Page 1

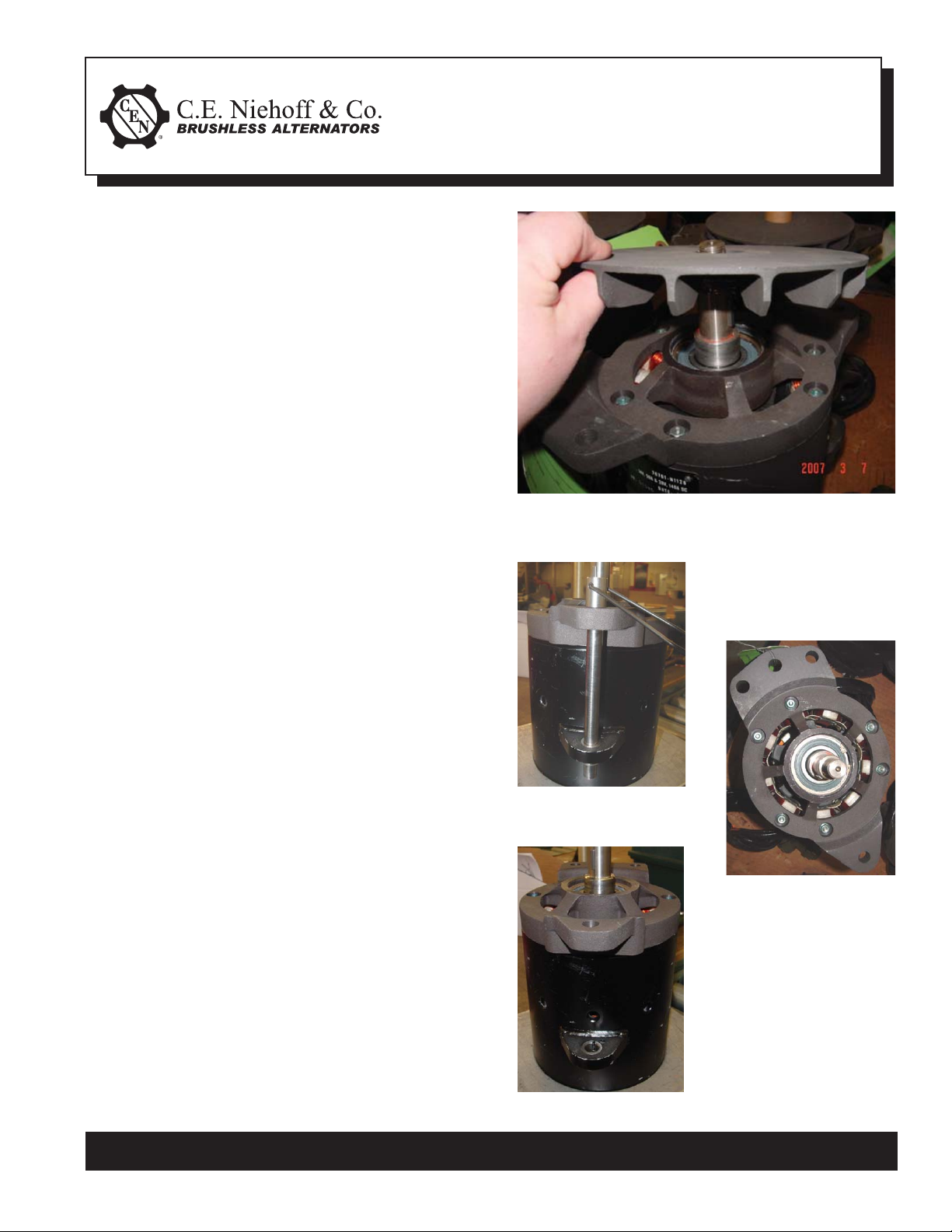

1. Remove pulley hardware, pulley, and DE fan. See

Figure 1.

2. Remove and save locknuts from through-studs

holding drive end housing to shell assembly.

3. Insert mounting lug alignment tool through

mounting lugs. See Figure 2.

NOTE: If tool does not penetrate mounting lug

in shell assembly, use a soft mallet to tap on the

drive end housing lug until both lugs are aligned

and tool can be easily inserted in both lugs.

4. Once both lugs are aligned, re-install locknuts

on through-studs. Use a suitable adhesive such

as Loctite®222 on studs. Follow manufacturer’s

instructions. Torque screws to 5.1 Nm/45 lb. in.

See Figure 3.

5. Remove mounting lug alignment tool. See Figure

4.

N1 127-3 Alternator

Mounting Lugs

Re-alignment Instructions

Figure 1

6. Re-install fan, pulley, and hardware. Torque hardware to 136 Nm/100 lb. ft.

Figure 2

Figure 3

Figure 4

C. E. Niehoff & Co. • 2021 Lee Street • Evanston, IL 60202 Tech Services Hotline 800-643-4633

II0119APage 1 of 1

Loading...

Loading...