Page 1

Operation Manual

600178

Rev. 5

Page 2

Page 3

Contents

Section 1: Introduction

Introduction 7

About This Manual 7

Common Abbreviations and Units 8

How to Obtain Support 10

Applications Support 10

Technical Support 10

Requested Information 10

Contact CEM 11

CEM Corporation Headquarters 11

CEM International Subsidiaries 11

CEM Distributors 12

Safety Information 13

Safety Notations 13

Safety Information 14

Fume Ventilation 14

Waste Disposal 14

System Requirements 14

Bench and/or Fume Hood Space 14

Environmental Conditions 15

Inert Gas Source 15

Electrical Requirements 15

Section 2: Operation of the Liberty

Introduction to the Liberty 16

Components and Parts 18

Reaction Vessel Components 19

Introduction to PepDriver 20

PepDriver Main Screen 21

Control Buttons 22

Menu Buttons 22

Indicators 22

Tabs 23

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Page 4

Editors 25

Microwave Editor 25

Microwave Method Folders 25

Microwave Method Types 25

Creating a New Microwave Method 26

Editing an Existing Microwave Method 27

Cycle Editor 28

Cycle Folders 28

Copying and Modifying an Existing Microwave Method 28

Cycle Types 29

Creating a Cycle 29

Editing an Existing Cycle 30

Copying and Modifying an Existing Cycle 31

Sequence Editor 32

Creating a New Sequence 32

Modifying a Sequence 33

Using the External Amino Acid Positions 33

Importing a Sequence 34

Method Editor 36

Creating a New Method 36

Modifying an Existing Method 38

Calculators 39

Usage Calculator 39

Reagent Calculator 40

Resin Calculator 40

Deprotection Calculator 41

Activator Base Calculator 41

Activator Calculator 42

Amino Acid Calculator 42

Cleavage Calculator 43

Setting up a Synthesis 44

Conguring Methods to Run 44

Loading a Method 44

Loading Multiple Methods 45

Preparing Reagents 45

Standard Concentrations 45

Preparing Activator Solution 46

Preparing Activator Base Solution 46

Preparing Amino Acids 46

Preparing Deprotection Solution 47

Preparing Capping Solution 47

Preparing Cleavage Solution 48

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Page 5

Setting up the Liberty 48

Loading Reagents onto the Liberty 48

Loading Resin onto the Liberty 50

Changing the Reaction Vessel 50

125 mL Reaction Vessel 50

10 mL Reaction Vessel 50

Running the Liberty 51

Preparing the Liberty to Run 51

Running the Liberty 52

Generating Reports 54

Method Reports 54

Creating a Method Report 54

Sample Method Report 55

Run History Reports 56

Creating a Run History Report 56

Sample Run History Report 56

Section 3: Quick Setup Guide

Peptide Setup 57

Create and Load the Method 57

Prepare Reagents 58

Ensure the Liberty is Ready to Run 59

Section 4: Mainteance of the Liberty

Routine Maintenance 61

Daily Maintenance 61

Weekly Maintenance 61

Biweekly Maintenance 61

Monthly Maintenance 61

Semiannual Maintenance 62

Standby Procedure 62

Maintenance Screen 63

Cleaning Tab 63

Using the Change Bottle Command 65

Performing a Backush 66

Performing a System Check 67

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Page 6

Sample System Check File 69

Volume Calibration Tab 70

Performing a Volume Calibration 70

Importing and Exporting Volume Calibration Values 72

Performing a Large Scale Calibration 73

Sensor Calibration Tab 76

Performing a Sensor Calibration 76

Importing and Exporting Sensor Calibration Values 79

Pressure Calibration Tab 79

Performing a Pressure Calibration 80

Section 5: Advanced Features

Default Cycle Editor 82

Changing Default Cycles 82

Options Menu 83

Program Options Tab 83

Defaults Tab 85

Run History Tab 85

Test System Screen 86

Pressure Adjustment 87

Main Pressure Adjustment 87

Low Pressure Adjustment 88

Leak Check 88

Test Rotary Valves 89

Internal, Nitrogen, and Liquid Delivery Tests 90

Setting Up the Liberty for a Delivery Test 90

Performing a Delivery Test 91

Test Sensors 91

Reagent, Amino Acid, and External Amino Acid Addition 93

Leak Check Reaction Vessel 94

Flow Performance 94

Diagnostics Screen 95

Commands Tab 95

Sensors Tab 95

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Page 7

Valves Tab 96

Status Tab 96

Delay Times Tab 97

Section 6: Troubleshooting

Tips for Recovering from Errors 99

Section 7: Spare Parts and Consumables

Reaction Vessel Parts 100

Filters 101

Solvent Keg 101

Bottles 102

Bulk Tubing and Fittings 103

Bottle Tubing Assemblies 104

Bottle Caps 105

Dip Tubes 106

O-Rings 106

Valves and Valve Wiring 107

Liquid Sensors 108

Waste Container 109

Accessories and Tools 109

Computer Accessories 110

Circuit Boards 111

Regulators 111

Documentation 111

Section 8: Index

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Page 8

6

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Page 9

Section 1: Introduction

Introduction

About This Manual

This manual (PN 600178) describes the operation and maintenance of the Liberty™ Automated

Microwave Peptide Synthesizer. The manual is intended for use by both novice and experienced

users.

This introductory section contains a list of common abbreviations and units used throughout the

manual, as well as important information for the safe operation of the unit. The manual assumes

that the Liberty was installed by a CEM certied service technician.

This manual refers to PepDriver™ version 2.5.4 Build 2 for all software information, including

screenshots and technical information. The latest version of PepDriver can be downloaded from

CEM’s website at http://www.cem-technet.com. A registered account is required for download.

Additional information is available in the Appendicies (PN 600183), which can be found on the

included CD-ROM (PN 900105).

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

7

Page 10

Common Abbreviations and Units

Abbreviation Definition

°C degrees Celsius

°F degrees Fahrenheit

AA amino acid

ACP acyl carrier protein 65-74

Amp amphere

Boc tert-butyloxycarbonyl

tBu tert-butyl

DCM dichloromethane

DIEA diisopropylethylamine

DMF N,N’-dimethylformamide

DODT 3,6-dioxa-1,8-octane dithiol

E

a

energy of activation

EDT ethanedithiol

Fmoc 9-uoroenylmethyloxycarbonyl

g gram

h height

HATU N-((dimethylamino)-1H-1,2,3-triazolo-4,5-bi-

pyridin-1-yl-methylene) N-methylmethan-

aminium hexauorophosphate N-oxide

HBTU 2-(1 H-benzotriazol-1-yl)-1,1,3,3-

tetramethyl-uronium hexauorophosphate

HCTU O-(6-chlorobenzotriazol-1-yl)-N,N,N’,N’-

tetramethyluronium hexauorophosphate

HF hydrouoric acid

HOAt 1-hydroxy-7-azabenzotriazole

HOBt 1-hydroxybenzotriazole

Hz Hertz

ID inner diameter

L liter

l length

m meter

8

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Page 11

Abbreviation Denition

meq milliequivalent

mg milligram

MHz megahertz

mL milliliter

mm millimeter

mM millimolar

mmol millimole

MW molecular weight

NMP 1-methyl-2-pyrrolidone

OAt 7-azabenzotriazole

OBt benzotriazole

OD outer diameter

PN part number

psi pounds per square inch

PyAOP (7-Azabenzotriazol-1-yloxy)

tripyrrolidinophosphonium

hexauorophosphate

PyBOP (Benzotriazol-1-yloxy)

tripyrrolidinophosphonium

hexauorophosphate

RV reaction vessel

s seconds

TBTU O-(Benzotriazol-1-yl)-N,N,N′,N′-

tetramethyluronium tetrauoroborate

TFA triuoroacetic acid

TIS triisopropylsilane

Trt trityl

VAC volts of alternating current

W Watts

w width

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

9

Page 12

How to Obtain Support

Applications Support

For the latest Liberty applications information, go to http://www.cem.com/bioscience. The CEM

Bioscience website contains downloadable applications notes, a listing of recent microwave

peptide synthesis publications, and more.

CEM is proud to provide applications support for any peptide synthesis related questions from

a team of trained chemists with a complete peptide synthesis lab. For applications support, call

(800) 726-3331 (inside the US) or (704) 821-7015 and ask for “Peptide Applications”, or email

CEM Liberty applications support at peptides@cem.com.

Technical Support

For the latest technical support information, go to http://www.cemservice.us. The CEM Service

website provides access to the CEM Knowledge Base, which contains helpful troubleshooting

information. From the website requests for phone or email support can also be submitted.

CEM is proud to provide technical support for the Liberty from a team of specially trained Service

Technicians. For technical support in the US and Canada, call (800) 726-5551 or (704) 821-7015

and ask for “Liberty Service”. For technical support outside the US and Canada, contact your

local CEM Subsidiary or Distributor.

Requested Information

When contacting CEM for support, please provide the following information about the instrument:

Liberty Serial Number•

Liberty Firmware Version•

Discover Serial Number•

Discover Firmware Version•

PepDriver Version Number•

A recent System Check report (see p. 67)•

The Run History report for the synthesis that was running when the error •

occurred (see p. 56)

Serial numbers, rmware versions, and software version can be found within PepDriver by

clicking the Help Menu (not the Help Button) and selecting About PepDriver.

10

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Page 13

Contact CEM

CEM Corporation Headquarters

Toll-Free Phone (US/Canada): (800) 726-3331

Phone: (704) 821-7015

Service Hotline: (800) 726-5551

Fax: (704) 821-7894

Mailing Address: PO Box 200

Matthews, NC 28106-0200

Physical Address: 3100 Smith Farm Rd

Matthews, NC 28104

Email (Applications Support): peptides@cem.com

Email (Technical Support): service@cem.com

CEM International Subsidiaries

France: CEM mWave S.A.S.

