Page 1

600141

Rev.3

Page 2

CEM

P.O. Box 200

Matthews, North Carolina 28106-0200

(704) 821-7015 FAX: 704-821-7894

e-mail: info@cemx.com

Copyright 2000 by CEM Corporation

All Rights Reserved

This manual contains proprietary information which shall not

be reproduced or transferred to other documents or disclosed

to others without prior written permission

of CEM Corporation

SMART System5™ is a trademark of CEM Corporation

CEM is a registered trademark of CEM Corporation

U.S. patent 4,291,775; 4,438,500; 4,457,632;

4,554,132; and 4,753,889

Other U.S. and foreign patents pending

MANUFACTURED IN THE

UNITED STATES OF AMERICA

This instrument complies with United States Code of Federal Regulations (CFR) Title

21, Part 1030 for microwave leakage. A verification report is on file.

This instrument complies with United States Code of Federal Regulations (CFR) Title

47, Federal Communications Commission (FCC) Part 18 – Industrial, Scientific and

Medical (ISM) Equipment – emissions requirements. A verification report is on file.

i

Page 3

NOTICE

The following precautions should be observed to avoid possible exposure to excessive

microwave energy:

• Do not tamper with the safety interlocks. The SMART System5 is equipped

with three safety interlocks which prevent the instrument from producing

microwave power if the cover is open.

• Do not place any object between the microwave cavity and the cover or allow

soil or cleaner residue to accumulate on sealing surfaces.

• Do not operate the instrument if it is damaged. It is particularly important that

the instrument cover close properly and that there is no damage to the cover

(bent), hinges and latch (broken or loosened), or sealing surfaces.

• The instrument should be adjusted or repaired only by qualified service

personnel.

The following precautions should be observed to avoid instrument-induced electromagnetic

interference:

• The possibility of instrument-induced electromagnetic interference (EMI) is

minimal if precautions outlined above are followed.

• The instrument should not be placed close to any electrical device susceptible

to EMI. It is suggested that the user post a sign warning pacemaker wearers

that a microwave device is in operation.

• If the instrument is suspected of inducing EMI, the cover should be carefully

inspected. A microwave leakage measurement should be performed as

outlined in the Troubleshooting, Maintenance and Service section of this

manual. Leakage measured above the legal limit of 5 mW/cm2 should be

reported to the CEM Service Department.

This instrument utilizes high voltages and microwave radiation.

Instrument service and

repair should be performed only by those trained in repair and maintenance of high

voltage and microwave power systems.

ii

Page 4

To the best of our knowledge, the information contained herein is accurate. However,

CEM cannot accept liability of any kind for the accuracy or completeness of the

information contained in this manual. The final determination of the suitability and

proper use of the instrument described herein, the accuracy of the information and data

obtained from such use, and whether such use infringes any patents or the legal

safeguards of others are the sole responsibility of the user.

Warnings, Cautions and Notes

Warnings, cautions and notes are included throughout this manual and should be read

thoroughly and strictly followed.

WARNING: A warning is inserted for essential information used to emphasize

dangerous or hazardous conditions to the operation, cleaning and maintenance of the

instrument which may result in personal injury.

CAUTION: A caution is inserted for essential information used to emphasize

procedures which, if not strictly followed, may result in damage or destruction to the

instrument or improper instrument operation.

NOTE: A note is inserted for emphasis of procedures or conditions which may

otherwise be misinterpreted or overlooked and to clarify possible confusing situations.

iii

Page 5

iv

Page 6

Table of Contents

Introduction......................................................................................................1

System Installation...........................................................................................3

External Printer ..........................................................................................7

External Balance ........................................................................................7

Personal Computer or Serial Printer Setup ................................................8

Instrument Description ...............................................................................9

Sample Analysis ............................................................................................13

Sampling ..................................................................................................13

Preparation ...............................................................................................14

Weight ......................................................................................................16

Holders .....................................................................................................16

Application ...............................................................................................18

Method Information .................................................................................22

Bias Identification ....................................................................................23

Determining Ash/COH for Processed Meats ...........................................25

Ash Contents of Meats .............................................................................26

Methods Development .............................................................................29

System Operation

Quick Test ................................................................................................31

Constant Weight..................................................................................31

Set Time ..............................................................................................37

Edit/Create Method ..................................................................................43

Edit Method ........................................................................................45

Create Method.....................................................................................47

Moisture/Solids - Standard Test ....................................................47

Moisture/Solids - Wastewater - TSS .............................................53

Moisture/Solids - Wastewater - TSS/TVSS ..................................59

Moisture/Solids - Dilution .............................................................65

Moisture/Solids - Syringe Weigh - Internal Balance ...................73

Moisture/Solids - Syringe Weigh - External Balance ..................79

Moisture/Solids - Ash....................................................................87

Moisture/Fat or Moisture/Fat/Protein - Standard ..........................93

Moisture/Fat or Moisture/Fat/Protein - Dilutions .......................101

Moisture/Fat or Moisture/Fat/Protein - Modified .......................111

Load Method ..........................................................................................121

Setup.......................................................................................................123

System Options .................................................................................123

System Information...........................................................................125

Printer................................................................................................125

Communication Port .........................................................................126

Contrast .............................................................................................126

Clock .................................................................................................127

Calibration.........................................................................................128

Security .............................................................................................129

Company Name ................................................................................133

Delete Method...................................................................................134

Serial Options....................................................................................135

Unit Serial Number ...........................................................................136

v

Page 7

vi

Table of Contents (Continued)

Print..............................................................................................................137

Statistics .......................................................................................................139

External Components...................................................................................141

Maintenance, Troubleshooting and Service.................................................143

Cleaning Recommendations...................................................................143

Routine Maintenance .............................................................................143

Special Tools and Kits ...........................................................................143

Troubleshooting .....................................................................................144

Error Messages .......................................................................................146

Standard Solution Test ...........................................................................147

Microwave Leakage Measurement ........................................................148

Intelli-Temp Calibration.........................................................................149

Intelli-Temp Verification .......................................................................151

Service and Repair .................................................................................153

Specifications .........................................................................................155

Warranty.................................................................................................156

Page 8

1

Introduction

The CEM SMART System5™ Moisture/Solids Analyzer is designed to provide a

rapid moisture/solids analysis on a broad range of products. The patented weighing

technology provides continuous weighing of the sample during the drying process.

The system determines the precise time the sample is dry, and the moisture or

solids content of the sample is then automatically calculated based on weight loss.

Microwave energy is used to dry the samples. Polar compounds such as water,

polar organic solvents such as alcohols or ketones, and ions in the solution will

absorb microwave energy and volatilize. Once water and/or other solvents have

volatilized, the remaining solid material does not usually absorb microwave energy

and will remain relatively cool. Thus, the weight loss is due only to the volatile

solvents present in the sample. “Moisture” is used throughout this manual to refer

to any volatile substance for which the system can measure weight loss after

drying the sample.

The SMART System5 delivers 150 - 300 watts of microwave energy when

programmed for 100 percent power. Voltage of the incoming electrical service is

measured and the microwave power is adjusted by the power control system in

order to normalize the power and provide repeatable power conditions. Magnetron

power automatically adjusted to deliver appropriate wattage to the instrument cavity.

The magnetron fan remains on for 15 minutes after the end of the specified drying

time to cool the instrument.

System components consist of a microwave drying chamber, an electronic balance,

a 1/4” VGA black and white screen, an infrared temperature controller, a

microprocessor and an internal impact printer. The Octawave™ cavity is designed

to effectively deliver the microwave energy directly to the sample to achieve rapid

test times. The 50 gram four-place analytical balance has a ±0.1 mg sensitivity.

Infrared temperature measurement permits automatic adjustment of microwave

power based on user defined temperature setpoint. The microprocessor controls

and monitors system operations, automatically calculates sample results and

enables interface with external printers, external balances and/or computers.

The system is equipped with three safety interlock switches to monitor the mating

of the cavity cover and floor and one safety interlock switch to monitor the cavity

cover latch. A flame detector with an infrared feedback automatically turns off the

microwave power if excessive burning is detected.

The SMART System5 software is user friendly and easy to operate. It is capable of

storing up to 100 methods and 300 test results, and is multilingual (English,

German, Spanish, and French).

Page 9

2

Page 10

3

System Installation

1. Following the instructions provided in the packing carton, carefully remove

the SMART System5 from its shipping carton and place it on a vibration-free

workbench or laboratory table in a location that:

a. provides at least 8 in (20 cm) open space on each side and 6 in. (15 cm)

open space in the rear of the instrument for ventilation.

b. is free from vibration of large equipment and/or excessive walk-through

traffic.

c provides a temperature range of 41 °F (5 °C) to 104 °F (40 °C) and a

humidity range of 10-85 percent relative humidity.

d. provides adequate bench space for sample handling.

e. allows the instrument to be connected to a dedicated, grounded 120 or

240 VAC outlet. The SMART System5™ should be operated on a

stabilized, constant voltage AC power supply. To operate properly, the

voltage must be within ±10% of the specified level.

2. Retain all packing materials.

3. Inspect the instrument for cracks, dents or warping.

4. Remove the tape from the instrument cover. Inspect the top cover for proper

alignment. The cover must open and close freely with no binding or

restriction of movement.

WARNING

If damage is noted, do not attempt instrument operation.

AVERTISSEMENT

Ne pas mettre en marche si l’instrument est endommagé.

5. If the instrument has been damaged in shipping, contact the freight

carrier to report the damage and to file a damage report. Contact the

CEM Service Department or the nearest subsidiary or distributor (page 4)

to request service information.

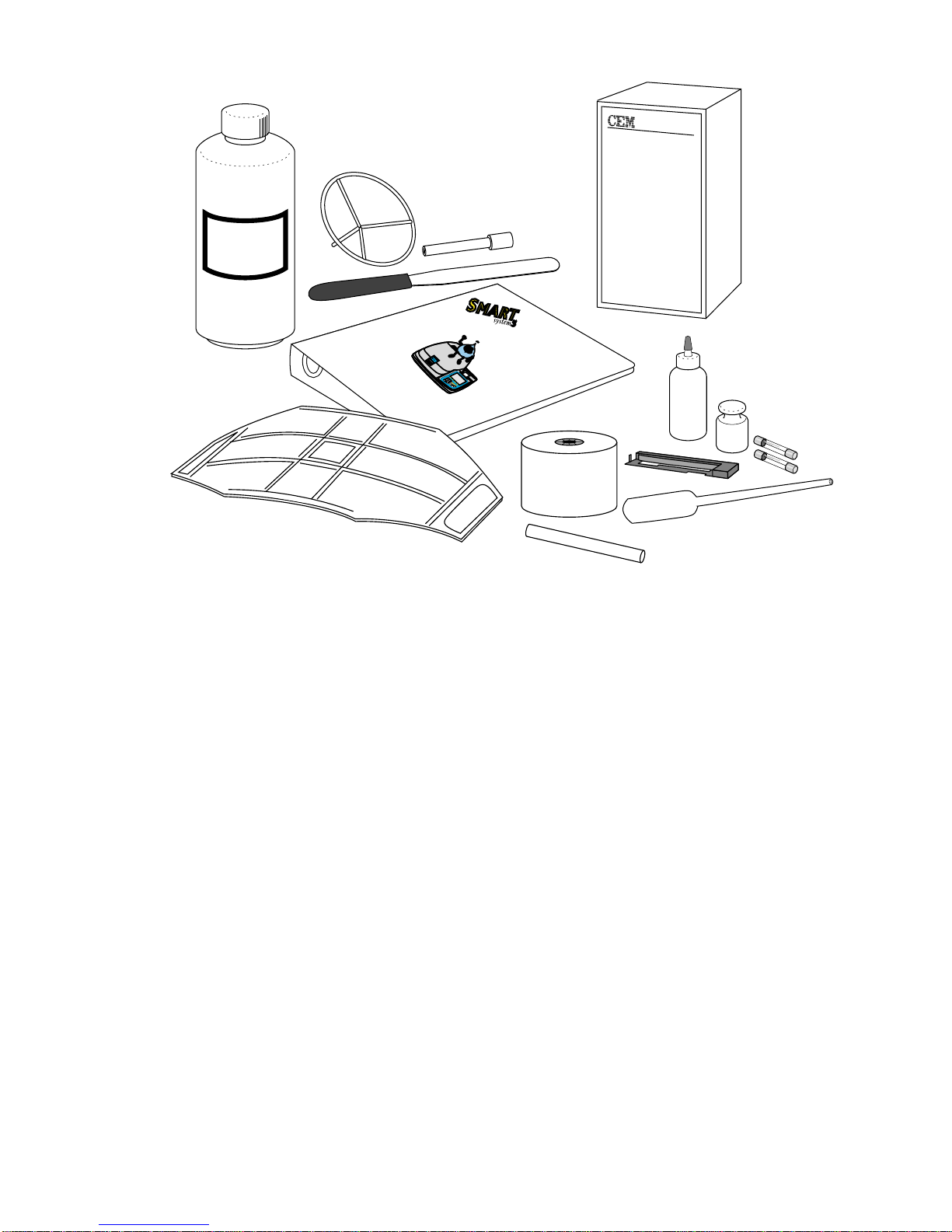

6. Verify that all accessories illustrated and listed in figure 1 are included.

7. Lift the instrument cover. Install the balance stem into the balance stem

retainer in the opening of the cavity floor, ensuring that the balance stem is

firmly seated. Install the balance pan onto the stem.

Note: If the balance stem requires removal, lift the stem straight up from its

installed position. Moving the balance stem from side to side can cause damage to

the balance assembly.

