CEN N1240, N1243 Troubleshooting Guide

C.E. Niehoff & Co.

R

N1240 / N1243 Alternators

Troubleshooting Guide

CONTENTS

Section 1: Wiring ................................................................2

Section 2: CAN/J1939 Diagnostics ...................................3

Section 3: Basic Troubleshooting .....................................4

Section 4: Advanced Troubleshooting .............................5

Battery Charging Conditions

The following conditions may be observed during coldstart voltage tests until temperatures of electrical system

components stabilize. The time it takes to reach optimum

voltage and amps will vary with engine speed, load, and

ambient temperature.

Maintenance/Low Maintenance Lead-Acid Battery:

Traditional lead acid batteries require lowest charge voltage of all vehicle battery chemistries. Battery cells must

be maintained by periodically topping off with distilled

water as required.

Maintenance-free Lead-Acid Battery:

Maintenance-free batteries are similar to Maintenance/

Low Maintenance batteries, but may require slightly higher

charge voltage.

Deep-cycle/Marine Maintenance-free Battery:

Charge acceptance of these batteries may display characteristics similar to maintenance-free batteries and may

charge faster due to generally lower capacity relative to

size.

AGM (Absorbed Glass Mat) Maintenance-free Battery:

These dry-cell batteries respond better than standard

maintenance-free batteries. If battery state of charge

(SOC) drops to 75% or less, batteries should be

recharged to 95% or higher separately from engine charging system to avoid damaging charging system

components and to provide best overall performance.

Charge acceptance of these batteries may display

teristics similar to maintenance batteries, but may require

higher charge voltage and will draw signicant current (<100

amps) when under 50% SOC.

Lithium Battery:

Lithium batteries have unique charging characteristics that

differ from lead acid. These batteries require charging

systems congured specically for lithium battery chemistries. Contact CEN for more information on lithium battery

charging systems and components.

charac-

Testing Guidelines

Professional service technicians rely on the following

guidelines when testing electrical components.

Voltage testing:

• Set meter to proper scale and type (AC or DC).

• Be sure to zero the meter scale or identify the meter

burden by touching meter leads together. Meter burden

must be subtracted from nal reading obtained.

• Be sure the meter leads touch source area only.

Prevent short circuit damage to test leads or source by

not allowing meter leads to touch other pins or exposed

wires in test area.

• Be sure to use CEN tools designed especially for troubleshooting CEN alternators when available.

Resistance (ohm) testing:

• Set meter to proper scale.

• Be sure to zero the meter scale or identify the meter

burden by touching meter leads together. Meter burden

must be subtracted from nal reading obtained.

• Be sure meter leads touch source area only. Allowing

ngers or body parts to touch meter leads or source

during reading may alter reading.

• Be sure reading is taken when source is at 70ºF. Readings taken at higher temperatures will increase the

reading. Conversely, readings taken at lower temperatures will decrease the reading.

• Be sure to test directly at the source. Testing through

extended harnesses or cable extensions may increase

the reading.

• "OL" as referenced in this document refers to open cir-

cuit: "innite" resistance, typically in very high kilo- or

megaohm range depending on meter and settings.

Diode testing:

• Diodes allow current to ow in one direction only. Typical voltage drop in forward bias can range from 0.1-

0.85V. Meter should read OL in reverse bias. Check

meter user manual for meter-specic testing guidelines.

Voltage drop testing:

• Measure voltage between B+ on alternator or power

source and B- (ground) on alternator or source. Record

reading. Move to batteries or other power source and

measure again between B+ and B- terminals on battery

or other power source. The difference between the two

readings represents voltage lost within circuit due to,

but not limited to, inadequate cable gauge or faulty connections.

• Voltage drop measurements must be taken with all electrical loads or source operating.

Dynamic/Live testing (Connecting power and ground to

component to test operation/function out of circuit):

• Connect jumper leads directly and securely to power

source contacts of component being tested.

• Make any connection to power and ground at power

supply or battery source terminals. Do not make connection at component source terminals, as that may

create an arc and damage component source terminals.

Page 1TG40B

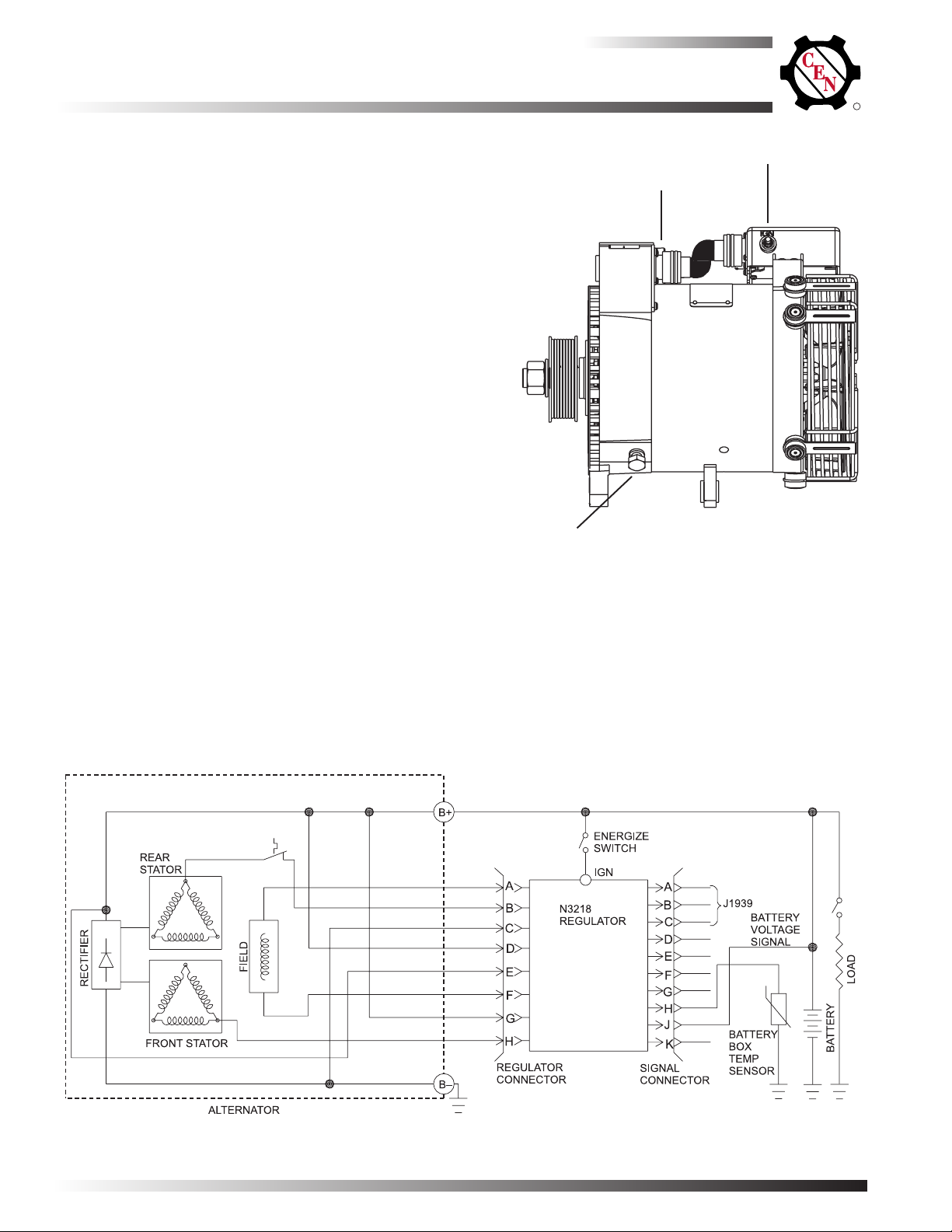

Section 1: Wiring Diagram

Section 1: Wiring Diagram

R

CEN N1240-3/N1243-2 Alternators

Description and Operation

N1240-3 and N1243-2 28 V 260 A alternators are

internally rectified. All windings and current-conducting components are non-moving, so there are no

brushes or slip rings to wear out.

After engine is running, N3218 regulator receives

energize signal. Regulator monitors alternator

rotation and provides field current only when it

detects alternator shaft rotating at or above idle

speed.

After regulator detects alternator rotation, it gradually applies field current, preventing an abrupt

mechanical load on accessory drive system. The soft

start may take up to 20 seconds.

N3218 regulator used with these units also

• is negative temperature compensated. Setpoint is

28.8 ± 0.5 V at 72 F when configured to operate

with 6TMF type batteries.

• provides overvoltage cutout (OVCO). Regulator

will trip OVCO when system voltage rises above

setpoint by 3 V for longer than 3 seconds. OVCO

feature detects high voltage and reacts by opening

alternator field circuit and turning off alternator.

Restarting engine or waiting until system voltage

drops 5 V below setpoint will reset OVCO circuit.

• maintains alternator steady-state output voltage

at regulated settings as vehicle electrical loads are

switched on and off.

(next to regulator connector)

Figure 1 — N1240-3/N1243-2 Alternators and

B+ terminal

TT

T

TT

TT

T

TT

B–

terminal

N3218 Regulator Terminals

IGN terminal

TT

T

TT

Page 2

Page 2

Figure 2 — N1240-3/N1243-2 Alternators with N3218 Regulator

TG0040A

TG40B

Section 2: CAN/J1939 Diagnostics

Section 2: CAN/J1939 Diagnostics

R

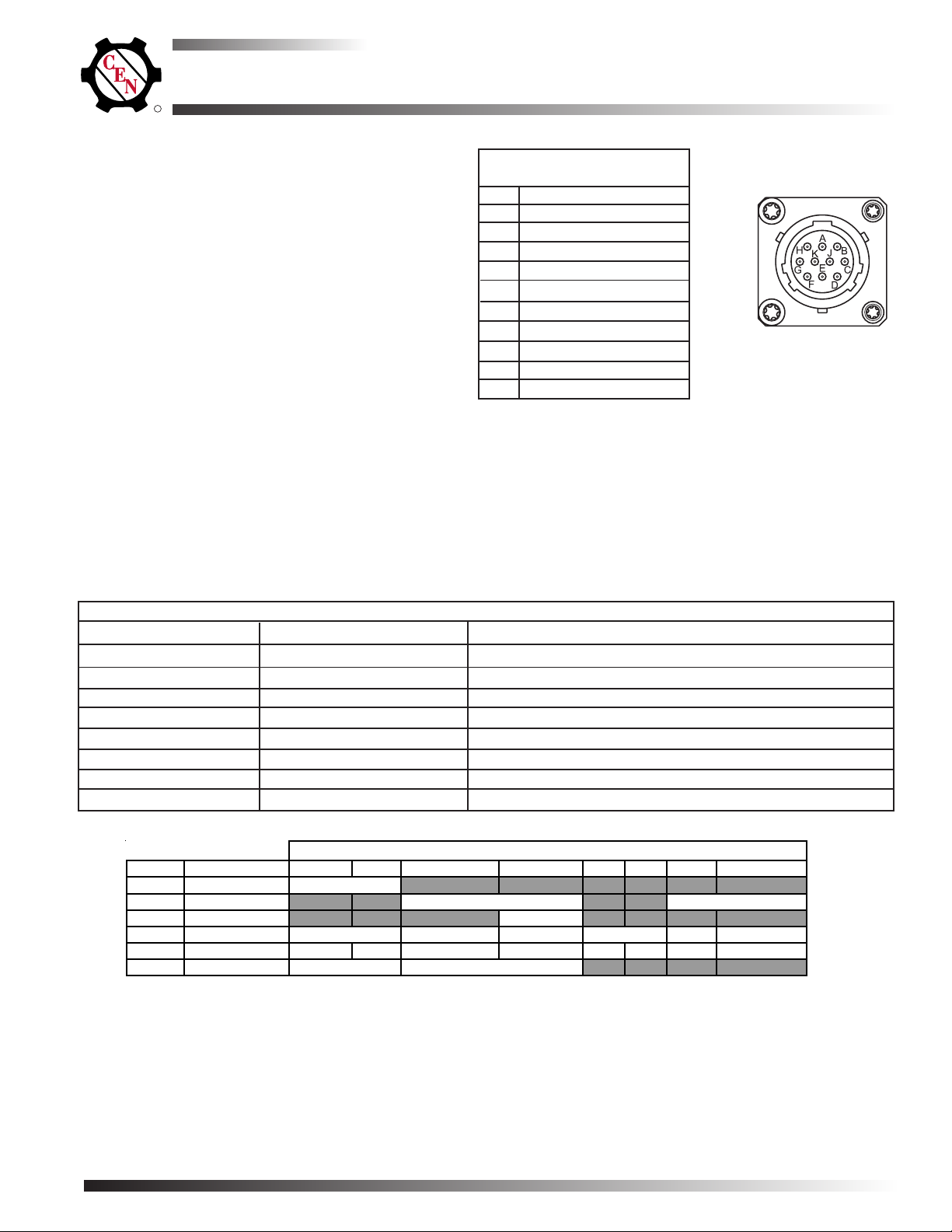

CAN/J1939 Interface

DESCRIPTION AND OPERATION

The CEN N3218 digital regulator is compatible with

SAE J1939 communications standard for vehicle

networking.

CEN uses MIL-STD connector MS3112E12-10P to

interface between the N3218 and the vehicle J1939

databus and battery box sensors. Mating connector is

MS3116E12-10S or equivalent. If this connection is

not used, it must be sealed with connector cover

MS3181-12CA or equivalent. Connector pinout is

shown in Table 1. Message content is shown in Table 2.

Battery box sensing inputs connect to battery pack

positive terminal (pin J) and battery box thermistor

(pin H). Thermistor is 10K NTC with 32650Ω at 0ºC,

10000Ω at 25ºC, 3601Ω at 50ºC and 1% interchangeability. Thermistor location should be chosen

so that it closely represents battery case temperature. Thermistor connects between pin H and vehicle

chassis, battery pack negative terminal, or negative

bus bar. If either sensing input (pin H or J) is not

used, regulator will default to internal temperature

and alternator voltage.

TABLE 1 – J1939 Connector

Circuit Identification

Pin

A

B

C

D

E

F

G

H

J

K

Identification

J1939+

J1939–

J1939/SHLD

B–/GND

Mfr use only

Mfr use only

Mfr use only

Ext. Temp. Sense

Ext. Voltage Sense

unused

Figure 3 – J1939

Connector Pins

TABLE 2 – N3218 Regulator/J1939 Readout Diagnostics (see Table 3)

Regulator Readout

Alternator Speed

Alternator Voltage

Battery Voltage

Regulator Temp.

Alternator Current

Alternator Load

Battery Temp.

Stator Voltages

Expected Reading

1500 to 8000 RPM

26 to 30 V (when charging)

26 to 30 V (when charging)

–40 to 125ºC

0 to 300 A

0 to 100%

–40 to 80ºC

10 to 18 V (when charging)

Table 3 — Message Data

PGN Name 1 (1) 2 3 4 5 6 7 8

FED5 Alt. Speed Alt. Speed

FEF7 Alt. Voltage Alt. Voltage Batt. Voltage

FEA7 Alt. Temp. Reg. Temp.

FFC8 Proprietary #1 Alt. Current

FFC9 Proprietary #2

FFCA Proprietary #3 Stator 1 Voltage Stator 2 Voltage

Notes:

(1) Byte 1 broadcast closest to CAN frame ID.

(2) Contact C. E. Niehoff & Co. for definition of custom proprietary message content.

(2) (2)

(2) (2)

OVCO Count

Action If Expected Reading Not Present

Check belts and pulley.

Check alternator drive and regulator IGN signal.

Check battery box voltage sense signal.

Check regulator.

Check alternator output cabling.

Check alternator output cabling.

Check battery box thermistor.

Check alternator belts and output.

Alt. Hrs. Load Batt. Temp.

(2) (2) (2) (2) (2)

TG0040A

Page 3

Page 3TG40B

Loading...

Loading...