Phone: (33-1) 69 35 57 80

Fax: (33-1) 60 19 64 91

Address: Immeuble Ariane Domaine Technologique de Saclay

4, rue René Razel

91892 ORSAY Cedex

France

Web Address: http://www.cemfrance.fr

Email: info.fr@cem.com

Germany: CEM GmbH

Phone: 011-49-2842-9644-0

Fax: 011-49-2842-9644-11

Address: Carl-Friedrich-GauB-Str. 9

47475 Kamp-Lintfort

Germany

Web Address: http://www.cem.de

Email: info@cem.de

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

11

Page 14

Italy: CEM SRL

Phone: 390-35-896224

Fax: 390-35-891661

Address: Via Dell Artigianato, 6/8

24055 Cologno Al Serio (BG)

Italy

Email: info.srl@cem.com

UK and Ireland: CEM Microwave Technology Ltd.

Phone: +44-1-280-822373

Fax: +44-1-280-822342

Address: 2 Middle Slade

Buckingham Industrial Park MK18 1WA

Buckingham

Great Britain

Email: info.uk@cem.com

CEM Distributors

For a complete list of distributors of CEM products, including contact information, go to the CEM

website (http://www.cem.com), select Contact Us, and then select Distributors.

12

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Page 15

Safety Information

Safety Notations

This manual uses three safety alert words at points in the documentation where the user should

be aware of potential hazards. The safety alerts are shown in color-coded boxes. The three

words–NOTE, CAUTION, and WARNING–indicate differing levels of observation or action as

described below:

NOTE

A NOTE is intended to provide emphasis of procedures that may be

misinterpreted or overlooked, or to otherwise clarify confusing situations.

CAUTION

A CAUTION is intended to provide essential information and to emphasize

procedures which, if not strictly followed, may result in improper instrument

operation.

WARNING

A WARNING is intended to provide emphasize dangerous or hazardous

conditions which may result in personal injury to the user and damage or

destruction of the instrument.

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

13

Page 16

Safety Information

Fume Ventilation

The Liberty operates as a semi-closed system, with minimal venting of any hazardous solvent

fumes through the vent line coming from the Waste Reservoir. The vent line from the Waste

Reservoir must be vented into a proper chemical fume hood or exhaust line no longer than six

feet (6’)/two meters (2 m) from the instrument.

In addition, adequate ventilation should be provided for preparation of reagents and solvents for

use on the system. All solvent bottles and the Waste Reservoir should be placed into proper

secondary containers to minimize the risk of exposure.

Waste Disposal

Waste produced by the Liberty can be hazardous. For detailed information on the safety

requirements for the chemicals used on the Liberty, refer to the appropriate MSDS documents.

WARNING

Handle all waste under a fume hood, and wear suitable protective clothing.

Dispose of all waste in accordance with all applicable local, state, and

federal health and safety recommendations.

Product Removal

When removing tubes containing cleaved peptide in TFA from the Product Manifold following

cleavage, wear suitable protective clothing. These tubes contain a mixture of TFA, DCM, and

peptide. The centrifuge tubes should be capped immediately after removal from the Liberty to

reduce exposure to solvent fumes.

System Requirements

Bench and/or Fume Hood Space

The Liberty should be positioned on the bench such that access to the electrical outlets for the

system is not restricted. The Liberty requires the following space for system components:

Liberty Instrument (Discover Module and Liberty Module):

30” (w) x 24” (d) x 33.5” (h) [76 cm (w) x 61 cm (d) x 85 cm (h)]

(Depth includes 3” (7.62 cm) clearance behind instrument for unimpeded airow at rear fan ducts)

CEM Supplied Controller:

Laptop:

12.5” (w) x 9.9” (d) x 15.5” (h) [32 cm (w) x 25 cm (d) x 39 cm (h)]

(Height includes 14.1” (35.8 cm) display)

Desktop:

Minitower: 7.4” (w) x 17.5” (d) x 16.1” (h) [19 cm (w) x 44.5 cm (d) x 41 cm (h)]

Monitor: 16” (h) x 8” (d) x 20” (h) [41 cm (h) x 20 cm (w) 51 cm (h)]

External Reagent Bottles:

16” (w) x 16” (d) x 15” (h) [41 cm (w) x 41 cm (d) x 38 cm (h)]

(Left side of instrument, facing front of instrument)

14

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Page 17

Waste Reservoir:

10” (w) x 16” (d) x 18” (h) [25 cm (w) x 41 cm (d) x 45.72 cm (h)]

(Must be vented into fume hood)

Approximate overall dimensions for Liberty and external reagents:

48” (w) x 24” (d) x 33.5” (h) [122 cm (w) x 61 cm (d) x 85 cm (h)]

Environmental Conditions

The Liberty is designed for indoor used only.

Temperature Range: 50 °F – 85 °F (10 °C – 29 °C)

Relative Humidity Range: 0 – 85%

Inert Gas Source

The Liberty requires an inert gas source (either high purity grade nitrogen or argon) capable of

supplying 25 psi (20 L/min ow) within ten feet (10’)/three meters (3 m) of the right side of the

instrument.

Electrical Requirements

The Liberty requires four (4) dedicated, grounded electrical connections operating at 120 VAC

(110-140 VAC, 60 Hz, 10 Amp @ 120 VAC) (or 240 VAC [202-250 VAC, 50 Hz, 10 Amp @ 240

VAC] where applicable). Specic power requirements (120 VAC vs. 240 VAC) can be found on

the nameplate afxed to the rear of the Liberty instrument.

One (1) electrical connection is required for each of the following components:

Liberty Module power cord

Discover Module power cord

Router power cord

Controller (laptop computer) power cord

NOTE

Five (5) electrical connections are required when using the desktop

computer controller option: Liberty module, Discover module, router,

controller minitower, controller monitor.

NOTE

Optionally, the router can be powered directly from the Liberty Module

without the need for an external electrical connection (using Router-Serial

Power Cable, PN 243290).

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

15

Page 18

Section 2: Operation of the

Liberty

Introduction to the Liberty

The Liberty Automated Microwave Peptide Synthesizer is the rst and only automated microwave

peptide synthesizer. Built on CEM’s exible Discover microwave platform, the Liberty is capable

of synthesizing up to twelve peptides in sequence on scales ranging from 0.05 to 5 mmol faster

and more efciently than conventional synthesizers thanks to the system’s patented circular

microwave cavity.

