Page 1

Liberty Blue

TM

Automated Microwave Peptide Synthesizer

Manual

Page 2

Page 3

Contents

Introduction

About the Instrument 1

Common Abbreviations and Units 1

How To Obtain Support

Applications Support 2

Technical Support 2

Requested Information 2

CEM Corporation Headquarters 2

CEM International Subsidiaries 3

Safety

Safety Notations 5

Personal Laboratory Safety 5

Waste Disposal 5

Fume Ventilation 5

Operating Precautions 6

System Requirements

Bench and/or Fume Hood Space 7

System Components Space Requirements 7

Environmental Conditions 7

Inert Gas Source 7

Electrical Requirements 7

Fuse Replacement 7

Introduction To The Liberty Blue

Components and Parts 8

Quick Setup Guide

Liberty Method Editor 22

Calculators 28

Edit Users and User Group 30

Setting up a Synthesis

Loading a Method 33

Standard Reagents and Concentrations 33

Recommended Reagents and Strategies for Microwave

SPPS on the Liberty Blue 33

Preparing Reagents 36

Setting up the Liberty Blue 37

Running the Liberty Blue 39

Generating A Run History Report 40

Cleavage 40

Maintenance of the Liberty Blue

Recommended Routine Maintenance Schedule 42

Maintenance Procedures 43

Maintenance Screen 47

Using the Change Bottle Operations 47

Calibration Screen 48

Advanced Features

Cycle Rules 50

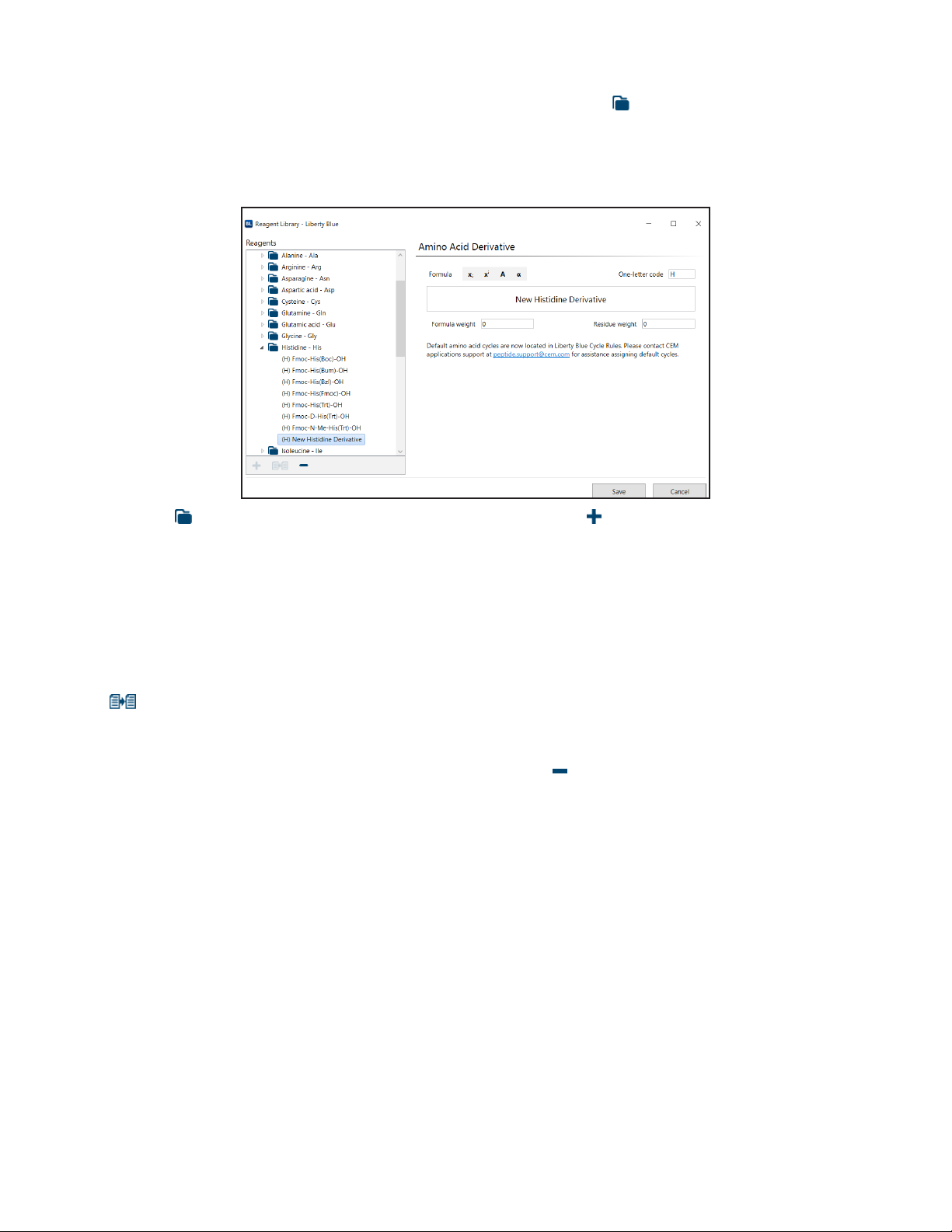

Reagent Library 50

Bottle Setup 52

Rell Reagents Button 53

Diagnostics Screen 53

Settings Screen 53

Reaction Vessel Camera Option 54

Create and Load the Liberty Method 10

Prepare and Load Reagents 11

Run the Method 12

Operation of the Liberty Blue

Software Terminology 14

Liberty Blue Software Main Screen 14

Microwave Editor 16

Cycle Editor 18

Warranty

Limited Warranty Information 55

Page 4

Page 5

Introduction

About the Instrument

This manual is intended for use by both novice and experienced users for operation and maintenance of the

Liberty Blue Automated Microwave Peptide Synthesizer. Installation of the Liberty Blue must be completed by a

CEM certied service technician. Additional information, including, but not limited to: training notes and videos,

application notes, software updates, and parts can be viewed on CEM’s website at http://cem.com/peptidesynthesis. A registered account is required for certain downloads.

This manual refers to Liberty Blue Software version 2.2 for all software information, including screen shots and

technical information.

Common Abbreviations and Units

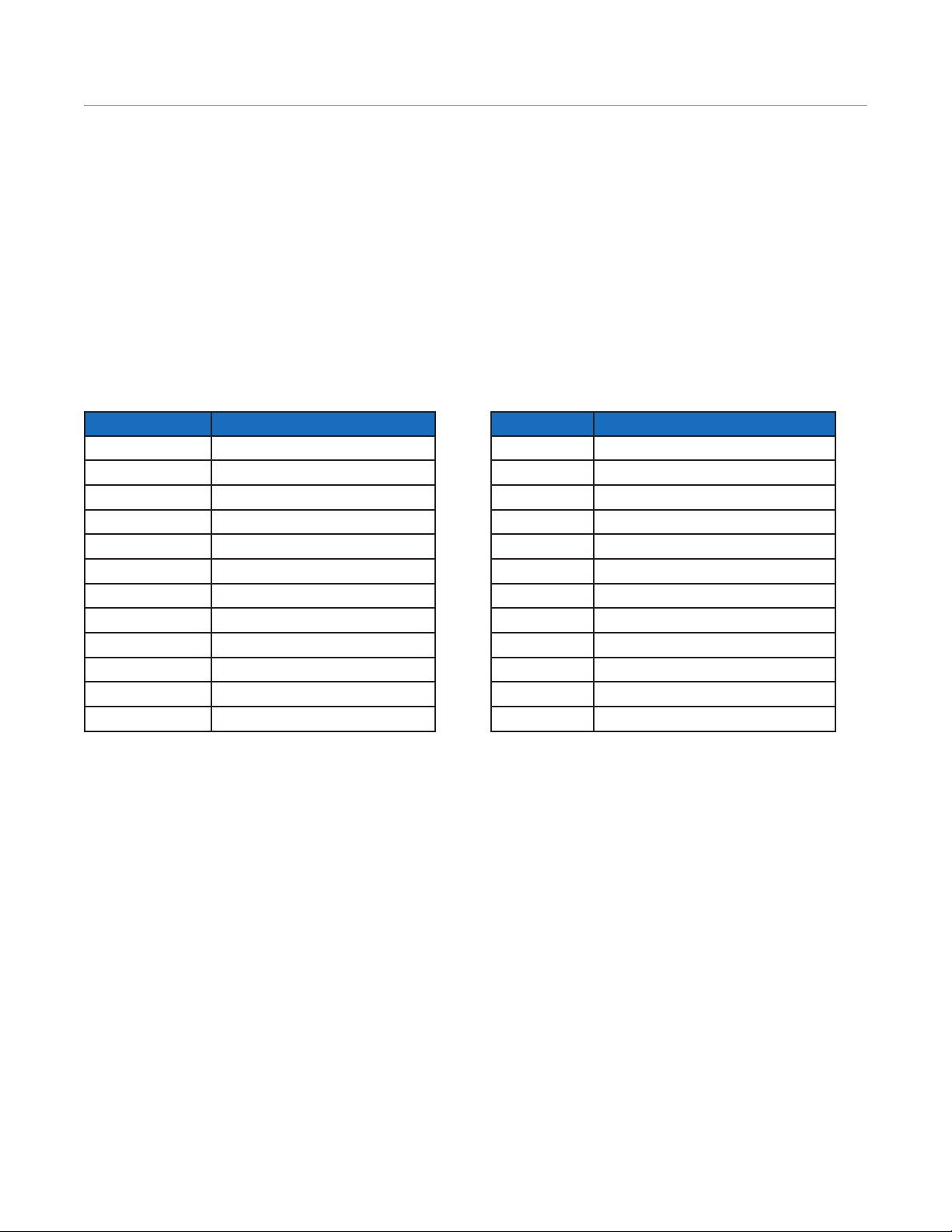

Abbreviation Denition Abbreviation Denition

°C degrees Celsius mL milliliter

AA amino acid mm millimeter

ACP acyl carrier protein 65-74 mmol millimole

DIC N,N’-Diisopropylcarbodiimide MW molecular weight

DMF N,N’-dimethylformamide OD outer diameter

Fmoc 9-uoroenylmethyloxycarbonyl Oxyma Pure ethyl 2-cyano-2-(hydroxyimino)acetate

g gram PN Part Number

Hz Hertz psi pounds per square inch

ID inner diameter RV reaction vessel

L liter s seconds

m meter VAC volts of alternating current

mg milligram W Watts

Introduction

1

Page 6

How To Obtain Support

Applications Support

For the latest Liberty Blue applications information, go to http://www.cem.com/liberty-blue.html. The CEM Liberty

Blue pages contain downloadable applications notes, a listing of recent microwave peptide synthesis publications,

and more. A registered account is required for download.

CEM is proud to provide applications support for any peptide synthesis related questions from a team of trained

chemists with a complete peptide synthesis lab. For applications support, call (800) 726-3331 (inside the

US) or (704) 821-7015 and ask for “Peptide Applications”, or email CEM Liberty Blue applications support at

peptide.support@cem.com.

Technical Support

For the latest technical support information, go to http://www.cemservice.us. The CEM Service website provides

access to the CEM Knowledge Base, which contains helpful troubleshooting information. From the website

requests for phone or email support can also be submitted.

CEM is proud to provide technical support for the Liberty Blue from a team of specially trained Service Technicians.

For technical support in the US and Canada, call (800) 726-5551 or (704) 821-7015 and ask for “Liberty Blue

Service”. For technical support outside the US and Canada, contact your local CEM Subsidiary or Distributor.

Requested Information

When contacting CEM for support, please provide the following information about the instrument:

Liberty Blue Serial Number

Liberty Blue Firmware Version

Discover Serial Number

Discover Firmware Version

Liberty Blue Software Version Number and Build Number

The report for the synthesis that was running when the error occurred

Troubleshooting Bundle (see below)

Firmware versions (both Liberty Blue and Discover) and Liberty Blue software version can be found within Liberty

Blue Software from the About Liberty Blue menu (Help Tab). Serial numbers can be found on the silver tags on the

rear of the Liberty Blue and on the side of the Discover.

In the event of a crash, the software will automatically create a Troubleshooting Bundle to be emailed to CEM

support for diagnosis. A Troubleshooting Bundle can be manually created from the Help Menu.

CEM Corporation Headquarters

Toll-Free Phone (US/Canada): (800) 726-3331

Phone: (704) 821-7015

Service Hotline: (800) 726-5551

Fax: (704) 821-7894

2

How To Obtain Support

Page 7

Mailing Address: PO Box 200

Matthews, NC 28106-0200

Physical Address: 3100 Smith Farm Rd

Matthews, NC 28104

Email (Applications Support): peptide.support@cem.com

Email (Technical Support): service@cem.com

CEM International Subsidiaries

France: CEM mWaves S.A.S.

