Page 1

iPrep

®

High Performance Vessels

Manual

Page 2

THIS PAGE INTENTIONALLY LEFT BLANK

Page 3

Contents

Safety Notations

Safety Notations 1

Introduction

About the iPrep Vessels 2

Important Safeguards

Operating Parameters 3

Sample Preparation Safeguards 3

Vessel Safeguards 4

Microwave Safeguards 4

Compounds Unsuitable for Closed Vessel Microwave

Digestion 5

Vessel and Accessories Overview

Vessel Components 6

Accessories 7

New Liner and Plug Conditioning

Routine Maintenance

After Every Use 22

Monthly 22

Annually 22

Bake-out Procedure 22

Troubleshooting

Problems and Possible Solutions 23

Nitric Acid Liner and Plug Conditioning 8

Non-Nitric Acid Liner and Plug Conditioning 9

Perform a Digestion

Vessel Assembly 10

Turntable Setup 13

Load and perform a Method 14

Vessel Removal 14

Vessel Cleaning and Inspection

Liners and Plugs 17

Liner and plug Bake-out Procedure 17

Turntable, Frame, Load Disc, Screw & Racks 18

Sleeves 18

Vessel Distribution

12 Place Turntable 19

16 Place Turntable 20

Methods

Create a One Touch Method 21

Create a Classic Method 21

Page 4

THIS PAGE INTENTIONALLY LEFT BLANK

Page 5

Safety Notations

Safety Notations

This manual uses three safety alert words at points in the documentation where the user should be aware of

potential hazards. The safety alerts are shown in color-coded boxes. The three words–NOTE, CAUTION, and

WARNING–indicate differing levels of observation or action as described below:

NOTE

A NOTE is intended to provide emphasis of procedures that may be misinterpreted or overlooked, or to

otherwise clarify confusing situations.

CAUTION

A CAUTION is intended to provide essential information and to emphasize procedures which, if not strictly

followed, may result in improper instrument operation.

WARNING

A WARNING is intended to emphasize dangerous or hazardous conditions which may result in personal

injury to the user and damage the instrument.

1Safety Notations

Page 6

Introduction

About the iPrep Vessels

The iPrep vessel is designed for microwave digestion in a MARS 6

is well suited for digestion of difcult matrices such as waste oils, APIs with multiple aromatic rings, polymers, and

geological samples. This vessel is also a great option when digesting 1 g or larger samples due to ppt detection

limit needs. Preinstalled methods take the guesswork out of method creation and sample preparation.

The MARS 6 requires the iWave temperature control with software version 1.43 or higher to operate iPrep vessels.

This Manual should be used in conjunction with the MARS 6 iWave Manual, PN 600832. Read and fully

understand all documentation before operating the instrument.

TM

with iWave®temperature control. This vessel

2 Introduction

Page 7

Important Safeguards

Microwave sample preparation imposes a unique set of safety considerations beyond the basics of good laboratory

practice. Additional Safeguards for the MARS 6 instrument are included in the manual, PN 600832. General

guidelines for safe operation of the iPrep are presented below and all specic safety messages are located

throughout the manual.

Proper precautions must be taken to avoid contact with reagents or reagent vapors. Protective gear should be worn

as outlined in the user’s safety program for hazardous materials and the reagent manufacturer’s safety data sheet.

Refer to these guidelines for proper handling and disposal of the reagents.

