Vibration equipment division

www.cemb.com

CEMB S.p.A.

Via Risorgimento, 9

23826 MANDELLO del LARIO (Lc) Italy

*Translation of the original instructions

N600

Dual chaNNel spectrum aNalyzer

aND BalaNciNg

u

se aND maiNteNaNce iNstructioN maNual

Vibration equipment division

N600 - Ver.2.2 09/2015

General Index

1. General descrIptIon 5

1.1 Standard acceSSorieS 5

1.2 optional acceSSorieS 5

1.3 connectionS 6

1.4 Battery 7

1.5 General advice 7

2. General layout 8

2.1 KeyS/ButtonS on the control panel 8

2.2 General purpoSe functionS 10

2.2.1 Functions associated with the measuring phase 10

2.2.2 Function “other Functions...” 10

2.2.3 Functions operating on the graphs 11

2.2.4 T

o save measurements 13

2.2.5 T

o capture and save displayed images 14

3. Home screen (menu) 15

4. setup mode 16

4.1 SenSor Setup 16

4.1.1 type oF sensor 16

4.1.2 sensitivity oF the sensor 17

4.1.3 photocell 17

4.2 MeaSureMent Setup 18

4.2.1 unit oF measure 18

4.2.2 measurement type 18

4.2.3 unit oF Frequency 19

4.2.4 max Frequency 19

4.2.5 no. oF lines 19

4.2.6 no. oF means 19

4.3 General Setup 20

4.3.1 date 20

4.3.2 time 20

4.3.3 language 20

4.3.4 measurement system 20

4.3.5 time zone 20

4.3.6 updating oF Firmware 20

5. VIbrometer mode 22

5.1 viBroMeter - MeaSureMent Screen 22

5.1.1 direct printing oF the vibration value (optional) 22

5.2 MonitorinG in tiMe 23

5.3 MonitorinG in Speed 23

6. FFt (Fast FourIer transForm) analyzer mode 25

6.1 SpectruM analySiS (fft) 25

6.2 harMonic curSor 25

6.3 WaveforM function 26

6.4 triGGer Setup 26

N600 - Ver.2.2 09/2015

6.4.1 modes 27

6.4.2 channel 27

6.4.3 threshold 28

7. balancer mode 29

7.1 Selection of the BalancinG proGraM 30

7.1.1 new program - balancing setup 30

7.1.1.1 number oF planes 30

7.1.1.2 Filter accuracy 30

7.1.2 load program From archive 31

7.1.3 use current program 31

7.1.4 copy archive to usb key 31

7.2 caliBration Sequence 32

7.3 execution of MeaSureMent 33

7.3.1 test weight 33

7.4 unBalance MeaSureMent and calculation of the correction 34

7.5 SplittinG of correction WeiGht 36

7.6 SavinG of a BalancinG proGraM 37

8. data manaGer mode 38

8.1 open exiStinG project 38

8.2 chanGe Selected pointS 39

8.3 neW project 40

8.4 iMport projectS froM

USB

Key 40

8.5 export projectS to uSB Key 40

8.6 delete projectS 41

9. arcHIVe FunctIon 42

9.1 load ScreenShot 42

9.2 delete ScreenShotS 43

10. cemb n-pro proGram (optIonal) 44

10.1 SySteM requireMentS 44

10.2 inStallation of the SoftWare 44

10.3 inStallation of driverS for uSB coMMunication With the n100, n300 inStruMentS

(for verSion 1.3.4 or earlier) 45

10.4 inStallation of driverS for uSB coMMunication With the n100 and n300 inStruMentS

(for 46

verSion 1.3.5 and later only) 46

10.5 activatinG the SoftWare 47

10.6 uSe of the SoftWare 48

10.6.1 Function bar 48

10.7 General SettinGS 49

10.8 readinG data froM the n100 or n300 inStruMent 50

10.9 data recordS iMported froM the n100 or n300 inStruMent 51

10.10 R

eadinG data froM the n600 inStruMent 51

10.11 diSplayinG data preSent in the recordS 52

10.12 Specific functionS for the SpectruM GraphS 52

10.13 SynchronouS viBration value MeaSureMent (only for n100 and n300 inStruMentS) 53

10.14 BalancinG data (only for n300 and n600 inStruMentS) 54

10.15 Generation and printinG of certificateS (reportS) 54

10.16 GeneratinG and printinG Multiple MeaSureMent certificateS (Multi-report) 55

Vibration equipment division

N600 - Ver.2.2 09/2015

Appendix A

specIFIcatIons 5

6

Appendix B

eValuatIon crIterIa 5

8

Appendix C

a rapId GuIde to InterpretInG a spectrum 6

2

Appendix D

laser sensor For cemb n Instruments 6

8

Appendix E

InFormatIon related to tHe creatIon oF customIsed templates (models) For certIFIcates Generated by

cemb n-pro soFtware 69

Attachment: Balancing accuracy for rigid rotors

N600 - Ver.2.2 09/2015

Vibration equipment division

5

N600 - Ver. 2.2 09/2015

1. General descrIptIon

The N600 instrument is supplied, together with its accessories, in a special case. It is advisable, each time the instrument is

used, to place back it in its case in order to avoid risk of damage during transit.

1.1 standard accessorIes

• No. 2 velocity transducers 100mV/g

• No. 2 transducer connection cables L 2.5 m

• No. 1 heavy duty spiral cable L 2 m

• No. 2 magnetic bases Ø 25 mm

• No. 2 probes

• No. 1 250.000 Cpm Hi-speed, laser photocell complete with upright and magnetic base

• No. 1 roll of reecting paper

• No. 1 USB stick for data transfer

• Angle rule

• Battery charger

• Universal plug

• Case complete with carry strap

• User manual

1.2 optIonal accessorIes

• Bluetooth thermal printer for direct printing of certicates on normal or adhesive thermal paper

• Protective cover

• Acceleration transducer type DM-40 complete with connection cable and magnetic base

• Proximity sensor type ARA-18 complete with stand, cable and magnetic base

• Connection cable for transducers L 5 m

• Extension cable, length 10 metres, for transducers

• Extension cable, length 10 metres, for photocell

• CEMB ADS software for data storage and management

aFter connecting the printer via bluetooth, wait For about 5 seconds to allow completion oF the automatic re-

cognition and initialization procedure. only at this point will it be possible to make a print-out by pressing relative

key F

3 .

6

N600 - Ver. 2.2 09/2015

1

23

4

5

6

7

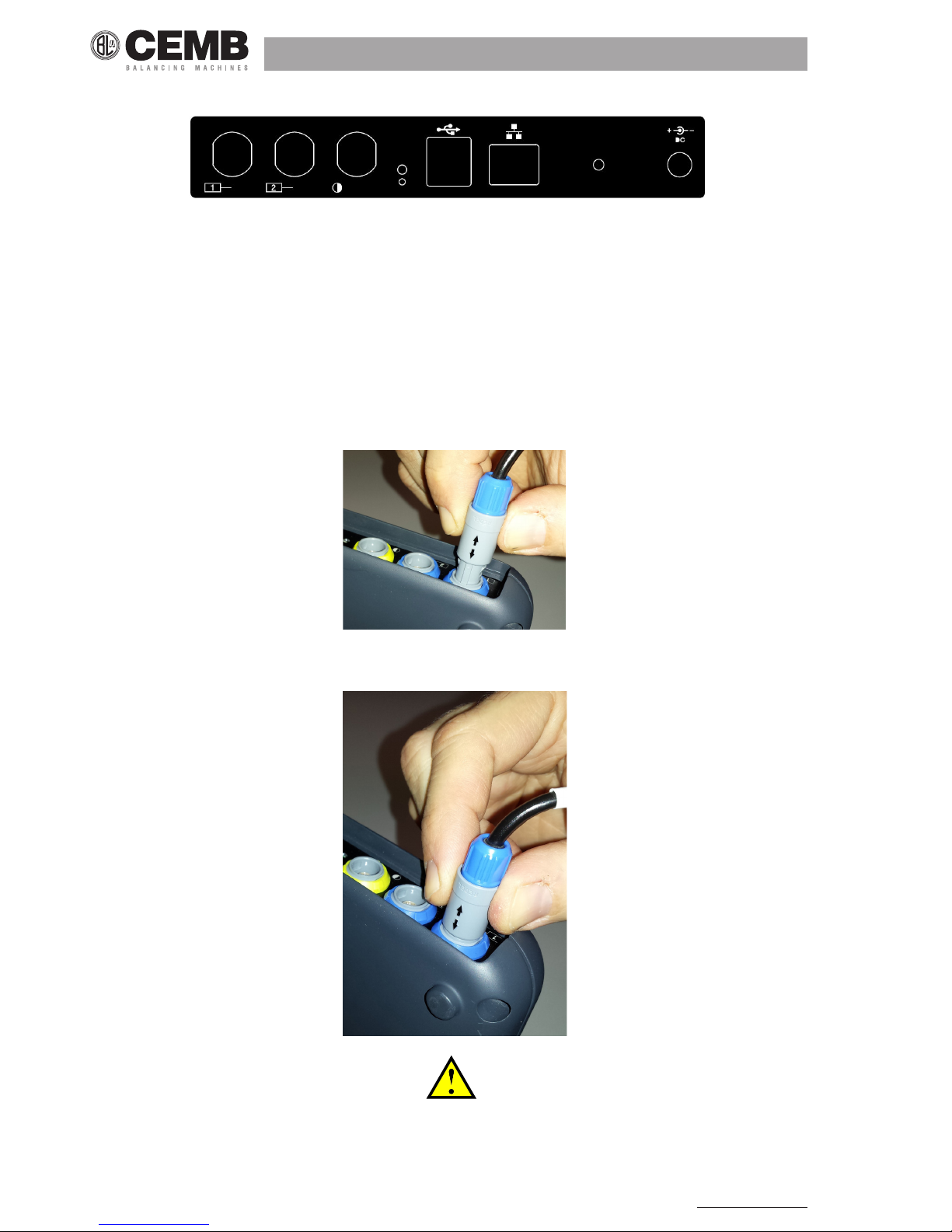

1.3 connectIons

1 Battery charger

2 Internal heat dissipation area (electronics)

3 Network port (useful to connect the instrument to a PC and share a folder for data exchange between the two)

4 2 USB ports type A (master)

5 Instrument reset button

6 Battery charge indication led

7 Photocell input

8 2 inputs, measuring channels

To connect the sensors and photocell, merely plug the connector in the corresponding socket, pushing it until it clicks into

place; make sure that the safety connection is correctly aligned as shown in the gure.

Instead, to extract the connector, press its end part (blue or yellow) and at the same time pull the main body (grey), in order

to release it.

————————————————————————————————————————————————————

warnInG!

aVoId pullInG tHe connector wItH Force beFore releasInG It as descrIbed aboVe,

otHerwIse tHere would be rIsk oF damaGInG It.

————————————————————————————————————————————————————

Vibration equipment division

7

N600 - Ver. 2.2 09/2015

1.4 battery

The N600 instrument is provided with a built-in rechargeable lithium battery, which allows autonomy of more than eight hours

under normal operating conditions of the instrument.

The battery status is indicated by an icon in the upper right hand corner of the screen.

battery fully charged

battery partly charged

battery almost at (battery life remaining when this appears is approx. one hour)

battery at: recharge within 5 minutes

In these conditions, any still active measurements are interrupted and therefore not yet saved.

————————————————————————————————————————————————————

warnInG!

It Is stronGly recommended to recHarGe tHe battery wItH tHe Instrument swItcHed oFF: as recHarGInG Is completed wItHIn

less tHan FIVe Hours sucH precautIon preVents tHe battery cHarGer From beInG connected For an excessIVely lonG perIod

oF tIme (max. 12 Hours).

————————————————————————————————————————————————————

————————————————————————————————————————————————————

warnInG!

tHe lItHIum battery Is able to wItHstand tHe recHarGInG-dIscHarGInG cycles, eVen on a daIly basIs, wItHout problems but It

could become damaGed IF allowed to be Fully dIscHarGed. For tHIs reason It Is adVIsable to recHarGe tHe battery at least

once eVery tHree montHs, eVen In tHe case oF extended Idle perIod

————————————————————————————————————————————————————

as the greater consumption is due to the back lighting oF the lcd display, the latter is switched oFF automatically

aFter two minutes iF no button is pressed. the pressing oF any button (except For and those oF the alphanu meric keypad) is suFFicient to switch the back lighting on again.

1.5 General adVIce

Keep and use the instrument far from sources of heat and strong electromagnetic elds (inverters and high-power electric

motors). Measurement accuracy could be impaired by the connection cable between the transducer and instrument, there-

fore it is recommended to:

• not allow such cable to have sections in common with power cables;

• prefer a perpendicular arrangement when overlapping power cables;

• always use the shortest possible length of cable; in fact oating lines would act as active or passive antennae.

8

N600 - Ver. 2.2 09/2015

2. General layout

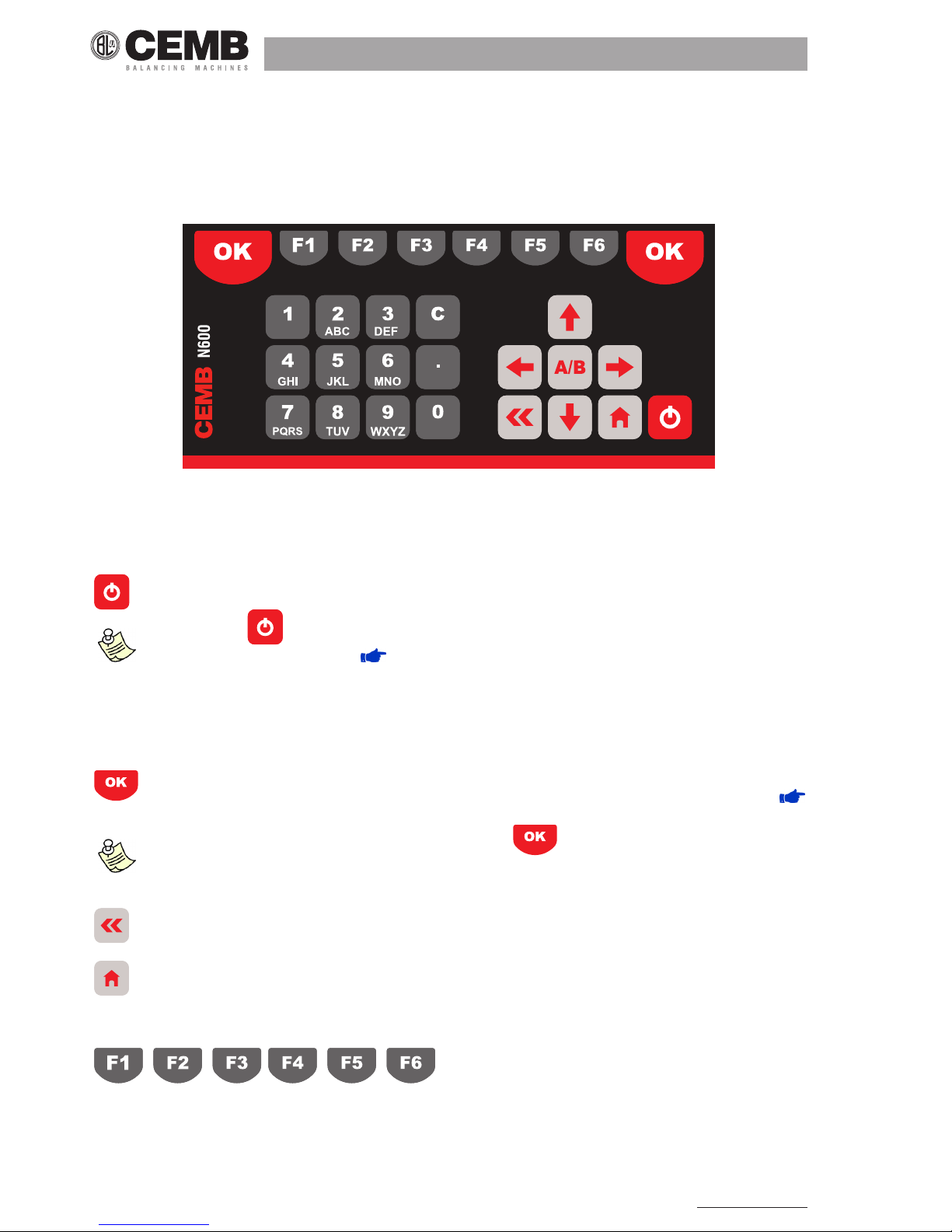

2.1 keys/buttons on tHe control panel

The control panel of the CEMB N600 instrument incorporates a keypad where the various keys or buttons can be subdivided

by function:

► ON / OFF button

Press this button to switch the instrument on; hold it down for at least 3 seconds to switch it off , then release the

button.

aFter pressing , the instrument is ready For use only at the end oF the switching on procedure, signalled by

the appearance oF the home screen (

home screen - menu

).

aFter the insrument has been switched oFF, about 30 seconds must pass beFore it can be switched back on again.

► Buttons for navigating between the pages

When this button is pressed in the setup screen, it conrms the settings selected and allows going onto the next

screen. Instead, in the Measurement screen, it has the function of starting/stopping the actual measurement (

START / STOP THE ACQUISITION).

to Facilitate use oF the instrument also with the leFt hand, the button is located on both sides oF the

display.

When this button is pressed, it causes quitting of the current screen with return to the previous one, without taking

into account any changes (or saves) in the settings

Used for returning to the Main page, from any other page.

► Function keys

Each function key is linked to different functions in the various screens. Such functions are indicated in each individual case

by the buttons shown at the bottom of the display: each function is activated by pressing the function key under it.

Vibration equipment division

9

N600 - Ver. 2.2 09/2015

T

T U

P

Q R

-

0

1

In the setup screens they are used for setting the various parameters, each one being indicated by a number corresponding

to that of the function key to be pressed to modify it.

► Tab key

This key can only be used when two graphs are plotted on the same page; when pressed, it changes the active

graph to which the selected functions will be applied. The active graph can be identied by the symbol loca ted on the right side.

► Arrow keys

When a graph is displayed, these keys increase or decrease respectively the minimum or max. value of the x axis ( ,

) or the y axis ( , ). Instead, when inputting a value for a parameter, they either shift the cursor to the

left or right ( , ) and increase or decrease the value in question ( , ).

► Alphanumeric keypad

This keypad serves for entering alphanumeric characters in the elds which do not allow just default selections. Where it is

possible to enter just numbers, it acts like a normal numeric keypad.

To enter a character, press a key repeatedly to scroll the characters assigned to it (e.g. M N O 6) until the required one is

displayed. The cursor passes on automatically to the next position after a pause of one second, or else after pressing another key.

With it is possible to delete the character to the left of the cursor.

For example, suppose we wish to enter the word “TUR-1” press:

10

N600 - Ver. 2.2 09/2015

an icon indicates whether the upper case style (selectable with ) or lower case (selectable

with

).

► Image capture key

Pressing of this key has the function of capturing the image present on the display and opening a screen which

allows it to be saved ( CAPTURE AND SAVING OF DISPLAYED IMAGES).

2.2 General purpose FunctIons

In addition to many functions, specic for each different purpose and described in relative sections, there are certain general

purpose functions which are described below.

2.2.1 Functions associated with the measuring phase

► Start / Stop acquisition

In all the Measurement screens, acquisition is started by pressing and is subsequently stopped by again pressing

. The active acquisition status is easily to recognize (except in the balancing function) by the presence of a bar indi-

cating level of the input signal to each of the activated channels.

Instead, in the Balancing functions, this status is signalled by an indication of the quality of the measurement in progress

( EXECUTION OF MEASUREMENT).

2.2.2 Function “other Functions...”

When there are more than six functions accessible from a certain screen, there are not enough function keys to correspond

to them; in such cases the key is associatedwith .

Pressing of this key causes substitution of the functions corresponding to with another ve. The original

correspondence can be reset by again pressing .

