Page 1

600857

Rev. 1

8/17

Operation Manual

i

Page 2

Copyrig h t 201 7 by

CEM Corporation

All Rights Reserved

This manual contains proprietary information, which shall not

be reproduced or transferred to other documents

or disclosed to others without prior written permission of

CEM Corporation.

CEM is a registered trademark of CEM Corporation.

Discover is a registered trademark of CEM Corporation.

Patents Pending

CEM Corporation

POB 200

3100 Smith Farm Road

Matthews, North Carolina 28106-0200

(704) 821-7015 (phone)

704-821-7894 (fax)

www.cem.com (website)

Manufactured in the

United States of America

600857

Rev. 1

8/17

ii

Page 3

Table of Contents

Operating Precautions ............................................................................................................................................................. 1

Warnings and Cautions ........................................................................................................................................................... 1

Introduction ............................................................................................................................................................................... 2

Instrument Description ............................................................................................................................................... 3

Front View .......................................................................................................................................................................... 3

User Interface .................................................................................................................................................................... 3

Keypad ............................................................................................................................................................................... 4

Method Status Bar ............................................................................................................................................................ 4

Rear View .......................................................................................................................................................................... 5

Side Views ......................................................................................................................................................................... 5

Sample Stirrer .................................................................................................................................................................... 6

Cooling ............................................................................................................................................................................... 6

System Installation ................................................................................................................................................................... 7

Installation Site .................................................................................................................................................................. 7

Unpacking .......................................................................................................................................................................... 7

Discover SP Installation .................................................................................................................................................... 8

Computer Installation (optional) ........................................................................................................................................ 9

User Login .................................................................................................................................................................. 11

User Logout ................................................................................................................................................................ 11

Microwave Tips........................................................................................................................................................... 12

Closed Vessel Extraction ........................................................................................................................................... 13

Items Required .................................................................................................................................................................. 13

Prepare the Vessel ............................................................................................................................................................ 13

Perform a Method ............................................................................................................................................................. 13

Vessel Removal ................................................................................................................................................................ 14

Load, Save, and Create a New Method .................................................................................................................................. 15

Create a New Method ....................................................................................................................................................... 15

Standard Control ............................................................................................................................................................... 16

Dynamic Control ................................................................................................................................................................ 16

Save Method ..................................................................................................................................................................... 20

Ramp to Temperature Control .......................................................................................................................................... 21

Load Method ...................................................................................................................................................................... 22

Data Review ...................................................................................................................................................................... 22

Delete Method ................................................................................................................................................................... 23

Discover Home ......................................................................................................................................................................... 24

Rxn Programming ............................................................................................................................................................. 24

Logout ................................................................................................................................................................................ 25

ActiVent Home, ActiVent Moving, ActiVent Closed, APM Recovery ............................................................................. 25

System Setup .................................................................................................................................................................... 26

User Setup ......................................................................................................................................................................... 27

Temperature Type ............................................................................................................................................................. 27

Release Limiits .................................................................................................................................................................. 27

User Profiles ................................................................................................................

Clear Password ................................................................................................................................................................. 28

Change Password ............................................................................................................................................................. 28

User Profile Defaults -1 ..................................................................................................................................................... 28

Hold Time .......................................................................................................................................................................... 28

Ramp Time ........................................................................................................................................................................ 29

Temperature ...................................................................................................................................................................... 29

µ Power ........................................................................................................................................................................... 29

...................................................... 28

iii

Page 4

User Profile Defaults- 2 ............................................................................................................................................................ 29

Stirring ................................................................................................................................................................................ 29

Pre-Mix Time ..................................................................................................................................................................... 30

Pressure ............................................................................................................................................................................. 30

Pressure Units .................................................................................................................................................................. 30

User Profile Defaults- 3 ............................................................................................................................................................ 30

Key Beep ........................................................................................................................................................................... 30

Clock Format ..................................................................................................................................................................... 30

Cooling Time ..................................................................................................................................................................... 31

Backup Methods ................................................................................................................................................................ 31

Restore Methods ............................................................................................................................................................... 31

Calibration Setup ............................................................................................................................................................... 31

Temperature ...................................................................................................................................................................... 32

Infrared ............................................................................................................................................................................... 32

Slope .................................................................................................................................................................................. 32

Fiber Optic ......................................................................................................................................................................... 33

Slope .................................................................................................................................................................................. 33

Pressure (10mL APM) ...................................................................................................................................................... 34

Network Setup ................................................................................................................................................................... 34

IP Address ......................................................................................................................................................................... 34

Sub Net Mask .................................................................................................................................................................... 35

Serial Number .................................................................................................................................................................... 35

Peripheral Setup ................................................................................................................................................................ 35

Information ......................................................................................................................................................................... 35

Administrative Functions ................................................................................................................................................... 35

Create New User ............................................................................................................................................................... 35

Create User ....................................................................................................................................................................... 35

User Name......................................................................................................................................................................... 36

Permissions ....................................................................................................................................................................... 36

User Profile ........................................................................................................................................................................ 36

Save User .......................................................................................................................................................................... 37

Edit User ............................................................................................................................................................................ 37

Permissions ....................................................................................................................................................................... 37

User Profile ........................................................................................................................................................................ 37

Save User .......................................................................................................................................................................... 37

Delete User ........................................................................................................................................................................ 38

Administration .................................................................................................................................................................... 38

Maintenance ............................................................................................................................................................................. 39

Interlocks ............................................................................................................................................................................ 39

Cavity ................................................................................................................................................................................. 39

ActiVent .............................................................................................................................................................................. 40

APM Cleaning.................................................................................................................................................................... 42

Clean ActiVent using Water .............................................................................................................................................. 43

Stirring Verification ................................................................................................................................................................... 45

Firmware Update ............................................................................................................................................................... 45

Service ...................................................................................................................................................................................... 47

Microwave leakage Measurement ................................................................................................................................... 47

Power Test ......................................................................................................................................................................... 48

Manual Power Test ........................................................................................................................................................... 48

Auto Power Test ................................................................................................................................................................ 49

Vessel Failure Cleanup Procedure .................................................................................................................................. 52

Troubleshooting Guide ...................................................................................................................................................... 54

Specifications .................................................................................................................................................................... 55

Warranty ............................................................................................................................................................................ 56

iv

Page 5

Operating Precautions

The Discover® SP-D Clinical System must be grounded. In the event of an electrical short circuit, grounding reduces

the risk of electric shock by providing an escape wire for electrical current. This instrument is equipped with a cord

having a grounding wire with a grounding plug. The plug must be installed into an electrical outlet that is properly

installed and grounded. Consult a qualified electrician or service technician if the grounding instructions are not

completely understood or if doubt exists as to whether the instrument is properly grounded. If it is necessary to use an

extension cord, use only a 3-wire extension cord that has a 3-blade grounding plug and a 3-slot receptacle that will

accept the plug from the instrument. The marked rating of the extension cord must be equal to or greater than the

electrical rating of the instrument.

