Page 1

N1304-1 Alternator to N1380-2 Alternator

.

C. E. Niehoff & Co

BRUSHLESS ALTERNATORS

The following terms are used to bring attention to the presence of hazards of various risk levels or to important information

concerning product life.

DANGER

CAUTION

Indicates the presence of

hazards that will cause severe

personal injury, death, or

substantial property damage if

ignored.

Indicates the presence of

hazards that will or can cause

minor personal injury or property

damage if ignored.

Using N7359-1 Conversion Kit

Conversion Instructions

NOTICE

Indicates special instructions on

installation, operation, or maintenance that are important, but

not related to personal injury

hazards.

NOTICE

DANGER

All hardware should be saved

for reuse unless otherwise

noted.

Do not allow hardware to drop

inside alternator. Loose hardware inside alternator cavity or

stator windings or field coil

will cause substantial

equipment damage.

Disassembly

1. To make reassembly easier, mark the following

junctions:

a. anti-drive end housing and shell.

b. drive end housing and shell. Transfer the

mark from the existing drive end housing

to the same location on the new drive end

housing.

2. Remove and save pulley (if installed), Woodruff

key, and pulley bushing on drive end.

3. Remove and discard:

a. regulator hardware and regulator.

b. control unit front cover hardware and

control unit front cover.

3. Remove and save nut and washer holding fan on

anti-drive end of shaft. Remove and save fan.

b. Use three 10-32 jacking screws to lift rotor

off core.