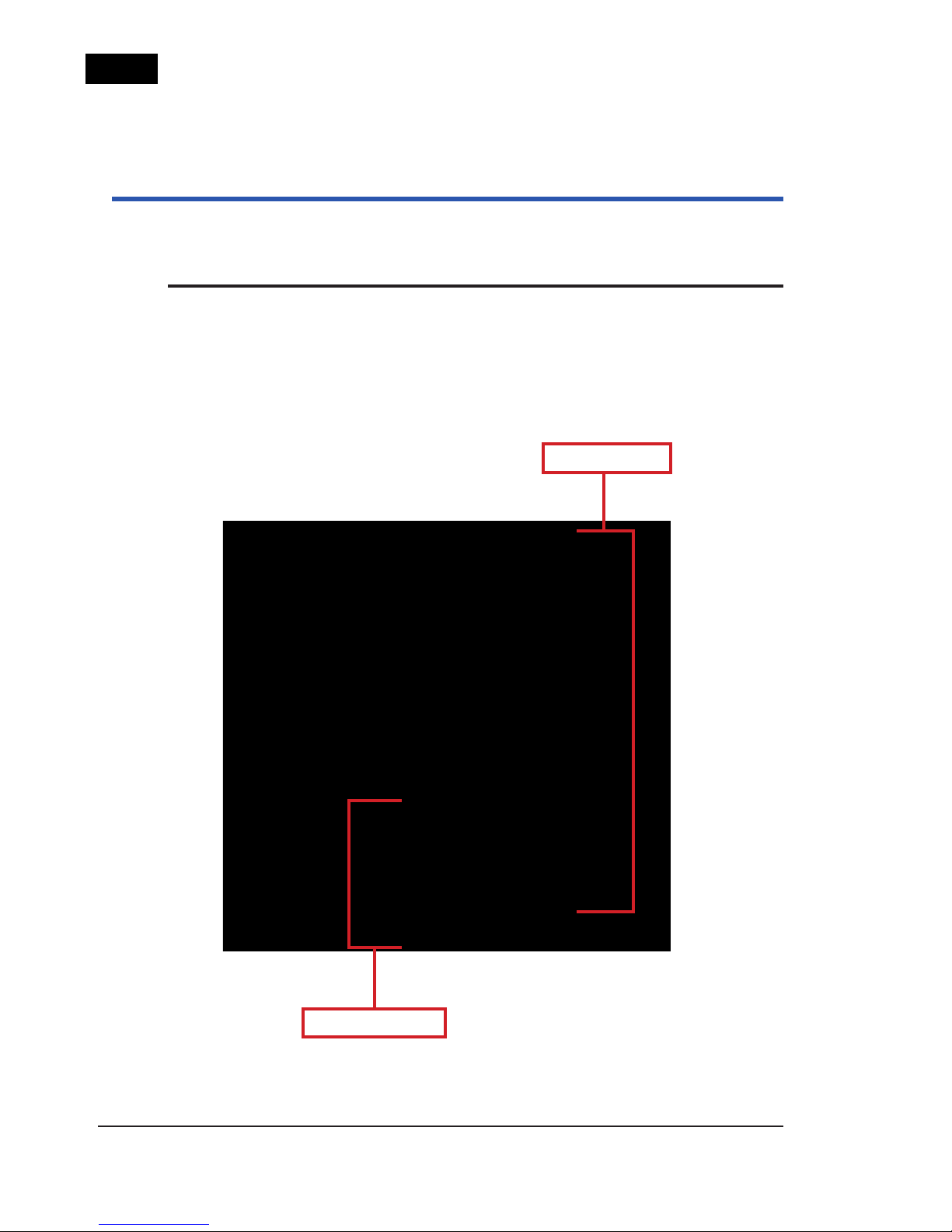

Liberty Module

Discover Module

16

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Page 19

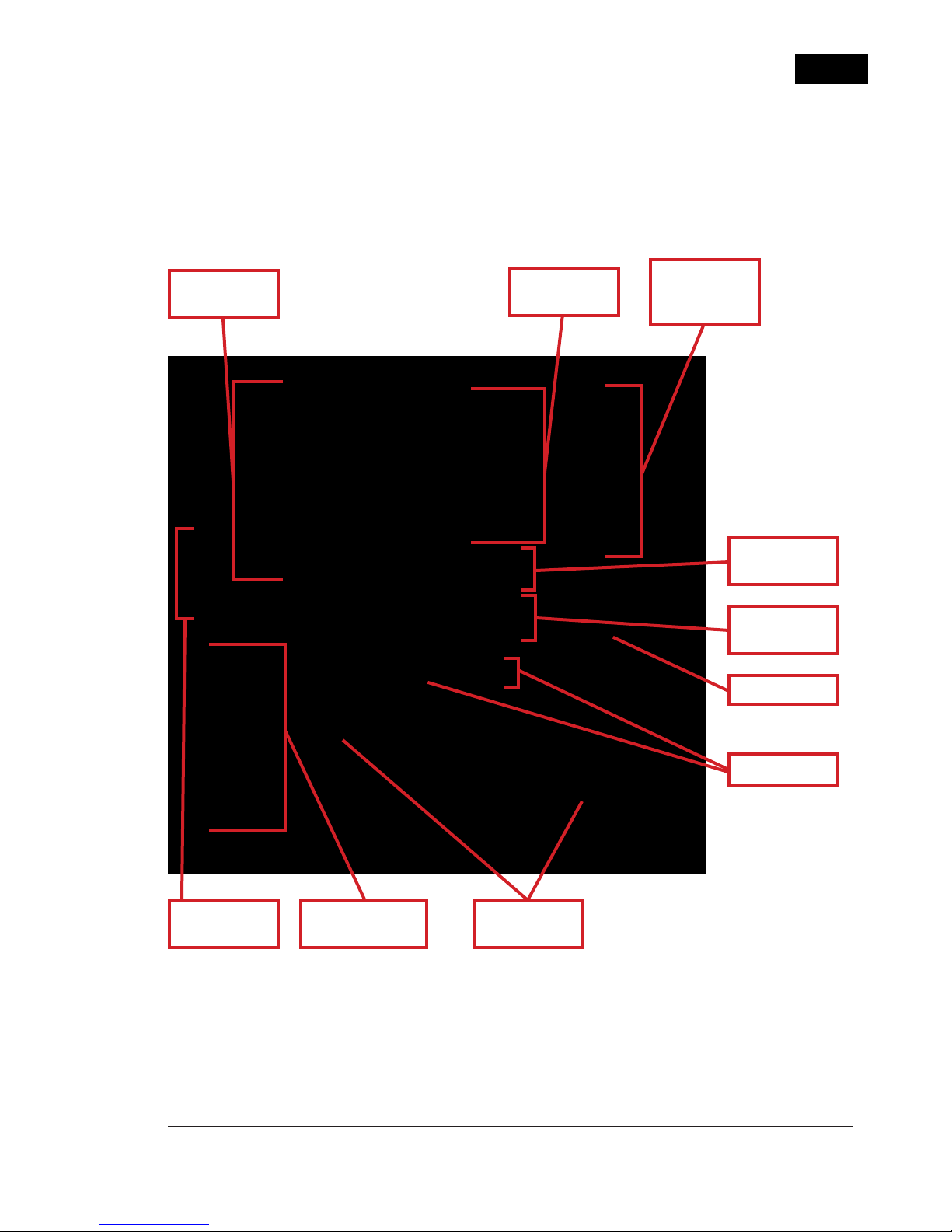

3-Port

Manifold

Amino Acid

Manifolds

External

Amino Acid

Manifold

Resin

Manifold

Product

Manifold

Waste Lines

Solvent

Lines

Deprotection

and Capping

Power

Switches

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Filters

17

Page 20

Components and Parts

Liberty Module: • The Liberty handles all of the uid transfer into and out of

the reaction vessel. In addition, the Liberty manages communications with the

computer controller and the Discover during peptide synthesis.

• Discover Microwave Reactor: The Discover microwave reactor holds the

reaction vessel and generates the microwave energy used to irradiate the

sample. The Discover is capable of operating independently of the Liberty.

Power Switches: • There are two power switches, one for the Discover and one

for the Liberty. Both switches must be on to operate the Liberty.

Solvent:• There are two bottles of Main Wash (DMF) and one bottle of Secondary

Wash (DCM) on the system (not shown). These positions are designed for use

with standard 4 L solvent bottles. The bottle caps and lines are color coded: black

for DMF and yellow for DCM. These bottles are pressurized at all times and the

Change Bottle command must be used to remove these bottles.

3• -Port Manifold: This manifold has three positions designated for activator,

activator base, and cleavage cocktail. These positions are designed for use with

250 mL glass bottles with GL45 thread.

Deprotection and Capping:• This shelf is designed to hold the Deprotection and

Capping bottles. The bottle caps and lines are color coded: blue for Deprotect

and purple for Capping. These positions are designed for use with 1 L glass

bottles with GL45 thread. These bottles are pressurized at all times and the

Change Bottle command must be used to remove these bottles.

Amino Acid Manifolds:• There are 20 positions on the manifold for amino acids,

each corresponding to a specic amino acid. Each position is labeled using the

3 letter abbreviations of the amino acids. These positions are designed for use

with 125 mL plastic bottles.

Resin Manifold:• Resin is added without liquid in standard 50 mL centrifuge

tubes to the twelve positions manifold. The resin will return to the same position

on the resin manifold after synthesis if cleavage is not done on the system.

Product Manifold:• If the peptide is cleaved on the system, the cleavage product

will be returned to an empty standard 50 mL centrifuge tube on one of the twelve

positions on this manifold. The spent resin will be ushed to waste.

• Reaction Vessel: The reaction vessel (not shown, see p. 19) is where the

synthesis takes place. Reagents are added to the vessel and washed out

throughout the synthesis of the peptide. There are different size vessels that can

be used depending on the scale of the synthesis.

Fiber Optic • Temperature Probe: The ber optic probe is inserted in the top

of the reaction vessel. It allows the system to monitor the temperature of the

reaction vessel.

• Waste Lines: The waste lines carry all of the system’s waste out into an external

waste container. The waste container is equipped with a level sensor and will

trigger the system to pause if the container is full.

Filters: • There are three in-line lters on the system. These lters should be

changed regularly as part of routine maintenance.

18

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Page 21

Optional Features•

•

External Amino Acid Manifold: This manifold allows for the addition of non-

standard amino acids and other reagents from ve positions using standard

50 mL centrifuge tubes.

DMF • Keg: An optional 20 L steel keg (not shown) is available for the DMF

position. This keg allows for synthesis of longer peptides where total solvent

usage would otherwise be a limitation.