Page 11

4

CEM Corporation

Service Department

P.O. Box 200

3100 Smith Farm Road

Matthews, NC 28104 -5044 USA

Within the continental United States

Telephone: (800) 726-5551

Fax: (704) 821-4368

Outside the United States

Telephone: (704) 821-7015

Fax: (704) 821-4368

Subsidiary Offices

CEM Ltd.

2 Middle Slade

Buckingham Ind. Part

Buckingham MK18 1WA

United Kingdom

Tel: (44) 1-280-822873

Fax: (44) 1-280-822342

CEM GmbH

Carl-Friedrich-Gauss-Str. 9

47454 Kamp-Lintfort

Germany

Tel: (49) 2842-96440

Fax: (49) 2842-964411

CEM S.r.l.

Via Dell’Artigianato, 6/8

24055 Cologno al Serio

Italy

Tel: (39) 35-896224

Fax: (39) 35-891661

Page 12

5

Figure 1. Accessories

• Starter Accessory Kit containing:

• Balance Stem (159600) (2)

• Balance Pan (004120) (2)

• Air Shield (568055M) (Installed in Instrument)

• Standard Solution (302600)

• Dispensing Bottle (230230)

• Spatula (302001)

• Disposable Pipette (302150)

• Glass Fiber Sample Pads (200150)

• 10 g Weight (260111)

• Fuses, 10AMP (2) (188340) and 5AMP (2) (188331)

• Operation Manual (600140)

• Printer Paper Holder (159065)

• Printer Ribbon (315122) (Installed in Instrument)

• Printer Paper (1 Roll) (315120)

Glass Fiber

Sample Pads

Reorder part # 200150

C

E

M

C

o

r

p

o

r

a

t

io

n

P

.

O

.

B

o

x

2

0

0

M

a

t

t

h

e

w

s

,

N

C

2

8

1

0

6

1

-

8

0

0

-

3

3

4

-

6

3

1

7

(

in

N

C

:

1

-

7

0

4

-

8

2

1

-

7

0

1

5

)

T

e

le

x

:

8

0

2

1

1

8

F

A

X

:

7

0

4

-

8

2

1

-

7

0

1

5

Moisture/Solids Analyzer

Operation Manual

Page 13

6

8. Using a voltage meter, measure the voltage of the dedicated power outlet to

verify voltage (120 VAC, 60 Hz or 220/240 VAC, 50 Hz).

9. Facing the back of the instrument, use a small screwdriver to pry the dual

voltage supply from the power module.

10. Install the voltage slide switch in the proper direction for the measured

voltage (120V, 60Hz or 220/240V, 50Hz).

11. Based on the voltage selected in step 9, install the proper fuses in the dual

voltage supply – 10 AMP (60 Hz) or 5 AMP (50 Hz).

12. Install the dual voltage supply with the appropriate fuses and the properly

installed voltage slide switch in the power module.

13. If applicable, install the exhaust hose.

14. Plug the power cord into the power cord receptacle in the rear of the

instrument and into a grounded, dedicated electrical outlet. Note: If using

external components such as a printer, computer or balance, install these

components as outlined in this manual.

15. Position the power switch located in the rear of the instrument above the

power cord receptacle in the “on” position.

CAUTION

Permit the SMART System5™ to warm up (power switch on,

microwaves not being produced) for at least 45 minutes prior to

operation. If the instrument is switched off for an extended

period of time (weekend, holidays, etc.), ensure that warmup

time is permitted prior to use.

Mise en garde

Permettre une période de 45 minutes de réchauffement du

SMART System5 avant l’utilisation (interrupteur de courant en

marche, aucune micro-onde n’est émise). Lorsque l’instrument

est en mode fermé pour un temps prolongé (fin de semaine,

vacances, etc. . .) il est important que la période de

réchauffement de 45 minutes soit observée.

16. Refer to the “Maintenance, Troubleshooting And Service” section of this

manual and perform the Standard Solution Test at least five times.

Note: CEM Corporation recommends that the power cord be connected to an AC

power outlet and the power switch remain in the “on” position at all times. After

15 minutes of idle time, the SMART System5 assumes a “sleep” mode.

Page 14

7

Instrument Description

Display – displays menu choices, instructional messages and analysis results on a

1/4 VGA black and white screen

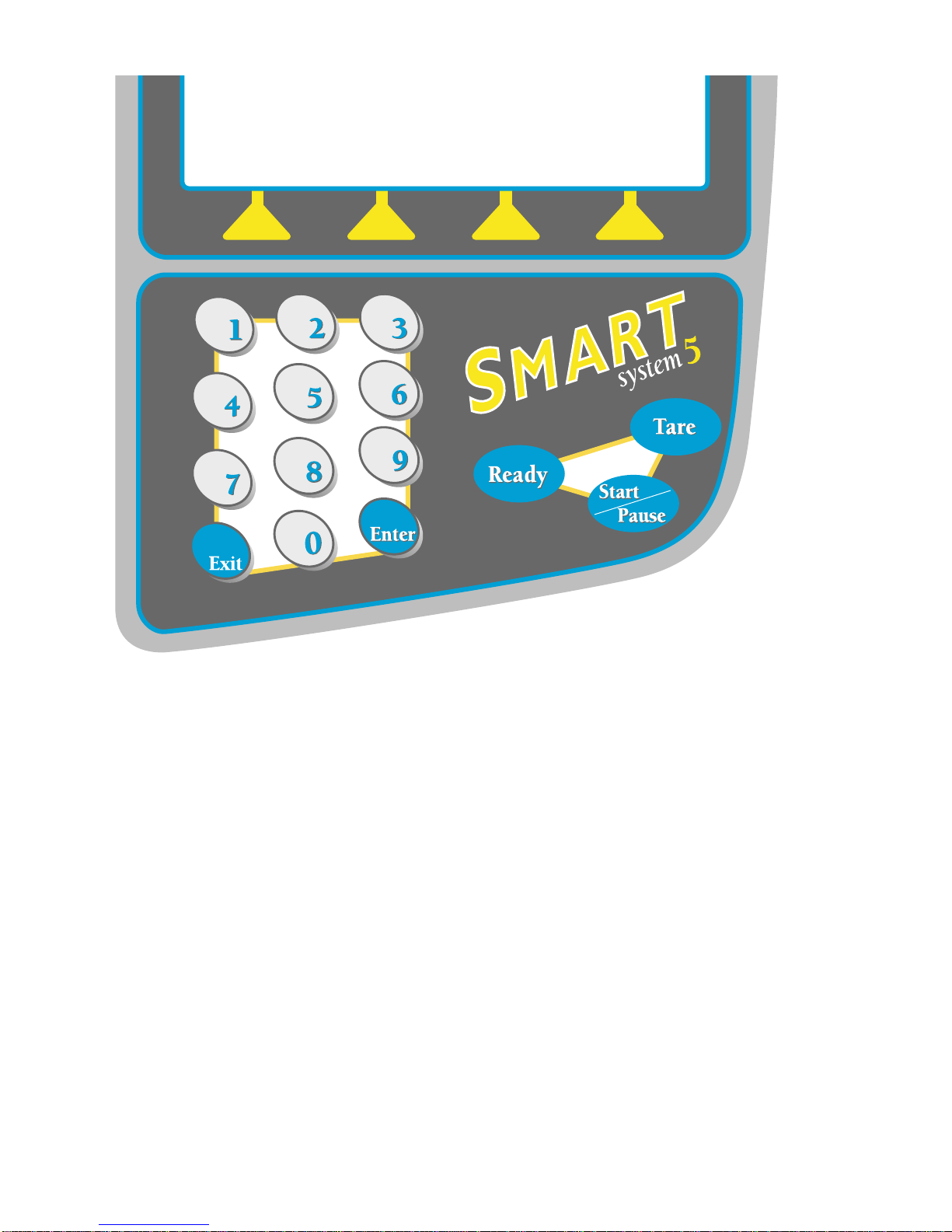

Keyboard – controls operation of the SMART System5. Temperature, time, or

other numeric data may be entered with the numeric keys as requested on the

display.

Internal Printer – provides printout of methods, data and results.

Cavity – decreases test times due to its patented compact Octawave™ design.

Air Shield – prevents air flow within the microwave cavity from affecting weight

measurements.

Balance Pan – holds sample and sample pads during analysis.

Interlock Assembly – monitors mating of cavity cover and instrument skirt.

Display

Keyboard

Internal

Printer

Cavity

Air Shield

Balance

Pan

Figure 2. Smart System5 Front View

Interlock

Assembly

Interlock

Assembly

Interlock

Assembly

Page 15

8

Enter – Press to store entered parameters and data in the computer memory.

Exit – Press to exit screen.

Ready – Press to initiate current method for a test or to reset method for next test.

Start/Pause – Press to begin or pause sample analysis. Microwave heating begins

when the Start/Pause button is pressed unless the cavity cover is open. Operation

will continue through the analysis unless the Start/Pause button is pressed to

interrupt the analysis or the operation key indicating “Stop Test” is pressed.

Tare – Press to tare or zero the weight of the sample pads prior to sample analysis.

0 - 9 – Press to select items from menus such as the Main Menu, setup screens, etc.

and to select values for parameters such as time and power.

▲ Operation Keys – Press to select specific operation options such as “Stop

Test,” “Print,” “Main Menu,” Prev. Page,” etc.

Figure 3. Smart System5 Keyboard

Page 16

9

Fuses – prevent electrical power overload.

Power Cord Receptacle – receives the female end of the power cord.

Power Switch – turns electrical power to the instrument on and off.

Nameplate – lists model and serial number.

Dual Voltage Selector Switch - permits electrical voltage for the instrument to be

switched from 110 VAC to 220 VAC.

PC Port – permits connection and communication with a personal computer for

data storage, etc.

Printer Port – permits connection and communication with an external printer.

External Balance Port – permits connection and communication with an external

balance for specific applications.

Internal

Printer

Power

Switch

Power

Cord

Receptacle

Dual Voltage

Selector

Switch &

Fuses

Printer

Port

External

Balance

Port

PC

Port

Figure 4. Smart System5 Rear View

CE

CEM

Nameplate

Page 17

10

Page 18

11

Sample Analysis

Proper sample preparation and testing are critical to obtaining accuracy and

precision. Each sample has a specific characteristic composition; therefore, each

sample may require an individual method of analysis. However, guidelines can be

established for analysis of general sample types.

• Sampling – A representative sample is critical to obtain proper analysis.

• Preparation – As with any chemical analysis, a homogeneous sample is

critical to obtaining precision and accuracy.

• Weight – A consistent sample size helps ensure precision and accuracy.

Most CEM applications specify a sample size of 2-5 grams, emphasizing

the importance of a homogeneous sample.

• Holders – Absorbent pads to which a sample can be applied are used for

most analyses. Glass fiber pads are recommended because glass fibers do

not absorb microwaves. Other holders include Teflon coated glass fiber

mesh, a drying basket and a thermapad.

• Application – Most samples should be spread smoothly, avoiding lumps,

peaks or any uneven areas. Sample spread must be consistent.

• Drying Time – The drying time is determined by the type of sample and its

microwave absorbency. Constant weight drying permits drying of a sample

until a constant weight is achieved. Set time drying permits the control of

the sample analysis by entering a specified time and power level.

• Infrared Temperature – The infrared temperature measurement may be

used to operate at temperatures used in standard or vacuum oven

procedures.

• Microwave Power – The power necessary to dry a sample is determined by

sample composition. A sample should be tested at the highest possible

power without burning or degradation of the sample.

Sampling

Proper sampling of a product or process is critical in achieving proper moisture/

solids analysis. A representative sample is required to ensure that the test results

are representative of the entire batch or lot of material.

Many standard procedures such as AOAC, USDA and ASTM methods reference

sampling techniques. It is extremely important to follow techniques outlined in

these procedures for a particular sample type.

Proper handling and storage of the sample prior to analysis is also critical in

achieving accurate and representative results. Samples should not be exposed to

the air for long intervals prior to analysis. Proper storage also ensures that no

moisture is lost.

Page 19

12

Preparation

Sample preparation is critical to achieving precise and accurate test results. The

sample should be properly prepared to achieve repeatable moisture results between

duplicate analyses of the same sample. Sample preparation is either a physical or

chemical modification of the sample. Physical modification may be as simple as

stirring or shaking the sample to ensure homogeneity or more complex such as

particle size reduction, dilution or deaeration.

Chemical modification is the addition of an enzyme to hydrolyze chemically

bound fat. The objective is to create a homogeneous sample and to improve the

correlation of the test method to standard methods. Some products, such as a beef

emulsion or comminuted poultry, may require no additional preparation. Other

materials will require particle size reduction, dilution or dearation prior to testing.

Samples should be kept cool and in sealed containers to prevent loss of moisture.

If repeatable results cannot be obtained on the same sample, re-blend the sample to

improve the homogeneity and repeat tests. Sample preparation methods include:

1. Mixing of Sample – Thoroughly stir or shake sample to ensure

homogeneity.

2. Particle Size Reduction – Many products require particle size reduction

prior to being applied to the glass fiber pad. Reduction, based on product

sample, can be accomplished with a meat grinder, either an industrial or

consumer grade food processor, a coffee mill or a cheese grater. The

meat grinder is the best choice for all meat products. USDA procedure

specifies three to four passes through a 1/8” or 5/64” blade with mixing

between grinds. A USDA inspector or outside laboratory can make

recommendations. An industrial grade food processor is a good

alternative for grinding meat products. A consumer grade food processor

is ideal for grinding frozen potatoes, breaded products, or “dry” snack

foods such as cookies, crackers, and chips. A coffee mill can be used to

grind or mix “dry” snack foods. A cheese grater can be used to grate

small quantities of hard cheese samples or soap.

3. Dilution – Products with a high carbohydrate content are strong

microwave absorbers and have a tendency to burn. These samples may

require either a water or salt dilution.