CAUTION

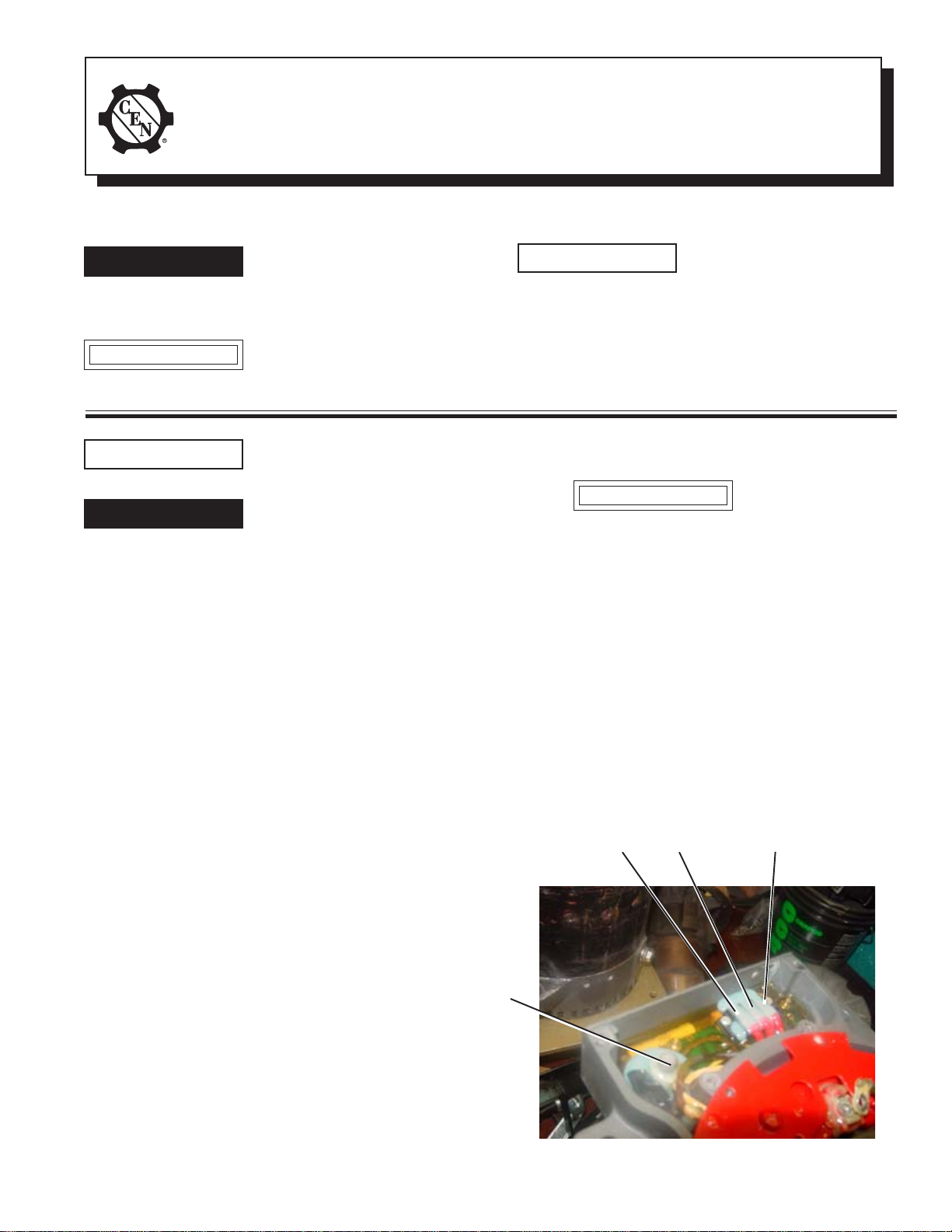

6. Inside control unit, remove coating material

covering three terminal leads and B+ stud.

7. Remove hardware holding three terminal leads

and B+ stud. Remove the three leads and the

leads from the B+ stud. See Figure 1.

8. Mark leads for reassembly and carefully pull

three terminal leads from coating material so as

not to damage leads. Clean coating material from

leads. Check terminals for rust or corrosion and

clean with wire brush if necessary.

9. Remove output lead attached to B+ stud.

Ground terminal

lead from heat

sink

F–

terminal lead

This method may

damage rotor if rotor

is rusted to core.

F+

terminal lead

4. Remove and save nuts holding anti-drive end

housing. Remove and save anti-drive end

housing. Bearing and seals should remain

on shaft.

5. Remove and save one nut and washer from

anti-drive end rotor. Mark across middle of

hole on face of rotor to realign rotor on shaft

core. Remove and save remaining nuts and

washers, then remove and save rotor.

a. To loosen rust, use an air chisel with a

rounded-point hammer bit to vibrate area

between screw holes on rotor face.

