Page 1

C.E. Niehoff & Co.

See Pages 2, 3, and 4 for Technical Specifi cations

This symbol is used to indicate presence

WARNING

of hazards that can cause severe

personal injury, death or substantial

property damage.

This symbol is used to indicate presence

CAUTION

of hazards that can cause minor

personal injury or property damage.

This alternator contains no serviceable

WARNING

parts except pulley, fan, and regulator.

Manufacturer’s hazardous location

certification is void if repaired except for

the pulley, fan, and regulator which may

be replaced with factory parts.

Explosion hazard—substitution of compo-

WARNING

nents may impair suitability for Class I,

Division 2.

Risque d’explosion—la substitution de

ADVERTISSEMENT

composants peut rendre ce matériel

inacceptable pour les emplacements

de Classe I, Division 2.

Explosion hazard—do not replace any

WARNING

component unless power has been

switched off or the area is known to be

non-hazardous.

Risque d’explosion—couper le courant

ADVERTISSEMENT

ou s’assurer que l’emplacement est

désigné non dangereux avant de

replacer le composants.

Explosion hazard—do not disconnect

WARNING

equipment unless power has been

switched off or area is known to be

non-hazardous.

Risque d’explosion—avant de décon-

ADVERTISSEMENT

necter l’equipement, couper le courant

ou s’assurer que l’emplacement est

désigné non dangereux.

Installation Instructions

Improper installation of alternator in an

WARNING

explosive environment can cause severe

personal injury, death, or substantial

property damage. Alternator must be

installed by a qualified person trained in

the installation of alternators in explosive

atmospheres. For CSA and UL classifica tions and atmospheric conditions, see

page 2 of these instructions.

