Page 1

1300 Series Troubleshooting Guide

for N1380-2 Alternator

Hazard Definitions

These terms are used to bring attention to presence of hazards

of various risk levels or to important information concerning

product life.

CAUTION

NOTICE

Indicates presence of hazards that

will or can cause minor personal

injury or property damage.

Indicates special instructions on

installation, operation or maintenance that are important but not

related to personal injury hazards.

Table of Contents

Section A: Wiring Diagram...................................... 2

Section B: Basic Troubleshooting ........................... 3

Section C: Advanced Troubleshooting .................... 4

Battery Conditions

NOTICE

conditions may be observed during cold start voltage tests.

• Maintenance/Low Maintenance Battery:

— Immediately after engine starts, system volts are

lower than regulator setpoint, and amps are

medium.

— 3-5 minutes into charge cycle, system volts

increase and amps decrease.

— 5-10 minutes into charge cycle, system volts

increase to, or near, regulator setpoint, and amps

decrease to a minimum.

— Low maintenance battery has same characteris-

tics with slightly longer recharge times.

• Maintenance-free Battery:

— Immediately after engine starts, system volts are

lower than regulator setpoint with low charging

amps.

— Once the charge cycle begins, low volts and low

amps are still present.

— After the alternator energizes, volts will increase

several tenths. Amps will increase gradually,

then quickly to medium to high amps.

— Finally, volts increase to setpoint and amps

will decrease.

The time it takes to reach optimum voltage and

amperage will vary with engine speed, load, and

ambient temperature.

• High-cycle Maintenance-free Battery:

— These batteries respond better than standard

maintenance-free. Charge acceptance of these

batteries may display characteristics similar to

maintenance batteries.

Until temperatures of electrical

system components stabilize, these

Charge Volt and Amp Values

Voltage and amperage levels are functions of the battery

state of charge. If batteries are in a state of discharge,

as after extended cranking time to start the engine,

system volts when measured after the engine is started

will be lower than the regulator setpoint, and system

amps will be high. This condition is normal for the

charging system. Measured values of system volts and

amps will depend on the level of battery discharge; in

other words, the greater the battery discharge level, the

lower the system volts and higher the system amps will

be.

Voltage and amperage readings will change: System

voltage reading will increase to regulator setpoint, and

system amps will decrease to low level (depending on

other loads) as batteries recover and become fully

charged.

• Low Amps: Minimum or lowest charging system

amp value required to maintain battery state of

charge; obtained when testing the charging system

with a fully charged battery and no other loads

applied. This value will vary with battery type.

• Medium Amps: System amp value that can cause

battery temperature to rise above adequate charging

temperature within 4-8 hours of charge time. To

prevent battery damage, charge amps should be

decreased when battery temperature rises. Check

battery manufacturer recommendations on proper

rates of charge amps.

• High Amps: System amp value that can cause

battery temperature to rise above adequate charging

temperature within 2-3 hours. To prevent battery

damage, charge amps should be decreased when the

battery temperature rises. Check battery manufacturer recommendations on proper rates of charge

amps.

• Battery Voltage: Steady-state volt value measured

with battery in open circuit with no battery load.

This value relates to battery state of charge.

• Charge Voltage: Volt value obtained when charging

system is operating. This value will be higher than

battery voltage and must never exceed the regulator

voltage setpoint.

• B+ Voltage: Volt value obtained when measuring

voltage at battery positive terminal or alternator B+

terminal.

• Surface Charge: Higher-than-normal battery voltage

occurring when battery is removed from battery

charger. Surface charge must be removed to determine true battery voltage and state of charge.

• Significant Magnetism: Change in strength or

intensity of a magnetic field present in the alternator

rotor shaft when the field coil is energized. The

magnetic field strength when the field coil is energized should feel stronger than when the field is not

energized.

• Voltage Droop or Sag: Normal condition which

occurs when the load demand on an alternator is

greater than rated alternator output at given rotor

shaft RPM.