A. Water Dilution – A specified amount of sample is diluted with a

specified amount of water and mixed in a blender. Typical samples

include doughs, cheese powders, corn syrups, dried meat bases and

sauces. An external balance and a blender are required for this

procedure.

(1) Interface an external balance with the SMART System5.

(2) Tare the blender cup on the external balance.

(3) Add product sample to the blender cup.

Page 20

13

(4) Add water to the product sample in the blender cup.

(5) Blend until a homogeneous mixture is obtained.

(6) Use the diluted sample to perform analysis.

B. Salt Dilution – A specified amount of salt is added to the product

sample prior to analysis. Typical samples include

frozen potatoes and frozen breaded products. This procedure

requires a teflon basket and dry table salt (sodium chloride).

(1) Line a teflon basket (CEM p.n. 200090) with two square glass

fiber pads.

(2) Place the lined basket on the balance of the Moisture/Solids

Analyzer. Press “Tare.”

(3) Place approximately 8g of salt in the lined basket. Press

“Tare.”

(4) Place the product sample on top of the salt. Press “Start” to

record the initial weight.

(5) Press “Stop.”

(6) Thoroughly mix the salt and sample in the basket.

(7) Return the basket to the balance of the Moisture/Solids

Analyzer. Press “Start” to continue the sample analysis.

4. Deaeration – Frozen dairy and imitation dairy products must be

deaerated to remove the excess air in order to provide reproducible test

results. This procedure requires a 125 mL Erlenmeyer flask, a 1 liter

beaker, a magnetic stirrer, a 11/2” x 3/8 magnetic stirring bar, and a #5

rubber stopper.

(A) Place 100 mL of sample in a 125 mL Erlenmeyer flask.

(B) Place a 11/2” x 3/8” magnetic stirring bar in the flask. Using a #5

rubber stopper, loosely cap the flask.

(C) Place flask in a 1 liter beaker containing 250 mL of water which has

been heated to 70°C.

(D) Place beaker with flask on a magnetic stirrer. Mix for 5 - 7 minutes.

(E) Cool sample to ambient temperature and thoroughly mix sample

prior to testing.

Page 21

14

5. Enzymatic Hydrolysis – The fat in processed cheese and dairy products

is often tightly bound to the protein. In order to achieve accurate test

results, the fat must be released from the protein prior to the fat extraction

process. This can be accomplished by a protease enzymatic hydrolysis of

the sample. Note: The sample must be in a liquid or “pourable” state for

the enzymatic hydrolysis to be effective.

(A) Thoroughly mix approximately 100g of sample. Heat sample in a

water bath at 60°C (± 5°C) for five minutes.

(B) Add eight (8) drops of CEM Enzyme (p.n. 302630) and mix well.

(C) Return sample to water bath for five minutes.

Weight

Sample weight can be very critical to the final test result. As with most analytical

procedures, a consistent sample size helps ensure precision and accuracy. Sample

sizes can vary, based on type of sample, from 1 gram on the low end (high percent

solids level) to 10-15 grams on the high end (very low percent solids level). Test

procedures documented by CEM and included in this manual, are for specific

sample types and suggested sample size. Sample size should remain within the

weight guidelines. CEM has determined that the suggested sample size results in

the most consistent drying and test results. Heavier sample weights may cause

sample degradation or burning, resulting in high moisture results. Lower sample

weights may result in under-drying of the sample.

Holders

Sample holders should be transparent to microwave energy.

CEM Square Sample Pad – The square pad is the most commonly used sample

holder. Typically, two (2) pads are used with the sample “sandwiched” between

the pads. For heat sensitive samples, only one pad is recommended to minimize

heat buildup. For low solids samples, three or four pads are used for absorption.

CEM Round Sample Pad – The round pad is used as a collection pad for fat

extraction and is recommended, but not required, for thermapad applications.

Sample Pads – CEM glass fiber pads are designed to provide optimum

conditions for rapid, thorough and repeatable drying. CEM Corporation

follows strict specifications in the manufacture of sample pads. Specifications

include low moisture content and optimum absorbency, density, porosity, and

strength for microwave drying.

• Moisture Content – Excessive moisture in sample pads will cause

moisture or solids values to be incorrect. Controlling the moisture

ensures that residual moisture is maintained to very close

tolerances.

Page 22

15

• Absorbency – The pad material must be absorbent enough to form a

wick for a liquid sample and to be a sample holder for more viscous

type samples.

• Density – The sample medium must have uniform density to guarantee

that the moisture will volatilize rapidly and evenly, without causing

residual heating.

• Porosity – Correct porosity of the pad material ensures maximum

surface area for liquid samples in order to increase

volatilization of moisture. Correct porosity helps prevent

sample degradation or burning.

• Strength – The tensile strength of the medium has a direct effect on the

ability of the sample pad to withstand the stress imposed during sample

application.

Teflon Coated Glass Fiber Mesh – The mesh is used as a holder for fiber

samples or as a “spacer” between multiple sheets of paper samples.

Drying Basket – The basket is made of Teflon coated glass fiber mesh. It is

typically lined with two square pads. It is used to hold large samples and for salt

dilutions.

Page 23

16

Application

The viscosity of the sample plays an important role in determining how the sample

is spread onto the pad for analysis. If a sample is thin, it can be pipetted onto the

pad and can be tested at high power levels. A thin sample spread over a large area

permits moisture to evaporate rapidly with little residual heat buildup. Glass fiber

pads may be stacked for increased absorbency.

High viscosity samples (samples that do not flow well) require a different

technique. If the sample can be easily spread across the glass fiber pad, no dilution

is required. A thick sample will tend to puddle and form a crust, sometimes trapping volatiles within the bubble. Overheating or burning can also occur on thick

samples. If repeatable results cannot be obtained by spreading the sample, a

dilution may be necessary. The sample must be soluble in the diluting agent, and

the diluting agent must be a microwave absorber.

To generate the appropriate amount of heat and achieve optimum moisture results,

different types of samples must be spread to different thicknesses over different

areas of the glass fiber sample pad. As a general guideline, the sample will

generate heat in direct proportion to the thickness of the sample layer on the pad.

A sample spread too thickly can cause sample burning; a sample spread too thinly

can cause insufficient drying. The prepared sample should be applied to a glass

fiber sample pad. Once the sample is properly applied to the sample pad, it should

be covered with a second glass fiber pad to ensure heat retention and to eliminate

splattering.

Liquid samples should be pipetted onto the pad. Solids samples should be spread

onto a pad placed on the edge of a clean, flat surface, such as a countertop. The

spatula should be held level with the pad when spreading the sample to ensure a

smooth, uniform application of sample to the pad surface.

If the sample is an organic solvent-based liquid, special handling is required.

Equipment and method modification may be required. CEM recommends using

the SMART System5 Exhaust Kit when analyzing solvent based samples.

Non-polar organic solvents do not absorb microwave energy; therefore, samples

containing this type of solvent will not dry unless they are mixed with a diluent

which absorbs microwave energy and has a higher boiling point than the non-polar

solvent.

If the sample is a polar organic solvent-based liquid, samples will absorb

microwave energy and dry as readily as a water-based liquid. If the organic solvent

is an alcohol, a ketone, or an ester, samples should be tested with water-based

techniques.

Page 24

17

Some base resins are microwave absorbers. Polyester is a known base resin that is

an absorber of microwaves. Titanium dioxide and calcium carbonate have also

been found to be microwave absorbent. If these materials are present in a sample,

usually enough heat is generated to remove most high boiling non-polar solvents

and any other volatiles. Oils become very hot when placed in the microwave field.

Some metal based samples can be tested. If carbon black is present in a sample, it

will heat very quickly and possibly burn even at low power levels.

It is recommended that CEM Corporation or a local distributor be consulted prior

to testing any solvent based sample.

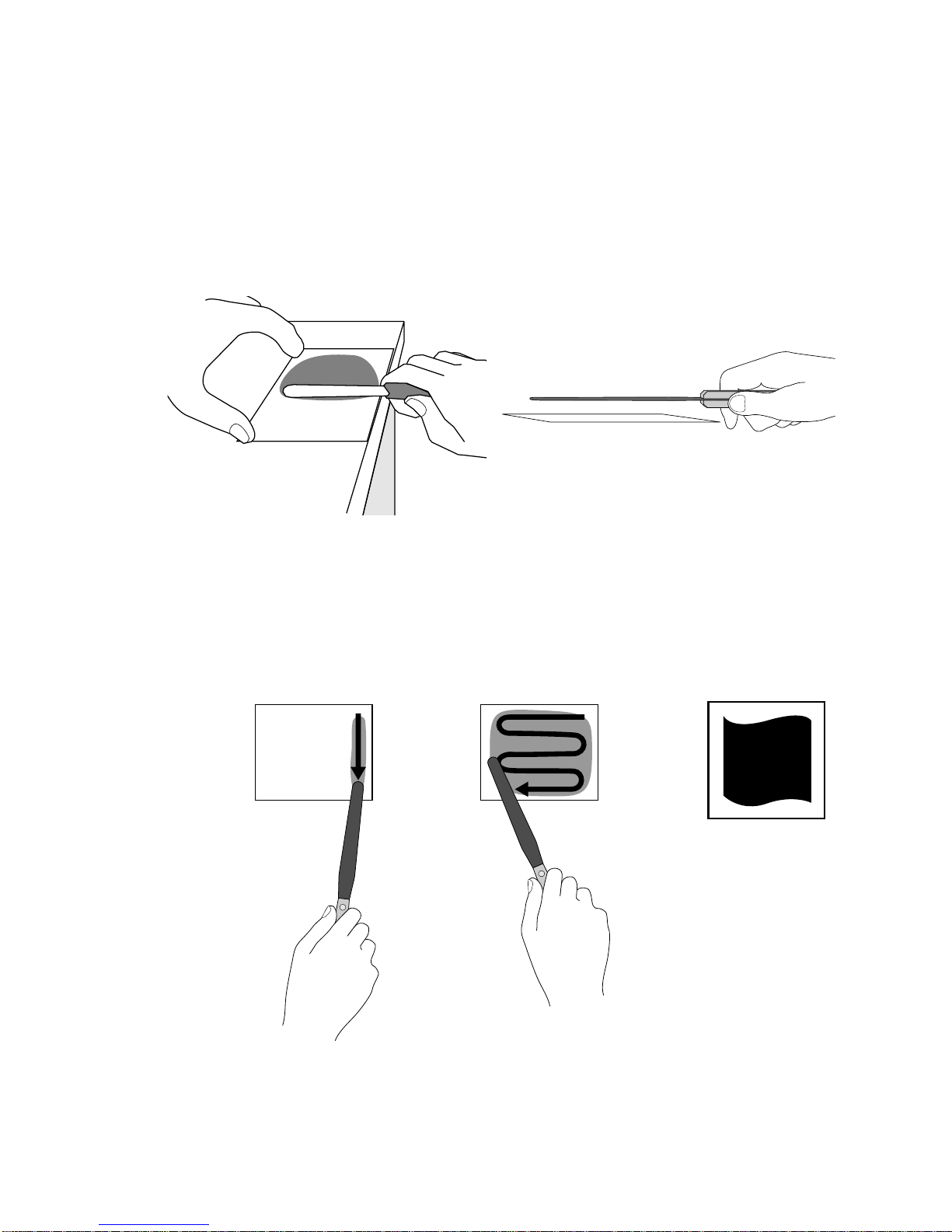

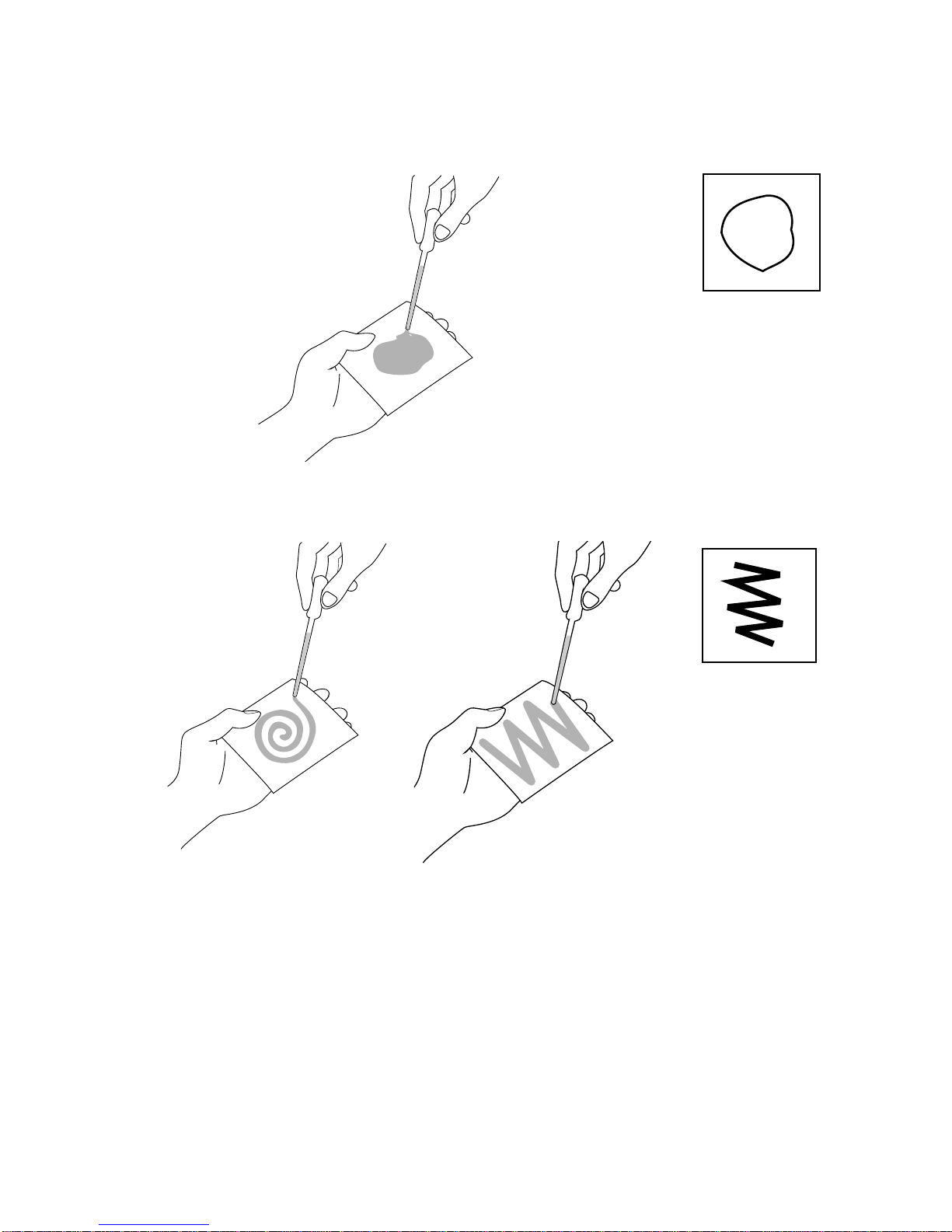

General Sample Application Technique

If the sample is in a paste, semi-solid, or crumb form or a raw or skeletal meat

product such as fresh pork, ground beef, or chicken, place the sample on the end

of a spatula and spread it across one end of the pad. Then spread the sample to a

uniform thickness covering approximately 90% of the pad surface area.

