Page 1

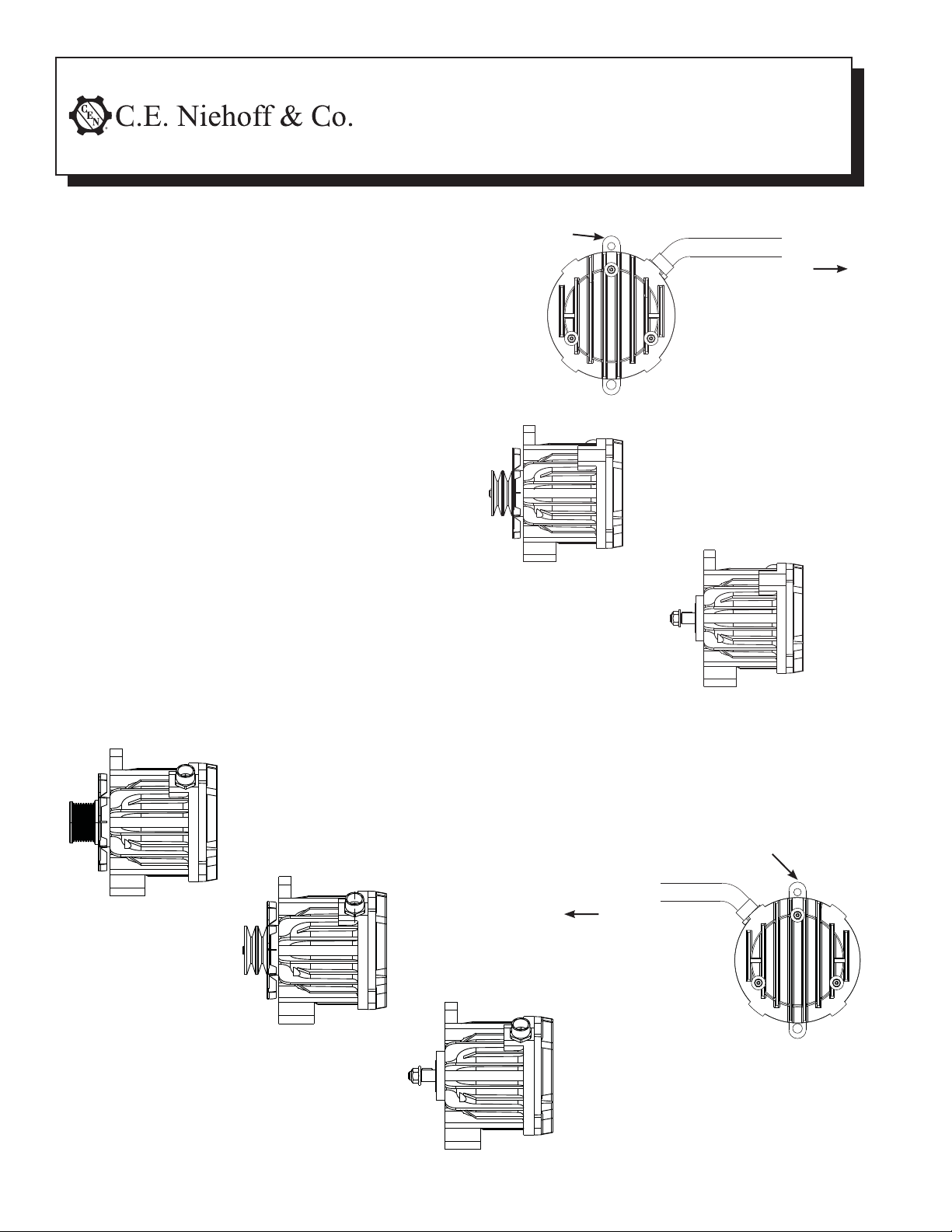

1. Install alternator with cover oriented in a position

that allows best vertical air flow through fins on

anti-drive end. See Figure 1 and 2:

a. C180-1, C180-2, and C181-1 units are shipped

with pulley/fan, f lat washer, and nut installed.

b. C180 and C181 units are shipped with shaft

collar, flat washer, and nut. Remove and

discard shaft collar. Install pulley/fan and

furnished flat washer. Torque furnished nut to

68 Nm/50 lb. ft.

c. Use Grade 5 flange bolt and locking type flange

nuts to mount alternator. Self-locking type

screw is required to clamp up belt adjusting

bracket. Tighten the adjusting bracket before

tightening alternator mounting bolts. Torque

12mm x 1.75 mounting bolts to 50 Nm/ 37 lb. ft.

d. Follow vehicle manufacturer’s recommenda-

tions for belt tension.

