Page 1

N1 126-2 Alternator

N9700 Filter Replacement Kit and

Diode Module Test

Field Instructions

Disassembly:

1. Disconnect alternator-to-regulator harness plug at

regulator.

2. Remove and discard four screws from black cover

plate on control unit. Loosen cover to access wiring

underneath.

3. Label and disconnect three harness leads, red

(B+), green (B–), and brown (AC) from defective

filter.

4. Label three black phase leads from diode module at

filter.

5. Remove and discard six screws attaching filter to

diode module.

6. Uncouple gray connector on harness.

7. Remove and discard filter.

8. Test diode module per Table 1, page 2.

• If defective, see diode replacement on page 2.

• If not defective, follow directions below for

reassembly.

Assembly:

NOTE: Before reassembly, make sure all ring, power,

and diode terminals are cleaned with a wire brush to

remove any conformal coating and ensure a good electrical connection.

1. Put end of harness with ring terminal through hole

in cover from outside.

2. Mate two ends of gray connector.

3. Install phase leads, copper links, and spacer

washer between new filter and diode module using

new hardware. Leave fasteners loose.

4. Install screws in terminals E, A, and C. Leave

fasteners loose. See Figure 3 on page 2.

5. Using new hardware, install red harness lead

(B+) in terminal D. Install brown harness lead (AC)

in terminal B and green harness lead in terminal F.

6. Torque down all fasteners (4.6 Nm/40 lb. in.) taking

caution to ensure proper connection.

7. Replace black cover plate and torque fasteners to

2.3 Nm/20 lb. in.

8. Reconnect alternator-to-regulator harness plug at

regulator.