1 Spread Thin Layer Across 90% of Pad

Page 25

18

If the sample contains bound water such as an all-meat emulsion, cooked all-meat

sausage, sausage with extenders, semi-dry sausage, or ham, place the sample on

the end of the spatula and apply the sample to the middle of the pad. Then spread

the sample around the pad in a circle to generate thermal heat.

2 Spread Layer on Pad

If the sample is a heat sensitive sample such as a water-based or solvent-based

liquid, use a pipette to dispense the sample onto the pad(s). Sample size should be

2-5 grams, based on solid content of the sample – 2-3 grams for high solids

samples, 4-5 grams for samples containing less than 15 percent solids. Samples

containing less than two percent solids may require as much as 10 grams for

analysis. Large quantity samples should be pipetted onto the pads in a thin even

layer. Additional glass fiber pads may be used for increased absorbency. A

sufficient number of pads should be used to ensure that liquid samples do not drip

onto the floor of the instrument cavity.

3 Puddle, Spread with Pipette and Cover

Page 26

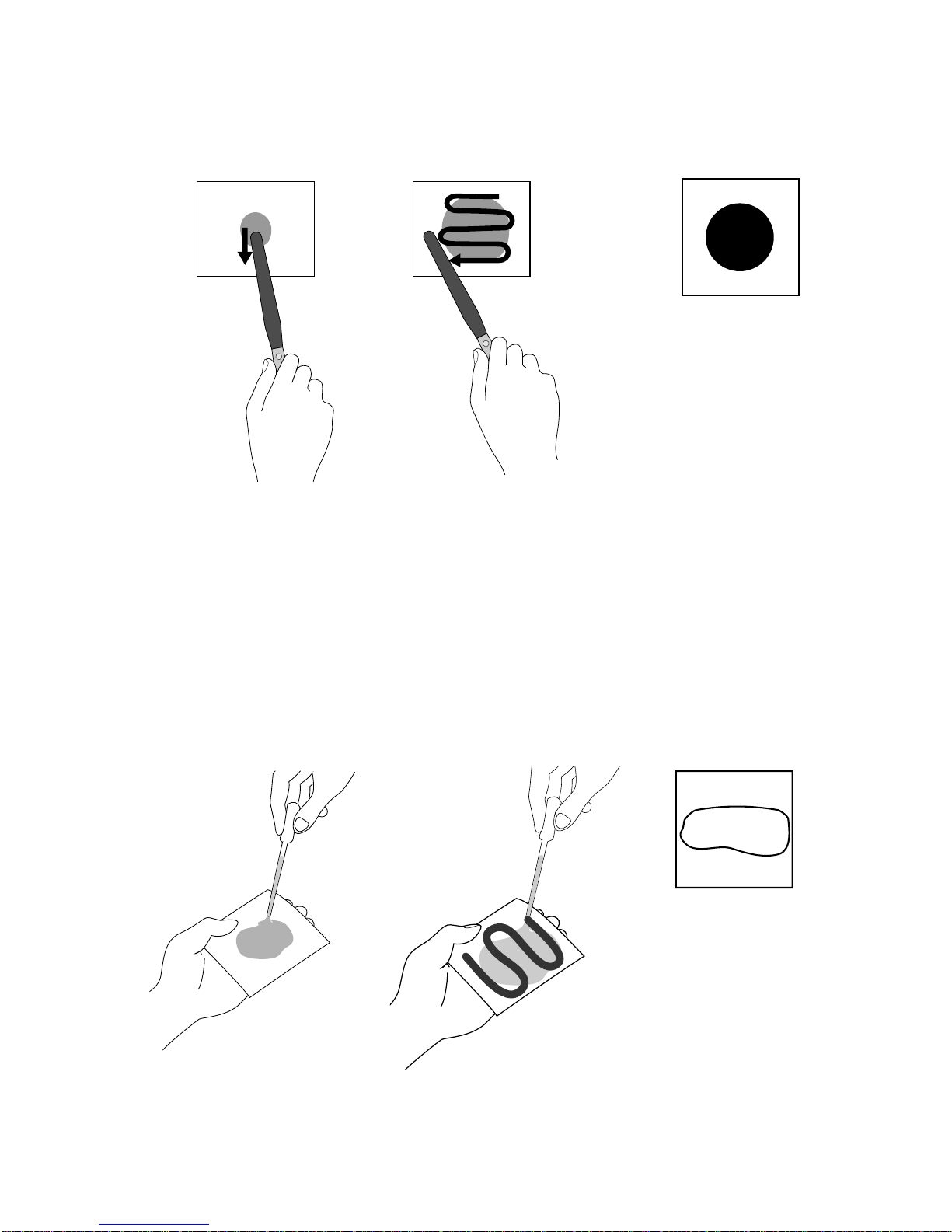

19

4 Puddle and Cover

5 Swirl or Zig-Zag Pattern, No Cover

Standard application used for heat sensitive samples if sample burns when using

the puddle and spread technique.

If the sample is a water-based liquid or solvent-based chemical, use a pipette to

puddle the sample onto the pad(s). Cover the sample with an additional pad. A

sufficient number of pads should be used to ensure that liquid samples do not drip

onto the floor of the instrument cavity.

Page 27

20

Method Information

Most water based samples should achieve constant weight settings in 1 - 3

minutes.

The microwave power and temperature settings should be appropriate to the

sample. The standard oven or vacuum oven temperature recommended in a

reference method for the sample should be followed. If no reference method is

available, a starting temperature of 100 °C should be programmed. Because the

power level in the instrument is adjusted based on temperature feedback, most

samples can be dried using a 100% power level setting. If a sample contains a

strong microwave absorber such as carbohydrates, the power level will likely need

to be adjusted. In most instances, a 10% power change will be sufficient to prevent

overheating.

During the initial testing of a new sample, the weight display should be monitored

to ensure that the sample does not ignite and that a stable weight reading is

displayed. Sharp declines in weight indicate excessive sample heating. If ignition

occurs, the flame detection sensor will abort the analysis.

Samples that are strong absorbers of microwave energy should be diluted or tested

at reduced power levels. These products usually contain simple carbohydrates or

tightly held moisture that will not readily escape, causing overheating and/or

burning and non-reproducible results. These samples should be tested at a low

power. Examples of heat sensitive samples include powders, paper fibers, candy

and black liquor.

Page 28

21

Bias Identification

Most samples can be analyzed for percent moisture content with a CEM drying

method, and results will compare precisely with the standard test method.

Occasionally, however, all volatiles in a particular sample cannot be removed with

microwave power. Different spread techniques can be used to eliminate the need

for a moisture bias in most samples. Sometimes browning of the sample in the

same manner as in the air oven will also produce test results comparable to the

standard test.

If microwave moisture test results are repeatable, but not comparable to the

standard test results, a bias can be identified. With most samples, the bias will

amount to only a few tenths of a percent. To determine a moisture bias, prepare a

sample for testing, ensuring that the sample is homogeneous. Test this sample by

both a standard method and the CEM microwave method. Perform at least ten tests

by each method to check repeatability, then figure an average of the ten results.

Subtract the average of the microwave test results from the average of the standard

test results. Enter the resulting number (moisture bias) into the CEM moisture/

solids instrument. Corrected moisture test results will be displayed and printed. If

the difference in the average test results is a negative number, the power level

should be reduced and the tests should be repeated.

Some meat and poultry products, whether raw or cooked, show a fat bias when

analyzed with the CEM instruments. Less fat is extracted by a short solvent

extraction than by the longer ether extraction of the traditional Soxhlet technique.

The bias will be a constant for a given product and should be considered when

generating data.

Cooked sausage (i.e. wieners, bolognas, etc. with extenders) and other cooked

products tend to bind fat in the carbohydrate/protein structure of the cooked

product and will generally yield a lower fat value when extracted in the CEM

instrument than when extracted with the Soxhlet.

For proper determination and use of biases, results from the CEM instrument

should be compared with the results from traditional “long” or standard methods

used by USDA laboratories for compliance testing. Standard methods consist of an

air oven (four hours, 125°C) for moisture and Soxhlet (four hour ether extraction)

for fat. USDA recommends correlation of rapid fat and moisture methods with

these long methods.

USDA Processed Products Inspection Division encourages the use of rapid

methods for fat and moisture analysis to assist in better process control and

compliance. USDA recommends periodic back-up analysis (one in every 10 - 20

analyses) by standard long methods when rapid methods are used in approved

Total and Partial QC (TQC/PQC) Programs. Backup checks can be performed less

frequently as laboratories gain confidence in the established biases. CEM

Corporation also recommends a Quality Assurance Program for establishing and

maintaining biases and to ensure USDA compliance.

Prior to establishing a fat bias for the Fat Analysis System, a laboratory should be

confident of obtaining the best possible results for moisture, since precision of the

fat results will depend on the moisture results. Moisture results should have

repeatability between duplicate analyses of the same sample and a mean or

Page 29

22

”average” moisture values that are close to the values being generated on the same

samples by standard oven. To obtain the best possible results for moisture, and

thus for fat, there are three factors to consider: 1) sample preparation, 2) sample

application technique and 3) power and time parameters.

After establishing moisture repeatability and achieving moisture results as close to

standard ”long” methods as possible, use the following procedure to identify fat

biases for different product categories.

1. Select three or more samples (approximately two pounds each) from

different lots of the same product.

2. Prepare each sample according to standard procedures (3 - 4 passes

through a 5/64” blade, with mixing between grinds, or equivalent).

3. Divide each ground sample in half and package and label sub-samples in

two separate, air-tight containers.

4. Analyze one set of the sub-samples (from step 3) in duplicate by standard

”long” methods – oven for moisture, Soxhlet for fat. If facilities and/or

personnel are not available for these tests, use an independent laboratory.

Request raw data (individual tests) from the laboratory, not the mean or

”average” value.

5. After obtaining the results from the standard ”long” methods, analyze the

other set of subsamples in the CEM Moisture/Solids Analyzer for

moisture only. Adjust power and spread technique until acceptable

moisture repeatability is achieved.

6. After obtaining acceptable moisture repeatability, use the Fat Analysis

System and perform 3 - 5 moisture and fat analyses for each sample. As

with moisture, fat results should be repeatable. To obtain optimum fat

results, use a sufficient redry time. Two minutes is typical, although some

samples may require more time. The sample weight should be stable

(<0.2 mg weight change in the last five seconds). An insufficient redry

time will yield artificially low fat results since the true dry, extracted

weight will not be reached.

7. Subtract values obtained from the SMART System 5 from Soxhlet values.

Average the differences to identify the average bias for a specific product

or product group.

Sample A B C

Average Soxhlet fat xx xx xx

- Average CEM fat xx xx xx

= Bias xx xx xx

(A + B + C)/3 = Average Fat Bias

8. The bias should be relatively less than 2.0% and must be added to the fat

results from the SMART System 5 to produce results that correlate closely

with official methods. Repeat this process on a regular basis to confirm

that the bias is consistent. Raw meats and blends will produce smaller

biases than cooked products with extenders.

Page 30

23

Determining Ash/COH for Processed Meats

For samples that contain salt, sugar, spice, cure or other added components, ash/

carbohydrate (COH) values must be determined by analysis. For purposes of

calculating the protein by difference, the specific amount of each component (salt,

spice, bone, etc.) is not important, only the total amount.

To determine ash/COH values for finished products or blends with sugar, salt,

spice, etc., use the following procedure:

1. Collect and prepare three (3) samples from different lots of the same

product. Store the samples in airtight containers until tested.

2. Analyze the 3 samples in duplicate for fat and moisture in the

SMART System 5 and Fat Analysis System and for protein using “long”

methods (Kjeldahl). If necessary, an independent laboratory can provide

this analysis.

3. Average the results of the duplicate analyses for each sample, then total

the % Protein + % Fat + % Moisture for each sample.

4. Subtract the sum from 100% to get an Ash/Carbohydrate factor. For

example, if the composition of a sample is:

Moisture 52.54%

Fat 28.36%

Protein 11.25%

Total 92.15%

Ash/COH = 100% - 92.15%

Ash/COH = 7.85%

5. Calculate an average of the the ash/COH values for each of the 3

samples and program that factor into the SMART System 5.

