Page 1

C. E. Niehoff & Co

.

BRUSHLESS ALTERNATORS

N7074

ADE Housing Assembly

for N1235 Alternators

Replacement Instructions

NOTICE

Do not cut field coil leads.

Reattachment will be rendered

impossible with shorter lengths

of leads.

Disassembly:

Anti-Drive End:

1. Remove ADE front cover plate, nut, washer.

2. The outer ring carrier and attached spiral ring

should remain inside the housing until the housing

is removed.

3. Remove silicone "plug" sealing the entrance on the

outside of the housing where the two field coil

leads enter the housing.

4. Remove the top cover plate on the ADE housing.

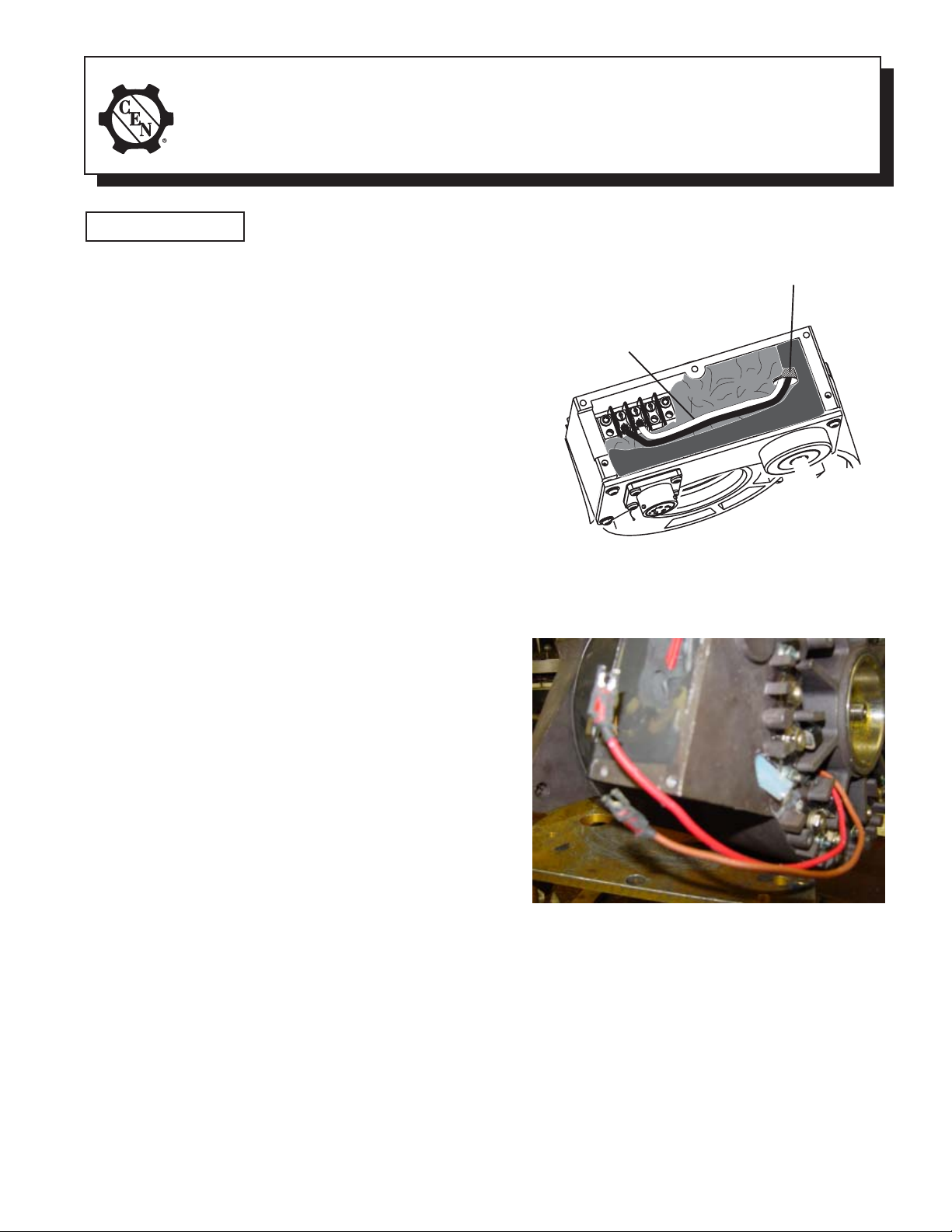

5. Carefully dig out the potting material inside the

control unit cavity with a blunt tool to not damage

the internal electrical components. The potting

should come loose in chunks. See Figure 1.