TG0037A

Page 1

Page 2

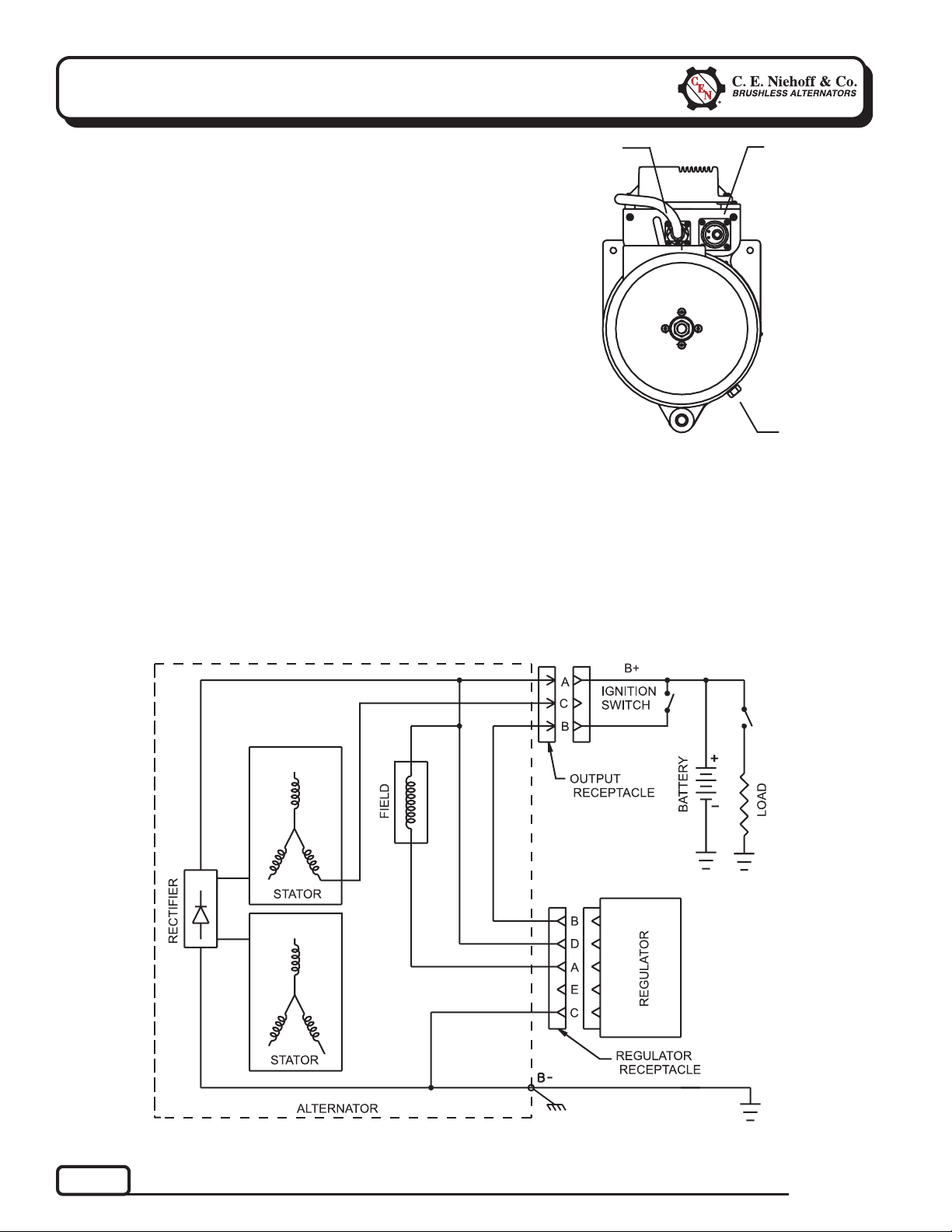

Section A: Wiring Diagrams

CEN N1380-2 Alternator

Description and Operation

N1380-2 28 V (220 A) alternator is self-rectifying.

All windings and current-transmitting components

are non-moving, so there are no brushes or slip rings

to wear out. Ignition switch energizes regulator.

Field coil is then energized.

N3109 regulator used with these units:

• is negative temperature compensated for 28.3

± 0.1 V at 72º F for temperature variation

at –0.1 volt per 10º F.

• provides overvoltage cutout (OVCO). Regulator

will trip OVCO when system voltage rises above

32 V for longer than 2 seconds. OVCO feature

detects high voltage and reacts by signaling relay

in F– alternator circuit to open, turning off

alternator. Restarting engine resets OVCO circuit.

Regulator

receptacle

TT

T

TT

T

TT

Figure 1 — N1380-2 Alternator Terminals

TT

Output receptacle

TT

T

TT

B– terminal

bolt

Page 2

Figure 2 — N1380-2 Alternator with N3109 Regulator

TG0037A

Page 3

Section B: Basic Troubleshooting

Tools and Equipment for Job

• Digital Multimeter (DMM)

• Ammeter (digital, inductive)

• Jumper wires

Identification Record

List the following for proper troubleshooting:

Alternator model number ____________________

❏

Regulator model number _____________________

❏

Setpoints listed on regulator __________________

❏

Preliminary Check-out

Check symptoms in Table 1 and correct if necessary.