Vibration equipment division

11

N600 - Ver. 2.2 09/2015

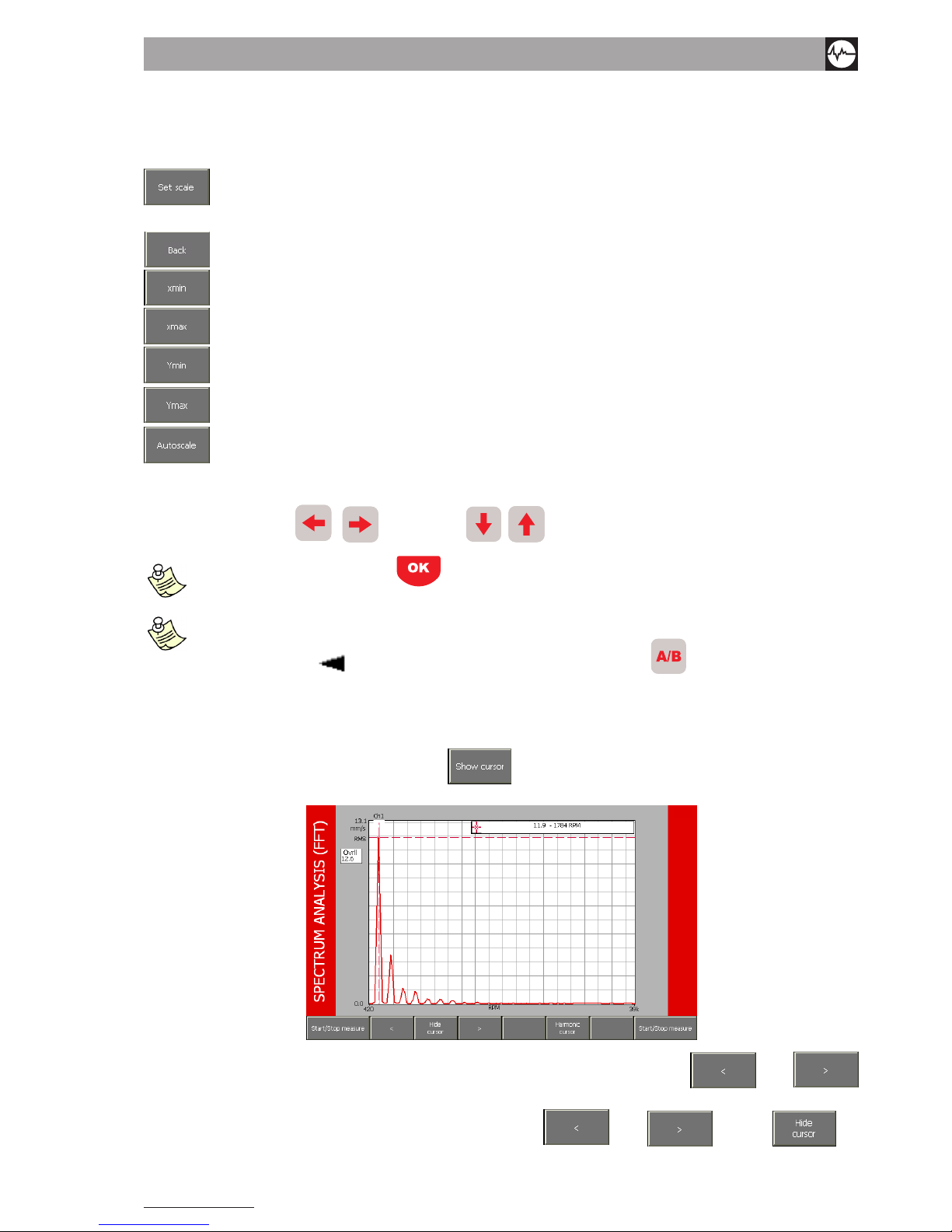

2.2.3 Functions operating on the graphs

► Scale setting

allows selecting the function for modication of the minimum and maximum values of the axes in a

graph; in this way it is possible to display just the zone of greater interest. When activated, the following

sub-functions are made available:

quit the Scale Setting function

preset minimum value of the x axis

preset maximum value of the x axis

preset minimum value of the y axis

preset maximum value of the y axis

sets the axis limits to be coherent with the graph data

The value of the limit selected (x

min

, x

max

, Y

min

or else Y

max

, displayed by white wording on black background), can be increased

or decreased by pressing

, for X axis and , for Y axis.

measurement can be started with also while set scale is activated but it would automatically cause exit

From this Function.

when two graphs are shown both at the same time on the same screen, the scale Functions operate on the active graph

(identiFied by symbol ). to change the active graph, proceed to press the key

.

► Use of the cursor

For easier reading and interpretation of the displayed data, it is possible to introduce a cursor in any graph, provided the

visible region is not blank: this can be done with F2

. A window at the top right corner of the graph contains the

co-ordinates of the point where the cursor lies.

The cursor can be shifted by one step to the right or to the left by using thefollowing keyse F1

or F3

respectively.

For quick reaching of points from the current position, hold down F1 or F3 . With F2 the

cursor is removed.

12

N600 - Ver. 2.2 09/2015

measurement can started with also while the cursor is visible; at the end oF the measurement, the cursor

remains visible.

when two graphs are represented on the same screen simultaneously, it is possible to display the cursor on both

in order to have easier comparisons and assessments. however, pressing oF the Function keys will only have eFFect

on that oF the currently activated graph (identiFied by the symbol ). to change the activated graph, proceed to

press the key.

► Change of display channel

If both measuring channels are enabled, various types of display are possible, namely:

• just graph of channel Ch1

• just graph of channel Ch2

• graphs of channels Ch1 and Ch2 simultaneously

The passing in sequence between the various possibilities is obtained by repeatedly pressing This corresponds in

each case to these options or

► List of peaks

When this function is selected, a table appears with the 10 peaks of highest value present in the zone of the spectrum displayed, and associated with the corresponding frequencies. Their value is calculated by applying an interpolation algorithm to

the FFT graph; this also allows identifying peaks not situated in correspondence to one of the lines of the spectrum.

When F5 is pressed, the system quits this function and again displays the graph (or graphs).

the 10 highest peaks are determined in relation to the highest value present in the spectrum; hence in certain cases

the list could contain less than 10 peaks..

Vibration equipment division

13

N600 - Ver. 2.2 09/2015

iF graphs oF both channels are displayed, the list oF peaks should be calculated For the active one (identiFiable by

the symbol

).

2.2.4 T

o save measurements

The N600 instrument, structured according to a route logic, allows easily saving acquired data; to this end, two different route

types are available ( DATA MANAGER MODE):

• Soft route

• Strict route

If using Soft Route, pressing allows viewing the PROJECT STRUCTURE screen relating to the tree corresponding to the currently active route. All the individual measurement points marked by the symbol

, allow saving the data

several times.

Select the measurement point in which to save the measurement made using the arrows

and , and then press

to save the measurement in the selected point.

If you have done a two-channel acquisition, both channels are automatically saved in the same le.

If using Strict Route, pressing F5

a pop-up will inform you that the measurement has successfully been saved.

the , button, accessible by pressing , allows reloading the measurements previously

processed.

U

sing the arrows and , select the measurement you want to reload (indicated by the date [mm/dd/yyyy]

and time [hh:mm:ss] oF acquisition) and conFirm by pressing the button

.

14

N600 - Ver. 2.2 09/2015

2.2.5 T

o capture and save displayed images

In all screens of the N600 instrument, the image visible on the display can be captured with then saved in png format

in an appropriate archive. This image can be used subsequently if required to accompany documentation produced by the

operator.

Selection of the position where to save can be done with the arrow keys and , then merely press F2

to display a pop-up where to enter the required name, as explained in ALPHANUMERIC KEYPAD.

To delete an image, and clear the corresponding position in the archive, merely press the button F3 .Instead with

F4 it is possible to fully clear the image le.

When pressing the above mentioned buttons, the popup shown below asks you to conrm the operation with the button

or quit with the button .

Finally, pressing F6 , all the image les on the instrument will be copied to a folder called Screenshots, which will

automatically be created on the USB key inserted in the instrument.

E

ach time you want to save new images on the same usb key, ’other subFolders named with the date and time will be

created in the screenshots Folder.

keys

and

, which either increase or decrease by 10 respectively the position selected, can be used

For quick scrolling oF the archive.

Vibration equipment division

15

N600 - Ver. 2.2 09/2015

3. Home screen (menu)

After fully switching on the N600 instrument, it shows its Home screen:

which, besides showing a set of information:

• manufacturer logo and name of the instrument

• serial number (S/N) of the instrument

• current program version

• battery state:

> fully charged

> partly charged

> almost at

> at

> instrument being charged (connection to socket via the battery charger supplied)

as a normal menu, it also proposes and allows selection of the available modes, namely:

► Vibrometer mode

• measurement of the total value and synchronous measurement of vibration

• measurement and memorization of the trend in vibration against variation in time or rotor speed

► FFT (Fast Fourier Transform)

• splitting of the vibration into its component frequencies

• display of waveform of the vibration

► Balancer mode

• balancing of rotors

► Setup mode

• setting of the characteristics of sensors connected to the instrument

• setting of the general operating parameters of the instrument

► Project management

• open an existing project

• modify the measurement points selectable in a project during a eld measurement campaign

• create a new project (Soft Route only)

• import new projects (Soft Route and Strict Route) from USB key

• export projects from the instrument to USB key

• delete existing projects

► Archive

• load a previously stored screenshot

16

N600 - Ver. 2.2 09/2015

• delete one or all the previously stored screenshots

it is possible to return to this screen From any other by pressing

.

4. setup mode

This function allows making all the possible conguration settings on the N600 instrument. More specically, these settings

are:

• Sensor setup: conguration of the sensors that interface with the instrument

• Measurement setup: conguration of the measurement settings

• General setup: conguration of the general operating parameters of the instrument.

4.1 sensor setup

The N600 instrument can be used with different types and models of sensors. Therefore in order to ensure correct measurement, it is necessary to preset exactly the type of sensitivity of the sensors actually connected.

although the instrument can operate correctly with any combination oF sensors, it is advisable to connect sensors

oF the same type and model to the two channels.

4.1.1 type oF sensor

Any one of the following possibilities can be selected:

• OFF : sensor not present (or else channel to be kept switched off)

• ACCEL : accelerometer

• VELOC : velocity sensor

• DISPLC : proximity sensor (non-contact)

it is not possible to set both channels to oFF; at least one oF the two channels should be activated

Vibration equipment division

17

N600 - Ver. 2.2 09/2015

although the required unit oF measurement can diFFer From the natural one oF the sensor, these are the only

combinations are possible.

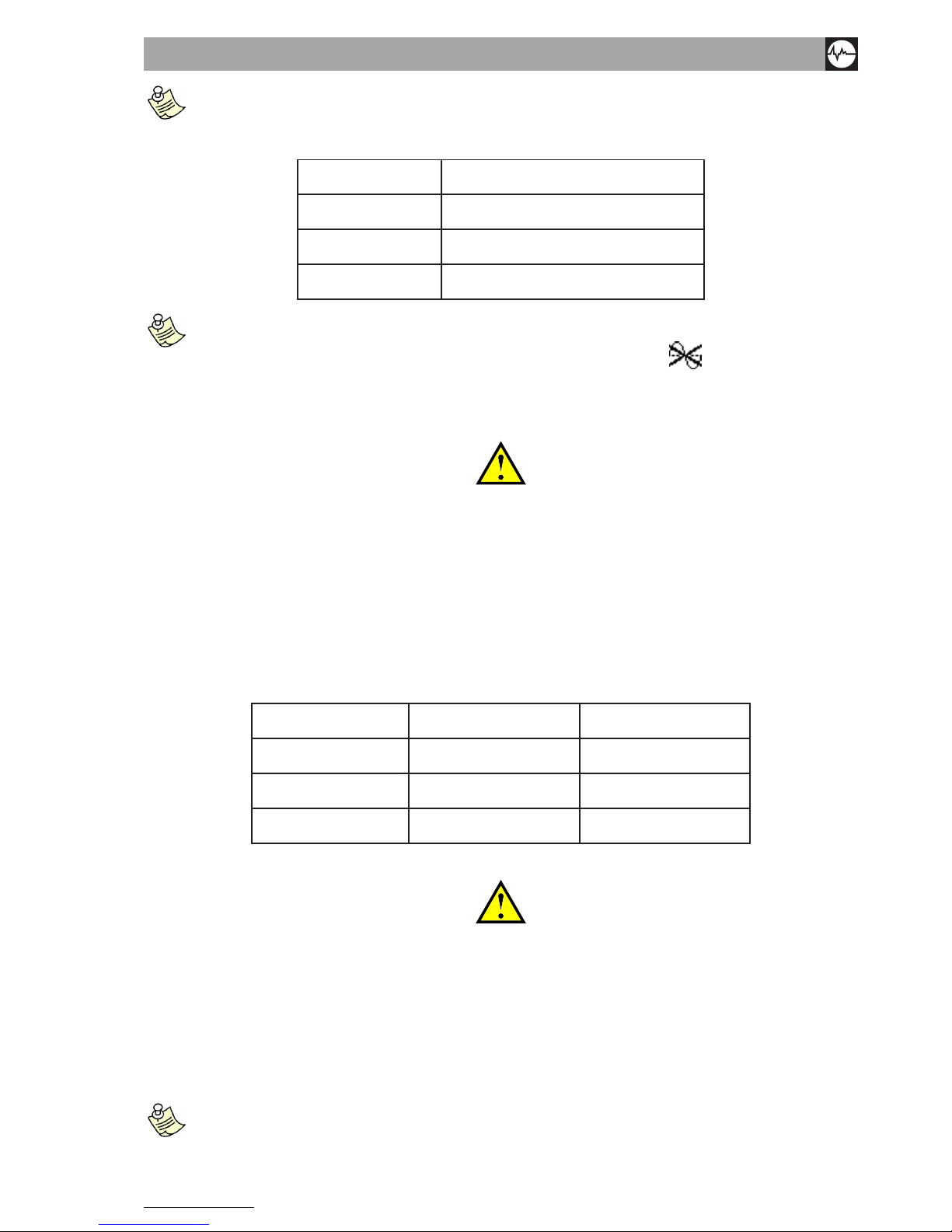

TYPE OF SENSOR REQUIRED MEASUREMENT

ACCEL acceleration, speed, displacement

VELOC speed, displacement

DISPLC displacement

the n600 instrument is able to determine automatically whether there is no sensor connected to an enabled chan-

nel (i.e. not set to oFF sensors setup) and it signals this by showing the symbol in the vicinity oF the signal

bar oF the corresponding channel (only during measurement). to avoid displaying this symbol, it is advisable to disa-

ble the channel when not used, by setting to oFF.

————————————————————————————————————————————————————

warnInG!

tHe appearance oF tHIs symbol For a cHannel wHere a sensor Is really connected,

could IndIcate a possIble malFunctIon oF tHe sensor or else a problem In connectIon

(e.G. tHe cable could HaVe been sHeared).

In sucH case It Is adVIsable to carry out a Few tests by connectInG a sensor (wHIcH Is known to be operatInG properly) to

tHe cHannel In questIon; IF tHe IndIcatIon persIsts, contact cemb tecHnIcal serVIce.

————————————————————————————————————————————————————

4.1.2 sensitivity oF the sensor

This is the number of volts per unit produced by the sensor: it is expressed for the various types in:

TYPE OF SENSOR SENSITIVITY TYPICAL VALUE

ACCEL mV/g 100

VELOC mV/(mm/s) 21,2

DISPLC mV/µm 4

————————————————————————————————————————————————————

warnInG!

dIFFerent models can HaVe sensItIVIty dIFFerInG From tHe typIcal Values; pay attentIon

wHen takInG tHe correct Value From tHe sensor documentatIon and preset It .

————————————————————————————————————————————————————

4.1.3 photocell

You can set activation of the photocell or its power circuit. Setting the parameter to ON, the photocell will continuously be

powered as soon as it is connected to the instrument.

iF the photocell is not enabled, when you select a program that requires’its use, a pop-up will ask you to activate it.

18

N600 - Ver. 2.2 09/2015

4.2 measurement setup

In the case of analysis using a Soft Route, this function allows making the necessary settings to obtain a correct overall value

measurement via the Vibrometer function as well as highlighting signicant data in the spectrum, separating them from the

ineliminable background noise relating to the FFT function.

I

n the case oF analysis using a strict route, this Function allows checking but not modiFying the parameters set.

the symbol allows identiFying a setup relating to a strict route.

4.2.1 unit oF measure

Select the unit of measure in which you want the vibration measurement to be provided; the options are:

• Acceleration (g) - strengthens the higher frequencies and weakens the lower frequencies

• Speed (mm/s or inch/s)

• Displacement (µm or mils) - strengthens the lower frequencies and weakens the higher frequencies

4.2.2 measurement type

This is the mode in which each component (line) of the spectrum is provided and may be:

• RMS (Root Mean Square):

This is the mean vibration value squared beforehand.

This value is typically used in the European standards, in particular for acceleration or speed measurements.

It is a direct index of the “energy” content of the vibration. In practice, it represents the power the vibration carries with it,

which is discharged onto the supports of the vibrating structure.

• PK (Peak):

This is the maximum value the vibration has reached in a certain time interval.

For purely sinosoidal signals, it is simply equal to the RMS value multiplied by 1.41.

• PP (Peak-to-Peak):

This is the difference between the maximum and minimum values the vibration has reached in a certain time interval; for

purely sinosoidal signals, it is simply equal to the RMS value multiplied by 2.82.

It is normally used for displacement measurements.

Vibration equipment division

19

N600 - Ver. 2.2 09/2015

linee

max

N

f

4.2.3 unit oF Frequency

There are two options:

• Hz - cycles (revolutions) per second

• RPM - revolutions per minute

evidently, there is a relation between the two units: 1 hz = 60 rpm.

4.2.4 max Frequency

This is the maximum frequency involved in the phenomenon under examination; in practice, it is the maximum frequency

viewable in the spectrum. You can choose from the default values 100, 500, 1000, 2500, 5000, 10000 Hz, based on which

the N600 instrument selects the appropriate frequency for data acquisition.

T

he typical choice appropriate For most situations is 1000 hz (60.000 rpm) consistent with what is indicated in iso

10816-1.

normal practice is to check that the maximum Frequency set is at least 20-30 times that oF rotation oF the shaFt

under test. this allows including in the spectrum also the high Frequency zone where bearing-related problems

normally occur.

at parity oF other conditions, choosing a low maximum Frequency (below 1000 hz) results in considerably longer

acquisition and measurement times.

4.2.5 no. oF lines

This parameter denes the number of lines used in the FFT algorithm, in practice related to the resolution in frequency in the

spectrum. This determines how close the frequency of two peaks may be for them to still be distinguished in the FFT graph.

This resolution is equal to:

therefore, in order to keep them constant, if the maximum frequency is increased, also the number of lines must be increased.

It should be pointed out that the time necessary to acquire the correct number of samples is exactly equal to the inverse

of the resolution to which the time necessary to process the data needs to be added. An example of the relation between

resolution and acquisition time is shown in the table below:

Resolution [Hz]

t

Acquisition [

sec

]

5 0,2

2,5 0,4

1,25 0,8

0,625 1,6

0,3125 3,2

it is inadvisable to use a too large number oF lines unless you have a situation where an extreme resolution is es-

sential.

T

his would in Fact translate into an increase in calculation time and the space required For data saving,

oFten without adding particular inFormation. a reasonable choice would be to use 200, 400 or 800 lines at most,

making sure that you set a maximum Frequency consistent with the situation under examination.

4.2.6 no. oF means

This is the number of spectrums/data that needs to be calculated and averaged in order to enhance measurement stability.

Four means are more than sufcient for normal vibration measurements on rotating machines.

Pressing

the settings are conrmed.