Remove enough potting to expose the terminal

block, the top two wires (field coil wires), and tube.

There will be another silicone "plug" sealing the

entrance of the plastic tube. The "plug" should be

removed.

6. Remove the two screws holding the red F+ and the

brown F- field coil leads to the terminal strip.

7. Carefully lift the field coil leads out of the potting.

Clean the field coil leads and terminals as much as

possible without damaging them. Then gently pull

them out of the tube from the outside entrance on

the front of the housing. See Figure 2. Ensure that

the leads are not damaged when pulling the forked

terminals through the tube.

8. Remove the phase leads from the diode studs on

the face of the ADE housing. Label each stud for

reattachment of phase leads.

9. Scribe marks at the joint of the ADE housing and

shell for reassembly.

10. Remove nuts from housing and separate the ADE

housing from the shell. Remove ADE bearing from

shaft and discard bearing.

11. Remove outer ring carrier located in front of the

bearing in the ADE housing from the inside out. If

carrier is stuck and spiral ring is lodged inside

bore, force the ring carrier out of the bore and save

ring carrier and spiral ring.

Red F+ field coil lead is

attached to the terminal

on the left of the brown

lead on terminal strip

Brown F– field coil lead is

attached to the middle terminal

on terminal strip

➛

➛

Figure 1 – Interior of Control Unit

Figure 2 – Field Coil Leads Removed

from Control Unit

II0087A

Page 1 of 2

Page 2

Assembly:

Anti-Drive End:

1. Install O-rings in grooves in inner bore of ADE

housing. Lubricate O-rings with DuPont™ Krytox®

GPL 225 or equivalent.

2. Lubricate inner ring carrier (on shaft land) with

DuPont™ Krytox® GPL 225 or equivalent.

3. Align scribe marks, then set ADE housing in

position, pulling phase leads and field coil leads

through vent holes in housing. Rotate shaft to

make sure phase leads or field coil leads do not

interfere with rotor.

4. Install locknuts on through-studs and use suitable

adhesive, such as Loctite® 222. Follow manufacturer's instructions. Torque screws to 5.1 Nm/

45 lb. in. Before Loctite® sets, tap around face of

housing with plastic-headed hammer to set housing against shell. Re-torque all screws.

