Page 1

INSTALLATION

C102/C102-1 Alternators

Installation Instructions

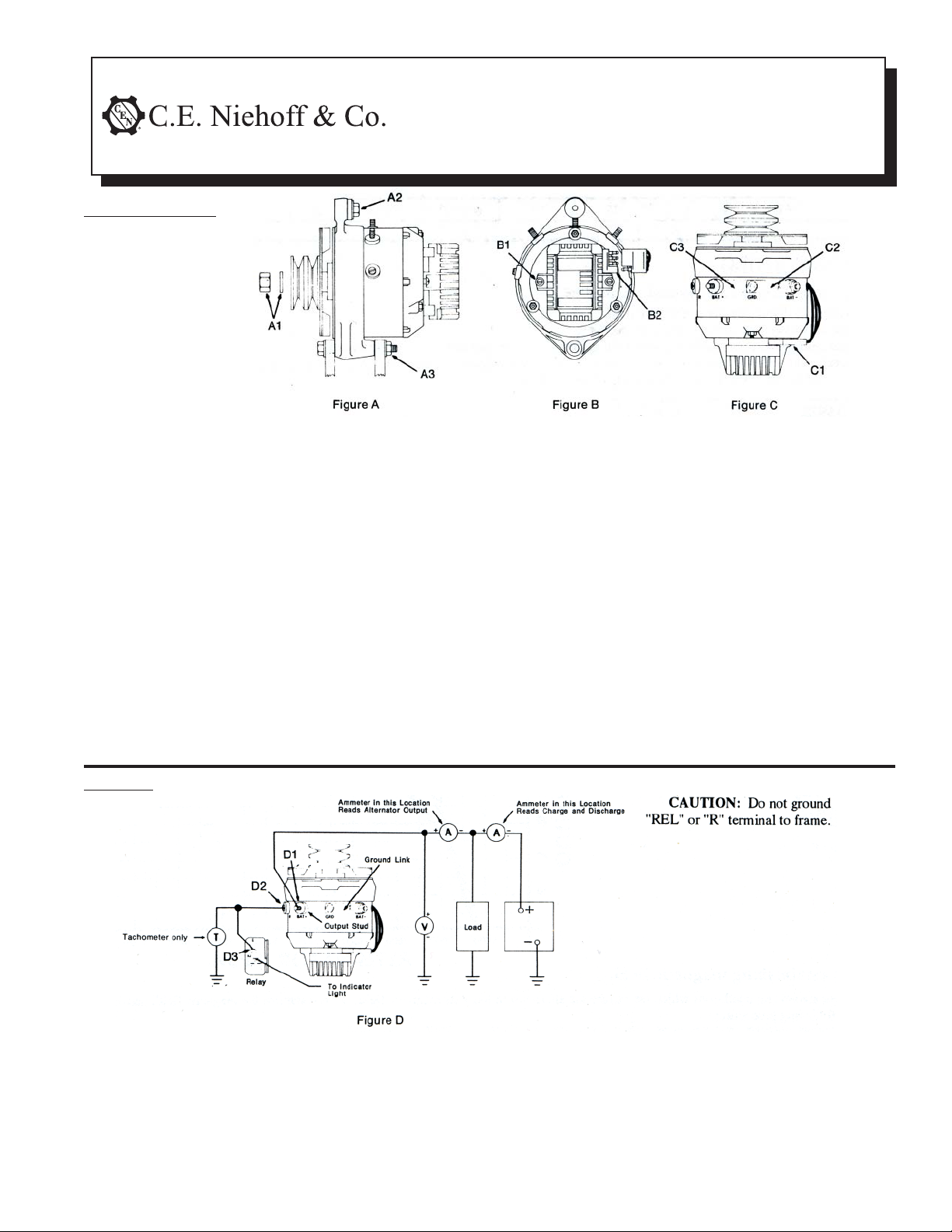

1. MOUNT FAN AND PULLEY (Figure A).

Torque to 50 ft. lbs. using locknut and hardened washer (A1)

supplied on alternator shaft.