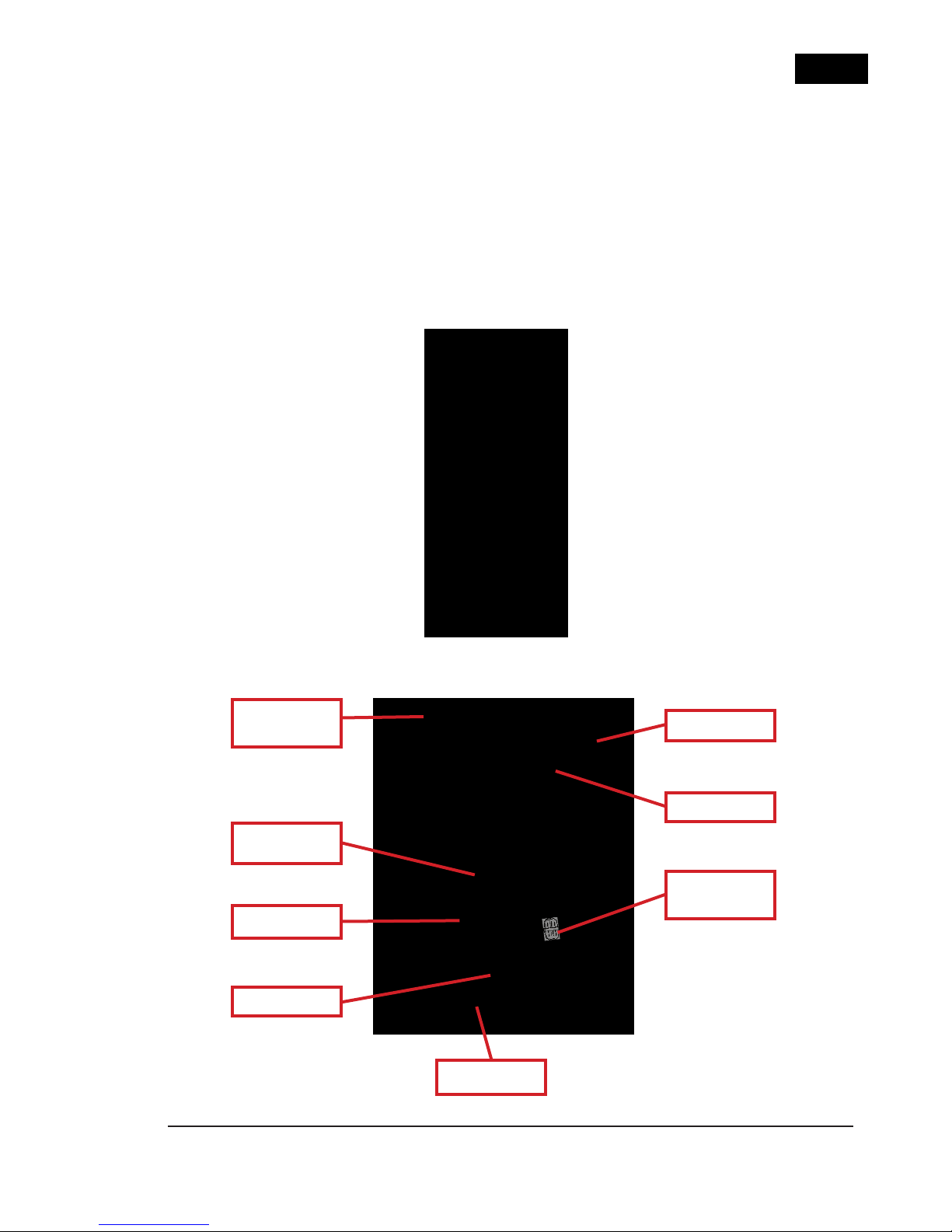

• 10 mL Reaction Vessel: A smaller reaction vessel assembly (shown below)

is available to allow synthesis on scales as low as 0.025 mmol.

Reaction Vessel Components

Fiber Optic

Probe

Spray Head

Thermowell

Resin Tube

Glass Frit

Filter

Drain Line

Quick

Disconnect

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

19

Page 22

Introduction to PepDriver

The operation of the Liberty is controlled through the PepDriver software package. The Liberty

includes an external computer controller (either a laptop or desktop Windows PC) for running

PepDriver. This computer is connected to the Liberty and the Discover through an ethernet

connection.

PepDriver Terminology

Throughout this manual, specic terms will be used to describe the various functions within

PepDriver.

• Microwave Method: The specic parameters used in a Microwave step

within a cycle. Microwave Methods can be created or modied using the

Microwave Editor (p. 25).

• Cycle: The specic steps used for each residue within a given sequence.

Cycles can be created or modied using the Cycle Editor (p. 28).

• Sequence: The specic peptide to be synthesized in a given method.

Sequences can be created or modied using the Sequence Editor (p. 32).

• Method: The specic parameters used to synthesize a peptide. For each

method, a sequence is selected, and then parameters (individual coupling

cycles for each residue, C-terminus type, nal deprotection, etc.) are also

selected as part of the method. Methods can be created or modied using

the Method Editor (p. 36).

• Run: A specic instance of a method being loaded and started in PepDriver.

A Run History le (p. 56) is recorded for each run.

20

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Page 23

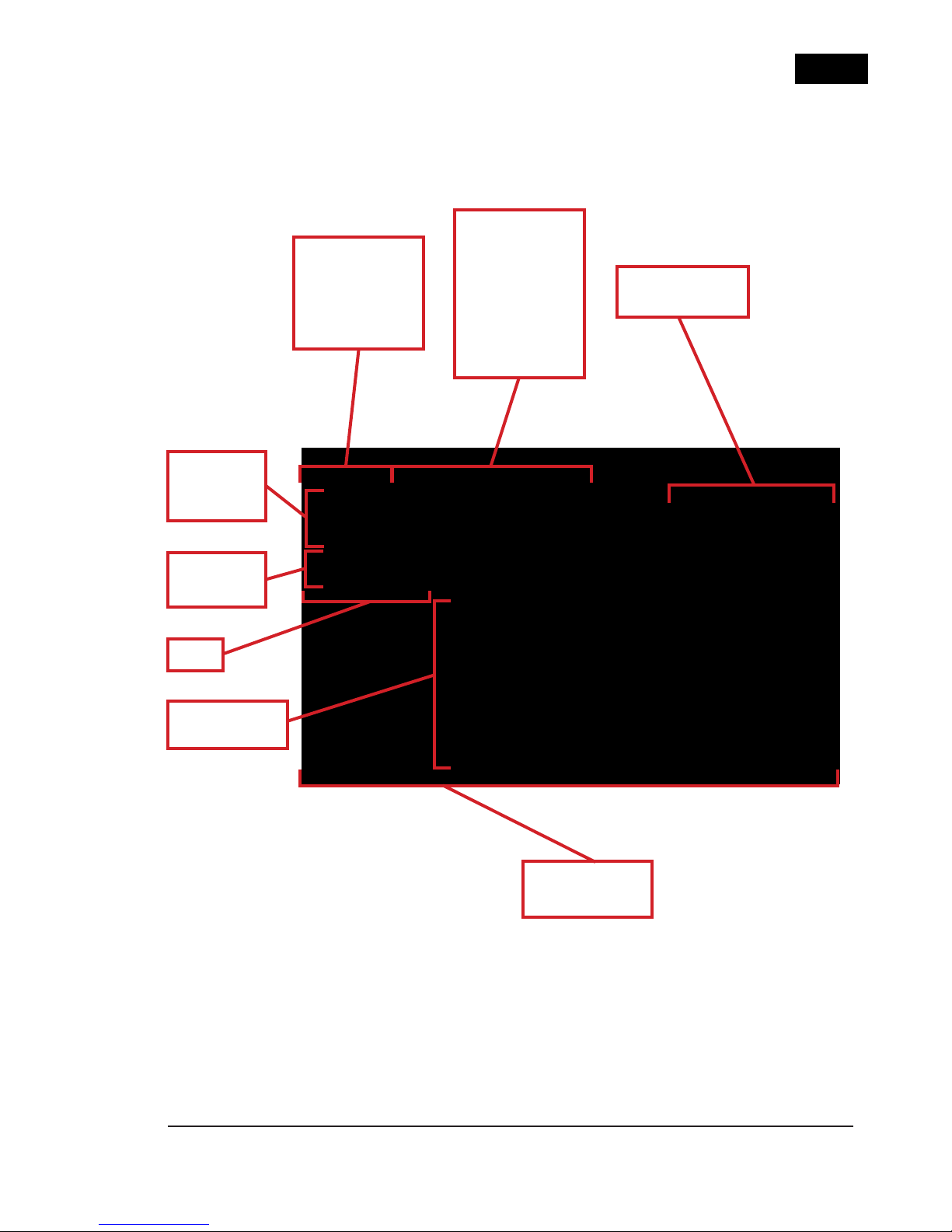

PepDriver Main Screen

Control

Buttons

Start

Pause

Stop

Peptide

Synthesis

Status

Resin

Positions

Menu Buttons

Methods

Sequences

Cycles

Setup

Maintenance

Calculator

Estimated Time

Remaining

Tabs

Current

Method Detail

System Status

Line

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

21

Page 24

Control Buttons

Start: • This button starts the rst method in the queue, or resumes a stopped

method.

Pause: • This button pauses or unpauses the current method.

Stop: • This button stops the current method. PepDriver will nish the operation it

is currently performing before stopping the method.

Menu Buttons

Methods:• This button opens the Method Editor. From the Method Editor, specic

parameters for each synthesis can be programmed.

Sequence:• This button opens the Sequence Editor, where peptide sequences

are entered to be used in methods.

Cycles:• This button opens the Cycle Editor. From the Cycle Editor, cycles can

be created or edited for use in any part of a method.

• This menu contains the Microwave Editor, Default Cycle Editor, Pepdriver

Setup:

Options Menu, and Communication options. From this menu, User Accounts can

also be accessed.

• Maintenance: From this menu, the Maintenance and Diagnostics screens can

be accessed. The Maintenance Screen allows for cleaning, volume calibration,

sensor calibration, and pressure calibration. The Diagnostics Screen contains

information about the sensors, valves, and delay times for the system.

• Calculators: This menu contains the Reagent and Usage calculators. The

Usage Calculator will calculate the amount of each reagent solution needed

for the currently loaded methods. The Reagent Calculator can then be used

to calculate how to make each of the stock solutions for the loaded methods

(including activator, activator base, deprotection, cleavage, and amino acids).

Indicators

Resin Positions:• The twelve positions on the screen correspond to the twelve

positions on the resin manifold of the Liberty. The resin should be loaded in the

same position on the manifold as the method has been loaded into in PepDriver.

Peptide Synthesis Status:• This displays the peptide sequence being

synthesized and indicates the status of the synthesis.

Current Method Detail: • This window displays the currently selected method.

When a method is running, the current step is indicated in yellow.

• System Status Line: The left box indicates the specic command the Liberty

is currently executing. The current temperature and pressure readings are

displayed next to the command indicator. Two indicators shows the computer’s

communication status with the Liberty and the Discover. The waste full and spill

tray warnings are also seen here. On the right, there is an indicator that shows

whether the microwave is running.

22

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Page 25

Tabs

• Methods: From this tab, methods are loaded into one of the twelve resin

positions to be run.

• Queue: This tab shows all currently loaded Methods. From this tab, the order

that each Method is run in can be changed.

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

23

Page 26

• Current Run: This tab displays the Method that is currently running.