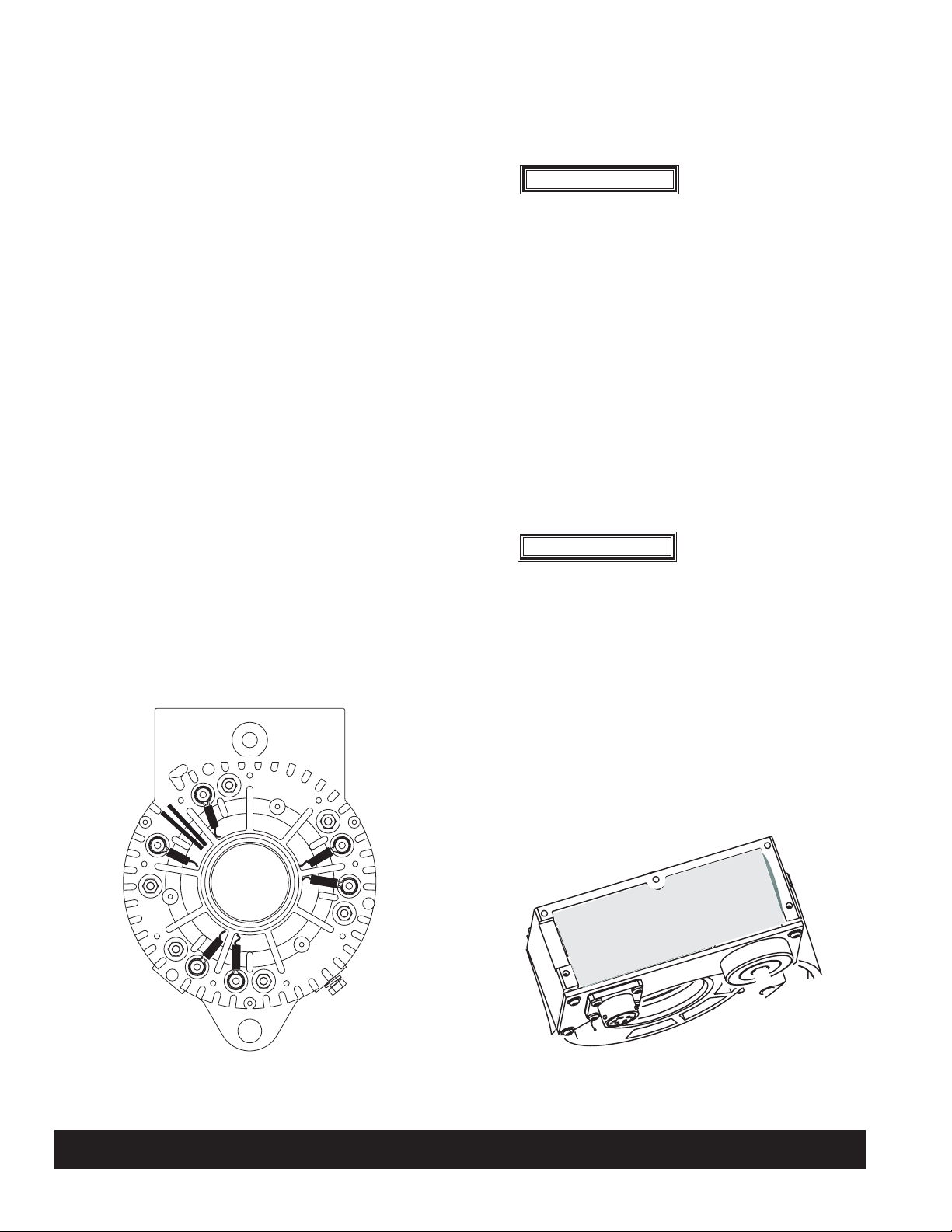

5. Attach phase leads to diode studs as marked in

Disassembly step 8. Torque nuts to 3.4 Nm/

30 lb. in. Coat all diode studs with Dow Corning®

3140 RTV or equivalent. See Figure 3.

6. Press new ADE bearing into bearing bore at

bearing inner race. Wind cleaned spiral ring

around groove in outer ADE ring carrier. Lubricate

spiral ring with DuPont™ Krytox® GPL 225 or

equivalent. Set ring carrier into ADE bearing bore.

7. Fasten with hardened washer and locknut. Torque

to 65 Nm/50 lb. ft.

8. Feed field coil leads up through tube and into

control unit in housing. Fill inside of tube with

Dow Corning® 3140 RTV or equivalent until

silicone appears at bottom of tube. Smooth away

the excess silicone at bottom of tube, forming a

seal.

WARNING

9. Attach field coil leads to terminals as shown in

Figure 1 on page 1. Make sure all wires are

pressed inside cavity so that they will not be

exposed after cavity is filled with replacement

potting.

10. Fill the cavity inside the control housing with GE

Silicones® RTV11® silicone 2-part system (see

Figure 4):

a. Mix 37 drops of cure into 1/4 cup of RTV. Mix

well to prevent incomplete deep-set. At this

point, there is a half hour before mixture

thickens and two hours until mixture deepsets.

b. Pour mixture into cavity until it reaches the top

of the old potting. Do not block opening on

side of control housing. Make sure all wiring is

covered with new potting material.

WARNING

11. Install ADE top cover plate. Torque screws to 4.5 5 Nm/40-45 lb. in.

12. When RTV has hardened, install ADE cover plate.

Torque screws to 4.5 - 5 Nm/40-45 lb. in.

Product warranty will be void if

tube is not sealed as indicated

in step 8.

Product warranty will be void if

cavity is not filled as indicated

in step 10.

Figure 3 – Phase Lead Connections

Figure 4 – Control Unit Filled with New Potting

C. E. Niehoff & Co. • 2021 Lee Street • Evanston, IL 60202 Tech Services Hotline 800-643-4633

Page 2 of 2

II0087A

Loading...

Loading...