Page 1

C703 Alternator with

Diode Isolator Module

Installation Instructions

STEPS 1—5 MUST BE PERFORMED WHEN ALTERNATOR IS ON BENCH.

1. Mount CEN Diode Isolator Module on

module bracket before attaching to

C703 alternator drive end housing.

a. Module bracket has countersunk

holes in face for screws. These holes

must face up when module is attached.

b. Apply a layer of heat sink compound

such as GC/Waldon HSC#10-8109 zinc

oxide-filled silicone or its equivalent

on the back of the module before setting

in place on the module bracket. See

Figure 1. The diagram stamped on the

side of the module can face either the

drive end or the anti-drive end of C703

alternator.

c. Secure module on bracket with 1/4-20 flat

head screws, lock washers, and nuts provid ed in the kit. See Figure 1. Torque to 5.1 Nm/

45 lb. in.

2. Mount module bracket (with module in place)

on C703 drive end housing as shown in

Figures 1 and 2:

1/4-20 fl at head screw,

lock washer, and nut

(one each per side)

#10-32

fl at head screws

(4)

T

T

T

T

FIGURE 1

a. Secure bracket with four #10-32 flat

head screws. Torque to 6.8 Nm/60 lb. in.

b. Use a suitable adhesive such as Loctite®

222 on screws. Follow manufacturer’s

instructions.

3. Attach black wires provided in kit to module.

See Figure 2. Connect small ring terminal end

of wire to module:

a. Shorter black wire should be attached to one

outside terminal on module.

b. Longer black wire should be attached to the

opposite outside terminal on module.

c. Tighten screws on module to 5.1 Nm/45 lb.in.

4. Attach other end of black wires to diodes.

Follow routing shown in Figure 3. Tighten hardware to 3.4 Nm/30 lb. in.

5. Coat phase terminals and module terminals

with Dow Corning® 1-2577 Low VOC RTV coating or equivalent. Do not use coating

containing acetic acid (vinegar smell) on

electrical components.

FIGURE 2

Page 1 of 2

FIGURE 3

II0054B

Page 2

6. Install C703 alternator and new mounting

bracket. See Figure 4. Make sure there is

enough clearance between mounting bracket

and drive end housing to prevent damage to

wires. See Figure 5.

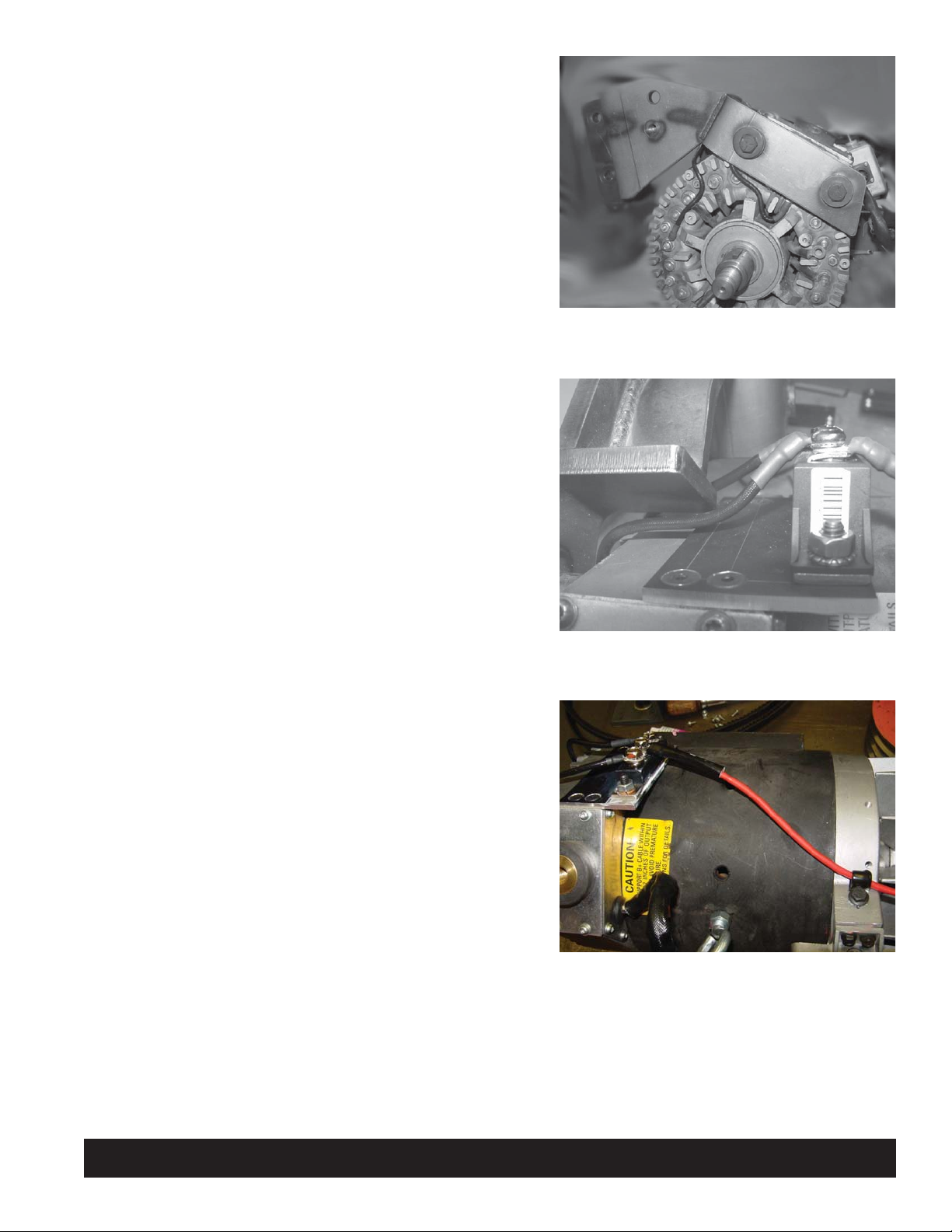

7. Attach cable from 12V Transformer-Rectifier

box on vehicle to middle terminal on module.

See Figure 6. Tighten screw on module to

5.1 Nm/45 lb. in. Coat module terminal with

Dow Corning®1-2577 Low VOC RTV coating

or equivalent. Do not use coating containing

acetic acid (vinegar smell) on electrical

components.

8. Slip cable into wire clamp and attach clamp

with bolt and lock washer to anti-drive end

housing as shown in Figure 6. Tighten

hardware to 5.1 Nm/45 lb. in.

9. Install drive end cover plate on alternator and

secure front cover bolts to 2.8 Nm/25 lb. in.

FIGURE 4

FIGURE 5

FIGURE 6

C. E. Niehoff & Co. • 2021 Lee Street • Evanston, IL 60202 Tech Services Hotline 800-643-4633

Page 2 of 2

II0054B

Loading...

Loading...