Page 1

-1 0

AUTOMOTIVE MULTIMETER

WITH PC INTERFACE

INSTRUCTION MANUAL

Contents

Introduction……………………………………………………………………….1

Safety………………………………………………………… …………………… 2

Getting Started…………………………………………………………………6

Meter Basics…………………………………………………………………………7

Digital and Analog display…………………………………………………………8

Function and Range Select…………………………………………………………9

Push-button Functions……………………………………………………10

Mode Button… ……… …… …… …… …… …… …… …… …… …… 10

Range Select Button…………………………………………………………10

Range Exit ……………………………………………………………………10

+ TRIG Button………………………………………………………………10

Data Hold /Backlight Button………………………………………………12

MAX/MIN/RS232 Button……………………………………………………12

Relative Button………………………………………………………………12

Meter Functions

Voltage (V)……………………………………………………………………14

Resistance (Ω ) ………………………………………………………………15

Diode Check( )……………………………………………………………16

Audible Continuity ( )……………………………………………………17

AC or DC Current (A) ………………………………………………………18

Temperature (℃/ 0F) ………………………………………………………19

Frequency (Hz) ……………………………………… …………………… 20

Dwell ( )……… …………………………………………………………21

Duty Cycle (%)………………………………………………………………22

Ms – PULSE& ms- PERIOD (ms) …………………………………………23

RPM ( ) ……………………………………………………………………25

Maintenance………………………………………………………………………26

Replacing The Battery……………………………………………………………26

Battery Installation…………………………………………………………………26

Replacing The Fuses………………………………………………………………27

Trouble Shooting………… ………………………………………………………28

General Specifications…………………………………………………………29

Electrical Specifications…………………………………………………………30

Ready – to – Use Windows® Application Program………………………35

his chapter covers brief, introductory information, You will find:

Page 2

1 2

Safety precautions

Safety

DANGER

Engines produce carbon monoxide which

is odorless, causes slower reaction time,

and can lead to serious injury. When the

engine is operating, keep service areas

WELL VENTILATED or attach the vehicle

exhaust system to the shop exhaust

removal system.

Set the parking brake and block the

wheels before testing or repairing the

vehicle. It is especially important to block

the wheels on front-wheel drive vehicles;

the parking brake does not hold the drive

wheels.

Wear an eye shield when testing or

repairing vehicles.

Exceeding the limits of this meter is

dangerous.This will expose you to serious

or possibly fatal injury. Carefully read and

understand the cautions and the

specification limits of this meter.

Voltage between any terminal and ground

must not exceed 1000V DC or 750V AC.

Use caution when measuring voltage above 25V DC or 25V AC.

Circuit tested must be protected by a 20A fuse or circuit breaker.

Do not use the meter if it has been damaged.

Do not use the test leads if the insulation is damaged or if metal

is exposed.

CAP

Hz

20A

MAX every

For

MAX

FUSED

15 min.

FUSED

20A MAX

30 sec.

400mA

500V

1000VDC

750VAC

MAX

-PERIOD

AmA

μ

DWELL

RPM

ms

¦¸

RPM

COM

DWELL

ms-PULSE

%duty

V

x10RPM

OFF

24

¡ã

C

CAP

¡ã

¦¸

Hz

20A

A

F

μ

mA

ms

TEMP.

%

CEM

TRIG¡À

Page 3

3 4

Safety Cont’d

…

Danger

Avoid electrical shock: do not touch the test

leads, tips or the circuit being tested.

Do not try a voltage measurement with the

test leads in the 20A or the mA terminal.

When testing for the presence of voltage or current, make sure

the meter is functioning correctly. Take a reading of a known

voltage or current before accepting a zero reading.

Choose the proper range and function for the measurement. Do

not try voltage or current measurements that may exceed the

ratings marked on the Function/Range switch or terminal.

When measuring current, connect the meter in series with the

load.

Never connect more than one set of test leads to the meter.

Disconnect the live test lead before disconnecting the common

test lead.

The mA and the 20A terminals are protected by fuses. To avoid

possible injury or damage, use only in circuits limited to 400mA

or 20A for 30 seconds.

See also…

Fuse Replacement

Safety Cont’d

…

IMPORTANT

To maintain accuracy of the meter,replace the discharged battery

immediately when the battery symbol appears on the

meter display.

Avoid measuring error from outside interference.Keep the meter

away from spark plug or coil wires.

Avoid damaging the meter when testing voltage.Disconnect the

test leads from the test points before changing functions.

Do not exceed the limits shown in the table below:

Function

Terminal

Input limit

AC Volts

V-Ω -RPM

750Volts AC rms

DC Volts

1000Volts DC

Frequency

V-Ω -RPM

250VoltsAC/DC

Ohm(resistance)

V-Ω -RPM

250VoltsAC DC

Diode

AC/DC μ A mA

μ A / mA

400mAAC/DC

AC/DC20A

20A

*20AAC/DC

RPM

V-Ω -RPM

250Volts AC/DC

Duty Cycle(%)

Dwell angle

* 20 Amp measurement for 30 seconds maximum.