The possibility of instrument-induced electromagnetic interference (EMI) is minimal if the instrument is operated as outlined

in this manual. The instrument should not be placed close to any electrical device susceptible to EMI. The manufacturer

suggests that the user post a sign warning pacemaker wearers that a microwave device is in operation. If the instrument is

suspected of inducing EMI, a microwave leakage measurement should be performed as outlined in this manual. Any leakage

above the legal limit of 5 mW/cm

Cardiac pacemakers require magnets to control their operation during checkout. Because the instrument is equipped

with an electromagnetic sample stirrer which contains very high static magnetic fields, some danger exists if a

pacemaker is positioned in close proximity of the instrument cavity. If the instrument is suspected of interfering with

the operation of a pacemaker, the instrument should be turned off or the pacemaker wearer should move away from

the instrument.

This instrument utilizes high voltages and microwave radiation. Only those trained in repair and maintenance of

high voltage and microwave power systems should perform instrument service and repair.

Use of the Discover instrument in any manner not specified by CEM Corporation could render the instrument

operation unsafe for the operator.

This instrument complies with United States Code of Federal Regulations 21CFR Part 1030.10 (C) for microwave leakage. A

verification report is on file. This instrument complies with FCC Requirements in the United States Code of Federal

Regulations (47CFR Part 18) Industrial, Scientific and Medical (ISM) Equipment emissions requirements. A verification

report is on file.

2 should be reported to the CEM Service Department.

Warnings and Cautions

Warnings, cautions and notes are included throughout this manual and should be read thoroughly and strictly followed.

WARNING

A warning is inserted for essential information used to emphasize dangerous or hazardous conditions to the operation,

cleaning and maintenance of the instrument which may result in personal injury.

CAUTION

A caution is inserted for essential information used to emphasize procedures which, if not strictly followed, may result

in damage or destruction to the instrument or improper instrument operation.

NOTE

A note is inserted for emphasis of procedures or conditions that may otherwise be misinterpreted or overlooked and

to clarify possible confusing situations.

1

Page 6

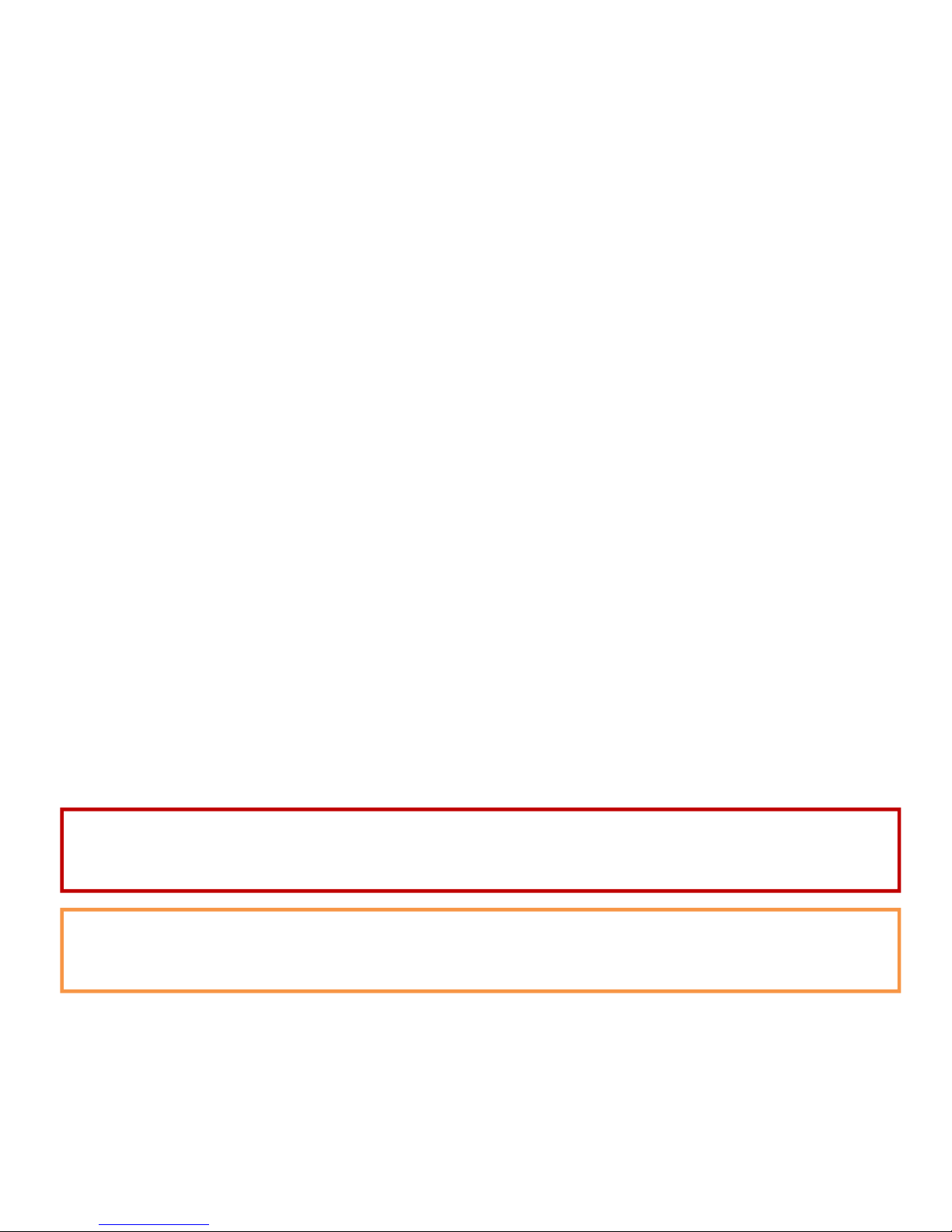

Introduction

The CEM Focused Microwave Discover® SP-D Clinical System is designed to enhance the ability to perform acid

digestions under controlled conditions on a laboratory scale. It accommodates 4 mL and 10 mL vessels for reactions

performed at elevated temperatures and pressures.

The SP-D Clinical system also incorporates ActiVent Technology that permits the user to release unwanted gaseous

byproducts from the reaction to prevent over pressurization and vial failure from gaseous buildup. This ensures safe

handling of the vial during and at the end of the reaction. The ActiVent safely bleeds the solvent/vapor from the reaction

vessel and releases it through the vent tube connected to the back of the system and into a controlled environment.

