Page 1

N1388 Alternator

N7153 Control Unit Assembly

and/or N7155 B+ Terminal

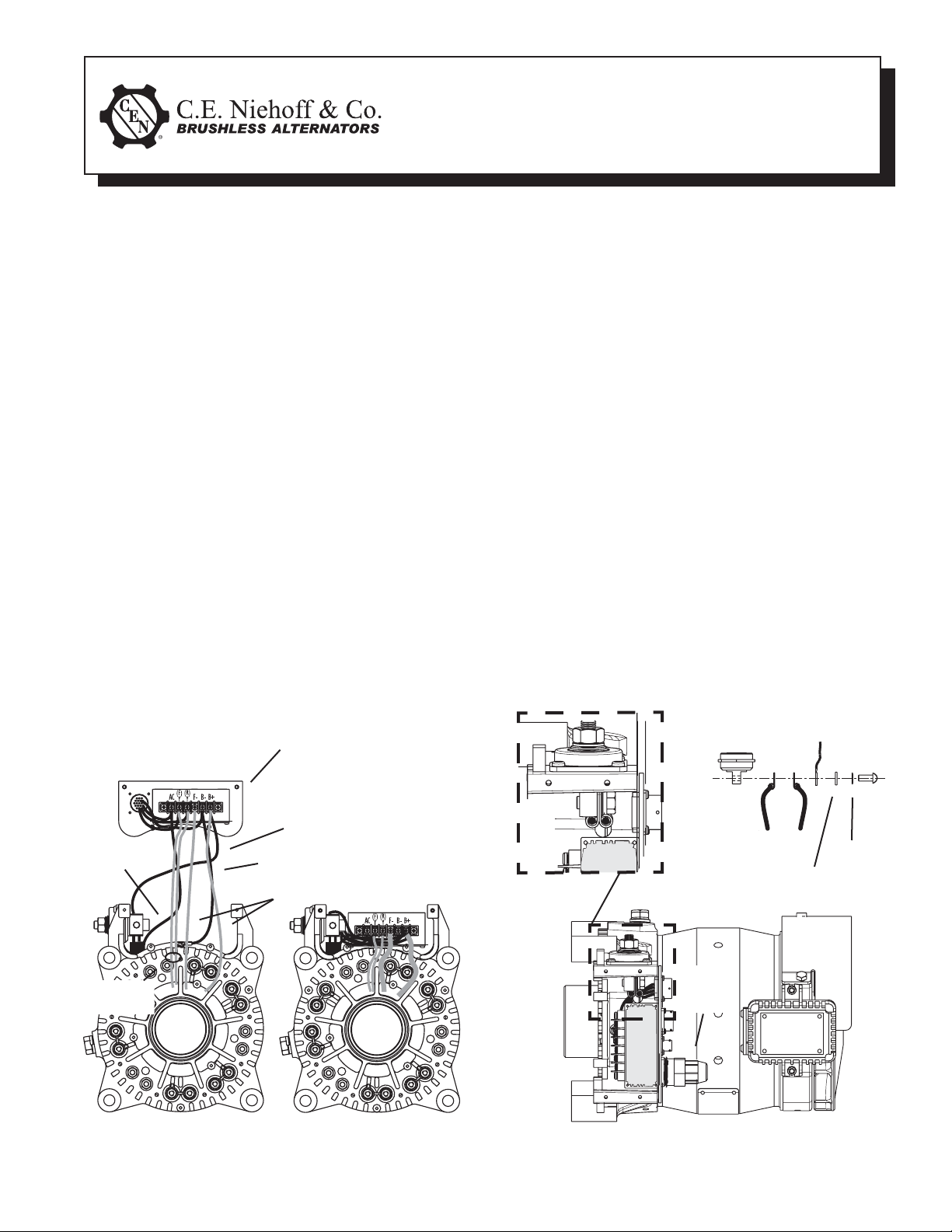

Replacement Instructions

1. Remove hardware and cover plates from:

a. top of control unit

b. front of control unit

c. drive end housing

2. Remove and save voltage adjust plug from control

unit assembly (this step is not necessary when

replacing B+ terminal).

3. Carefully remove potting in front of terminal strip

in control unit to expose six terminals.