— OR—

II0063A

B+ stud and

output lead

from heat

sink

TT

T

TT

TT

T

TT

TT

T

TT

TT

TT

T

Figure 1—Control Unit Connections

Page 1

Page 2

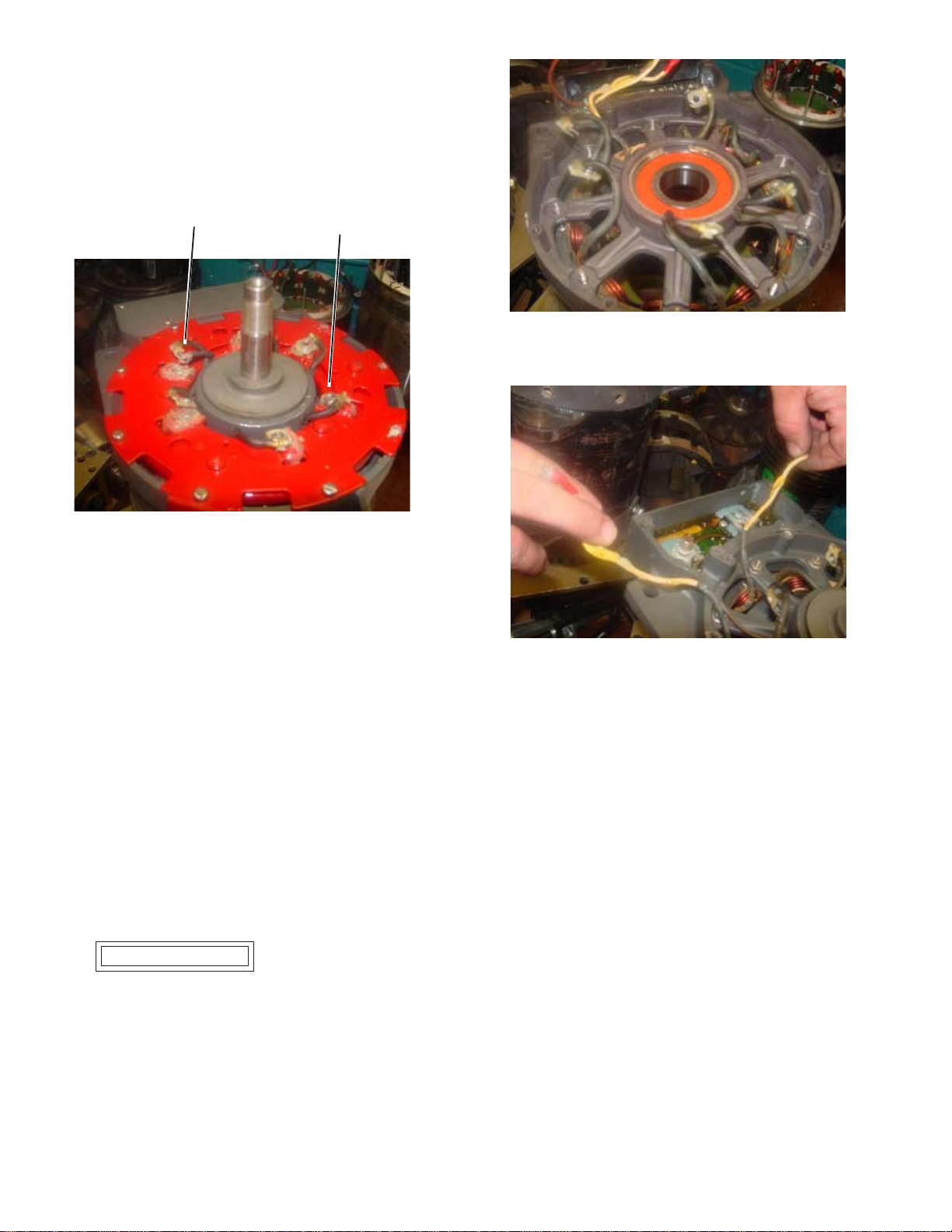

10. Remove and save hardware holding stator leads

and phase lead (attached to stator lead (at 10:00

position) to heat sink assembly. See Figure 2.

Clean coating material from leads. Check terminals for rust or corrosion and clean with wire

brush if necessary.

Phase lead

TT

T

TT

TT

T

TT

TT

T

TT

Figure 2—Phase Lead and Stator Leads Connections

11. Remove and save heat sink hardware (including

ground bolt and lockwasher on tab on side of

housing) and heat sink assembly.

12. Remove and save drive end housing hardware.

13. Remove drive end housing from shell.

Stator lead

(one of six)

TT

T

TT

Figure 3—Phase Leads and Field Coil Leads

Figure 4—Field Coil Leads

14. Press shaft out of bearing in drive end housing.

Discard drive end housing and bearing. Save

shaft core/drive end rotor assembly.

Assembly

1. New drive end housing has bearing and retaining

rings installed at factory. Using CEN A10–109

bearing tool or equivalent placed on bearing

inner race, press shaft into bearing in DE

housing. Rotate shaft to make sure bearing

moves freely.

2. Support shell/field coil/stator assembly on

blocks while installing DE housing and shaft.

CAUTION

3. Align scribed marks, then set housing assembly

in position. Pull stator leads and field coil leads

through vent holes in assembly. See Figures 3

and 4. Securely mate housing to shell. Rotate

shaft to make sure rotor does not interfere with

stator leads or field coil leads.

Do not damage stator

windings or through-studs

while assembling DE housing and shell. Make sure

support is tall enough so

that shaft clears bench.

4. Install existing locknuts on through-studs. Use

a suitable adhesive, such as Loctite® 222.

Follow manufacturer’s instructions. Torque

locknuts to 2-2.25 Nm/18-20 lb. in.

5. Guide field coil leads through channel in housing. See Figure 2. Attach field coil leads to

terminal block. See Figure 1 for correct locations. Tighten screws just enough to firmly hold

leads in terminal block. Wire-tie field coil leads

together inside channel.

6. Install heat sink assembly, guiding stator leads

and phase lead through center opening to their

respective positions. See Figure 2.

7. Install existing hardware to hold heat sink in

position. Use a suitable adhesive, such as

Loctite

tions. Torque screws to 2-2.25 Nm/18-20 lb. in.

8. Loosely install ground bolt and lockwasher in

tab on side of heat sink into housing.

9. Install ground lead in terminal block. Tighten

screw just enough to firmly hold leads in terminal block. See Figure 1 for position.

®

222. Follow manufacturer’s instruc-

Page 2

II0063A

Page 3

10. Remove two top nuts on B+ stud and discard

one nut. Install output lead and remaining nut

on B+ stud and tighten firmly enough to hold

output lead on stud.

CAUTION

11. Connect stator leads and phase lead to proper

stator terminals as shown in Figure 2. Torque

hardware to 3.4 Nm/30 lb. in.

12. Coat stator terminals and terminal block and

B+ stud terminal inside control unit with Dow

Corning

not use coating containing acetic acid (vinegar

smell) on electrical components.

13. Install new control unit cover on control unit

with tab on top facing out. Use a suitable adhesive, such as Loctite

Follow manufacturer’s instructions. Torque

screws to 2-2.25 Nm/18-20 lb. in.

14. Remove and discard two existing screws on top

of control unit.