Microwave energy is applied to the vessel contents (reactants, catalysts, salts, solvents and/or solid supports) to

accelerate the chemical reaction. The microwave absorption properties of some liquid and solid materials, due to their

polar and ionic characteristics, have the capability to significantly enhance chemical reactions relative to traditional energy

application (heating) techniques. The microwave interaction properties with the reactants, intermediates, catalysts, solid

supports and salts provide unique opportunities for the synthetic chemist.

The Discover SP-D Clinical Sy stem consi sts of:

• A continuous microwave power delivery system with operator selectable power output from 0 - 300 watts (+/- 30

watts) programmable in 1-watt increments.

• A self-adjusting, single mode microwave cavity that is manually accessed via multiple attenuator ports.

• A 256 x 128 graphics display and on-board computer for programming and operational control of the system. The

memory will store and recall methods.

• 3 safety interlocks and an interlock monitoring system to prevent microwave emission when the attenuator port is

not properly installed.

• One (1) serial port (1 RS 232).

• Two (2) ethernet ports for computer interface and network connection (optional configuration).

• One RJ-11 port for peripheral connection.

• An accessory kit.

• Two (2) USB ports..

• Infrared Temperature Control System - This temperature control system uses a non-contact, infrared sensor to

measure temperature. It is located below the microwave cavity floor and measures the temperature on the bottom of

the vessel. The sensor is vessel volume independent and is used in a feedback loop with the on-board computer to

control the temperature rise rate and control point of the vessel contents. Temperature is programmable from

o

0

C to 220oC.

• Stirring Option - The stirring option consists of an electromagnetic plate located below the floor of the microwave

cavity. Stirring occurs when the magnetic field couples with a stir bar in the vessel. The method setup enables

the stirring feature and the stirring speed. Standard stir bars appropriate to the vessel size are used.

• Cooling Option - The cooling option consists of necessary valves and ports to direct a cooling gas (either

nitrogen or clean air) onto the vessel in the system cavity. This option will decrease the temperature of a 2mL

solution in a 4 mL or 10 mL Pyrex reaction vessel from ~150ºC to ~50ºC in less than 120 seconds. Method setup

enables the cooling feature.

2

Page 7

Instrument Description

Front View

User Interface

The user interface consists of the keypad and display which provide the means for the user to input information into and output

information from the Discover System.

The input functions are performed with the keypad and provide the ability to

● create new methods and edit existing methods,

● recall and delete methods,

● change operating parameters during method operation in real time,

● start, pause and stop operation,

● set up a computer (optional),

● configure the sensor options and system options,

● create and edit user profiles.

The output functions are obtained from the display and computer/ethernet port. The display provides visual information of the

keypad entry and permanently stored instrument information. The computer/ethernet port provides the option of using an

offboard PC to program the system and to collect data.

● Display - displays menus, method parameters and instrument status on a 256 x 128 graphics display.

● Keypad - allows the operator to create, edit, store and recall methods, start and stop methods and change

programmed parameters during operation.

● Attenuator - provides access to the instrument cavity while preventing microwave leakage during operation.

The attenuator can be installed or removed with a twist-lock action (no tools required).

Never modify the attenuator access port or insert metallic objects such as wire into the port. Serious microwave

leakage and/or electrical shock may result. The access port of the Discover SP-D Clinical is electrically grounded to

the microwave cavity and is designed to prevent leakage of microwave energy.

● Interlock Assembly - monitors mating of the attenuator to the cavity. If the attenuator is not properly installed,

the instrument will not deliver microwave power nor permit the system to operate.

WARNING

3

Page 8

Keypad

• HOME - Press to return to the main screen from any menu in the software. Within the System Setup portion of

the software, press this key to return to the previous menu.

• START/PAUSE - Press to start the current method or press during method operation to pause or suspend

operation. Pressing the key again will restart the method from the paused point.

• ENTER - Press to accept entries while editing or creating a method or in System Setup.

• DISCOVER - Press to load, save and create methods and review data. Pressing this key permits navigation

through and selection of program options.

• STOP - Press to stop any process. Pressing this key when performing a method will stop microwave radiation

and launch the cooling function. Pressing this key during the cooling cycle will abort the cooling cycle and return

the system to the home screen.

• ARROW - Press to navigate through method programming or System Setup steps.

• +/- Press to increase or decrease highlighted method parameters or to navigate through System Setup steps.

• POWER - Press this key to change the maximum applied microwave power setting prior to or during a method.

Use the +/- keys to increase or decrease the setting. If this key is pressed during a method, this does not stop or

pause the method but updates the setting in real time. The updated setting is not captured as part of the saved

method file in the method library.

• STIRRING - Press this key to change the stirring setting prior to or during a method. Use the +/- keys to toggle to

the appropriate setting (High, Medium, Low, Off). If this key is pressed during a method, this does not stop or

pause the method but permits changing the setting in real time. The updated setting is not captured as part of the

saved method file in the method library.

• COOLING - Press this prior to beginning a method or during a method to perform the cooling function. If this key

is pressed during a method, it does not stop or pause the method but updates the setting in real time. The

updated setting is not captured as part of the saved method file in the method library. If this key is pressed while

the instrument is idle, the PowerMax option appears.

• TEMPERATURE - Press this key to change the temperature setpoint before or during a method. Use the +/- keys

to increase or decrease the setting. If this key is pressed during a method, this does not stop or pause a method but

updates the setting in real time. The updated setting is not captured as part of the saved method file in the

method library.

• PRESSURE - Press this key to change the pressure set point prior to or during a method. Use the +/- keys to

increase or decrease the setting. If this key is pressed during a method, this does not stop or pause a method but

updates the setting in real time. The updated setting is not captured as part of the saved method file in the

method library.

• TIME - Press this key to change the time value during or after a method. Use the +/- keys to increase or decrease

the time setting. Pressing this key allows for real time changes to this value. This does not stop or pause a

method but updates the setting in real time.

Method Status Bar

4

Page 9

Rear View

Power Cord Receptacle - Receives the female end of the power cord.

Magnetron Cooling Fan - Draws room air past the magnetron for cooling purposes.

Power Supply Cooling Fan - Draws room air past the power supply for cooling purposes.

Fuses - Prevent electrical power overload.

Electrical Connector - Connects autosampler or other peripheral accessory to the reactor

module.

RS232 Port - Allows additional connection and communication.

Spill Tray - Removable collection tray for cavity contents in case of a vessel failure.

Ethernet Port - Allows communication and connection to an external computer for data collection,

a local area network (LAN) or the Internet. (Optional).

Nameplate - Lists the model, serial number, Product Tag, operating voltage, frequency and

current of the instrument.

Side Views

Power Switch - Turns AC power on and off to the instrument.

