Page 1

C717, C717-1, and

C717-2 Alternator

Installation Instructions

This symbol is used to indicate presence

WARNING

of hazards that can cause severe personal

injury or substantial property damage.

This symbol is used to indicate presence

CAUTION

of hazards that can cause minor property

damage.

The C717 alternator has maximum ambi-

WARNING

ent operating temperate range of 65°C/

149°F. Operating above this temperature

range may cause irreparable damage to

the alternator.

1. Install alternator:

a. Carefully place alternator on alternator

mounting bracket.

Use caution when lifting

alternator to prevent possible

minor personal injury. Use hoist

along with alternator lifting ring

located on top of alternator.

b. Secure alternator to alternator mounting

bracket using four .5000-13 UNC-2A, grade 5

or higher mounting bolts with lock washers.

Mounting bolts should extend 17.8/25.4 mm

(0.7/1.0 in.) into alternator mounting rail.

Torque mounting bolts to 88 Nm/65 lb. ft.

2. Units without pulley are shipped with shaft collar,

disc spring washer, and nut. Customer should

replace shaft collar pulley and secure with hardware furnished from factory. Torque hardware

to 163 Nm/120 lb. ft. Some units are already

shipped with pulley installed and torqued to

proper value.

CAUTION

3. Install alternator drive belt and secure belt tension bracket assembly. Loop alternator drive belt

over pulleys and align belt with polyvee grooves.

Follow vehicle manufacturer’s recommendations

for belt tension.

4. All cabling, wiring or conduit must be supported

within 305 mm/12 in. of termination on alternator.

5. Choose wire gauge capable of handling maximum alternator output with no more than 0.4 V

drop on each leg from alternator to battery.

6. Regulator is furnished with OEM units and is

supplied separately by request with aftermarket

units. Mounting screws on regulator should be

torqued to 8.5 Nm/75 lb. in.

7. Make electrical connections to CEN regulator as

required, using proper ring terminals (follow

vehicle manufacturer’s diagram and separate

instructions packed with extended wiring

harness when used):

a. Make sure alternator-to-regulator harness

is plugged securely in regulator receptacle.

b. A2-351 regulator furnished with some units

has additional J1939 connector to vehicle.

Securely attach additional vehicle cable to

this connector as required.

D+ terminal M6 nut – torque to

4.5 Nm/40 lb. in.

IGN terminal M5 nut – torque to

4.5 Nm/40 lb. in.

B– terminal M10 bolt –

torque to 15 Nm/11 lb. ft.

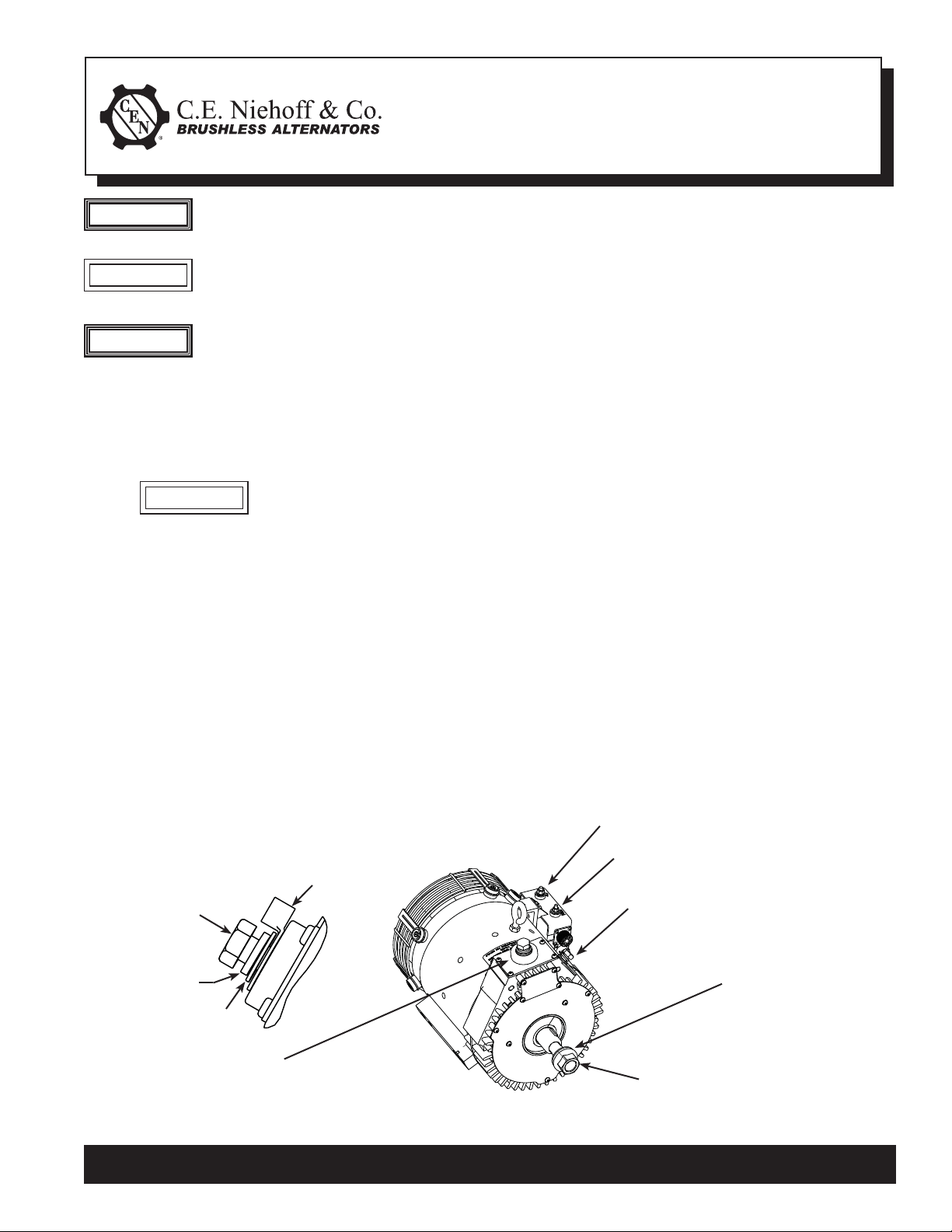

Disc spring

washer

M20 fl ange nut–

torque to 163 Nm/120 lb. ft.

B+ terminal M12 bolt –

torque to 30 Nm/22 lb. ft.

Lock washer

Washer

B+ terminal –

see inset above

Battery output

cable terminal

Figure 1 - C717-1 Alternator Installation Details

C. E. Niehoff & Co. • 2021 Lee Street • Evanston, IL 60202 Tech Services Hotline 800-643-4633

Page 1 of 1

II215A

Loading...

Loading...