① Ohms can not be measured if voltage is present, ohms

can be measured only in a non-powered circuit. However,

the meter is protected to 250 volts.

Page 4

5 6

Notes:

Getting Started

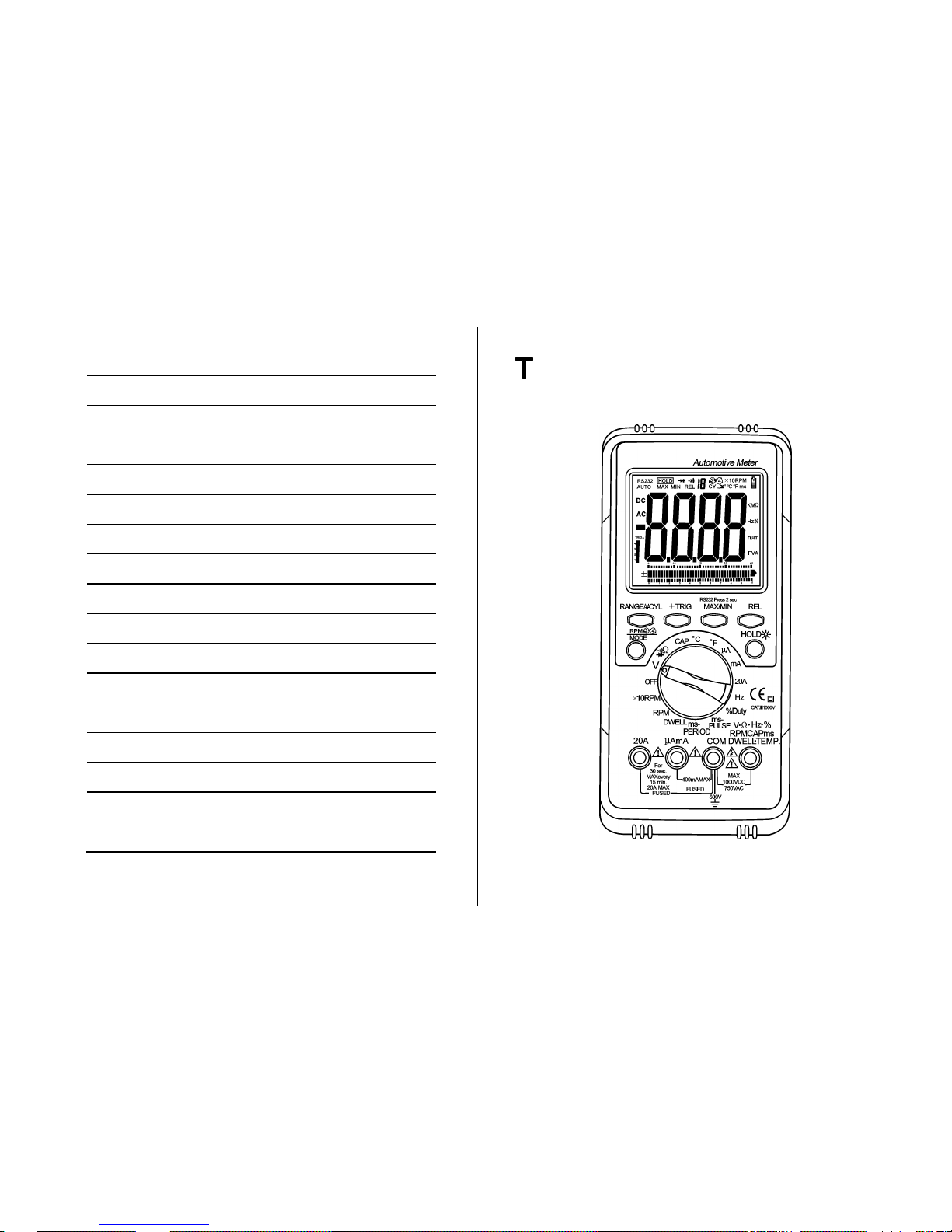

his chapter will help you get started. It describes the basic

functions of the Meter.

Page 5

7 8

Meter Basics

1. Digital and Analog display

Display features:

a. Four character digital display

b. Symbols to identify function

c. Analog bar graph

The digital display is best for

stable input. The bar graph is best

for rapidly changing input.

2. Function buttons

Press the button to select a

function. A symbol will display to

verify your choice.

3. Rotary Selector Switch

Turn this switch to select a

function or turn the meter OFF.

4. Volts Terminal

The Red test lead is used to

measure Amps, Volts, Ohms,

TEMP, Hz, RPM, Cap, mS and

Dwell.