Cooling Gas Line - Provides a hose connection for the cooling gas source.

7-Pin Connector - Connects pressure measurement device to the main controller board.

USB Ports - Permit installation of USB flash drive to import, export, backup and/or save instrument data.

RJ 11 Port - Permits connection and use of additional accessories.

5

Page 10

Sample Stirrer

The sample stirrer is a plate containing electromagnetic coils positioned beneath the instrument cavity floor. The

electromagnetic stirring plate works in conjunction with stirring bars placed in the reaction vessel to affect stirring and

ensure a homogeneous sample. An initial supply of magnetic stir bars are provided with the system. Additional stir bars are

available from CEM Corporation. Commercial Teflon® coated magnetic stir bars can be used.

NOTE: The stir bars are Teflon®-coated iron oxide bars. When placed in the microwave field, the iron oxide bars will reflect

the microwave energy without damaging the instrument.

WARNING

Cardiac pacemakers require magnets to control operation during checkout. If the Discover System is equipped with a

sample stirrer, some danger exists if a pacemaker is positioned in close proximity to the instrument cavity. If the

instrument is suspected of interfering with the operation of a pacemaker, the instrument should be turned off or the

pacemaker wearer should move away from the instrument.

Cooling

The cooling feature directs a gas source onto the outside wall of the reaction vessel. This provides the ability to rapidly

cool (quench) a reaction after the application of microwave energy. The cooling feature is either on or off and is part

of the method. The feature consists of:

• plumbing to direct the gas from the inlet point of the Discover to the reaction vessel in the cavity, a solenoid

valve connected to the CPU (controller) board to turn the gas flow on and off,

• A hose fitting to connect the Discover to the gas source via hose, and

• 8 feet (2.44 meters) of 1/4 inch (6.35 mm) inside diameter air hose.

The gas source is user supplied. CEM Corporation recommends either nitrogen or clean air at a minimum pressure of 25 psi

(~ 1.5 bar). This will provide a flow rate of 20 liters per minute and will cool a 5mL volume of ethylene glycol in a 10mL reaction

vessel from 150°C to less than 50°C in less than 2 minutes.

6

Page 11

System Installation

Installation Site

The Discover System is designed for installation in a laboratory fume hood or on a laboratory bench with proper ventilation.

Choose a location that

provides at least 8 in. (20 cm) of open space on each side and 6 in. (15 cm) of open space in the rear of the

instrument for ventilation. The space should be at least 22 in. (46 cm) wide by 25 in. (64 cm) deep with a height

clearance of at least 35 in. (89 cm).

Is free from vibration of large equipment and/or excessive walk-through traffic.

provides a temperature range of 41 °F (5 °C) to 104 °F (40 °C) and a humidity range of ±10-85% relative humidity.

provides adequate space for sample handling (and computer placement if applicable),

permits the system to be connected to a dedicated, grounded 120 or 240 VAC outlet. The Discover System should be

operated on a stabilized, constant voltage AC power supply. To operate properly, the voltage must be within 10% of

specified level.

Unpacking

Carefully remove the system from its shipping carton and place it in an appropriate location in the fume hood or on a

laboratory bench.

Note: Retain all packing material for use if returning the system to the manufacturer, subsidiary or distributor for service.

Inspect the instrument for shipping damage such as cracks, dents or warping.

WARNING

Upon receipt, if damage to the instrument is noted, do not attempt to operate the instrument.

This instrument utilizes high voltages and microwave radiation. Only technicians trained in repair and maintenance

of high voltage and microwave power systems should perform instrument service and repair.

Never modify the attenuator access port or insert metallic objects such as wire into the port. Serious microwave

leakage and/or electrical shock may result. The access port of the instrument is electrically grounded to the

microwave cavity and is designed to prevent leakage of microwave energy.

Cardiac pacemakers require magnets to control operation during checkout. Because the Discover System is

equipped with a variable-speed, electromagnetic sample stirrer, some danger exists if a pacemaker is positioned in

close proximity to the instrument cavity. If the instrument is suspected of interfering with the operation of a

pacemaker, the instrument should be turned off or the pacemaker wearer should move away from the instrument.

Disconnect the instrument from the AC power source prior to performing any service procedure.

If the instrument has been damaged in shipping, contact the freight carrier to report the damage and to file a damage

report. Contact the CEM Service Department or the local subsidiary or distributor to report damage and to request

service information.

7

Page 12

Discover SP-D Clinical Installation

1. Place the Discover in a hood or on bench.

2. Plug the power cord into the back of the instrument.

3. Remove the vent tubing from the accessory kit and connect to the rear of the ActiVent.

4. Place the other end in the back of the fume hood or other location appropriate for solvent exposure.

5. Plug the power cord into the wall outlet.

6. To set up the air regulator:

a. Splice the tubing supplied by CEM in half.

b. Install one length of the tubing into the left side of the Discover by pushing in on the tubing

until resistance is felt.

c. Place the opposite end of the tubing into the regulator.

