Page 1

Razor™

Parallel Cleavage System

Installation and Operation Instructions

600850

Rev. 2

July 2017

Page 2

Introduction to the Razor

The RazorTM parallel cleavage system is an isolated heating module designed for performing the peptide cleavage step. The isolated

module provides the advantage of protecting the Liberty Blue system from the harsh reagents required for the cleavage all while

allowing the use of heat to provide high quality peptides in excellent yields in a fraction of the time.

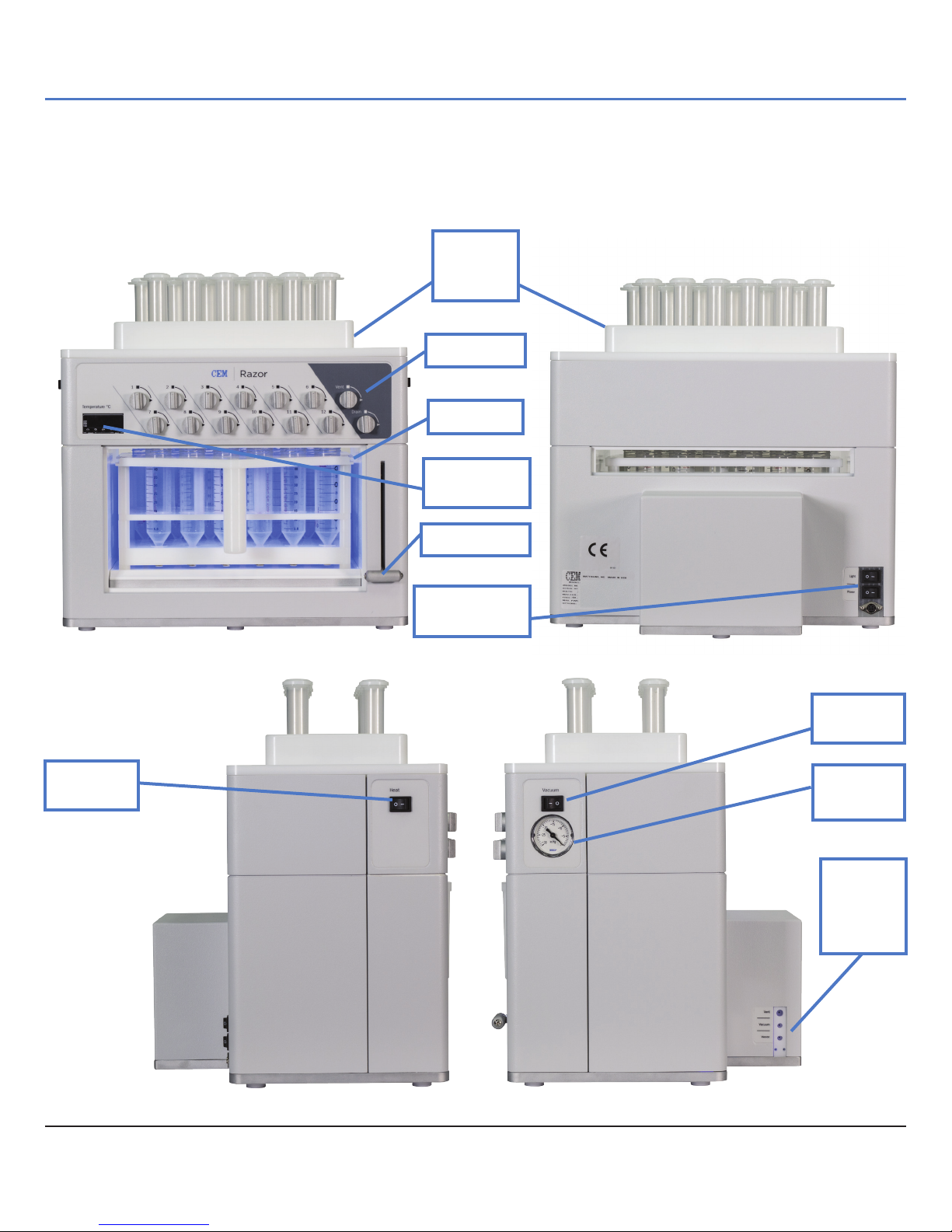

Razor Hardware

Vessel

Hot block

Valve Panel

Vessel Tray

Temperature

Control Panel

Heat

Switch

Locking Lever

Power

Switches

Vacuum

Switch

Vacuum

Gauge

Vent,

Vacuum,

and Waste

Ports

Razor™ Parallel Peptide Cleavage System

600850 • Revision 2 • July 2017

1

Page 3

Hardware Installation

Installation Site Preparation

The Razor parallel cleavage system should be installed in a functioning laboratory fume hood. Choose a location that:

• can accomodate the Razor system [15” x 11.5” x 15.5” (38.1 cm x 29.2 cm x 39.4 cm) (L x W x H)] as well as an

additional 8” (20 cm) of open space on each side and 6” (15 cm) at the rear of the instrument for proper ventilation.

