Page 1

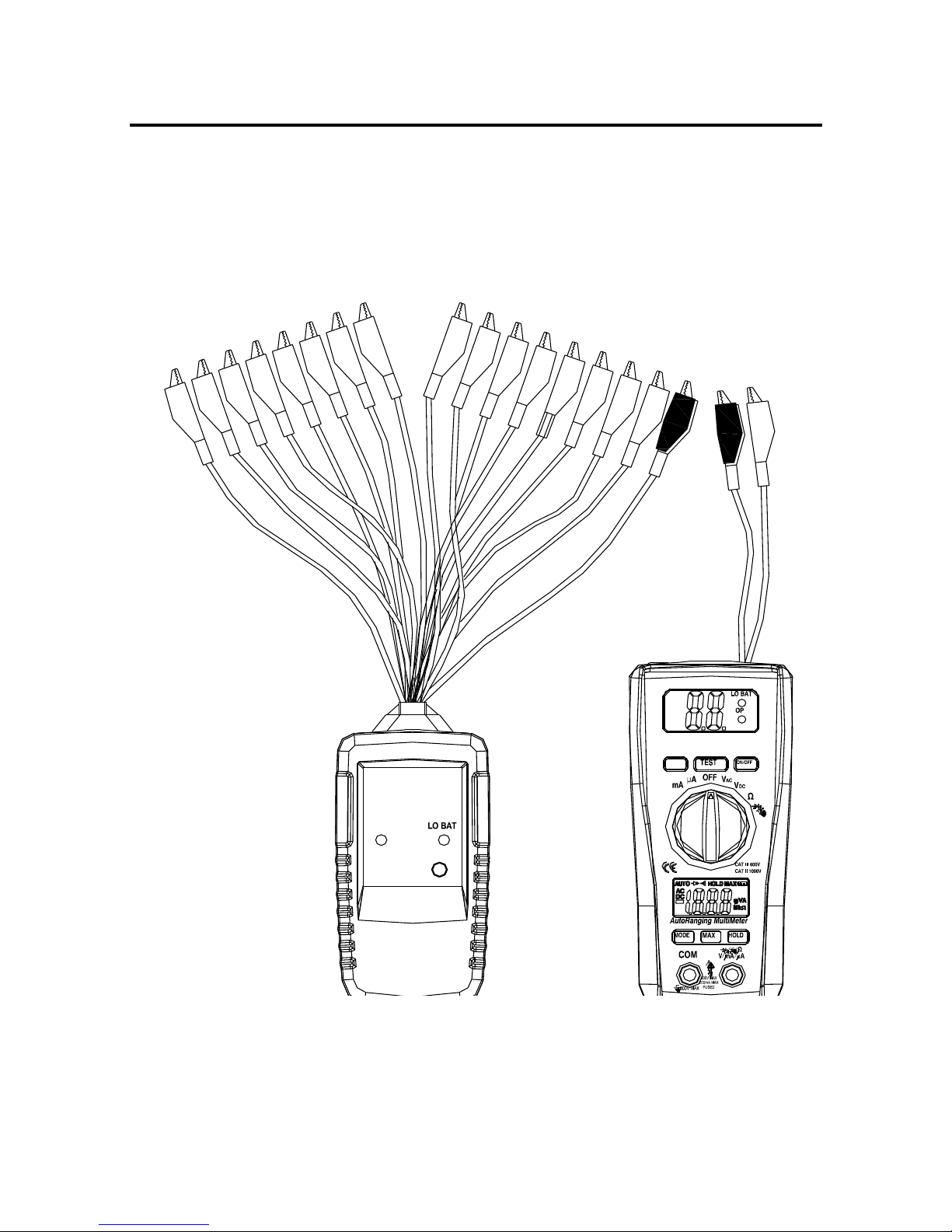

CABLE TESTER&DIGITAL MULTIMETER

Cable Identifier&DMM User’s Guide

OP

ON

CABLE TESTER

CABLE IDENTIFIER

CABLE TESTER

CABLE IDENTIFIER

Vcheck

Page 2

2

TABLE OF CONTENTS

1.APPLICATIONS GENERAL--------------------------------------3

2.FRONT PANEL DESCRIPTION---------------------------------3

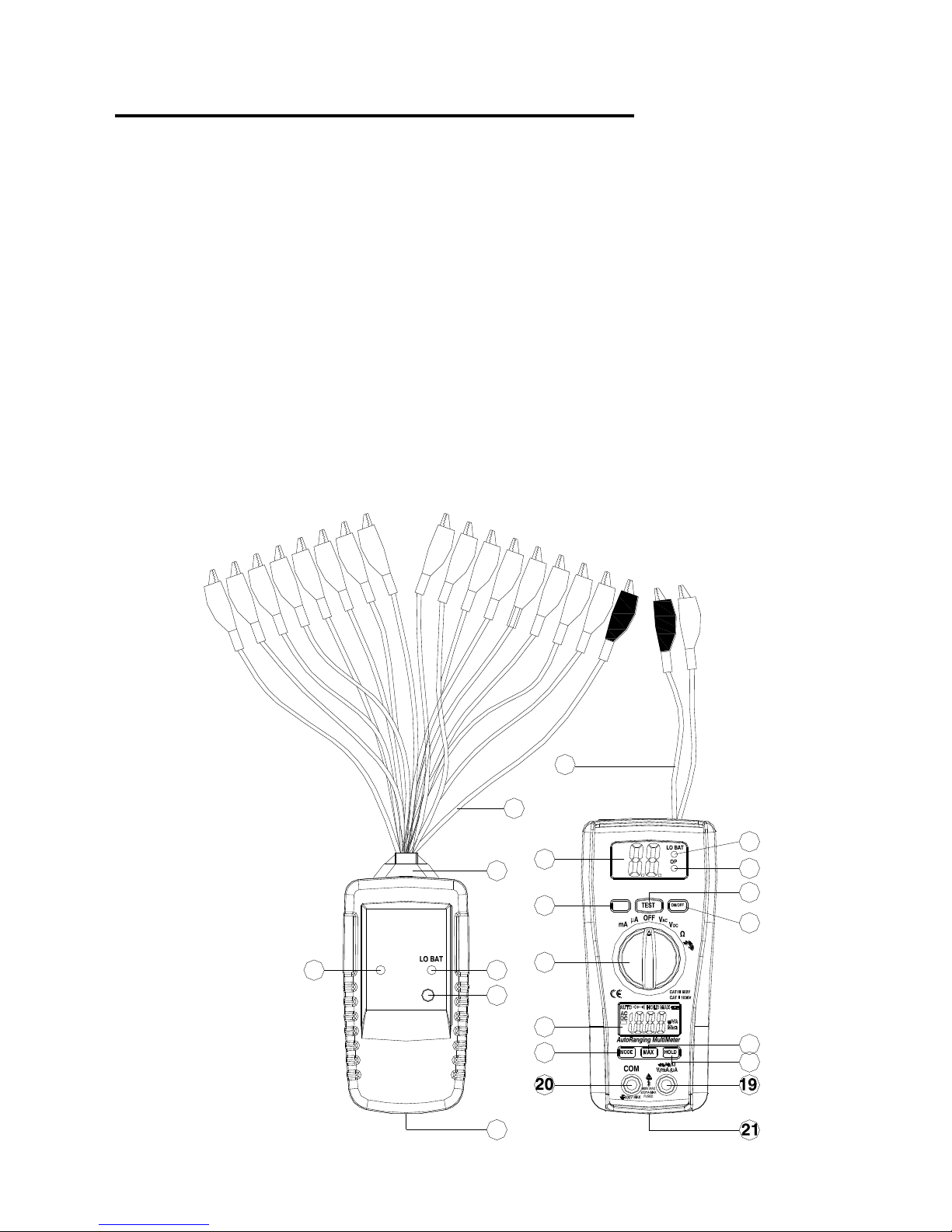

2.1 Transmitter Description---------------------------------------4

2.2 Receiver Description--------------------------------------------4

2.3 Digital Multimeter Description-------------------------------4

3. SPECIFICTIONS&TETHNICAL DATA------------------------4

3.1DMM----------------------------------------------------------- ----4-5

3.2Transmitter----------------------------------------------------------6

3.3 Receiver----------------------------------------------------- ------6

4.MEASURING PROCEDURE-------------------------------------7

4.1 Transmitter&Receiver operation-------- -------------------7

4.2 Beep alarm test-----------------------------------------------.---7

4.3 Voltage check------------------------------ ---------------------8

4.4 Digital Multimeter test--------------------------------------8-12

5.BATTERY REPLACEMENT------------------------------------12

Page 3

3

CABLE TESTER&DIGITAL MULTIMETER

Cable Identifier&DMM LA-1015

1.APPLICATIONS GENERAL

LA-1015 is a transmitter/receiver device which enbles

one person to instantly match up ends of indivdual

cores at either end of a multi-core cable .With the remote

kit it can tester cables installed far away either on wall

plate or patch panel .Digital multimeter function make it

easy to measure DC/AC voltage ,DC/AC current ,

Resist-ance,conTinuity &diode.