Phone: (33-1) 69 35 57 80

Fax: (33-1) 60 19 64 91

Address: Immeuble Ariane Domaine Technologique de Saclay

4, rue René Razel

91892 ORSAY Cedex

France

Web Address: http://www.cemfrance.fr

Email: info.fr@cem.com

Germany: CEM GmbH

Phone: 011-49-2842-9644-0

Fax: 011-49-2842-9644-11

Address: Carl-Friedrich-GauB-Str. 9

47475 Kamp-Lintfort

Germany

Web Address: http://www.cem.de

Email: info@cem.de

Italy: CEM SRL

Phone: 390-35-896224

Fax: 390-35-891661

Address: Via Dell Artigianato, 6/8

24055 Cologno Al Serio (BG)

Italy

Web Address: http://www.cemmicroonde.it

Email: info.srl@cem.com

Japan: CEM Japan K.K.

Phone: +81-3-5793-8542

Fax: +81-3-5793-8543

Address: 2-18-10 Takanawa

Minato-Ku

Tokyo

108-0074

Japan

Web Address: http://www.cemjapan.co.jp

Email: info@cemjapan.co.jp

How To Obtain Support

3

Page 8

UK: CEM Microwave Technology Ltd.

Phone: +44-1-280-822873

Fax: +44-1-280-822342

Address: 2 Middle Slade

Buckingham Industrial Park MK18 1WA

Buckingham

Great Britain

Web Address: http://www.cemmicrowave.co.uk

Email: info.uk@cem.com

Ireland: CEM Technology (Ireland) Ltd.

Phone: +353 (0) 1 885-1752

Address: Sky Business Centre

9a Plato Business Park

Damastown Dublin 15

Ireland

Web Address: http://www.cemmicrowave.co.uk

Email: info.ireland@cem.com

CEM Distributors

For a complete list of distributors of CEM products, including contact information, go to the CEM website (http://

www.cem.com), select Contact CEM, and then select your region to see a list of distributors by country.

4

How To Obtain Support

Page 9

Safety

Safety Notations

This manual uses three safety alert words at points in the documentation where the user should be aware of

potential hazards. The safety alerts are shown in color-coded boxes. The three words–NOTE, CAUTION, and

WARNING–indicate differing levels of observation or action as described below:

NOTE

A NOTE is intended to provide emphasis of procedures that may be misinterpreted or overlooked, or to

otherwise clarify confusing situations.

CAUTION

A CAUTION is intended to provide essential information and to emphasize procedures which, if not strictly

followed, may result in improper instrument operation.

WARNING

A WARNING is intended to emphasize dangerous or hazardous conditions which may result in personal

injury to the user and damage or destruction of the instrument.

Personal Laboratory Safety

Solvents and chemical reagents used on the Liberty Blue can be hazardous and should only be handled under a

fume hood. Personal protective gear, including but not limited to safety glasses, chemical resistant gloves, and a

laboratory coat are highly recommended when operating the Liberty Blue. For detailed information on the safety

requirements for the chemicals used on the Liberty Blue, refer to the appropriate SDS documents.

Waste Disposal

Waste produced by the Liberty Blue can be hazardous. For detailed information on the safety requirements for the

chemicals used on the Liberty Blue, refer to the appropriate SDS documents.

WARNING

Handle all waste under a fume hood, and wear suitable protective clothing such as safety glasses,

chemical resistant gloves, and a laboratory coat. Dispose of all waste in accordance with all applicable

local, state, and federal health and safety recommendations.

Fume Ventilation

The Liberty Blue operates as a semi-closed system, with minimal venting of any hazardous solvent fumes through

the vent lines coming from the side of the unit. The vent lines must be vented into a proper chemical fume hood or

exhaust line no longer than six feet (6’)/two meters (2 m) from the instrument.

Safety

5

Page 10

In addition, adequate ventilation should be provided for preparation of reagents and solvents for use on the

system. All solvent bottles and the Waste Reservoir should be placed into proper secondary containers to minimize

the risk of exposure.

Operating Precautions

The Liberty Blue must be grounded. In the event of an electrical short circuit, grounding reduces the risk of electric

shock by providing an escape wire for electric current. This instrument is equipped with a cord having a grounding

wire with a grounding plug. The plug must be plugged into an outlet that is properly installed and grounded.

Consult a qualied electrician or service technician if the grounding instructions are not completely understood or

if doubt exists as to whether the instrument is properly grounded. If it is necessary to use an extension cord, use

only a 3-wire extension cord that has a 3-blade grounding plug and a 3-slot receptacle that will accept the plug

from the instrument. The marked rating of the extension cord must be equal to or greater than the electrical rating

of the instrument.

Do not replace detachable main supply cord with inadequately rated cords.

The possibility of instrument-induced electromagnetic interference (EMI) is minimal if the instrument is operated as

outlined in this manual. The instrument should not be placed close to any electrical device susceptible to EMI.

This instrument utilizes high voltages and microwave radiation. Only those trained in repair and maintenance of

high voltage and microwave power systems should perform instrument service and repair.

This instrument complies with United States Code of Federal Regulations 21 CFR Part 1030.10 (C) for microwave

leakage. This instrument complies with FCC Requirements in the United States Code of Federal Regulations

(47CFR Part 18) – Industrial, Scientic and Medical (ISM) Equipment – emissions requirements.

WARNING

Only accessories which meet the manufacturer’s specications shall be used.

Do not attempt to lift or move the Liberty Blue system. Contact CEM Corporation if the Liberty Blue system

needs to be moved.

If instrument is used in a manner not specied by CEM Corporation in this manual, then the protection provided by

the equipment may be impaired.

6

Safety

Page 11

System Requirements

Bench and/or Fume Hood Space

The Liberty Blue should be positioned on the bench such that access to the electrical outlets for the system is not

restricted.

System Components Space Requirements

Liberty Blue Instrument (Discover Module and Liberty Blue Module):

20 in (50.8 cm) W x 21 in (53.3 cm) D x 30 in (76.2 cm) H

(Depth includes 3” (7.62 cm) clearance behind instrument for unimpeded airow at rear fan ducts)

CEM Supplied Controller:

15 in (38.1 cm) W x 10 in (25.4 cm) D x 16 in (40.6 cm)

(Height includes 14.1” (35.8 cm) display)

Environmental Conditions

The Liberty Blue is designed for indoor use only.

Temperature Range: 50 °F – 85 °F (10 °C – 29 °C)

Relative Humidity Range: 10 – 85%

Inert Gas Source

The Liberty Blue requires an inert gas source (either high purity grade nitrogen or argon) capable of supplying 25

psi (20 L/min ow) within ten feet (10’)/three meters (3 m) of the right side of the instrument.

Electrical Requirements

The Liberty Blue requires electrical power of 120 VAC (60 Hz, 1.7 A) (or 240 VAC [50 Hz, 1.7 A] where applicable).

Specic power requirements (120 VAC vs. 240 VAC) can be found on the nameplate afxed to the rear of the

Liberty module and on the side of the Discover module.

Three (3) grounded electrical connections providing a total of 10 A are required for all components:

Liberty Blue power cord

Router power cord

Controller (laptop computer) power cord

Fuse Replacement

The Liberty Blue has four operator replaceable fuses located in the power inlet module (at the rear of the

instrument, where the power cord connects to the Liberty Blue module). The fuses are rated F 250 V 2 A. The

top pair of fuses (PN BR198826) are North American style, 5 mm x 20 mm size, and are rated F 250 V 2 A. The

bottom pair of fuses (PN 188340) are North American style, 5 mm x 20 mm size, and are rated F 250 V 10 A.

NOTE

Optionally, the router can be powered directly from the Liberty Blue module without the need for an

external connection (using Router-Serial Power Cable, PN 243290).

System Requirements

7

Page 12

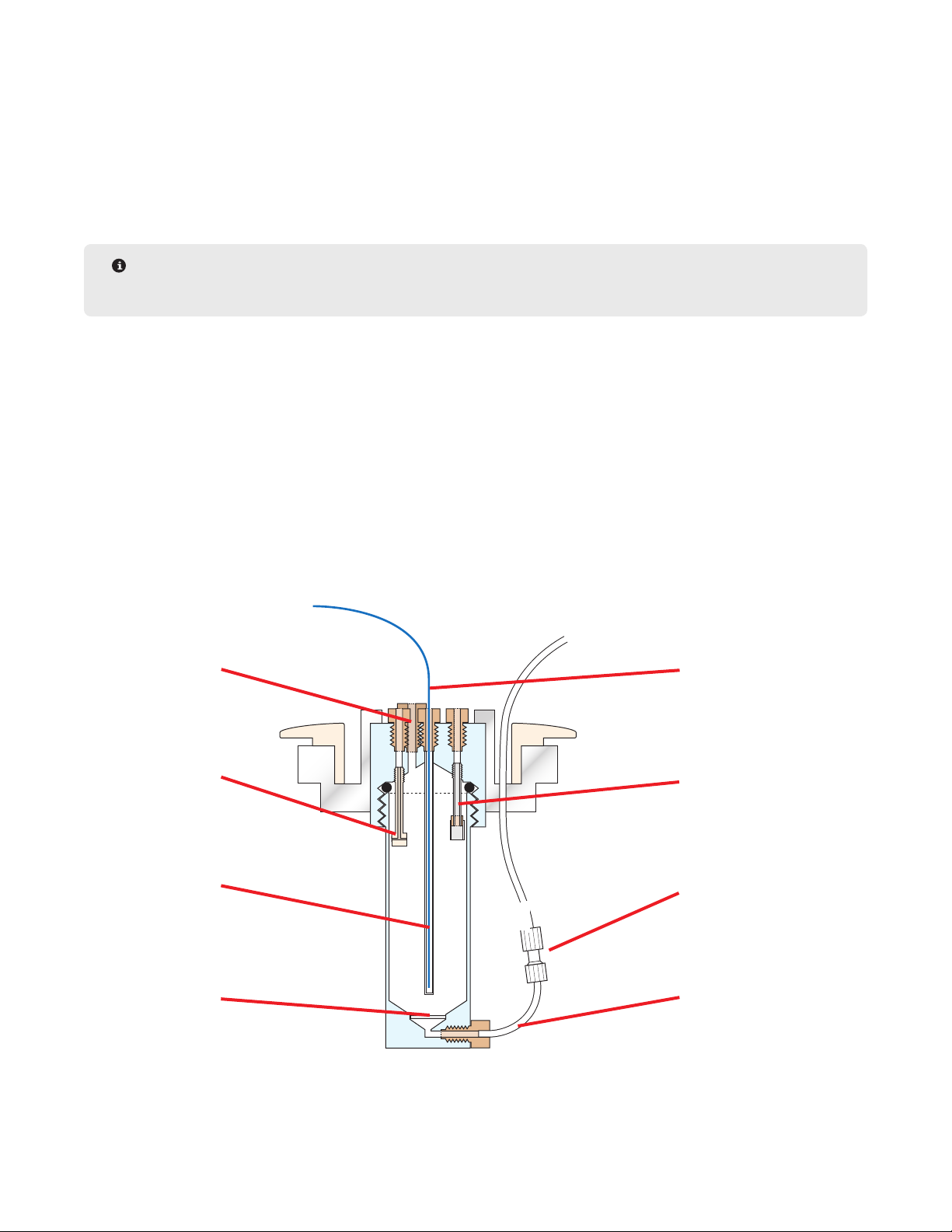

Introduction To The Liberty Blue

The Liberty Blue is the latest generation of automated microwave peptide synthesizer. Built on CEM’s exible

Discover microwave platform, the Liberty Blue is capable of synthesizing peptides faster and more efciently than

conventional synthesizers, thanks to the system’s patented circular microwave cavity. The Liberty Blue’s efcient

Flex-Add™ technology eliminates the need for sample loops and allows innite volume delivery options for a wide

range of synthesis scales.

Amino Acid

Manifolds

Activator Bottle

Activator Base Bottle

Liberty Blue

Module

Reaction Vessel

Waste Bottle

Solvent Bottle

Deprotection Bottle

Power Switches

Calibration

Stand

Discover Module

Components and Parts

Liberty Blue Module: The Liberty Blue handles all of the uid transfer into and out of the reaction vessel. In

addition, the Liberty Blue manages communications with the computer controller and the Discover during peptide

synthesis.

Discover Microwave Reactor: The Discover microwave reactor holds the reaction vessel and generates the

microwave energy used to irradiate the sample. The Discover is capable of operating independently of the Liberty

Blue.