• Run History: From this tab, detailed logs of each Method that has been run can

be accessed. In addition, Method Reports can be generated for each Method

that has been run.

24

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Page 27

Editors

Microwave Editor

The Microwave Editor allows for the control and customization of the microwave steps of any

cycle. By editing the power and duration of a microwave step difcult peptides can be synthesized

with higher purity and yield.

The Microwave Editor can be accessed by clicking the Setup Button on the PepDriver main

screen and selecting Microwave Editor from the menu.

Microwave Method Folders

The Microwave Editor contains separate folders for each type of microwave method. Within each

method folder, there are subfolders for each scale, allowing for the development of optimized

microwave methods for each scale. A microwave method will only appear in the Cycle Editor

when creating a cycle of the same scale.

PepDriver comes with optimized default microwave methods for deprotection, coupling, capping,

and cleavage.

Microwave Method Types

• Standard: A Standard method applies a set microwave power until the set

temperature is reached, and then turns off the microwave until the temperature

drops to 5 °C below the set temperature. The total agitation time can also be

selected.

• Multi-Step: Multi-Step methods allow for a single microwave method to use

multiple power, temperature, or time settings.

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

25

Page 28

Creating a New Microwave Method

Microwave methods allow for detailed control of the microwave heating and reaction time for

each step in the synthesis. The Microwave Editor allows the user to select the microwave time,

microwave power, maximum temperature, and sample agitation.

Open the folder of the appropriate method type, then open the subfolder for the 1.

appropriate scale.

NOTE

A microwave method saved in a specic scale folder will only be available

for use in Cycle Editor for cycles created in the same scale folder.

Click the New Method button.2.

The new method will appear in the selected folder. Enter a name for the method 3.

and press Enter.

Select the type of microwave method to make.4.

4.1. Standard

Enter the desired 4.1.1. microwave power setting (in Watts), maximum

temperature (in °C), and time for the microwave step (in seconds).

If 4.1.2. agitation is desired during the microwave step, check the box for

Bubbling During Microwave. Enter the amount of time to bubble and

the time between each bubbling. (Bubbling is enabled by default.

The default setting is 3 seconds On Time, 7 seconds Off Time, low

pressure)

High Pressure bubbling is not recommended as this can deposit resin on the

top of the reaction vessel. This can lead to poor synthesis quality, product

loss, and contamination between syntheses.

26

Liberty™ Automated Microwave Peptide Synthesizer

CAUTION

600178 • Revision 5 • October 2009

Page 29

4.2. Multi-Step

Enter the microwave power (in Watts), time (in seconds), and 4.2.1.

maximum temperature (in °C) for the rst step in the method.

Add the next step to the microwave method by clicking the Add Step 4.2.2.

button, and then enter the power, temperature, and time settings for

the second step.

Repeat step 4.2.2. for each step in the method.4.2.3.

If 4.2.4. agitation is desired during the microwave step, check the box for

Bubbling During Microwave. Enter the amount of time to bubble and

the time between each bubbling. (Bubbling is enabled by default.

The default setting is 3 seconds On Time, 7 seconds Off Time, low

pressure.)

CAUTION

High Pressure bubbling is not recommended. Bubbling at high pressure

can deposit resin on the top of the reaction vessel. This can lead to poor

synthesis quality, product loss, and contamination between syntheses.

Save the method by clicking the Save button.5.

Editing an Existing Microwave Method

The Microwave Editor allows for settings on existing methods to be modied and saved as

needed. The most common reason to modify an existing method is to increase or decrease the

microwave power to optimize peptide synthesis. To modify an existing method:

Open the folder of the appropriate method type, then open the subfolder for the 1.

appropriate scale.

Click on the microwave method to be modied.2.

Make any changes as needed.3.

Click Save to save the changes to the method.4.

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

27

Page 30

Copying and Modifying an Existing Microwave Method

Often, it is easier to copy and modify an existing microwave method rather than creating an

entirely new method. Methods can easily be duplicated and modied within the Microwave

Editor, and then be moved to different scale folders as needed. To copy an existing method:

Open the folder of the appropriate method type, then open the subfolder for the 1.

appropriate scale.

Right click on a microwave method and select Copy Method.2.

The new method will appear named “Copy of (method name)”. Type a new name 3.

and press Enter.

Any settings in the method can be changed. If the copied method was a Multi-4.

Step method, steps can also be added or deleted by using the Add Step and

Delete Step buttons.

When all changes have been made, click Save to save the modied method.5.

If the new method is to be used at a different synthetic scale, drag the method 6.

from the folder it was created in to the appropriate folder.

Cycle Editor

The Cycle Editor allows for the full control and customization of any step of a synthesis. This

allows for optimization of each step of a given peptide synthesis.

The Cycle Editor can be accessed by clicking on the Cycles Button on the main screen of

PepDriver, or by clicking the Cycle Editor button from the Method Editor.

Cycle Folders

The Cycle Editor contains separate folders for each type of cycle. Within each cycle folder, there

are subfolders for each scale, allowing for the development of optimized cycles for each scale. A

cycle will only appear in the Method Editor when creating a method of the same scale.

28

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Page 31

PepDriver comes with optimized default cycles for resin transfer, amino acid addition, nal

deprotection, and cleavage for each of the available synthetic scales.

Cycle Types

• Resin: Resin cycles control how resin is transferred from the resin position into

the reaction vessel at the beginning of a synthesis, as well as the resin swelling

step.

• Amino Acid: Amino acid cycles control how the deprotection and coupling steps

of one amino acid in the sequence occur.

• Cleaving: Cleaving cycles control if and how the peptide is removed from the

resin following synthesis, including the return of either cleaved peptide to the

product position or peptide on resin to the resin position.

• Final Deprotection: Final deprotection cycles control the removal of the

N-terminal protecting group, and also allow for N-terminal acetylation of the

peptide before cleavage.

Creating a Cycle

Cycles allow for detailed control of each action taken in a given step of a peptide synthesis run.

PepDriver comes with default cycles of each type for each synthetic scale; however, cycles can

be customized to accomplish a number of non-standard chemistries. To create a new cycle:

Click the New Cycle button at the top of the Cycle Editor window and select the 1.

type of cycle to be created. For Amino Acid, Cleaving, and Final Deprotection the

synthesis scale must be selected.

NOTE

A cycle saved in a specic scale folder will only be available for use in

Method Editor for methods created at that scale.

The cycle will appear in the appropriate folder. Enter a name for the cycle and 2.

press Enter.

Step 1 will appear in the cycle window. 3.

Click the 4. Operation box and select the operation to be performed. (For a full list

of available operations, see Appendix 3: Operations in the Cycle Editor.)

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

29

Page 32

The default parameter and volume for the chosen operation will appear in the 5.

appropriate boxes. Click on the Parameter box to select a different parameter.

Click on the volume to enter the desired volume.

If the Drain box is checked, the reaction vessel will be drained using a ltered 6.

drain after the operation is carried out. Uncheck the box to leave any liquid

reagents in the vessel.

Enter the number of times the operation is to be carried out in the Cycles box.7.

If the 8. Pause box is checked, the method will be paused after the operation is

carried out. To insert a pause, check the box.

NOTE

The method will not resume until the user presses the Start button on the

main screen of PepDriver.

Click the Add Step button to add a new step to the cycle.9.

Repeat steps 3 through 9 until the cycle is fully programmed. 10.

Click Save to save the cycle.11.

Editing an Existing Cycle

The Cycle Editor allows for settings on existing cycles to be modied and saved as needed. To

modify an existing cycle:

Open the folder for the appropriate cycle type, then open the subfolder for the 1.

appropriate scale if necessary.

Click on the cycle to be modied.2.

Make any changes as needed.3.

Click Save to save the changes to the cycle.4.

30

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Page 33

Copying and Modifying an Existing Cycle

Often, it is easier to copy and modify an existing cycle rather that creating an entirely new cycle.

Cycles can easily be duplicated and modied within the Cycle Editor, and then they can be

moved to different scale folders as needed. To copy an existing cycle:

Open the folder of the appropriate method type, then open the subfolder for the 1.

appropriate scale if necessary.

Right click on a cycle and select Copy Cycle.2.

The new cycle will appear named “Copy of [cycle name]”. Type a new name and 3.

press Enter.

Any setting can be changed. Steps may be added or deleted as necessary using 4.

the Add Step and Delete Step buttons.

When all changes have been made, click Save to save the modied cycle.5.

If the new cycle is to be used at a different synthetic scale, drag the cycle from 6.

the folder it was created in to the appropriate folder.

NOTE

When copying a cycle to use with a different scale, verify that the volumes

used are appropriate for the new scale before using the cycle.

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

31

Page 34

Sequence Editor

Peptide sequences to be synthesized are entered in the Sequence Editor. The Sequence Editor

allows for the use of all twenty standard amino acids as well as the ve external amino acid

positions. In addition, the Sequence Editor will automatically calculate the total molecular weight

of the peptide sequence.

The Sequence Editor can be accessed by clicking on the Sequences button on the PepDriver

main screen, or by clicking the Sequence Editor button from the Method Editor.

Creating a New Sequence

Open the appropriate folder for the new sequence.1.

Click the New Sequence button.2.

The new sequence will be created in the selected folder. Enter a name for the 3.

sequence (the default is “New Sequence”) and press Enter.

The 4. amino acids for the sequence can be entered in two ways:

Click the amino acid buttons:4.1.

Click the white Sequence box at the bottom of the Sequence Editor.4.1.1.

Click the button corresponding to rst (N-terminal) amino acid. The 4.1.2.

one letter abbreviation will appear in the Sequence box.

Repeat step 4.1.2. for the remaining amino acids.4.1.3.

