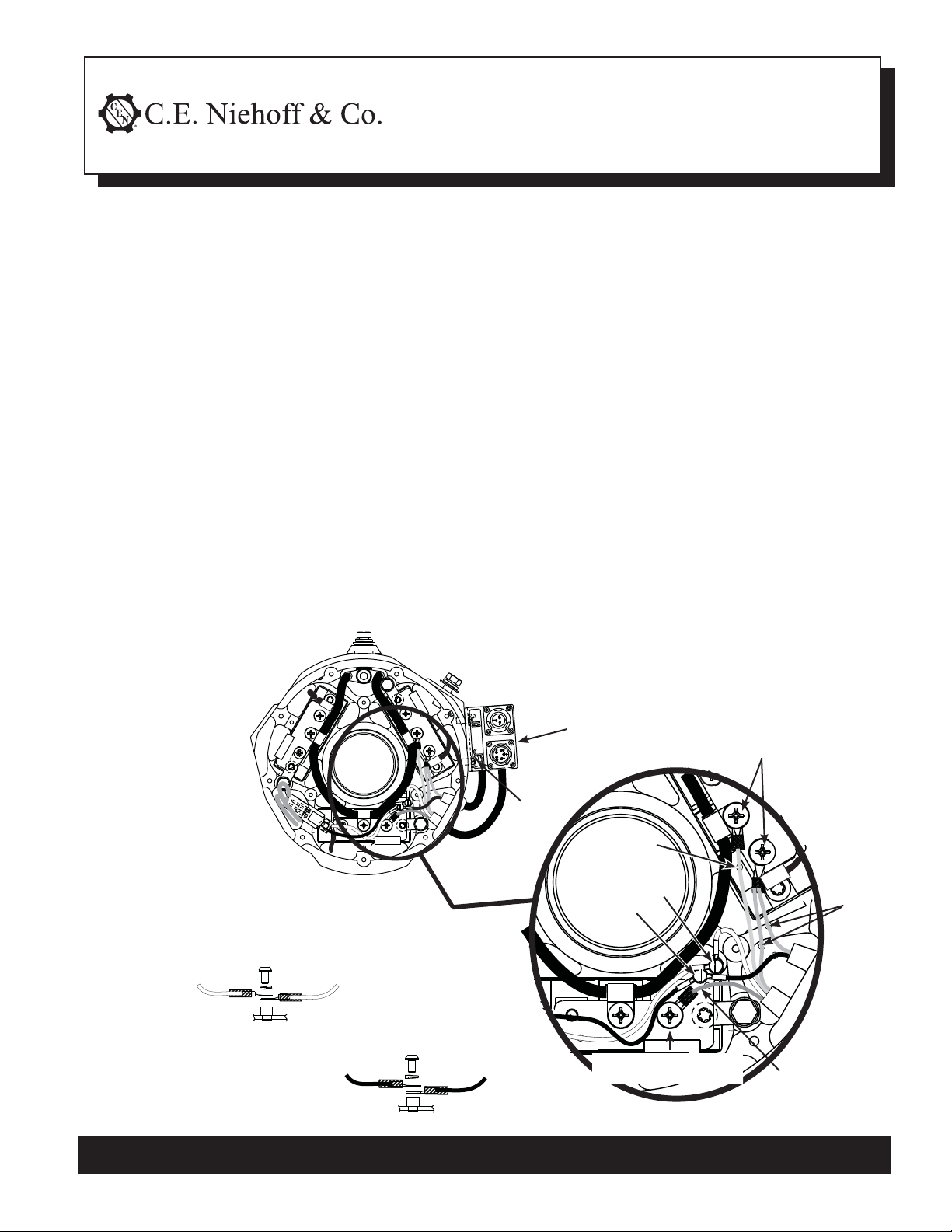

See Figure 1 below and:

2. Disconnect wire terminals from both wiring

harnesses at diode modules, saving hardware

for reassembly.

3. Pull grommets and harness wires through holes in

housing. Some wire terminal ends will need to be

snipped off to clear hole diameters.

4. Loosen four screws holding J2 harness to bracket.

Discard J2 harness.

5. Remove and discard bolts and lock washers

attaching old bracket to housing. Be careful not to

damage threads in housing when removing bolts.

Remove and discard bracket with J1 harness.

6. Attach new bracket and harnesses assembly to

housing:

a. Install bracket in position, hand-tighten with

one bolt and lock washer in hole

nearest J1 harness.

b. Loosen four screws

holding J2 harness

to new bracket.

Pull harness far

enough away

from bracket

to access the

second bolt hole

in the bracket.

J2

J1

c. Install second bolt and lock washer in position.

Torque both bolts to 13.5 Nm/120 lb. in.

d. Tighten four screws holding J2 harness to

bracket, torquing to 1.2 Nm/10 lb. in.

7. Install new grommets in holes in housing.

8. Feed harness wires through grommets. Lubricate if

necessary. See Figure 1.

9. Attach new terminals to harness wires.

a. Field connection terminals shown in Details A

and B: Insert new regular sleeves. Crimp and

solder new terminals on wires. Slide regular

sleeves over their soldered connections.

b. Remaining three connections: Insert new shrink

sleeves on wires as shown in Close-up. Brown

wires are combined into one shrink sleeve.

Crimp and solder new terminals on wires. Slide

shrink sleeves over soldered connections. Use

heat gun to tighten sleeves.

10. Clean old RTV coating from diode modules.

11. Secure wire terminals as shown in Close-up and

Details A and B. Torque screws as indicated.

12. Coat electrical terminals with Dow Corning®1–2577

Low VOC RTV coating or equivalent. Do not use

coating containing acetic acid (vinegar smell) on

electrical components.

13. Follow steps 9 and 10 in service manual to complete

assembly of alternator.

Screws

(4 plcs)

J2 bolt

Red wire

Torque to 7.4 Nm/

65 lb. in.

Figure 1 – N1611 ADE Rectifier/Housing Assembly

with N9745 Bracket Assembly

White wire

from gray

connector

Detail A—Stacking Order

Torque 15-18 lb. in.

White wire

from

J2 harness

Torque 15-18 lb. in.

Black wire

from gray

connector

Detail B—Stacking Order

Black wire

from

J1 harness

Detail A

Detail B

Torque to 7.4 Nm/

65 lb. in.

J2

Green

wire

Close-up

2 Brown

wires

J1

C. E. Niehoff & Co. • 2021 Lee Street • Evanston, IL 60202 Tech Services Hotline 800-643-4633

Page 1 of 1

II0159A

Loading...

Loading...