Check samples periodically to verify the ash/COH values. Variations in the

amount of added constituents (salt, sugar, spice, extenders, etc.) can cause the ash/

COH factor to vary.

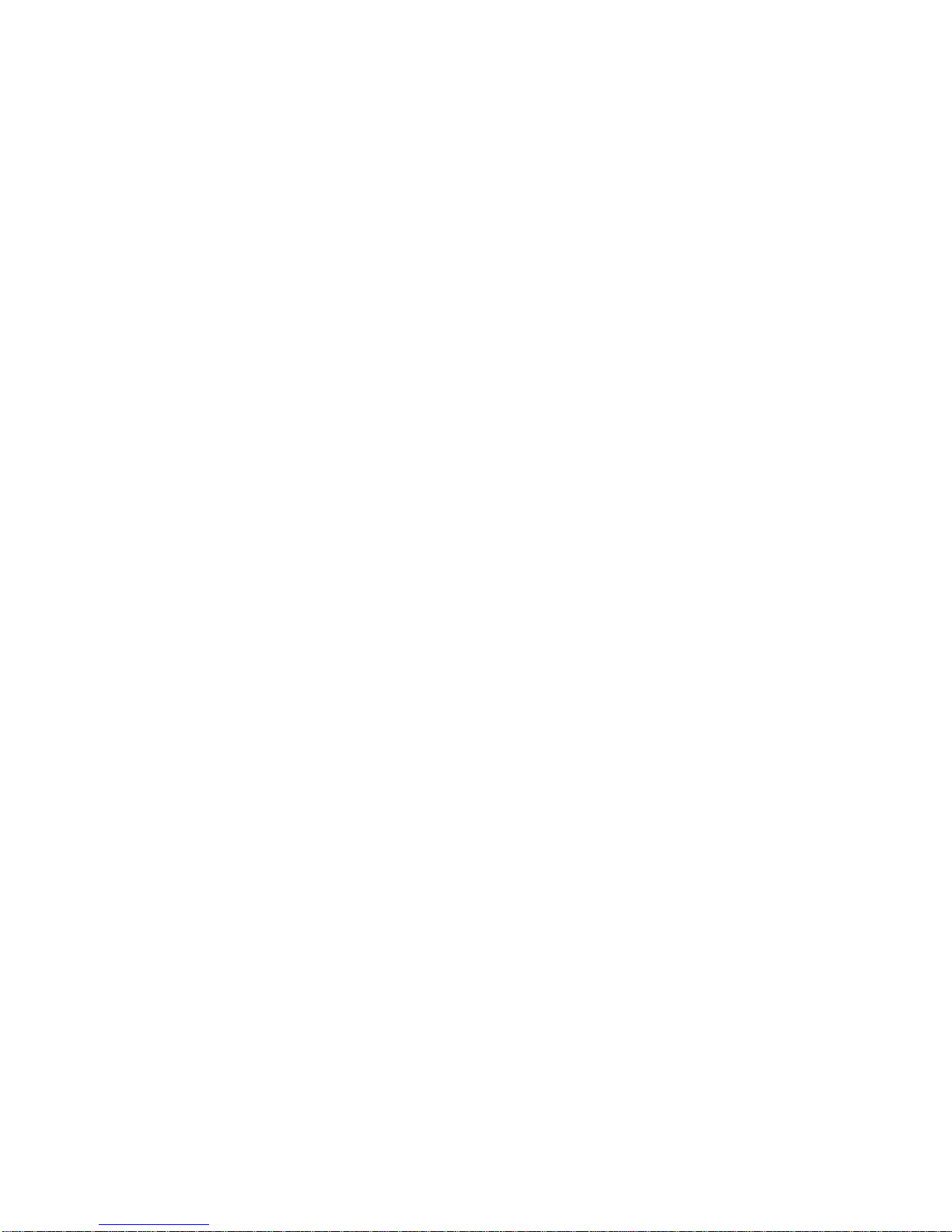

7.85%

11.25%

8.36%

52.54%

Moisture

Fat

Protein

Ash/COH

Page 31

24

Ash Content Of Meats

The following values should be helpful in establishing ash/carbohydrate factors for

raw meats. Since the carbohydrate values for these meats are so low, the ash alone

is usually adequate. Obviously, for meats with added salt, spice, cure, sugars, soy,

etc., the ash/COH values will vary.

The following values are estimates since composition may vary due to individual

differences in the the meat sources, seasonal variations, processing, etc.

Moisture Protein Fat Ash

Green Beef Material

Bull Meat 67.90 19.40 11.70 1.00

Ship Boneless Beef 64.00 16.20 19.00 .80

Regular Boneless Beef 70.00 20.00 9.00 1.00

Boneless Beef Pad. for Ck. 65.70 18.30 15.00 1.00

Boneless Bull Chux 72.50 19.80 7.20 .50

Boneless Chux C. & C. 70.00 19.30 9.70 1.00

Boneless Ship Chux 62.10 17.55 19.35 1.00

Shank Meat 72.60 19.80 6.60 1.00

Clods 72.30 20.18 6.90 .62

Sirloin Butts 66.60 19.40 13.00 1.00

Star Beef (Dry Saus.) 70.00 20.00 9.00 1.00

Spcl. Beef 69.00 19.00 11.00 1.00

Spcl. Bf. Trmgs. 52.50 14.60 31.90 1.00

Reg. Bf. Trmgs. 64.60 19.40 15.00 1.00

Bnls. Plates 43.60 13.40 42.00 1.00

Bnls. Flanks 41.90 13.10 44.00 1.00

Bnls. Plate Trmgs. 40.30 12.70 46.00 1.00

Beef Fat 11.80 5.10 82.90 .20

Beef Fat from Old Cow 22.20 5.60 71.80 .40

Brains 77.40 11.40 9.80 1.40

Cheeks 70.00 19.30 9.70 1.00

Diaphragm Meat 65.79 18.21 15.60 .50

Gullet Meat 73.20 16.80 9.00 1.00

Head Meat 68.45 18.96 11.59 1.00

Hearts 72.40 16.55 9.80 1.25

Lips 59.40 17.07 22.53 1.00

Lungs 78.00 18.80 2.20 1.00

Tongues 64.25 17.75 17.00 1.00

Tongue Trmgs. 69.40 19.17 10.43 1.00

Tripe, Cooked 81.90 15.50 2.10 .50

Page 32

25

Ash Content Of Meats (Continued)

Moisture Protein Fat Ash

Green Pork Material

Spiced Ham Trmgs. 61.10 16.90 21.00 1.00

Lean Ham Trmgs. 63.80 17.70 17.50 1.00

Hamette 66.40 18.40 14.20 1.00

Corned Pk. Shldr. Mt. 61.80 15.00 20.00 3.20

A Shoulder Trmgs. 61.80 17.10 20.10 1.00

B Shoulder Trmgs. 45.40 12.70 40.90 1.00

B & F Shldrs. 1/2” Fat 49.20 13.80 36.00 1.00

B & F Shldrs. 1” Fat 45.30 12.70 41.00 1.00

Lean Picnic Trmgs. 59.90 16.60 22.50 1.00

C.T. Butts 57.90 16.10 25.00 1.00

Boneless Boston Butts 47.30 13.20 38.50 1.00

Bnls. Packer Side Mt. 124-55 41.10 11.30 46.60 1.00

Skd. Belly Mt. 24.80 7.00 67.50 .70

Reg. Pk. Trmgs. 34.30 9.70 55.00 1.00

Neck Bone Trmgs. 51.50 14.40 33.10 1.00

Spec. Lean Trim. 58.10 15.90 25.00 1.00

A Pk. Trmgs. 68.80 22.50 8.00 .60

Blade Meat 73.10 18.00 7.80 1.10

Picnic Shank Meat 65.30 18.90 15.00 .80

Ham Shank Meat 62.60 17.60 19.00 .80

Pk. Trmgs. Pad for Ck. 64.00 15.00 20.00 1.00

Neck Fat Skin Off 13.00 2.60 84.00 .40

Skd. Jowls 22.10 5.70 71.70 .50

Belly Fat Skin Off 6.40 1.30 92.20 .10

Ham Fat Skin Off 11.80 3.10 84.90 .20

Back Fat Skin Off 5.70 1.30 92.90 .10

Gelatin Skins 10% Fat 47.50 22.80 28.50 1.20

Brains 77.40 11.80 9.80 1.00

Cheeks 67.25 15.75 16.00 1.00

Cheeks Pad. for Ck. 67.25 15.75 16.00 1.00

Diaphragm Meat 68.20 17.00 13.65 1.15

Gullet Mt. 74.60 16.20 8.00 1.20

Head Mt. 58.00 15.25 25.00 1.75

Head Skins 32.40 9.25 57.37 .98

Hearts 74.40 17.50 7.00 1.10

Jaw Mt 69.00 18.73 11.27 1.00

Livers 69.80 23.50 3.85 2.85

Melts 79.30 17.70 1.80 1.20

Snouts 52.25 14.61 32.14 1.00

Snout Mt. 59.00 16.43 23.57 1.00

Stomachs 70.25 13.85 13.50 1.90

Tongues 58.35 16.25 24.50 1.00

Tongue Trmgs. 26.50 8.65 64.85 .10

Page 33

26

Ash Content Of Meats (Continued)

Moisture Protein Fat Ash

Cured Pork Material

Clear Fat 18.10 2.30 78.10 1.50

DS Fat Backs 9.20 1.80 85.00 4.00

Smoked Pk. Skins 12.80 38.00 46.50 2.70

Bacon Ends and Pcs. 14.50 7.70 76.00 2.50

High Fat Cracklings 6.00 19.00 74.00 0.00

Med. Fat Cracklings 5.00 43.00 51.00 0.00

Low Fat Cracklings 8.00 84.50 6.50 0.00

Green Calf Material

Reg. Bnls. Veal 72.25 19.80 6.95 1.00

Cheeks 74.50 17.21 7.21 1.00

Gullet Mt. 76.50 15.20 7.30 1.25

Hearts 71.70 19.67 7.63 1.00

Tripe 87.30 9.00 3.20 .50

Green Sheep Material

Reg. Boneless Mutton 69.40 19.17 10.43 1.00

Cheeks 67.90 18.84 12.26 1.00

Gullett Mt. 75.00 15.40 9.10 .50

Hearts 67.20 14.90 14.40 3.50

Tripe 90.05 8.07 1.40 .48

Page 34

27

Methods Development

The CEM Applications Laboratory has developed procedures for various types of

samples. These procedures include parameters (program, power, time, sample

preparation, etc.) needed to program the SMART System5™ and analyze samples

in the SMART System5 and Fat Analysis System. CEM sample analysis

procedures can be requested from the CEM Applications Laboratory.

If a procedure for a particular sample is not included in the applications list, review

all information in this chapter relating to sample preparation, sample spread

technique, time and power parameters, redry time, and bias identification to

develop an application method. If necessary, call the CEM Applications

Laboratory for additional information and assistance (800) 726-3331.

1. Begin testing at 100% power and 100 °C.

2. If the sample has high solids content (approximately 75% solids), begin

testing with a low sample weight (1 - 2 grams).

3. Use Quick Test, Constant Weight for testing.

4. Observe weight change closely. The weight should steadily decline. If

weight is erratic (±1 mg), the test should be stopped because the sample is

probably burning. Reduce the power to 50% and perform the test again. If

the sample continues to burn, adjust the power in 5 degree increments.

5. Record final weight result and time.

6. Perform multiple sample tests with determined power and time. Results

should be within ±0.2%.

7. For fat content results, the re-dry power setting should be no higher than the

power setting used to remove moisture.

Page 35

28

Page 36

29

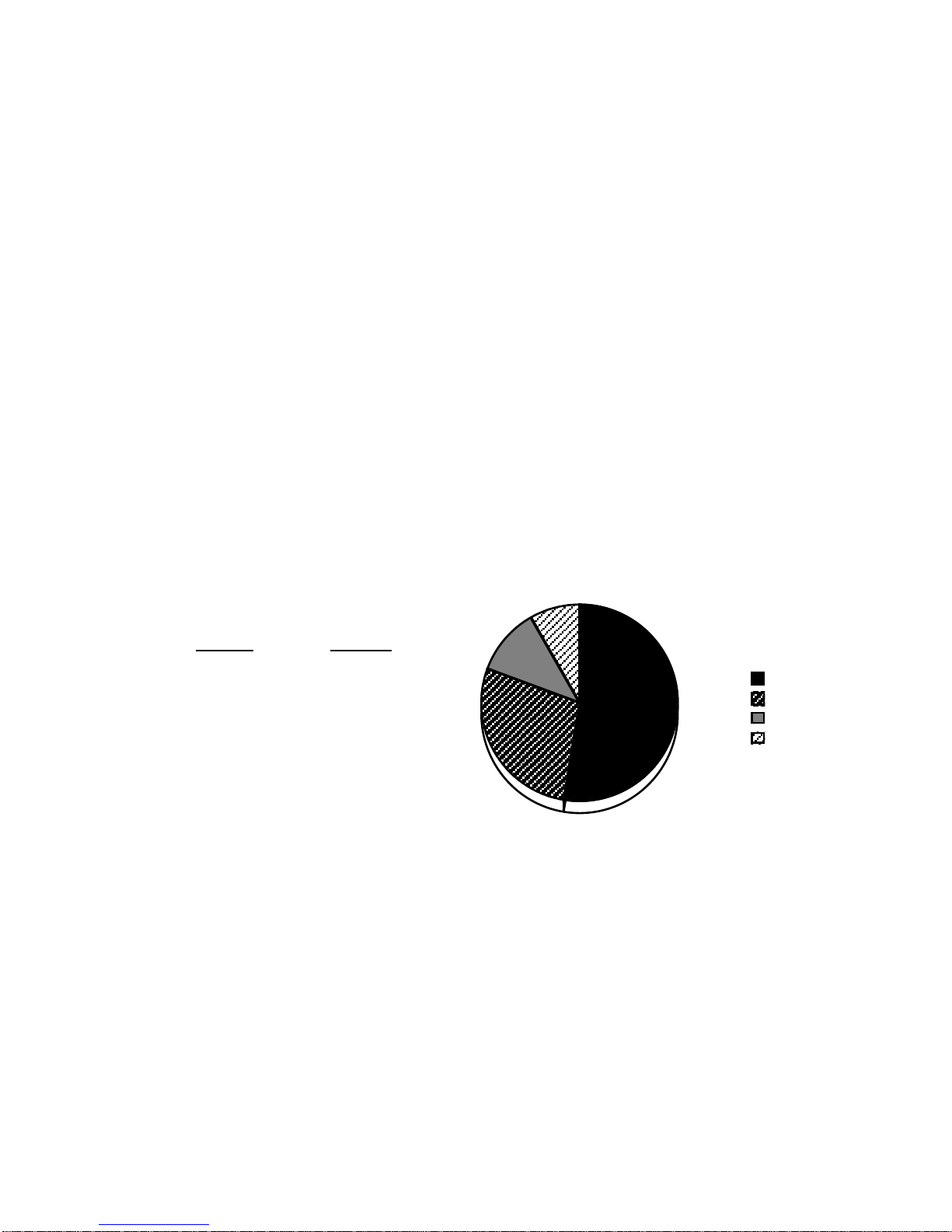

Quick Test

1. POWER: 0%

2. DELTA WEIGHT: 0.0 mg

3. DELTA TIME: 0 secs

4. MAX TIME: 10 mins

5. MAX TEMP: 110 C

6. MIN WT RANGE: 2.00 g

7. MAX WT RANGE: 4.00 g

8. WT COMPENSATION: OFF

Input power, press ENTER.