Power Switches: There are two power switches, one for the Discover and one for the Liberty Blue. Both switches

must be on to operate the Liberty Blue.

External Bottles: Bottles for waste, main solvent, and deprotection connect to the manifold on the side of the

Liberty Blue using GL45 caps and tubing assemblies. The external bottles sit in a bottle holder magnetically

8

Introduction To The Liberty Blue

Page 13

secured to the front of the Liberty Blue module. Optimal large capacity pressure rated bottles are available (PN

551240, 551245, 551250, 551255).

Amino Acid Manifolds: There are 27 positions on the manifold for amino acids, 20 corresponding to a specic

amino acid, and 7 extra positions. Each position is labeled using the position number and 3-letter abbreviations of

the amino acids. These positions are designed for use with 50 mL centrifuge tubes for the amino acids and 250

mL bottles for activator and activator base. Optional 120 mL tubes (PN 216560-M, pack of 30) are available for

the amino acid positions. Up to one liter GL45 threaded bottles can be used with optional adapters (PN 909465),

for the activator and activator base positions.

NOTE

The 7 external positions are not available with the Liberty Lite.

Reaction Vessel: The reaction vessel is where the synthesis takes place. Reagents are added to the vessel and

washed out throughout the synthesis of the peptide. There are different size vessels that can be used depending

on the scale of the synthesis.

Fiber Optic Temperature Probe: The ber optic probe is inserted in the top of the reaction vessel. It allows the

system to monitor the temperature of the reaction vessel.

Waste Container: The waste lines carry all of the system’s waste out into an external waste container. The waste

container is equipped with a level sensor and will trigger the system to pause if the container is full. An optional

large capacity (20 L) waste container is available (PN 909490).

Reaction Vessel Components

Vent Line

Wash Line

Thermowell

Glass Frit

Fiber Optic Probe

Reagent Line

Union

Drain Line

Introduction To The Liberty Blue

9

Page 14

Quick Setup Guide

Create and Load the Liberty Method

NOTE

To load an existing method, skip to step 9.

Create the Method

1. Open the appropriate folder or sub folder in the Methods box for the new method.

2. Click the New Method button.

3. The method will appear in the appropriate folder. Enter a name for the method and press Enter.

4. Click into the Sequence box. A list of the amino acids in the current bottle setup will drop down. To enter the

sequence, either click the appropriate amino acid positions in the drop-down, or type the one-letter abbreviation

for the desired amino acids.

NOTE

The amino acids in the sequence should be entered from N-terminus to C-terminus.

5. Select the scale (0.005 mmol to 5.0 mmol) from the Synthesis Scale box, then select the resin type (Standard

or High Swelling) from the Resin Type box.

NOTE

The scale and resin type must be selected before changing any of the other parameters, as each scale

and resin type has specic default options that will be loaded upon selection.

6. The remaining options can now be selected.

6.1. C-Terminus: The C-terminus (acid or amide) is only used to calculate the molecular weight, and does

not affect the synthesis conditions.

6.2. Resin Type: The resin type will determine the rst coupling step of the reaction. If Preloaded is

checked, the software assumes the C-terminal amino acid is already loaded on the resin and

therefore skips that coupling. If Not Preloaded is selected, the rst coupling will proceed as normal.

If Chloride Loading is selected, a chloride coupling step will be used for the C-terminal amino acid

coupling.

6.3. Resin Name: The resin name entered in this box will appear in the Method Report, but will not affect

the synthesis conditions.

6.4. Resin Loading: The substitution value entered in this box (in meq/g) will appear in the Method

Report, but will not affect the synthesis conditions.

6.5. Resin Cycle: The resin cycle determines the swelling conditions used to prepare the resin at the

beginning of the synthesis. Make sure the amino acid cycles match the Resin Swelling Cycle (HS

vs. non HS).

6.6. Final Deprotection Cycle: By default, the N-terminal protecting group is removed at the end of the

synthesis. Selecting an alternate Final Deprotection cycle allows control of this step.

6.7. Bottle Setup: If using a bottle setup other than the standard default, it must be selected prior to

entering the sequence.

10

Quick Setup Guide

Page 15

7. Assign cycles for each residue in the sequence that will not use the default cycle.

NOTE

For long peptides, clicking the Quick Jump button will open a shortcut to view all amino acids in the

sequence.

7.1. From the Amino Acid Cycles table, click on the amino acid to highlight it, then double-click the cycle

to open the drop-down of available amino acid cycles.

7.2. From the drop-down, select the desired cycle. This will change the cycle for that highlighted amino

acid only. To change the cycle for all amino acids to the selected cycle, right-click the cycle and

select “Apply this cycle to all”.

NOTE

To select multiple amino acids, hold Ctrl and left-click the desired amino acids. This will highlight multiple

rows in the Amino Acid Cycles table. When all the desired amino acids are highlighted, click the Mark Rows

button at the top of the Amino Acid Cycles table. The total number of selected rows will be listed next to

the ag icon. When multiple rows are marked (indicated by a blue highlight), any change made to one

row will be made to all selected rows. When all changes are made, click the Clear button to deselect all

rows.

8. When the method is complete, click Save to save the method, then close the Liberty Method Editor.

Load the Method

1. From the Liberty Blue application software main screen, open the appropriate folder in the Methods tab.

2. Click on the desired method, and drag the method to the resin position. Alternatively, right-click on the desired

method and select “Queue for run”.

3. The method name will appear in the Loaded Method indicator. The indicator will turn blue, meaning the method

is loaded and ready to run.

Prepare and Load Reagents

Prepare Reagents

1. To determine the amount of each reagent needed and how to prepare them, use the Usage and Reagent

Calculators.

1.1. From the Calculators tab, select the Usage Calculator.

1.1.1 If the method is not already loaded, from the Methods box at the bottom left of the Usage

Calculator, select the method to be included in the calculation and drag the method into the

table on the top left of the Usage Calculator.

1.1.2 The calculator will automatically determine the total usage for each reagent. For amino acids,

enter the desired concentration in the Amino Acid Concentration box, and the calculator will

automatically determine the mass of each amino acid to weigh out.

1.1.3 If desired, print a Usage Report.

1.2. From the Calculators menu, select the Reagent Calculator.

1.2.1 Resin: Enter the scale of the synthesis and the resin substitution to determine the mass of

resin needed.

Quick Setup Guide

11

Page 16

1.2.2 Other Reagents: For the other reagents, click on the appropriate tab (Activator, Activator Base,

Deprotection) and then select the appropriate reagent from the list. Enter the concentration

and nal volume needed, and the calculator will update with the mass required.

1.2.3 If desired, print a Reagent Report.

Load the Reagents onto the Liberty Blue

1. Load all reagents onto the Liberty Blue.

1.1. Connect centrifuge tubes with amino acid solution to the appropriate positions. Connect empty

centrifuge tubes to all unused positions.

1.2. Connect activator and activator base bottles to the appropriate positions on the system.

1.3. Check the level of solvent remaining in the solvent bottle. If more solvent is required, use the Change

Bottle Main Solvent operation to replace the bottle (see Change Bottle Main Solvent in Section 4).

1.4. Check the level of deprotection solution remaining in the deprotection bottle. If more deprotection

is required, use the Change Bottle Deprotection operation to replace the bottle (see Change Bottle

Deprotection in Section 4).

Load the Resin into the Reaction Vessel

1. Load the resin (100-200 mesh only) into the reaction vessel.

CAUTION

The 30 mL reaction vessel should be used for 0.005 - 0.25 mmol syntheses (up to 1 g of resin). The 125

mL reaction vessel should be used for 0.5 - 5 mmol syntheses (up to 8 g of resin).

1.1. Remove the reaction vessel from the microwave cavity.

1.2. Unscrew the bottom port of the beige union connector on the vessel drain line. Then, unscrew the

vessel body from the attenuator.

1.3. Weigh the appropriate amount of dry resin (100-200 mesh only) into the vessel body.

1.4. Connect the vessel body to the attenuator, then connect the drain line to the vessel body using the

union connector tting.

1.5. Place the vessel back into the microwave cavity, securing the attenuator.

Run the Method

Ensure the Liberty Blue is Ready to Run

1. Verify that the waste container has sufcient capacity.

2. Verify that the ber optic probe is fully inserted into the thermowell.

WARNING

If the probe is not inserted all the way to the bottom of the vessel the Liberty Blue will not accurately

measure the temperature, and signicant overheating of the vessel will occur. This will result in poor

synthesis quality and/or serious damage to the vessel.

3. Verify that the method is correct by looking at the steps outlined in the Liberty Methods widow, and then load the

method from the Methods tab. If there are any errors, make corrections and reload the method.

12

Quick Setup Guide

Page 17

3.1. Clear the method by clicking the small X at the top of the resin indicator.

3.2. To correct the method:

3.2.1 Open the Liberty Method Editor.

3.2.2 Open the folder where the method was saved, then click on the method to load it.

3.2.3 Click Save to save the method after editing, then close the Liberty Method Editor.

3.2.4 Load the corrected method as described above.

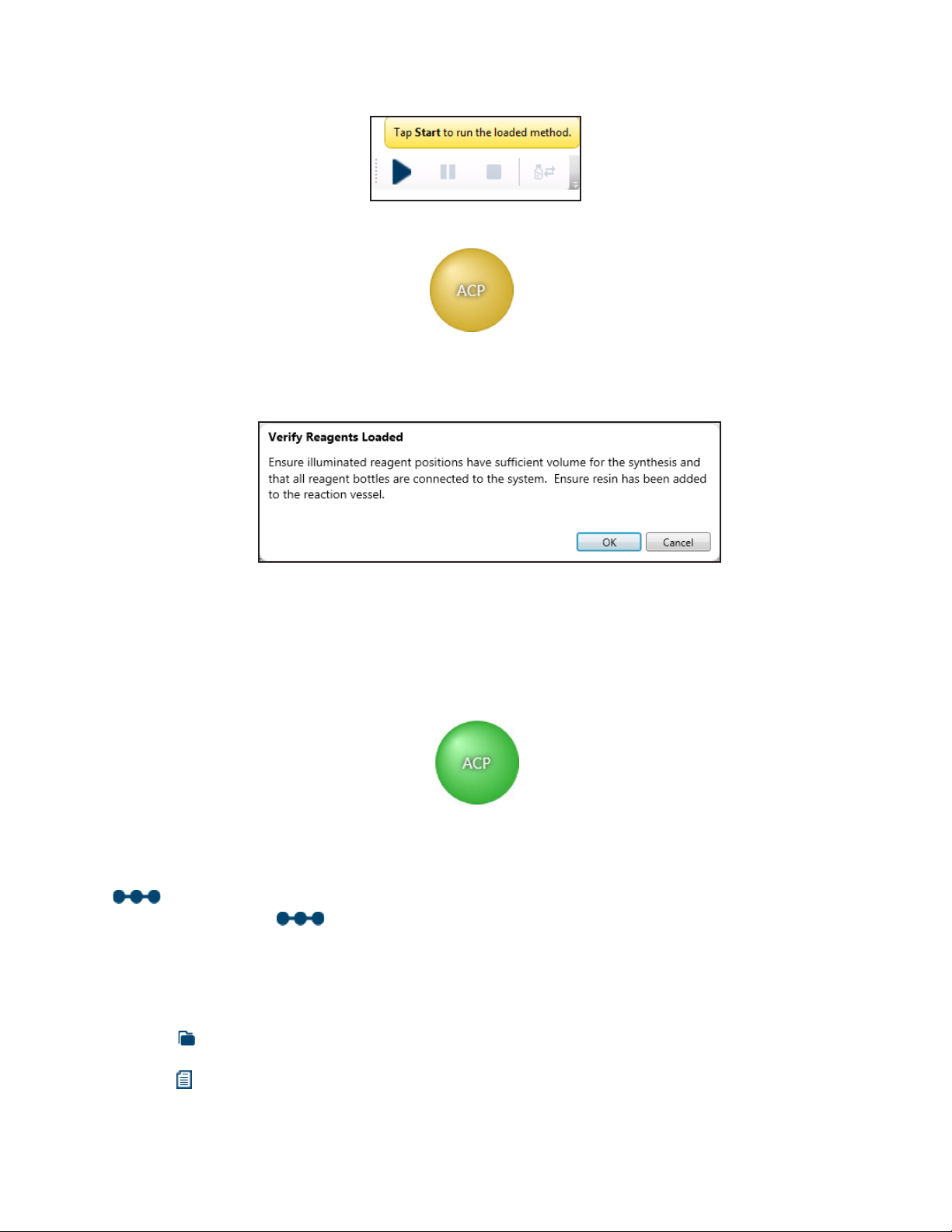

Run the Method

1. Click the Start button at the top of the Liberty Blue Software main screen.

2. The Loaded Method indicator will turn yellow to indicate the method is running.

3. The Liberty Blue will illuminate all required amino acids positions for the method. Ensure that all reagents

are connected to the correct reagent positions, empty centrifuge tubes are connected to any unused reagent

positions, and that there is sufcient solvent and deprotection solution, then click OK to continue.