The Black test lead is used

in the Common(COM) terminal for

all tests

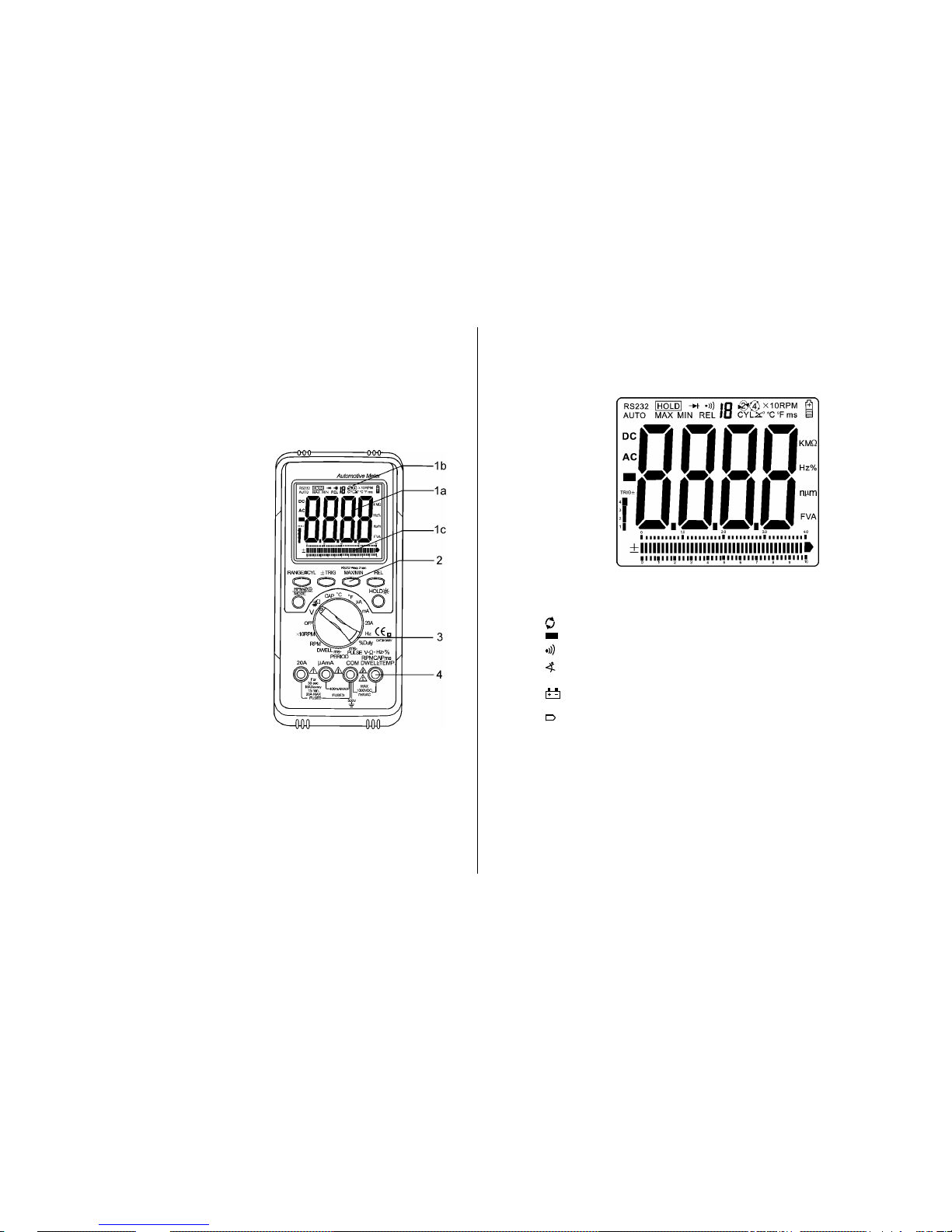

Meter Basics Cont’d…

Digital and Analog display

AC DC Press the Mode button to select Alternating Current

(AC) or Direct Current (DC)

HOLD Press Hold to hold data display or resume testing.

RPM (Tach)

Negative Polarity Indicator

Continuity Test

When Dwell (# of cylinders) is selected with the

rotary switch.

Low Battery Replace the master battery when this

symbol displays.

Analog bar Graph display with polarity.

Units of measure:

Kilo (k=1,000)

Hertz (Hz)

Milli (M=1/1000,)

Volts (V)

mega(m=1,000,000)

ohms (Ω)

dwell degrees

duty percent (%)

Page 6

9 10

Meter Basics Cont’d…

Function and Range Select

Turn the rotary switch in either

direction to select a function.

Most functions also have ranges.

Always select a range higher

than you expect the current or

voltage to be. Then select a lower

range if better accuracy is

needed.

If the range is too high, the

readings are less accurate.

If the range is too low, the

meter shows (over

limit).