2.FRONT PANEL DESCRIPTION

OP

ON

CABLE TESTER

CABLE IDENTIFIER

CABLE TESTER

CABLE IDENTIFIER

Vcheck

1

2

3

4

5

6

8

12

14

15

17

7

9

10

11

13

16

18

Page 4

4

3. SPECIFICTIONS&TETHNICAL DATA

3.1 DMM:

Page 5

5

Function

Range

Accuracy

DC Voltage

200mV,

(0.5% rdg + 3d)

2.000V, 20.00V,

(1.0% rdg + 3d)

200.0V, 600V

(1.0% rdg + 3d)

AC Voltage

50-60Hz

2.000V, 20.00V

(1.0% rdg + 5d)

200.0V, 600V

(1.5% rdg + 10d)

DC Current

200.0µA, 2000µA

(1.5% rdg + 3d)

20.00mA, 200.0mA

(2.0% rdg + 3d)

AC Current

200.0µA, 2000µA

(1.8% rdg + 8d)

20.00mA, 200.0mA

(2.5% rdg + 8d)

Resistance

200.0

(0.8% rdg + 5d)

2.000k , 20.00k ,

200.0k

(1.2% rdg + 3d)

2.000M

(2.0% rdg + 5d)

20.00M

(5.0% rdg + 8d)

Max input voltage 600V AC/DC

Diode Test Test current 1mA max., open circuit

voltage of 1.5V typical

Continuity Check Audible signal if the resistance is <150

Display 2000 count 3 -1/2 digit LCD

Over range indication

LCD displays “OL”

Polarity Minus (-) sign for negative polarity.

Low Battery Indication “BAT” symbol

indicates low battery condition.

Input Impedance >7.5MΩ (VDC & VAC)

AC Response Average responding

ACV Bandwidth 50Hz to60Hz

Page 6

6

Auto Power Off 15 minutes (approximately)

Fuse mA, µA ranges; 0.2A/250V fast acting

Fuse

Batteries 9V battery and two “AAA” batteries

Operating Temperature 32oF to 104oF (0oC to 40oC)

Storage Temperature 14oF to 122oF (-10oC to 50oC)

Weight 308g

Size 162x74.5x44.0mm

Standard IEC61010-1 CAT III-600V Pollution degree II,

CE Approved

3.2 Transmitter:

Display Two red LED lamps

Aligators 17Croc clips-red*16,black*1

Cable resistance 30K Ohm max

Power 9V battery

Power current 1.8mA

Operating temperature 0℃ to 40℃(32℉ to 104℉)

Storage temperature –10℃ to 50℃(14℉ to 122℉)

3.3 Receiver:

Display Two digit blue LED display

Aligators 2Croc clips-red*1,black*1

Power 9V battery

Power current 23mA

Operating temperature 0℃ to 40℃(32℉ to 104℉)

Storage temperature –10℃ to 50℃(14℉ to 122℉)

Continuity test Beep if less than 100Ω

Page 7

7

Cable voltage check 5V to 16V DC

4.MEASURING PROCEDURE

4.1 Transmitter&Receiver operation

1).At one end of the cable, Connect one of the transmitter

terminals marked “CH1 to CH16”to each core of the cable

under tester.Connect the “COM”reference lead (black

alligator) of the transmitter to a core which is the only known

one.

2).At the other end of the cable ,connect the “COM

terminal”(black alligator) of the receiver.

When the “input terminal”(red alligator) of the receiver is

successively touched on the cores of the cable under test,the

relevant number of the way is indicated on the display of the

receiver(1-16).

Operation example 1: Cable trace test

Operation example 2: Metal water pipe trace test

CAUTION: Though the units already build in the

protection circuit,however do not apply voltage that over

50V(AC or DCV)toany alligator clips of

transmitter&receiver. Otherwise the instruments may

defect permanently.

4.2 Beep alarm test : “TEST”button to down use receiver of

2Croc clips connect cable of two port if cable is put through

will have beep sound.otherwise cable isn’t put through or isn’t

same a cable.