4. The Liberty Blue will go through a series of initialization steps and leak checks.

5. During the run, the current step of the method is highlighted in yellow in the Cycle Steps table of the Current Run

tab. A status bar in the lower right of the main screen indicates relative progress of the run.

6. When the run is complete, the Loaded Method indicator will turn green, indicating the method was successfully

completed.

7. When the run is complete, remove the resin from the reaction vessel.

7.1. Remove the reaction vessel from the microwave cavity.

7.2. Unscrew the bottom port of the beige union connector on the vessel drain line. Then, unscrew the

vessel body from the attenuator.

7.3. Using dicholormethane (DCM) or another appropriate solvent, rinse the resin into a clean, empty

centrifuge tube.

NOTE

The Liberty Blue is not equipped to perform peptide cleavage. All cleavage must be carried out at either

room temperature or in the Razor™ Peptide Cleavage system.

7.4. Rinse any resin clinging to the thermowell into the centrifuge tube. Ensure there is no resin on the

top of the reaction vessel attenuator.

7.5. Connect the vessel body to the attenuator, then connect the drain line to the vessel body using the

beige union connector.

7.6. Place the vessel back into the microwave cavity, securing the attenuator.

8. The peptide is now ready to be cleaved and analyzed, and the Liberty Blue is ready for its next run.

Quick Setup Guide

13

Page 18

Operation of the Liberty Blue

The operation of the Liberty Blue is controlled through the Liberty Blue application software. The Liberty Blue

includes an external computer controller for running the Liberty Blue Software. This computer is connected to the

Liberty Blue and the Discover through an Ethernet connection or wireless router.

Software Terminology

Microwave Method: The specic microwave parameters used in a cycle. Microwave Methods can be created or

modied using the Microwave Editor.

Cycle: The specic steps used for each residue within a given sequence, including deprotection, washing, and

coupling. Cycles can be created or modied using the Cycle Editor.

Liberty Method: The specic parameters used to synthesize a peptide. For each Liberty Method, a sequence is

entered, and then parameters (individual coupling cycles for each residue, C-terminus type, nal deprotection, etc.)

are selected. Liberty Methods can be created or modied using the Liberty Method Editor.

Run: A specic instance of a method being loaded and started in Liberty Blue Software. A Run History le is

recorded for each run.

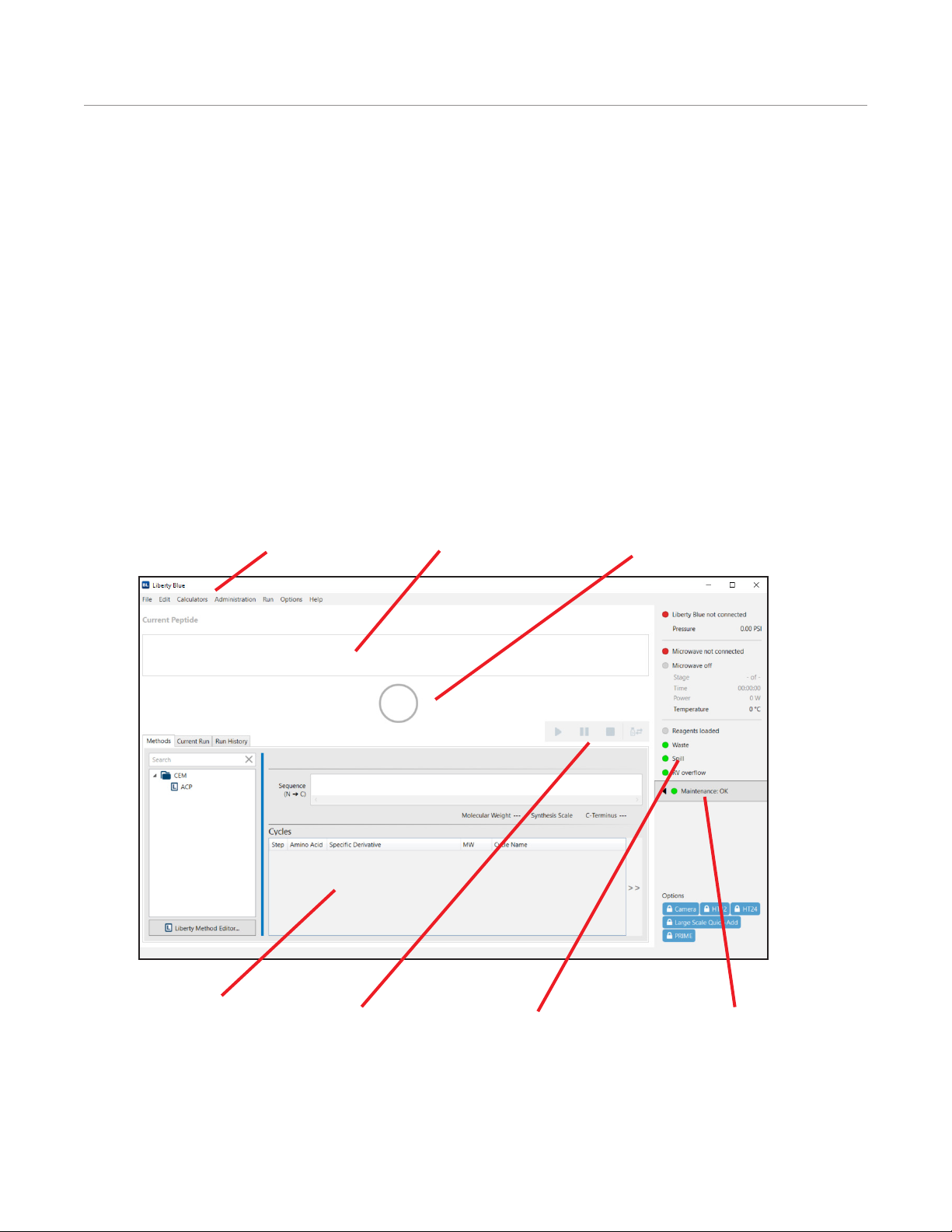

Liberty Blue Software Main Screen

Control Buttons

Menus

Peptide Synthesis Status

Resin Indicator

Current Method Detail

Start/Resume: This button starts the rst method in the queue, or resumes a paused method.

Pause: This button pauses the current method.

Stop: This button stops the current method. Liberty Blue Software will nish the operation it is currently performing

before stopping the method.

14

Control Buttons

Operation of the Liberty Blue

System Status Box

Maintenance Tracker

Page 19

Rell Reagents: This button allows for the replacement of reagent bottles (including amino acids, activator,

activator base, deprotection, and main solvent) without stopping the run.

Menus

File: This menu contains the Import and Export commands which will import and/or export a copy of selected

methods, associated cycles, and operations from the database. These les can be transferred to another Liberty

Blue database or submitted to CEM for troubleshooting purposes.

Edit: This menu contains the Liberty Method, Cycle, and Microwave editors, as well as the Reagent Library and

Bottle Setup editors, and the Notication screen.

Calculators: This menu contains Reagent and Usage Calculators.

Administration: This menu contains the View Audit Trail screen. If users are enabled, this menu also allows

administrators to create Users and User Groups.

Run: This menu contains the Control Buttons (Start/Resume, Pause, Stop).

Options: This menu contains the Maintenance, Diagnostics, Calibration, and Settings screens, and the Check Data

Integrity command (which will verify there are no problems with the Liberty Blue Software database).

Help: This menu contains the About Liberty Blue screen (which displays the software and rmware version

numbers), and allows you to create a troubleshooting bundle.

Indicators

Resin Indicator: The Resin Indicator shows the status for the currently loaded method: blue when ready to run,

yellow when running, red when stopped, green when complete.

Peptide Synthesis Status: This displays the peptide sequence being synthesized and indicates the status of the

synthesis.

Current Method Detail: This window displays the currently selected method.

System Status Box: The System Status Box contains indicators that show Liberty Blue and Discover

communication status, current temperature and system pressure readings, microwave method parameters, sensor

status for the waste container, spill tray, and reaction vessel overow sensors, and maintenance tracker.

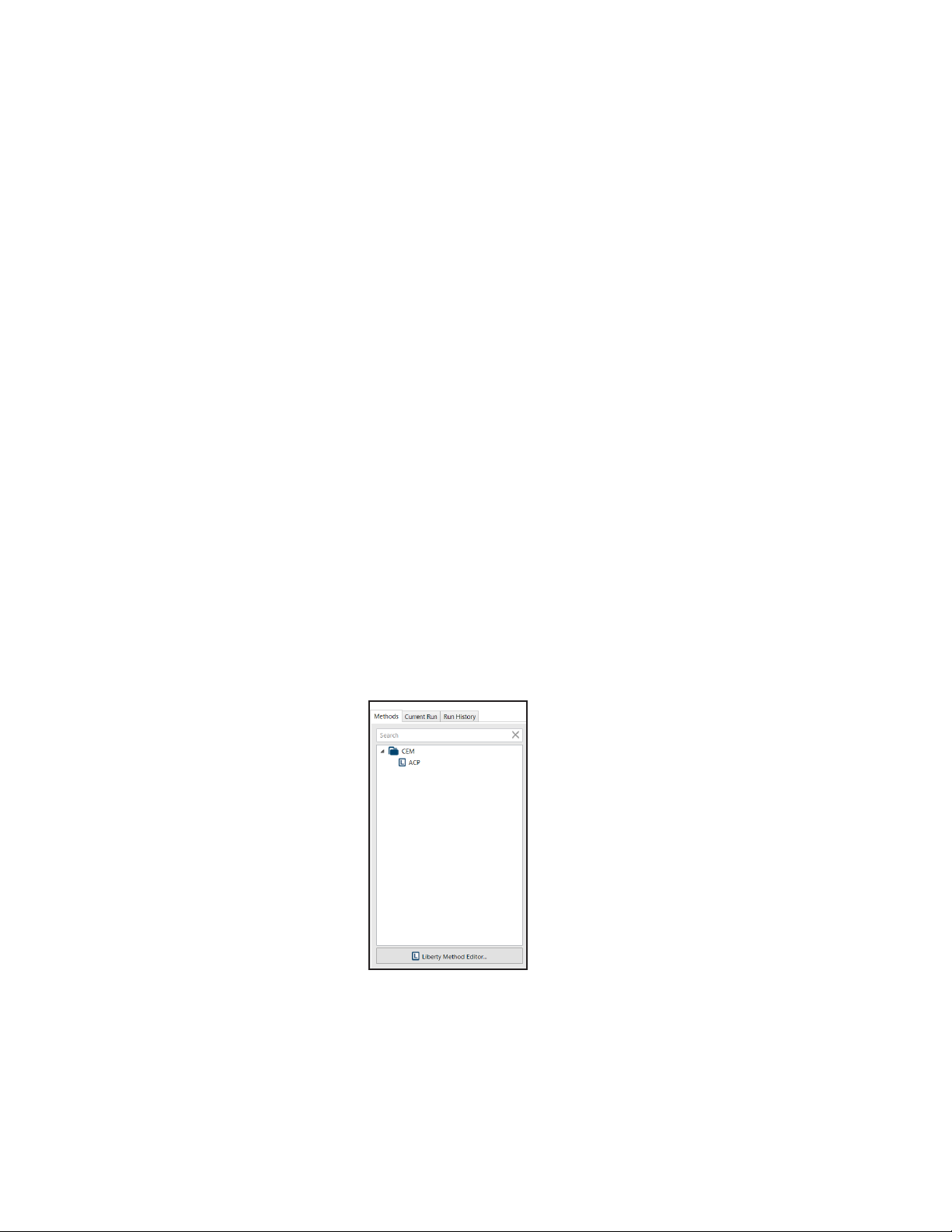

Tabs

Methods: From this tab, methods are loaded into the resin position.

Current Run: This tab displays the Method that is currently running. The current step of the method is highlighted

in yellow. When the “Keep Cycles table synced” box is checked, the cycles tables will automatically move to the

next cycle as the method progresses.

Run History: From this tab, detailed logs of each run can be accessed.

Operation of the Liberty Blue

15

Page 20

Microwave Editor

The Microwave Editor allows for the control and customization of the microwave steps of any cycle. By editing

the power and duration of a microwave step, difcult peptides can be synthesized with higher purity and yield. The

Microwave Editor can be accessed from the Edit menu.

The specic microwave power setting required to obtain acceptable heating rates will vary from unit to unit. As

such, care must be taken to optimize the microwave settings.