2. Connect alternator and rectifier/regulator:

• C180-1—see page 2

• C180-2—see page 3

• C181-1—see page 4

• C180 and C181 alternators are replacements for

their corresponding dashed numbered alterna tors. Follow appropriate instructions listed above.

C180-1 Alternator w/ A8-206 Rectifi er-Regulator

C180-2 Alternator w/ A8-207 Rectifi er-Regulator

C181-1 Alternator w/ A8-208 Rectifi er-Regulator

C180/C181 Alternators

Installation Instructions

Mounting lugs (2)

To rectifier-regulator

C181-1

C181

C180-2

Figure 1 - C181-1/C181 Alternator Details

Mounting lugs (2)

To rectifier-regulator

C180-1

C180

Page 1 of 4

Figure 2 - C180-2/C180-1/C180 Alternator Details

II162A

Page 2

C180-1 Alternator

w/ A8-206 Rectifi er-Regulator

1. Install rectifier-regulator assembly in location

determined by customer, using hardware and

torque specified by customer.

2. Remove shipping spacers from both sides of

rectifier-regulator.

3. Connect rectifier-regulator to alternator

with wiring conduit shown in

Figure 3 and 4.

4. Output conduit supplied by customer

connects rectifier-regulator with

customer circuit and consists of

B+ and B– output leads plus

R terminal lead if used.

5. R circuit current: 3 A max

Square wave signal: 0-30 V

Alternator speed formula: RPM=f(Hz)•10

6. Alternator is configured for selfenergization. Regulator brown wire

is connected to R circuit. If external

energize is required, remove brown

wire between R terminal and module

terminal A. Connect energize signal,

which must open when alternator shaft

is not rotating.

7. Series connected isolation diode in the B+ circuit is

not permissible.

8. When wiring inside rectifier-regulator cover is

complete, re-install cover and torque hardware

to 5.4 Nm/48 lb. in.

See step 2.

M25 x 1.25 pipe thread

for connecting output

conduit assembly

To alternator

Figure 3 - A8-206 Rectifier-Regulator Cover Connections

Page 2 of 4

Figure 4 - C180-1/A8-206 Component Interconnect Diagram

II162A

Page 3

C180-2 Alternator

w/ A8-207 Rectifi er-Regulator

1. Install rectifier-regulator assembly in location

determined by customer, using hardware and

torque specified by customer.

2. Remove shipping spacers from both sides of

rectifier-regulator.

3. Connect rectifier-regulator to alternator

with wiring conduit shown in

Figure 5 and 6.

4. Output conduit supplied by customer

connects rectifier-regulator with

customer circuit and consists of

B+ and B– output leads plus

R and D+ terminal leads if used.

5. R circuit current: 3 A max

Square wave signal: 0-30 V

Alternator speed formula: RPM=f(Hz)•10

6. Alternator is configured for selfenergization.

7. D+ terminal is the charge warning

lamp (CWL) connection.

8. Series connected isolation diode in the

B+ circuit is not permissible.

9. When wiring inside rectifier-regulator cover is

complete, re-install cover and torque hardware

to 5.4 Nm/48 lb. in.