• is free from vibration of large equipment and/or excessive walk-through trac,

• provides a temperature range of 41 - 104 ºF (5 - 40 ºC) and a humidity range of 10 - 85% relative humidity

• provides adequate space for sample handling, and

• permits the system to be connected to a dedicated, grounded 120 VAC outlet. The Razor should operated on a

stabilized, constant voltage AC power supply. To operate properly, the voltage must be within ±10% of the specied

level.

Razor Hardware

The Razor accessory kit comes with the following items:

1. Razor vessel rack (P/N: 547205)

2. Razor vessel rack cover (P/N:

170875)

3. 1 L glass bottle (P/N: 167550)

4. Waste tubing bundle (P/N: 547225)

5. GL45 waste cap (P/N: 167545)

2

6. Razor power supply (P/N: 267080)

7. Power cord

8. Razor vessel caps (P/N: 170875)

9. 50 mL centrifuge tubes, set of 25

(P/N: 330090)

10. Razor cleavage vessel, 120 pack

(P/N: NP-1392) (not pictured)

Razor™ Parallel Peptide Cleavage System

600850 • Revision 2 • July 2017

Page 4

Hardware Assembly and Setup

WARNING

The Razor should be installed in a ventilated fume hood.

1. Remove the Razor from it’s shipping box and place the system in a well ventilated fume hood.

2. Connect the power cord to the power supply box. Attach the power supply to the connector on the rear of the

system, and plug the power cord into an appropriate outlet.

3. Attach the two tubes on one end of the waste tubing bundle to the GL45 cap. It does not matter which tube is

connected to which hole. Secure the cap to the 1 L bottle.

4. Connect the labeled waste cap assembly tubes to the vacuum and vent ports on the side of the system.

Razor™ Parallel Peptide Cleavage System

600850 • Revision 2 • July 2017

3

Page 5

5. Load the vessel tray with 12 clean 50 mL centrifuge tubes (P/N: 330090), and slide into the Razor cavity. Make sure

the tray has been pushed all the way to the back of the cavity. Lock the vessel tray in place by pulling the locking

lever down.

6. Switch the system power and cavity lights ON using the power switches on the rear of the system.

7. Switch the system heat ON using the power switch on the left side of the system.

8. Set and verify the system temperature.

8.1. Using the up and down arrows on the temperature screen, set the temperature to 40 - 42 ºC. The set

temperature is displayed in green in the lower right corner of the screen.

8.2. The current temperature is displayed in white in the center of the screen. The system is ready for use when

the current temperature matches the set temperature.

Current Temperature

Set Temperature

Change Temperature

Recommended Cleavage Parameters

In Fmoc synthesis, the removal of the peptide from the solid support is typically accomplished with triuoroacetic acid (TFA). Because

the side chain protecting groups used in Fmoc synthesis are acid labile, a single step both cleaves the peptide from the resin and

removes the protecting groups. Various scavenger molecules are added to the TFA to prevent the cleaved protecting groups from

reattaching to the peptide. The particular scavengers used depend on the specic peptide sequence. Common scavengers include

water (scavenges t-butyl cations), triisopropyl silane (TIS, scavenges trityl and Pbf cations), ethane dithiol (EDT, scavenges t-butyl

cations, reduces oxidation of Cys/Met side chains), dioxa-1,8-octane-dithiol (DODT, scavenges t-butyl cations, suppresses oxidation

of Cys/Met side chains), phenol (protects Tyr and Trp side chains from oxidation), and thioanisole (aids in removal of Pbf protecting

groups from Arg(Pbf), suppresses oxidation of Cys/Met side chains).

CEM recommends using a cocktail of TFA/TIS/H2O/DODT (92.5/2.5/2.5/2.5).

4

Razor™ Parallel Peptide Cleavage System

600850 • Revision 2 • July 2017

Page 6

General Procedures

Razor Cleavage Protocol

1. Verify the current system temperature has reached the set temperature.

2. Load the vessel tray with 12 clean 50 mL centrifuge tubes (P/N: 330090), and slide into the Razor cavity. Make sure

the tray has been pushed all the way to the back of the cavity. Lock the vessel tray in place by pulling the locking

lever down.

CAUTION

The vessel tray must have all 12 centrifuge tubes loaded to operate correctly. If a tube is missing, the system will fail to

create a vacuum during draining.

3. Insert a new, clean reaction tube into the washing station. Switch the vacuum pump ON using the power switch on

the right side of the system. Verify there are no leaks by checking the vacuum gauge below the vacuum switch, and

then turn the pump OFF.