Entry: 000

SET

TIME

CEM Main Menu

1. QUICK TEST

2. EDIT/CREATE METHOD

3. LOAD METHOD

4. SETUP

5. PRINT

6. STATISTICS

Press item number to select.

METHOD - QUICK TEST

Quick Test

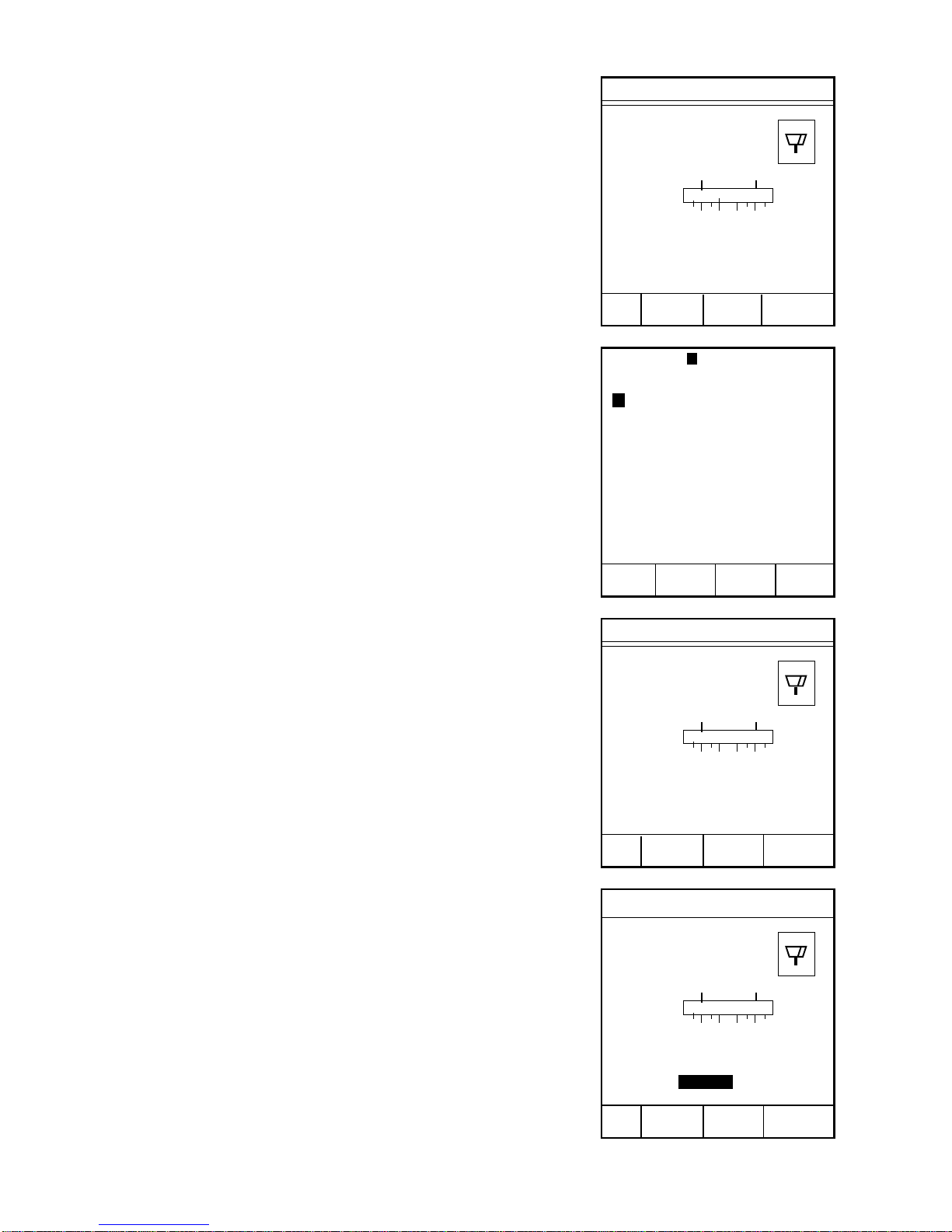

Quick Test permits entry of parameters for a onetime analysis or method development. The Quick

Test method permits two sample analysis

procedures – Constant Weight and Set Time.

Constant Weight

Constant weight permits the operator to dry a

sample until a constant weight is achieved.

Dryness is specified by defining a maximum

acceptable weight loss over a specified time

interval. During the specified time, when the

weight loss is equal to or less than that which

was specified, the analysis stops and results are

calculated.

1. With the CEM Main Menu displayed, press

“1” to activate Quick Test.

2. Press “1” to select and enter power.

3. Using the numeric keys, enter the power

level (1 - 100%).

4. Press ENTER.

5. Press “2” to select and enter delta weight.

Note: To edit any of the parameters, press the

numeric key of the parameter to be edited and

use the numeric keys to enter the new parameter.

Then, press ENTER.

6. Using the numeric keys, enter the delta

weight (.1 - .9). Normally a weight loss

differential of 0.2 - 0.5 mg is used.

7. Press ENTER.

Quick Test

1. POWER: 0%

2. DELTA WEIGHT: 0.0 mg

3. DELTA TIME: 0 secs

4. MAX TIME: 10 mins

5. MAX TEMP: 110 C

6. MIN WT RANGE: 2.00 g

7. MAX WT RANGE: 4.00 g

8. WT COMPENSATION: OFF

Press item number to select.

SET

TIME

Quick Test

1. POWER: XXX%

2. DELTA WEIGHT: 0.0 mg

3. DELTA TIME: 0 secs

4. MAX TIME: 10 mins

5. MAX TEMP: 110 C

6. MIN WT RANGE: 2.00 g

7. MAX WT RANGE: 4.00 g

8. WT COMPENSATION: OFF

Input delta weight, press ENTER.

Entry: 0. 0

SET

TIME

➞

➞

Page 37

30

Quick Test

1. POWER: XXX%

2. DELTA WEIGHT: X.X G

3. DELTA TIME: XX secs

4. MAX TIME: XX mins

5. MAX TEMP: XXX C

6. MIN WT RANGE: 2.00 g

7. MAX WT RANGE: 4.00 g

8. WT COMPENSATION: OFF

Input min wt range, press ENTER.

Entry: 02.00

SET

TIME

Quick Test

1. POWER: XXX%

2. DELTA WEIGHT: 0.0 mg

3. DELTA TIME: 0 secs

4. MAX TIME: 10 mins

5. MAX TEMP: 110 C

6. MIN WT RANGE: 2.00 g

7. MAX WT RANGE: 4.00 g

8. WT COMPENSATION: OFF

Input delta time, press ENTER.

Entry: 00

SET

TIME

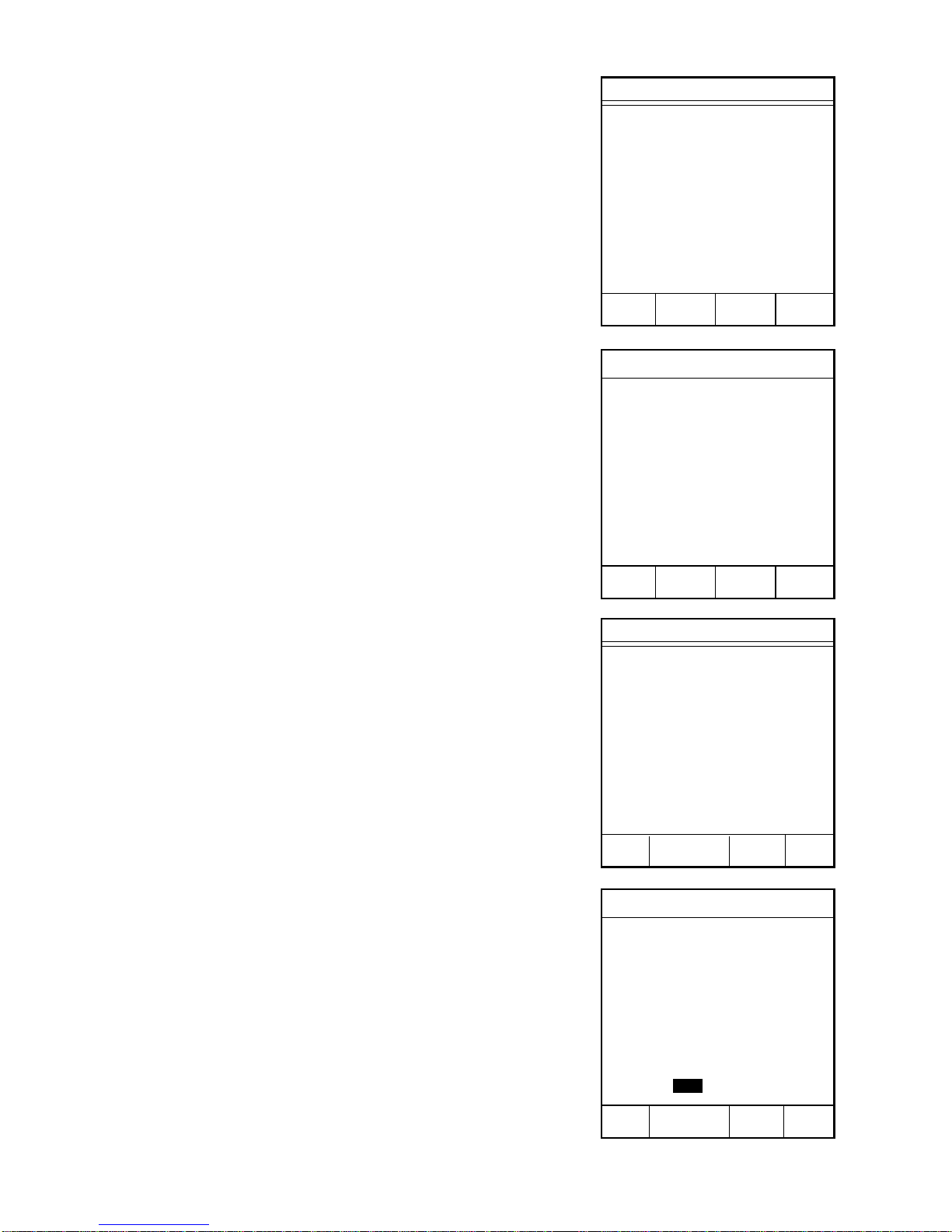

8. Press “3” to select and enter delta time.

9. Using the numeric keys, enter the delta

time

(1 - 60 seconds). Normally a differential

time interval of 10 - 15 seconds is used.

10. Press ENTER.

Note: Maximum run time is the amount of time

the instrument will operate prior to shutdown if a

constant weight has not been reached. A

maximum run time must be entered or the

program will be invalid. If the instrument shuts

down due to maximum run time, parameters

should be adjusted prior to repeating the

analysis.

11. Press “4” to select and enter maximum run

time. If using the default value of 10

minutes, omit step 12.

12. Using the numeric keys, enter the

maximum run time (1 - 60 minutes).

13. Press ENTER.

14. Press “5” to select and enter maximum

temperature. If using the default value of

110°C, omit step 15.

15. Using the numeric keys, enter the

maximum temperature (0 - 300 °C) of the

instrument during the analysis.

16. Press ENTER.

17. Press “6” to enter a minimum weight

range. If using the default minimum

weight range of 2.00 g, omit step 18.

18. Using the numeric keys, enter the

minimum weight range of the sample (0 50 g).

19. Press ENTER.

Quick Test

1. POWER: XXX%

2. DELTA WEIGHT: X.X mg

3. DELTA TIME: XX secs

4. MAX TIME: 10 mins

5. MAX TEMP: 110 C

6. MIN WT RANGE: 2.00 g

7. MAX WT RANGE: 4.00 g

8. WT COMPENSATION: OFF

Input max time, press ENTER.

