Page 1

C621

Drive End (DE) or

Anti-drive End (ADE) Stator

Replacement Instructions

C621 alternator has a special

CAUTION

splice connecting the Y leads

between the ADE and DE stators

which must be handled carefully

for the stators to function prop erly after replacement.

The steps in this instruction sheet

replace the corresponding steps

in the CEN 600 Series Service

Manual SM6.

Before replacing stator, verify

NOTICE

that the correct replacement

stator is used. See additional

instructions provided with

stator.

If replacing DE stator, only DE

NOTICE

stator should be removed.

If replacing ADE stator, both

stators should be removed.

Section E in CEN 600 Series Service Manual

SM6:

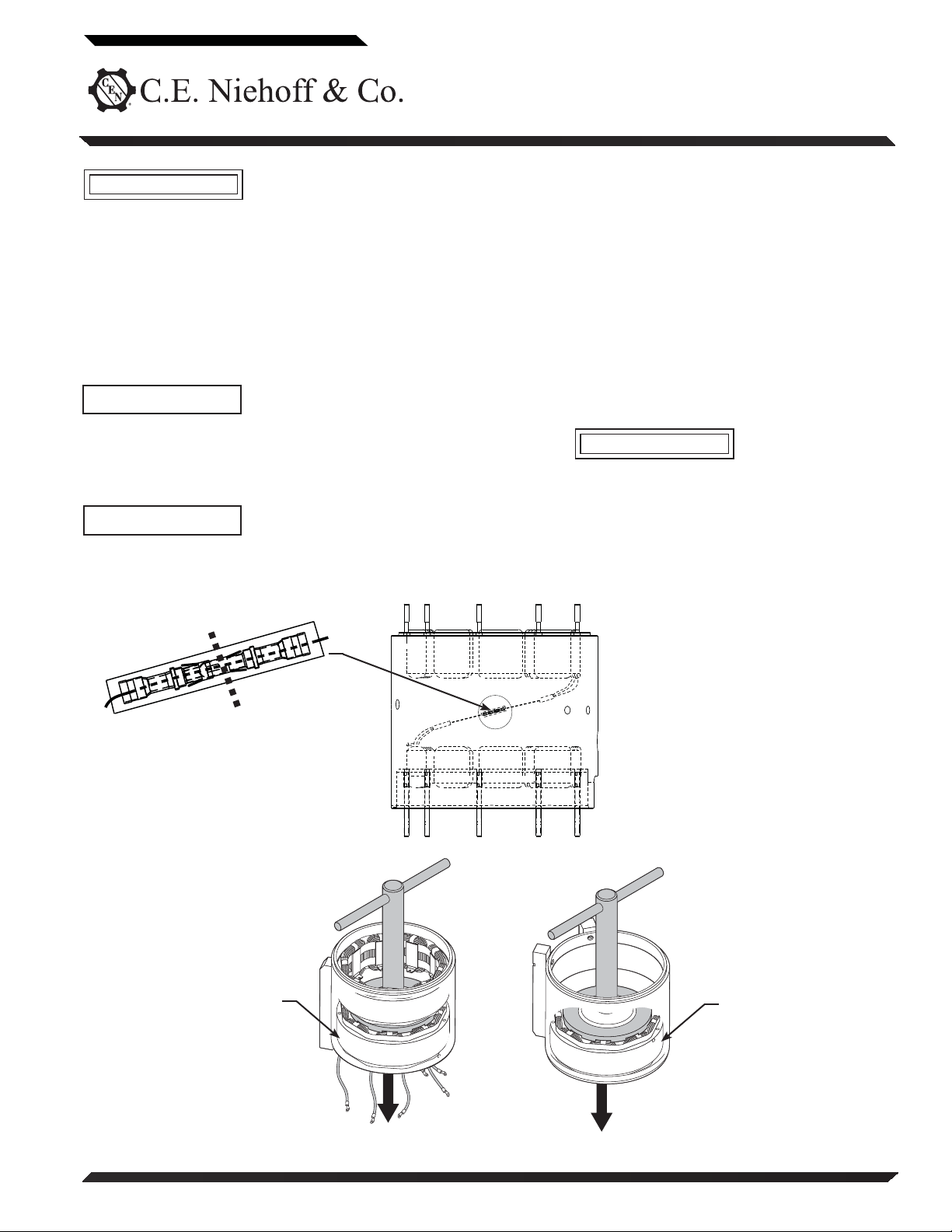

14. Remove ADE and DE Stators

(See Figure E-7)

a. Ensure scribe marks are visible on DE and

ADE edges of shell where tabs are missing

on DE and ADE stators.

b. Remove long nuts securing through-studs.