Type in the one letter abbreviations:4.2.

Click the white Sequence box at the bottom of the Sequence Editor.4.2.1.

Type the sequence (N-terminus to C-terminus) using the one letter 4.2.2.

abbreviations.

Click Save to save the sequence.5.

32

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Page 35

Modifying a Sequence

If a sequence is entered incorrectly, there are a few ways to correct the error.

To insert an amino acid:

Right-click on the amino acid that will come after the inserted amino acid.1.

Select Insert Amino Acid.2.

A box will pop up stating that the next amino acid entered will be inserted before 3.

the current amino acid. Click OK to close the box.

Click on the desired amino acid button or type the one letter abbreviation of the 4.

desired amino acid.

To delete an amino acid:

Right-click on the amino acid.1.

Select Remove Amino Acid.2.

To move an amino acid within a sequence:

Click on the amino acid to be moved.1.

Click the Move Left (<-Move) or Move Right (Move->) buttons at the bottom of 2.

the Editor window to move the amino acid one position in the indicated direction.

Repeat as needed until the amino acid is in the correct position.

Using the External Amino Acid Positions

There are ve external positions amino acid positions, labeled in the Sequence Editor as EX1

through EX5. The external amino acids can be used in a sequence by either clicking the

corresponding button or by typing the number of the external position into the sequence.

By default, the molecular weight of the external amino acids will not be included in the sequence

molecular weight calculation. To enable an external amino acid weight:

Click the MW box next to the appropriate external amino acid button. This will 1.

open the Amino Acid Weight conguration window for that position.

Check the Enable Ext Amino Acid Weights box.2.

Enter the protected and unprotected molecular weights for the amino acid being 3.

used.

Click OK. The Amino Acid Weight conguration window will close, and the 4.

unprotected weight will appear in the MW box next to the button.

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

33

Page 36

NOTE

The protected weight refers to the molecular weight of the fully protected

amino acid, and is used in the Reagent Calculator to determine how much of

the amino acid is required for the run.

The unprotected weight refers to the residue weight (the molecular weight

of the fully deprotected amino acid minus 18 g/mol due to the loss of water

from the formation of the peptide bond) and is used in the Sequence Editor

to calculate the total molecular weight for the nal peptide.

For example, Fmoc-Ala-OH has a protected weight of 312 g/mol, and a

residue weight of 71 g/mol:

312 (protected weight) - 223 (Fmoc) - 18 (water) = 71 (unprotected weight)

Importing a Sequence

PepDriver includes an option for importing sequences from external documents such as Microsoft

Word documents, PDF documents, or webpages. This is useful for longer sequences because it

minimizes the possibility of incorrectly entering the sequence.

Create a Microsoft Excel spreadsheet containing the sequence or sequences to 1.

be imported.

In Excel, create a new document.1.1.

In cell A1, enter the words SequenceImport (without a space between the 1.2.

words).

Highlight the sequence in the source document (PDF, webpage, etc.) and 1.3.

press Ctrl+C (or right-click and select Copy).

Paste the sequence into the rst open cell in column A of the Excel 1.4.

spreadsheet.

Enter a name for the sequence in column B.1.5.

Repeat steps 1.3 through 1.5 for any other sequences to be imported.1.6.

Save the le and close Excel.1.7.

NOTE

If using Excel 2007 or later, the le must be saved as an Excel 97-2003

compatible le (.xls, not .xlsx). The le name should be in English.

34

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Page 37

From PepDriver, open the Sequence Editor.2.

Click Import Sequence to open the Import window.3.

In the Import window, open the destination folder for the sequences.4.

Click Import. In the window that appears, select the Excel document created 5.

earlier and click Open.

The Import window will be updated to reect the successful import of the 6.

sequences. The imported sequences are now available for use in the Sequence

Editor and Method Editor.

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

35

Page 38

Method Editor

The Method Editor is used to program the specic conditions to be used for a given synthesis.

Once a sequence is selected, several options for the run can be congured that will determine the

specic steps to be used in the synthesis.

The Method Editor can be accessed by clicking the Methods button on the PepDriver main

screen, or by clicking the Method Editor button from the Sequence Editor.

Creating a New Method

Open the appropriate folder in the Methods box for the new method.1.

Click the New Method button.2.

Enter a name for the method and press Enter.3.

Open the appropriate folder in the Sequences box, and click on the desired 4.

sequence. The sequence will then be loaded into the sequence box at the bottom

of the Method Editor window.

Select the synthetic scale (0.05 mmol to 5.0 mmol) from the Resin Information 5.

box.

NOTE

The scale must be selected before changing any other parameters, as each

scale has specic default options that will be loaded upon selection.

The remaining options can now be selected.6.

Skip Resin Load: This will skip the initial loading of the resin into the 6.1.

reaction vessel. Select this option only if the resin has been placed directly

into the reaction vessel. This will also skip the resin swelling step.

36

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Page 39

C-Terminus: This corresponds to the type of resin used. Selecting 6.2. Acid

assumes the resin is preloaded (the rst amino acid is already attached)

and therefore skips that coupling. If the resin is not preloaded, Amide

should be selected.

6.3. Final Deprotection: If No Final Deprotection is selected, the N-terminal

Fmoc group will not be removed from the peptide prior to cleavage.

Default Cycles:6.4.

Resin: The resin loading cycle selected depends on the reaction 6.4.1.

vessel required for the synthesis.

NOTE

The 125 mL vessel must be used for syntheses above 0.25 mmol, and the

Large Vessel - Resin method should be selected.

The 10 mL vessel assembly must be used for syntheses below 0.1 mmol,

and the 10 mL Vessel - Resin method should be selected.

Cleaving: To cleave the peptide on the system automatically, select 6.4.2.

the Cleavage cycle. The cleaved peptide will be transferred to the

Product position on the Liberty. Selecting Non-Cleavage will skip

the cleavage step and return the peptide on resin to the same Resin

position from which the resin was loaded.

Final Deprotection: By default, the N-terminal Fmoc group is 6.4.3.

removed and left as the free amine. To perform N-terminal

acetylation, select the Acetylation method from the Final

Deprotection pull-down.

NOTE

Acetylation requires capping solution to be prepared and loaded on the

Liberty in the Capping bottle.

Enter the substitution value in the Resin Substitution box. This value is provided 7.

by the supplier of the resin, and is usually expressed in mmol/g or meq/g

NOTE

The substitution value entered here will not affect the operation of the

Liberty. It is only needed for the Usage Calculator to calculate how much

resin is required for the synthesis.

8. Assign cycles for each residue in the sequence that will not use the default cycle.

NOTE

Each amino acid is assigned an optimized default coupling cycle. By default,

the Double Arg cycle is used for arginine, and the Single 50 C cycle is used

for cysteine and histidine. The Single coupling cycle is used for all other

amino acids. To restore all amino acids in a sequence to the default cycles,

click the Restore Defaults button.

Click on the amino acid to highlight it.8.1.

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

37

Page 40

Click on the drop-down box above the sequence and select the desired 8.2.

cycle. This will change the cycle for that highlighted amino acid only.

To change the cycle for all amino acids to the selected cycle, click Apply to 8.3.

All button on the left.

Amino acids assigned cycles other than the default will be highlighted in

yellow in the Method Editor.

When the method is complete, click Save to save the method.9.

Modifying an Existing Method

Open the Method Editor.1.

Open the folder containing the method in the Methods window.2.

Click on the method to be modied. The sequence will automatically be selected 3.

and loaded.

Make any changes to the method as needed.4.

Click Save to save the changes to the method.5.

NOTE

38

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Page 41

Calculators

PepDriver contains two calculators that allow for easy determination of reagent needs and

reagent preparation: the Usage Calculator and the Reagent Calculator. These calculators are

accessed from the Calculator Button on the PepDriver main screen.

Usage Calculator

Once a method has been loaded to run, the Usage Calculator can be used to determine the

amount of each reagent needed. If multiple methods are loaded, the calculator can calculate the

amounts needed for all runs together, or each run individually. To use the Usage Calculator:

Load any methods to be run by dragging them to the appropriate resin positions 1.

(see p. 46).

Click on the Calculator button, and select Usage from the menu.2.

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

39

Page 42

The calculator will display the volume of each reagent required for all methods 3.

currently loaded. To exclude a loaded method from the calculation, uncheck the

box next to the method name in the Current Methods window.

To print a Usage Report, click the Print button at the bottom of the Usage 4.

Calculator. This will open the report as a PDF which can be printed or saved for

future reference.

Reagent Calculator

The Reagent Calculator can be used to determine how to prepare all reagents to be loaded

on the system at the correct concentrations. There are six tabs: Resin, Deprotectors, Bases,

Activators, Amino Acids, and Cleavage.

NOTE

The Reagent Calculator contains a library of common reagents. The Liberty

is not limited to only these reagents; however, the Reagent Calculator can

only perform calculations using reagents in the library.

Resin Calculator

Enter the scale for the synthesis.1.

Enter the resin substitution value in the Resin 2. Substitution box. This value is

provided by the supplier of the resin, and is usually expressed in mmol/g or

40

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Page 43

meq/g.

Click Calculate. The required mass of resin will be reported in the Grams of 3.

Resin box (in grams).

Deprotection Calculator

Click on the desired deprotection reagent from the list.1.

Enter the desired concentration (in percent volume).2.

The default concentration is 20%. Piperazine should be prepared at a 5%

solution due to its solubility in DMF.

CAUTION

Enter the total volume of deprotection solution required.3.

Click Calculate. The calculator will report the required amount of deprotection 4.

reagent in milliliters (for liquids) and grams (for solids).

