Page 1

A9-169 Bearing Upgrade Kit

C. E. Niehoff & Co.

BRUSHLESS ALTERNATORS

CAUTION

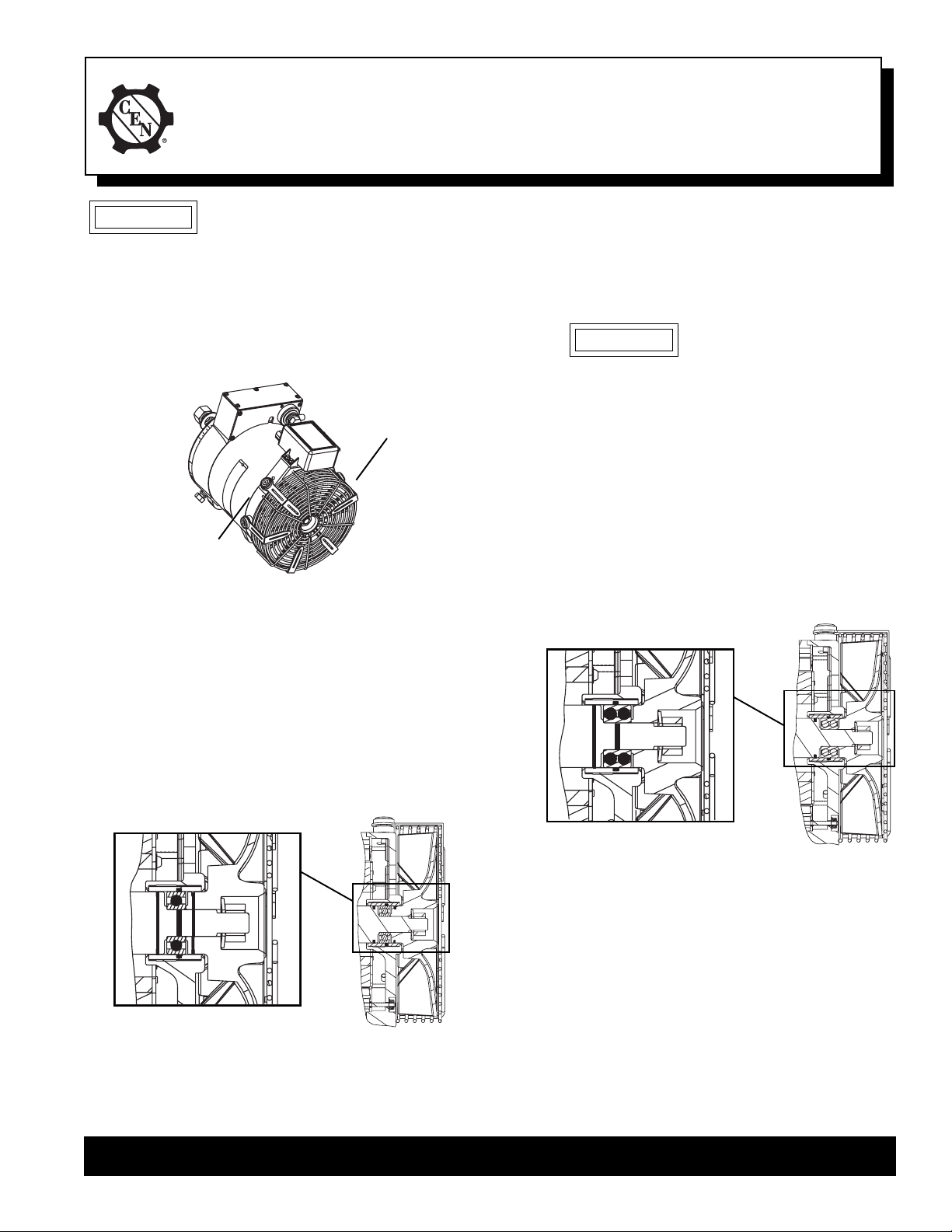

1. Remove the following anti-drive end parts from

the alternator:

a. Fan guard screws, grommets/grommet inserts,

and fan guard.

b. Fan nut, fan washer and fan - save fan washer

for reassembly. Discard fan and fan nut.

2. Remove anti-drive end housing:

a. Scribe marks across ADE housing and shell

to ensure proper position when alternator is

reassembled.

b. Remove ADE locknuts and housing (discard

locknuts).

c. Remove and discard O-ring from bearing bore.

3. Remove and discard anti-drive end bearing from

shaft using a bearing puller.

4. Remove and discard spiral ring seal from groove

in shaft.

This symbol is used to indicate

presence of hazards that can cause

minor property damage.

Fan guard

(fan below)

G

G

ADE

housing

Figure 1 - C612 Alternator

for C612 Alternator

Installation Instructions

6. Re-install anti-drive end housing:

a. Install new O-ring in bearing bore of anti-drive

end housing. Lubricate with Klüber Asonic

HQ72-102 or equivalent.

b. Align scribe marks on shell and anti-drive

end, then lower ADE housing in position.

CAUTION

c. Secure anti-drive end housing with new

locknuts. Use a suitable adhesive such as

Loctite®2 222 on studs and nuts. Follow adhesive manufacturers instructions. Torque

screws to 5.1 Nm/45 lb. in.

7. Support drive end of shaft with ADE housing

facing up. Install new double-wide bearing in

position by pressing on inner race of bearing,

using suitable tool (such as CEN part no. A10-

102).

There will be a slight resistance as spiral ring seal

enters bearing bore. Do not

force housing on shaft. Spiral

ring seal can be damaged by

too much pressure.

®

Figure 3 - C612 Assembly with New-style Bearing

8. Install fan and fan guard:

a. Install new fan on shaft. Fasten with fan

washer and new fan nut. Torque nut to

67.8 Nm/50 lb. ft.

b. Install fan guard. Fasten with new grommets/

Figure 2 - C612 Assembly with Old-style Bearing

5. Wind new spiral ring seal in groove on shaft

closest to rotor. Lubricate with Klüber Asonic

HQ72-102 or equivalent.

®1

grommet inserts and screws. Use a suitable

adhesive such as Loctite

Follow adhesive manufacturers instructions.

Torque screws to 1.1 Nm/10 lb. in.

1

Loctite is a registered trademark of Loctite Corporation.

2

Asonic is a registered trademark of Klüber Lubrication.

®

222 on screws.

C. E. Niehoff & Co. • 2021 Lee Street • Evanston, IL 60202 Tech Services Hotline 800-643-4633

II0023APage 1 of 1

Loading...

Loading...