8

Page 13

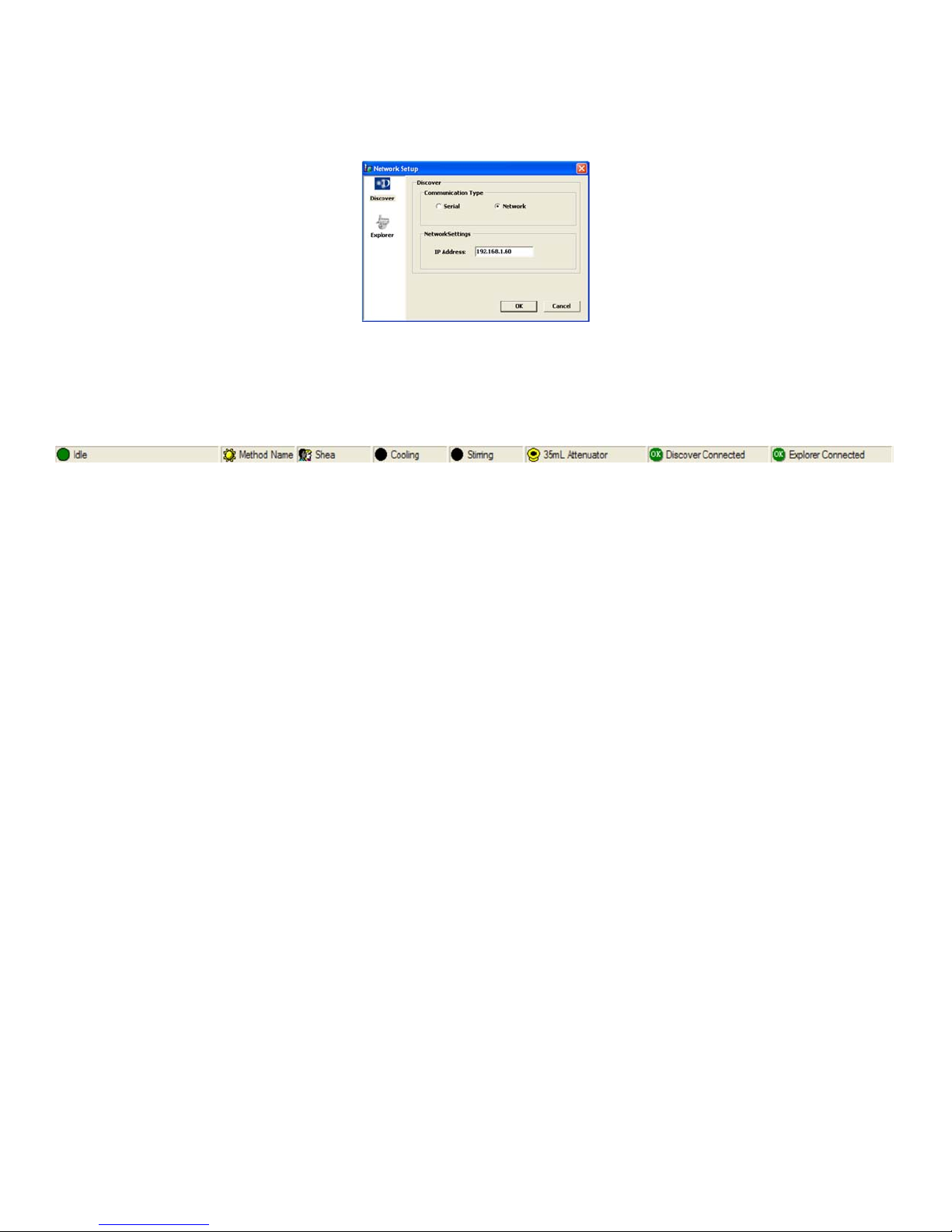

NOTE: The regulator has an arrow printed on it to show the direction that the air must flow. Set up the regulator according to

A

the arrow.

ir Flow Arrow

d. Place the second length of tubing into the opposite end of the regulator.

e. Connect the opposite end of the tubing to the air source.

f. To change the amount of air flow from the regulator:

Pull the knob on the regulator outward.

Rotate the knob clockwise to increase the amount of air flow.

Rotate the knob counterclockwise to decrease the amount of air flow.

The minimum compressed gas requirement is 25 PSI (20L/min flow).

The maximum flow rate is 60 PSI.

Note: The air flow should remain on at all times when a reaction is being performed.

7. Check the cavity for debris.

8. Using the power switch located on the left side of the Discover, turn the instrument on.

9. The ActiVent (pressure device) will return to the home position once the Login screen appears. Remove the 10mL

shipping device.

Note: Do not discard the 10mL shipping device. It will be required if returning the system to CEM Corporation for service.

Computer Installation (optional)

1. Connect one end of the Ethernet cable to one of the Ethernet ports located at the rear of the Discover.

2. Connect the opposite end of the Ethernet cable extending from the Discover to the computer.

3. Ensure that the computer is turned on and the desktop is visible. Select the Synergy icon to activate the Synergy

software. If the Synergy icon is not visible on the desktop, insert the Synergy CD and follow the on-screen

instructions.

Note: If this is the first time the software has been activated on the computer, the user will be prompted to create a new

account.

9

Page 14

4. Using the pull-down menu, select the proper name and enter the appropriate password. Select “OK.” Synergy will

automatically load the user’s preferences and connect to the Discover and Explorer modules during the login

process.

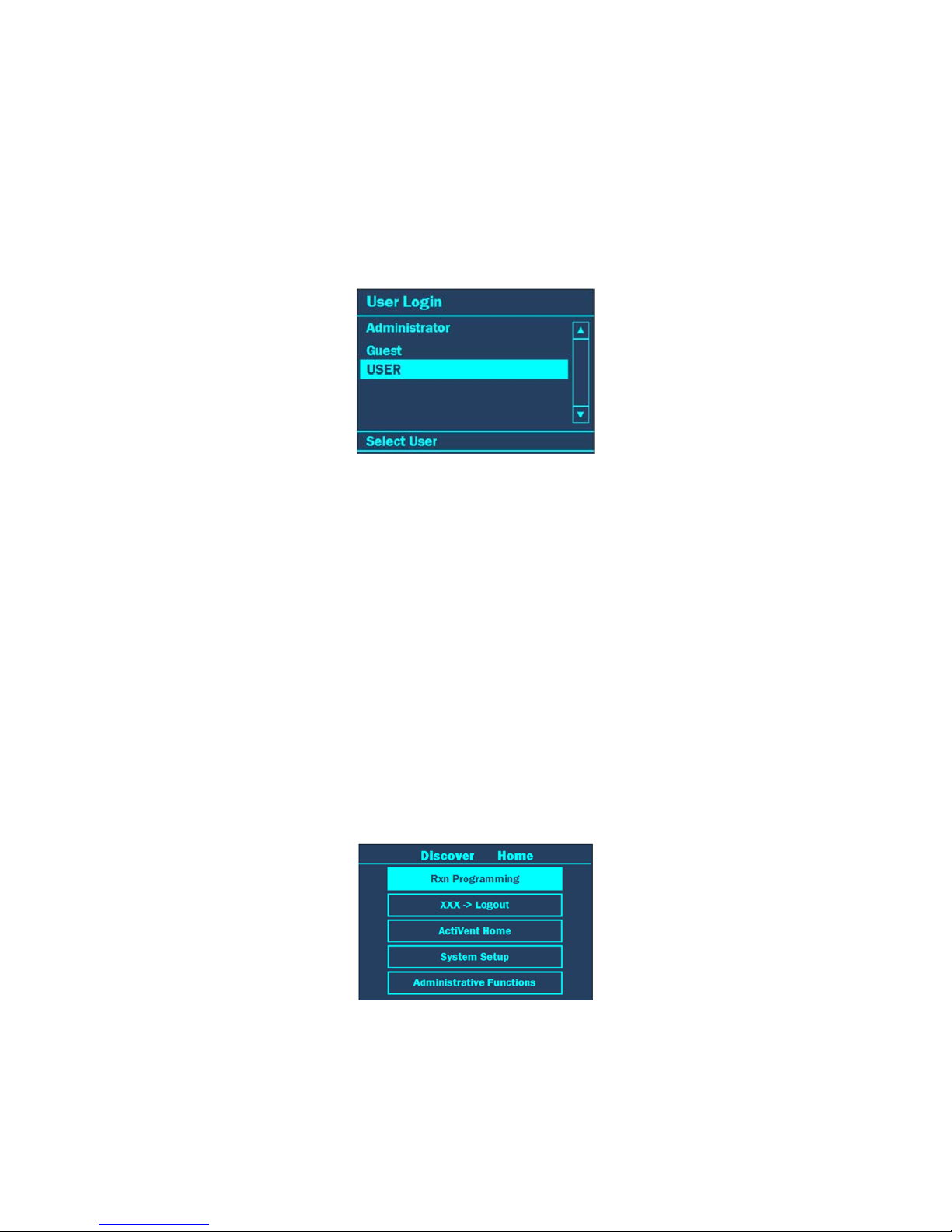

5. Select “Network Setup.” The following screen will appear.

6. Select the Discover icon.

7. The IP Address should read “192.168.1.60.” If the IP Address does not read as shown, highlight the IP Address, and

using the computer keyboard, enter the correct IP Address.