4. Disconnect two field coil wires, B+ wire, ground

wire, two stator Y-taps, and phase (AC) wire from

terminal strip.

5. Remove and save the hardware attaching the control

unit assembly.

6. Carefully dig out all of the potting inside the control

unit cavity. DO NOT DESTROY ANY INTERNAL

WIRING.

7. Remove control unit assembly from cavity.

8. Clean out any loose debris in exposed cavity hole

and from wire terminals that will be reattached to

the control unit assembly.

9. Replacing control unit assembly ONLY—proceed

to step 19 on page 2.

Replacing B+ terminal—proceed to step 10 at

right.

Control unit assembly

V

Follow steps 10-18 below to complete B+ terminal

replacement:

10. Remove and save hardware and stud on external B+

terminal.

11. From internal B+ stack, disconnect hardware,

B+ wire, and two rectifier wires.

12. Remove and save hardware attaching the defective

B+ terminal to the housing.

13. Remove defective B+ terminal.

14. Apply bead of Dow Corning® SE9186L RTV

coating or equivalent on mating surfaces between

new B+ terminal plate and drive end housing.

15. Install new B+ terminal in cavity. Use a suitable

adhesive such as Loctite® 222 on three mounting

screws. Torque mounting screws to 4.8 Nm/40 lb. in.

16. Using sandpaper and a cloth, remove all potting

debris from both rectifier wire terminals and B+

wire terminal to ensure the mating faces make

clean contact with each other.

17. Reconnect wiring removed from internal B+ stack in

step 11 according to the stacking order shown in

Figure 2. Torque to 28.2-29.3 Nm/20.3-21.6 lb. ft.

18. Proceed to step 19 on page 2 to complete assembly.

B+

terminal

B+

wire

V

Bolt

V

B+ wire

Phase

(AC) wire

V

Ground wire

V

Two fi eld coil wires

V

V

V

V

Two stator

Y-taps

Figure 1 – Replacing Control Unit Assembly and/or

B+ Terminal on N1388 Alternator

Page 1 of 2

Two

rectifi er

wires

Flat

washer

voltage

adjust

plug

V

Figure 2 – Internal B+ Stacking Order

Disc

spring

washer

II0114B

Page 2

19. Apply bead of Dow Corning® SE9186L RTV coating

or equivalent on mating surfaces between control

unit assembly and drive end housing.

20. Install control unit assembly in cavity. Use a suit able adhesive such as Loctite® 222 on screws.

Torque mounting screws to 2.3 Nm/20 lb. in.