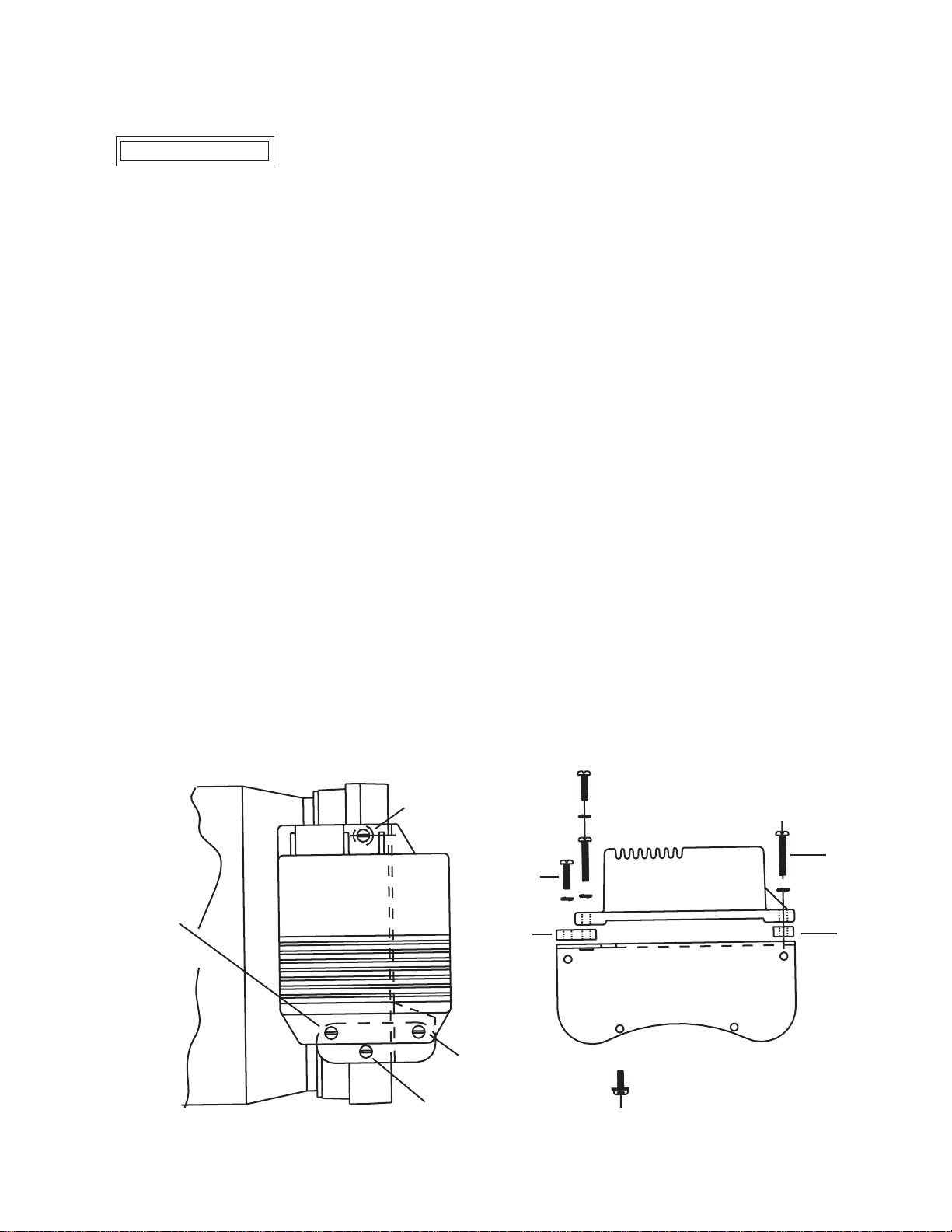

15. Place bracket, spacer, and regulator on top of

control unit as shown in Figure 5.

16. Use a suitable adhesive, such as Loctite

new hardware. Follow manufacturer’s instructions. Loosely install (see Figure 5):

a. one long screw and washer in regulator

b. remaining long screw and washer in front

c. one short screw and washer in rear regulator

d. remaining short screw and washer in

17. Torque screws in a-b-c-d order listed in step 16

®3

3140 RTV coating or equivalent. Do

mounting hole above spacer.

regulator mounting hole above bracket.

mounting hole above bracket.

bracket.

Out put terminal may

be damaged if nut is

overtightened.

®

222 on new hardware.

®

222 on

to 2-2.25 Nm/18-20 lb. in.