NOTE

Up to 11 additional vessels can be washed and added to the Razor hotblock. To prepare an additional vessel, wash

the resin as instructed while keeping the valves for the already prepared vessels in the CLOSED position to prevent

premature draining.

An optional Teon® cap (P/N: 170810) can be placed on reaction vessels during cleavage to reduce evaporation.

4. Transfer the resin with the completed peptide into the reaction tube. Move the Drain valve knob to the OPEN

position and turn the vacuum pump ON to drain any solvent from the resin.

OpenClosed

5. Rinse the resin three times with an appropriate volume of dichloromethane (DCM), leaving the pump ON and the

Drain knob OPEN to drain the liquid. After rinsing, turn the vacuum pump OFF and CLOSE the Drain knob.

CAUTION

DMF is a base and will react with TFA. DCM should be used to rinse the resin prior to cleavage to ensure that no residual

DMF is present before adding the cleavage cocktail.

Razor™ Parallel Peptide Cleavage System

600850 • Revision 2 • July 2017

5

Page 7

6. Move the reaction tube containing the rinsed resin to an empty, clean position in the Razor hot block and turn the

numbered valve knob to the CLOSED position.

7. Add cleavage cocktail to the reaction vessel, double that of the volume of the resin bed. For 0.25 mmol cleavages,

the resin mixture may be visible above the hot block. Up to 12 reaction vessels can be loaded into the hot block.

8. Allow the vessel(s) to remain in the Razor for 30 minutes each at 40 - 42 ºC.

NOTE

If the peptide has multiple Arg residues, increase the cleavage time by 5 min for every additional Arg after the third Arg

residue. Do not exceed 45 min for the total cleavage time.

9. After cleavage has ended, turn the appropriate numbered valve knob to the OPEN position to begin draining the

cleavage solution.

CAUTION

Drain one cleavage position at a time, do not drain multiple positions at once.

10. Turn the vacuum pump ON to drain any remaining liquid, then turn OFF.

11. Move the Vent valve knob to the OPEN position to release pressure.

12. Unlock the vessel tray by pushing the locking lever up. This will lower the tray for removal.

13. Carefully remove the vessel tray from the Razor cavity and remove the centrifuge tubes containing cleaved peptide.

If moving the tray to a new location, the vessel tray cover (P/N: 170875) can be installed.

14. Replace the used 50 mL centrifuge vessels with clean vessels and move the Vent valve to the CLOSED position.

15. Run a cleaning procedure on each cleavage position used (see Maintenance Procedures).

16. To empty the waste bottle, remove the waste cap and discard the waste then rmly re-secure the cap.

Precipitation and Analysis

1. To precipitate the cleaved peptide, add ice cold ether up to 50 mL (or 8 times the amount of drained liquid). If the

volume exceeds 50 mL, use a second centrifuge tube. The ether should be ice cold to ensure the maximum amount

of peptide precipitates out.

2. Centrifuge the peptide solution for 5 min at 3500 rpm or until a white or clear peptide pellet forms on the bottom of

the tube. Repeat the centrifuge process if necessary to remove any oating particles.

3. Decant the ether, leaving the precipitated peptide in the tube.

4. The peptide can be resuspended in ice cold ether and centrifuged again to ensure all protecting groups are gone.

6

Razor™ Parallel Peptide Cleavage System

600850 • Revision 2 • July 2017

Page 8

5. The peptide can be analyzed immediately on an HPLC or UPLC for purity, or can be lyophilized overnight.

6. To lyophilize, suspend the peptide gel in 1% acetic acid in deionized water then freeze with liquid nitrogen before

placing on the lyophilizer.

Maintenance Procedures

Cleaning

Each vessel position should be cleaned before and after use to prevent cross contamination. To clean a vessel position:

1. Insert a 50 mL centrifuge tube in the vessel tray and lock the tray in position.

2. Insert an empty reaction vessel into the appropriate cleavage position.

3. Turn the vacuum pump ON and rinse ethanol or isopropanol through the reaction vessel.

WARNING

Do not use DCM to rinse any cleavage positions post-cleavage as this can lead to more frequent seal replacements.

4. Turn the vacuum pump OFF and vent the system by turning the Vent valve knob to OPEN.

5. Remove the vessel tray and discard the wash solvent.

Spare Parts

Part Number Description

330090 50 mL centrifuge tube, pack of 25

167550 1 L glass waste bottle (no cap)

167545 GL45 waste cap

547225 Waste Tubing Bundle

NP-1392 Cleavage vessels, pack of 120

170810 Cleavage vessel cap

170875 Vessel rack cover

Razor™ Parallel Peptide Cleavage System

600850 • Revision 2 • July 2017

7

Page 9

Limited Warranty

What Is Covered:

CEM Corporation warrants that the instrument will be free of any defect in parts or workmanship and will, at its option,

replace or repair any defective part (excluding consumables) or instrument.