20

N600 - Ver. 2.2 09/2015

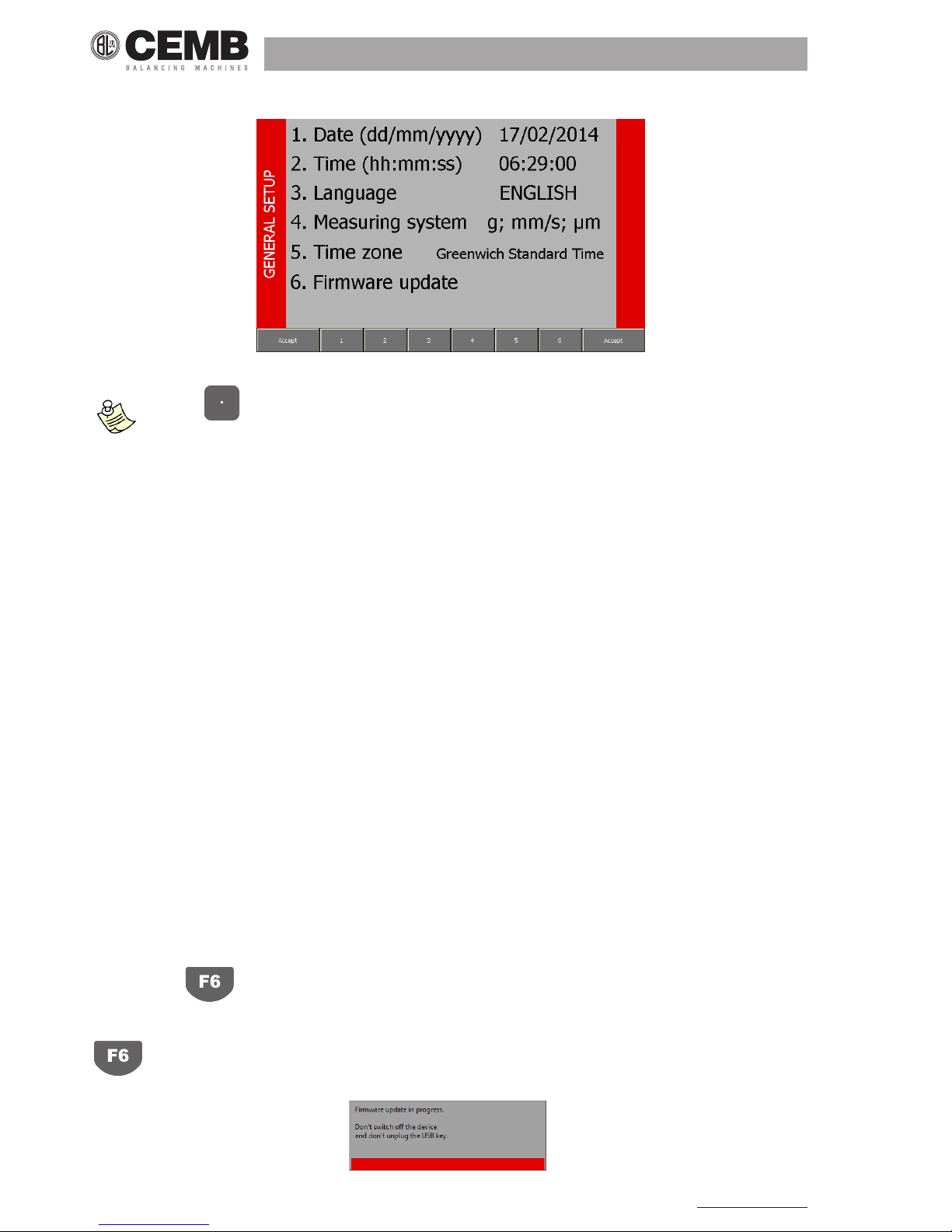

4.3 General setup

The parameters for general use of the instrument should be preset in this page.

when the key is pressed, the system inFo pop-up appears, containing Full inFormation concerning the

system. strike any key to close this window.

4.3.1 date

Use the alphanumeric keypad to enter the date in the format DD/MM/YYYY.

4.3.2 time

Use the alphanumeric keypad to enter the date in the format HH:MM:SS.

4.3.3 language

Select one of the possible languages:

• ITALIANO

• ENGLISH

• DEUTSCH

• FRANÇAIS

• ESPAÑOL

4.3.4 measurement system

The units of measure for the acceleration, speed and displacement values can be the following respectively:

• g; mm/s; μm : metric units

• g; inc/s; mils : imperial units

4.3.5 time zone

Allows setting the time zone. This setting is important if the instrument is associated with the CEMB Advanced Diagnostic

Software for data processing.

4.3.6 updating oF Firmware

Pressing of key does not set any parameter, but it does allow updating the program (rmware) inside the instrument,

if this proves necessary. Each new rmware version consists of a le with the extension fmw, which should be copied in the

main directory on the USB key supplied. Merely insert the pendrive in one of the USB ports of the instrument, then press

to start the automatic updating procedure, at the end of which the pop-up:

Vibration equipment division

21

N600 - Ver. 2.2 09/2015

signals successful transfer of the le and requests switching the instrument off, then on again to complete the operation.

————————————————————————————————————————————————————

cautIon!

updatInG oF tHe FIrmware Is a delIcate operatIon, wHIcH could last a Few mInutes. It sHould be carrIed out by payInG careFul

attentIon to tHe InstructIons supplIed In order not to cause malFunctIons or data loss; For tHIs reason, a conFIrmatIon Is

requested beFore actIVatInG tHIs procedure.

————————————————————————————————————————————————————

Only the rmware obtained directly from CEMB Technical Service should be used. It is advisable to remove the USB key

before rebooting the instrument.

If using invalid rmware, the following pop-up will appear:

————————————————————————————————————————————————————

warnInG!

IF tHe automatIc updatInG operatIon Is not perFormed successFully, contact cemb

tecHnIcal serVIce, cItInG tHe type oF error sIGnalled.

————————————————————————————————————————————————————

22

N600 - Ver. 2.2 09/2015

1

3

8

4

5

2

6

7

9

5. VIbrometer mode

One of the simplest, but at the same time most signicant information in vibration analysis, is the overall value of the actual

vibration. In fact, this is very often the rst parameter to be considered when evaluating the operating conditions of a motor,

fan, pump, machine tool.

Appropriate tables allow discrimination between an optimum state and a good state, or from an allowable, tolerable, nonpermissible or even a dangerous one. ( APPENDIX B - EVALUATION CRITERIA).

In certain situations instead, it could be interesting to know the values of modulus and phase of the synchronous vibration

(1xRPM), i.e. corresponding to the speed of rotation of the rotor.

The vibrometer mode is designed to make this type of measure and also makes available two monitoring functions, for

observing the trend of vibration plotted against time or against variation in rotor speed.

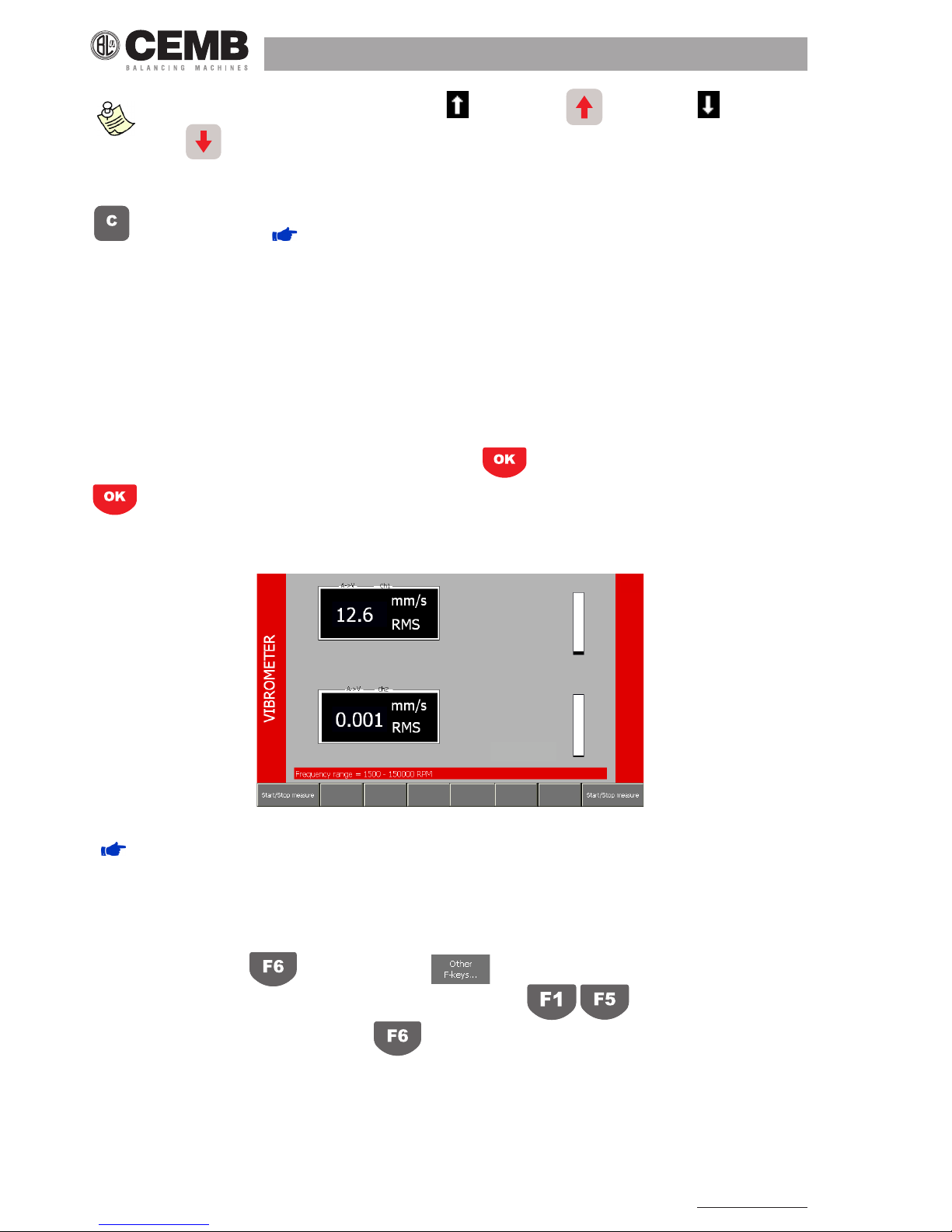

5.1 VIbrometer - measurement screen

The Measurement page supplies a series of information, organized as shown in the gure:

1. measurement information: indicates unit of the sensor (A, V or D) and any conversion made to supply the overall value

(e.g. A→V means that the measurement is made with an accelerometer, but the vibration is supplied in speed)

2. channel measured

3. overall value of the vibration

4. unit of measurement

5. type of measurement

6. value of the synchronous vibration

7. phase of the synchronous vibration

8. speed rotation of rotor

9. signal level bar

the values obtained in this mode can be reused to evaluate the operating status oF the instrument by using, For

example, the tables and graphs given in appendix B oF this manual.

The default measurement is that of the total vibration value, but by pressing F4 it is possible to switch to measu-

rement of the synchronous value: in this mode, information appears concerning the modulus, phase and speed of rotation.

Pressing of F4 allows return to measurement of the overall. value.

to perForm a synchronous measurement, it is necessary to connect the photocell and make sure that it is positio-

ned correctly (

SPEED MONITORING).

5.1.1 direct printing oF the viBration value (optional)

By connecting the portable printer supplied (optional) then pressing F3 it is possible to print directly in eld the

vibration values displayed in the VIBROMETER PAGE.

Vibration equipment division

23

N600 - Ver. 2.2 09/2015

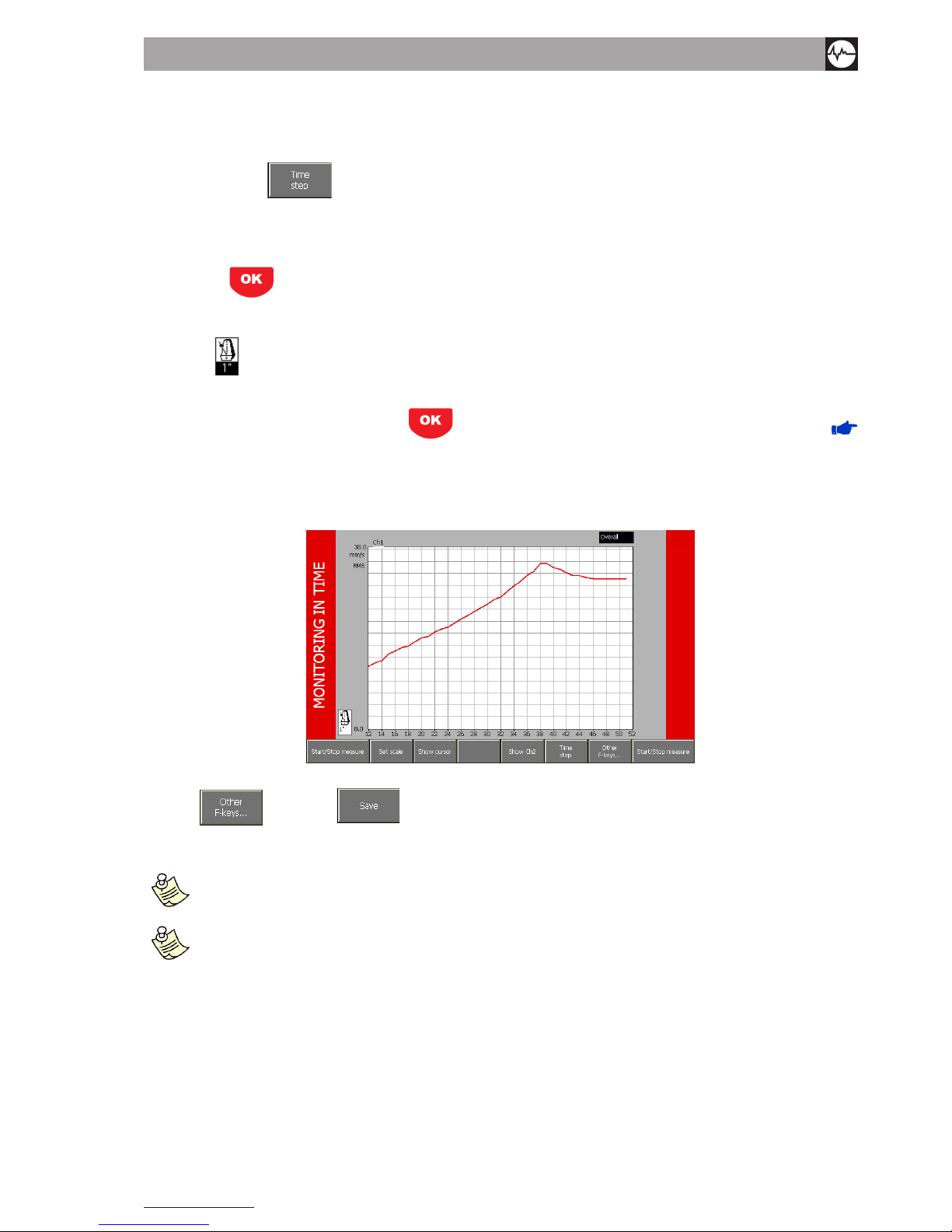

5.2 monItorInG In tIme

The monitoring in time function allows observing (and memorizing if necessary) of the

trend of the overall vibration value plotted against time. For such purpose, it is necessary to preset a value which is adequate

for the parameter F5

by selecting from the following possibilities:

• 1’’ - one second

• 10’’ - ten seconds

• 1’ - one minute

• 15’ - fteen minutes

After pressing

a measurement is made of the overall value, indicated by a point on the graph; such measurement

is automatically repeated according to the preset time step, and a new point is represented in the graph. Availability of a

new measurement is signalled by momentarily displaying the time step in white on black background (under the icon with

metronome

).

When the number of measurements made exceeds forty, just the most recent forty measurements are shown in the graph.

Monitoring is stopped by a further pressing of

and the typical control functions of the graphs become available (

FUNCTIONS OPERATING ON THE GRAPHS).

• Set scale (with which it is also possible display all the measurements made)

• Show cursor

• Change of channel displayed

• List of peaks

When F6

and then F4 is selected, the entire monitoring can be saved in a le for subsequent analysis.

When the acquisition is enabled for both channels, the data save is performed automatically for both channels in the same

le.

as access to the monitoring in time Function is gained From the vibrometer screen, the settings used For cal-

culation oF the overall value are the ones selected in the vibrometer setup screen.

the memory allotted For a single monitoring, allows memorizing a maximum oF 1024 values per channel: when the

limit is reached, the acquisition is stopped automatically without data loss. For this reason, it is important to use

the most suitable Frequency according to the duration oF the phenomenon concerned.

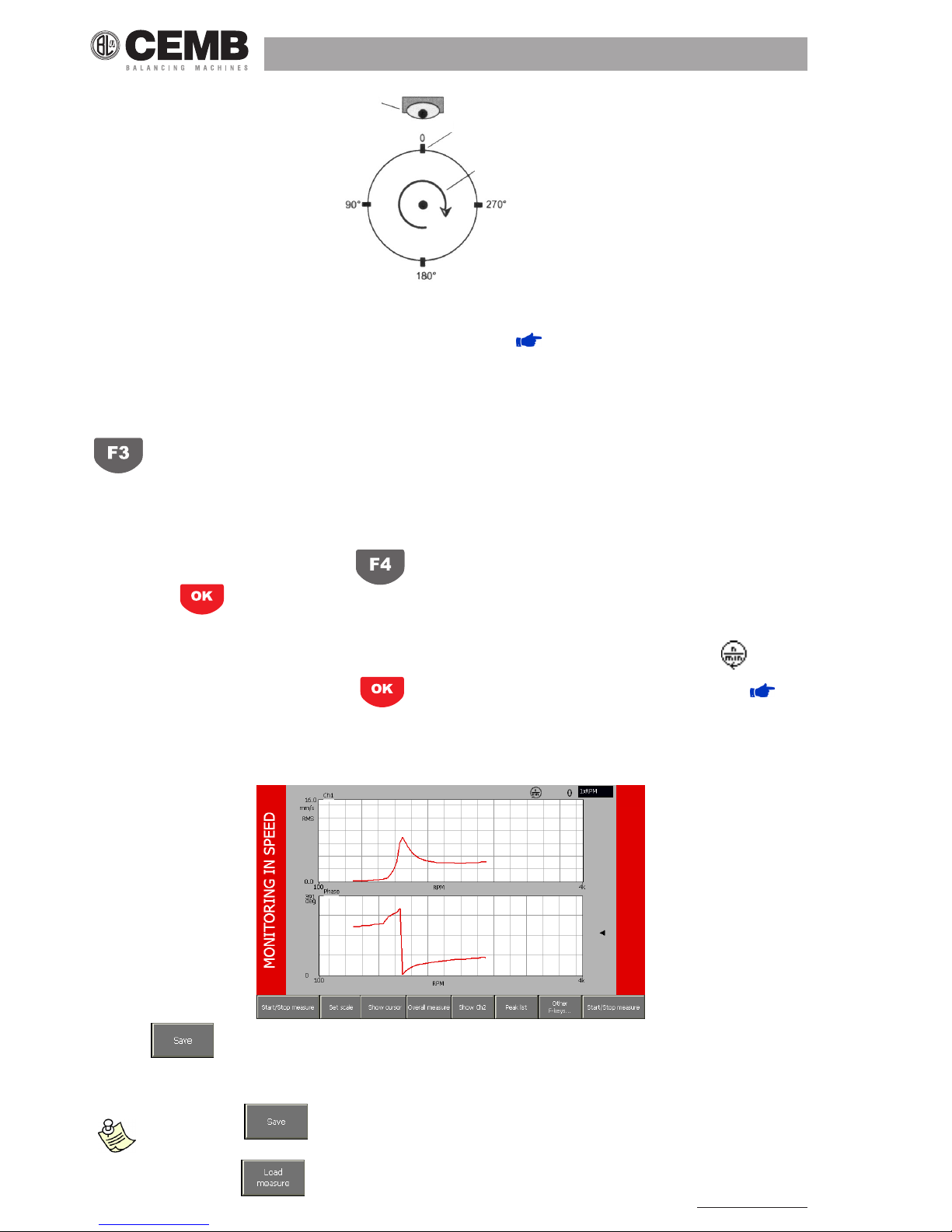

5.3 monItorInG In speed

In many situations it could prove useful to associate the vibration value with that of the speed of rotation of a shaft; in this

way it could be possible to investigate, for example, how the overall or the synchronous component varies during machine

starting or stop phase, with identication of any critical zones or zones with risk of resonance, which are best to avoid.

In order to be able to use this function, it is essential to have the tachometric signal; therefore it is necessary:

• to apply a reecting label on the rotor as reference mark (0°). Starting from this position, proceed to measure the angles

in direction opposite to that of the shaft rotation.

24

N600 - Ver. 2.2 09/2015

photocell

reference MarK

rotation SenSe

• connect the photocell and position it correctly (50 - 400 mm), so that the led located behind it lights up once for each rev.

when the reference mark is illuminated by the light beam. If the operation is not regular, either retract or approach the

photocell, or else incline it with the respect to the workpiece surface. APPENDIX D - LASER SENSOR FOR CEMB

N INSTRUMENTS.

Speed monitoring can be performed according to two different modes, namely:

• monitoring of overall vibration (overall)

• monitoring of modulus and phase of the vibration synchronous with the speed of rotation (1xRPM)

An icon on the top part of the page indicates which mode is currently selected; this mode can be changed by pressing

.

Two graphs are always displayed simultaneously in a synchronous monitoring. Such graphs can be:

• modulus and phase of the vibration of channel 1

• modulus and phase of the vibration of channel 2

• modulus of the vibration for both channels

To switch between the various modes, press

After pressing a vibration measurement is made and a speed reading taken, these are then plotted by a point on

the graph; such measurements are repeated automatically, with a new point added each time to the graph. For the sake of

convenience, the current rotor speed, expressed in RPM, is displayed at the top right, alongside the symbol .

Monitoring is stopped by a further pressing of , and the typical graph control functions become available ( FUN-

CTIONS OPERATING ON THE GRAPHS).

• Set scale

• Show cursor

• Change of channel displayed

• List of peaks

When F4 is pressed, the entire monitoring can be saved in a le for subsequent analysis.

When the acquisition is enabled for both channels, the data save is performed automatically for both channels in the same

le.

the F4 button allows saving the measurements, selecting the appropriate measurement point in the

tree element relating to the currently selected route.

the F2 button allows reloading the measurements previously processed by the instrument.

Vibration equipment division

25

N600 - Ver. 2.2 09/2015

6. FFt (Fast FourIer transForm) analyzer mode

A complete analysis of the vibration cannot fail to take into account the study of the various factors contributing towards

forming its overall value. Hence it is essential to be able to carry out spectrum analysis with FFT (Fast Fourier Transform)

algorithm. Such technique allows splitting and memorizing a measured signal into its component frequencies in a certain

period of time, thus making it easier to discover their causes. Analysis of the highest peaks in the spectrum, together with

analysis of the frequencies to which they correspond allows determining which are the principle sources of vibration and,

therefore, the aspects on which to act in order to reduce them. Although a spectrum contains a series of very signicant

information, its interpretation requires a certain amount of experience and attention; for this purpose, the material given in

APPENDIX C - A RAPID GUIDE TO INTERPRETING A SPECTRUM COULD BE USEFUL.

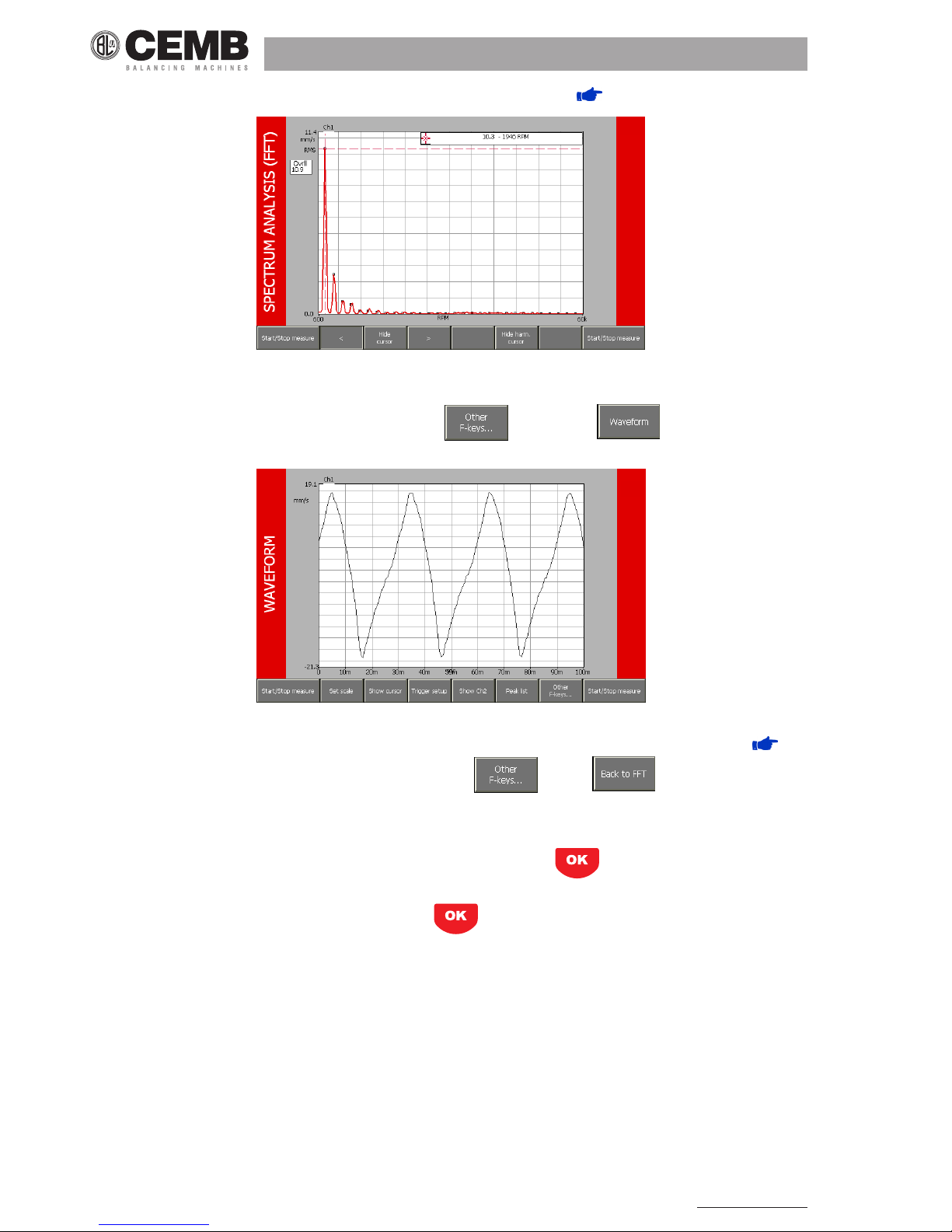

6.1 spectrum analysIs (FFt)

The so-called FFT algorithm is applied to the signals acquired with due respect for the settings made; in accordance with the

recommendations deriving from the mathematical treatment from which it has been taken, such numeric processing is preceded by application of a Hanning window to the acquired signal. This allows attenuating the edge effects due to digitizing as

well as reducing phenomena of leakage in the spectrum. The Measurement page appears like the one shown in the gure.

It is organized so as to maximize as much as possible the area dedicated for representation of the FFT graph.

A box Ovrll is located on the left side giving the overall value of the signal for the channel displayed; it has the same units

of measurement as those of the FFT. Such information allows monitoring the total vibration, also during the analysis of its

single components.

Beside the usual graphic control functions (

FUNCTIONS OPERATING ON GRAPHS), namely:

• Set scale

• Show cursor

• Change of displayed channel

• List of peaks in order to display the list of highest peaks in the spectrum ( LIST OF PEAKS).

the following are available:

• Waveform ( WAVEFORM FUNCTION)

• Trigger Setup to set a trigger to be used for starting the acquisition ( TRIGGER SETUP).

6.2 HarmonIc cursor

When the cursor is displayed on an FFT graph ( USE OF THE CURSOR), it means that a special mode known as harmonic

cursor is available.

The frequency at which the cursor is currently positioned when F5

is pressed, is considered as the fundamental

frequency of the signal under examination, and on the graph all the harmonics of higher order (2nd, 3rd, 4th, …) are marked

Shifting of the cursor, which varies the frequency considered as fundamental, causes the automatic updating of the position

of all the multiple ones.

Use of the harmonic cursor allows easy recognition in the spectrum of families of peaks in correspondence of frequencies,

26

N600 - Ver. 2.2 09/2015

which are multiples between each other, and typically indicative of special defects ( APPENDIX C).

6.3 waVeForm FunctIon

In the second series of functions (accessed by pressing F6 ) is present F1 which allows access to a

page where the vibration signals are shown in relation to time.

In this mode, the N600 instrument can be used as an actual oscilloscope, and further enhances the variety of information

which can be deduced from the vibration signals. This mode also contains all the typical graph control functions ( FUN-

CTIONS OPERATING ON GRAPHS).

It is possible to return to SPECTRUM ANALYSIS by selecting F6 e poi F1 .

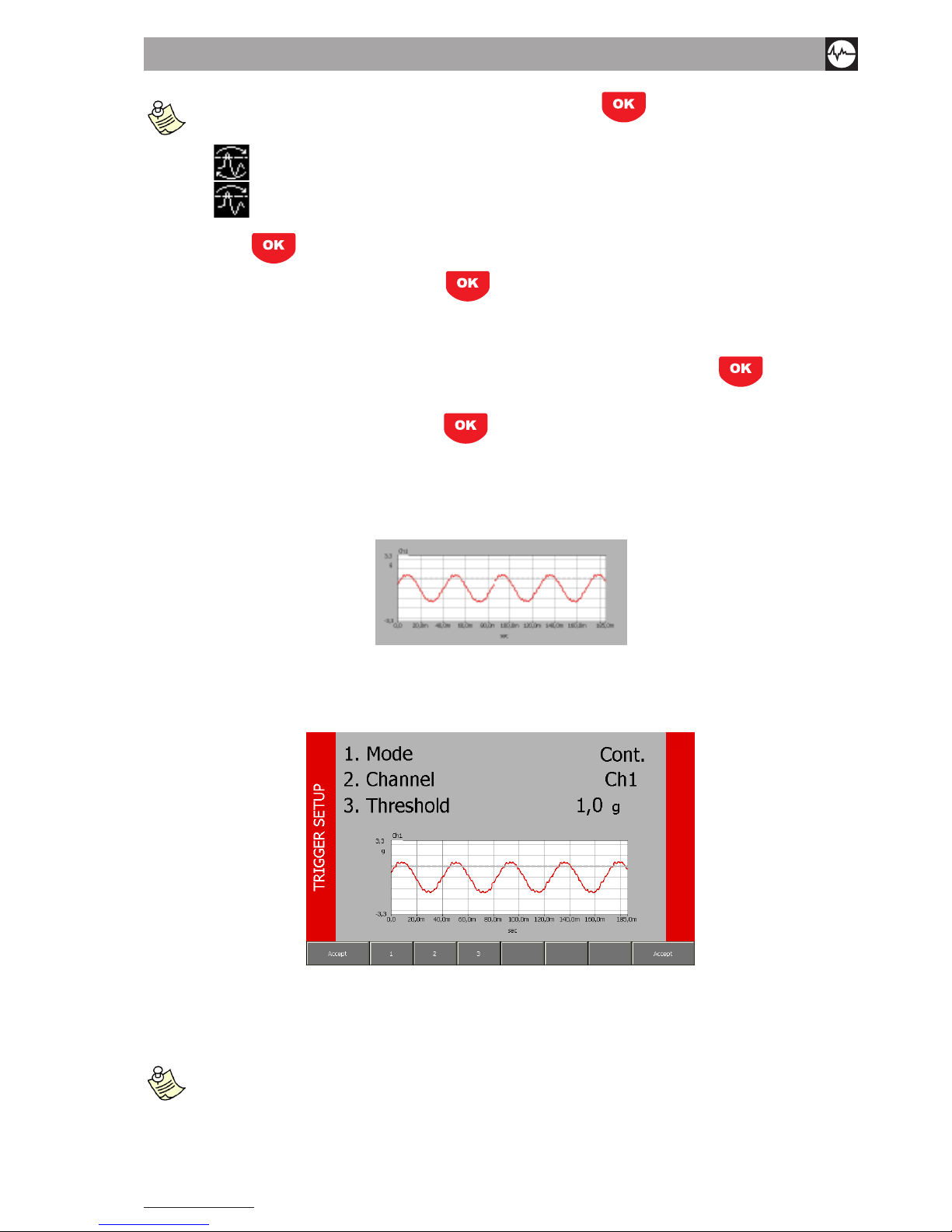

6.4 trIGGer setup

In certain cases, it could be useful for acquisition not to start with the pressing of by the operator, rather with a certain

condition associated with the phenomenon being observed; this is possible by enabling the so-called trigger. In this way, the

measurement does not started immediately after pressing , but only when the signal of the trigger channel exceeds

a preset threshold.

Operation of a trigger can be enabled in two distinct modes, namely:

• Cont. (continuous mode)

• Single (single measurement)

and requires presetting of

• a channel

• a threshold

One of the most frequent uses is the so-called Impact test: A hammer is used to stress a structure and to cause it to vibrate

in order to determine its natural frequencies. For such purpose, a sensor should be placed in the zone to be examined and

a threshold value chosen, which is higher than the background noise read, but lower than that produced by the hammering

with which the structure is stressed.

Vibration equipment division

27

N600 - Ver. 2.2 09/2015

Trigger threshold

aFter enabling the trigger and selecting the required settings, press to return to the measurement page

in which the mode selected For the trigger is speciFied by a speciFic icon:

-

continuous mode

-

“single measurement” mode

Now merely press , and wait for the trigger threshold to be exceeded. If it is required to stop the procedure manually

(before or after exceeding the threshold), just press again.

6.4.1 modes

This is the parameter which indicates whether the trigger is:

• OFF (disabled): the measurement is started and stopped manually by the operator on pressing

• Cont. (enabled in continuous mode): acquisition is started when the signal exceeds the trigger threshold, and continues

until the operator stops it manually (by pressing )

• Single (enabled in “single measurement” mode): when the signal exceeds the trigger threshold, a single measurement

is made (duly observing the parameters set for the FFT), then the acquisition is stopped automatically; this is the most

frequently used mode because it allows analyzing phenomena of transitory type; by suitably presetting the FFT parame-

ters, it is possible to obtain an acquisition time sufciently long for containing all the important information.

Subsequent acquisitions would only succeed in capturing noise, therefore they would be counter-productive.

When the trigger is enabled, the following settings become visible in the TRIGGER SETUP page:

• Channel

• Threshold

6.4.2 channel

This indicates on which channel (Ch1 or Ch2) to make the comparison between the signal value and the threshold value in

order to activate the acquisition.

iF just one oF the two measuring channels is enabled, obviously choice oF the trigger channel is obligatory, hence

it is Forced automatically.

28

N600 - Ver. 2.2 09/2015

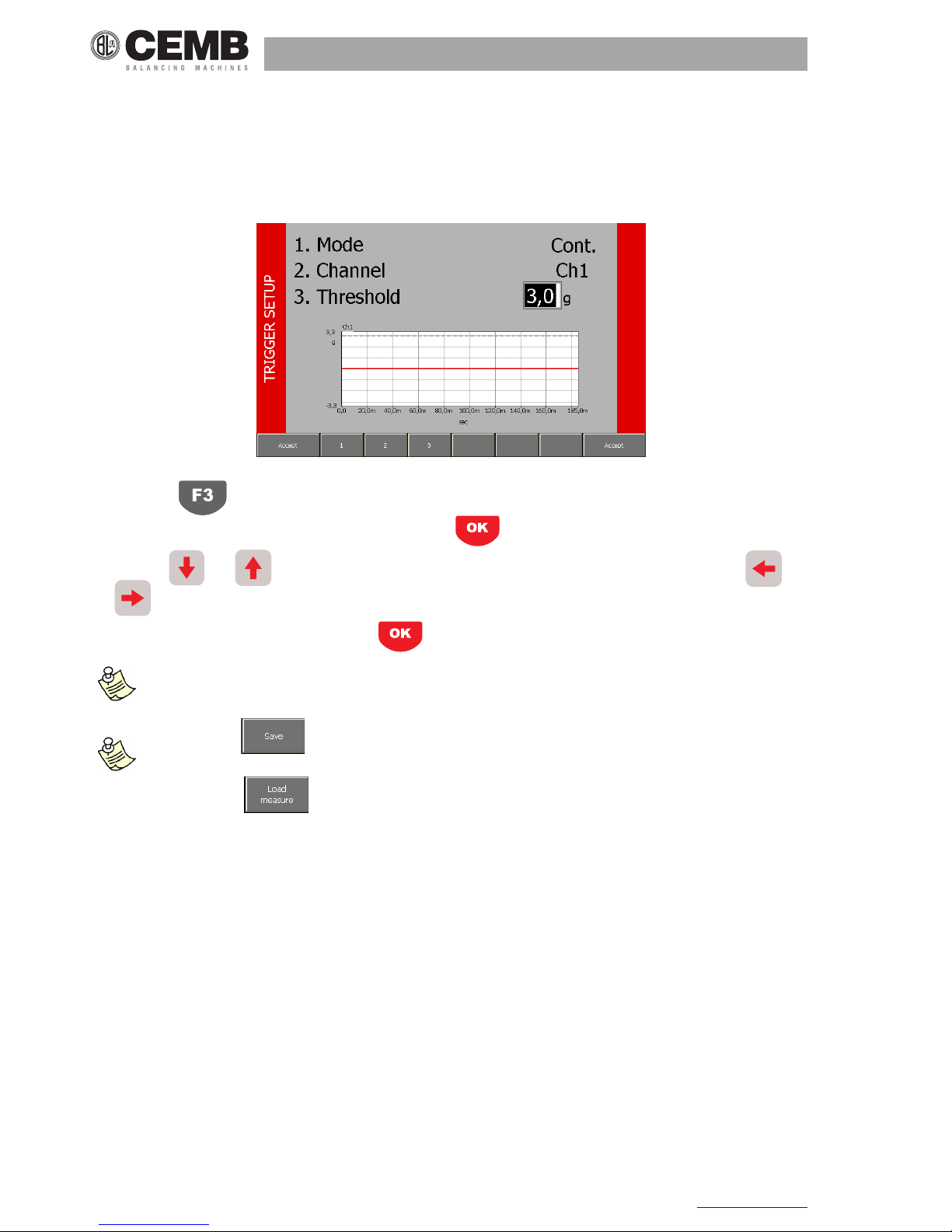

6.4.3 threshold

This is the level which the signal must exceed (in a leading edge of the waveform) in order for the acquisition to be started

automatically. The selection of a suitable value is normally one of the most delicate operations, but by using the N600 instru-

ment it is considerably simplied. The graph at the bottom of the page shows in real time the signal of the trigger channel (in

continuous line) and the current threshold (broken line). Hence the effect of different values can be assessed immediately,

thus making it easier to make a rapid choice of the value considered most appropriate.

After pressing the threshold value can be preset in two ways, namely:

• by typing, using the numeric keyboard (only after pressing , it is possible to shift the broken line in the graph);

• by using and , to increase or decrease the value of a single digit, which can be selected with and

(the broken line in the graph is shifted

• immediately, however at the end, pressing of is always necessary in order to conrm).

the trigger threshold should always be set in the unit oF natural measurement oF the sensor. however, in the

measurement page, it is possible to supply the vibration in other units even iF this is not recommended when making

measurements with the trigger enabled.

the F5 button allows saving the measurements, selecting the appropriate measurement point in the

tree element relating to the currently selected route.

the F2 button allows reloading the measurements previously processed by the instrument.

Vibration equipment division

29

N600 - Ver. 2.2 09/2015

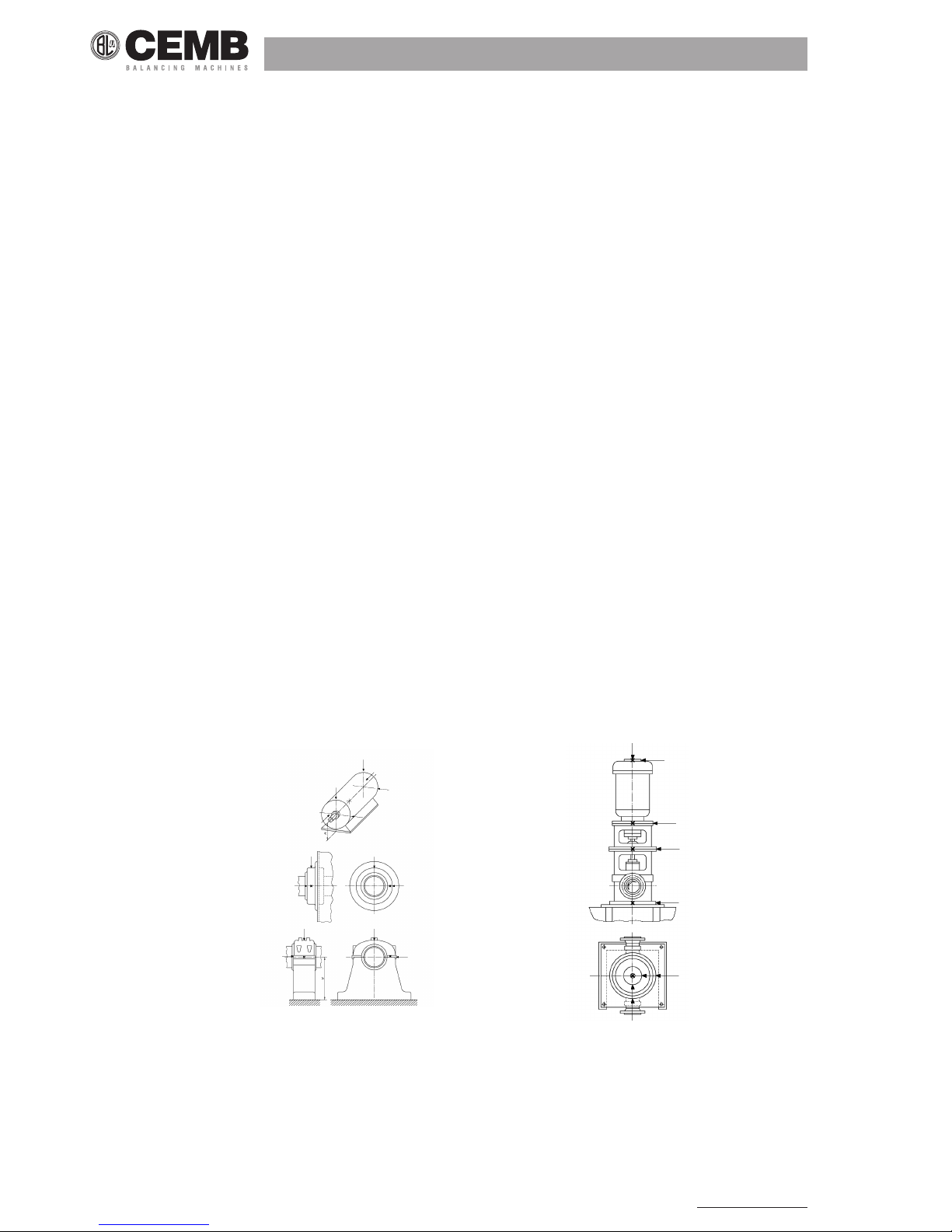

7. balancer mode

One of the causes of vibration most frequently encountered in actual practice, is the unbalance of a rotating part (lack of

uniformity of the mass about its axis of rotation); such unbalance can be corrected with a balancing procedure.

The N600 instrument allows balancing any rotor under service conditions in one or two planes, by using one or two vibration

pick-ups and a photocell.

Ad hoc procedures have been drawn up for the most frequent situations (balancing on one plane with just one sensor and

balancing on two planes with two sensors). These procedures guide the operator step-by-step through the sequence of

operations. A general guided procedure is available for all the other cases (rarely used).

Some rules to be observed in order to perform correct balancing are as follows:

• place the sensors as close as possible to the supports of the rotor to be balanced, by using the magnetic base or by

fastening via a tapped hole to ensure good repeatability;

• apply a reecting label on the rotor as reference mark (0°). The angles are measured, starting from this position, in direc-

tion opposite to that of shaft rotation.

• connect the photocell and place it in correct position (50 – 400 mm), so that the led at the back of the photocell lights up

only just once per rev. when the light beam illuminates the reference mark. If operation is incorrect, either retract or approach the photocell or else incline it with respect to the workpiece surface. ( APPENDIX D - Laser sensor for CEMB

N instruments).

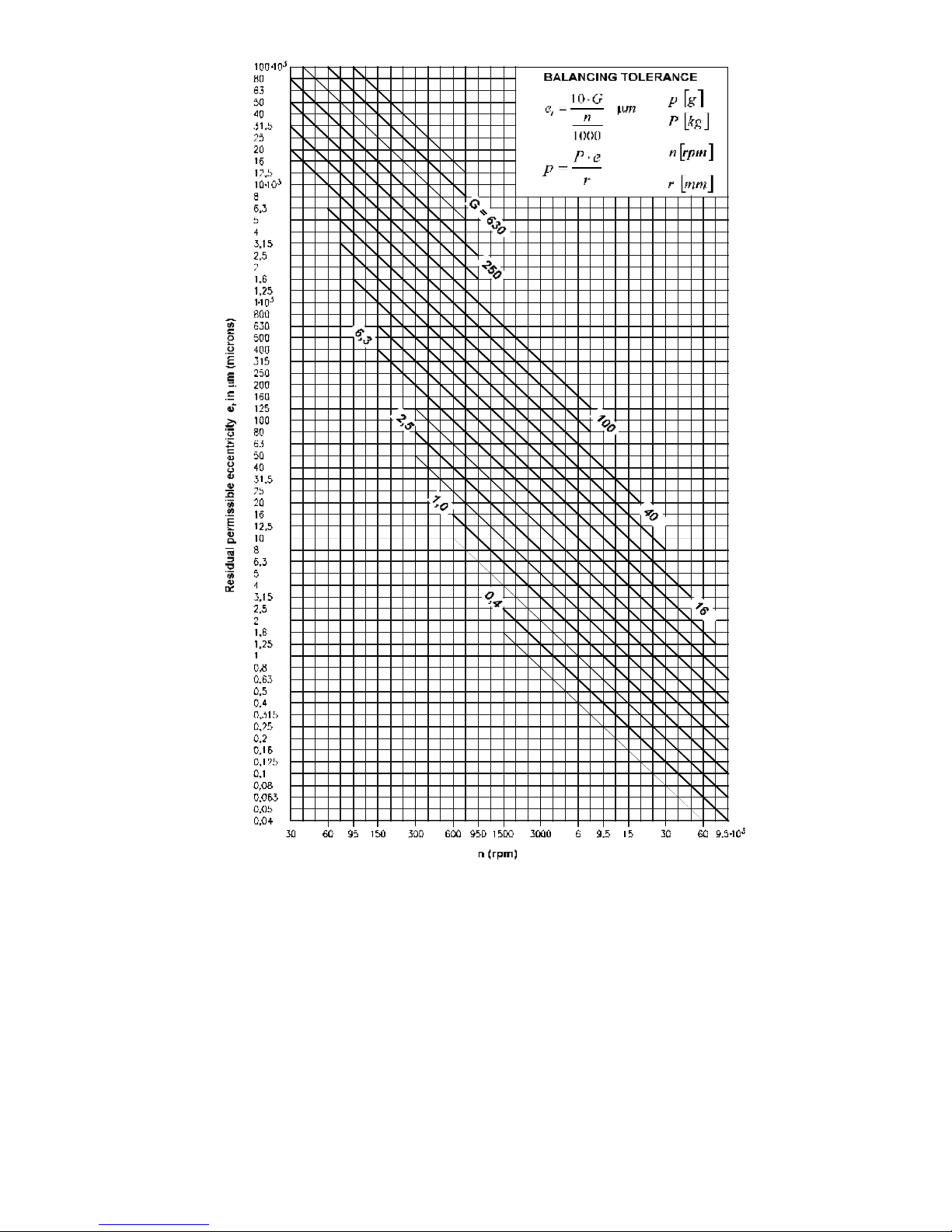

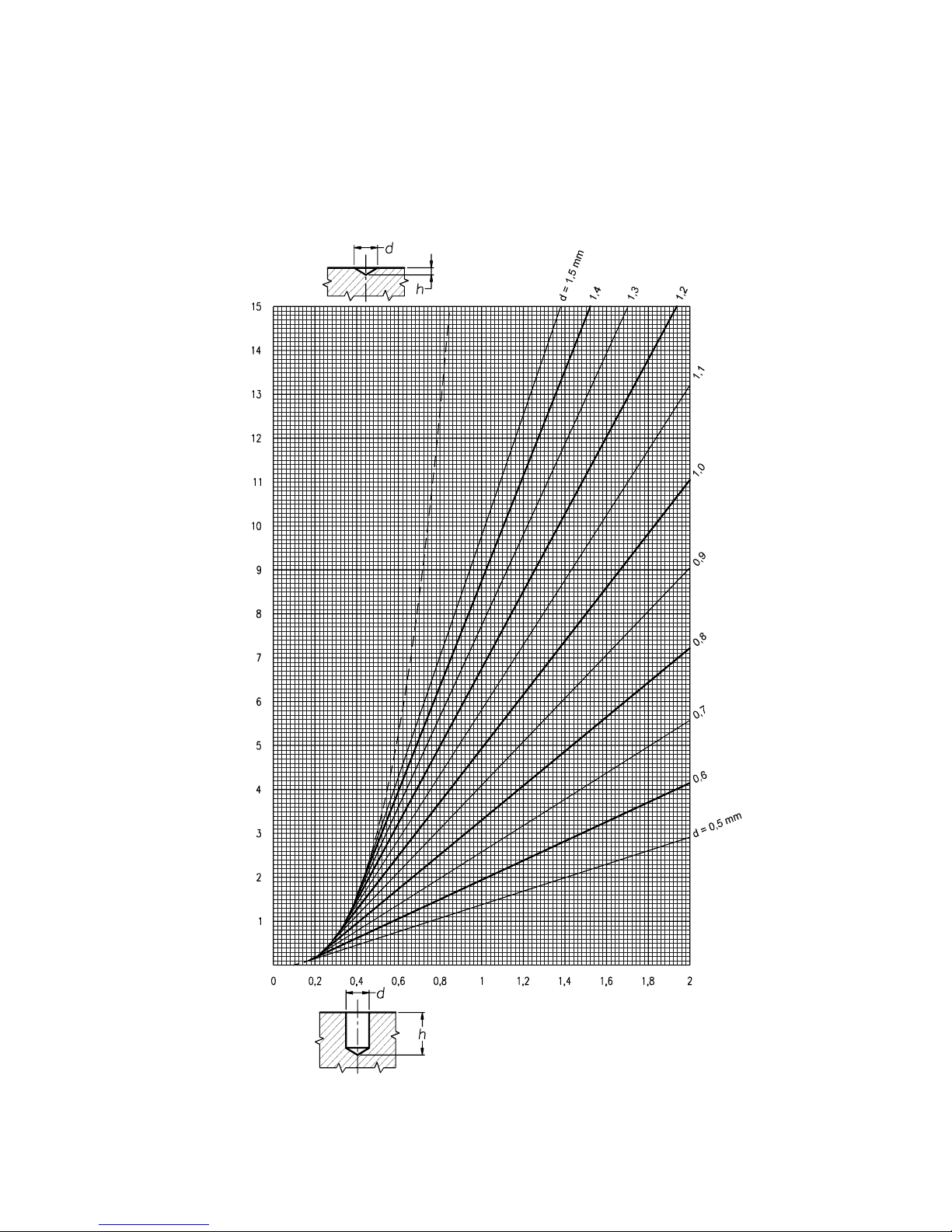

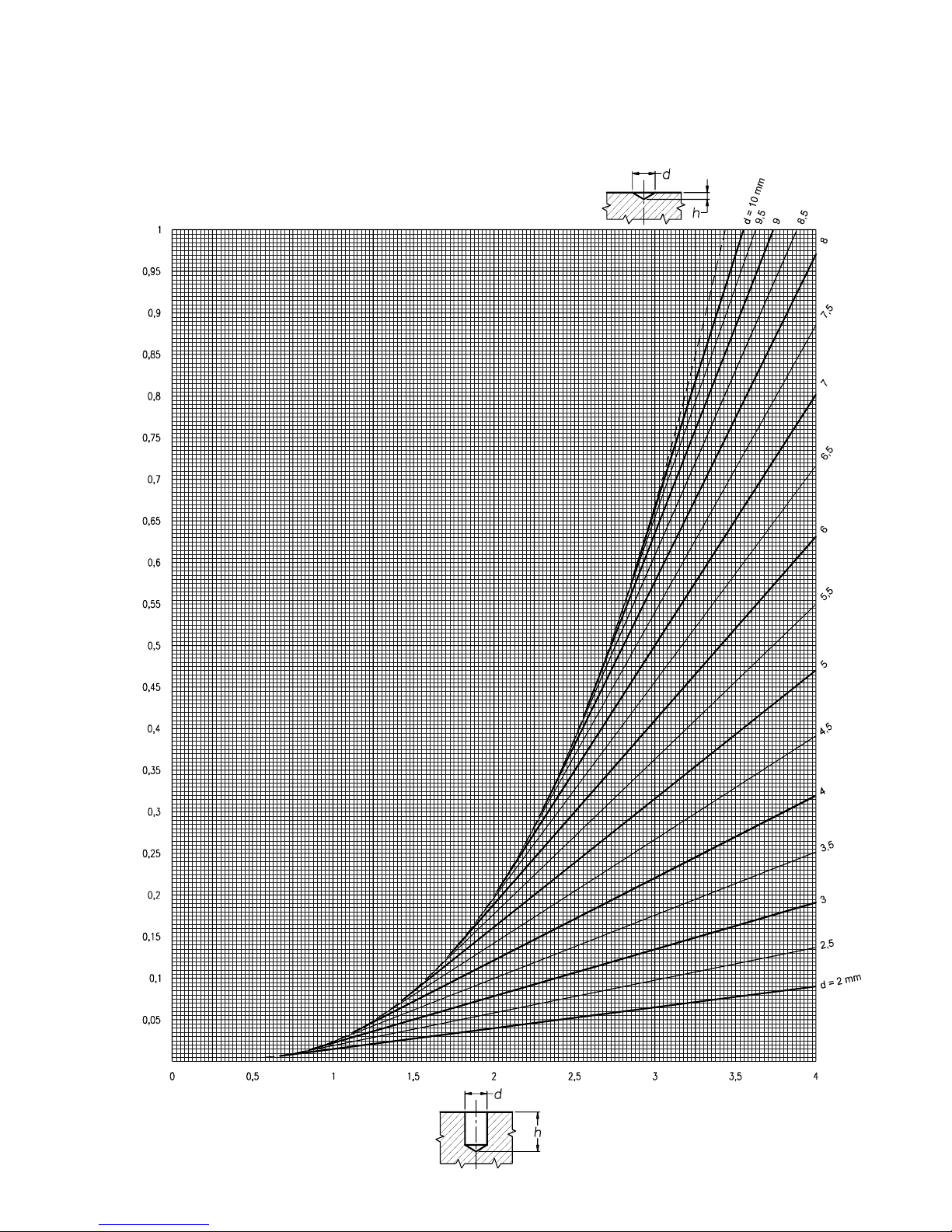

For further consideration, see attached brochure BALANCING ACCURACY FOR RIGID ROTORS.

The balancing procedure consists of two parts, namely:

• calibration: a series of spins allows determining the parameters required for balancing in the case of a given rotor

• measurement of the unbalance and calculation of the correction.

As the calibration is normally a laborious procedure, the parameters derived should be memorized, then called in the case

of subsequent maintenance work on the same machine. This is possible via the balancing programs: a program is dened

with a series of settings in order to work on a particular rotor and it contains all the information and data acquired regarding

such rotor. It is possible to save the current program at any moment in a special archive so that it is available at later dates.

iF it is required to use data and parameters oF a previously stored program, it is essential to mount the transducer

in exactly the same position on the rotor..

30

N600 - Ver. 2.2 09/2015

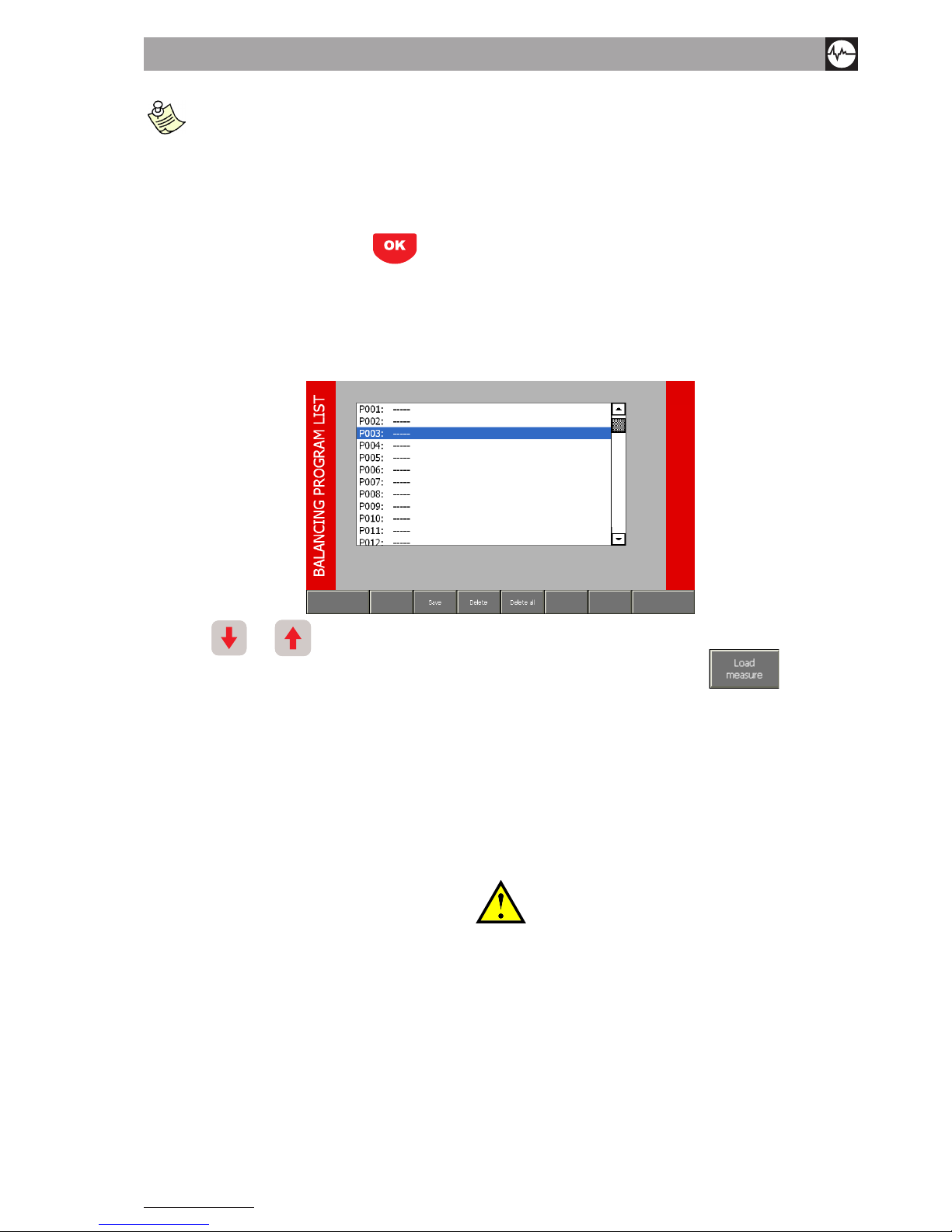

7.1 selectIon oF tHe balancInG proGram

When the balancing function is selected, a page is presented to the operator in which to select the balancing program to be

used, choosing between the following options:

• new program

• loading of program from archive

• use of current program (only available if a program has been previously created or loaded)

• copy archive to USB key

7.1.1 new program - Balancing setup

The creation of a new program entails setting of a series of parameters. This is done in the BALANCING SETUP screen.

7.1.1.1 numBer oF planes

This is the number of planes on which to act to correct the unbalance of the rotor. The number can be 1 or 2..

7.1.1.2 Filter accuracy

Balancing under not particularly stable signal conditions is certainly critical and needs acquisition for longer times in order to

obtain a satisfactory quality of the value measured. This can be achieved by acting on the lter accuracy:

acquisition made with a broad lter: faster, but only suitable for particularly stable signal conditions (high

unbalance values)

acquisition made with a narrow lter: suitable in most conditions

acquisition made with a very narrow lter: suitable for particularly critical signal conditions (low unbalan-

ce values); requires longer times

Vibration equipment division

31

N600 - Ver. 2.2 09/2015

depending on the accuracy selected For the Filter, the instrument automatically determines the number oF revs. ne

cessary For each acquisition. as it could be necessary to have up to some hundred revs. in certain situations, the

time required For each measurement could likewise be equal to some tens oF a second. taking into account that a

certain number oF consecutive acquisitions is necessary so that the quality oF the measurement can reach accepta-

ble levels, the time required For an acquisition could also entail several minutes in the case oF slow rotors. For

example, For a rotor with speed oF rotation 600 rpm, it could be necessary to wait up to 10 seconds beFore being

able to view the First result oF the measurement.

Conrmation of the settings made (with ) creates a new balancing program not associated with any name, seeing as

though it is directly accessible as current program. Only when saving in the archive, will there be a request to the operator

to enter a special name which will characterize it from that moment on.

7.1.2 load program From archive

When this option is selected, access is gained to the program archive.

Arrow keys and allows scrolling the 10 available positions, thus selecting the required program (visible in nega-

tive, i.e. with white writing on black background); the program can then be loaded by pressing F1 .

If it is not possible to carry out the operation correctly (e.g. attempt made to load a program from an empty position, indicated

by the symbol -----), an error message appears in the black band in the bottom area of the page.

After loading, the following is displayed:

• the measurement and unbalance correction screen, if the calibration procedure has already been completed

• the calibration screen, if not.

7.1.3 use current program

This option allows resuming the last program used (new or loaded), exactly from the point where it had been abandoned.

————————————————————————————————————————————————————

warnInG!

wHen tHe Instrument Is swItcHed oFF, tHIs causes loss oF unsaVed data (and tHereFore oF tHe current proGram); Hence tHIs

optIon Is not InItIally aVaIlable wHen tHe Instrument Is swItcHed on aGaIn; It becomes aVaIlable only aFter

a proGram Has been created or loaded From tHe arcHIVe.

————————————————————————————————————————————————————

7.1.4

copy archive to usB key

Allows to export on a USB key connected to the instrument all balancing programs previously saved.

It will create a le “Unb_Data.ini”, necessary to do custom balancing reports (using N-Pro software).

32

N600 - Ver. 2.2 09/2015

2

1

3

4

7

9

5

6

8

10

1

5

2

3

4

7

9

6

8

10

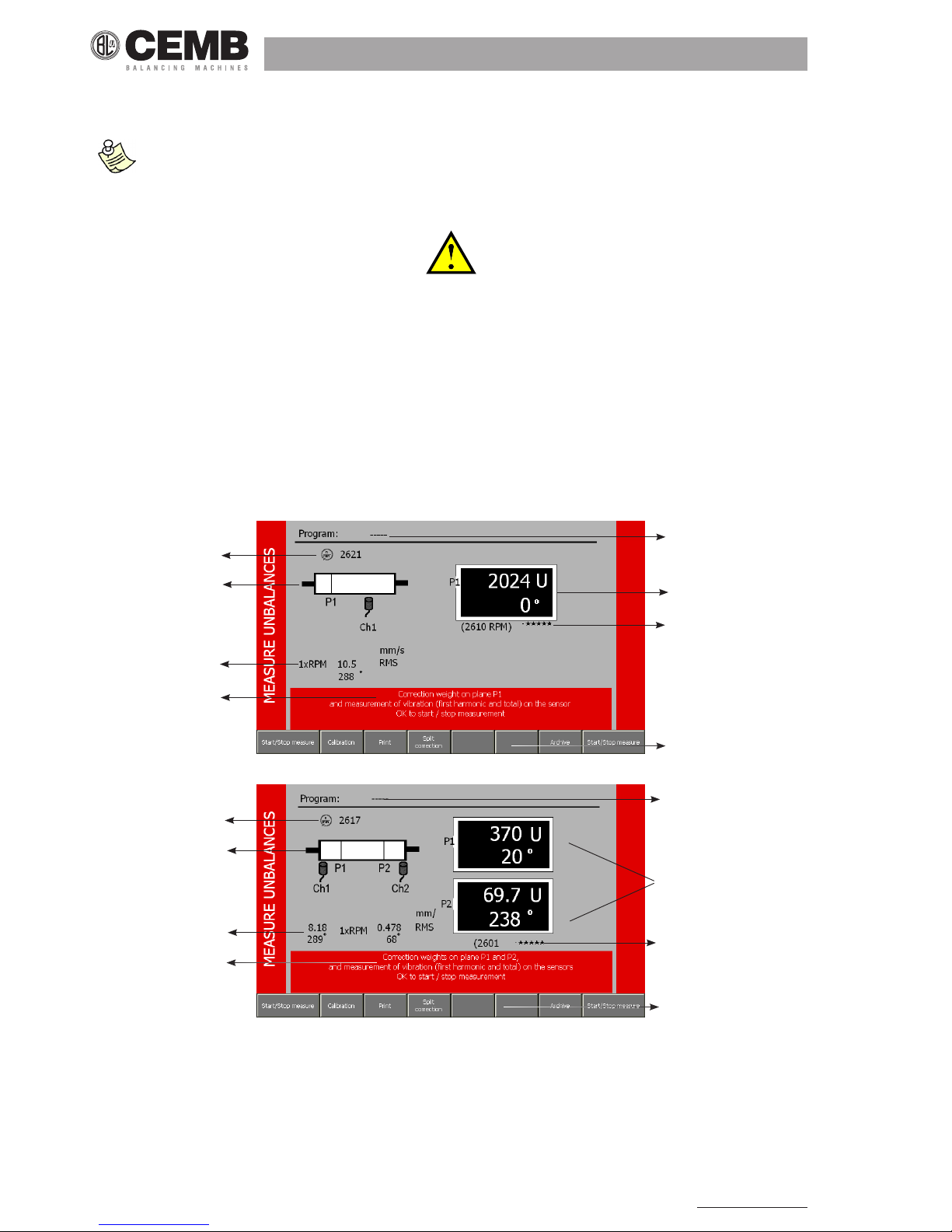

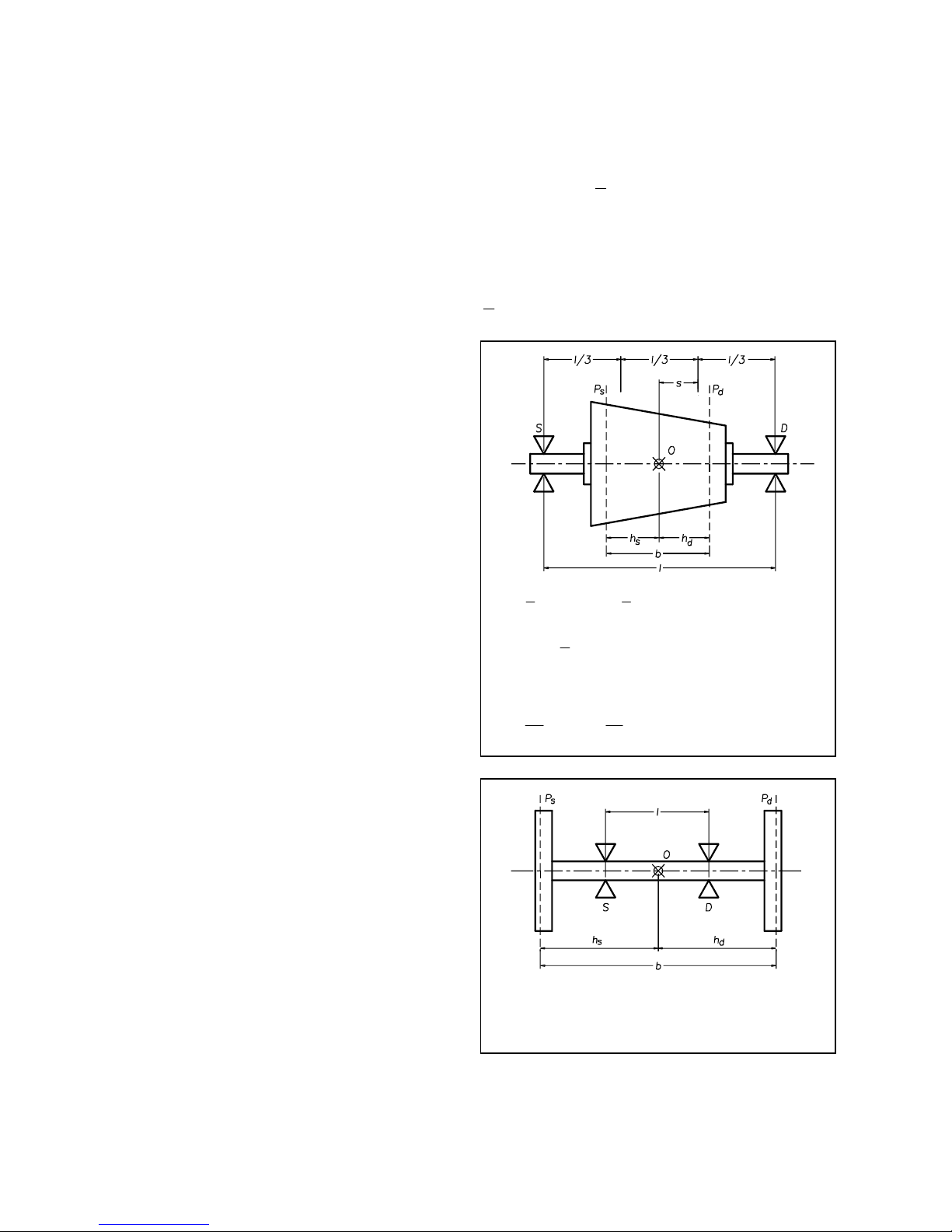

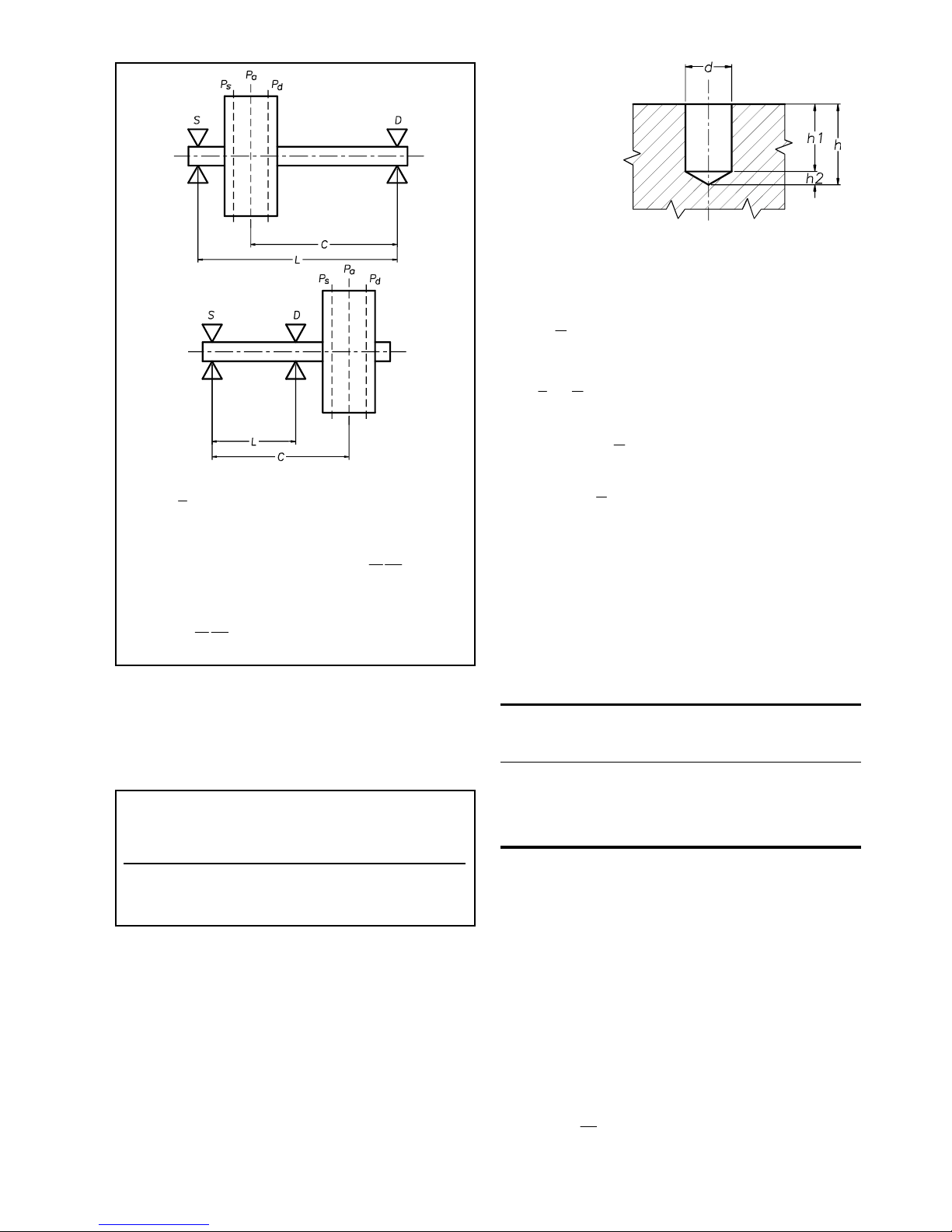

7.2 calIbratIon sequence

The calibration operation, necessary for assessing the unbalance of a rotor, is normally a procedure consisting of various

steps. Above all, for the most common two cases, it consists of:

• Calibration for balancing on one plane:

> rst spin without test weight

> second spin with test weight on the balancing plane

• Calibration for balancing on two planes:

> rst spin without test weight

> second spin with test weight only on the rst balancing plane

> third spin with test weight only on the second balancing plane

For the two congurations:

• correction on one plane with one sensor

• correction on two planes with two sensors

The calibration sequence screen on the N600 instrument is organized as in the gures:

1. number and name of the balancing program (if loaded from the archive), or else ----

2. current speed of rotation, in RPM

3. ayout of the position of the sensors and correction planes on the rotor; indication of the plane on which to apply the test

weight

this representation is approximate only; the sensors and correction planes can be chosen in any position relative

to each other (external sensors or sensors inside planes, ... ) since the calibration serves especially For determi-

ning correctparameters For balancing in any conFiguration.

4. value and angular position of any test weight

5. indication of the vibration component synchronous with the rotation (unbalance) in value and phase for every measuring

channel

6. average speed of rotation and lter accuracy with which the vibration has been measured

Vibration equipment division

33

N600 - Ver. 2.2 09/2015

the average speed value is highly important because the calibration procedure can only be considered as properly

perFormed iF between one step and the other, such speed does not exhibit diFFerences exceeding 5%. it is up to the

operator to check For this condition.

7. indication of the number of calibration step selected

8. indication of the status of the calibration steps

> completed

> to be done

9. instructions for the current calibration step

10. functions for selecting the calibration step

(F1): go the previous step

(F6): go to next step (if the current step is the last step of the sequence, this function, which is indicated by

F6 , ends the calibration and loads the unbalance measuring page)

when each already completed step is selected, the available data appear on the monitor (vibration, average measu-

ring speed, ... ). such inFormation is useFul, also at a later date, to decide whether to repeat or not to repeat the

measurement.

although it is advisable to perForm the calibration steps in the order in which they appear, it is perFectly possible

to select a diFFerent order according to your particular requirements.

7.3 executIon oF measurement

To start the measurement in any of these steps, press ; a pop-up panel appears showing, in real time, the quality of

the current measurement (for each channel).

The higher is the level of the bars, the better will be the quality of the measurement (which is averaged over time). After

reaching the required level, stop the measurement again by pressing

.

If the operator decides to accept the value, then he must press

corresponding to the option , which

ashes in order to warn the operator the importance of pressing it.

When the measurement is accepted, the corresponding calibration step is indicated as complete

.

unstable signals produce measurements whose quality is unable to reach acceptable levels; under these conditions, it

is advisable to increase Filter accuracy (

Filter accuracy) and consequently repeat the entire procedure.

iF the quality oF a particular measurement has been altered by a special event (e.g. an impact), the time required

to go back to it could be excessively long; to speed it up, the measurement can be reset manually by pressing

.

7.3.1 test weight

Calibration requires the use of a test weight, to be applied in succession on the various correction planes. These two para-

meters should be preset, with the appropriate functions F2

and F3 by typing the appropriate values

with the numeric keypad, and conrming with

.

34

N600 - Ver. 2.2 09/2015

2

1

3

6

7

5

8

1

4

2

3

6

7

5

8

4

To cover the various operational requirements when balancing on two planes, it is possible to specify a different test weight

(value and angular position) on plane 1 and on plane 2.

the value oF the test weight should be indicated in general units u. the operator can decide independently to make

these u correspond to the physical units preFerred by him, bearing in mind that also the unbalance and necessary

correction will be indicated in the same units u.

————————————————————————————————————————————————————

warnInG!

correct cHoIce Has been made oF tHe test weIGHt IF It produces, In eacH oF tHe spIns, a suFFIcIent VarIatIon In tHe VIbratIon

compared to tHat oF tHe InItIal spIn.

tHIs may be consIdered satIsFactory IF we HaVe at least one From tHe FollowInG:

- VarIatIon In module oF at least 30%

- VarIatIon In pHase oF at least 30°

————————————————————————————————————————————————————

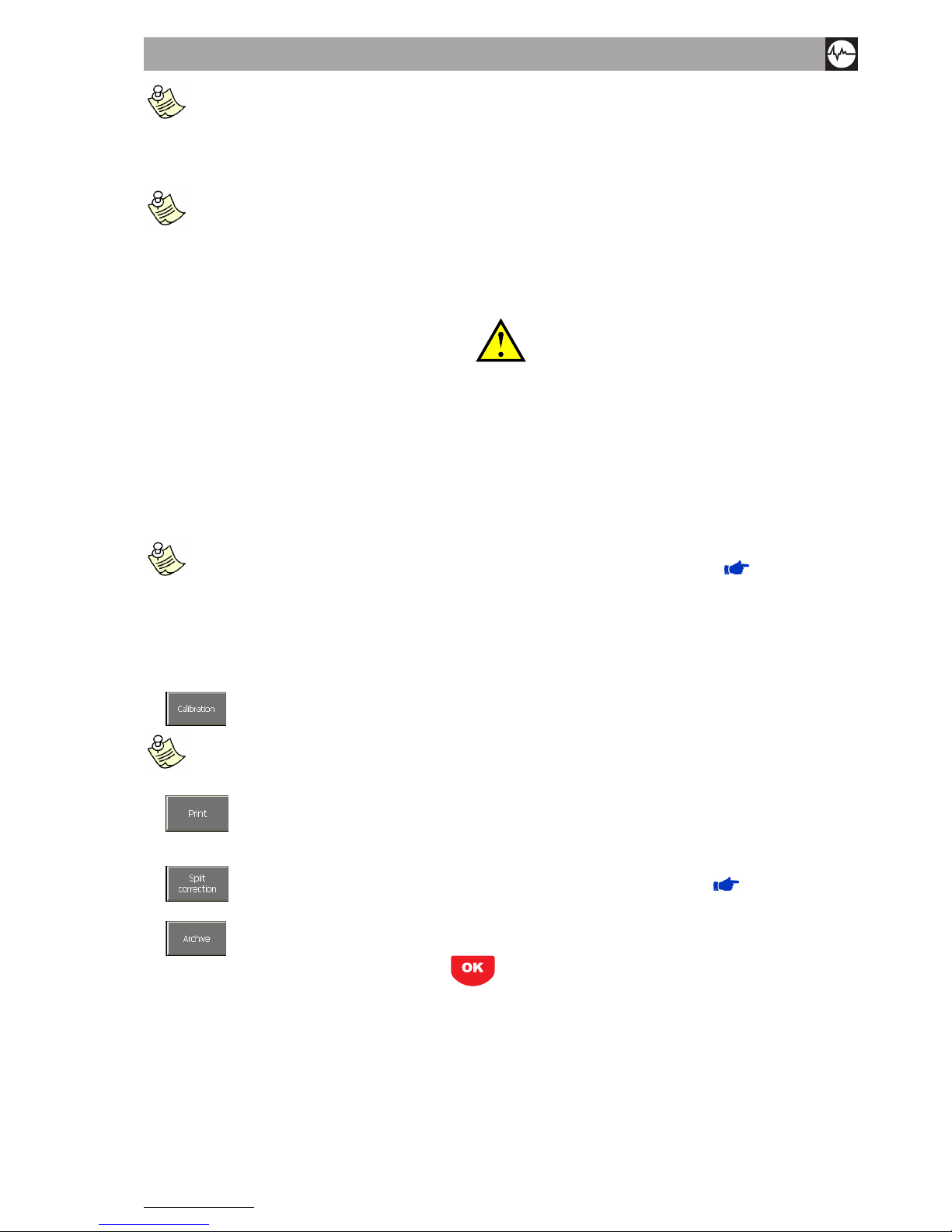

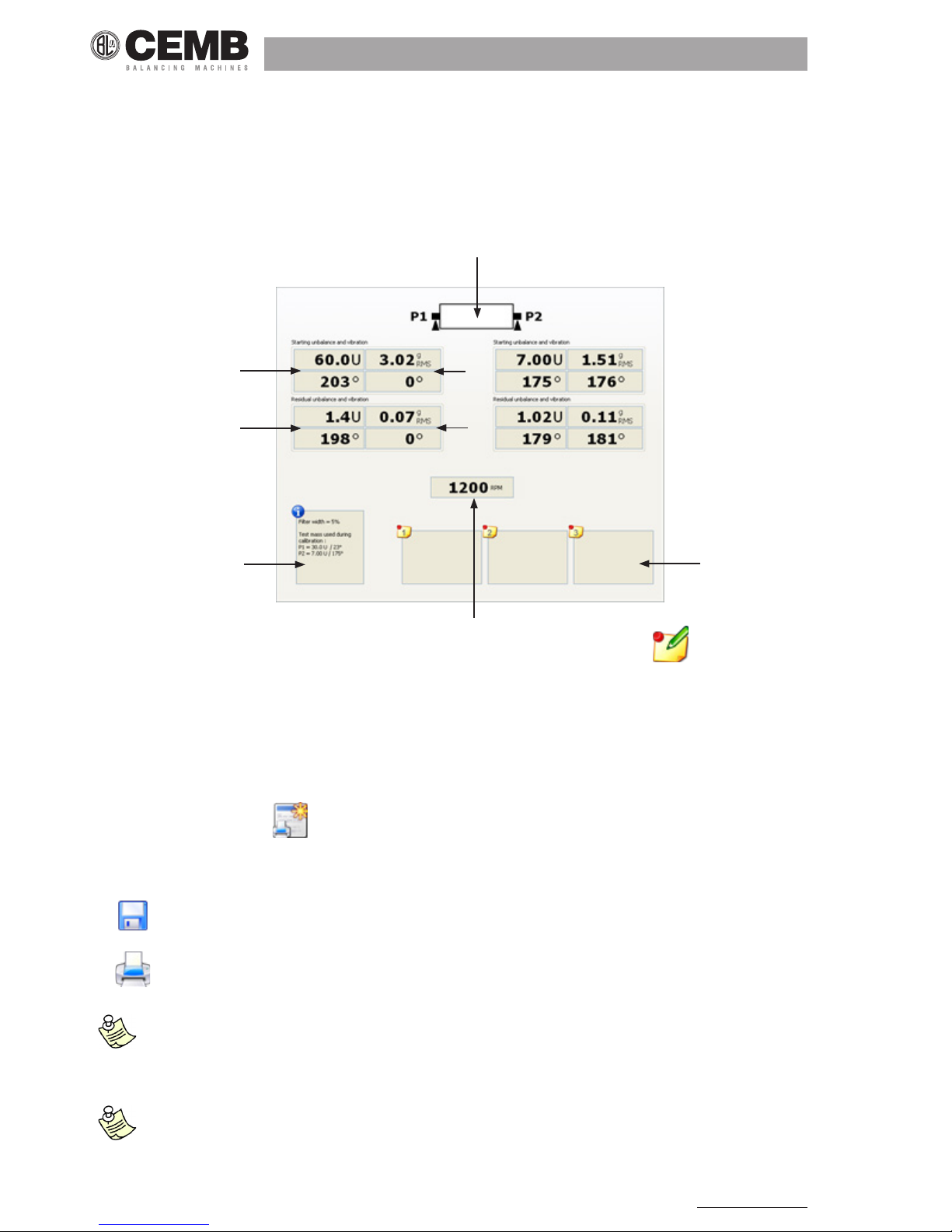

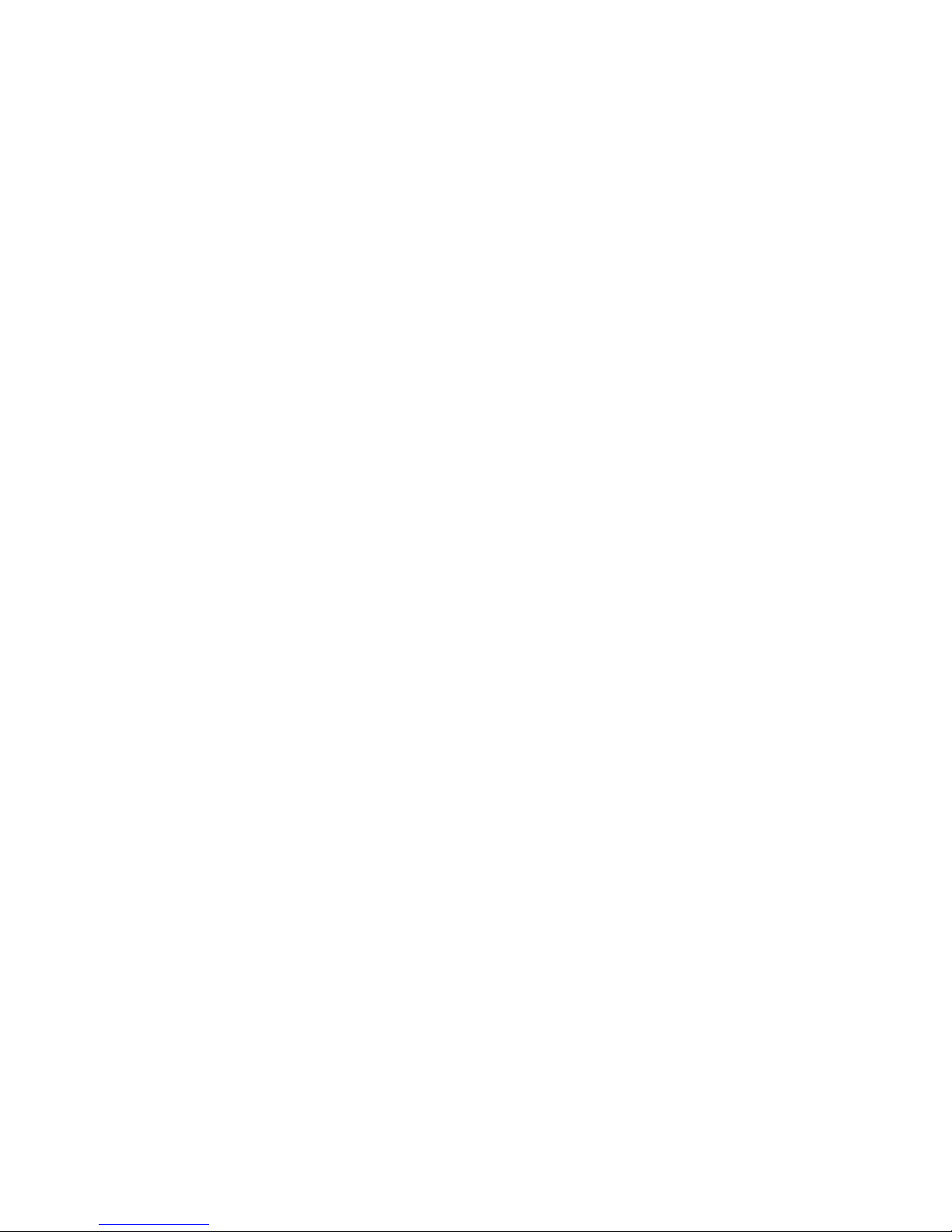

7.4 unbalance measurement and calculatIon oF tHe correctIon

In appearance the UNBALANCE MEASUREMENT page is very similar to the calibration page:

and the following information is given:

1. number and name of the balancing program (when loaded from the archive), otherwise ----

2. current speed of rotation, in RPM

3. layout of the position of the sensors and correction planes on the rotor

Vibration equipment division

35

N600 - Ver. 2.2 09/2015

this representation is approximate only; the sensors and correction planes can be chosen in any position relative

to each other (external sensors or sensors inside the planes, ... ) since the calibration serves especially For de-

termining correct parameters For balancing in any conFiguration.

4. indication of the correction weight, in value and position on every plane

the module is indicated in general units u, corresponding to those used in setting the test weight. as the program

makes use oF correction through addition oF material, the position indicated is the one where to add the correc-

tion weight. when it is required to proceed by removal oF material, act in a position diametrically opposite (add

180° to the displayed phase)

5. average speed of rotation and lter accuracy with which the unbalance has been measured

————————————————————————————————————————————————————

warnInG!

tHe aVeraGe speed Value Is Important because It allows cHeckInG wHetHer tHe measurement Has been made at a speed not

too dIFFerent From tHat used In tHe calIbratIon spIns (dIFFerences less tHan 5%). owInG to small amounts oF non

lInearIty always preset In actual practIce, It Is not adVIsable to proceed to calculate tHe correctIon at a speed too wIdely

dIFFerent From tHe calIbratIon speed. cHeckInG oF tHIs condItIon Is up to tHe operator.

————————————————————————————————————————————————————

6. value and phase of the vibration synchronous with the rotation (1xRPM) and total value(Overall) vibration measured via

the sensors

this inFormation is considerably important as indicator oF the reliability oF the balancing: what concerns us in

actual practice is to reduce the vibration to under a certain value considered as tolerable ( appendix B

).

however reduction oF the unbalance only has eFFect on the 1xrpm component. a low value oF this component,

accompanied by a high overall indicates problems diFFering From those oF unbalance, which, thereFore, cannot be

corrected by balancing.

7. instructions for unbalance measurement and calculation of the correction

8. functions available

(F1): calibration procedure

iF the calibration procedure has not been completed, this button starts Flashing, to warn the operator to return

to the calibration procedure beFore being able to make unbalance measurements. iF not, indication is already given

oF the correction weights and positions where to act, deduced From the calibration spins.

(F2): direct printing of a balancing certicate by using the portable printer provided (optional). The certicate

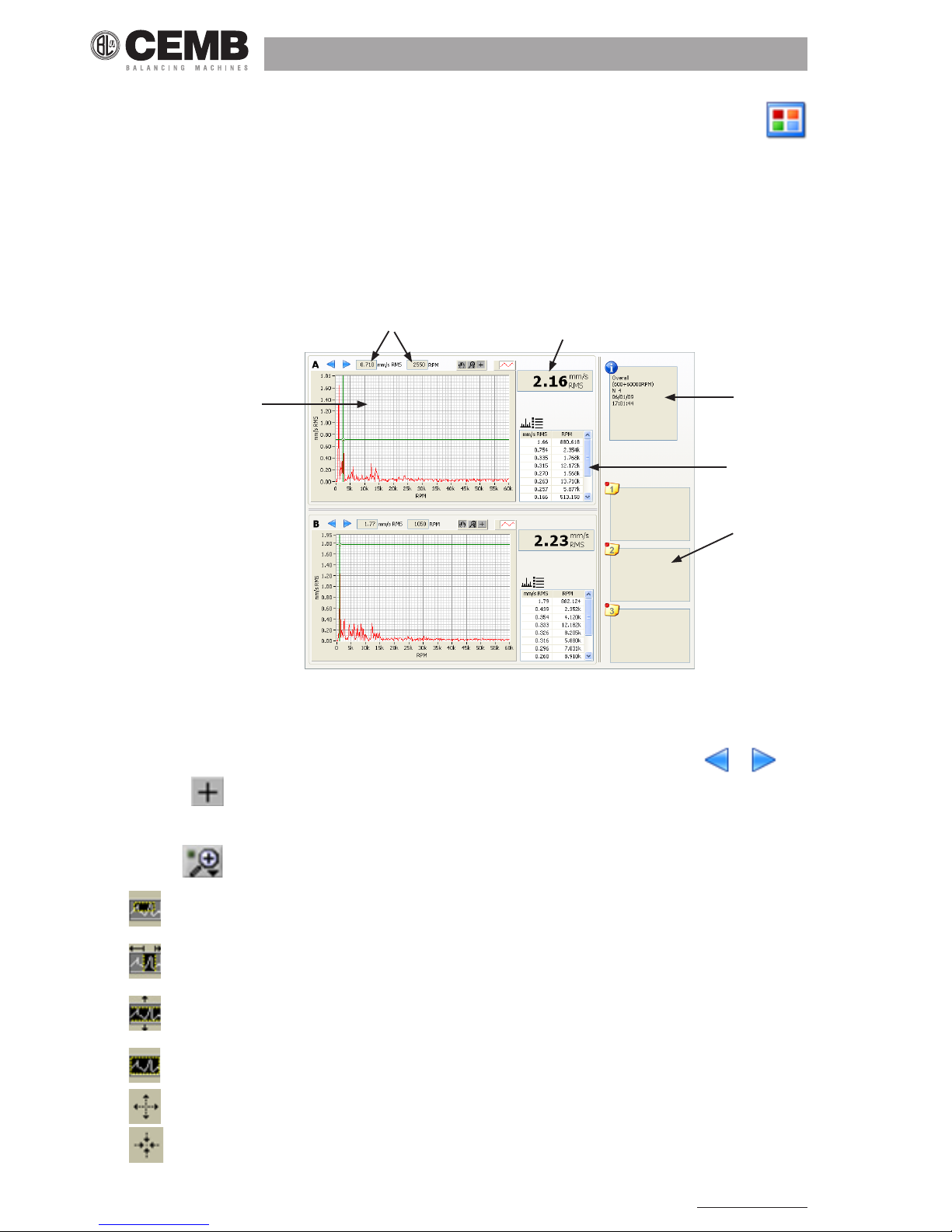

gives the unbalances on the correction planes (in units U), as well as the values of vibration (overall and

synchronous) of these planes.

(F3): function involving splitting of the correction weight on two presettable angles ( SPLITTING OF COR-

RECTION WEIGHT).

(F6): shows the program archive (to allow saving or eliminating a program).

As in calibration, to start or stop measurement, press ; while the measurement is active a pop-up appears to indicate

the quality of measurement of each channel. After making the corrections indicated, the measurement-correction procedure

can be repeated until the required conditions are met (typically vibration measured by the sensors lower than a certain value).

36

N600 - Ver. 2.2 09/2015

7.5 splIttInG oF correctIon weIGHt

In this page it is possible to select between the correction modes:

• by addition of material

• by removal of material

•

by pressing push buttons F1 and respectively.

In certain practical situations it is not possible to correct in the position calculated theoretically as optimum position: in the

case of a fan, for example, such position could fall in the gap between two blades, where obviously it is not possible to add

or remove material. However, it is often the case also for uniform rotors, to prefer to correct where holes are already present,

or else to avoid acting in particular zones.

The split function of the N600 function calculates the weights to be applied or to remove corresponding to any two positions

α1 and α2, so that their effects are equivalent to those of the correction calculated by the balancing algorithm.

When F3

or F4 is pressed, the user can assign the most appropriate value to these two positions,

by selecting from those effectively available in practice for that particular rotor. By pressing

the two corresponding

correction weights are automatically calculated and displayed.

Such operation can be performed separately on each of the planes, after selecting the required one by pressing

.

Pressing F6 you go back to the residual unbalance page.

————————————————————————————————————————————————————

warnInG!

wHateVer tHe Value oF α1 and α2, tHe anGle oF reVolutIon Is subdIVIded Into two parts, one part

conVex (<180°) and tHe otHer concaVe (>180°).

In order to carry out tHe splIttInG, anGles α1 and α2 sHould be cHosen so tHat tHe correctIon posItIon

calculated durInG balancInG, lIes wItHIn tHe conVex zone.

IF not, sucH splIttInG would be ImpossIble, and tHe n600 Instrument would IndIcate zero as correctIon

weIGHt For botH posItIons

α

1 and

α2.

————————————————————————————————————————————————————

Vibration equipment division

37

N600 - Ver. 2.2 09/2015

it is useFul to observe that the more the α1 and α2 positions are Further apart From the position calculated in

balancing, the higher must be the values oF the corresponding weights. hence it is advisable to select α1 and α2 as

close as possible to the correction angle obtained by the balancing operation, or at least to make sure that they

diFFer by less than 150°.

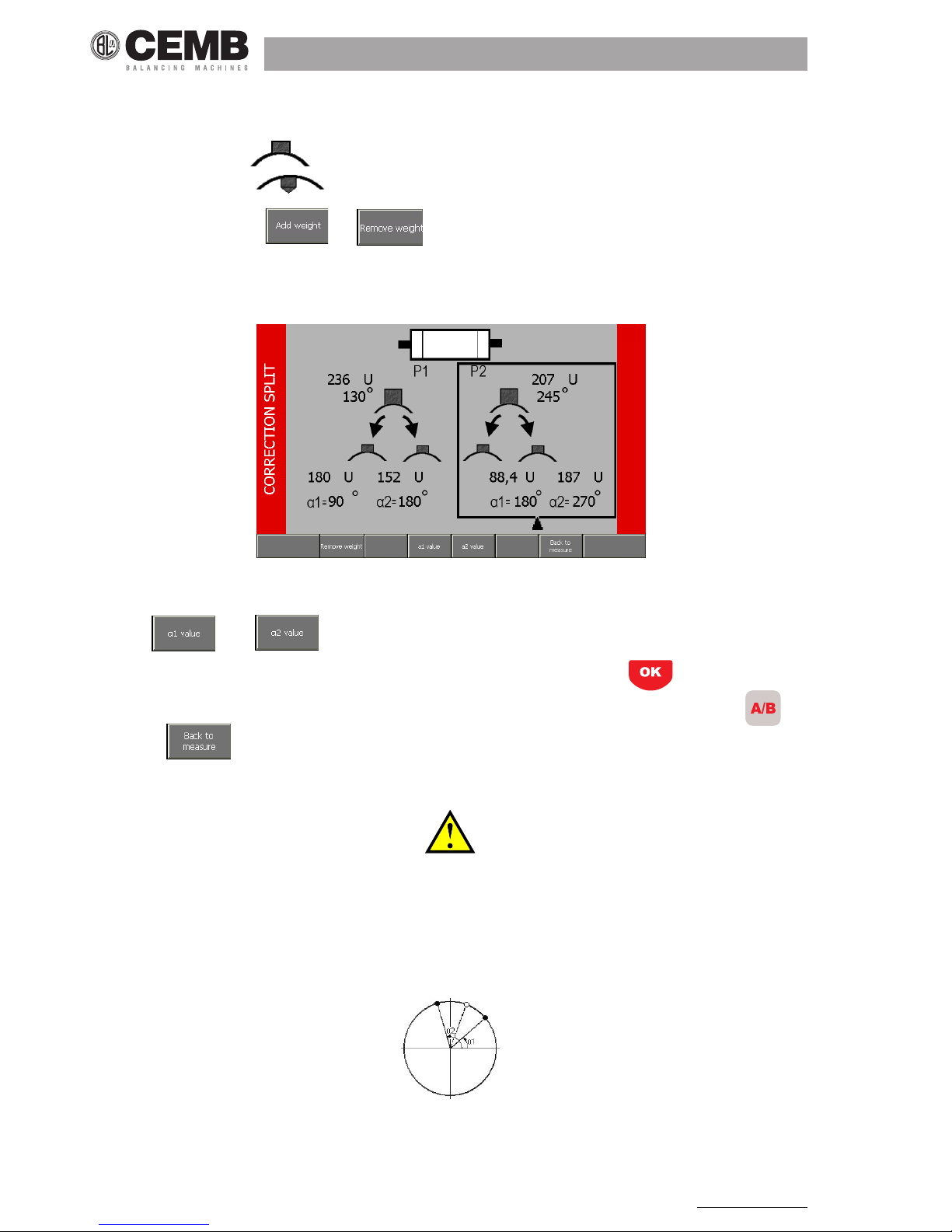

7.6 saVInG oF a balancInG proGram

After displaying the program archive, proceed to select (with and the position in which to save the current program.

When F2 is pressed, a pop-up appears in which to enter the program name, as explained in ALPHANUMERIC

KEYPAD.

Instead, when F3 is pressed, the selected program can be eliminated, provided it is not the current one.

With F4 it is possible to eliminate all the balancing programs contained in the archive.

38

N600 - Ver. 2.2 09/2015

8. data manaGer mode

The N600 instrument operates following a route logic in which all the data processed and collected by the measuring instrument can be saved.

These routes are divided into two distinct types:

• Soft Route (can be created with the RouteManager software). You can create a “simplied” route directly on the instru-

ment - NEW PROJECT.

It is characterised by the fact that two measurement points are created, whose measurement setup can be modied at

any time.

• Strict Route (can only be created with RouteManager). It is characterised by the fact that the measurement points crea-

ted have a measurement setup set via software and is hence not modiable during data acquisition.

When pressing a PROJECT MANAGEMENT screen appears in which you can select from the following options:

• Open existing project (select the available projects from a list)

• Change selected points (select a measurement point in the tree element of the project selected)

• New project (create a new Soft Route)

• Import projects from USB key (import a Soft/Strict Route created via software and previously saved to USB key)

• Export projects to USB key (export a route from the instrument to USB key)

• Delete projects (delete an existing project from the instrument).

8.1 open exIstInG project

The projects (routes) saved on the N600 instrument can be selected via this function. To change the active project, scroll

through the list using the arrows and ; and select the project involved (recognisable by white text on a blue

background) and conrm by pressing F1 .

Vibration equipment division

39

N600 - Ver. 2.2 09/2015

If you select a Strict Route, the PROJECT STRUCTURE screen will appear; scroll through the list of measurement points

using the arrows

and and select the rst point in the list by pressing F2 .

The measurement acquired will be set according to the settings made during route creation; the measurement functions

(vibrometer, FFT, waveform, monitor_T and monitor_V) will be characterised by the logo

, and the name of the mea-

surement point will be shown at the top of the graph.

in the case oF analysis using a strict route, this measurement setup Function allows checking but not modiFying

the parameters set.

T

he symbol allows identiFying a setup relating to a strict route.

iF you select a soFt route, a pop-up will appear inForming you oF the route type selected and the procedure to

save the acquired data.

press to conFirm the above pop-up.

8.2 cHanGe selected poInts

If a Strict Route is active, this function can be used to change the points of the tree element related to the selected route. For

each measurement point selected, the measurement will be acquired according to the settings made during route creation

via the RouteManager software.

Accessing this function, you can view the PROJECT STRUCTURE screen relating to the tree corresponding to the currently

active route. Use the arrows

and to select the measurement point involved and press F5 to conrm

the measurement point.

in case oF analysis with soFt route active, accessing this Function, a pop-up inForms you that the measurement

points to which to attribute/save the reading are to be selected at the time oF saving the measurement. pressing

,

you go back to the initial screen.

40

N600 - Ver. 2.2 09/2015

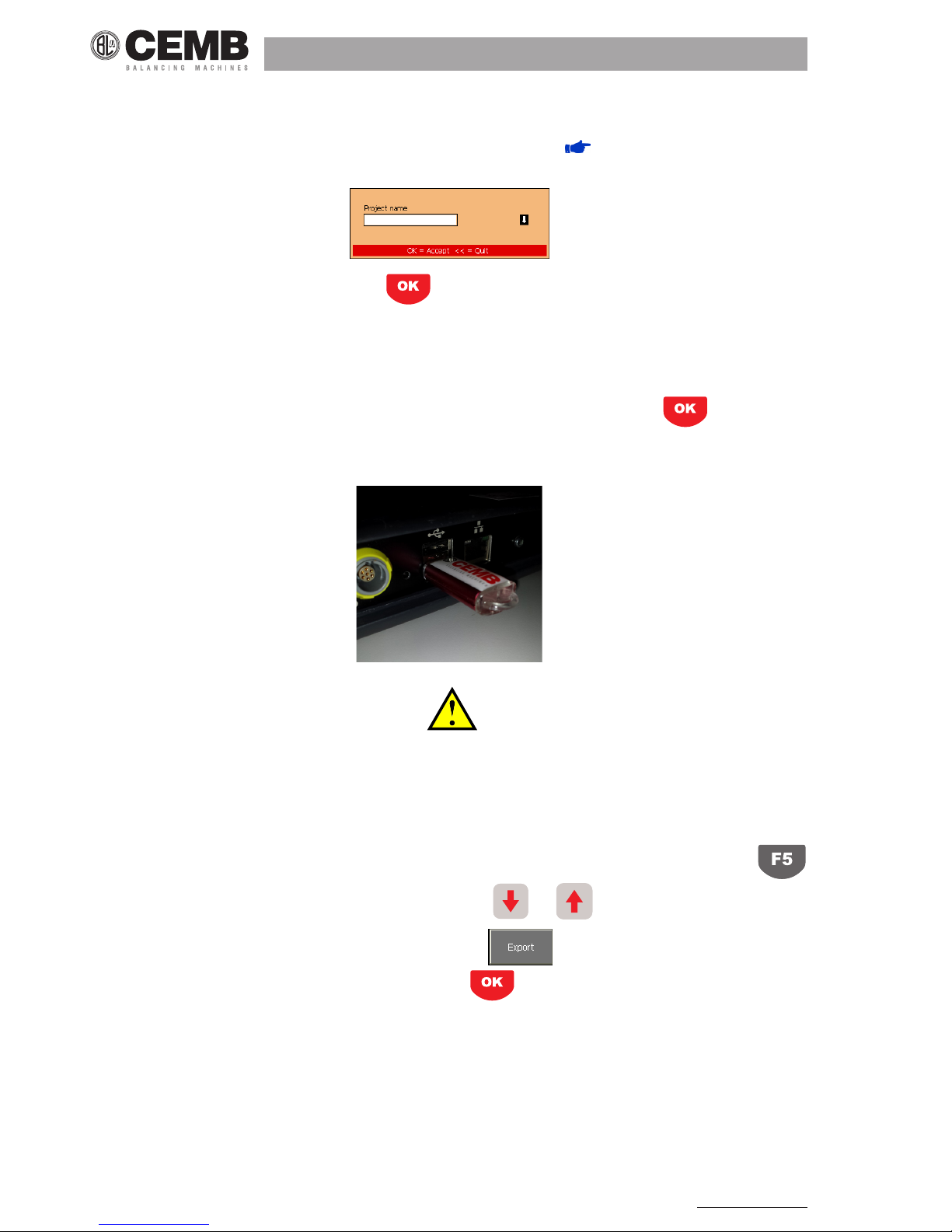

8.3 new project

This function allows creating a Soft Route directly on the N600 instrument characterised by only two measurement points.

A pop-up window will appear in which to enter the desired name, as explained in ALPHANUMERICAL KEYPAD.

Type in the desired name and conrm by pressing . At this point, the Soft Route previously created will automatically

be activated.

8.4 Import projects From

USB

key

This function allows copying all the projects saved on the USB key inserted in the N600 instrument to its internal memory. A

pop-up will inform you when the operation has successfully been completed. Conrm by pressing .

As the instrument is characterised by a Windows-based operating system, any USB key formatted with this system can be

connected to the instrument.

————————————————————————————————————————————————————

cautIon!

IF you access tHIs FunctIon wItHout HaVInG FIrst Inserted a usb key In tHe dedIcated port,

a pop-up wIll InForm you to Insert It.

————————————————————————————————————————————————————

8.5 export projects to usb key

This function allows exporting the routes saved on the N600 instrument to a USB key. Accessing this function via ,

the Project List page appears. Scroll through the list using the arrows and and select the route you want to copy

to USB key (white text on blue background). Conrm by pressing F2 , A pop-up will inform you when the operation

has successfully been completed. Close the pop-up by pressing .

Vibration equipment division

41

N600 - Ver. 2.2 09/2015

iF you want to copy a project already saved to the

USB

key, a pop-up will ask you to conFirm that you want to

overwrite the File.

iF you access this Function without having inserted a

USB

key in the dedicated port, a pop-up will ask you to insert

it.

8.6 delete projects

This function allows deleting projects saved in the instrument. To delete a single project, press F5 , scroll through

the Project List using the arrows

and and select the project you want to delete.

You can delete all the projects saved in the instrument by pressing F6

.

you cannot delete the currently active project From the list.

42

N600 - Ver. 2.2 09/2015

9. arcHIVe FunctIon

The N600 instrument allows viewing and managing screenshots previously stored by pressing , using this specic

function directly accessible from the start screen.

Pressing F6 an ARCHIVE screen is shown where you can select from two options:

• load screenshot (view previously stored screenshots)

• delete screenshots (delete one or all the stored screenshots).

9.1 load screensHot

You can load and view the previously stored screenshots on the display.

The page shows as a list of positions where the screenshots are stored:

Select the screenshot to be loaded using the arrows

and ; then press F1 to load the screenshot

selected.

Vibration equipment division

43

N600 - Ver. 2.2 09/2015

To go back to the list of stored screenshots, press or to go back to the main screen.

the screenshots loaded will be characterised by the icon , to indicate that you are not viewing data but a

screenshot acquired previously.

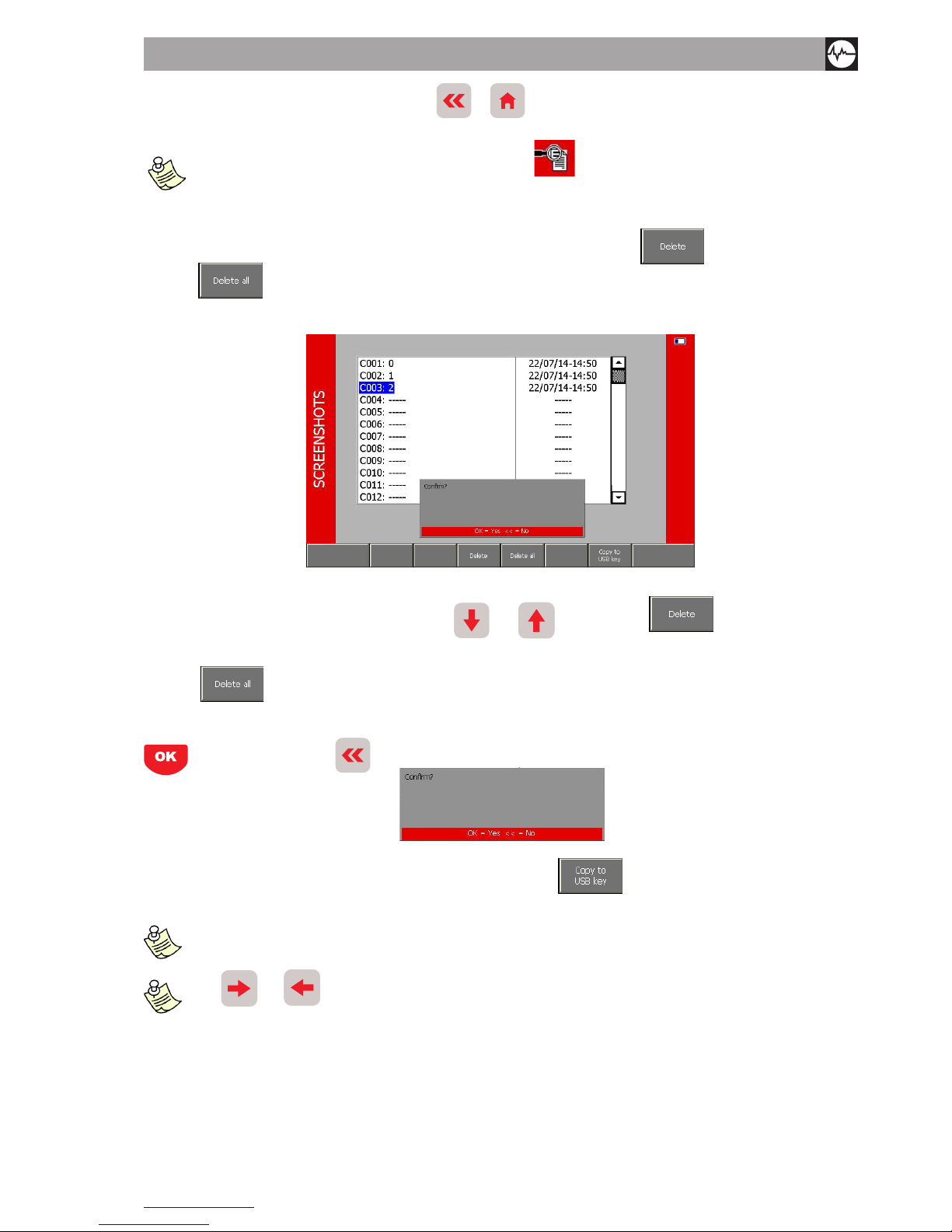

9.2 delete screensHots

To delete a screenshot and clear the corresponding position in the archive, press F3 .To delete all screenshots,

press F4

.

The page shows a list of positions where the screenshots are stored.

Select the screenshot to be deleted using the arrows

and ; then press F3 to delete the screenshot

selected.

Press F4

, to delete all the screenshots at the same time.

When pressing the above mentioned buttons, the popup shown below asks you to conrm the operation with the button

or to quit with the button .

For the functions “Load screenshot” and “Delete screenshots”, press F6

to copy all the screenshots stored on the

instrument to a Screenshots folder that will automatically be created on the USB key inserted in the instrument.

each time you want to save new screenshots to the same usb key, new subFolders will be created in the

screenshots Folder named with the date and time.

the and , buttons, which respectively increase and decrease the position selected by 10 can be used to

quickly scroll through the archive.

44

N600 - Ver. 2.2 09/2015

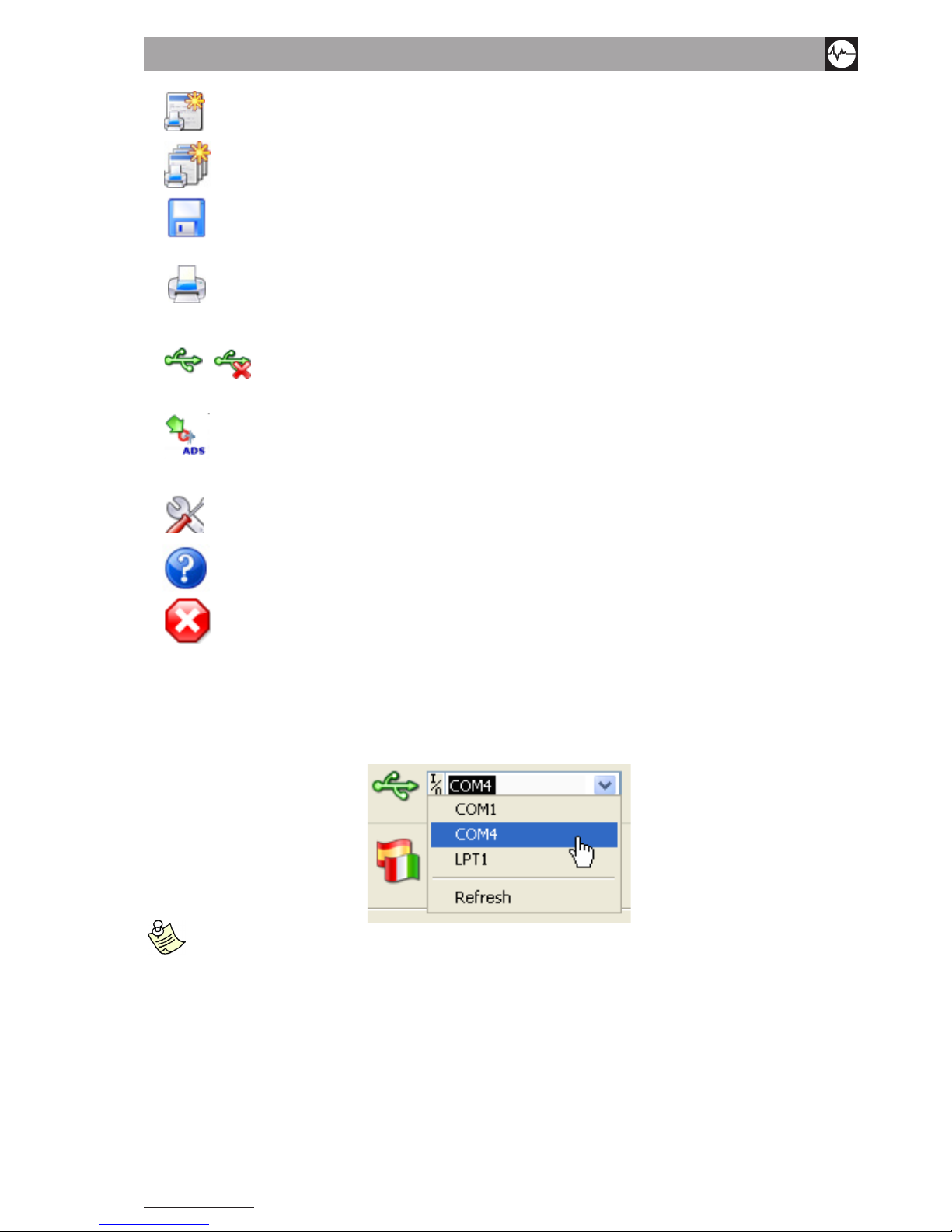

10. CEMB N-Pro PrograM (oPtioNal)

Data saved in the N100, N300 and N600 instruments can easily be imported into a PC, organised and saved to the hard disk

and subsequently analysed, compared, printed, etc.

These operations are made possible thanks to CEMB N-Pro software (Professional Environment for N-Instruments), available for Microsoft Windows operating systems. The interface has been carefully designed to make it intuitive and therefore

extremely simple to use even for inexperienced users.

This chapTe r refers To The “N iNsTrumeNT” or “N apparaTus”, geNe ric expressioNs ThaT refer exclus ively To The

N100, N300 aNd N600 models wiTh which cemB N-pro sofTware caN Be used (commuNicaTioN, daTa orgaNisaTioN,

priNTiNg, eTc...).

N-pro sofTware caNNoT Be used wiTh oTher cemB iNsTrumeNTs, iNcludiNg Those from The N raNge.

10.1 SyStEM rEquirEMENtS

Installation and use of the CEMB N-Pro program requires:

• a processor: at least Intel Pentium IV 1GHz, or Athlon equivalent

• memory: 512MB (recommended: 1GB or more)

• space on disk: at least 400MB free before installation (excluding space subsequently required for the data records)

• operating system:

> Microsoft Windows 2000 almeno Service Pack 4