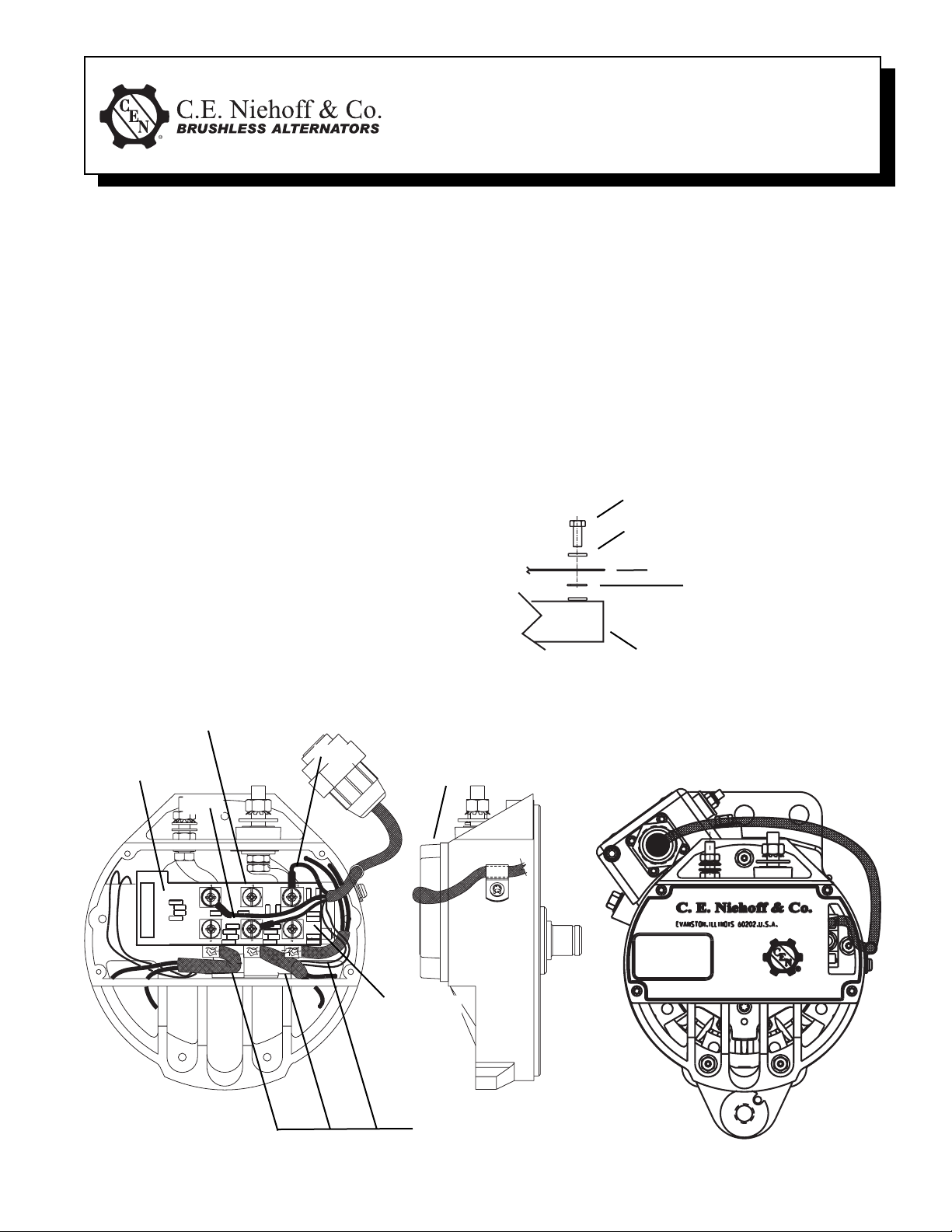

Screw

V

Washer

V

Filter

V

V

er terminal (phase lead,

Pow

copper link, or spacer washer)

V

Diode module

Use washer as spacer between fi lter and di-

ode module in this position only

Red

Filter

Green

V

V

V

V

V

V

V

V

V

Figure 1 – Diode Module Stacking Order

Black cover plate

V

Brown

Three phase leads

Page 1 of 2

Figure 2 – Replacing Filter and Black Cover Plate on N1126-2 Alternator

II0120A

Page 2

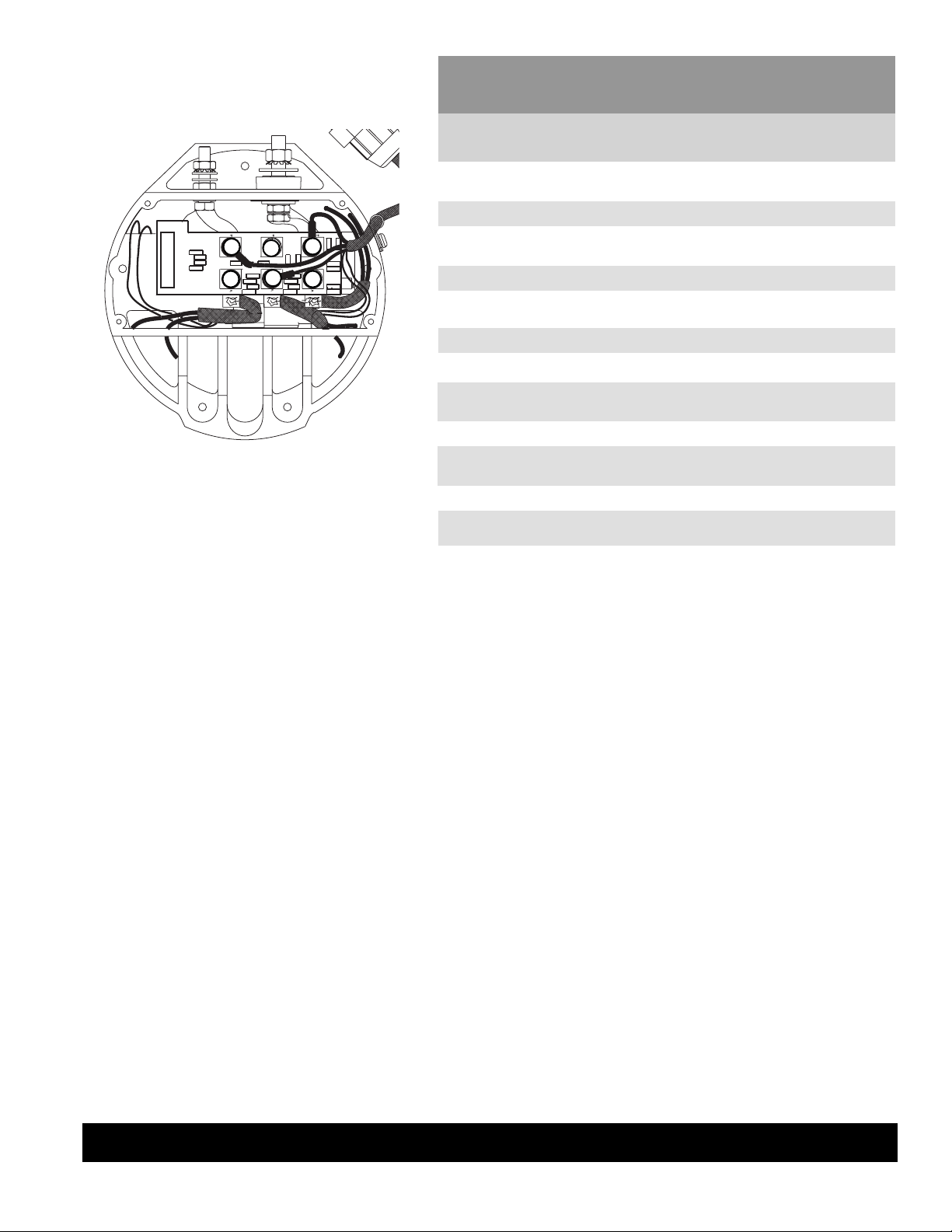

Diode module tests:

F

C

Figure 3 – Diode Module Terminal Designations

D

E

B

A

TABLE 1 Diode Module Tests

TABLE C– 4 C704 Diode Module Tests

REMOVE PHASE LEADS. USE DIODE TEST SCALE ON DMM.

REPEAT TESTS FOR EACH MODULE. SEE FIGURE C–11.

TEST

NO.

1

2

3

4

5

6

7

8

9

10

11

12

CONNECTION

USE DIODE TEST SCALE ON DMM.

SEE FIGURE 3.

METER

(+) LEAD

Terminal A

Terminal A

Terminal B

Terminal B

Terminal C

Terminal C

Terminal D

Terminals E & F

Terminal D

Terminals E & F

Termi n a l D

Terminals E & F

METER

(–) LEAD

CONNECTION

Terminal D

Terminals E & F

Terminal D

Terminals E & F

Terminal D

Terminals E & F

Terminal A

Terminal A

Terminal B

Terminal B

Terminal C

Terminal C

TESTED

CIRCUIT

(+) side diode

(–) side diode

(+) side diode

(–) side diode

(+) side diode

(–) side diode

(+) side diode

(–) side diode

(+) side diode

(–) side diode

(+) side diode

(–) side diode

EXPECTED

READING

<1.0 volts

(fl ow)

OL (blocking)

<1.0 volts

(fl ow)

OL (blocking)

<1.0 volts

(fl ow)

OL (blocking)

OL (blocking)

<1.0 volts

(fl ow)

OL (blocking)

<1.0 volts

(fl ow)

OL (blocking)

<1.0 volts

(fl ow)

To replace diode module:

1. Reference disassembly steps on page 1.

2. Remove and discard hardware and defective diode

module.

3. Clean housing surface to remove old heatsink

compound. Surface must be clean and flat before

applying new heatsink compound.

4. Apply a layer of heat sink compound, such as GC/

Waldon HSC # 10-8109 zinc oxide filled silicone or

its equivalent on the back of the new diode module

between the module and housing surface.

5. Install new diode module in orientation shown in

Figure 3. Stack mounting hardware on mounting

studs: nut, disc spring washer, flat washer. Torque

nuts to 12.5 Nm/9.2 lb. ft.

6. After diode module is secured in place, reference

reassembly instructions on page 1.

C. E. Niehoff & Co. • 2021 Lee Street • Evanston, IL 60202 Tech Services Hotline 800-643-4633

Page 2 of 2

II0120A

Loading...

Loading...