See step 2. M25 x 1.25 pipe thread for

connecting output conduit assembly

To alternator

Figure 5 - A8-207 Rectifier-Regulator Cover Connections

Page 3 of 4

Figure 6 - C180-2/A2-207 Component Interconnection Diagram

II162A

Page 4

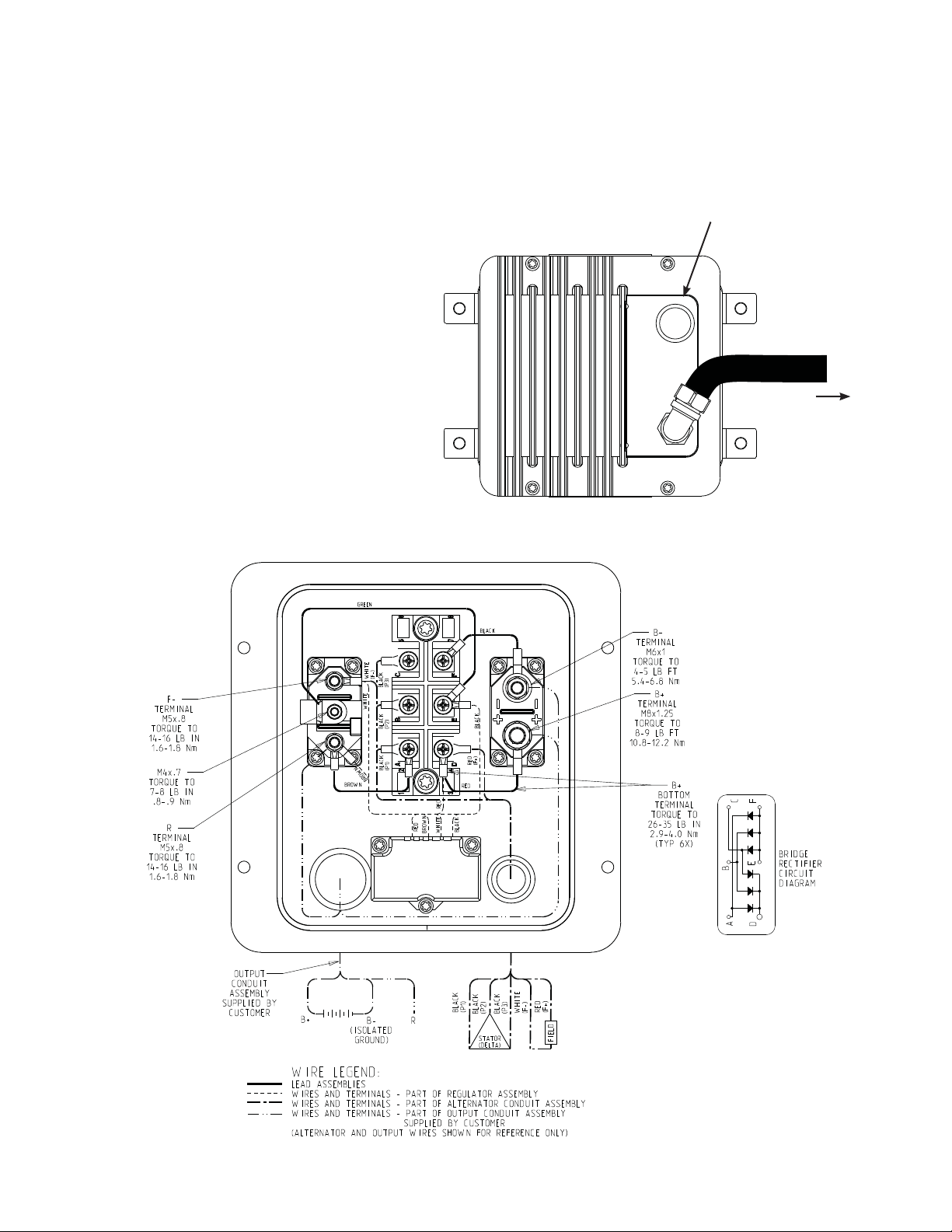

C181-1 Alternator

w/ A8-208 Rectifi er-Regulator

1. Install rectifier-regulator assembly in location

determined by customer, using hardware and

torque specified by customer.

2. Remove shipping spacers from both sides of

rectifier-regulator.

3. Connect rectifier-regulator to alternator

with wiring conduit shown in

Figure 7 and 8.

4. Output conduit supplied by customer

connects rectifier-regulator with

customer circuit and consists of

B+ and B– output leads plus

R and D+ terminal leads if used.

5. R circuit current: 3 A max

Square wave signal: 0-30 V

Alternator speed formula: RPM=f(Hz)•10

6. Alternator is configured for selfenergization.

7. D+ terminal is the charge warning

lamp (CWL) connection.

8. Series connected isolation diode in the

B+ circuit is not permissible.

9. When wiring inside rectifier-regulator cover is

complete, re-install cover and torque hardware

to 5.4 Nm/48 lb. in.

See step 2. M25 x 1.25 pipe thread for

connecting output conduit assembly

To alternator

Figure 7 - A8-208 Rectifier-Regulator Cover Connections

Figure 8 - C181-1/A2-208 Component Interconnection Diagram

C. E. Niehoff & Co. • 2021 Lee Street • Evanston, IL 60202 Tech Services Hotline 800-643-4633

Page 4 of 4

II162A

Loading...

Loading...