Entry: 10

SET

TIME

Quick Test

1. POWER: XXX%

2. DELTA WEIGHT: X.X mg

3. DELTA TIME: XX secs

4. MAX TIME: XX mins

5. MAX TEMP: 110 C

6. MIN WT RANGE: 2.00 g

7. MAX WT RANGE: 4.00 g

8. WT COMPENSATION: OFF

Input max temp, press ENTER.

Entry: 110

SET

TIME

➞

➞

➞

➞

Page 38

31

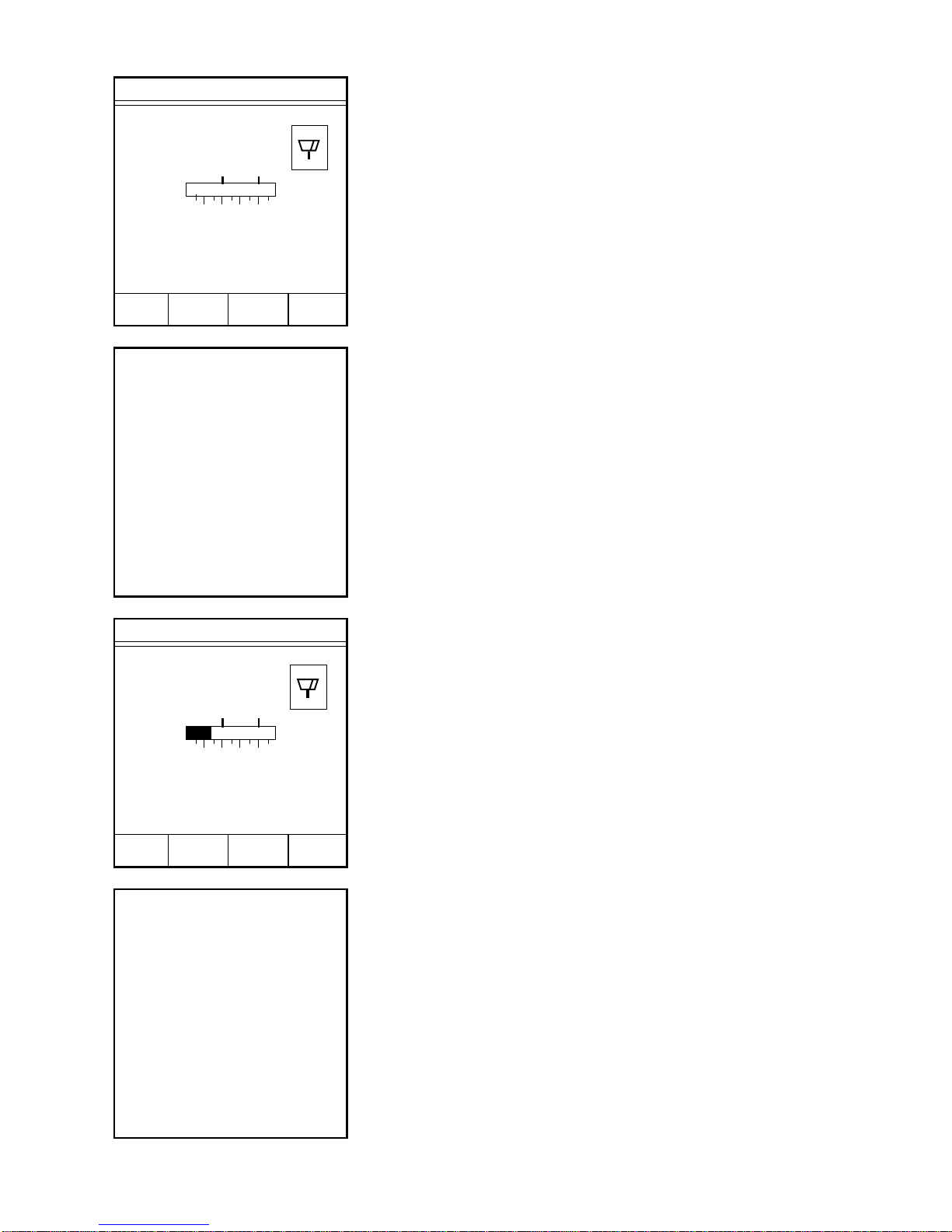

20. Press “7” to enter a maximum weight

range. If using the default maximum

weight range of 4.00 g, omit step 21.

21. Using the numeric keys, enter the

maximum weight range of the sample (0 50 g).

22. Press ENTER.

Note: Weight compensation is designed for use

with samples having a buoyancy effect created

by heat. It should be used (turned on) for

samples, such as milk, margarine, condiments,

etc., which have a higher temperature when the

final weight is calculated than at the beginning of

the test.

23. Press “8” to toggle weight compensation

“on” or “off.”

Note: To edit any of the parameters, press the

numeric key of the parameter to be edited and

use the numeric keys to enter the new parameter.

Then, press ENTER.

24. Press READY to begin the analysis.

Note: The Quick Test screen appears indicating

the power, temperature and time.

Note: Press the operation key below EDIT to

return to the Quick Test parameter screen to edit

method parameters.

25. If Autotrack is turned off, a sample identification is required. Press the operation key

below ID.

Quick Test

1. POWER: XXX%

2. DELTA WEIGHT: X.X mg

3. DELTA TIME: XX secs

4. MAX TIME: XX mins

5. MAX TEMP: XXX C

6. MIN WT RANGE: X.XX g

7. MAX WT RANGE: X.XX g

8. WT COMPENSATION: OFF

Press READY to run test.

SET

TIME

Quick Test

1. POWER: XXX%

2. DELTA WEIGHT: X.X mg

3. DELTA TIME: XX secs

4. MAX TIME: XX mins

5. MAX TEMP: XXX C

6. MIN WT RANGE: X.XX g

7. MAX WT RANGE: 4.00 g

8. WT COMPENSATION: OFF

Input max wt range, press ENTER.

Entry: 04.00

SET

TIME

QUICK TEST

Power: xxx%

Temp (xxx): xx.x

Time: xx:xx

Wt: x.xxxxg

Place pads on balance and

press TARE.

ID EDIT

1 2 3 4 5

➞

Quick Test

1. POWER: 0%

2. DELTA WEIGHT: 0.0 mg

3. DELTA TIME: 0 secs

4. MAX TIME: 10 mins

5. MAX TEMP: 110 C

6. MIN WT RANGE: 2.00 g

7. MAX WT RANGE: 4.00 g

8. WT COMPENSATION: OFF

Press item number to select.

SET

TIME

➞

Page 39

32

26. Using the operation keys below the arrows,

position the cursor on (select) the first

number or letter of the sample identification. Press ENTER. Continue to position

the cursor on each letter or number and

press ENTER until the identification is

complete.

Note: If using an identification number only, use

the numeric keys to enter the number.

27. Press READY to return to the Quick Test

screen.

28. Lift the top cover of the SMART System

5™. Place two glass fiber sample pads on

the balance pan. Close the top cover.

29. Press TARE.

30. Wait for the instrument to tare the weight

of the sample pads. The Quick Test screen

will reappear when the tare function is

complete.

Note: The “T” in the lower left corner of the

balance icon indicates that the weight of the

sample pads has been tared.

31. Lift the instrument cover. Apply the

sample in a thin, even layer to one of the

sample pads. Quickly and gently place the

sample pads back on the balance pan.

Close the top cover.

32. Press START.

QUICK TEST

Sample ID: xxxxxx

Power: xxx%

Temp (xxx): xx.x

Time: xx:xx

Wt: x.xxxxg

Place pads on balance and

press TARE.

ID EDIT

QUICK TEST

Sample ID: xxxxxx

Power: xxx%

Temp (xxx): xx.x

Time: xx:xx

Wt: x.xxxxg

Place sample and pads on

balance and press START.

ID EDIT

1 2 3 4 5

TARING BALANCE . . .

T

1 2 3 4 5

SAMPLE ID:

0 1 2 3 4 5 6 7 8 9 A B

C D E F G H I J K L M N

O P Q R S T U V W X Y Z

Space Delete

Highlight choice, press ENTER.

Press READY to continue.

➞

➞

➞

➞

Page 40

33

The instrument reads and records the initial

weight of the sample prior to beginning the

analysis.

As the analysis begins, the flashing microwave

indicators in the balance icon appear and the

time begins counting upward. The sample weight

decreases as the moisture is removed.

During the drying time, the operation key below

SOLIDS or MOISTURE may be pressed to

display % solids or % moisture.

When the weight loss is equal to or less than the

selected parameter, five short beeps will be

heard, and the Data Results screen will appear,

displaying either the % moisture or % solids as

selected.

Note: Press READY to analyze additional

samples using the same method.

Note: Press the operation key below FORM

FEED to advance paper from the internal printer.

33. Press the operation key below DATA to

display the analysis data.

QUICK TEST

Sample ID: xxxxxx

Power: xxx%

Temp (xxx): xx.x

Time: xx:xx

Moisture: xx.xx%

Wt: x.xxxxg

STOP

SOLIDS TEST

QUICK TEST

Sample ID: xxxxxx

Power: xxx%

Temp (xxx): xx.x

Time: xx:xx

Solids: xx.xx%

Wt: x.xxxxg

STOP

MOISTURE TEST

Data Results

XX.XX%M

Press READY to continue.

MAIN FORM

MENU FEED DATA PRINT

READING BALANCE . . .

Page 41

34

Sample Weight Data

Initial Wt: xx.xxxxg

Final Wt: xx.xxxxg

Diff Wt: xx.xxxxg

Press READY to continue.

MAIN PREV

MENU PAGE

34. Press the operation key below SAMPLE

WEIGHTS to view sample weight

information.

The Sample Weight Data screen displays the

initial weight, the final weight and the

differential weight.

35. Press the operation key below PREV

PAGE to return to the Data Results screen.

36. Press the operation key below PRINT to

print the analysis results either on the

internal printer or an external printer, if

installed.

Note: Press READY to analyze additional

samples using the same method.

37. Press the operation key below MAIN

MENU to return to the CEM Main Menu

screen.

Data Results

Sample ID: xxxxxxxxx

Dry Time: xx:xx

Moisture: xx.xx%

Solids: xx.xx%

Press READY to continue.

MAIN FORM SAMPLE

MENU FEED WEIGHTS PRINT

CEM Main Menu

1. QUICK TEST

2. EDIT/CREATE METHOD

3. LOAD METHOD

4. SETUP

5. PRINT

6. STATISTICS

Press item number to select.

METHOD - QUICK TEST

Data Results

Sample ID: xxxxxxxxx

Dry Time: xx:xx

Moisture: xx.xx%

Solids: xx.xx%

Press READY to continue.

MAIN FORM SAMPLE

MENU FEED WEIGHTS PRINT

Page 42

35

Quick Test

1. POWER: 0%

2. RUN TIME: 00:00 min:sec

3. MAX TEMP: 110 C

4. MIN WT RANGE: 2.00 g

5. MAX WT RANGE: 4.00 g

6. WT COMPENSATION: OFF

Press item number to select.

CONSTANT

WEIGHT

Quick Test

1. POWER: 0%

2. RUN TIME: 00:00 min:sec

3. MAX TEMP: 110 C

4. MIN WT RANGE: 2.00 g

5. MAX WT RANGE: 4.00 g

6. WT COMPENSATION: OFF

Input power, press ENTER.

Entry: 000

CONSTANT

WEIGHT

CEM Main Menu

1. QUICK TEST

2. EDIT/CREATE METHOD

3. LOAD METHOD

4. SETUP

5. PRINT

6. STATISTICS

Press item number to select.

METHOD - QUICK TEST

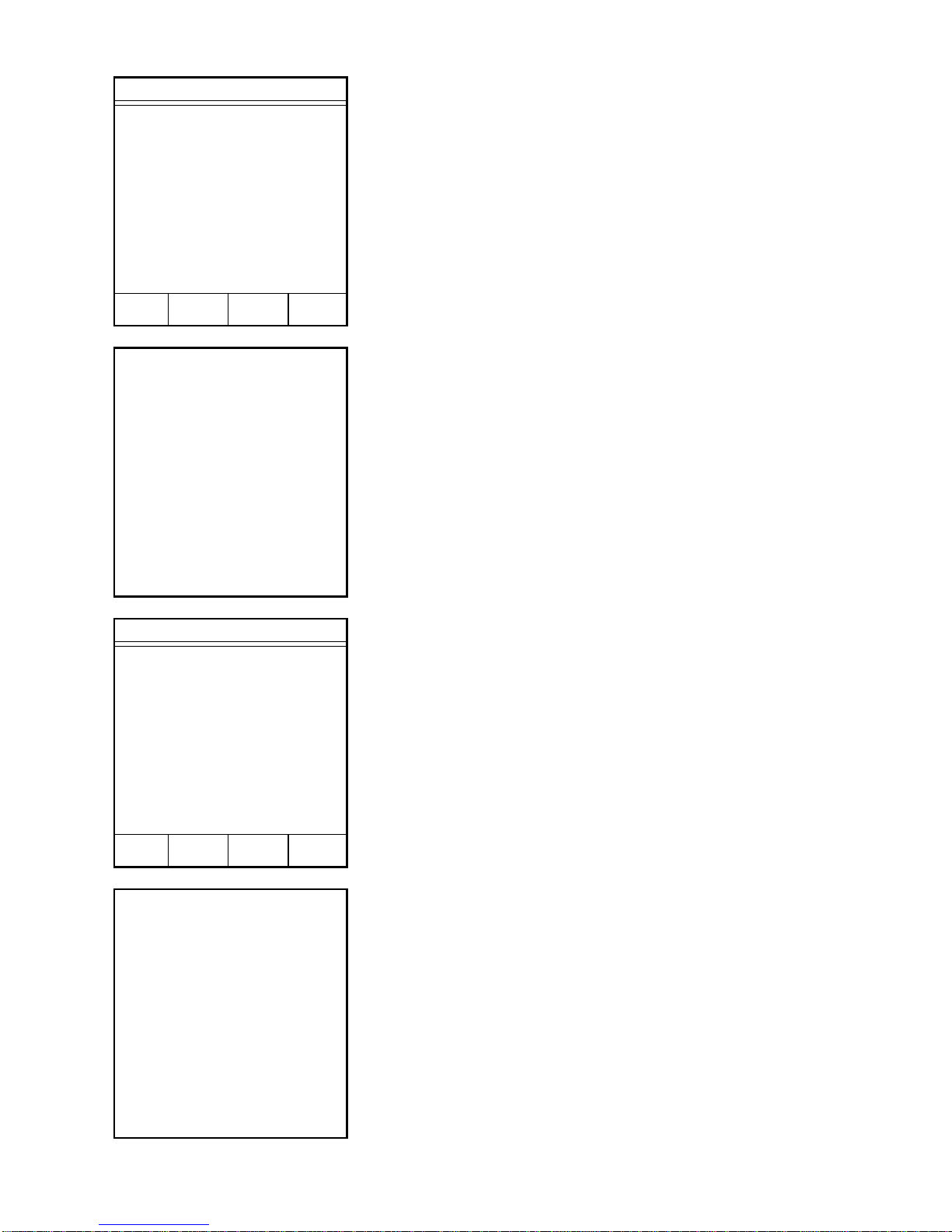

Set Time

Set time permits the operator to control the

sample analysis by entering a specified analysis

time and power level. At the end of the specified

time, the percent solids and/or moisture of the

sample is calculated and displayed.