8. Select “OK.” The icons in the status bar will become green and show that the instruments are connected.

9. If the icons are red and the system is not connected, follow the procedure as outlined below to assign a fixed IP

Address to the PC/Laptop:

a. Right click the “My Network Places” icon on the desktop and select “Properties.” This will open the “Network

Connections” window.

b. Right click “Local Area Connection” and select “Properties.” This will open the “Local Area Connections

Properties” window.

c. Select the “General” tab; highlight the “Internet Protocol (TCP/IP) connection and select “Properties.” This will

open the Internet Protocol (TCP/IP) Properties 168.1.window.

d. Select “Use the following IP Address.”

e. Assign 192.168.1.10 to the IP Address.

f. Press the “tab” button. Tthe subnet mask box should populate with 255.255.255.0

NOTE: The IP address consists of up to 12 numeric characters. The address is broken into 4 sets of up to 3 numeric

characters per set. Each set is separated by a period (.). In the Discover System, the first character after a period can be

a zero (0). However the first numeric character cannot be a zero when entered into the PC/Laptop IP Address box. The

first two sets of Fixed IP Address numbers for the PC/Laptop must match the first two sets of numbers in the Discover IP

Address. However, the PC/Laptop’s Fixed IP Address must be unique, thus the reason to decrement the last set of

numbers.

g. Press the “OK” button. This will close the Internet Protocol (TCP/IP) Properties window and return the user to the

“Local Area Connections Properties” window.

h. Select the “close” button to return to the “Network Connections” window.

i. Close this window to return to the Desktop.

j. Follow the above steps 1 – 8.

10

Page 15

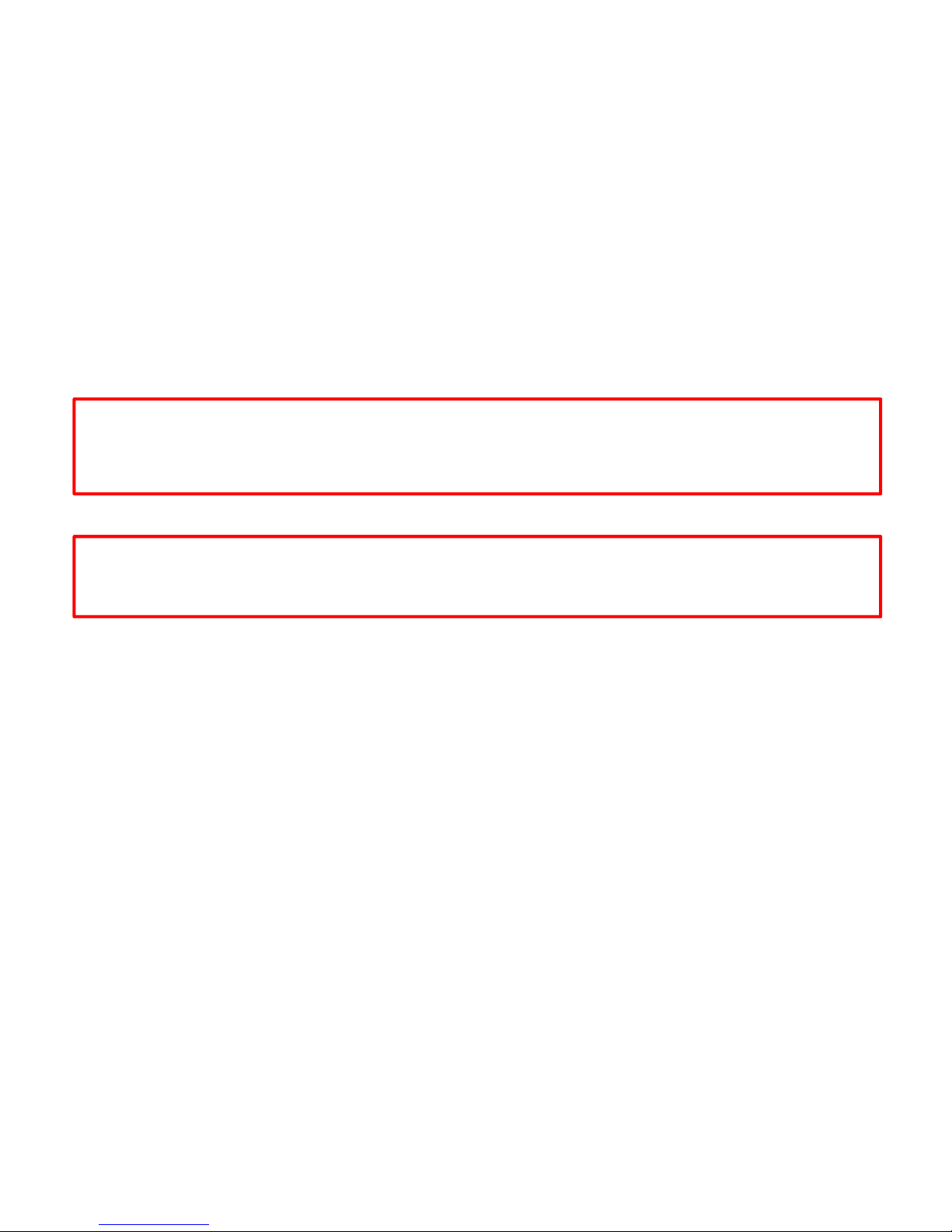

User Login

Before system operation can begin, the user is required to log into the Discover system. The Discover software is

designed to permit use by three types of users: Standard, Administrator and Guest. The Discover is originally equipped

with an “Administrator,” “User” and “Guest”. The “Administrator” login cannot be deleted. Refer to instrument setup for

instructions to create administrative, guest and standard user profiles.

Administrator- can add, modify, or delete users; perform tasks related to the maintenance of the

system; modify all system settings and perform methods.

Standard- can perform methods and modify all system settings.

Guest- can perform methods.

1. When the instrument is turned on, the “Login” screen will appear. Use the “+/-” keys to select the appropriate user.

2. Press ENTER.

3. If the user is prompted to provide a password:

a. Use the ARROW and “+/-” keys to highlight the first letter or number of the password.

NOTE: The “Shift” key changes the letters and/or symbols to lowercase.

b. Press ENTER to accept the first letter.

c. Continue highlighting the letters or numbers of the password and pressing the ENTER key for each

letter/number until the password has been entered.

d. Once the password is entered, use the ARROW and “+/-” keys to highlight “OK.”

e. Press ENTER to log in.

User Logout

Once system operation is complete, the user can log out of the system. If the system is idle for 20 minutes or longer, the

system will automatically go into an idle mode and the user will be required to log in to continue operation.

1. To log out, press HOME until the “Discover Home” screen appears.

2. Use the “+/-” keys to highlight “XXX-Logout.”

NOTE: The user name will appear where the “XXX” are located.

3. Press ENTER to log out.

11

Page 16

Microwave Tips

Cover all solids in the reaction vessel with liquid.

Never exceed the maximum working volume of the vial.

Always use a stir bar that adequately mixes the reaction contents in the microwave.

Reactions can be performed under an inert atmosphere.

Try performing the reaction at higher concentrations.

How to Cautiously Microwave

Start with a low power input - 200 W or less (this can be adjusted as necessary)

Watch the first minute of the reaction.

If a gas forms during the reaction, Cool the reaction completely. Allow the ActiVent to release the excess gas.

Standard Vessel

Total Volume/

Vessel Name

4 mL 0.200 – 2.0 mL Sealed

10 mL 0.200 – 5.0 mL Sealed

Working Volume Sealed/Pressurized or

Open/Atmospheric

12

Page 17

Closed Vessel Extraction

Items Required:

4mL/10mL Attenuator

4mL/10mL mL Vial

Stir bar appropriate for vial size

4mL/10mL Cap

Prepare the Vial

1. Select the vial based on the volume of solvents being used.

NOTE: The working volume for the 10mL vial is 0.2mL to 5mL. The working volume for the 4mL vial is 0.2mL to

2mL.

2. Place an appropriate stir bar into the vessel.

3. Place the reaction components into the vessel.

Proper precautions must be taken to avoid contact with acids or acid vapors. Protective gear should be worn as outlined

in the user’s safety program for hazardous materials and the reagent manufacturer’s material safety data sheet. Refer to

these guidelines for proper decontamination, handling and disposal of reagents or any hazardous materials.

4. Place the cap onto the vial.

The Discover SP-D Clinical is usable only with CEM supplied 4mL or 10mL reaction vessels and caps for sealed

reactions.

5. Install the appropriate attenuator assembly with the large slot positioned toward the back of the instrument.

6. Rotate the attenuator assembly clockwise until the attenuator locks into position.

7. Place the vessel into the attenuator.

Perform a Method

1. Load or create the appropriate method into the instrument on the Discover SP-D Clinical or the Synergy software

(see section “Load Method” or “Create New Method or the Synergy software “Help” text for creating a method).

2. Press the START/PAUSE key. The ActiVent will close and lock onto the vessel. The “Waiting” screen appears prior

to irradiation initiation. Once the method begins, the system ramps to set-point temperature. The system continues to

meet method parameters to perform the complete method.

NOTE: The information across the bottom of the screen displays the parameter status as follows:

Pressure (Bar or PSI)

Power (W)

Stirring (H {High}, M {Medium}, L {Low} or Off (X)

Temperature Control (IR {Infrared} or FO {Fiber Optic)}

Vessel Type - If the vessel is a sealed vessel, the size will be displayed beside the picture of the vessel.

Cooling (Off or On) - If Cooling is “on,” a snowflake is displayed.

Microwaves (Off, On)

System accessories (D {Discover}, or E {Explorer})

WARNING

WARNING

13

Page 18

Remove the Vessel

1. Once the vessel is properly cooled, the ActiVent will release the vessel and “Complete” will appear on the

Display. If the ActiVent does not automatically release the reaction vessel, the pressure (or temperature) is above the

release limit. A message will appear indicating the current temperature and pressure value. Cool the reaction vessel

completely and manually release the ActiVent.

2. Rotate the attenuator assembly counterclockwise and lift it from the instrument.

WARNING

To prevent the possibility of severe burns, wear insulated gloves and protective gear as outlined in the user’s safety

program.

3. Carefully remove the vessel from the attenuator.

NOTE: If the cap still holds residual pressure, place the cap and vial in a fume hood or other well-ventilated area.

Use a needle to pierce the septa to vent the pressure.

4. Remove the cap from the vessel by pressing upward on one side of the cap.

WARNING

Vessels and caps are designed for only one use. Do not use vessels and/or caps more than one time.