For How Long:

This warranty remains in eect for 365 days from date of delivery to the original purchaser.

What Is Not Covered:

This warranty does not cover parts or workmanship damaged due to:

• Neglect, abuse or misuse, or theft

• Damage caused by or to test samples,

• Damage incurred during instrument relocation,

• Damage caused by or to any attached equipment,

• Use of incorrect line voltages or fuses,

• Fire, ood, “acts of God” or other contingencies beyond the control of CEM Corporation,

• Improper or unauthorized repair, or

• Any other damage caused by purchaser or its agents.

Responsibilities of Purchaser:

• To ensure warranty coverage, the purchaser must:

• Use the instrument according to directions,

• Connect the instrument properly to a power supply of proper voltage,

• Replace blown fuses,

• Replace consumables and

• Clean the instrument as required.

How to Get Service:

Purchaser should contact the Service Department of CEM Corporation or the nearest CEM subsidiary or distributor for

return authorization and for proper crating and shipping instructions to return instrument, freight prepaid, for service.

On-site repairs by an authorized service technician are available through the CEM Service Department. Travel costs will be

charged to the purchaser for onsite repairs.

Within the U.S. Outside the U.S.

CEM Corporation CEM Corporation

3100 Smith Farm Rd. 3100 Smith Farm Rd.

Matthews, NC 28104-5044 Matthews, NC 28104-5044

(800) 726-5551 (704) 821-7015

Fax: (704) 821-4368 Fax: (704) 821-4368

Warranty Disclaimer:

CEM Corporation hereby excludes and disclaims any warranty of merchantability or tness for any particular purpose. No

warranty, express or implied, extends beyond the face hereof. CEM Corporation shall not be liable for loss of use of instrument or other incidental or consequential costs, expenses or damages incurred by the purchaser or any other user. This

warranty is not transferable.

Purchaser’s Rights under State Law:

This warranty gives the purchaser specic legal rights, and the purchaser may also have other rights that vary from state

to state.

8

Razor™ Parallel Peptide Cleavage System

600850 • Revision 2 • July 2017

Page 10

CEM Corporation

PO Box 200

Matthews, NC 28106

Tel: 800-726-3331

Tel: 704-821-7015

Fax: 704-821-7894

Email: info@cem.com

www.cem.com

France

CEM μWave S.A.S.

Immeuble Ariane

Domaine Technologique de Saclay

4, rue Rene’ Razel

91892 ORSAY Cedex

Tel: 33 (01) 69 35 57 80

Fax: 33 (01) 60 19 64 91

Email: info.fr@cem.com

www.cemfrance.fr

Germany, Austria, Swit-

zerland

CEM GmbH

Carl-Friedrich-Gauss-Str.9

47475 Kamp-Lintfort

Tel: (49) 2842-9644-0

Fax: (49) 2842-9644-11

Email: info@cem.de

www.cem.de

Ireland

CEM Technology (Ireland) Ltd.

Sky Business Centre

9a Plato Business Park

Damastown

Dublin 15

Tel: +353 (0) 1 885 1752

Fax: +353 (0) 1 885 1601

Email: info.ireland@cem.com

www.cemmicrowave.co.uk

Italy

CEM S.R.L.

Via Dell’ Artigianato, 6/8

24055 Cologno al Serio (Bg)

Tel: (39) 35-896224

Fax: (39) 35-891661

Email: info.srl@cem.com

www.cemmicroonde.com

Japan

CEM Japan K.K.

2-18-10 Takanawa

Minato-ku, Tokyo

108-0074

Tel: +81-3-5793-8542

Fax: +81-3-5793-8543

Email: info@cemjapan.jp

www.cemjapan.co.jp

CEM has been an ISO-certied

facility since 1994.

All Rights Reserved. This manual contains proprietary information which shall not be

reproduced or transferred to other documents or disclosed to others without prior written

permission of CEM Corporation. CEM® is a registered trademark of CEM Corporation.

www.cem.com • peptide.support@cem.com • (800) 726-3331 (US + Canada) • (704) 821-7015

Copyright 2017 by CEM Corporation.

Razor™ is a trademark of CEM Corporation.

Copyright CEM Corporation 2017 • Revision 2

United Kingdom

CEM Microwave Technology Ltd.

2 Middle Slade

Buckingham Industrial Estate

Buckingham MK181WA

Tel: (44) 1280-822873

Fax: (44) 1280-822342

Email: info.uk@cem.com

www.cemmicrowave.co.uk

Loading...

Loading...