Activator Base Calculator

Click on the desired base from the list.1.

Enter the desired concentration (in M)2.

The default concentration is 2 M. DIEA should be prepared using NMP as

the solvent because of its miscibility in DMF.

CAUTION

Enter the total volume of activator base solution needed.3.

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

41

Page 44

Click Calculate. The calculator will report the required amount of base in 4.

milliliters.

Activator Calculator

Click on the desired activator from the list.1.

Enter the desired concentration (in M). The default is 0.5 M.2.

Enter the total volume of activator solution needed.3.

Click Calculate. The calculator will report the required amount of activator in 4.

grams.

Amino Acid Calculator

To calculate a specic amino acid, click on that amino acid in the list so that it is 1.

highlighted and then click the Selected box. To calculate all amino acids at the

same volume, click the All box.

Enter the total volume of amino acid solution.2.

Click Calculate. The calculator will report the required amount of amino acid(s) in 3.

grams.

42

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Page 45

Cleavage Calculator

The Cleavage Calculator allows for the custom calculation of each scavenger and additive for

whatever cocktail will be best for a given peptide. To calculate how to make a cleavage cocktail:

Enter the total volume required for the method in the Total Volume box at the top 1.

of the calculator.

Click on the rst reagent to be used. Enter the desired nal percent of that 2.

reagent in the Percent box on the right.

The percent and volume of 3. TFA required will automatically be updated. Repeat

step 2 for the remaining scavengers.

The calculator will automatically update the amounts required for each reagent 4.

as changes are made. When all of the percentages are correct, the required

amount of each reagent to be added will be displayed in grams (for solids) and

mL (for liquids).

NOTE

CEM recommends using 95% TFA, 2.5% TIS, 2.5% DODT, and 2.5% water

as the cleavage cocktail.

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

43

Page 46

Setting up a Synthesis

Conguring Methods to Run

Loading a Method

Once a method has been created and saved in the Method Editor, it is available from the

Methods tab on the main PepDriver screen. Methods can be loaded to run in two ways.

To load by clicking:

Open the appropriate folder in the Methods tab.1.

Right-click on the desired method, select Place Method, and then select the 2.

number of the appropriate resin position.

The resin position in PepDriver will turn green, indicating the method is loaded 3.

and ready to run.

Methods can be loaded to any of the twelve resin positions. The order of

the resin positions does not affect the order in which the peptides will be

synthesized.

To load by dragging:

Open the appropriate folder in the Methods tab.1.

Click on the desired method, and drag the method to the appropriate resin 2.

position.

44

Liberty™ Automated Microwave Peptide Synthesizer

NOTE

600178 • Revision 5 • October 2009

Page 47

The resin position in PepDriver will turn green, indicating the method is loaded 3.

Reagent

Standard

Concentration

0.05 mmol Scale

Concentration

and ready to run.

Loading Multiple Methods

The Liberty is capable of running up to twelve peptide sequentially. When loading multiple

methods, the methods will be run in the order they were loaded. The run priority will be indicated

by the black number in the center of the resin position in PepDriver. The run priority can also be

viewed from the Queue tab.

To change the run priority:

Right-click on a green resin position and select Change Run Priority.1.

Select the new priority.2.

To remove a method from the queue, right-click on the green resin position and select Clear

Method. To empty the queue, right-click on a green resin position and select Clear All Methods.

Preparing Reagents

Standard Concentrations

The Liberty uses stock solutions of all reagents. The default cycles are designed to deliver

enough of each stock solution to give 5 eq of amino acid and activator and 10 eq of activator

base for each coupling. The table below details the standard concentrations used on the Liberty.

Activator 0.5 M 0.25 M

Activator Base 2 M 1 M

Amino Acid 0.2 M 0.2 M

NOTE

When working on 0.05 mmol scale, due to the size of the sample loops used

for reagent delivery, activator and activator base should be made at half the

standard concentration. Amino acids do not need to be diluted.

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

45

Page 48

Amino acid, activator, activator base, and deprotection solutions can be

used for up to two weeks. Some amino acids, notably His, will begin to

crash out of solution after two weeks.

Preparing Activator Solution

Weigh out the appropriate amount of the desired activator (as calculated using 1.

the Usage and Reagent Calculators) and transfer to a 250 mL amber glass

bottle.

Some activators, especially the aminium activators such as HBTU, are light

sensitive and should be prepared in an amber glass bottle.

Add the appropriate volume of DMF.2.

Put a cap on the bottle. Gently swirl the bottle to ensure that all of the activator 3.

has gone into solution.

Some activators, notably HBTU, may take up to 10 minutes to fully go into

solution.

NOTE

NOTE

NOTE

Preparing Activator Base Solution

Measure out the appropriate amount of activator base and transfer to a clear 250 1.

mL glass bottle.

Add the appropriate volume of NMP to give the correct nal volume.2.

NOTE

CEM recommends using DIEA as the activator base. When using DIEA,

NMP must be used as the solvent because DIEA is not miscible in DMF at

the standard concentration of 2 M. The nal concentration of DIEA in the

reaction vessel is low enough that miscibility is not an issue.

Put a cap on the bottle. Gently swirl the bottle to ensure all of the activator base 3.

has gone into solution.

Preparing Amino Acids

CEM offers a full line of pre-weighed amino acids in 5 mmol, 10 mmol, and 20 mmol sizes. It is

not required to use the pre-weighed amino acids.

To use CEM pre-weighed amino acids:

Open the bottles, breaking the safety seals.1.

Add the appropriate amount of DMF to each bottle (25 mL for 5 mmol bottles, 50 2.

mL for 10 mmol bottles, and 100 mL for 20 mmol bottles).

Replace the caps and shake vigorously to ensure all amino acid has gone into 3.

solution.

46

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Page 49

To use bulk amino acids:

Weigh out the appropriate amount of the amino acid as calculated using the 1.

Usage and Reagent Calculators.

Transfer the amino acid to a clean 125 mL plastic bottle.2.

NOTE

If the amino acid is to be used on one of the external positions, instead

transfer it to a 50 mL centrifuge tube.

Add the appropriate volume of DMF to the bottle.3.

Place a cap on the bottle and shake vigorously to ensure the amino acid has fully 4.

gone into solution.

Preparing Deprotection Solution

Measure out the appropriate amount of deprotection reagent as calculated using 1.

the Usage and Reagent Calculators.

Transfer the deprotection reagent to a 1 L clear glass bottle.2.

Add the appropriate volume of DMF to give the correct nal volume as calculated 3.

in the Reagent Calculator.

Add HOBt if necessary.4.

NOTE

For sequences susceptible to aspartimide formation, CEM recommends

the addition of 0.1 M HOBt to the deprotection solution as this signicantly

reduces levels of aspartimide. The appropriate mass of HOBt can be

calculated in the Reagent Calculator under the Activators tab. Enter the

total volume of deprotection and change the concentration to 0.1, then click

Calculate.

Place a cap on the bottle. Swirl the bottle gently to ensure the deprotection 5.

reagent (and HOBt, if used) has fully gone into solution.

Preparing Capping Solution

Capping is optional, and is not necessary for most routine syntheses. The capping bottle

does not need to be in place unless capping is being used in the method(s) being run. CEM

recommends using 0.5 M acetic anhydride in DMF with 0.125 M DIEA and 0.015 M HOBt. To

prepare capping solution:

Determine the total volume of capping solution needed using the Usage 1.

Calculator.

Calculate the amount of acetic anhydride needed. Measure out the appropriate 2.

amount and transfer to a 1 L glass bottle.

Use the reagent calculator to determine the volume of DIEA and mass of HOBt 3.

required. Measure out the appropriate amount of each and add to the acetic

anhydride.

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

47

Page 50

Add an appropriate amount of DMF to reach the correct nal volume.4.

Place a cap on the bottle. Swirl the bottle gently to ensure all reagents have fully 5.

gone into solution.

Preparing Cleavage Solution

Cleavage is optional. There does not need to be a bottle on the cleavage position unless

cleavage is being performed as part of the loaded methods.

Measure out the appropriate volume of TFA as calculated by the Reagent 1.

Calculator into a 250 mL clear glass bottle.

Add the appropriate volume of the remaining reagents as calculated by the 2.

Reagent Calculator.

Place a cap on the bottle and swirl gently to ensure all the reagents have fully 3.

gone into solution.

Setting up the Liberty

Loading Reagents onto the Liberty

NOTE

Reagent positions that are not used in a given run do not require dip tube

lters or bottles.

1. Load amino acids onto the Amino Acid Manifolds.

Ensure each dip tube to be used has a dip tube lter in place.1.1.

Remove the caps from each bottle of amino acid. Screw the bottle onto 1.2.

the designated position for that amino acid.

2. Load activator, activator base, and cleavage (if needed) onto the 3-Port Manifold.

Ensure each dip tube has a dip tube lter in place.2.1.

Remove the cap from each bottle. Screw the activator bottle into the top 2.2.

port on the manifold. Screw the activator base bottle into the center port

on the manifold. Screw the cleavage bottle (if needed) into the bottom port

on the manifold.

WARNING

TFA should only be connected to the Cleavage position. The use of TFA on

any other position will cause serious damage to the Liberty.

3. Load deprotection and capping (if needed) using the Change Bottle command.

(For more information about the Change Bottle command, see p. 65.)

Click on the Maintenance button in PepDriver and select Maintenance.3.1.

Select Deprotect from the pull-down box next to the Change Bottle button, 3.2.

then click Change Bottle.

48

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Page 51

The Change Bottle window will appear. Follow the onscreen instructions to 3.3.

depressurize and remove the existing bottle.