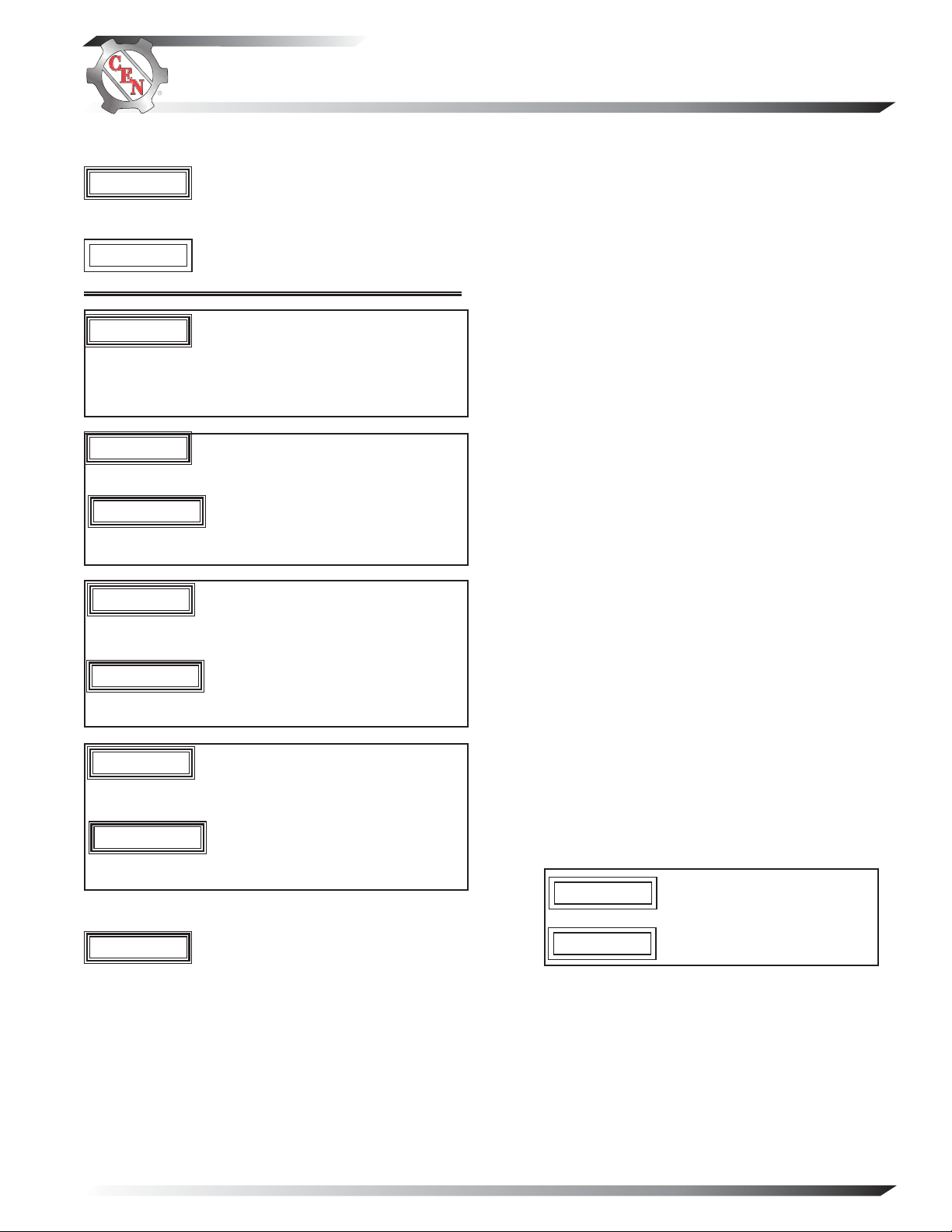

1. Mount alternator on a suitable bracket and

secure with hardware per alternator drawing

on page 2 of these instructions.

© 2014, C. E. Niehoff & Co. All rights reserved.

SM40A

C130, C131, and C132 Alternators

Combo Guide

2. Remove anti-drive end (ADE) cover from the

alternator.

3. One of the following two alternator circuits

described below is required to operate alternator.

a. If alternator is to be self-energized, be sure

the link is connected between B+ stud and

IGN terminal (as shipped). This alternator

relies on residual magnetism to operate.

Observe all applicable safety procedures when

performing the following operation: If neces sary, restore lost magnetism by connecting

test light between B+ stud and R terminal for

1-3 seconds while alternator shaft IS NOT

TUR NING and battery is connected to illumi nate test light. Check for magnetic field at

pulley. If magnetized, remove test light, start

alternator, and test.

b. If the alternator is to be energized through

ignition key, connect energizing signal lead

directly to IGN terminal and remove link

between B+ stud and IGN terminal. Torque

IGN terminal bolt to 2 Nm/18 lb. in. This

alternator relies on residual magnetism to

operate. Ensure battery voltage is present at

IGN terminal. Observe all applicable safety

procedures when performing the following

operation: If necessary, restore lost magnetism

by connecting test light between B+ stud and

R terminal for 1-3 seconds while alternator

shaft IS NOT TURNING and battery is con nected to illuminate test light. Check for

magnetic field at pulley. If magnetized, remove

test light, start alternator, and test.

4. Connect B+ cable to B+ stud on alternator. See

wire chart on page 3 for correct cable size and

length. Torque terminal nut to 9 Nm/80 lb. in.

5. Connect R lead to R terminal on alternator if required for vehicle operation (optional connection).

Torque R terminal bolt to 2 Nm/18 lb. in.

6. Connect B– cable to B– terminal stud on alternator (B– is an isolated ground). B– cable gauge

should be same as gauge of battery positive

cable. Torque terminal nut to 9 Nm/80 lb. in.

Supply wires suitable for rated

Utiliser des câbles d’alimentation

7. Perform a final inspection on the installation.

8. Re-install anti-drive end cover on alternator. Posi-

9. Install suitable alternator drive belt.

10. Start engine. Confirm operation of charging

CAUTION

load at 90°C ambient shall not

exceed 200°C.

