Page 1

A9-305

Mid-to-High Frequency EMC

Filter Assembly

Installation Instructions

EMC filter can be installed either

NOTICE

at power supply of the affected

component or at the B+ terminal

on the alternator.

To connect filter assembly to B+ terminal

on alternator, see page 1.

To connect filter assembly to power source

of other affected electrical/electronic

components, see page 2.

1. Before connecting filter assembly to B+

terminal on alternator, determine where to

install unit:

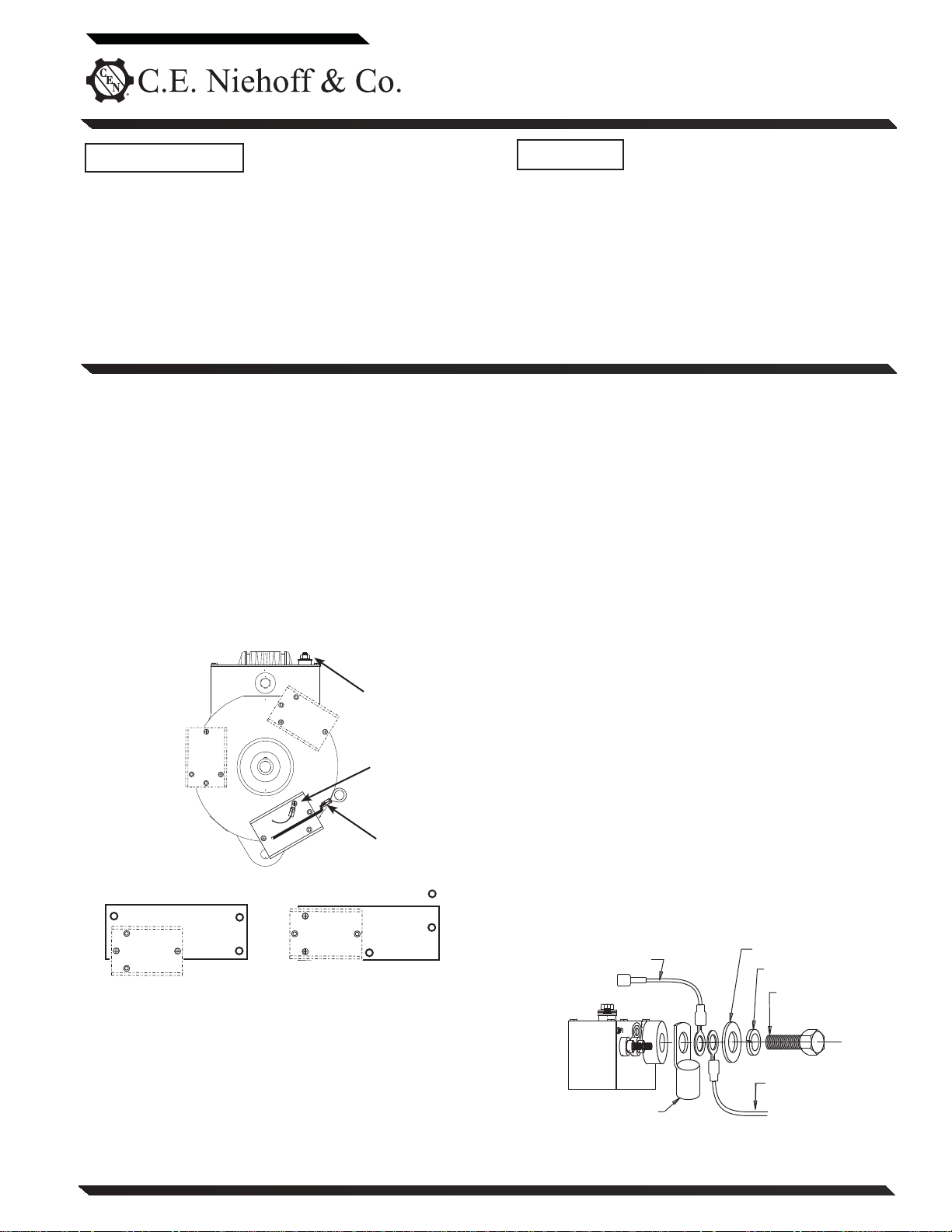

For alternators with front housings that look

like Figure 1: Choose location on alternator best

suited for vehicle conditions to install filter

assembly. B+ connecting wire as provided on

unit is 12 inches long.