Remove through-studs.

c. Cut the middle of interconnect splice holding Y

leads to separate the stator connections.

d. Arrange CEN A10–132 field coil/stator tool.

e. Press DE stator out of shell.

Do not damage phase

leads when removing

stators from shell.

f. If replacing ADE stator, rearrange tool and

press ADE stator from shell.

CAUTION

II202A

Interconnect splice

First press out

DE stator

from shell

Then press out

ADE stator

from shell

Figure E–7 Removing Stators

Page 1 of 4

Page 2

Section F in CEN 600 Series Service Manual

SM6:

If replacing ADE stator or both

NOTICE

stators, start with step 2a.

If replacing DE stator only, start

with step 2d.

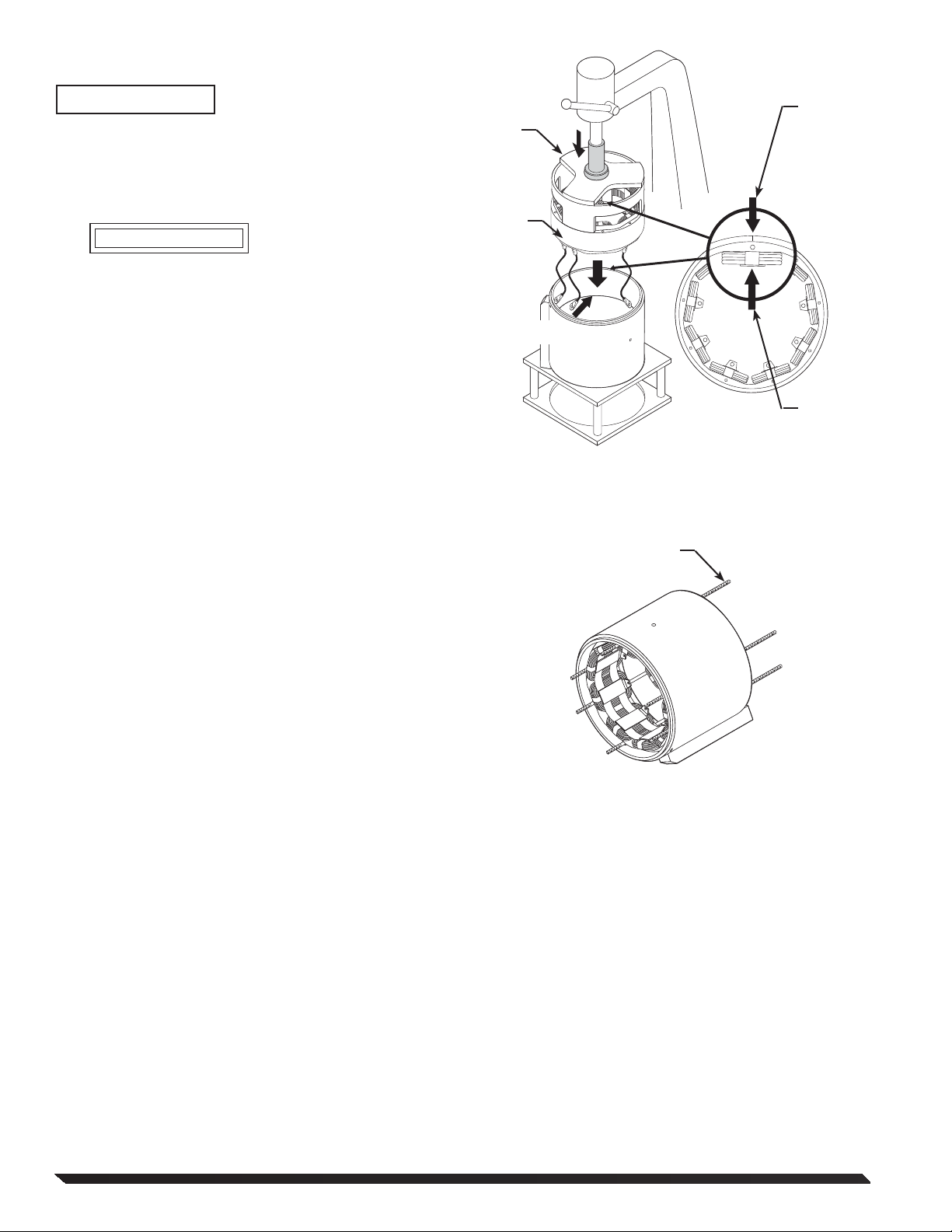

2. Install new ADE Stator or both new ADE/

DE Stators

CAUTION

when inserting stators in shell.

a. Set new ADE stator (longer phase leads face

down) on ADE edge of shell. Align scribe mark

on shell where tab is missing on ADE stator.