ATTENTION

appropriée pour 200ºC.

tion louvers consistent with deflection of rain or

fluids during normal operating conditions. Fasten

with screws and washers in four places. Use a

suitable adhesive such as Loctite® 222. Follow

manufacturer’s instructions. Torque screws to 3.4

Nm/30 lb. in.

system meets specification.

Page 1

Page 2

Installation Instructions (CONT’D)

Page 2

SM40A

Page 3

Installation Instructions (CONT’D)

(OPTIONAL)

on page 1

on page 1

Step 6 on page 1

SM40A

Page 3

Page 4

Installation Instructions (CONT’D)

0

10

20

30

40

50

60

70

0 1000 2000 3000 4000 5000 6000 7000 8000

RPM

OUTPUT/ A

0

1

2

3

4

5

6

7

TORQUE/Nm

OUTPUT/ A TORQ UE/ Nm

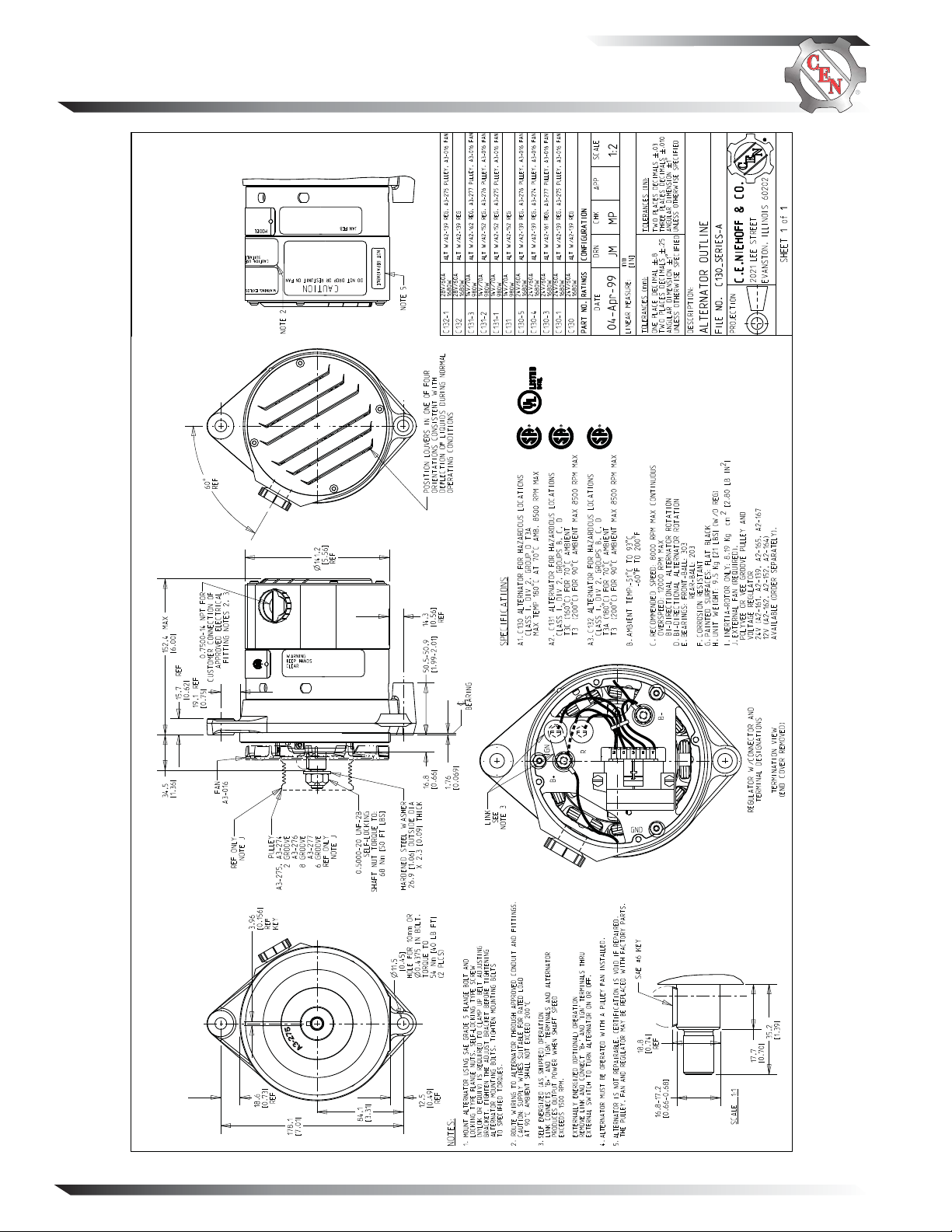

ALTERNATOR CHARACTERISTICS FOR 28 VOLTS/ 60 AMPS:

APPLICABLE MODELS: C130, C132

OUTPUT CURVE: OUTPUT AMPERES VERSUS ALTER NATOR SHAFT SPEED IN RPM AT 28.0 VOLTS.

TORQUE CURVE: DRIVE TORQUE IN Nm VERSUS ALTERNATOR SHAFT SPEED IN RPM REQUIRED TO

PRODUCE OUTPUT CURVE.

ALL MEASUREMENTS DEPICTED ON PERFORMANCE CURVES ARE TAKEN AT 22ºC/72ºF AMBIENT

TEMPERATURE (UNLESS OTHERWISE SPECIFIED) AND A STABILIZED MACHINE TEMPERATURE

AT MA XIMUM OUTPUT WITH VOLTAGE CONSTANT AS SPECIFIED.

ABBREVIATIONS:

RPM REVOLUTIONS PER MINUTE

Nm NEWTON-METER

Conversion: 1 Nm = 8.85 Pound Inch (LBIN)

Page 4

SM40A

Page 5

Installation Instructions (CONT’D)

ALTERNATOR CHARACTERISTICS FOR 14 VOLTS/ 70 AMP:

APPLICABLE MODELS: C131

OUTPUT CURVE: OUTPUT AMPERES VERSUS ALTERNATOR SHAFT SPEED IN RPM AT 13.8

VOLTS.

TORQUE CURVE: DRIVE TORQUE IN Nm VERSUS ALTERNATOR SHAFT SPEED IN RPM

REQUIRED TO PRODUCE OUTPUT CURVE.

SM40A

ALL MEASURMENTS DEPICTED ON PERFORMANCE CURVES ARE TAKEN AT 104°F (40°C)

AMBIENT TEMPERATURE (UNLESS OTHERWISE SPECIFIED) AND A STABILIZED MACHINE

TEMPERATURE AT MAXIMUM OUTPUT WITH VOLTAGE CONSTANT AS SPECIFIED.

ABBREVATIONS:

RPM REVOLUTIONS PER MINUTE

Nm NEWTON-METER

Conversion: 1 Nm = 8.85 Pound Inch (LBIN)

Page 5

Page 6

Parts Replacement Instructions

Pulley Replacement

Remove existing pulley (see Figure 1):

1. Remove pulley nut and washer.

2. Remove and discard pulley.

Install new pulley (see Figure 1):

1. Install new pulley and fasten with pulley nut and

washer.

2. Keep pulley, fan, and shaft from spinning while

torquing pulley nut to 68 Nm/50 lb. ft.

Drive End (DE) Fan Replacement

Remove existing DE fan (see Figure 1):

1. Remove pulley nut and washer.

2. Remove pulley.

3. Remove woodruff key and discard fan.

Install new DE fan (see Figure 1):

1. Place new fan on shaft.

2. Install woodruff key.

3. Install pulley and fasten with pulley nut and washer.

4. Keep pulley, fan, and shaft from spinning while

torquing pulley nut to 68 Nm/50 lb. ft.

Anti-drive End (ADE) Cover Replacement

Remove ADE Cover on Alternator (see Figure 1):

1. Remove hardware and discard ADE cover plate.

Install New ADE Cover on Alternator (see Figure

1):

1. Install new ADE cover plate. Position louvers consistent with def lection of rain or fluids during normal

operating conditions.

2. Fasten in four places with screws and washers. Use a

suitable adhesive such as Loctite® 222. Follow manufacturer’s instructions. Torque screws to 3.4 Nm/30

lb. in.

Fan

Woodruff

Key

Alternator

Pulley

Regulator

F

E

ADE Cover

Page 6

Figure 1 – Parts Replacement

SM40A

Page 7

Parts Replacement Instructions (CONT’D)

Anti-drive End (ADE) Regulator

Replacement

Remove ADE Regulator on Alternator (see Figures 1

and 2):

1. Remove hardware and ADE cover plate.

2. Remove and discard hardware attaching regulator

to plate.

3. Unplug alternator-to-regulator harness from

regulator.

4. Discard regulator.

Regulator

Install New ADE Cover on Alternator (see Figures 1

and 2):

1. Plug alternator-to-regulator harness securely into new

regulator.

2. Install new regulator on plate using new screws from

kit. Use a suitable adhesive such as Loctite® 222.

Follow manufacturer’s instructions. Torque screws to

2.8 Nm/25 lb. in.

3. Re-install ADE cover plate. Position louvers consis-

tent with def lection of rain or fluids during normal

operating conditions.

4. Fasten in four places with screws and washers. Use a

suitable adhesive such as Loctite® 222. Follow manufacturer’s instructions. Torque screws to 3.4 Nm/

30 lb. in.

Alternator-to-regulator harness plug

SM40A

E

D

C

B

A

Figure 2 –Regulator Replacement

Page 7

Page 8

Troubleshooting

Tools and Equipment for Bench Testing

• Testing Electrical Components, page 12.

• Digital Multimeter (DMM)

• Ammeter (digital, inductive)

• Test bench with 5–10 hp motor able to drive

alternator to 8000 rpm. Mount alternator per test

bench manufacturer’s instructions. Make sure test

bench batteries are charged at 95% or higher.

Bench Tests

• Voltage at regulator setpoint ±0.2 V is considered

“normal.”

• Alternator rated output (listed on nameplate) ±10%

is determined at 5000 rpm at 72ºF.

• Run alternator for 15 minutes to stabilize readings.

• Alternator/regulator should be connected to test

bench per schematic diagram on page 3.

test bench, make sure batteries

CAUTION

are connected per schematic

diagram on page 3.

Alternator/regulator will not

BENCH TEST 1: NO-LOAD TEST

With battery connected and nominal electrical load

set as shown in Table 1, run alternator at 2000-2500

rpm shaft speed.

• If alternator passes No-Load Test, go to Full Load

• If alternator fails No-Load Test, go to Static Tests.

BENCH TEST 2: FULL LOAD TEST

With battery connected and electrical load set as

shown in Table 2, run alternator at 5000-8000 rpm

shaft speed.

• If alternator passes Full Load Test, alternator is

• If alternator fails Full Load Test, go to Static Tests.

NOTICE

function without being properly

connected to power source.

Test.

TAB LE 1 No-Load Test

ALT. AMPS VOLTS

C130

C132

C131 5 - 40 14±0.2

functioning properly.

TABLE 2 Full Load Test

ALT. AMPS VOLTS

C130

C132

C131 70 14±0.2

When connecting alternator to

28V

5-40 28±0.2

28V

60 28±0.2

Alternators should not be powered

WARNING

during static tests. Connections

required during testing can cause

shorts and damage alternator.

Static tests should confi rm

NOTICE

on-vehicle and on-bench tests.

Tools and Equipment for Static Testing

• Testing Electrical Components, page 12.

• Digital Multimeter (DMM)

• Ammeter (digital, inductive)

• Regulator tester

Regulator Test

• Regulator tester tests all regulator functions.

• If regulator tester is used, follow regulator tester

manufacturer’s instructions.

• If regulator tester is not available, regulator can

only be tested for a shorted field-switching transistor. Follow Regulator Test below.

REGULATOR TEST: CHECK FOR SHORTED FIELDSWITCHING TRANSISTOR

1. Set DMM to diode test scale.

2. See Figure 3. Connect one meter lead to pin C in

regulator receptacle and connect other lead to

pin A in regulator receptacle. Observe meter reading. Reverse leads and observe meter reading. If

DMM reads zero in either direction, field-switching

transistor is shorted. Replace regulator. If regulator

failure is indicated, field coil failure must also be

suspected.

CONNECTIONS

A B–

B IGN

C F–

D Phase (R)

E B+

Figure 3 Regulator Harness Connections

Regulator Receptacle

Alternator-to-Regulator

Harness Plug

Page 8

SM40A

Page 9

Troubleshooting (CONT’D)

Internal Circuit Tests

• Internal Circuit Tests will show the condition of

internal circuits through the alternator via alternatorto-regulator harness.

• Some disassembly will be necessary to access the

components. Do not disassemble the alternator

beyond what the tests require.

• Before performing Internal Circuit Tests, check for

visible signs of damaged components.

• The expected reading/result listed for each test must

be obtained. Replace any component that fails the test.

TABLE 3 Pin-to-Pin Tests (See Figure 4)

TEST

NO.

1

2*

3

4

5

6

7

8

9

10

11

12

13

* Applies only when f ield coil is att ached to rectifier/housing assembly.

METER SCALE

& SYMBOL

Ohms Ω

Ohms Ω

Ohms Ω

Ohms Ω

Ohms Ω

Ohms Ω

Diode Test

Diode Test

Diode Test

Diode Test

Ohms Ω

Ohms Ω

Diode Test

Diode Test

Ohms Ω

METER (+) LEAD

CONNECTION

Socket A

Socket E

Socket E

Socket E

Socket C

Socket C

Socket D

Alt. B+ Terminal

Socket D

Alt. B– Terminal

Socket E

Socket A

Alt. B+ Terminal

Alt. B– Terminal

R Terminal

Failure to perform the complete

series of Internal Circuit Tests can

result in improper diagnosis of

alternator condition.

METER (–) LEAD

CONNECTION

Alternator Case

Socket C

Alt. B– Terminal

Alternator Case

Alt. B– Terminal

Alternator Case

Alt. B+ Terminal

Socket D

Alt. B– Terminal

Socket D

Alt. B+ Terminal

Alt. B– Terminal

Alt. B– Terminal

Alt. B+ Terminal

Alternator Case

NOTICE

CAUTION

TESTED CIRCUIT

Isolated ground

Field coil resistance

Field coil insulation

Field coil insulation

Field coil insulation

Field coil insulation

Phase winding and diode

Phase winding and diode

Phase winding and diode

Phase winding and diode

Regulator power circuit

Regulator ground circuit

All diodes in parallel

All diodes in parallel

Stator insulation

Service technicians should

understand and follow all

information in the service manual

when servicing the product.

EXPECTED

READING

OL (infinity)

4.8±0.2 ohms

OL (infinity)

OL (infinity)

OL (infinity)

OL (infinity)

<0.7 volts (flow)

OL (blocking)

OL (blocking)

<0.7 volts (flow)

0 ohms

0 ohms

OL (blocking)

<0.8 volts (flow)

OL (infinity)

CONNECTIONS

A B–

B IGN

C F–

D Phase (R)

E B+

Alternator-to-Regulator Harness Connector

SM40A

Figure 4 Alternator Connections

B+

IGN

R

DE

C

AB

B−

Page 9

Page 10

Exploded Parts View

Pulley

C130/C131/C132 Parts View

Fan

C130/C131/C132

Woodruff

Key

Page 10

Regulator

F

E

Alternator

ADE Cover

Contact CEN Service Dealer, CEN Warehouse Dealer, or CEN Service Department for current exploded view and par ts list

SM40A

Page 11

ALTERNATOR

MODEL

C130/C130-1/

C130-4/C13 0 - 5

VOLTS

24

AMPS

60

WATTS

1680

C130/C131/C132

Model

A2-139

Steps

N/A

Specifi cations and Data

REGULATOR

Settings

28.0

Temp. Comp.(4)

Flat

10.17/22.4

ALT.