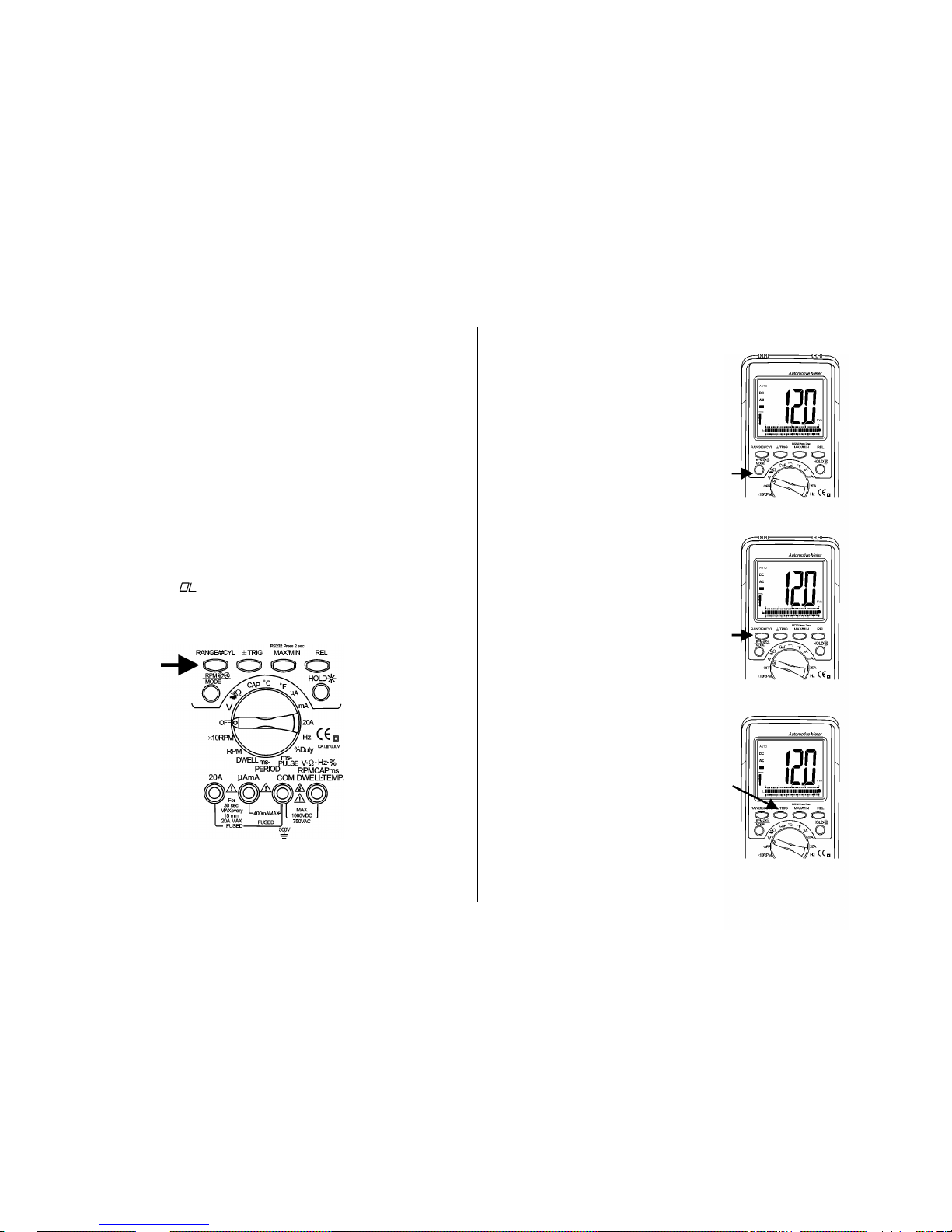

Push–button Functions

Mode Button

Press the Mode button to toggle

between DC and AC in the

voltage & current measurements.

Range / # CYL Select

The range is automatically

selected by the meter. You can

also manually select a range or

DWELL (#CYL) range within a

function by pressing the

RANGE button.

Range Exit

To exit the RANGE mode and

return to autoranging, press and

hold the RANGE button for 2

seconds.

Note:

· If the range is too high, the

readings are less accurate.

· If the range is too low, the

meter shows OL (over limit).

+ TRIG

Toggles between a Negative (-)

and Positive (+) Trigger Slope

when the Meter is in the

ms-pulse, %duty cycle mode,

press this button down for 2

seconds to toggle between

a negative(-) and positive (+)

trigger slope.

Page 7

11 12

The change in the trigger slope is indicated by a + or – shown at

the lower left corner of the display.

The Meter defaults to a – trigger slope whenever the Meter is in

the Hz, %duty, ms-pulse, ms-period, dwell & RPM.

Once the trigger slope is selected, press this button repeatedly to

adjust trigger level if the meter reading is too high or unstable

The Trigger Level has five steps and is different for each function

combination.

Press this TRIG button to move one step at a time in order to

select a suitable trigger level.

The trigger level is indicated by the number above the “trig” symbol

at the lower left corner of the LCD.

The number of steps on the LCD is also a good indication of the

trigger level.

Function Step

Trigger Level

RPM, ms-Pulse,ms-Period,Dwell, %Duty,Hz

4

+7.2v 3 +4.1V 2 +2.1 V

1

+0.8 V

Data Hold/ Backlight

The Data Hold Feature stores the

last reading in memory.

Press the Data Hold button

once to hold the present

reading.

Press the Data Hold button

again to exit and resume

normal readings.

Press the Data Hold button for one

second to turn the backlight on

and press the button a second

time to turn the backlight off.

MAX/ MIN /RS232

Press MAX/MIN to enter, MAX MIN

recording mode. MAX/MIN function is

operative in manual range only!

Select the proper range before

activating MAX MIN to ensure that the

MZX/MIN reading will not exceed the

testing range. Press once to select MAX

Press again to select MIN and

press again release MAX/MIN

recording function.

Press this button down for 2 seconds to

select RS232 PC interface mode.

Relative Mode

The relative measurement feature

allows you to make measurements

relative to a stored reference value.

A reference voltage, current, etc.

can be stored and measurements

made in comparison to that value.

Page 8

13 14

The displayed value is the difference between the reference value

and the measured value.

1. Perform the measurement as described in the operating

instructions.

2. Press the REL button to store the reading in the display and

the "REL" indicator will appear on the display.

3.The display will now indicate the difference between the stored

value and the measured value.

4.Press the REL button to exit the relative mode.

Meter Functions - Voltage (V)

The meter will automatically

select he best voltage (V) range.

Select DCV or ACV with the

MODE button.

Insert:

Black lead in COM terminal.

Red lead in V-Ω -PRM terminal

Touch the Black probe to ground or

to the negative (-) circuit

Touch the Red probe to the circuit

coming from the power source

IMPORTANT: Voltage must be

measuring in parallel (Red probe

measuring circuit from power

source).

Accuracy

Selection of a lower range will

move the decimal point one

place and increase the accuracy.

An “OL” display means the

range is too low. Select the next

higher range.

Analog Bar Graph

The Bar Graph is easiest to

read when the data causes

the digital display to rapidly

change. It is also useful for

trend setting or directional

data.

WARNING

When measuring voltage,

be sure the Red test lead is

in the terminal marked “V”.

If the test lead is in an Amp

(A) or

Milliampere (mA) terminal,

you may be injured or the

meter damaged.

Page 9

15 16

Meter Functions – Resistance (Ω)

IMPORTANT: If you are testing

an application that has capacitors

in the circuit, be sure to turn the

power OFF on the test circuit and

discharge all capacitors. Accurate

measurement is not possible if

external or residual voltage is

present.

Select the resistance ( Ω )

range with the rotary switch.

Select the resistance( Ω )

range with the button labeled

“R ANGE” , if m or e a ccu ra te

measurement is desired.

Insert:

Black lead in COM terminal.

Red lead in V- Ω -RPM

terminal.

Touch the test lead probes across

the resistor to be tested.

Meter Functions –Diode Check ( )

IMPORTANT: Turn the power OFF to

the test circuit

Select the Diode Check ( )

function with the rotary switch.

Insert:

Black lead in COM terminal.

Red lead in V-Ω-RPM terminal.

Touch the Black test probe to the

negative (-) side of the diode.

Touch the Red test probe to the positive

(+) side of the diode.

Reverse the probes: Black to the positive

(+) side and Red to the negative (-) side.

Note:

A “good” diode will read low in one

`direction and high in the other direction

when the probes are reversed (or vice

versa).

A defective diode will have the same

reading in both directions or read

between 1.0 to 3.0 V. in both directions

Diode

- to +

Reverse

Probes

+ to -

Good

.4 to .9V

OL

OL

.4 to .9V

Bad

OL

1.0 to 3.0V

1.0 to 3.0V

OL

.4 to .9V

.4 to .9V

OL

OL

.000V

.000V

Page 10

17 18

Meter Functions –Audible Continuity ( )

IMPORTANT: Turn the power

OFF on the test circuit

Select the Audible Continuity

( ) function with the rotary

switch and mode button

Insert:

Black lead in COM terminal.

Red lead in V- Ω -RPM

terminal.

Connect one test probe to each

end of the circuit to be tested.

Circuit complete, the meter will

beep continuously.

Circuit open, there is no beep

and the display shows to OL

(over limit).

Meter Functions –AC or DC Current (A)

IMPORTANT: All current measured

flows through the meter.

It is important that you do not:

Measure current greater than

600 Volts AC or DC, with

respect to ground.

Do Not Exceed 30 seconds

when measuring continuous

current between 1A-20A.

Allow five minutes for cool

down before continuing.

Select the 20A., mA or μA

range with the rotary switch.

Press the Mode button to

select AC or DC.

Insert:

Black lead in COM terminal.

Red lead in the 20A or mA

terminal (select 20A if you are

unsure of the current draw).

IMPORTANT: Turn OFF all power

to the circuit or disconnect the

circuit from the power source.

Connect:

The Red probe to the side of the

circuit closest to the power

source.

The Black probe to the side of

the circuit to ground.

Turn the power ON and test.

Note:

Current must always be

measured with the meter test

probes connected in series,

as described.

Page 11

19 20

Meter Functions –Temperature (℃/ 0F )

IMPORTANT: To avoid heat

damage to the meter, keep

it away from sources of

very high temperature. The

life of the Temperature

Probe is also reduced

when subjected to very

high temperatures. Probe

operating range is

–4o to 1,400 oF.

Select the Temperature

( ℃ / 0F ) function with the

rotary switch.

Insert the temperature probe

connector into the K-type

thermocouple socket.

Touch the end of the

temperature sensor to the area

or surface of the object to be

measured.

Temperature

Sensor

Temperature probe

Meter Functions –Frequency(Hz)

Select the Frequency

(Freq) setting with the rotary

switch.

Adjust the trigger level to

the setting that gives the

most stable and

accurate reading.

Insert:

Black lead in COM terminal.

Red lead in V-Ω-RPM terminal.

Connect the Black test probe

to ground.

Connect the Red test probe to

the “signal out” wire of the

sensor to be tested.

Page 12

21 22

Meter Functions-Dwell ( )

Select the proper Dwell

range with the rotary switch.

Insert:

Black lead in COM terminal.

Red lead in V- Ω -RPM

terminal.

Connect the Black test probe to

ground.

Connect the Red test probe to

the wire that connects to the

breaker points (see illustration).

Meter Functions-Duty Cycle (%)

Select the % Duty Cycle

range with the rotary switch.

Insert:

Black lead in COM terminal.

Red lead in V-Ω-RPM terminal.

Connect the Black test probe to

ground.

Connect the Red test probe to

the signal wire circuit.

The illustration for a mixture

control solenoid is shown with the

metering rod in the closed

position. The meter will display

the percentage of time the

plunger is in the closed position.

(low duty cycle) during one duty

cycle.

Page 13

23 24

Meter Functions- ms-PULSE (Pulse Width) &

ms- PERIOD (Period)

Pulse Width is the length of time an actuator is energized. For

example, fuel injectors are activated by an electronic pulse from

the Engine Control Module (ECM).

This pulse generates a magnetic field that pulls the injectors nozzle

valve open.

The pulse ends and the injector nozzle is closed.

This open to close time is the Pulse Width and is measured in

milliseconds( ms).

The most common automotive application for measuring pulse

width is on fuel injectors.

You can also measure the pulse width of the fuel mixture control

solenoid and the idle air control motor.

This exercise shows how to measure Pulse Width on Port Fuel

injectors.

To measure pulse width (mS):

Select the mS-Pulse function

with the rotary switch .

Press the ± TRIG button for

2 seconds until the negative

(-) trigger slope is displayed

on the lower left side of the

display.

NOTE : The applied time for

most fuel injectors is

displayed on the

negative (-) slope.

Insert:

Black lead in COM jack.

Red lead in RPM-V-Ω jack.

Connect:

Jumper wires between the fuel

injector and the harness

connector.

Black test probe to a good

ground at the fuel injector or the

negative (-) vehicle battery post.

Red test probe to the fuel

injector solenoid driver input on

the jumper cable.

Start the engine. A pulse width in

milliseconds should be read.

If reading is too high or

unstable,,adjust the trigger level

by pressing the ± TRIG button

for improved reading.

Page 14

25 26

Meter Functions-RPM/×10RPM

Select the RPM range with the

rotary switch.

OR

Select the × 10RPM range

with the rotary switch (1,000 to

12,000 RPM). Multiply the

displayed reading by ten to get

actual RPM.

Press STROKE / DIS

button toward select through

RPM for 4-stroke, RPM

For 2-stroke and DIS.

Insert the inductive pickup

connecting terminal into the

meter.

Black lead in COM terminal.

Red lead in V- Ω -RPM

terminal.

Connect the inductive pickup to

a spark plug wire. If no reading

is received, unhook the clamp,

turn it over and connect again.

Note:

Position the inductive pick-up as far away from the distributor and the

exhaust manifold as possible.

Position the inductive pick-up to within six inches of the spark plug or move

it to another plug wire if no reading or an erratic reading is received.

RPM 4 : For RPM of 4-stroke engines which have 1 ignition on

every 4 engine strokes

RPM 2 : For RPM of DIS ( Distributorless lgnition System) &

2-stroke engines which Have 1 ignition on every 2

engine strokes

PLEASE NOTE- THE RPM PICK-UP HAS AN ADJUSTABLE SENSITIVITY

SWITCH THAT CAN ALSO BE USED TO CORRECT AN

UNSTABLE READING.

Maintenance

Replacing The Battery

WARNING: To avoid electric shock, disconnect the test leads

from any source of voltage before removing the battery door.

1. When the battery become drained or drop below the operating

voltage, “ ” will appear in the right-hand side of the LCD

display. The battery should be replaced.

2. Follow instructions for installing battery. See the Battery

Installation section below.

3. Dispose of the old battery properly.

WARNING: To avoid electric shock, do not operate your meter

until the battery door is in place and fastened securely.

Battery Installation

WARNING: To avoid electric shock, disconnect the test leads

from any source of voltage before removing the battery door.

1. Disconnect the test leads from the meter.

2. Open the battery door by loosening the screw using a Phillips

head screwdriver.

3. Insert the battery into battery holder, observing the correct

polarity.

4. Put the battery door back in place. Secure with the one screw.

WARNING: To avoid electric shock, do not operate the meter

until the battery door is in place and fastened securely.

NOTE: If your meter does not work properly, check the fuses and

battery to make sure that they are still good and that they

are properly inserted.

4

2 4 2

Page 15

27 28

Replacing The Fuses

WARNING: To avoid electric shock, disconnect the test leads

from any source of voltage before removing the fuse door.

1. Disconnect the test leads from the meter and any item under

test.

2. Open the fuse door by loosening the screw on the door using a

Phillips head screwdriver.

3. Remove the old fuse from its holder by gently pulling it out.

4. Install the new fuse into the holder.

5. Always use a fuse of the proper size and value (0.5A/250V fast

blow for the 400mA range, 20A/500V fast blow for the20A

range).

6. Put the fuse door back in place. Insert the screw and tighten it

securely.

WARNING: To avoid electric shock, do not operate your meter until

the fuse door is in place and fastened securely

Trouble Shooting

1. Meter will not turn ON.

Check the battery contacts for a tight fit.

Check for a minimum battery voltage of 8.0 volts.

2. Ampere reading is erratic or there is no reading at all.

Disassemble the meter back cover and test the fuses for

continuity.

3. Meter reading is erratic.

Printed circuit board damaged from handling with hands.

Low battery.

Open circuit in a test lead (frayed or broken wire).

Wrong range selected.

“Blown” fuse.

4. Meter readings do not change.

“Hold” feature is still toggled ON.

F20A,500V

Page 16

29 30

General Specifications

General Specifications

· Safety: Designed to Protection Class III requirement of

EN61010-1 over-voltage Category III (CATIII).

· Maximum Voltage: 500V rms. (Between any terminal and

earth ground)

· RS232: Optically isolated PC interface-optional RS-232 cable

windows® 95/98/2000/XP compatible software allows

user to collect, display, plot and save data.

Display: 4 3/4 digit (4000 counts) liquid crystal display (LCD),

with function and units sign annunciators.

Analog Bar Graph: 40 segments with measurements 15 times

per second.

Polarity: Automatic, (-) negative polarity indication.

Overrange Indication: “OL” mark indication.

Low Battery Indication: The is displayed when the

battery voltage drops below the

operating level.

Auto power off: Meter automatically shuts down after approx.

30 minutes of inactivity.

Measurement Rate: 2 times per second, nominal.

Operating Environment: 0℃ to 50℃

(32 0F to 122 0F) at<70% R.H.

Storage Environment: -20℃ to 60℃ (-4 F to 140 )

at<80% R.H.

Temperature Coefficient: 0.2×(specified accuracy)/ ℃

(<18℃ or>28℃) .

Power: Single standard 9 Volt battery

(NEDA 1604 or IEC 6F22).

Battery Life: 200 hours typical with alkaline battery.

Fuse: 20A/500V, φ 10.3 × 38mm fast acting ceramic type.

0.5A/250V,φ 5×20mm fast acting ceramic type.

· Dimensions: 197 (H) x 88.4 (W) x 41.2 (D) mm

· Weight: Approx.: 635g including holster.

Electrical Specifications

Electrical Specifications

*Accuracy is given as±([% of reading]+[number of least significant

digits]) at 18℃ to 28℃(65 F to 83 F), with relative humidity up to

70%.

RPM (Tach)

Range

Resolution

Accuracy

RPM 4

600~4000

RPM

1 RPM

+2 % of rdg + 4 dgts

600~12000

RPM

(X10 RPM)

10 RPM

RPM2/DIS

300~4000

RPM

1 RPM

300~6000

RPM

(X10 RPM)

10 RPM

Effect Reading: >600 RPM

Overload protection: 250V dc or ac rms.

Dwell Angle

Cylinder

Range

Resolution

Accuracy

1CYL

0~360.0°

0.1°

+2.0% of rdg + 4 dgts

2CYL

0~180.0°

3CYL

0~120.0°

4CYL

0~90.0°

5CYL

0~72.0°

6CYL

0~60.0°

8CYL

0~45.0°

10CYL

0~36.0°

12CYL

0~30.0°

Page 17

31 32

Overload protection: 250V dc or ac rms.

DC Voltage (Auto-ranging for uA and mA)

Range

Resolution

Accuracy

400.0mV

0.1mV

+0.5% of rdg + 2 dgts

4.000V

1mV

+1.5% of rdg + 2 dgts

40.00V

10mV

400.0V

100mV

1000V

1V

+1.8% of rdg + 2 dgts

Input Impedance: 10MΩ .

Maximum Input: 1000V dc or 750V ac rms.

AC Voltage (Auto-ranging except 400mV)

Range

Resolution

Accuracy

400.0mV

0.1mV

+1.5%of rdg + 60 dgts

4.000V

1mV

+1.0% of rdg + 3 dgts

40.00V

10mV

+1.5% of rdg + 3 dgts

400.0V

100mV

750V

1V

+2.0% of rdg + 4 dgts

Input Impedance: 10MΩ

Frequency Range: 50 to 400Hz

Maximum Input: 1000V dc or 750V ac rms.

DC Current (Auto-ranging for uA and mA)

Range

Resolution

Accuracy

400.0uA

0.1uA

+1.0% of rdg + 3 dgts

4000uA

1uA

+1.5% of rdg + 3 dgts

40.00mA

10uA

400.0mA

100uA

4A

1mA

+2.5% of rdg + 5 dgts

20A

10mA

Overload Protection: 0.5A / 250V and 20A / 500V Fuse.

Maximum Input: 400mA dc or 400mA ac rms on uA / mA ranges,

20A dc or ac rms on 20A range.

AC Current (Auto-ranging)

Range

Resolution

Accuracy

400.0uA

0.1uA

+1.5% of rdg + 5 dgts

4000uA

1uA

+1.8% of rdg + 5 dgts

40.00mA

10uA

400.0mA

100uA

4A

1mA

+3.0% of rdg + 7 dgts

20A

10mA

Overload Protection: 0.5A / 250V and 20A / 500V Fuse.

Frequency Range: 50 to 400 Hz

Maximum Input: 400mA dc or 400mA ac rms on uA / mA ranges,

20A dc or ac rms on 20A range.

Resistance (Auto-ranging)-

Range

Resolution

Accuracy

400.0Ω

0.1Ω

+1.2% of rdg + 4 dgts

4.000kΩ

1Ω

+1.0% of rdg + 2 dgts

40.00kΩ

10Ω

+1.2% of rdg + 2 dgts

400.0kΩ

100Ω

4.000MΩ

1kΩ

40.00MΩ

10kΩ

+2.0% of rdg + 3 dgts

Input Protection: 250V dc or 250V ac rms.

Capacitance (Auto-ranging)

Range

Resolution

Accuracy

40.00nF

10pF

+5.0% of rdg + 7 dgts

400.0nF

0.1nF

Page 18

33 34

4.000uF

1nF

+3.0% of rdg + 5 dgts

40.00uF

10nF

100.0uF

0.1uF

+5.0% of rdg + 5 dgts

Input Protection: 250V dc or 250V ac rms.

Frequency (Auto-ranging)

Range

Resolution

Accuracy

5Hz

0.001Hz

+1.5% of rdg + 5 dgts

50Hz

0.01Hz

500Hz

0.1Hz

+1.2% of rdg + 3 dgts

5kHz

1Hz

30.00kHz

10Hz

Sensitivity: >5V RMS MIN.

Overload protection: 250V dc or ac rms.

Duty Cycle

Range

Resolution

Accuracy

0.1%~99.9%

0.1%

+1.2% of rdg + 4 dgts

Pulse width: >100us, <100ms; (Continued next page)

Sensitivity: <0.5V RMS

Overload protection: 250V dc or ac rms.

Period

Range

Resolution

Accuracy

2.0~ 20.0ms

0.1ms

+3% of rdg + 10 dgts

Overload protection: 250V dc or ac rms.

Pulse Width

Range

Resolution

Accuracy

2.0~ 10.0ms

0.1ms

+3% of rdg +10 dgts

Overload protection: 250V dc or ac rms

Temperature

Range

Resolution

Accuracy

-20oC~+760oC

1 oC

+3% of rdg +5dgts(Meter only,

probe accuracy not included)

-4 oF~+1400 oF

1oF

Sensor: Type K Thermocouple

Diode Test

Test current

Resolution

Accuracy

0.3mA typical

1 mV

+10% of rdg + 5 dgts

Open circuit voltage: 1.5V dc typical

Overload protection: 250V dc or ac rms.

Audible continuity

Audible threshold: Less than 150Ω Test current: <0.3mA

Overload protection: 250V dc or ac rms.

Page 19

35 36

Ready – to – Use Windows® Application

Program

Hardware and Software Requirements

386/25 personal computer, 4 Megabytes of memory or better.

windows® 95 or above.

RS232: Optically isolated PC interface-optional RS-232 cable

windows® 95/98/2000/XP compatible software allows user to

collect, display, plot and save data.

Printing Data and Graph tester report

·Print data tester report

·Please press off line

·Move the cursor to the number of data that you want to print out.

(e.g.: If you want to print the date area from number 0 to 100,

move the cursor to number 0 and click. If you want to print the data

area from number 50 to 100, move the cursor to number 50 and

click).

·Please press printer icon.

·A information show: List "Y" or "N" - press "Y".

·The data tester report will print out the selected data sets.

Print graph tester report

·Please press off line

·Move the cursor to the number of data that you want to print out.

(e.g.: If you want to print the graph area from number 0 to 100,

move the cursor to number 0 and click. If you want to print

the graph area from number 50 to 100, move the cursor to number

50 and click).

·Please press printer icon.

· A information show: List "Y" or "N" - press "N". A information

show Graph "Y" or "N" press "Y".

·The graph tester report will print out the selected graph sets.

Installation of the Windows Application program

A. Start Microsoft ® Windows®

B. Insert disk in drive CD

C. From the program Manager, select file menu and choose Run

D. For Win98 from the start, select Execute.

E. Type E :\setup and press Enter Key

Note: If you are using 386 PC, it might takes more than 3 minutes.

Description of Windows® Application Program

When the ICON “Panel” is selected and executed,the program

automatically search for connected DMM/Data Logger or available

serial port. If no serial port is available, then a message of “:No

Com:” shall be displayed, and the program exits itself. Once

communication port is setup, a main window will be displayed on

the screen. The Layout of the window is as Figure:

Page 20

37 38

Note: Please click “Help” on the PC interface for detailed

instruction.

Loading...

Loading...