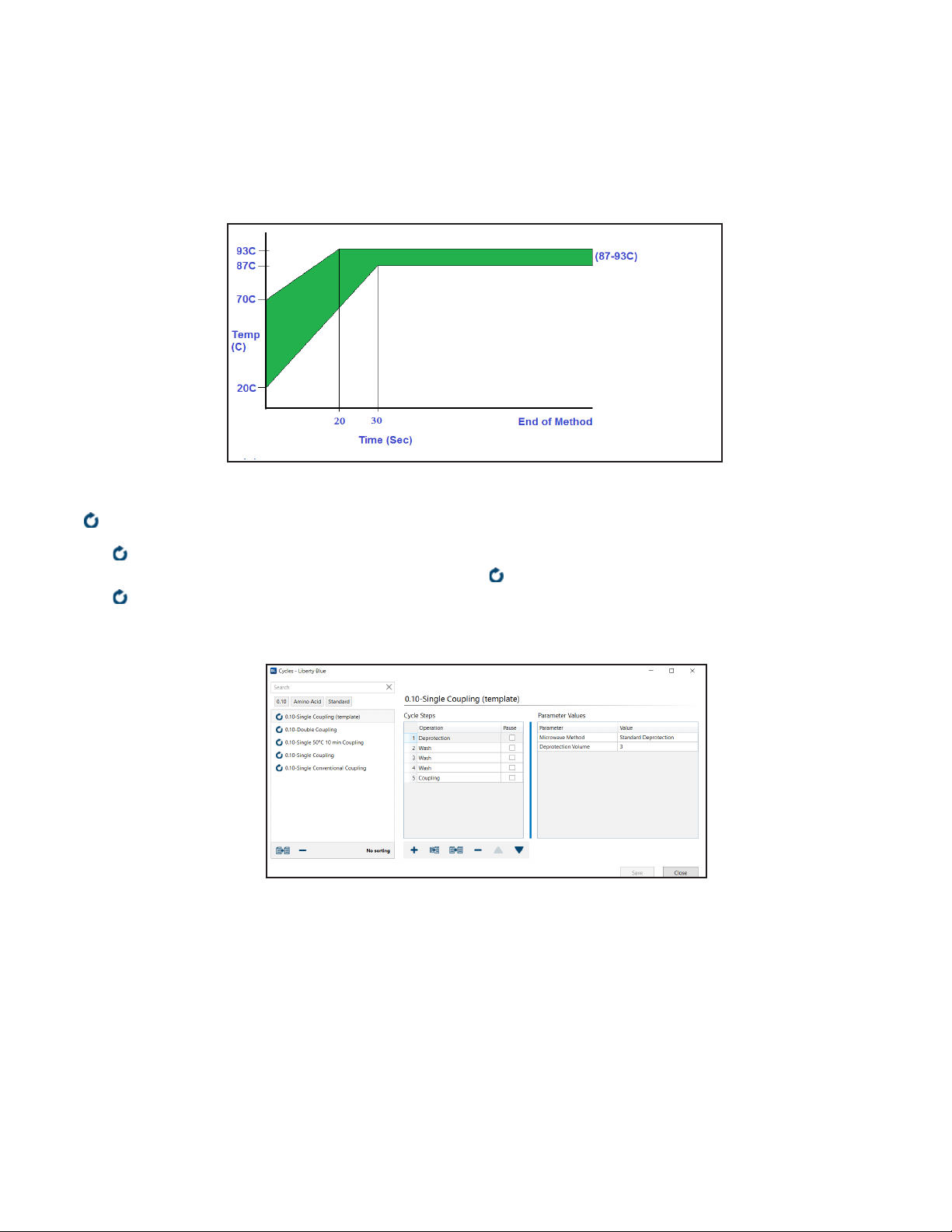

There are two key times for optimal microwave heating:

• Ramp Time: This refers to the approximate time it takes to heat the reaction mixture from its starting

temperature to its desired temperature.

• Total Time: This refers to the total reaction time including both the ramp and hold time.

NOTE

It is important to note that the Liberty microwave methods are not programmed by specifying a set ramp

time. This term is only guidance for what should be observed when applying the method. The actual ramp

time is controlled by adjusting the MW power within each method. Default power settings are given that

serve as a starting point for optimizing the MW power settings.

Microwave Method Folders

The Microwave Editor contains a variety of optimized default microwave methods separated by scale and type

(deprotection or coupling).

Creating a New Microwave Method

Microwave Methods allow for detailed control of the microwave heating and reaction time for each step in the

synthesis. The Microwave Editor allows the user to select the microwave time, microwave power, maximum

temperature, and sample agitation.

To create a new Microwave Method:

1. Click on the lter buttons at the top of the Microwave Editor to open the lter list.

16

Operation of the Liberty Blue

Page 21

NOTE

A Microwave Method created at a specic scale will only be available for use in the Cycle Editor for

cycles created at the same scale.

2. Select a scale and method type (the currently selected parameters will be highlighted). Click out of the lter list

to open the selected cycle type.

3. Click the New Method button.

4. The new Microwave Method will appear in the selected folder. Enter a name for the Microwave Method and

press Enter.

5. Enter the temperature (in °C), Power (in W), Time (in s), and Delta T (in °C) for the rst step in the method.

6. Add the next step to the method by clicking the Add Step button, and then enter the power, temperature, and

time settings for the second step.

7. Repeat step 5 for each step in the method.

8. Enter the amount of time to bubble and the time between each bubbling pulse (the default setting is on for 2

seconds, off for 3 seconds).

9. Save the method by clicking the Save button.

NOTE

To delete a step, click the step to highlight it, then click the Delete Step button. To insert a new step

between existing steps, click a step to highlight it, then click the Insert Step button. The new step will

be inserted above the selected step. To move a step up or down, click the step to highlight it, then click

the Move Up or Move Down buttons.

Editing an Existing Microwave Method

The Microwave Editor allows for settings on existing methods to be modied and saved as needed. The most

common reason to modify an existing method is to increase or decrease the microwave power to optimize peptide

synthesis. To modify an existing method:

1. Click on the lter buttons at the top of the Microwave Editor to open the lter list.

2. Select a scale and method type (the currently selected parameters will be highlighted).Click out of the lter list

to open the selected cycle type.

3. Click on the Microwave Method to be modied.

4. Make any changes as needed.

5. Click Save to save the changes to the method.

Duplicating and Modifying an Existing Microwave Method

Often, it is easier to copy and modify an existing microwave method rather than creating an entirely new method.

Methods can easily be duplicated and modied within the Microwave Editor, and then be moved to different

scale folders as needed. To copy an existing method:

1. Click on the lter buttons at the top of the Microwave Editor to open the lter list.

2. Select a scale and method type (the currently selected parameters will be highlighted).Click out of the lter list

to open the selected cycle type.

3. Click on a Microwave Method to select it and click the Duplicate button.

4. The new Microwave Method will appear named “Copy of (method name)”. Type a new name and press Enter.

5. Make any changes to the method, then click Save to save the modied method.

Operation of the Liberty Blue

17

Page 22

Calibrating Rapid Liberty Blue Microwave Methods

The rapid microwave methods used by the Liberty Blue employ rapid heating rates. For both the deprotection and

coupling methods the set temperature of 90 °C should be reached within 20-30 seconds and maintained for at

least 45 seconds and 100 seconds respectively. The starting temperature for each reaction will be signicantly

warmer than room temperature as residual heat will remain from the previous reaction. The graph below shows

the desired heating prole for Liberty Blue rapid deprotection and coupling microwave methods. The green area

represents the acceptable temperature range.

Cycle Editor

The Cycle Editor allows for the full control and customization of any step of a synthesis. This allows for

optimization of each step of a given peptide synthesis. The Cycle Editor can be accessed from the Edit menu.

The Cycle Editor contains separate cycles for each scale. Within each scale, cycles are sorted by type and then

by resin type, allowing for the development of optimized cycles for each scale. A cycle will only appear in the

Method Editor when creating a method of the same scale.

The Liberty Blue application software comes with optimized default cycles for resin swelling, amino acid addition,

and nal deprotection for each of the available synthetic scales for both standard and high swelling resins. The

default cycle for each scale is listed rst in the Cycle Editor.

Cycle Types

Resin: Resin cycles control the swelling of the resin before synthesis.

Amino Acid: Amino acid cycles control how the deprotection and coupling steps of any one amino acid in the

sequence occur.

Final Deprotection: Final deprotection cycles control the removal of the N-terminal protecting group, and also allow

for N-terminal acetylation of the peptide before cleavage.

18

Operation of the Liberty Blue

Page 23

Operations in the Cycle Editor

The Cycle Editor allows for full customization of cycles using a number of modular, preset operations. An operation

is selected for a given step, and then the parameters for that operation are selected.

Addition Operations

Add Deprotection: This will add deprotection solution (in mL) from the deprotection bottle to the reaction vessel

through the bottom, then purge the line (in seconds) to the reaction vessel.

Add Reagent: This will add solution (in mL) from any of the 27 amino acid positions or from the activator or

activator base position through the Reagent line. Reagent: Any of the of the 27 amino acid positions, activator, or

activator base can be selected. Selecting “(from method)” will add from the amino acid the cycle is assigned to in

the method.

Add Main Solvent (MS2): This will add main solvent (in mL) to the reaction vessel through the Wash line.

Wash Operations

Wash: This will wash the vessel by adding main solvent (in mL) through the Wash line, bubbling the vessel, then

draining the vessel (in seconds).

Wash Thru Manifold: This will wash the manifolds and the vessel by adding main solvent (in mL) through the

Reagent line, purging the manifold to the vessel, bubbling, then draining the vessel (in seconds).

Microwave Operations

Microwave Deprotection: This will add deprotection solution (in mL) from the deprotection bottle to the reaction

vessel through the bottom, then purge the line to the reaction vessel. The microwave will then microwave the

vessel using the selected method, then drain the vessel.

Microwave Coupling: This will add amino acid, activator, and activator base (in mL) from the selected bottles to the

reaction vessel. The microwave will then microwave the vessel using the selected method, then drain the vessel.

• Amino Acid: This is the amino acid that will be added. Any of the of the 27 amino acid positions, activator, or

activator base can be selected. Selecting “(from method)” will add from the amino acid the cycle is assigned

to in the method.

• Delayed Reagent Time (After Purge): This is the time (in seconds) after the 30 second purge that the fourth

reagent (in mL) will be added to the reaction vessel. This should not exceed the total microwave time of the

selected microwave method.

• Delayed Reagent Bottle Position: Any of the of the 27 amino acid positions, activator, or activator base can

be selected. Selecting “(from method)” will add from the amino acid the cycle is assigned to in the method.

Microwave Coupling (Chloride Loading): This is the operation used for loading the rst amino acid on CEM

ProTide™ Chloride resin. The vessel is drained afterwards.

Microwave Method: This will run the selected microwave method and then drain the vessel.

Microwave Method NO DRAIN: This will run the selected microwave method, but will not drain the contents of the

reaction vessel after the method has nished.

Miscellaneous Operations

Swell Resin: This will add main solvent (in mL) to the reaction vessel through the Wash line, wait a specied time

(in seconds) to allow the resin to swell, then drain the reaction vessel.

Drain: This will drain the reaction vessel for the specied time (in seconds).

Creating a Cycle

Cycles allow for control of each action taken in a given step of a run. The Liberty Blue application software

comes with default cycles for each synthetic scale; however, cycles can be customized to accomplish a number of

Operation of the Liberty Blue

19

Page 24

non-standard chemistries.

To create a new cycle:

1. Click on the lter buttons at the top of the Cycle Editor screen to open the lter list.

2. Select a scale, cycle type, and resin type. The currently selected parameter for each will be displayed in bold.

Click out of the lter list to open the selected cycle type.

3. Select a default cycle to use as a template and click the Duplicate button.

NOTE

A cycle will only be available for use in the Method Editor for methods created at that scale and with that

resin type.

4. The new cycle will appear named “(cycle name) 2”. Type a new name and press Enter.

5. Make any desired changes to the cycle.

5.1. To modify an existing step:

5.1.1 Click on the step to be modied to highlight it.

5.1.1.1 To change the operation, double-click the Operation box to open the operations drop-down

and select the operation to be performed.

5.1.1.2 To change the parameters, double-click on the parameter value in the Parameter Values

table. A pop-up will appear to congure the parameter. Make any changes, then click OK

to close the pop-up.

20

Operation of the Liberty Blue

Page 25

5.1.1.3 To add a pause after the operation is carried out, check the Pause box.

NOTE

The method will not resume until the user presses the Start button on the main screen of Liberty Blue

Software.