TABLE 1 – System Conditions

SYMPTOM

Low Voltage Output

High Voltage Output

No Voltage Output

Check: loose drive belt; low

battery state of charge.

Check: current load on system

is greater than alternator can

produce.

Check: defective wiring or poor

ground path; low regulator

setpoint.

Check: defective alternator and/

or regulator.

Check: wrong regulator.

Check: high regulator setpoint.

Check: defective regulator.

Check: alternator.

Check: broken drive belt.

Check: battery voltage at alter-

nator output terminal.

Check: defective alternator

and/or regulator.

ACTION

Basic Troubleshooting

1. Inspect charging system components for

damage

Check connections at B– cable, B+ cable, and

alternator-to-regulator harness. Repair or

replace any damaged component before troubleshooting.

2. Inspect all vehicle battery connections

Connections must be clean and tight.

3. Determine battery voltages and states of

charge

If batteries are discharged, recharge or replace

batteries as necessary. Electrical system cannot

be properly tested unless batteries are charged

95% or higher.

4. Connect meters to alternator

Connect red lead of DMM to alternator B+ terminal and black lead to alternator B– terminal.

Clamp inductive ammeter on B+ cable.

5. Operate vehicle

Observe charge voltage.

CAUTION

shut down system. Electrical system damage may occur if

charging system is allowed to operate at high voltage. Go to

Table 1 at left.

If voltage is at or below regulator setpoint, let

charging system operate for several minutes to

normalize operating temperature.

6. Observe charge volts and amps

Charge voltage should increase and charge amps

should decrease. If charge voltage does not increase within ten minutes, continue to next step.

7. Batteries are considered fully charged if charge

voltage is at regulator setpoint and charge amps

remain at lowest value for 10 minutes.

8. If charging system is not performing properly,

go to Chart 1, page 4.

9. Check OVCO circuit

Shut down vehicle and restart engine. If alternator functions normally after restart, a “no output

condition” was a normal response of voltage

regulator to “high voltage” condition. Inspect

condition of electrical system, including loose

battery cables, both positive and negative. If

battery disconnects from system, it could cause

“high voltage” condition in electrical system,

causing OVCO circuit to trip.

If you have reset alternator once, and electrical

system returns to normal charge voltage condition, there may have been a one time, high voltage spike, causing OVCO circuit to trip.

If OVCO circuit repeats cutout a second time in

short succession and shuts off alternator F–

circuit, try third restart. If OVCO circuit repeats

cutout, go to Chart 1, page 4.

If charge voltage is above

33 volts, immediately

TG0037A

Page 3

Page 4

Section C: Advanced Troubleshooting

Chart 1 – No Output

Ignition switch on, engine off: Check for battery voltage between B–

terminal on alternator and Pin A on output receptacle (back-probe pin).

Ye s

TT

T

TT

Ignition switch off: Back-probing pins, momentarily (1 sec.) jumper

Pins A and B in the output receptacle. Touch shaft with steel tool

to detect any magnetism. Is shaft magnetized?

Yes

TT

T

TT

Check ignition switch

and vehicle wiring.

Disconnect regulator harness and output harness. Perform series

of tests with DMM:

No

TT

T

TT

1) With meter set on diode test, connect red lead to pin C of output

receptacle and black lead to pin D of regulator receptacle. Meter

should read continuity. Reverse leads. Meter should read OL.

2) With meter set on ohms, check field coil resistance across

pins A and D of regulator receptacle. Resistance should measure

less than 3 ohms.

3) With meter set on ohms, check for continuity between pin C of

regulator receptacle and B– terminal on alternator.

Did all three tests provide correct readings?

Ye s

TT

T

TT

Regulator is defective.

No

TT

T

TT

Repair vehicle wiring to

output receptacle.

No

TT

T

TT

Alternator is defective.

PIN CONNECTIONS

Figure 3 – Regulator 5-pin Receptacle

If you have questions about your alternator or any of these test procedures, or if you need to locate a Factory Authorized Service Distributor, please contact us at:

TEL: 800.643.4633 USA and Canada • TEL: 847.866.6030 outside USA and Canada • FAX: 847.492.1242

Page 4

Pin A Field –

Pin B Energize

Pin C Ground

Pin D B+

Pin E Not Used

C. E. Niehoff & Co.• 2021 Lee Street • Evanston, IL 60202 USA

Figure 4 – Output 3-pin Receptacle

E-mail us at support@ceniehoff.com

PIN CONNECTIONS

Pin A B+

Pin B Energize

Pin C Phase

TG0037A

Loading...

Loading...