CAUTION: Beep if less than 100Ω

Page 8

8

4.3 Voltage check: “V check” button to down use receiver

of 2Croc clips.Black alligator connect the “COM”reference

other red alligator connect the cable port .if Two digit blue

LED display is “ UU ” prove cable have voltage .only check is

mainly voltage.

CAUTION: Check voltage range at 5V to 16V DC

4.4 Digital Multimeter test

AC/DC VOLTAGE MEASUREMENTS

1).Insert the black test lead into the negative COM terminal

and the red test lead into the positive V terminal.

2).Set the function switch to VAC or VDC position.

3).Connect the test leads in parallel to the circuit under test.

4).Read the voltage measurement on the LCD display.

CAUTION: Do not measure AC/ DC voltages if a motor

on the circuit is being switched ON or OFF. Large voltage

surges may occur that can damage the meter.

AC/DC CURRENT MEASUREMENTS

1).Set the function switch to the µA/mA position.

2).Insert the black test lead into the negative COM terminal

and the red test lead into the positive µA/mA terminal.

Page 9

9

3).For current measurements up to 2000µA DC/AC, set the

function switch to the mA position

4).Press the MODE button to indicate “DC” / “AC” on the

display.

5).Remove power from the circuit under test, then open up

the circuit at the point where you wish to measure current.

6).Touch the black test probe tip to the negative side of the

circuit.

Touch the red test probe tip to the positive side of the circuit.

7).Apply power to the circuit.

8).Read the current in the display

RESISTANCE MEASUREMENT

1).Set the function switch to the Ω position.

2).Insert the black test lead into the negative COM terminal

and the red test lead into the positive Ω terminal.

3).Touch the test probe tips across the circuit or part under

test. It is best to disconnect one side of the part under test so

the rest of the circuit will not interfere with the resistance

reading.

4).Read the resistance in the display

Page 10

10

WARNING: To avoid electric shock, disconnect power to

the unit under test and discharge all capacitors before

taking any resistance measurements. Remove the

batteries and unplug the line cords.

CONTINUITY CHECK

1).Set the function switch to the position.

2).Insert the black test lead into the negative COM terminal

and the red test lead into the positive Ω terminal.

4).Touch the test probe tips to the circuit or wire you wish to

check.

5).If the resistance is less than approximately 150Ω, the

audible signal will sound. If the circuit is open, the display will

indicate “OL”.

WARNING: To avoid electric shock, never measure

continuity on circuits or wires that have voltage on them.

DIODE TEST

1).Set the function switch to the position.

2).Press the MODE button to Touch the test probes to the

diode

Page 11

11

indicate on the display. under test. Forward voltage

will typically indicate 0.400 to 0.700V. Reverse voltage will

indicate “OL”. Shorted devices will indicate near 0V and an

open device will indicate “OL” in both polarities

MAX Hold button

To hold the highest reading on the LCD

1).Press the MAX hold button. The meter reading will not

change as readings change

2). Press the MAX hold button again to return to normal

operation.

Hold Button

The Data Hold function allows the meter to “freeze” a

measurement for later reference

1).Press the “DATA HOLD” button to “freeze” the display, the

“HOLD” indicator will appear.

2).Press the “DATA HOLD” button to return to normal

operation.

AUTO POWER OFF

The auto off feature will turn the meter off after 15

minutes.

REPLACING THE FUSES

1).Disconnect the test leads from the meter.

Page 12

12

2).Remove the protective rubber holster.

3).Remove the battery cover (two “B” screws) and the

battery.

4).Remove the four “A” screws securing the rear cover.

5).Lift the center circuit board straight up from the connectors

to gain access to the fuse holders.

6).Gently remove the old fuse and install the new fuse into the

holder.

7).Always use a fuse of the proper size and value (0.2A/250V

fast blow for the 200mA range).

8).Align the center board with the connectors and gently

press into place.

9).Replace and secure the rear cover, battery and battery

cover.

WARNING: To avoid electric shock, disconnect the test leads

from any source of voltage before removing the fuse cover.

5. BATTERY REPLACEMENT

1). Both for the transmitter or receiver,when the “Low

battery indicator” is lit,it is necessary to replace the

battery.Measur-

Ements may still be made several hours after the low

battery indicator

Page 13

13

2).Remove the bottom cover and secure the screw.

3).Replace old battery with fresh two 1.5V AAA or 9V type

batery.

4).Replace the bottom cover and secure the screw.

Loading...

Loading...