WEIGHT

kg/lb

C130-3

C131/C131-1/

C131-2

C131-3

C132 /C132 -1

1. Measurements are taken at the listed ambient

temperature and a stabilized machine temperature at maximum output with voltage constant

as specified.

2. The alternator has an isolated ground.

3. Temperature compensation—see definition below.

Flat temperature compensation: Regulator controls

voltage range in a near-constant state during the

vehicle operating conditions. CEN flat-temperature

compensated regulators have preset voltage setpoints.

24

14

14

28

NOTES

60

70

70

60

1680

980

980

1680

A2-161

A2-152

A2-162

A2-139

N/A

N/A

N/A

N/A

27.6

14. 2

13.8

28.0

Flat

Flat

Flat

Flat

10.17/22.4

10.17/22.4

10.17/22.4

10.17/22.4

Setpoint: Voltage value to which regulator is set.

Voltage value is established by battery type and

vehicle duty cycle. Setpoint value is fixed (flat compensation).

SM40A

Page 11

Page 12

Testing Electrical Components

Testing Guidelines

Professional service technicians rely on these

guidelines when testing electrical components.

Voltage testin g:

• Set meter to proper scale and type (AC or DC).

• Be sure to zero the meter scale or identify the

meter burden by touching meter leads together.

Meter burden must be subtracted from final

reading obtained.

• Be sure the meter leads touch source area only.

Prevent short circuit damage to test leads or

source by not allowing meter leads to touch other

pins or exposed wires in test area.

Resistance (ohm) testing:

• Set meter to proper scale.

• Be sure to zero the meter scale or identify the

meter burden by touching meter leads together.

Meter burden must be subtracted from final

reading obtained.

• Be sure the meter leads touch source area only.

Prevent altering the reading by not allowing fingers

or body parts to touch meter leads or source

during reading.

• Be sure reading is taken when source is at 70ºF.

Readings taken at higher temperatures will

increase the reading. Conversely, readings taken at

lower temperatures will decrease the reading.

• Be sure to test directly at the source, testing

through extended harnesses or cable extensions

may increase the reading.

Voltage drop testing:

• Measure voltage between B+ on alternator or

source and B- (ground) on alternator or source.

Record obtained reading. Move to batteries or

other source and measure again between B+ and

B- terminals on battery or other source. Difference

between the two readings represents voltage lost

within the circuit due to but not limited to inade quate cable gage or faulty connections.

• Voltage drop measurements must be taken with

all electrical loads or source operating.

Dynamic/Live testing:

• Definition: Connecting power and ground to a

component to test operation/function out of circuit.

• Be sure to directly and securely jumper leads to

source terminals of the component being tested.

• Be sure to touch the contact end of jumper leads

only to the power supply or battery terminals.

Touching a contact end to component terminals

may create an arc and damage component terminals.

If you have quest ions about your a lternator or a ny of these test procedures, or i f you need to locate a Factory Authorized Ser vice Dealer, please contact us at:

C.E. Niehoff & Co.

2021 Lee Street • Evanston, IL 60202 USA

TEL: 800.643.4633 USA and Canada •

TEL: 847.866.6030 outside USA and Canada •

E-mail us:

Visit our Web site:

Page 12

FAX: 847.492.1242 •

service@ CENiehoff.com

www.CENiehoff.com

SM40A

Loading...

Loading...