21. Reconnect wiring removed from terminal strip.

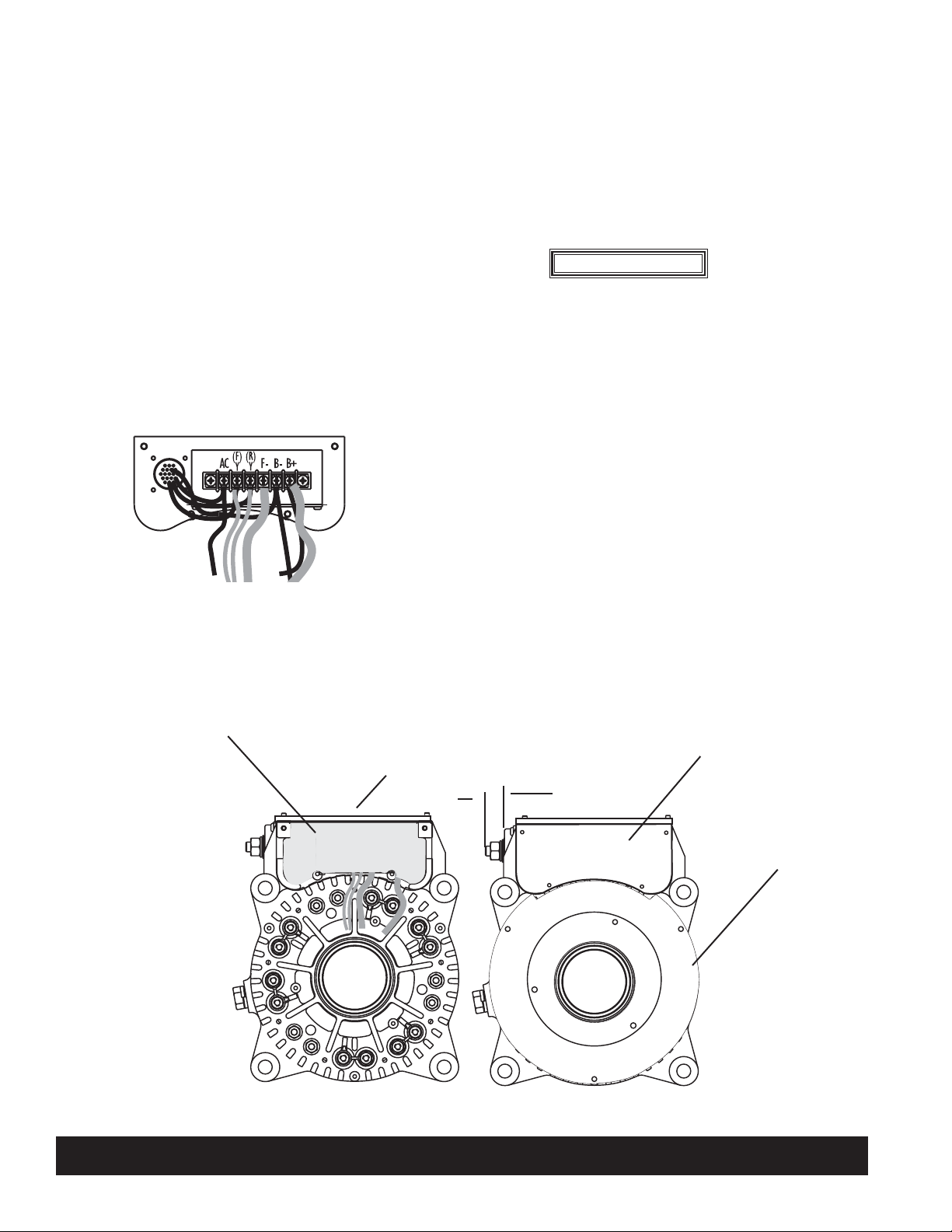

See Figure 1 on page 1 and Figure 3 below.

Torque screws to 1.2 Nm/10 lb. in.

22. Apply bead of Dow Corning® SE9186L RTV

coating or equivalent on mating surfaces between

top control unit cover plate and drive end housing.

23. Re-install top control unit cover plate. Use a suit able adhesive such as Loctite® 222 on screws.

Torque mounting screws to 2.3 Nm/20 lb. in.

24. Turn alternator on anti-drive end and brace to

prevent movement. Press down all exposed wiring

so they will be covered by replacement potting.

25. Fill the cavity inside the control housing with GE

Silicones® RTV11® silicone 2-part system:

a. Mix 148 drops (0.1 ounce) of cure per 1 cup of

RTV. Mix well to prevent incomplete deep-set.

At this point, there is a half hour before mixture

thickens and two hours until mixture deep-sets.

b. Pour mixture into cavity until it covers the

terminal screws on the terminal strip. Make

sure all screws are covered with new potting

material.

Product warranty will be

void if cavity is not fi lled as

indicated in step 25.

26. When new potting is dry, re-install control unit

cover plate and drive end housing cover plate. Use

a suitable adhesive such as Loctite® 222 on screws.

Torque mounting screws to 2.3 Nm/20 lb. in.

27. Re-install voltage adjust plug in appropriate position

for use.

28. If B+ terminal was replaced, re-install external

hardware. Use a suitable adhesive such as Loctite®

222 on the middle of stud threads. Screw stud into

terminal until only 11/16" is protruding from surface of terminal. See Figure 4.

WARNING

Figure 3 – Reattaching Wiring to Terminal Strip

New potting

control unit

cover plate

V

V

Top

V

V

See step

28 above

V

Control unit

cover plate

Drive end

cover plate

V

Figure 4 – Replacing Control Unit Assembly and/or B+ Terminal on N1388 Alternator

C. E. Niehoff & Co. • 2021 Lee Street • Evanston, IL 60202 Tech Services Hotline 800-643-4633

Page 2 of 2

II0114B

Loading...

Loading...