5.2. To add a new step:

5.2.1 Click the Add Step button. The new step will appear at the end of the cycle.

5.2.2 Double-click the Operation box to open the operations drop-down and select the operation to

be performed.

5.2.3 The default parameters for the chosen operation will appear in the Parameter Values table.

Double-click on a Parameter Value to change the value.

5.2.4 To add a pause after the operation is carried out, check the Pause box.

5.3. To delete a step, click the step to highlight it, then click the Delete Step button.

5.4. To insert a new step between existing steps, click a step to highlight it, then click the Insert Step

button. The new step will be inserted above the selected step.

5.5. To copy a step, click a step to highlight it, then click the Duplicate Step button. The copy will be

inserted after the highlighted step.

5.6. To move a step up or down, click the step to highlight it, then click the Move Up or Move Down

buttons.

6. Click Save to save the cycle.

Operation of the Liberty Blue

21

Page 26

Editing an Existing Cycle

The Cycle Editor allows for settings on existing cycles to be modied and saved as needed. To modify an existing

cycle:

1. Click on the lter buttons at the top of the Cycle Editor screen to open the lter list.

2. Select a scale, cycle type, and resin type. The currently selected parameter for each will be displayed in bold.

Click out of the lter list to open the selected cycle type.

3. Click on the cycle to be modied.

4. Make any changes as needed.

5. Click Save to save the changes to the cycle.

6. Click the Add Step button. The new step will appear at the end of the cycle.

6.1. Double-click the Operation box to open the operations drop-down and select the operation to be

performed.

6.2. The default parameters for the chosen operation will appear in the Parameter Values table. Doubleclick on a Parameter Value to change the value.

6.3. To add a pause after the operation is carried out, check the Pause box.

7. To delete a step, click the step to highlight it, then click the Delete Step button.

8. To insert a new step between existing steps, click a step to highlight it, then click the Insert Step button. The

new step will be inserted above the selected step.

9. To copy a step, click a step to highlight it, then click the Duplicate Step button. The copy will be inserted

after the highlighted step.

10. To move a step up or down, click the step to highlight it, then click the Move Up or Move Down buttons.

11. Click Save to save the cycle.

Liberty Method Editor

The Liberty Method Editor is used to program the specic conditions to be used for a given synthesis. Once the

sequence is entered, several options for the run can be congured that will determine the specic steps to be

used in the synthesis. The Liberty Method Editor can be accessed from the Edit menu.

22

Operation of the Liberty Blue

Page 27

Creating a New Liberty Method

1. Open the appropriate folder or sub folder in the Methods box for the new method.

2. Click the New Method button.

3. The method will appear in the appropriate folder. Enter a name for the method and press Enter. Click into the

Sequence box. A list of the amino acids in the current bottle setup will drop down. To enter the sequence, either

click the appropriate amino acid positions in the drop-down, or type the one-letter abbreviation for the desired

amino acids.

NOTE

To delete an amino acid from the sequence, press the backspace key (to delete the residue before the

cursor) or click the delete button on the drop-down (to delete the highlighted residue).

To insert an amino acid into the sequence, click an amino aid in the sequence to highlight it, then either

click the desired amino acid in the drop-down, or type the one-letter abbreviation for the desired amino

acid. The new residue will be inserted before the highlighted amino acid.

4. Select the scale (0.005 mmol to 5.0 mmol) from the Synthesis Scale box, then select the resin swelling type

(Standard or High Swelling) from the Resin Swelling box.

NOTE

The scale and resin type must be selected before changing any other parameters, as each scale and resin

type has specic default options that will be loaded upon selection.

5. The remaining options can now be selected.

5.1. C-Terminus: The C-terminus (acid or amide) is only used to calculate the molecular weight, and does

Operation of the Liberty Blue

23

Page 28

not affect the synthesis conditions.

5.2. Resin Type: The resin type will determine the rst coupling step of the reaction. If Preloaded is

checked, the software assumes the C-terminal amino acid is already loaded on the resin and

therefore skips that coupling. If Not Preloaded is selected, the rst coupling will proceed as normal.

If Chloride Loading is selected, a chloride coupling step will be used for the C-terminal amino acid

coupling.

5.3. Resin Swelling: Choosing the correct resin swelling condition ensures the resin is completely

submerged during a run. Select (HS) for high swelling resins such as PEG-based resins, and Standard

for polystyrene resins.

5.4. Resin Name: The resin name entered in this box will appear in the Method Report, but will not affect

the synthesis conditions.

5.5. Resin Loading: The substitution value entered in this box (in meq/g) will appear in the Method

Report, but will not affect the synthesis conditions.

5.6. Resin Cycle: The resin cycle determines the swelling conditions used to prepare the resin at the

beginning of the synthesis. Make sure the amino acid cycles match the Resin Swelling Cycle (HS

vs. Standard).

5.7. Final Deprotection Cycle: By default, the N-terminal protecting group is removed at the end of the

synthesis. Selecting an alternate Final Deprotection cycle allows control of this step.

5.8. Bottle Setup: If using a bottle setup other than the standard default, it must be selected prior to

entering the sequence.

NOTE

The Chloride Loading resin type is not available for Liberty Lite.

6. Assign cycles for each residue that will not use the default cycle.

NOTE

By default, the Double Coupling cycle is used for arginine. The default standard bottle setup uses

His(Boc). For other His derivatives, use Single 50°C 10 min Coupling cycle. The Single Coupling cycle

is used for all other amino acids. To restore all amino acids in a method to the default cycles, click on

Reapply Cycle Rules.

NOTE

Clicking the Quick Jump button will open a shortcut to all amino acids in the sequence.

6.1. From the Amino Acid Cycles table, click on the amino acid to highlight it, then double-click the cycle

to open the drop-down of available amino acid cycles.

NOTE

To select multiple amino acids, hold Ctrl and left-click the desired amino acids. This will highlight multiple

rows in the Amino Acid Cycles table. When all the desired amino acids are highlighted, click the Mark Rows

button at the top of the Amino Acid Cycles table. The total number of selected rows will be listed next to

the ag icon. When multiple rows are marked (indicated by a blue highlight), any change made to one

row will be made to all selected rows. When all changes are made, click the Clear button to deselect all

rows.

24

Operation of the Liberty Blue

Page 29

6.2. From the drop-down, select the desired cycle. This will change the cycle for that highlighted amino

acid only. To change the cycle for all amino

“Apply this cycle to all”.

7. When the method is complete, click Save to save the method.

Importing a Sequence to the Method Editor

When creating a new method, the sequence can be copied and pasted from outside the Liberty Blue application

software, allowing for the importation of sequences from documents, presentations, websites, etc. To paste a

sequence:

1. Highlight the sequence in the source document and press CTRL + C to copy to the system clipboard.

2. In the sequence editor, click the Paste Sequence button. (If the object on the clipboard is not able to be imported,

the Paste Sequence button will be inactive.)

3. If there are any amino acids in the sequence that are not a part of the current bottle setup, the Sequence

Importer will open and display the sequence. The amino acids shown in red will not be imported.

4. The sequence should be in N-terminal to C-terminal order.

5. If the sequence appears correct, click Import Sequence. The sequence will be loaded into the method.

acids to the selected cycle, right-click the cycle and select

Importing a Batch of Sequences to the Method Editor

1. From the Liberty Blue Software, save the Batch Sequence Import Template (File -> Import -> Save Batch Sequence

Import Template).

2. Open the Batch Sequence Import Template.

Operation of the Liberty Blue

25

Page 30

3. Input the Name, Scale, and Sequence of each Liberty Method to be created, and save/rename the le.

NOTE

To load the Liberty Methods into the HT Grid immediately upon import, input the desired HT position for

each Liberty Method.

4. Import the Batch Sequence Import Template le into the Liberty Blue Software (File -> Impor t -> Sequences). The

Liberty Method Editor window will open, revealing the recently imported sequences.

Editing an Existing Liberty Method

1. Open the Liberty Method Editor.

2. Open the appropriate folder or sub folder in the Methods box for the new method.

26

Operation of the Liberty Blue

Page 31

3. Click on the method to be modied.

4. Make any changes to the method as needed.

5. Click Save to save the changes to the method, or click Save As to save the changes as a new Liberty method.

Duplicating and Modifying an Existing Liberty Method

Liberty methods can easily be duplicated and modied within the Liberty Method Editor, and then they can be

moved to different folders as needed. To copy an existing Liberty method:

1. Open the Liberty Method Editor.

2. Open the appropriate folder or sub folder in the Methods box for the new method.

3. Click on a Liberty method to select it and click the Duplicate button.

4. The new Liberty method will appear named “Copy of [method name]”. Type a new name and press Enter.

5. Make any changes to the method as needed, then click Save to save the changes to the method.

Generating a Method Report

A Liberty Method Report records all settings selected in the Method Editor when creating the method. Liberty

Method Reports are created as PDF les which can be saved and printed to allow for easy recording of

experimental parameters.

The level of detail included in a Liberty Method Report can be congured during report generation. To generate a

Liberty Method Report:

1. Open the Liberty Method Editor.

2. Open the appropriate folder or sub folder in the Methods box for the new method, then click on the method to

be reported.

3. Click the View Report button in the upper right corner of the Liberty Method Editor screen to open the Liberty

Method Report Generator.

4. Select the options to be included in the Liberty Method Report.

4.1. To include a header image, check the Image box under Header. To select a custom image, click the

image on the right, then open the desired image.

4.2. To include the calculated molecular weight in the header, check the Molecular Weight box.

4.3. Select the details to be included in the report by checking the appropriate boxes.

4.3.1 Selecting Sequence will include the sequence.

4.3.2 Selecting Method Details will include the synthesis scale, resin type, preloaded or not preloaded

status, C-terminus, resin cycle, nal deprotection cycle, resin name (if entered), and resin

loading (if entered).

4.3.3 Selecting Method Notes will include any text entered in the Notes eld.

4.3.4 Selecting Amino Acid Cycles will include a list of the cycles assigned to each amino acid in the

sequence. This list only includes the names of the cycles.

4.3.5 Selecting Cycle Details will include the details for each cycle used in the Liberty Method

(including all operations and parameters in the cycle).

4.4. To include a footer image, check the Image box under footer. To select a custom image, click the

image on the right, then open the desired image.

Exporting Microwave Methods and Operations

The Liberty Blue application software allows operations, microwave methods, and associated microwave cycles to

be transferred from one Liberty Blue Software database to another.

To export existing operations:

1. Open the Expor t Menu (File Export).

2. Click on the Operations tab and select the operations and categories to export. Click Select All to select all

operations.

Operation of the Liberty Blue

27

Page 32

3. Click Expor t. The selected operations will be saved as an XML le (.xml).

To export existing Liberty methods:

1. In the Export menu, click on the Methods tab and select the methods to export. Click Select All to select all

methods.

2. Click Expor t. The selected operations will be saved as a JSON le (.json).

CAUTION

All operations must be exported separately from the Liberty methods. Attempting to export methods and

operations at the same time will not work as two different le types cannot be created at the same time.

NOTE

When exporting Liberty methods, all associated cycles are also exported with the method. These include

default and custom resin, amino acid, and nal deprotection cycles.

Importing Microwave Methods, Operations, and Settings

The Liberty Blue application software allows settings, operations, Liberty methods, cycles, and associated

microwave methods to be transferred from one Liberty Blue Software database to another. To import existing

operations, settings, or Liberty methods:

1. To import les, select File then Import.

2. To import methods and cycles, select “Methods and Cycles…”. Select the appropriate JSON le from the

computer then click Open. The Liberty methods will automatically start importing to the current database.

3. To import operations, select “Operations…”. Select the appropriate XML le from the computer then click Open.

The operations will automatically start importing to the current database.

4. To import settings, select “Settings...”. Select the appropriate JSON le from the computer then click Open. The

settings will automatically start importing to the current database.

NOTE

When importing Liberty methods into a new database, all associated cycles are also imported. These

cycles include default and custom resin, amino acid, and nal deprotection cycles.

Calculators

The Liberty Blue application software contains two calculators that allow for easy determination of reagent needs

and reagent preparation: the Usage Calculator and the Reagent Calculator. These calculators are accessed

from the Calculators menu.

28

Operation of the Liberty Blue

Page 33

Usage Calculator

The Usage Calculator can be used to determine the amount of each reagent needed for a given method.

Multiple methods can be loaded into the calculator, so that sufcient reagents can be loaded onto the Liberty Blue

for multiple peptides.

To use the Usage Calculator:

1. From the Calculators menu, select Usage Calculator.

2. From the Methods box at the bottom left of the Usage Calculator, right-click the method to be included in the

calculation and select Add to Calculation. The method will then appear in the table at the top left of the Usage

Calculator.

3. The calculator will automatically determine the total usage for each reagent, as well as the mass of each amino

acid required, and estimate the total waste produced.

4. To prepare enough reagents for multiple runs, repeat step 2 for each method to be included in the calculation.

The calculator will automatically update the total usage for each reagent. To remove a selected method from

the calculation, uncheck the box next to the method name. If different amino acid concentrations are required

across the selected runs, a warning will appear to notify that amino acid concentration from the largest scale

will be used in the calculation.

5. To run using a different concentration of amino acid, enter the desired concentration in the box at the top of

the Required Reagent Amounts table. The calculator will automatically update to reect the new concentration.

6. To print a Usage Report, click the View Report button at the bottom of the Usage Calculator screen. This will

generate a report as a PDF which can be printed or saved for future reference.

Reagent Calculator

The Reagent Calculator can be used to determine how to prepare all reagents to be loaded on the system at

the correct concentrations. There are ve tabs: Resin, Deprotection, Activators, Activator Bases, and Amino Acids.

Resin Calculator Tab

1. Enter the scale for the synthesis.

2. Enter the resin substitution value in the Resin Substitution box. This value is provided by the supplier of the

resin, and is usually expressed in mmol/g or meq/g.

3. The mass required will automatically be calculated (in grams).

4. To include this reagent in the Reagent Report, check the Include In Report box.

Operation of the Liberty Blue

29

Page 34

Deprotection Calculator Tab

1. Click on the desired deprotection reagent from the list.

2. Enter the desired concentration (in percent volume).

3. Enter the total volume of deprotection solution required.

4. The required amount of deprotection reagent in milliliters (for liquids) and grams (for solids) will automatically

be calculated.

5. To include the desired reagent in the Reagent Report, check the Include In Report box.

Activators and Activator Bases Calculator Tabs

1. Click on the desired reagent from the list.

2. Enter the desired concentration (in M).

3. Enter the total volume of reagent solution needed.

4. The required mass or volume (in grams or mL respectively) will automatically be calculated.

5. To include the desired reagent in the Reagent Report, check the Include In Report box.

Amino Acids Calculator Tab

1. Click on an amino acid to select it, then double-click the volume and enter the desired volume (in mL).

2. Double-click the concentration and enter the desired concentration (in M).

3. The required mass (in grams) will automatically be calculated for the selected amino acid.

4. To calculate for all amino acids, right-click and select “Apply volume to all” and/or “Apply concentration to all”.

The required mass (in g) will automatically be recalculated for all amino acids using the selected parameter.

5. To include amino acids in the Reagent Report, check the Include In Report box for each amino acid to be reported.

Reagent Calculator Report

A Reagent Calculator Report includes the required masses and volumes for all selected reagents for a given

synthesis. The report will be generated as a PDF which can be printed or saved for future reference.

To Generate A Reagent Calculator Report:

1. For each reagent to be included in the report, check the Include in Report box for that specic reagent.

2. Click View Report to render the repor t.

Edit Users and User Group

New users and user authority is determined by the default administrator. User group privileges can also be edited

by the administrator. All changes are tracked in the audit trail. To enable users/user groups, click on the Options

tab and select Settings. In the Application folder, select User/Password Security. In the drop-down next to Enable

users - authentication type, select Local and click Save.

Creating a new user

1. Log in as administrator.

2. In the Administration menu, select Edit Users.

3. To edit a current user (Name, Group, or add picture), select the user name.

4. To create a new user, select the “+” icon.

5. Create user name, group type, and change password.

6. Follow the prompts. Password must be at least 8 character(s) and cannot contain any part of user name.

7. Select the green Save icon.

30

Operation of the Liberty Blue

Page 35

Removing a user

1. Log in as administrator.

2. In the Administration menu, select Edit Users.

3. Once a user is created, they cannot be removed. They can be deactivated.

4. Select the user.

5. Select the “-“ icon and select “Deactivate” to deactivate the account or “Cancel” to ignore.

6. To reactivate, select the “reactivate” icon (curved circular arrow).

7. Re-enter new password credentials.

Edit a User Group

1. Log in as administrator.

2. In the Administration menu, select Edit User Groups.

3. Select the user group and make edits as needed. The following is the comprehensive list of user groups and

default privileges.

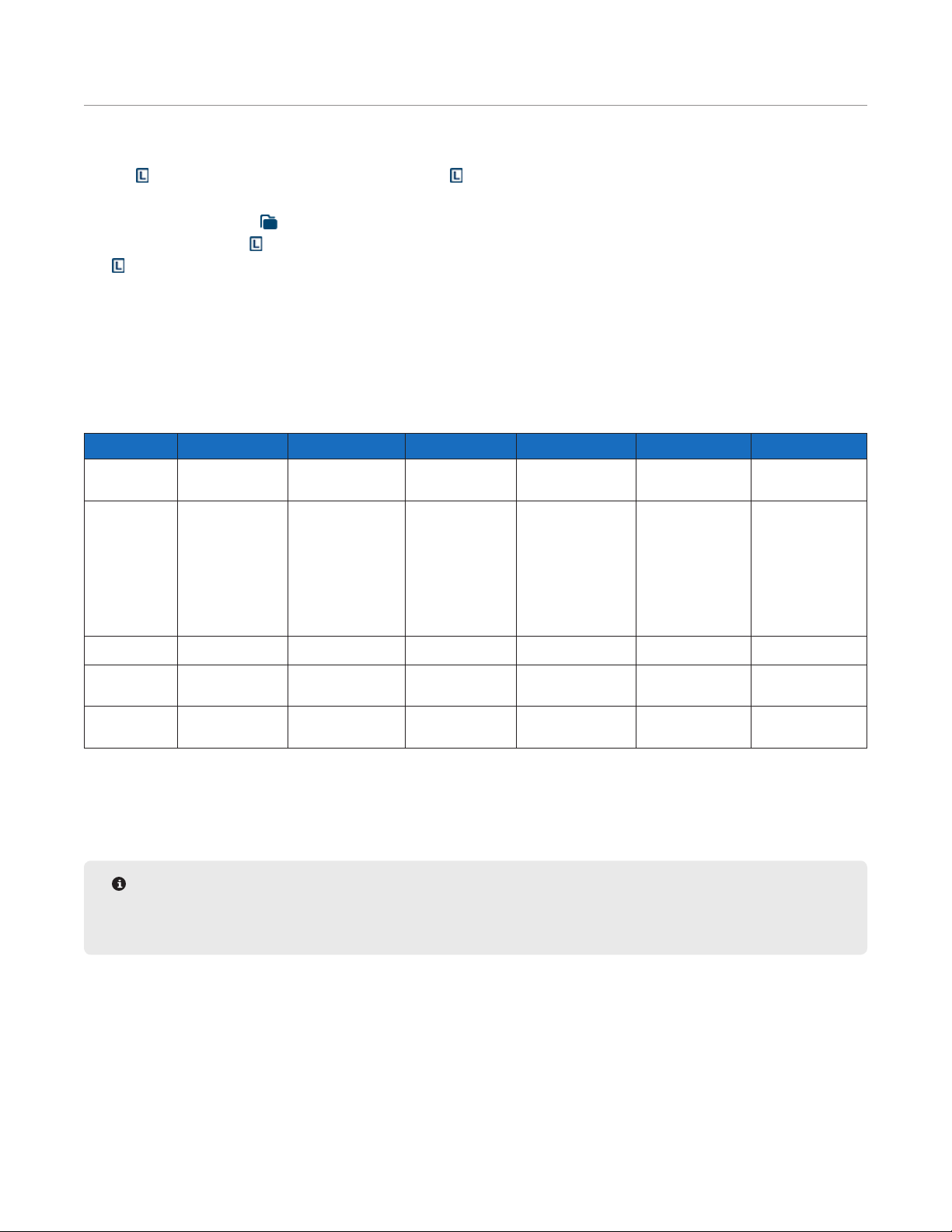

Permission Administrator Power User User Guest

Admin

Edit users Permitted Denied Denied Denied

Edit system settings Permitted Permitted Denied Denied

Edit calibrations Permitted Permitted Permitted Denied

Approve changes Permitted Permitted Denied Denied

Make changes without approval Permitted Denied Denied Denied

View audit trail Permitted Permitted Denied Denied

View hardware conguration Permitted Permitted Denied Denied

View current operation step Permitted Denied Denied Denied

View components status Permitted Denied Denied Denied

View application state via OPC Permitted Permitted Permitted Denied

Call OPC methods Permitted Permitted Denied Denied

Methods

View methods (all) Permitted Permitted Denied Denied

View methods (group) Permitted Permitted Permitted Denied

View methods (lesser groups) Permitted Permitted Permitted Denied

Edit methods (all) Permitted Denied Denied Denied

Edit methods (group) Permitted Permitted Permitted Denied

Edit methods (lesser groups) Permitted Permitted Permitted Denied

Create methods Permitted Permitted Permitted Denied

Edit template cycles and microwave methods Permitted Denied Denied Denied

Import/Export methods Permitted Permitted Permitted Denied

Results

View results (all) Permitted Permitted Permitted Permitted

View results (group) Permitted Permitted Permitted Permitted

View results (lesser groups) Permitted Permitted Permitted Permitted

Miscellaneous

View camera Permitted Permitted Permitted Permitted

Operation of the Liberty Blue

31

Page 36

Data Integrity

The Liberty Blue provides a software solution for automated microwave peptide synthesis users to aid in achieving

compliance with the FDA’s guidance on electronic records and electronic signatures: 21 CFR Part 11.

1. Software allows viewing of records for validity. Records include a date of last modication and a revision number

which is incremented upon modication.

2. Software has the ability to authenticate individuals via local accounts within the application software. User

accounts can be created, disabled and re-enabled by the administrator.

3. Software authenticates users based on both a unique user name and password security. Each user is a member

of a particular user group. Each user group species a list of privileges allowed and disallowed to users of that

group.

4. Software stores records in encrypted databases to ensure easy retrieval and prevents records being read or

altered outside of the application.

5. Software requires user to sign records and reports as well as changes in methods with a unique user name

and password. User name, the date and time the signature was executed, and the meaning of the signing are

recorded.

6. Software records the signature(s) in the record audit trail which may also be viewed and printed.

32

Operation of the Liberty Blue

Page 37

Setting up a Synthesis

Loading a Method

Once a method has been created and saved in the Liberty Method Editor, it is available from the Methods tab

on the main Liberty Blue Software screen. To load a method:

1. Open the appropriate folder in the Methods tab.

2. Click on the desired method, and drag the method to the resin position. Alternatively, right-click on the desired

method and select “Queue for run”.

3. The method name will appear in the Loaded Method indicator. The indicator will turn blue, meaning the method

is loaded and ready to run.

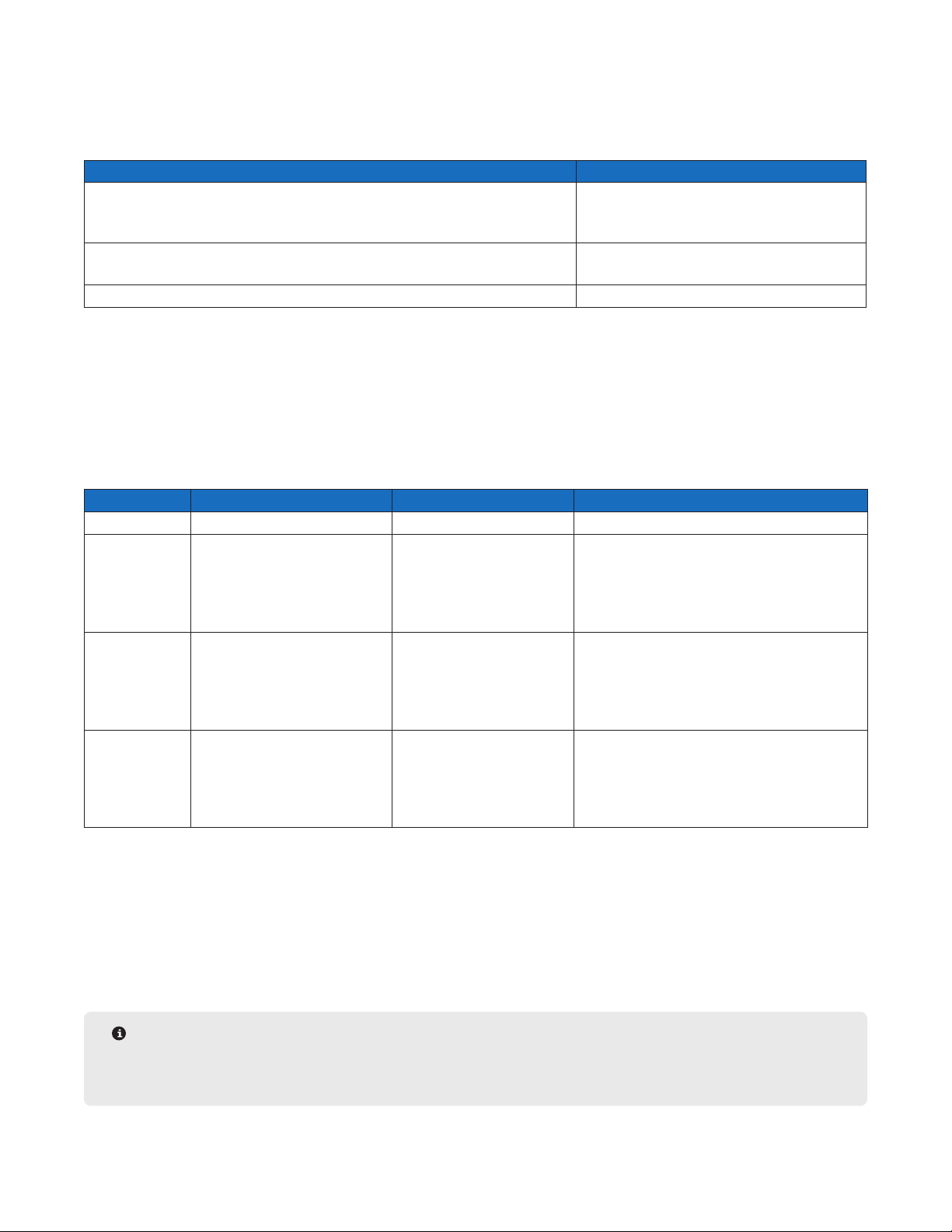

Standard Reagents and Concentrations

The Liberty Blue uses stock solutions of all reagents. The table below details the concentrations used on the

Liberty Blue and/or CEM’s preferred reagents.

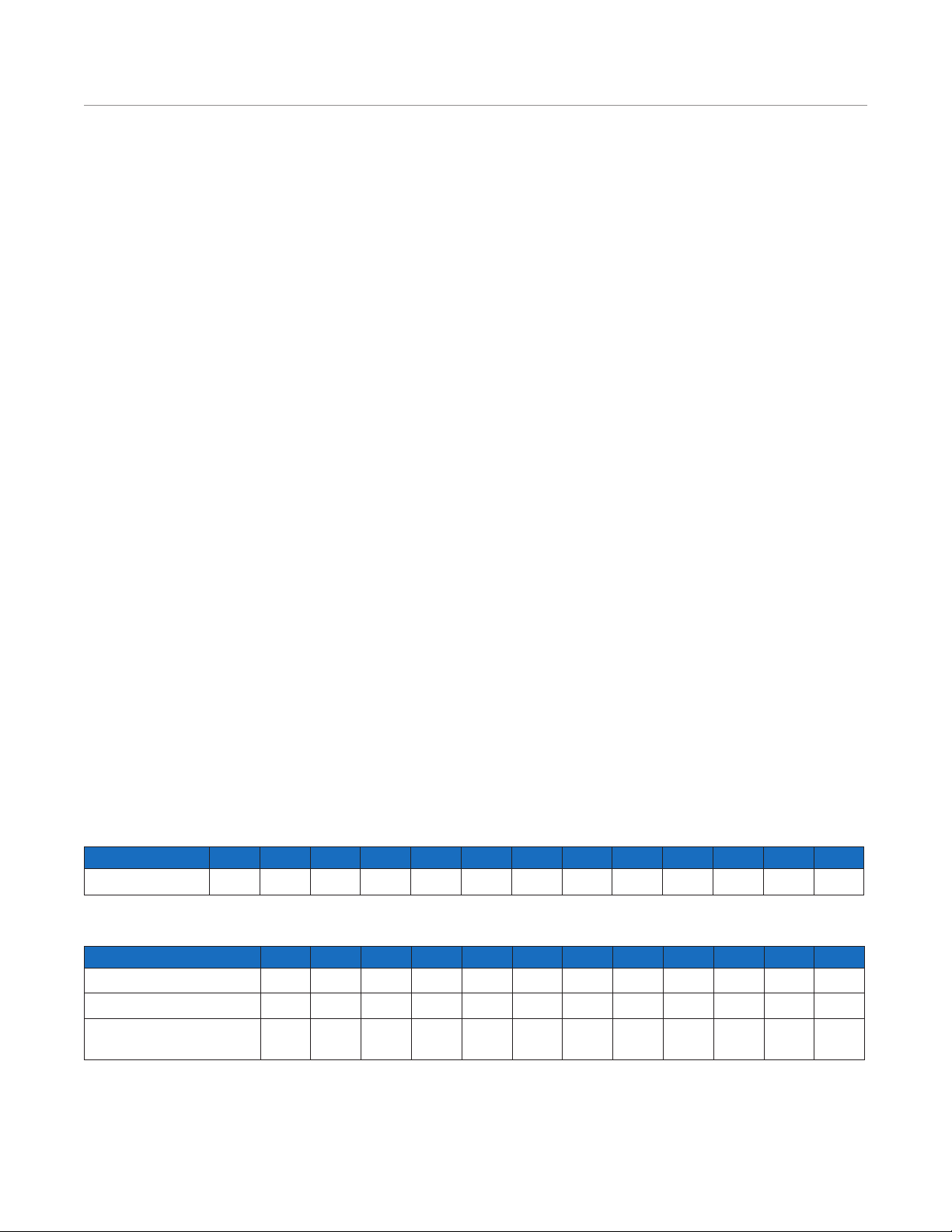

Reagents 0.005 mmol 0.01 mmol 0.025 mmol 0.05 mmol 0.1 - 0.5 mmol 1.0 - 5.0 mmol

Wash

Solvent*

Deprotection

Cocktail

Amino Acids 0.04 M in DMF 0.08 M in DMF 0.2 M in DMF 0.2 M in DMF 0.2 M in DMF 0.4 M in DMF

Activator** 0.05 M DIC in DMF 0.10 M DIC in

Base 0.05 M Oxyma in

*NMP is suitable as a wash solvent or for dissolution/dilution of reagents, but requires 75°C coupling cycles to reduce the risk of

insertions.

**View the CarboMAX application note, ap0124, at www.cem.com for further details.

NOTE

The Liberty Blue is not equipped to perform peptide cleavages. Cleavages should be carried out at room

temperature or heated in the Razor™.

DMF DMF DMF DMF DMF DMF

4% Piperidine

in DMF

or

2% Piperazine

(w/v) in

EtOH:NMP

(10:90)

DMF

4% Piperidine in

DMF

or

2% Piperazine

(w/v) in

EtOH:NMP

(10:90)

DMF

0.1 M Oxyma in DMF 0.25 M Oxyma in

20% Piperidine in

DMF

or

10% Piperazine

(w/v) in

EtOH:NMP

(10:90)

0.25 M DIC in DMF 0.50 M DIC in

DMF

20% Piperidine

in DMF

or

10% Piperazine

(w/v) in

EtOH:NMP

(10:90)

DMF

0.5 M Oxyma in DMF 1.0 M Oxyma in DMF 1.0 M Oxyma

20% Piperidine

in DMF

or

10% Piperazine

(w/v) in

EtOH:NMP

(10:90)

1.0 M DIC in

DMF

20% Piperidine

in DMF

or

10% Piperazine

(w/v) in

EtOH:NMP

(10:90)

1.0 M DIC in

DMF

in DMF

Recommended Reagents and Strategies for Microwave SPPS on the Liberty Blue

This section is intended to provide general guidance for reagent selection when synthesizing peptides on the

Liberty Blue. For each case CEM’s preferences are ranked in order with #1 being the preferred choice. The

corresponding MW methods recommended are subsequently described in the Microwave Methods Selection.

Setting up a Synthesis

33

Page 38

WARNING

Handle all chemicals under a fume hood, and wear suitable protective clothing such as safety glasses,

chemical resistant gloves, and a laboratory coat. Dispose of all waste in accordance with all applicable

local, state, and federal health and safety recommendations. For detailed information on the safety

requirements for the chemicals used on the Liberty Blue, refer to the appropriate SDS documents.

Resin Selection

Default cycles are available for both standard resins (such as polystyrene) and high-swelling resins (such as PEG).

It is important to use the appropriate cycles for the resin being used in the synthesis. When the resin type is

selected in the Liberty Method Editor, the appropriate default cycles for that type will automatically be loaded.

Although most resins are compatible with microwave SPPS on the Liberty Blue, CEM recommends the resins

shown in the table below for optimal results.

Peptide Length C-Terminal Acid C-Terminal Amide

Standard (<25 residues) Cl-TCP(Cl) ProTide Fmoc Rink Amide ProTide

Long (>25 residues) Cl-MPA ProTide (LL) Fmoc Rink Amide ProTide (LL)

Mesh Size

Only 100-200 mesh (or lower) resin (>75 micron) should be used with the Liberty Blue. The use of higher mesh

resins will result in clogging of the reaction vessel frit and damage to the system.

Deprotection Solution Selection

General Strategy

Historically, piperidine has been the most common deprotection reagent. Piperazine, however, is a great alternative

and is growing in popularity; it is a non-controlled substance, relatively inexpensive, and less malodorous than

piperidine. Although piperizine has limited solubility in DMF and NMP, it shows improved solubility and deprotection

activity in a solution of 10% ethanol in NMP.

CEM Preference Deprotection Cocktail Microwave Method

1 20% Piperidine (v/v) in DMF or NMP Standard

2 10% (w/v) Piperazine in EtOH:NMP (10:90) Standard

For sequences where aspartimide formation is a concern, 0.1 M HOBt or 0.1 M Oxyma should be added to the

deprotection cocktail to suppress the side reaction.

NOTE

Allow up to 1 hour for piperazine to completely dissolve with stirring. If 0.1 M Oxyma is added then 30

minutes is enough to completely dissolve with stirring. Gentle heating on a hotplate can help. Calibration

of the deprotect timed addition should be performed for the particular reagent used (piperazine or

piperidine).

34

Setting up a Synthesis

Page 39

Special Case: Sequences Containing Asp-Gly (DG)

The Asp-Gly (DG) segment is particularly sensitive to base-catalyzed aspartimide formation. Simple addition

of HOBt or Oxyma to the standard deprotection solutions may not be sufcient to prevent this side reaction.

Therefore, less aggressive deprotection conditions should be used or a Dmb protected dipeptide that prevents this

side reaction. Below are a few additional approaches for combating aspartimide formation.

Supression Strategy Microwave Method

5% (w/v) Piperazine w/ 0.1 M Oxyma Pure in EtOH:NMP (10:90) Two step room temperature deprotection:

1. Conventional initial deprotection

2. Conventional deprotection

Use Fmoc-Asp(OtBu)-(Dmb)Gly-OH dipeptide and any deprotection cocktail applicable for

Standard

standard peptides

Use Fmoc-Asp(OMpe)-OH and any deprotection cocktail applicable for standard peptides. Standard

Activation Strategy Selection

General Strategy

The two most popular activation strategies for solid phase peptide synthesis are carbodiimide promoted coupling

(using a carbodiimide such as DIC with an additive such as HOBt or Oxyma to quickly convert the O-acylisourea

intermediate to a reactive ester) and onium salt promoted coupling (using a base such as DIEA to initiate

conversion of the amino acid to the activated ester through reaction with an onium salt such as HBTU). The table

below details CEM’s preferred strategies and recommended microwave conditions for each strategy.

CEM Preference Reagents Cycle Exceptions

1 AA/DIC/Oxyma1 in DMF Single Coupling

2 AA/HBTU3/DIEA4 in DMF

90°C 1 min Deprotection

Wash (x4)

75°C 5 min Single Coupling

2

Arg: Double Coupling

Cys: Single 50°C 10 min Coupling

His: Single 50°C 10 min Coupling

Arg:

1st Coupling: 25 min room temp, 75°C 2 min

2nd Coupling: 75°C 5 min

3 AA/DIC/Oxyma1 in NMP

90°C 1 min Deprotection

Wash (x4)

75°C 10 min Coupling

Cys: Double 50°C 10 min Coupling

His: Double 50°C 10 min Coupling

Arg:

1st Coupling: 25 min room temp, 75°C 2 min

2nd Coupling: 75°C 5 min

4 AA/HBTU3/DIEA4 in NMP

90°C 1 min Deprotection

Wash (x4)

75°C 5 min Single Coupling

Cys: Single 50°C 10 min Coupling

His: Single 50°C 10 min Coupling

Arg:

1st Coupling: 25 min room temp, 75°C 2 min