For other alternators: Select location for filter

within 12 inches of B+ terminal on alternator.

If location within 12 inches is not practical,

B+ connecting wire can be spliced to increase

d i s t a n c e u p t o 2 f e e t f r o m a l t e r n a t o r B + t e r m i n a l .

Increased wire length reduces filter effectiveness.

F+ terminal

1

2

3

Drive end housing cover plate

not on all units

Green ground

wire

B+ connecting

wire

A9-305 Filter Assembly is designed only to

NOTICE

reduce electromagnetic interference (EMI)

from CEN alternator/regulator to acceptable

levels as defined by Society of Automotive

Engineers (SAE) specification J1113/41. This

device will NOT reduce EMI from sources

s uch as vehi cle di gital s ystems, w irele ss lin ks ,

digital devices, antennas, poor cable routing

practice, and other electrical/electronic

devices that cause EMI. If EMI continues after

installing A9-305 per these instructions,

consult an electromagnetic compliance

(EMC) specialist to determine EMI source.

2. Install filter assembly to be connected to

B+ terminal on alternator:

a. Disconnect vehicle battery master switch or

vehicle battery cables.

b. To install unit directly on alternator:

1) Remove and discard two short screws from

selected location on alternator (see Figure 1).

2) Make sure ring terminals on filter assembly

are clean and have good contact surface.

Place filter assembly on alternator.

3) Use one new screw and lockwasher supplied

i n k i t t o s e c u r e r i n g t e r m i n a l o f g r e e n g r o u n d

wire in closest mounting hole in alternator.

Insert second screw and lockwasher in

remaining mounting hole.

4) Torque both screws to 2.3Nm / 20 lb.in.

c. To install unit in location other than alternator:

1) Set unit in mounting location. Secure green

ground wire from unit to grounded surface,

using one mounting hole in unit. Use second

mounting hole to finish securing unit to

mounting location.

d. Connect B+ connecting wire from unit to alter-

nator B+ terminal, splicing B+ wire length if

required from step 1, as shown in Figure 2.

e. Reconnect vehicle battery master switch or

vehicle battery cables.

f. Operate engine and check alternator output.

4

5

Control unit cover

Figure 1 - Filter Assembly Location on Alternator

(choose one of five locations)

Page 1 of 2

Only on units

with F+ terminal

Term i n al fr om

vehicle battery B+ cable

Figure 2 - Alternator B+ Terminal Stacking Order

Flat washer

Lock washer

B+ Terminal Bolt

(torque varies with

alternator model)

B+ connecting wire

from A9-305

II1B

Page 2

To connect filter assembly to power

source of other affected electrical/

electronic components:

1. Disconnect vehicle battery master switch or

vehicle battery cables.

2. To install unit:

a. Select location to mount filter within 12 inches

of power source on the affected component.

If location within 12 inches is not practical,

B+ connecting wire can be spliced to increase

distance up to 2 feet from power source on

component. Increased wire length reduces filter

effectiveness.

b. Secure green ground wire (see Figure 1, page 1)

from unit to grounded surface, using one

mounting hole in unit. Use second mounting hole

to finish securing unit to mounting location.

Unit MUST be connected

properly to grounded

surface directly back to

battery negative terminal.

3. Connect “B+” connecting wire from unit to component power supply, splicing B+ wire length if

required from step 2a. See Figure 2 on page 1 for

stacking order.

4. Reconnect vehicle battery master switch or vehicle

battery cables.

5. Operate engine and check component operation.

CAUTION

If you have questions about your alternator or any of t hese instructions, or if you need to locate a Factory Authori zed Service Dea ler, please contact us at:

TEL: 800.643.4633 USA and Canada • TEL: 847.866.6030 outside USA and Canada • FAX: 847.492.1242

Page 2 of 2

C. E. Niehoff & Co.• 2021 Lee Street • Evanston, IL 60202 USA

E-mail us at service@CENiehoff.com

II1B

Loading...

Loading...