2. MOUNT AND CONNECT REGULATOR (Figures B and C).

a.

Position regulator plug and secure regulator with screws (B1)

provided in regulator package. Regulator plug must be securely

held in place by regulator (B2).

b.

Connect alternator plug to regulator plug (C1).

3. POSITION GROUND LINK (Figure C).

Units are shipped with the ground link installed for negative

ground as shown (C2). Reverse connections for positive ground

as indicated by dotted line (C3).

WIRING

4. INSTALL ALTERNATOR (Figure A).

a.

Attach belt adjusting bracket with bolt (A2) included in parts

package.

Insert mounting bolt and hand tighten nut (A3). Bolt should be

b.

new and SAE Grade 5 or better. Nut should be self locking or

coated with "Loctite Lock and Seal" or equivalent.

5. SET BELT TENSION (Figure A).

a.

On engines where the belt drives only the alternator, use a belt

tension gauge and set tension at 40 to 50 lbs. New belts should

be set at 75 lbs. On engines where the belt also drives other accessories, consult manufacturer's specifi cations. If belt tension

gauge is not available, set tension so that the fan cannot be turned

by hand. CAUTION: DO NOT SET TENSION TOO HIGH AS

THIS WILL CAUSE PREMATURE BEARING FAILURE.

b.

Tighten bolt (A2) on belt adjusting bracket. Torque to 17 ft. lbs.

c.

Tighten mounting bolt (A3). Torque to 35 ft. lbs.

CAUTION: Connecting the alternator improperly can cause serious damage.

1. For negative ground systems, connect existing battery wire to "BAT+" (D1) on alternator. For positive ground systems, connect battery wire

to "BAT-" on alternator. Be sure ground link is positioned correctly (C2 or C3).

2. On negative ground applications where a warning light is used, connect wire from "R" (D2) terminal on the alternator to the A2-250 relay

(D3).

NOTE: For isolated ground applications, discard the ground link. Attach both the positive and negative leads directly to the alternator.

Page 1 of 2

II128A

Page 2

SYSTEM SPECIFICATIONS

BRUSHLESS

ALTERNATOR

C102/C102-1

A1-102 A2-102 6 12 60 N OR P 10,000 2 13.8 / 14.5 18

EXTERNAL

REGULATOR

MINIMUM

WIRE SIZE

(AWG)

VOLTS AMPS GROUND

MAXIMUM

RPM

REGULATOR

STEPS

VOLTAGE

SETTIN GS

WEIGHT

(POUNDS)

TROUBLE SHOOTING

If, after installation, the system does not meet specifi cations:

1. Review installation instructions step by step.

2. Check all wiring for clean and secure connections.

3. Excite fi eld coil to re-establish magnetic fi eld in rotor core. See instructions below for details.

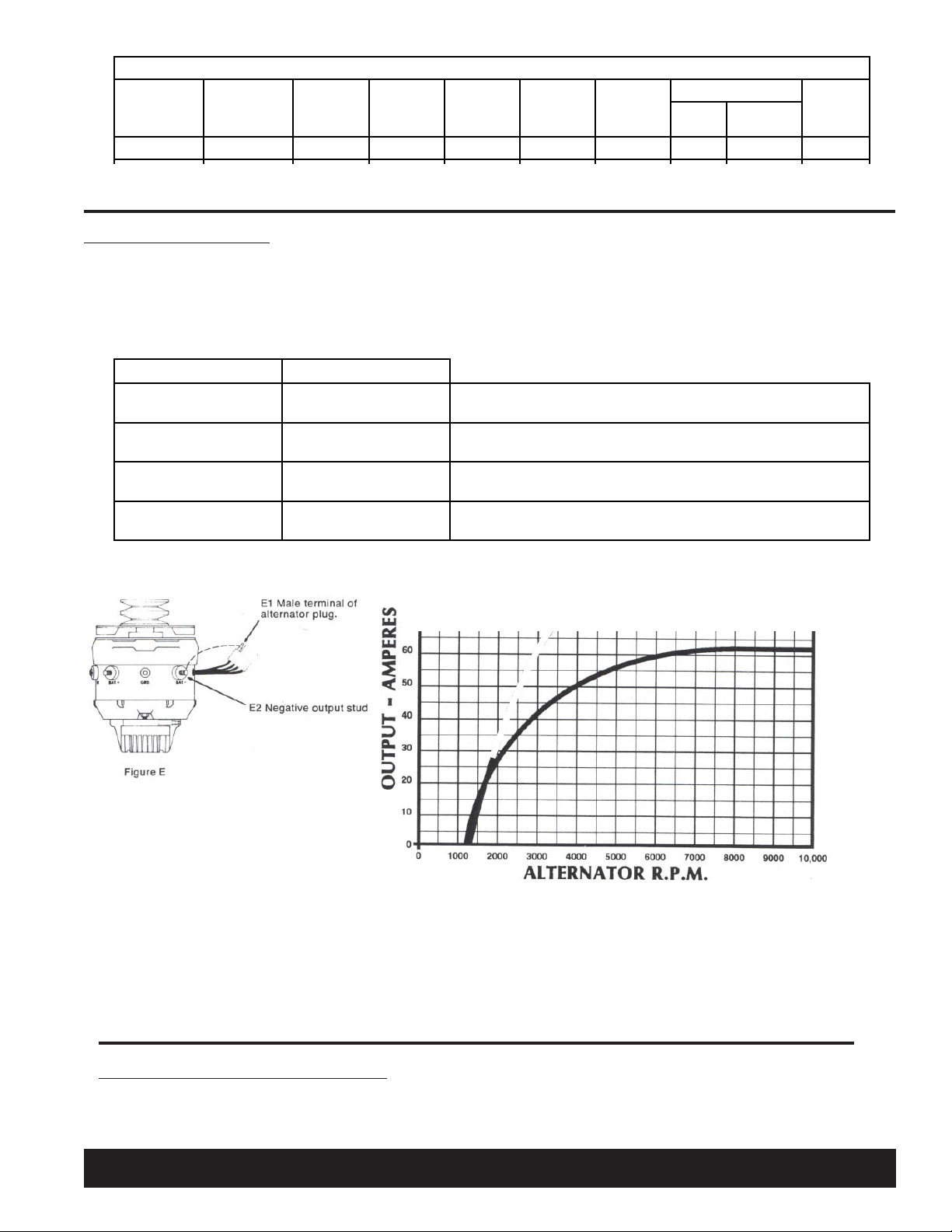

4. If system still does not operate properly, connect ammeter and voltmeter to read alternator output. Set engine R.P.M. at 1500 to 2000.

Read amps and voltage and compare to chart.

AMPS VOLT S

LOW OR 0

LOW OR 0

HIGH

HIGH

NORMAL

13.0 to 14.8

LOW

Less than 13.0

HIGH

More than 14.8

LOW

Less than 13.0

Charging sy stem operating proper ly .

1. Check belt tension.

2. Bypass re gulator. See figure C below.

1. Check r egulator connections and grounds.

2. I f voltage is still high, r eplace regulator.

Dischar ged or defective battery .

Charge or rep lac e battery.

C102/C102-1

Re-establishing magnetic fi eld.

There are several conditions which may cause the alternator to loose its magnetic fi eld. To re-establish the magnetic fi eld, perform the

following procedure:

With engine running, disconnect plug between alternator and regulator and momentarily touch the male terminal (E1) from

the alternator plug to the negative output stud (E2) on the alternator (Figure E). Caution: Touching regulator terminal to

the negative output stud must be rapid to avoid possible alternator damage.

If no output is obtained - See Service Manual for specifi c alternator test.

FAN AND PULLEY INFORMATION

Use Fan & Pulley Assembly: A3-302

C. E. Niehoff & Co. • 2021 Lee Street • Evanston, IL 60202 Tech Services Hotline 800-643-4633

Page 2 of 2

II128A

Loading...

Loading...