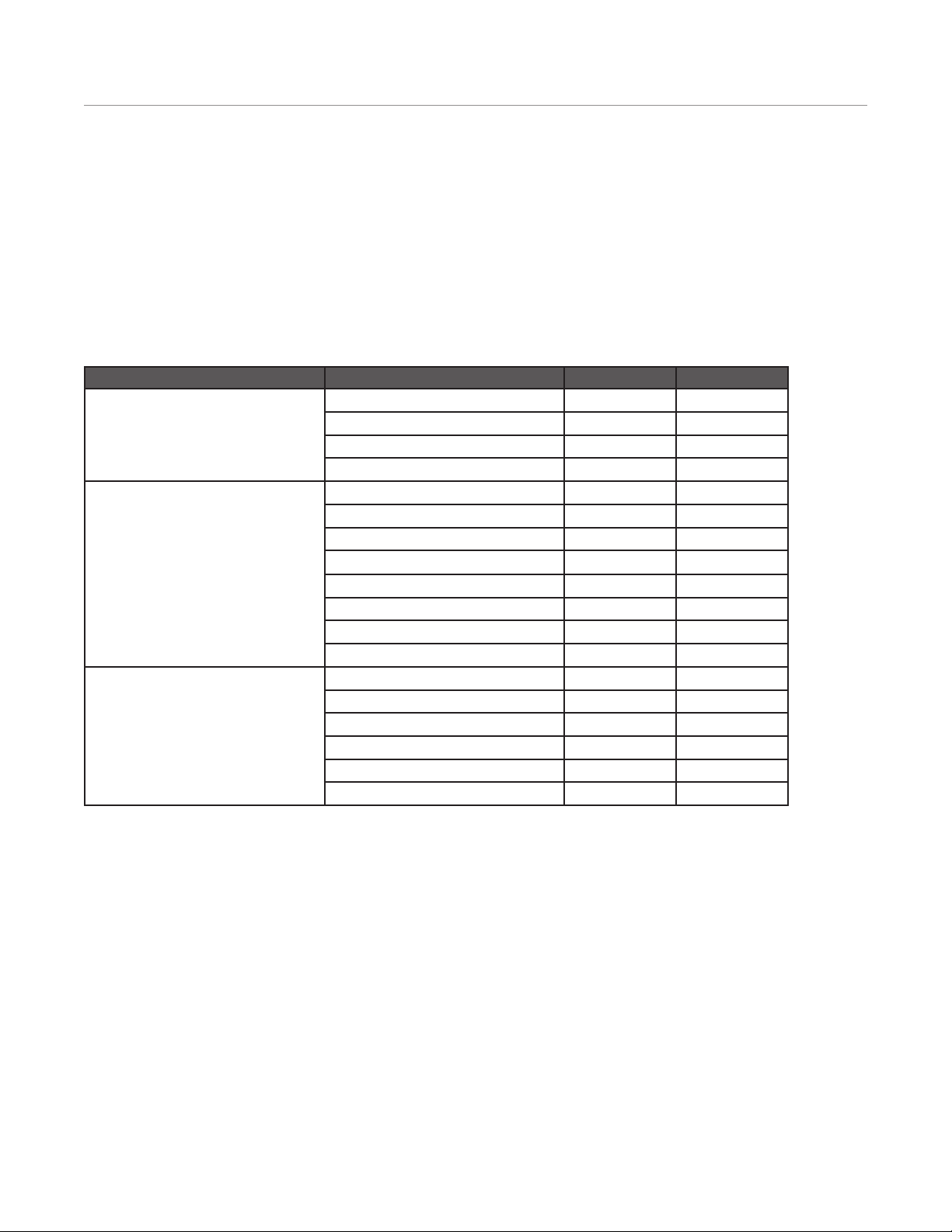

Operating Parameters

iPrep 12 iPrep 16

iPrep Parameters Minimum Volume 5 mL 5 mL

Maximum Volume 30 mL 30 mL

Maximum Pressure 1500 psi 1500 psi

Maximum Hold Time 45 min 45 min

Maximum Temperature Maximum Programmable Temperature 300 ºC 300 ºC

Nitric Acid 250 ºC 250 ºC

Hydrochloric Acid* 250 ºC 250 ºC

Hydrouoric Acid* 250 ºC 250 ºC

Sulfuric Acid 300 ºC 300 ºC

Phosphoric Acid 300 ºC 300 ºC

Aqua Regia* 250 ºC 230 ºC

Water 180 ºC 180 ºC

Maximum Sample Weight Food, Plant, and Animal Tissue 1.5 g 1.5 g

Oil and Plastic 0.5 g 0.5 g

Pharmaceutical 1.5 g 1.5 g

Inorganic 1.5 g 1.5 g

Metallurgical 1.5 g 1.5 g

Clinical 1.5 g 1.5 g

* The maximum achievable temperature is 210 °C if running more than 6 vessels.

Sample Preparation Safeguards

• Do not use water to dilute the acid(s) greater than 25% when running over 220 ºC or to add volume before

digestion. This can cause uneven heating of vessels

• Run similar sample types with the same acid(s) and acid volume in each vessel

• Optimal Sample Volume is 10mL and will result in more even heating

• Minimum acid volume is 5 mL

• Maximum volume is 30 mL

• Maximum sample weight varies per sample type. See "Operating Parameters" for weights

• Acid blanks cannot account for more than 25% of turntable when mixed with samples

• Acid blanks cannot be run with organic samples > 230 °C

• Acid blanks cannot be run with samples when acid mixtures are > 50% hydrouoric acid. Acid blanks must

be run separately

3Important Safeguards

Page 8

Vessel Safeguards

• Only use vessels and vessel components purchased directly from CEM or through its authorized dealer

network.

• All vessel components must be dry prior to use

• Always condition new liners and plugs

• Do not batch old liners with new liners unless new liners have been conditioned with at least 3 runs using

the customer’s sample

• Ensure vessels are assembled properly

• Align tab on load disc in center notch of liner

• Look for vent hole through the frame

• Align liner properly on insulator disc at bottom – liner ush with tab

• Use torque block

• Invert sleeves after every run to extend lifetime and promote better sealing & even heating

• Slide liner into the end of the sleeve with most resistance felt if unsure which side was previously

used

• CEM recommends using a high temperature pen to mark sleeves for a visual reference.

• Try to group liners with similar sample history and usage

• Segregate liners for HNO3 and non-HNO3 applications

• Do not use a new liner with a set of liners that has been run consistently until the new liner has

been conditioned with that sample type

• Pull ones that run 20 ºC hotter than average and run them together

• Bake out liners and plugs to remove residual HNO3 & NOx gases

• Use Bake Out procedure for iPrep vessels (210 °C for 6 hrs – overnight)

• Bake out liners if TempGuard

TM

is triggered

Microwave Safeguards

• Always use the TempGuard feature in the method

• Set the TempGuard limit at 30 °C > control temperature if control temperature is < 250 °C.

• Set the TempGuard limit at 20 °C > control temperature if control temperature is > 250 °C

• Limit TempGuard to 270 °C for digestion of organics with HNO3 (primarily)

• Limit TempGuard to 300 °C for H3PO4/H2SO4 (primarily) applications

• Limit control temperature of organics with HNO3 to 250 °C

• Choose Sample Type in method with software version 1.45 or higher as follows:

• Standard = Any acid mixture other than HCl or HF dominant

• HCl = aqua regia or acid mixtures that are ≥ 75% HCl

• Always use the Max Power Monitor and set the alarm time for 10 minutes

• Maximum programmable temperature is 300 °C

• Maximum temperature varies per acid. See "Operating Parameters" for temperatures

• Maximum programmable Hold Time is 45 minutes

• If a run is stopped or paused for more than 30 seconds during the digestion, do not restart the method

with hot vessels

• Allow vessels to cool < 80 °C

• Vent vessels and reseal

• Restart method from the beginning

• Allow vessels to cool below 80 ºC before opening the microwave door.

4 Important Safeguards

Page 9

Compounds Unsuitable for Closed Vessel Microwave Digestion

WARNING

CEM will not be responsible for damage to equipment and facilities or personal injuries resulting from

microwave digestion of samples that are deemed unsuitable for closed vessel microwave digestion.

Acid decomposition of certain chemical compounds or types of samples constitutes unreasonable, hazardous

misuse of CEM microwave digestion systems. The classes of compounds listed below are unsuitable for closed

vessel microwave digestion because they are highly reactive with oxidizing acids and/or may become nitrated and

potentially explosive. Absence of a particular chemical compound from this list does not imply microwave acid

decomposition of such a sample is safe under all conditions.

• Explosives (TNT, Nitrocellulose, etc.)

• Propellants (Hydrazine, Ammonium Perchlorate, etc.)

• Pyrophoric chemicals

• Hypergolic mixtures (Nitric Acid and Phenol, Nitric Acid and Triethylamine, Nitric Acid and Acetone,

etc.)

• Animal Fats (Esters of glycerol capable of nitration and the formation of nitroglycerin or other nitrated

organic compounds)

• Aviation Fuels (JP-1, etc.)

• Acetylides

• Glycols (Ethylene Glycol, Propylene Glycol, etc.)

• Perchlorates (Ammonium, Potassium, etc.)

• Ethers (Cellosolve - Ethylene Glycol Phenyl ether, etc.)

• Lacquers

• Alkanes (Butane, Hexane, etc.)

• Ketones (Acetone, Methyl Ethyl Ketone, etc.) and alcohols (methanol, etc.)

5Important Safeguards

Page 10

Vessel and Accessories Overview

For a list of parts and part numbers, visit our website at www.cem.com. A list of parts can be found on the

“Products” page under “MARS 6”.