Ensure the dip tube has a dip tube lter in place, then screw the cap onto 3.4.

the deprotection bottle.

Click Next to continue with the Change Bottle procedure. The Liberty will 3.5.

automatically pressurize the bottle and ensure the lines are lled and ready

to add.

Repeat steps 3.1 through 3.5 for capping if needed.3.6.

Check the level of 4. DMF remaining in the DMF bottles. If more DMF is required,

use the Change Bottle command (p. 65) to replace the bottles.

NOTE

The two bottles of DMF should have approximately equal amounts of

solvent.

Click on the Maintenance button in PepDriver and select Maintenance.4.1.

Select Main Wash from the pull-down box next to the Change Bottle button, 4.2.

then click Change Bottle.

The Change Bottle window will appear. Follow the onscreen instructions to 4.3.

depressurize the existing bottles.

Slowly loosen one of the DMF bottle caps to release any residual pressure, 4.4.

then remove both caps.

Ensure each dip tube has a dip tube lter in place, then screw the caps 4.5.

onto the new solvent bottles.

Click Next to continue with the Change Bottle procedure. The Liberty will 4.6.

automatically pressurize the bottles and ensure the lines are lled and

ready to add.

Check the level of 5. DCM remaining in the DCM bottle. If more DCM is required,

use the Change Bottle command (p. 65) to replace the bottle.

Click on the Maintenance button in PepDriver and select Maintenance.5.1.

Select Secondary Wash from the pull-down box next to the Change Bottle 5.2.

button, then click Change Bottle.

The Change Bottle window will appear. Follow the onscreen instructions to 5.3.

depressurize and remove the existing bottle.

Ensure the dip tube has a dip tube lter in place. Ensure the o-ring inside 5.4.

the cap is secure, then screw the cap onto the DCM bottle.

Click Next to continue with the Change Bottle procedure. The Liberty will 5.5.

automatically pressurize the bottle and ensure the lines are lled and ready

to add.

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

49

Page 52

Loading Resin onto the Liberty

Use the Reagent Calculator to determine the amount of resin required for the 1.

synthesis.

Weigh the appropriate amount of dry resin into a clean 50 mL centrifuge tube.2.

NOTE

Some resins will cling to the sides of the tube. If necessary, wash the resin

from the sides of the tube using a small amount (less that 5 mL) of DCM.

Connect the resin tube onto desired position on the Resin Manifold.3.

If cleavage is being performed, connect a clean, empty 50 mL centrifuge tube 4.

onto the corresponding position of the Product Manifold.

Changing the Reaction Vessel

When working on large or small scales, the reaction vessel will need to be swapped out for one of

an appropriate volume. The large (125 mL) vessel is necessary for reactions of 0.5 mmol scale

or higher. The small (10 mL) vessel is necessary for reactions of 0.05 mmol scale or lower.

125 mL Reaction Vessel

Remove the 35 mL (Standard) reaction vessel from the microwave cavity.1.

Disconnect the ltered drain line from the vessel body.2.

Disconnect the vessel body from the attenuator.3.

Connect the 125 mL vessel body to the attenuator.4.

Connect the ltered drain line to the 125 mL vessel body, being careful not to 5.

crossthread or overtighten the tting.

Place the vessel back into the microwave cavity, securing the attenuator.6.

Perform a Reaction Vessel Leak Check (see p. 94).7.

10 mL Reaction Vessel

Remove the 35 mL (Standard) reaction vessel from the microwave cavity.1.

Carefully remove the temperature probe from the thermowell.2.

Disconnect the four lines from the manifold on the front of the Liberty.3.

Place the 10 mL vessel into the microwave cavity, securing the attenuator.4.

Connect the four line from the 10 mL vessel to the manifold on the front of the 5.

Liberty, ensuring each line is connected to the correct position.

Insert the temperature probe into the thermowell, ensuring the probe is inserted 6.

to the bottom of the thermowell.

Perform a Reaction Vessel Leak Check (see p. 94).7.

50

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Page 53

Running the Liberty

Preparing the Liberty to Run

Verify the level of the waste container to ensure there is sufcient room before 1.

starting another synthesis.

Verify the nitrogen supply to ensure there is sufcient nitrogen to complete the 2.

synthesis.

Verify that all amino acids required for loaded methods are loaded in the 3.

appropriate positions.

Verify that the resins are loaded into the positions corresponding to the correct 4.

methods in PepDriver, and that tubes are connected to the corresponding

product positions if cleaving.

Verify the levels of both wash solvents (DMF and DCM) to ensure there is 5.

sufcient solvent.

Verify that all sequences and methods are correct and that they are loaded in the 6.

correct positions.

Verify that the appropriate reaction vessel for the scale of the loaded methods is 7.

connected, and that the ber optic probe is fully inserted into the thermowell.

WARNING

If the probe is not inserted all the way to the bottom of the vessel the Liberty

will not accurately measure the temperature, and signicant overheating of

the vessel will occur. This will result in poor synthesis quality and/or serious

damage to the vessel.

Verify that the method is correct by looking at the steps outlined in the Method 8.

box. If there are any errors, make corrections and reload the method.

Right-click on the green resin position where the method was loaded and 8.1.

select Clear Method.

To correct the method:8.2.

Open the Method Editor. In the Methods box on the left, open the 8.2.1.

folder where the method was saved. Click on the method to load it.

Make any corrections as needed (see p. 38). 8.2.2.

Click Save the save the method, then close the Method Editor.8.2.3.

Load the corrected method as described above.8.2.4.

To correct the sequence:8.3.

Open the Sequence Editor. In the Sequences box on the left, open 8.3.1.

the folder where the sequence was saved. Click on the sequence to

load it.

Make any corrections as needed (see p. 33).8.3.2.

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

51

Page 54

Click Save to save the sequence, then close the Sequence Editor.8.3.3.

Open the Method Editor and correct the method as described above.8.3.4.

Running the Liberty

Click the Start button at the top of the PepDriver main screen.1.

If the Method is for 0.5 mmol scale or larger, a warning to verify that the 125

mL reaction vessel is connected will pop up. Verify the 125 mL vessel is

connected and then click OK to continue.

The Liberty will go through a series of initialization steps to ensure all valves are 2.

in the correct positions and that there is sufcient nitrogen pressure.

The rst method in the queue (indicated by a 1 inside the resin position on the 3.

main screen) will be loaded into the Current Run tab. The outline of the resin

position will turn yellow to indicate the method is running.

The Liberty will run a4. leak check on the reaction vessel to ensure the vessel is

properly connected. This option may be disabled from the Setup menu under

Options.

NOTE

The Liberty will perform a 5. sensor test to ensure all sensors are operational. This

option may be disabled from the Setup menu under Options.

Once all initialization and testing is complete, the Liberty will begin the Resin 6.

Loading step of the rst method.

During this step, solvent will be added to the resin tube and the resin will be

agitated with nitrogen bubbling to suspend it in solution before transferring to the

reaction vessel. This operation will be performed three times to ensure all resin

52

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

Page 55

is transferred to the reaction vessel.

The status of the peptide is displayed above the resin positions. In this example,

the resin was preloaded with Fmoc-Gly-OH, so the C-terminal Gly is already

shown on the resin bead with the Fmoc attached. The estimated time remaining

is indicated in the top right. The current step of the method is highlighted in

yellow in the Current Method Display.

The Liberty will enter a wait state for 15 minutes following resin transfer to allow 7.

the resin to swell. The time remaining (in seconds) will be displayed on the

System Status Line.

After the swelling step, the vessel will be drained. The resin will be rinsed 8.

several times, and then the Liberty will begin the deprotection step for the rst

coupling.

Once all couplings are completed, the Liberty will perform the nal deprotection if 9.

one was selected in the Method Editor.

Following nal deprotection (if selected), the Liberty will begin the cleavage cycle.10.

For methods with 10.1. cleavage:

The resin will be rinsed with DCM, and then cleavage cocktail will be 10.1.1.

added from the Cleavage position.

Following the cleavage step, the cleavage solution containing the 10.1.2.

free peptide will be transferred to the corresponding centrifuge tube

on the Product Manifold.

The Liberty will wash the reaction vessel, sending the spent resin out 10.1.3.

to waste.

The Liberty will perform a neutralization procedure on the reaction 10.1.4.

vessel to ensure no residual TFA will interfere with subsequent

syntheses.

The Liberty will perform a reaction vessel cleaning cycle.10.1.5.

For non-cleavage methods:10.2.

Solvent will be added to the reaction vessel followed by bubbling, 10.2.1.

and the resin will be transferred back to the resin tube from which

it was loaded. This will be repeated once to ensure all resin is

returned.

The Liberty will perform a reaction vessel cleaning cycle.10.2.2.

The resin position on the PepDriver main screen will turn blue, indicating the 11.

method was successfully completed.

If multiple methods are loaded, the Liberty will load the next method in the queue 12.

into the Current Run tab, and begin the resin loading cycle for that method.

Liberty™ Automated Microwave Peptide Synthesizer

600178 • Revision 5 • October 2009

53

Page 56

Generating Reports

Method Reports

Method reports record all settings selected in the Method Editor when creating the method.

Method reports are created as PDF les, which can be saved and printed to allow for easy

recording of experimental parameters.

A method report consists of two sections. The rst section contains information about the

synthesis parameters: the sequence with calculated molecular weight, the selected C-terminus

(acid or amide), the resin parameters (loading, scale), and a list of the cycles selected for each

residue in the sequence. The second section shows every cycle used in the method, including

the nal deprotection and cleavage cycles. This section includes a full outline of each cycle,

providing a record of exactly what was performed at each step.

Creating a Method Report

From the Method Editor: