Page 1

C810 Alternator

with External Rectifi er Assembly

Installation Instructions

This symbol is used to indicate

CAUTION

presence of hazards that can cause

minor property damage.

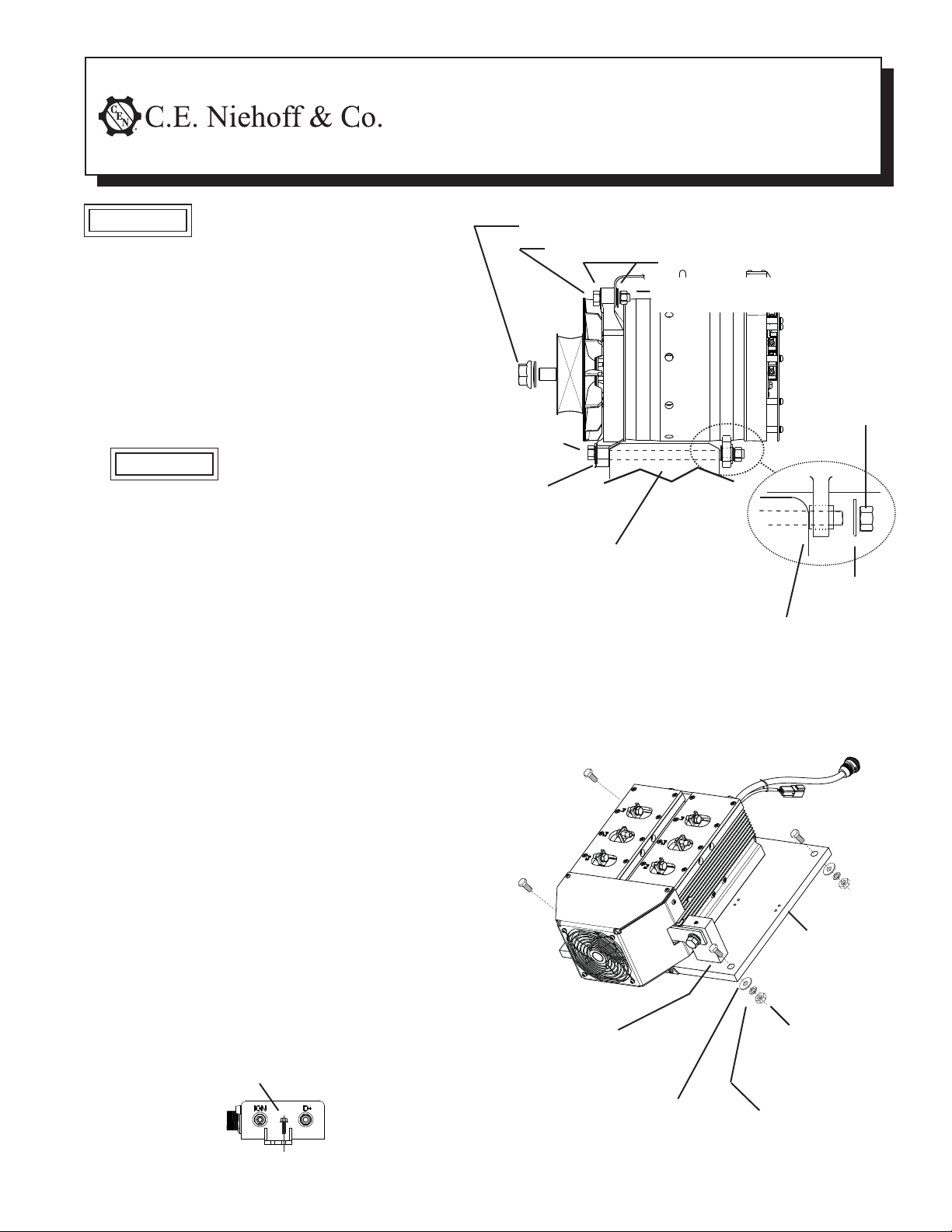

C810 Alternator

1. C810 alternator has 7” hinge mount.

2. Units are shipped with shaft collar, hardened

washer and locknut. Remove and discard shaft

collar. Install pulley and furnished hardened

washer. Torque locknut to 163 Nm/ 120 lb. ft.

3. Use hardened washers between aluminum surfaces and bolt heads and nuts. See Figure 1 for

torque.

Slip bushing in lower rear

CAUTION

mounting lug must be securely

tightened against mounting

bracket on engine. Failure to

do so can result in broken

mounting lugs or broken upper

mounting bracket.

External Rectifier Assembly

1. Mounting location of external rectifier assembly

should provide proper cooling and protect rectifier from direct water, road debris, or chemicals.

It can be mounted horizontally or vertically.

2. Using the standard A9-4026 wiring harness, the

external rectifier assembly can be mounted up to

7 feet away from the alternator.

3. Use hardened washers between aluminum

surfaces and bolt heads and nuts. See Figure 2

for torque values.

4. Use a suitable adhesive such as Loctite

or equivalent on bolts. Follow manufacturer’s

instructions.

Regulator

1. Regulator is located on the bracket that supports

the external rectifier assembly (see Figures 2 and

4).

2. If P terminal is used (located on opposite side of

D+ and IGN terminals), regulator will need to be

removed and electrical connection to P terminal

installed. See step 7 in “Electrical Connections.”

3. See Figure 3 for torque values.

4. Make sure regulator harness is securely plugged

into regulator receptacle. See Figure 4.

M5 x .80 screw (4 places) – torque to 8.5 Nm/75 lb. in.

®

222

M20x1.5 nut and disk spring washer—

torque to 163 Nm/120 lb.ft.

M10/0.3750 in. Mounting bolt (2 plcs)

Hardened washers

M10/0.3750 in. Locknut (2 plcs)–

torque to 38 Nm/29 lb. ft.

M12/0.50 in.

Mounting bolt

Hardened

washer

Alternator mounting

bracket on engine

Slip bushing must be tightened against bracket —

see “CAUTION” at left

Bracket

on engine

Figure 1 - C810 Alternator Installation

13 mm/0.5 in.

Mounting bolt

grade 5 or better

(4 places)

M12/0.50

lock nut –

torque to

88 Nm/65 lb. ft.

Regulator

mounting holes

Locknut –

torque to

54 Nm/40 lb.ft.

Hardened

washer

Page 1 of 2

Figure 3 - Regulator Installation

Flat

washer

Lockwasher

Figure 2 - External Rectifi er Assembly Installation

II170A

Page 2

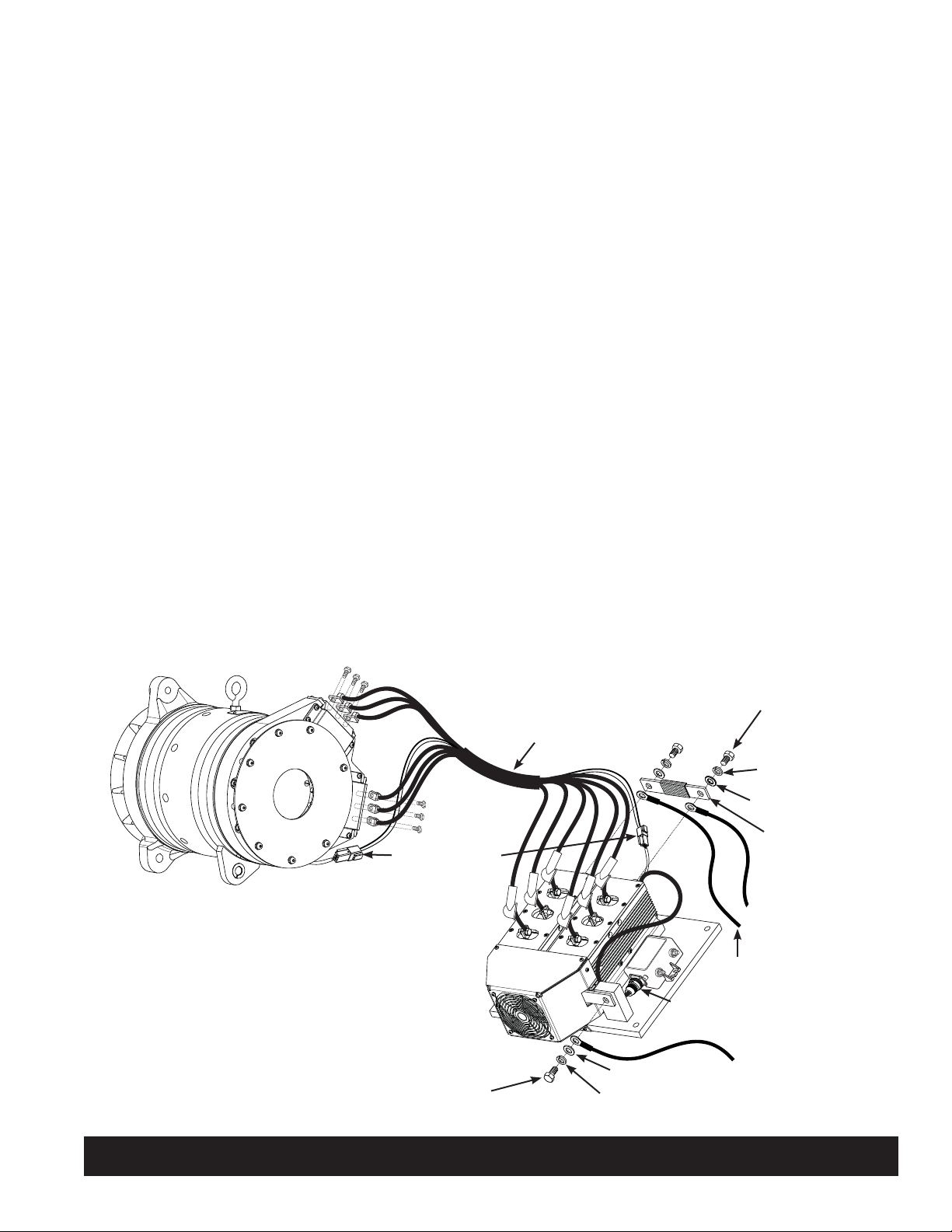

Electrical Connections

1. Connect phase harness between alternator and

rectifier as shown in Figure 4: P1 to P1, P2 to P2,

and P3 to P3 for each set of three cables. Do not

cross the connections between sets of three.

Secure with hardware and use torque values

shown.

2. Securely connect gray field receptacles at

alternator and at external rectifier assembly.

3. Connect B+ and B- terminals. See Figure 4.

Make sure insulated sleeve is in place on busbar.

Choose wire gauge for B+ and B– cables capable

of handling maximum alternator output with

minimum voltage drop.

4. If an additional cable connection is necessary,

connect where/as shown. See Figure 4.

5. All output leads must be supported within

305 mm/12 in. of termination and cabling,

wiring, or conduit run supported at 406 mm/

16 in. maximum intervals. Strain relief must be

provided and cable ties used.

6. Connect IGN terminal on regulator to ignition

source. Torque M5 terminal nut to 4.5 Nm/

40 lb. in.

7. Connect optional P terminal to tachometer or relay.

See step 2 in “Regulator.” Torque M6 terminal nut

to 4.5 Nm/40 lb.in.

8. Connect optional D+ terminal (provides 28 VDC

sense voltage) to multiplex controller. When

connecting D+ terminal to controller through a

relay, the relay coil must be diode protected and

rated for proper voltage. Torque M6 terminal nut

to 4.5 Nm/40 lb. in.

Sealing Wiring Connections

On ALL metallic electrical connections to external

rectifier assembly (including B+ and B– connections),

alternator, regulator, and their harness connectors,

apply Dow Corning® 1-2577 Low VOC RTV coating or

equivalent. Do not use coating containing acetic acid

(vinegar smell) on electrical components.

Phase terminal bolts connected to alternator (6 places) –

torque to 9 Nm/80 lb. in.

P3

P2

P1

P3

P2

P1

Field receptacles

Phase terminal bolts connected

to rectifi er (6 places) –

torque to 8 Nm/70 lb. in.

1/2-13 x 1.75 B- bolt

torqued to 30 Nm/22 lb. ft.

Phase

harness

P1

P2

P3

P1

P2

P3

Flat washer

Lockwasher

1/2-13 x 1 B+ bolt torqued

to 30 Nm/22 lb. ft. (2 plcs)

Lockwasher (2 plcs)

Flat washer (2 plcs)

Busbar with

insulated sleeve

Battery B+ cable

primary location

Additional cable

location, as needed

Regulator harness

Battery B- cable location

Figure 4 - Electrical Connections

C. E. Niehoff & Co. • 2021 Lee Street • Evanston, IL 60202 Tech Services Hotline 800-643-4633

Page 2 of 2

II170A

Loading...

Loading...