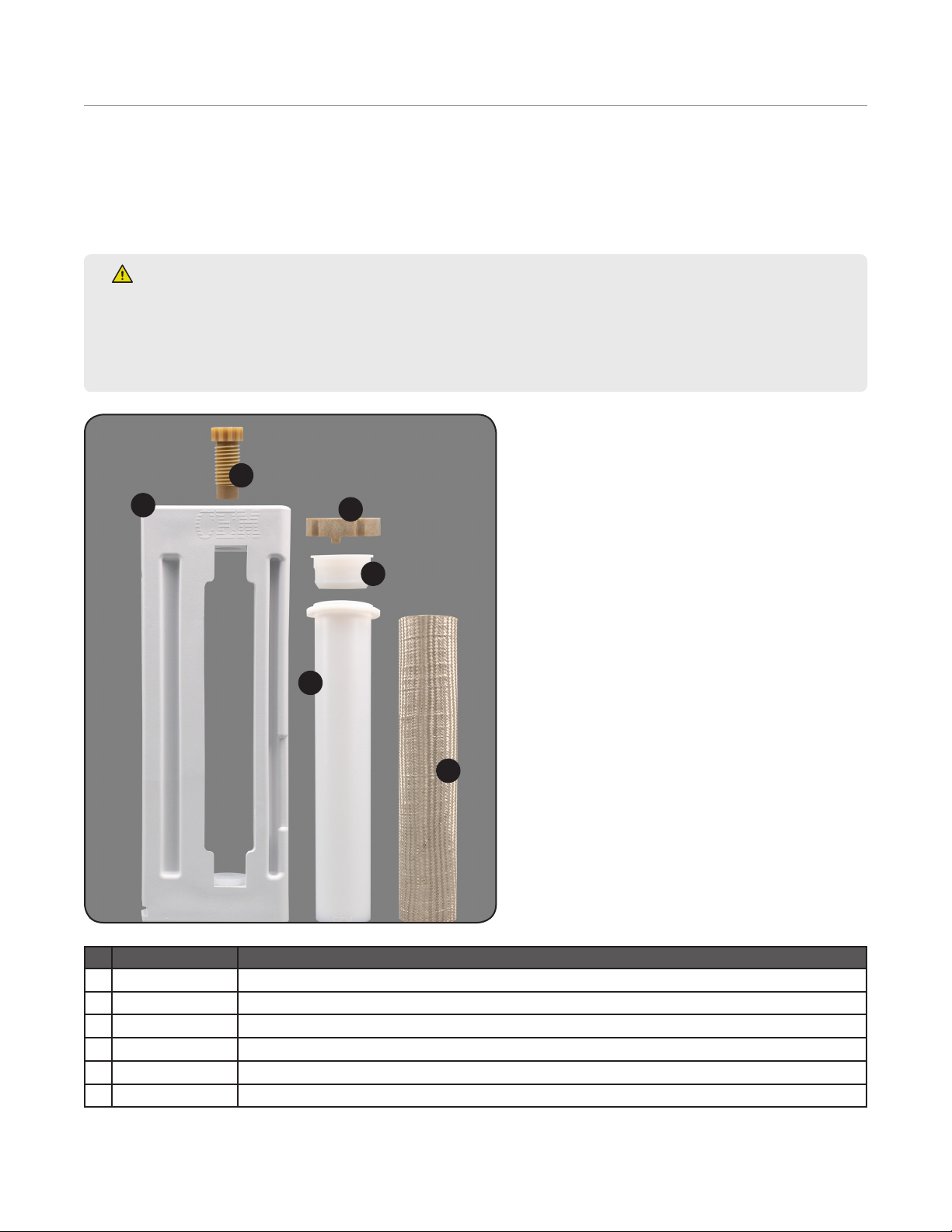

Vessel Components

WARNING

Only use vessels and vessel components purchased directly from CEM or through its authorized dealer

network. The use of vessels and vessel components other than original CEM parts will put operators and

equipment at risk; therefore, CEM will not assume any liability for use of these parts and all warranties,

either written or implied, will immediately become void.

6

1

3

5

4

2

Item Description

1 Frame Module Supports sleeve, load disc, vessel liner, plug and screw

2 Sleeve Supports vessel liner

3 Load Disc Evenly distributes load from plug

4 Vessel Liner Contains acid and sample. 110 mL Liner (5 -30 mL working volume)

5 Plug Seals liner to contain acid and sample

6 Frame Screw Uniformly provides pressure seal among vessels when torqued

6 Vessel and Accessories Overview

Page 11

Accessories

3

4

5

1

Item Description

1 Torque Tool Provides appropriate vessel seal. Includes plug removal tool

2 Vessel Liner Holder Holds up to a set of 16 vessel liners

3 12 Place Turntable Holds assembled vessels inside MARS 6 cavity and provides rotation

4 16 Place Turntable Holds assembled vessels inside MARS 6 cavity and provides rotation

5 Frame Carrier Holds up to 4 assembled vessels

2

7Vessel and Accessories Overview

Page 12

New Liner and Plug Conditioning

All new liners and plugs should be conditioned as a set prior to being put into service. The break-in procedure is

used to condition the Teon® to ensure a proper seal. CEM recommends conditioning the plugs and liners based

on the acid type that will be used: HNO3, HCl, H2SO4, H3PO4, HF. Aqua Regia, or H2O2.

Nitric Acid Liner and Plug Conditioning

1. Use hot soapy water and foam brush to clean the liners and plugs. Rinse thoroughly with DI water and allow to

dry completely before use.

NOTE

Micro 90 Cleaner® liquid detergent works well on Teon. Avoid detergents that contain ingredients that

could cause potential contamination such as Na and P. Avoid abrasive cleansers and stiff brushes which

can scratch the Teon surface.

2. Place 0.25 g ± 0.05 g of tea leaves or appropriate sample into each liner. Never add sample or liquid to liner

with sleeve in place.

WARNING

Proper precautions must be taken to avoid contact with reagents or reagent vapors. Protective gear should

be worn as outlined in the user’s safety program for hazardous materials and the reagent manufacturer’s

safety data sheet. Refer to these guidelines for proper handling and disposal of the reagents.

3. Add 10 mL of HNO3 to each liner. Use the acid to rinse the inside of the liner to ensure that the sample is in

the base of the liner.

4. Wait 15 minutes to allow pre-digestion.

5. Assemble and torque each vessel. See “Vessel Assembly” for detailed instructions.

6. Place the turntable into the MARS 6 cavity and symmetrically distribute vessels. See “Turntable Setup” and

"Vessel Distribution" for detailed instructions.

7. Select and load the “Plant Material” method from the One Touch directory.

8. Close the instrument door and run the preprogrammed “Plant Material” method.

9. After completion of the method, permit the vessels to cool in the automated sequence until the vessels cool to

below 80 ºC.

WARNING

Allow vessels to cool below 80 ºC before opening the microwave door.

To prevent the possibility of severe burns, ensure that gloves and protective gear as outlined in your safety

program are worn.

10. Remove the vessel assemblies from the turntable. See "Vessel Removal" for detailed instructions.

11. If the normal method temperatures are greater than 230 °C AND new liners will be mixed with old liners, the

new liners will need to be conditioned three times using the method that exceeds 230 °C before mixing in.

12. Rinse the liners and plugs with deionized water.

8 New Liner and Plug Conditioning

Page 13

Non-Nitric Acid Liner and Plug Conditioning

1. Use hot soapy water and foam brush to clean the liners and plugs. Rinse thoroughly with DI water and allow to

dry completely before use.

NOTE

Micro 90 Cleaner® liquid detergent works well on Teon. Avoid detergents that contain ingredients that

could cause potential contamination such as Na and P. Avoid abrasive cleansers and stiff brushes which

can scratch the Teon surface.

2. Place 0.25 g ± 0.05 g of your sample into each liner. Never add sample or liquid to liner with sleeve in place.

WARNING

Proper precautions must be taken to avoid contact with reagents or reagent vapors. Protective gear should

be worn as outlined in the user’s safety program for hazardous materials and the reagent manufacturer’s

safety data sheet. Refer to these guidelines for proper handling and disposal of the reagents.

3. Add 10 mL of the digestion acid to each liner. Use the acid to rinse the inside of the liner to ensure that the

sample is in the base of the liner.

4. Wait 15 minutes to allow pre-digestion.

5. Assemble and torque each vessel. See “Vessel Assembly” for detailed instructions.

6. Place the turntable into the MARS 6 cavity and symmetrically distribute vessels. See “Turntable Setup” and

"Vessel Distribution" for detailed instructions.

7. Select and load the “Easy Prep Clean” method from the One Touch directory.

8. Close the instrument door and run the preprogrammed “Plant Material” method.

9. After completion of the method, permit the vessels to cool in the automated sequence until the vessels cool to

below 80 ºC.

WARNING

Allow vessels to cool below 80 ºC before opening the microwave door.

To prevent the possibility of severe burns, ensure that gloves and protective gear as outlined in your safety

program are worn.

10. Remove the vessel assemblies from the turntable. See "Vessel Removal" for detailed instructions.

11. Rinse the liners and plugs with deionized water.

NOTE

When using HCl, if a dark ring appears in liner, use hot soapy water and foam brush to clean. Rinse

thoroughly with DI water and allow to dry completely before use.

9New Liner and Plug Conditioning

Page 14

Perform a Digestion

Vessel Assembly

CAUTION

Never add sample or liquid to liner with sleeve in place. Use the vessel liner holder.

1. Place liners in vessel liner holder. All vessel components must be dry prior to use.

2. Add sample to the liner(s).

WARNING

Proper precautions must be taken to avoid contact with reagents or reagent vapors. Protective gear should

be worn as outlined in the user’s safety program for hazardous materials and the reagent manufacturer’s

safety data sheet. Refer to these guidelines for proper handling and disposal of the reagents.

2.1. Weigh and place the sample into the liner. The maximum sample weight varies per sample

type. See "Operating Parameters" for specic weights.

2.2. Add the acid (5 mL - 30 mL working volume). Use the acid to rinse the inside of the liner to

ensure that the sample is in the base of the liner. If running more than one vessel, you must

run similar samples and the same acids and acid volume in each vessel. See "Sample Prepa-

ration Safeguards" for information regarding acid blanks along with additional safeguards.

2.3. Ensure that the acid covers the sample and the base of the liner (5 mL minimum).

CAUTION

Do not use water to dilute the acid(s) greater than 25% when running over 220 ºC or to add volume before

digestion. This can cause uneven heating of vessels.

Do NOT batch old liners with new liners unless new liners have been conditioned with at least 3 runs.

3. Wait 15 minutes to allow pre-digestion.

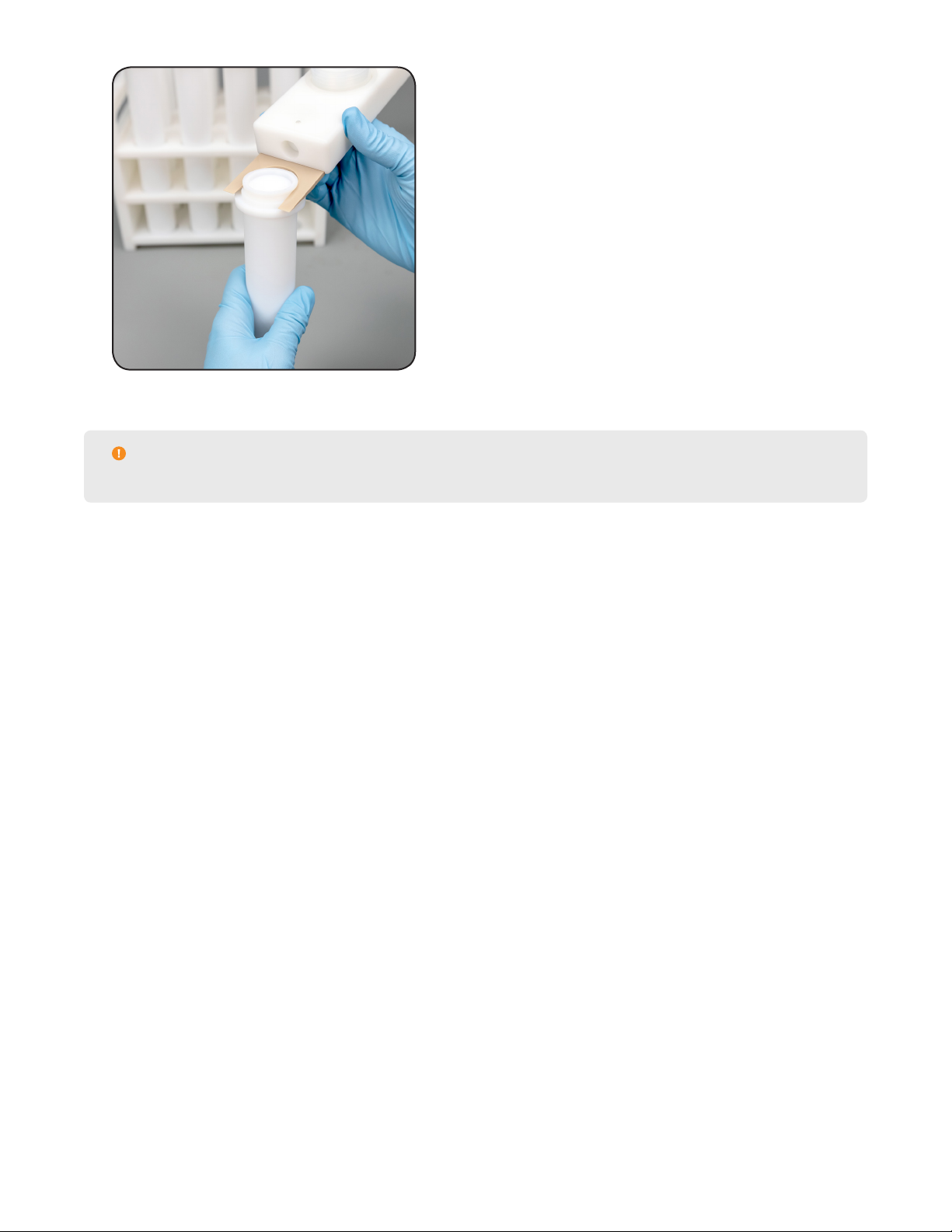

4. Install the plug into the liner. Slight resistance should be felt when placing the plug into the liner. If resistance

is not felt, try using another plug.

10 Perform a Digestion

Page 15

CAUTION

If multiple plugs fall freely into liner, discard liner. Invert sleeves between tests to prevent liners from

stretching.

5. Carefully slide the liner into the sleeve.

NOTE

Invert the vessel sleeves after every test to help maintain uniformity of the liner and sleeves.

6. Place the load disc on the plug with the tab on the disc facing downward so that it ts into the center notch of

the liner.

7. Position the sleeve into the frame. Verify vertical placement by ensuring the sleeve is aligned on the disc at the

bottom of the frame.

11Perform a Digestion

Page 16

8. Tighten the screw onto the top of the load disc until it is nger tight.

9. Use the provided torque block and tighten the screw until a single click is heard or felt.

12 Perform a Digestion

Page 17

WARNING

Vessel torquing is critical to optimize controlled venting of the system and for the integrity of the vessel.

Over or under torquing may lead to sealing issues. If any issue is noted, contact CEM Corporation

10. Verify the vessel alignment by looking through the viewing port located on the vessel frame. A tiny vent hole

aligned with the window should be visible.

Turntable Setup

1. Verify the oor mat positioning, ensuring that the mat is not covering the iWave sensors.

2. Load the empty turntable into the instrument by aligning position “1” with the front of the instrument.

3. Turntable must be seated down on drive lug.

NOTE

CEM suggests that the iPrep vessel set be loaded into the turntable inside the instrument due to the

weight and height of the vessels.

4. Load the vessel assemblies into the turntable one by one, ensuring that the notch in the bottom rear of the

frame engages the locking ring on the turntable. For assistance in loading the vessels, use the Turntable Icon

in the upper right corner of the MARS 6 screen to rotate the turntable. See “Vessel Distribution” section

13Perform a Digestion

Page 18

of this manual for optimal vessel distribution.

5. With the door open, use the Turntable Icon to rotate the turntable. Observe the positioning and balance of

the turntable. Make adjustments by reseating the turntable if necessary.

Load and perform a Method

1. Verify Max Power Monitor is enabled and the alarm time is programmed for 10 minutes (Settings > Run > Max

Power Monitor).

2. Select/load the method from the directory, One Touch or Classic. See "Methods" section or contact CEM Cor-

poration if assistance is needed creating a new method.

3. Close the instrument door.

4. Select “Start” to run the method. The instrument will begin the method according to the selected parameters

– initializing, ramping, holding, cooling, etc.

NOTE

If a run is stopped during the digestion, do not restart the method with hot vessels. Allow vessels to cool

< 80°C, vent vessels and reseal, and restart method from the beginning.

CAUTION

Observe the entire digestion sequence when establishing a procedure for the rst time.

5. Verify that vessel count, type and position are correct.

6. After completion of the method, permit the vessels to cool in the microwave cavity below 80 ºC.

Vessel Removal

1. Allow the vessels to cool below 80 ºC before opening the microwave door.

WARNING

To prevent the possibility of severe burns, ensure that gloves and protective gear as outlined in your safety

program are worn.

Proper precautions must be taken to avoid contact with reagents or reagent vapors. Protective gear should

be worn as outlined in the user’s safety program for hazardous materials and the reagent manufacturer’s

safety data sheet. Refer to these guidelines for proper handling and disposal of the reagents.

2. Remove the vessel assemblies from the turntable one by one, keeping the vent hole pointed away from the

user, and load them into the vessel carrier rack. Keep the vent holes facing away from the user during trans-

portation of the rack.

14 Perform a Digestion

Page 19

3. Place the vessel carrier rack into a fume hood, keeping the vent hole pointed away from the user.

4. Use the torque block to carefully loosen the vessel screws, allowing them to vent.

5. Remove the vessels from the frame carrier rack.

6. Place the liner and plug into the liner holder rack.

7. Use the plug removal tool to remove the plug from each liner.

15Perform a Digestion

Page 20

8. Transfer the digested sample from liner and proceed with work-up.

CAUTION

Never pour sample or liquid from liner with sleeve in place.

9. Clean vessels as outlined in “Vessel Cleaning ” Section.

16 Perform a Digestion

Page 21

Vessel Cleaning and Inspection

WARNING

Proper precautions must be taken to avoid contact with reagents or reagent vapors. Protective gear should

be worn as outlined in the user’s safety program for hazardous materials and the reagent manufacturer’s

safety data sheet. Refer to these guidelines for proper handling and disposal of the reagents.

Liners and Plugs

1. Rinse the liners and plugs with deionized water and allow to dry completely before use.

2. Inspect liners and plugs. Liners should be smooth and white.

• Liners that are rough in texture on the outside may be ok to run but will need to be grouped with like

vessels.

• Liners that have stretching along top with a visible dark line must be discarded. See "Vessel Assembly" for

preventative measures.

3. If measuring ppm, ppb and/or ppt analyte levels, proceed with steps below.

4. Clean liners and plugs with hot, soapy water and foam brush. Rinse thoroughly with deionized water and allow

to dry completely before use.

NOTE

Micro-90® cleaning solution works well on Teon. Avoid detergents that contain ingredients that could

cause potential contamination such as Na and P. Avoid abrasive cleansers and stiff brushes which can

scratch the Teon surface.

5. Clean liners and plugs using the microwave as outlined below. All vessel components must be dry before use.

5.1. Add 10 mL of acid that had been used for sample digestion, HNO3, HCl, H2SO4, H3PO4 or HF.

5.2. Prepare vessel and turntable as outlined in manual.

5.3. Depending on acid type, select and run the appropriate method in the One Touch directory.

• HNO3, HCl or HF: Select “Easy Prep Clean.”

• H2SO4 or H3PO4: Select “High Temp Clean”. If “High Temp Clean” is not available, create a One Touch

method with the following parameters: Temperature=240 °C, Sample Type=Organic, Hold Time=15

minutes and TempGuard=270 °C.

5.4. Wait for vessels to cool below 80 °C before opening microwave door.

5.5. Discard acid and rinse the liners and plugs with deionized water.

Liner and plug Bake-out Procedure

As needed: The bake out procedure can be used to remove residual acid vapors and other trapped gases from the

Teon® material. Trapped gases can potentially cause uneven heating between new and used liners.

The bake out procedure can be used to remove residual NOx gases from liners following digestion with HNO3 that

may interfere in subsequent runs. This procedure has been successfully used to remove sulfur contamination from

the Teon following digestion of samples with high sulfur content.

17Vessel Cleaning and Inspection

Page 22

Procedure:

1. Place the plugs and liners on their side in an air oven at room temperature.

CAUTION

Only the plugs and liners should be placed in the air oven at 210 ºC. Sleeves can be placed in an air oven

no greater than 105 °C. See "Sleeves" section for more detail.

2. Set the oven temperature to 210 °C and let the liners warm slowly. Do not exceed an oven temperature of 215

°C.

3. Leave the liners in the oven for a minimum of 6 hours. Leaving them in overnight is acceptable.

4. After the heating time is complete, turn the oven off and let the liners cool slowly back to room temperature

inside the oven. It is important to let the liners cool slowly back to room temperature following the bake out

procedure.

5. Remove the liners from the oven. The liners should be white in color, comparable to new liners with no acid

history.

Turntable, Frame, Load Disc, Screw & Racks

1. Wash in hot, soapy water as needed and allow to dry completely before use.

2. Inspect the turntable, frames, load discs, and screw for acid marks, cracks or discoloration.

Sleeves

1. If water or acid gets on a sleeve, wipe it off with a damp paper towel and allow to dry. Never soak sleeves.

2. Inspect the sleeves. Sleeves should be smooth and golden brown.

• Sleeves that are distorted or ared must be discarded. See "Vessel Assembly"for preventative measures.

• Sleeves that have turned white should be discarded. This is a result of temperatures greater than 250 ºC

for long periods of time.

• Sleeves can be dried in 105 °C oven for 8 - 12 hours.

• If a sleeve becomes wet (submerged in liquid) discontinue use.

CAUTION

Never soak sleeves in water or detergent.

Remove composite sleeves before adding acid to vessel liners or before pouring digested solutions out to

prevent liquid from wicking into the composite material.

18 Vessel Cleaning and Inspection

Page 23

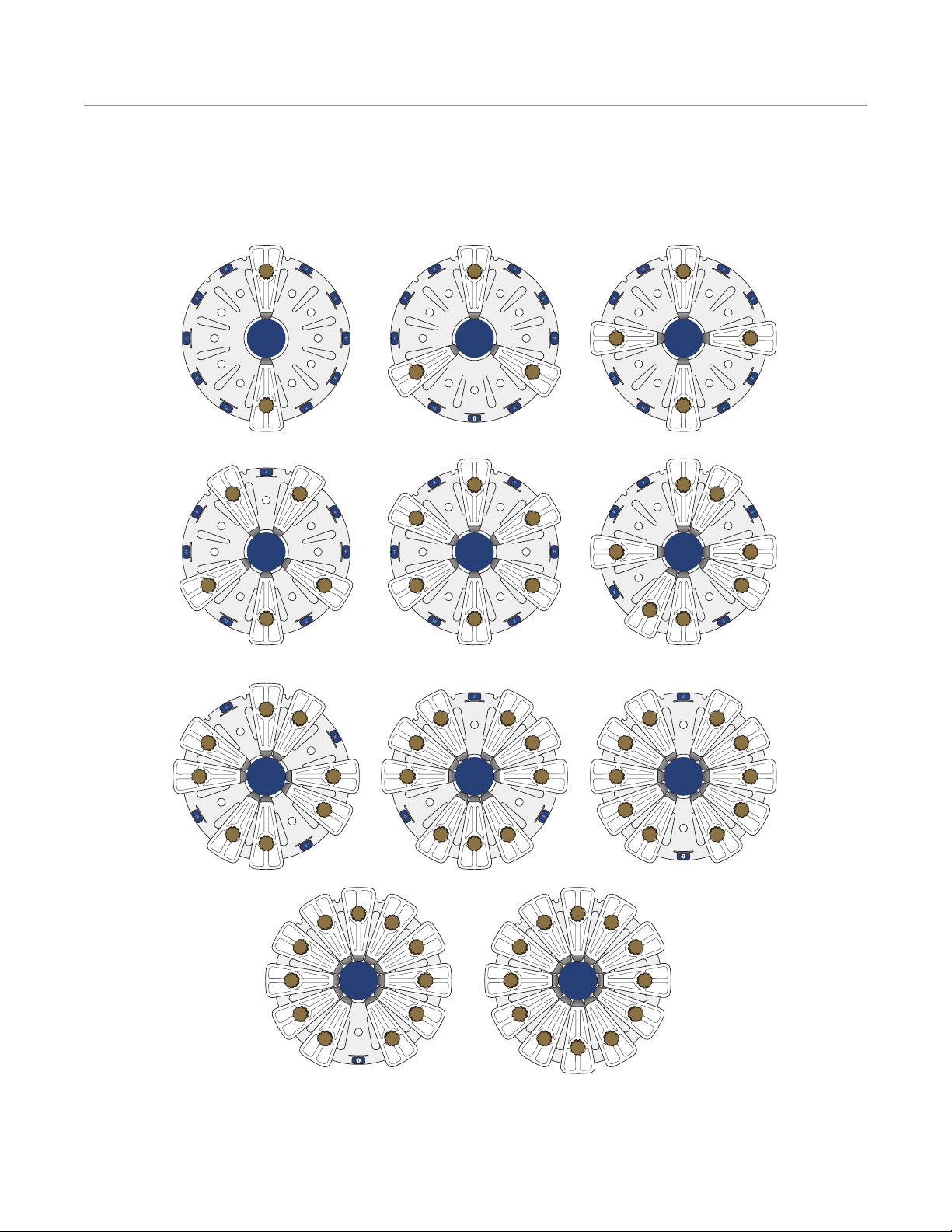

Vessel Distribution

12 Place Turntable

Even vessel distribution is required for optimal performance. Proper spacing will eliminate hot spots, issues

regarding turntable balance, and provide optimal temperature sensing.

2 vessels 3 vessels 4 vessels

5 vessels

8 vessels

6 vessels 7 vessels

9 vessels 10 vessels

11 vessels 12 vessels

19Vessel Distribution

Page 24

16 Place Turntable

Even vessel distribution is required for optimal performance. Proper spacing will eliminate hot spots, issues

regarding turntable balance, and provide optimal temperature sensing.

2 vessels 3 vessels 4 vessels

5 vessels

6 vessels 7 vessels 8 vessels 9 vessels

10 vessels 11 vessels 12 vessels 13 vessels

14 vessels 15 vessels 16 vessels

20 Vessel Distribution

Page 25

Methods

Visit our website for Method and Application Notes or contact CEM Corporation before creating a method. Creation

of a method for use in the MARS 6 requires knowledge and selection of the method control type and sample type

for some vessels as well as temperature control options.

Create a One Touch Method

The MARS 6 has preinstalled methods to cover a large variety of samples. If there is not a current One Touch

Method to digest a sample, a One Touch method can be programmed as outlined below.

1. From the MARS 6 home screen, select “One Touch Methods.”

2. Select “+” at the top of the screen to begin creating a One Touch Method.

3. Select “Method Name” and enter in a name.

4. Select “Temperature” and enter the desired temperature.

CAUTION

Limit control temperature of organics with HNO3 to 250 °C. Higher temperatures will permanently damage

liner and sleeve

5. Select “Sample Type” and select the appropriate type. Choose Sample Type in method with software version

1.45 or higher as follows:

• Standard = Any acid mixture other than HCl or HF dominant

• HCl = Aqua Regia or acid mixtures that are greater than or equal to 75 % HCl

6. Select “Hold Time” and enter in the appropriate hold time.

7. Enable “TempGuard”.

• Always use TempGuard

• Set the TempGuard limit at 30 °C > control temperature if control temperature is < 250 °C.

• Set the TempGuard limit at 20 °C > control temperature if control temperature is > 250 °C

• Limit TempGuard to 270 °C for digestion of organics with HNO

• Limit TempGuard to 300 °C for H3PO4/H2SO4 applications

8. If applicable, select “Sample Prep Notes.”

9. The MARS 6 will complete all other necessary information to perform the method.

10. Select “Next.” View the method by scrolling down. If any parameters require revisions, select “Previous” and

make appropriate revisions.

11. Once the method parameters are entered properly, select the disk icon located in the top right corner. Once

the method is saved, the method may be run by selecting the play icon.

CAUTION

Observe the entire digestion sequence when establishing a procedure for the rst time.

3

Create a Classic Method

Contact CEM Corporation before creating Classic Methods.

21Methods

Page 26

Routine Maintenance

A routine maintenance protocol is vital for the long-term operation of the iPrep vessels. For maintenance

instructions for MARS 6 instrument, see the MARS 6 manual (PN 600832.)

After Every Use

• Clean all vessel components. See “Vessel Cleaning” section of this manual.

• Wipe inside of MARS 6 cavity, including the iWave sensors, with a lint free damp cloth.

Monthly

• Inspect liners - Liners should be smooth, white, and do not are at top or bottom.

• Inspect sleeves. Discard Sleeves that have lightened in color or turned white, or are ared at the ends.

Annually

Contact CEM Service Department, local CEM subsidiary or distributor for information on CEM Service contracts.

Bake-out Procedure

As needed: The bake out procedure can be used to remove residual acid vapors and other trapped gases from the

Teon® vessel liner material. Trapped gases can potentially cause uneven heating between new and used liners.

The bake out procedure can be used to remove residual NOx gases from liners following digestion with HNO3 that

may interfere in subsequent runs. This procedure has been successfully used to remove sulfur contamination from

the Teon liners following digestion of samples with high sulfur content.

22 Routine Maintenance

Page 27

Troubleshooting

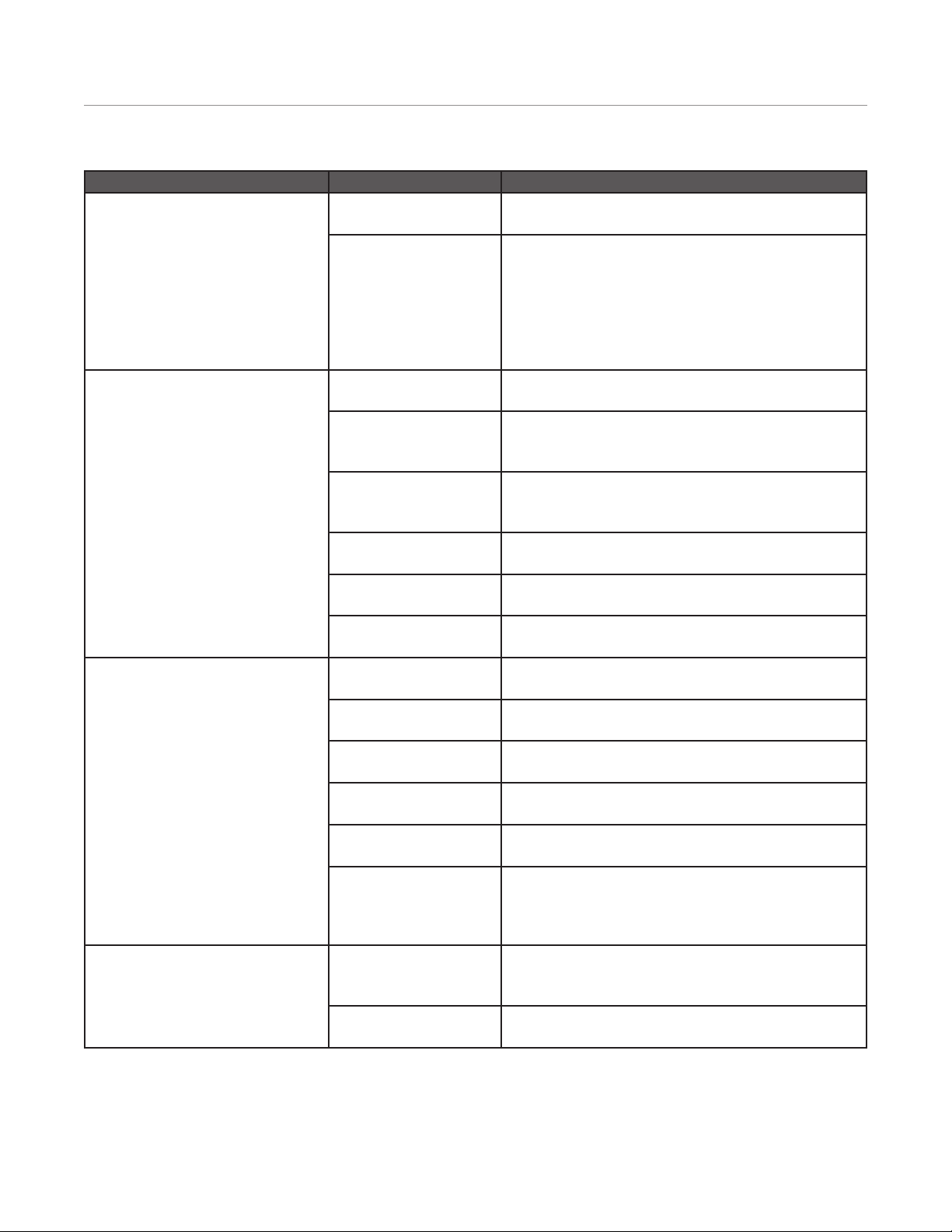

Problems and Possible Solutions

Problems Possible Cause Possible Solutions

TempGuard message appears during run Some vessels are hotter

than others

TempGuard variables

programmed incorrectly

Uneven bar graphs during run Acid diluted with water Do not dilute acids greater than 25% when running over 220

Not enough similarity in

sample type or sample

weight

Different acid(s) or acid

volumes being used in

vessels

Some vessels are hotter

than others

Some vessels contain acid

blanks

Liner not getting as hot due

to leaking

Vessel Liner or sleeve appearance has

changed

Max Power Monitor message appears

during run

Dark ring along bottom of

liner

Liner not tting into Sleeve Determine if liner or sleeve is problem. Invert sleeves after

Alligator skin on outside of

liner

Stretching along top of liner

along with visible dark line

Sleeve distorted or ared Discard Sleeve - See “Vessel assembly” for preventative

Sleeve has turned white (no

longer golden brown)

Max Power Monitor

variables programmed

incorrectly

Vessels leaking Vessels possibly not assembled properly or not torqued using

• See “Bake-out Procedure” to reduce differences in liners

• Do not batch old and new liners. Run in separate turntables

• Set the TempGuard limit at 30 °C > control temperature if

control temperature is < 250 °C.

• Set the TempGuard limit at 20 °C > control temperature if

control temperature is > 250 °C

• Limit TempGuard to 270 °C for digestion of organics with

HNO

3

• Limit TempGuard to 300 °C for H3PO4/H2SO4 applications

ºC

Select samples with similar properties or use same in all

vessels and similar sample amounts

Run the same acid and acid volume in each vessel in the

turntable

See “Bake-out Procedure” to reduce differences in liners

See "Sample Preparation Safeguards" for specic details

when running acid blanks.

Pair liners with plugs that offer resistance. Invert sleeves after

every test to prevent.

Liner needs cleaning - See “Vessel Cleaning” section

every run to extend lifetime of liner and sleeve

Result of high heat/pressure. May be ok to run but will need

to be grouped with like vessels

Discard liner - See “Vessel assembly” for preventative

measures

measures

Replace sleeve. To prevent sleeve damage, avoid high

temperatures for long periods of time. Wipe sleeves with

damp cloth and allow to dry if sleeve comes in contact with

acid.

Verify Max Power Monitor is enabled and the alarm time is

programmed for 10 minutes (Settings > Run > Max Power

Monitor)

torque tool

23Troubleshooting

Page 28

THIS PAGE INTENTIONALLY LEFT BLANK

Page 29

THIS PAGE INTENTIONALLY LEFT BLANK

Page 30

USA:

CEM Corporation (Headquarters)

PO Box 200

Matthews, NC 28106

United States

800-726-3331

704-821-7015

Fax: 704-821-7894

info@cem.com

www.cem.com

France:

CEM μWave S.A.S.

Immeuble Ariane

Domaine Technologique de Saclay

4, rue Rene’ Razel, 91892 ORSAY Cedex

33 (01) 69 35 57 80

Fax: 33 (01) 60 19 64 91

info.fr@cem.com

Germany, Austria, Switzerland:

CEM GmbH

Carl-Friedrich-Gauss-Str.9, 47475 KampLintfort

(49) 2842-9644-0

Fax: (49) 2842-9644-11

info@cem.de

Ireland:

CEM Technology (Ireland) Ltd.

Sky Business Centre, 9a Plato Business Park,

Damastown, Dublin 15

+353 (0) 1 885 1752

Fax: +353 (0) 1 885 1601

info.ireland@cem.com

Italy:

CEM S.R.L.

Via Dell’ Artigianato, 6/8

24055 Cologno al Serio (Bg)

(39) 35-896224 • Fax: (39) 35-891661

info.srl@cem.com

Japan:

CEM Japan K.K.

2-18-10 Takanawa, Minato-ku, Tokyo 1080074

+81-3-5793-8542 • Fax: +81-3-5793-8543

info@cemjapan.co.jp

United Kingdom:

CEM Microwave Technology Ltd.

2 Middle Slade, Buckingham Industrial Estate,

Buckingham MK181WA

(44) 1280-822873

Fax: (44) 1280-822873

info.uk@cem.com

Copyright 2019 by CEM Corporation

All Rights Reserved. This guide contains

proprietary information which shall not

be reproduced or transferred to other

documents or disclosed to others without

prior written permission of CEM Corporation.

iWave and iPrep are registered trademarks

of CEM Corporation. MARS 6, TempGuard

and One Touch are trademarks of CEM

Corporation.

Teon is a registered trademark of the

Dupont Corporation.

For a complete list of distributors of CEM

products, including contact information, go to

the CEM website (http://www.cem.com)

Part Number 600856

February 11, 2019

Rev. 4

Copyright CEM Corporation 2019

Loading...

Loading...