1. With the CEM Main Menu displayed, press

“1” to activate Quick Test.

2. Press the operation key below SET TIME.

3. Press “1” to enter power.

4. Using the numeric keys, enter the power

level (1 - 100%).

5. Press ENTER.

Quick Test

1. POWER: 0%

2. DELTA WEIGHT: 0.0 mg

3. DELTA TIME: 0 secs

4. MAX TIME: 10 mins

5. MAX TEMP: 110 C

6. MIN WT RANGE: 2.00 g

7. MAX WT RANGE: 4.00 g

8. WT COMPENSATION: OFF

Press item number to select.

SET

TIME

➞

Page 43

36

Quick Test

1. POWER: XXX%

2. RUN TIME: XX:XX min:sec

3. MAX TEMP: XXX C

4. MIN WT RANGE: X.XX g

5. MAX WT RANGE: 4.00 g

6. WT COMPENSATION: OFF

Input max wt range, press ENTER.

Entry: 04.00

CONSTANT

WEIGHT

Quick Test

1. POWER: XXX%

2. RUN TIME: XX:XX min:sec

3. MAX TEMP: XXX C

4. MIN WT RANGE: 2.00 g

5. MAX WT RANGE: 4.00 g

6. WT COMPENSATION: OFF

Input min wt range, press ENTER.

Entry: 02.00

CONSTANT

WEIGHT

Quick Test

1. POWER: XXX%

2. RUN TIME: 00:00 min:sec

3. MAX TEMP: 110 C

4. MIN WT RANGE: 2.00 g

5. MAX WT RANGE: 4.00 g

6. WT COMPENSATION: OFF

Input run time, press ENTER.

Entry: 00:00

CONSTANT

WEIGHT

6. Press “2” to select and enter the sample

drying time.

7. Using the numeric keys, enter the run time

(1 sec. - 99 min. 59 sec.).

8. Press ENTER.

9. Press “3” to select and enter maximum

temperature. If using the default value of

110°C, omit step 10.

10. Using the numeric keys, enter the

maximum temperature (0 - 300 °C) of the

instrument during the analysis.

11. Press ENTER.

12. Press “4” to enter a minimum weight

range. If using the default minimum weight

range of 2.00 g, omit step 13.

13. Using the numeric keys, enter the

minimum weight range of the sample (0 50 g).

14. Press ENTER.

15. Press “5” to enter a maximum weight

range. If using the default maximum

weight range of 4.00 g, omit step 16.

16. Using the numeric keys, enter the

maximum weight range of the sample (0 50 g).

17. Press ENTER.

Quick Test

1. POWER: XXX%

2. RUN TIME: XX:XX min:sec

3. MAX TEMP: 110 C

4. MIN WT RANGE: 2.00 g

5. MAX WT RANGE: 4.00 g

6. WT COMPENSATION: OFF

Input max temp, press ENTER.

Entry: 110

CONSTANT

WEIGHT

➞

➞

➞

➞

Page 44

37

Quick Test

1. POWER: XXX%

2. RUN TIME: XX:XX min:sec

3. MAX TEMP: XXX C

4. MIN WT RANGE: X.XX g

5. MAX WT RANGE: 4.00 g

6. WT COMPENSATION: OFF

Press item number to select.

CONSTANT

WEIGHT

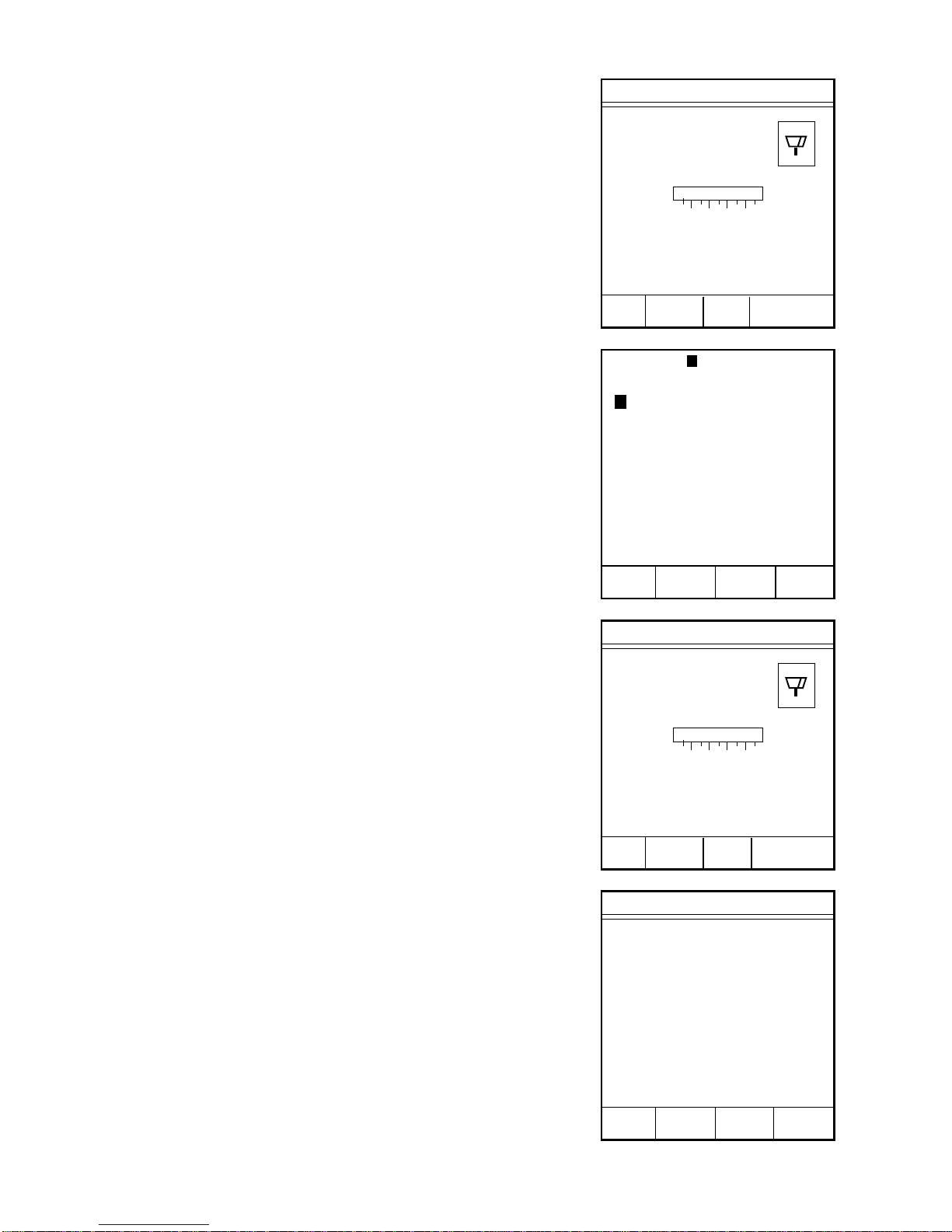

Note: Weight compensation is designed for use

with samples having a buoyancy effect created

by heat. It should be used (turned on) for

samples, such as milk, margarine, condiments,

etc., which have a higher temperature when the

final weight is calculated than at the beginning of

the test.

18. Press “6” to toggle Weight Compenstaion

“on” or “off.”

Note: To edit any of the parameters, press the

numeric key of the parameter to be edited and

use the numeric keys to enter the new parameter.

Then, press ENTER.

19. Press READY to begin the analysis.

Note: The Quick Test screen appears indicating

the power, temperature and time.

Note: Press the operation key below EDIT to

return to the Quick Test parameter screen to edit

method parameters.

20. If Autotrack is turned off, a sample identification name or number is required. Press

the operation key below ID.

21. Using the operation keys below the arrows,

position the cursor on (select) the first

number or letter of the sample identification. Press ENTER. Continue to position

the cursor on each letter or number and

press ENTER until the identification is

complete.

Note: If using an identification number only, use

the numeric keys to enter the number.

22. Press READY to return to the Quick Test

screen.

Quick Test

1. POWER: XXX%

2. RUN TIME: XX:XX min:sec

3. MAX TEMP: XXX C

4. MIN WT RANGE: X.XX g

5. MAX WT RANGE: 4.00 g

6. WT COMPENSATION: OFF

Press READY to run test.

CONSTANT

WEIGHT

QUICK TEST

Power: xxx%

Temp (xxx): xx.x

Time: xx:xx

Wt: x.xxxxg

Place pads on balance and

press TARE.

ID EDIT

SAMPLE ID:

0 1 2 3 4 5 6 7 8 9 A B

C D E F G H I J K L M N

O P Q R S T U V W X Y Z

Space Delete

Highlight choice, press ENTER.

Press READY to continue.

➞

➞

➞

➞

1 2 3 4 5

➞

Page 45

38

TARING BALANCE . . .

23. Lift the top cover of the SMART System

5™. Place two glass fiber sample pads on

the balance pan. Close the top cover.

24. Press TARE.

25. Wait for the instrument to zero the weight

of the sample pads. The Quick Test screen

will reappear when the tare function is

complete.

Note: The “T” in the lower left corner of the

balance icon indicates that the weight of the

sample pads has been tared.

26. Lift the top cover. Remove the sample pads

from the balance pan. Apply the sample in

a thin, even layer to one of the sample

pads. Quickly and gently place the sample

pads back on the balance pan. Close the top

cover.

27. Press START.

The instrument reads and records the initial

weight of the sample prior to beginning the

analysis.

1 2 3 4 5

QUICK TEST

Sample ID: xxxxxx

Power: xxx%

Temp (xxx): xx.x

Time: xx:xx

Wt: x.xxxxg

Place sample and pads on

balance and press START.

ID SOLIDS EDIT

T

READING BALANCE . . .

QUICK TEST

Sample ID: xxxxxx

Power: xxx%

Temp (xxx): xx.x

Time: xx:xx

Wt: x.xxxxg

Place pads on balance and

press TARE.

ID EDIT

1 2 3 4 5

Page 46

39

As the analysis begins, the flashing microwave

indicators in the balance icon appear and the

time begins counting down. The sample weight

decreases as the moisture is removed.

During the drying time, the operation key below

SOLIDS or MOISTURE may be pressed to

display % solids or % moisture.

Note: Press the operation key below STOP

TEST to stop the method test.

When the drying time is complete, five short

beeps will be heard, and the Data Results screen

will appear, displaying either the % moisture or

% solids as selected.

Note: Press READY to analyze additional

samples using the same method.

Note: Press the operation key below FORM

FEED to advance blank paper from the internal

printer.

28. Press the operation key below DATA to

display the analysis data.

29. Press the operation key below SAMPLE

WEIGHTS to view sample weight

information.

Data Results

Sample ID: xxxxxx

Dry Time: xx:xx

Moisture: xx.xx%

Solids: xx.xx%

Press READY to continue.

MAIN FORM SAMPLE

MENU FEED WEIGHTS PRINT

QUICK TEST

Sample ID: xxxxxx

Power: xxx%

Temp (xxx): xx.x

Time: xx:xx

Solids: xx.xx%

Wt: x.xxxxg

STOP

SOLIDS TEST

Data Results

XX.XX%M

Press READY to continue.

MAIN FORM

MENU FEED DATA PRINT

QUICK TEST

Sample ID: xxxxxx

Power: xxx%

Temp (xxx): xx.x

Time: xx:xx

Moisture: xx.xx%

Wt: x.xxxxg

STOP

SOLIDS TEST

Page 47

40

Data Results

Sample ID: xxxxxx

Dry Time: xx:xx

Moisture: xx.xx%

Solids: xx.xx%

Press READY to continue.

MAIN FORM SAMPLE

MENU FEED WEIGHTS PRINT

The Sample Weight Data screen displays the

initial weight, the final weight and the

differential weight.

30. Press the operation key below PREV

PAGE to return to the Data Results screen.

31. Press the operation key below PRINT to

print the analysis results either on the

internal printer or an external printer, if

installed.

Note: Press READY to analyze additional

samples using the same method.

32. Press the operation key below MAIN