18. Place ADE rotor on shaft. Align scribe mark.

Loosely install all nuts and washers except for

the nut for the marked hole. Before securing

nuts, make sure scribe mark in last hole is

aligned. Then secure all nuts. On all screws, use

a suitable adhesive, such as Loctite

Follow manufacturer’s instructions.Torque to

3.4 Nm/30 lb. in.

19. Align scribed marks, then set ADE housing

assembly in position on shell. If bearing remained in housing, use CEN A10–109 bearing

tool or equivalent placed on bearing inner race.

Press on bearing and guide ADE housing on

shell. Rotate shaft to make sure bearing moves

freely.

20. Install existing locknuts on through-studs. Use

a suitable adhesive, such as Loctite

Follow manufacturer’s instructions. Torque

locknuts to 2-2.25 Nm/18-20 lb. in.

21. Press fan assembly into bore of ADE housing.

Fasten with existing hardware and torque to

67.8 Nm/50 lb. ft.

22. Install pulley bushing on drive end shaft with

short hub facing bearing.

23. Install Woodruff key in slot in shaft.

24. Install pulley on shaft. Torque to 162.7 Nm/

120 lb. ft.

25. Plug regulator harness plug into regulator

receptacle in housing.

®

222.

®

222.

Test unit on bench to verify proper operation

after assembling.

Short screw -

step 16c

II0063A

Long screw -

step 16a

TT

TT

T

Short

screw

Bracket

T

TT

TT

TT

T

T

TT

TT

Figure 5—New Regulator and Bracket Assembly

TT

Long screw -

step 16b

Short screw -

step 16d

TT

TT

T

TT

TT

T

TT

TT

T

TT

TT

T

Long

screw

Spacer

Page 3

Page 4

Page 4

II0063A

Page 5

Service Parts List * N1380-1 Date: 09/03/04

y

y

t

g

y

y

y

y

y

g

y

g

y

y

No. Part No. Qty. Description

Ke

1A N9001 1 Pulle

2 N7212 1 Fan

3 N7403 1 Front Housing & Control Uni

3A N9009 1 Retaining Ring (Beveled)

3B N9010 1 Front Bearing

3C N9008 1 Retaining Rin

3D N7368 1 Cover Plate, Plug Nut Assembl

3E N9450 1 Bracket

4 N7449 1 Rotor, Shaft & Core Assembl

4A N7003 2 Rotor Assembl

4B N7278 1 Core & Shaft Assembl

5 N7280 1 Shell, Stator, Field Coil Assembl

6 N7281 1 End Housing

6A N9302 2 Bearing Seals

6B N9303 1 Rear Bearing (Roller)

6C N9405 1 Tension Bushin

7 N7227 1 Heatsink Assembl

8 N3109 1 Regulator

10 N8051 1 Small Parts Packa

1001 N9265 17 Lockwasher (#8 .17"ID x .30"OD x 040" T SST)

1002 N9186 13 TXT-20 Screw (8-32UNC-2A x .37"L)

1003 N9039 6 Pan Head Screw (10-32UNF-2A x .37"L)

1004 N9018 6 Lockwasher (#10 .20"ID x .33"OD x .05"T SST)

1005 N9016 6 Flat Washer (.20"ID x .375"OD x .040"T SST)

1006 N9014 1 Bolt (5/16-16UNC-2A x .75"L)

1007 N9015 1 Lockwasher (.32"ID x .60"OD x.08 "T SST)

1008 N9399 2 Pan Head Screw (8-32UNC-2A x .62"L)

1009 N9400 2 Pan Head Screw (8-32UNC-2A x 1.0"L)

1010 N9447 1 Spacer (.18"ID x .50"OD x .25"T STL)

1011 N9218 1 Hex Nut (3/8-16 Zn)

1012 N9099 18 Flange Locknut (8-32 S-Grip)

1013 N9091 12 Locknut ((10-32UNF-2B)

1014 N9320 12 Flat Washer (.200"ID x .437"0D x 031"T)

1015 N9040 1 Woodruff Ke

1016 N9217 1 E

1017 N9063 1 Flat Washer (.53"ID x 1.06"OD x .09"T BLKOXD.)

1018 N9092 1 Locknut (1/2-20UNF-2B ZN)

*1019 N9587 12 Torx Screw Taptite (10-32 x .5"L)

Bushing (.785"ID x 2.79"OD x .695"T)

e

(3/16" x 3/4")

ebolt / Nut (3/8-16UNC-2A x 1.75"L)

* - Part not shown on Exploded View.

C. E. Niehoff & Co. • 2021 Lee Street • Evanston, IL 60202 Tech Services Hotline 800-643-4633

II0063A

Page 5

Loading...

Loading...