Arrange CEN A10–136 stator insertion tool on

stator. See Figure F–1a.

b. Press new ADE stator into position using a

spray lubricant if necessary. Make sure the

stator stops on the ledge inside the shell.

See Figure F–1a.

c. From the anti-drive end, insert 6 insertion

studs provided with CEN A10-136 stator inser tion tool into new ADE stator. See Figure F–1b.

Do not damage phase leads

A10–136

stator

insertion

tool

ADE stator

Ledge inside shell

Original

scribe

mark

on shell

Missing

tab on

ADE stator

Figure F–1a ADE Stator Assembly

Stator

insertion

studs (6)

Page 2 of 4

Figure F–1b Stator Insertion Studs

II202A

Page 3

d. Turn shell so drive end is up. To properly

position DE stator inside shell (see Figure F–1c):

1) Coil longer ADE stator leads inside ADE stator.

2) Align scribe mark on shell with missing tab

on DE stator. Align 6 insertion studs with

holes in DE stator.

3) Arrange CEN A10–136 stator insertion tool

on DE stator.

e. Press DE stator i n place. Insertion studs shou ld

enter holes in DE stator. Make sure DE stator

stops on ledge inside shell. See Figure F–1c.

Remove 6 insertion studs.

Do not use insertion

studs in place of through studs in fi nal assembly.

f. On DE stator, remove stator wedges from open-

ings where A DE stator leads and field coil lead s

will pass between DE stator windings. See Fig ure F–1c for locations of DE stator phase leads

and ADE stator phase leads as arranged in

stator windings.

g. Insert ADE stator phase leads between openings

in DE stator.

Do not damage phase

leads when threading

leads through openings.

h. Insert through-studs from anti-drive end.

See Figure F–1d.

i. Use locknuts to secure through-studs on drive

end of shell. See Figure F–1d. Hex flat on screw head must be parallel to winding. Use a suitable

adhesive such as Loctite

Follow manufacturer’s instructions. Torque nuts

on drive end to 4.5 Nm/40 lb. in.

CAUTION

CAUTION

®

222 on threads.

Scribe mark on DE of shell

Scribe mark on

ADE of shell

Phase Lead and Field Coil Lead Orientation—C621

A10–136

stator

insertion

tool

DE stator

Insertion

studs (6)–

not for fi nal

assembly

Ledge inside shell

II202A

Figure F–1c DE Stator Assembly

Long nuts

Through-stud

Figure F–1d Through-stud Assembly

Page 3 of 4

Page 4

j. Reconnect stators with interconnect splice:

1) Slide new sleeve over end of DE or ADE lead.

2) Crimp new connector socket on the DE

stator Y lead. Crimp new connector pin on

the ADE stator Y lead. Securely mate the

connectors.

3) Apply hi-temp solder over mated connection.

4) Completely cover mated connection with

Dow Corning

equivalent—wait until coating has hardened

to ensure waterproofness.

5) Position new sleeve over sealed connection.

6) Position spliced Y leads against wall of shell

so that field coil can fit into space between

stators wit hout damagi ng interconnect splice

or Y leads.

®

SE 9186L RTV coating or

Return to CEN 600 Series Service Manual SM6

to fi nish C621 alternator assembly

Connector

socket

Sleeve

Connector pin

Interconnect

splice

Figure F–1e Interconnect Splice Assembly

If you have questions about your a lternator or any of these instruct ions, or if you need to locate a Factory Authorized Service Dealer, please contact us at:

C. E. Niehoff & Co.• 2021 Lee Street • Evanston, IL 60202 USA

Page 4 of 4

TEL: 800.643.4633 USA and Canada • TEL: 847.866.6030 outside USA and Canada • FAX: 847.492.1242

E-mail us at service@CENiehoff.com

II202A

Loading...

Loading...