14

Page 19

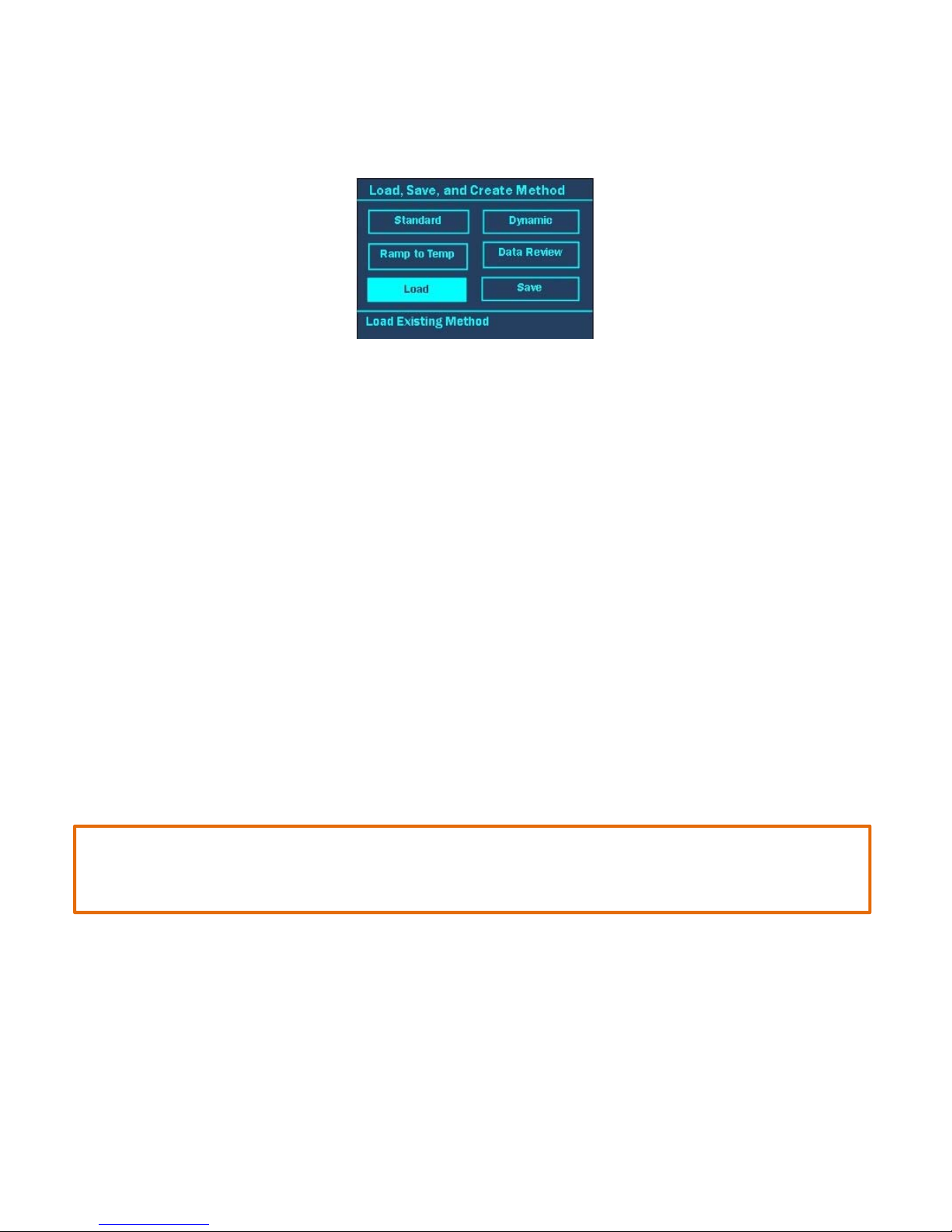

Load, Save, and Create a New Method

The “Load, Save, and Create a New Method” screen allows all users to create new methods, save them to the Discover

data base and Load (recall) the methods at a later time. From this screen, the user can also recall data from a reaction

previously run on the Discover system. To access this screen press the Discover key on the Discover keypad.

Create a New Method

The Discover System has three (3) control options for programming a method – Standard, Dynamic and Ramp-toTemperature. These options permit the user to control how the system applies the microwave energy to the reaction.

In all control options, the user inputs control parameters to create the method. The user enters more control information

as the level of control increases. The Standard control option is the recommended control technique for routine operation.

The Dynamic method allows the user to implement the ActiVent feature. The SP-D Clinical system permits the user to

release unwanted gaseous byproducts from the reaction to prevent over pressurization and vial failure from gaseous

buildup. This ensures safe handling of the vial during and at the end of the reaction. The ActiVent safely bleeds the

solvent/vapor from the reaction vessel and releases it through the vent tube connected to the back of the system and into

a controlled environment.

If the reaction generates a gaseous byproduct or an extreme amount of pressure during the reaction, the ActiVent will

vent at a specific set point for a pre-determined number of times.

• The “Delta Pressure” is the assigned amount of pressure to drop from the pressure set point. A delta of 50 PSI

(1.7 BAR) is recommended.

• The “PressureSP” is the pressure set point at which the venting will begin. If the gaseous byproduct that is

generated is the only pressure in the reaction vial (the reaction temperature does NOT exceed the boiling point of

the solvent), the ActiVent pressure release can be set below the control point. If a gas is generated, but some of

the pressure is due to vapor pressure, then the release point for the ActiVent must be set at or above the

pressure control point.

• The “Times at SP” is the maximum number of times a reaction will vent during the assigned ramp and hold time.

However, this parameter can be adjusted based on specific reaction conditions. For a typical reaction, 5 vents

are recommended.

CAUTION

If the reaction temperature exceeds the acid boiling point and too many venting actions are performed, the vial

could become dry and superheat.

• The number of stages is the stage at which the PressureSP will be active for a multistage method. A maximum of

5 stages can be added.

15

Page 20

Standard

The Standard Control is a fast and simple reaction method. The user programs

A temperature control point and

A run time (time held at the specified temperature).

All other method parameters are controlled by the instrument defaults. All method parameters can be edited with the

Discover hotkeys.

1. With the main menu displayed, press the DISCOVER key.

2. Using the ARROWS and “+/-” keys highlight “Standard.”

3. Press the ENTER key.

4. Press the temperature hotkey on the Discover keypad to modify the method.

5. Use the “+/-” keys to increase or decrease the temperature to the desired parameter. (0 - 220°C)

6. Press the right ARROW key to highlight “Time”.

7. Use the ARROW keys to select the hours, minutes, and/or seconds of time to edit. Use the “+/-” keys to increase

or decrease the selected time parameter. (1 second to 99 hours, 59 minutes and 59 seconds).

8. Once the time is entered properly, press the ENTER key to accept all method parameters.

Dynamic

The Dynamic Control option provides more flexibility in how the user programs a reaction method. It applies to a

specified amount of power, defined by the user, to reach the control point. It modulates this set power automatically,

based on the sensor feedback data, to ensure the control point is reached rapidly, but with limited error (temperature or

pressure “overshooting”). The user programs:

the maximum amount of microwave power that can be applied to the method,

a temperature control point,

a pressure control point,

a hold time (the time the system maintains the control parameters),

a stirring function with speed control and a pre-stir option, and

PowerMAX (simultaneous cooling).

The ActiVent feature can be implemented in Dynamic Control. If the reaction generates a gaseous byproduct or an

extreme amount of pressure during the reaction, the ActiVent will vent at a specific setpoint for a pre-determined number

of times.

The “Delta Pressure” is the assigned amount of pressure to drop from the pressure set point. A delta of

50 PSI (1.7 BAR) is recommended.

The “PressureSP” is the pressure set point at which the venting will begin. If the gaseous byproduct that

is generate is the only pressure in the reaction vial (the reaction temperature does NOT exceed the

boiling point of the solvent), the ActiVent pressure release can be set below the control point. If a gas is

generated, but some of the pressure is due to vapor pressure, the release point for the ActiVent

must be set at or above the pressure control point.

16

Page 21

The “Times at SP” is the maximum number of times a reaction will vent during the assigned ramp and

hold time. However, this parameter can be adjusted based on specific reaction conditions. For a typical

reaction, 5 vents are recommended.

CAUTION

If the reaction temperature exceeds the acid boiling point and too many venting actions are performed, the vial

could become dry and superheat.

The number of stages is the stage at which the PressureSP will be active for a multistage method. A

maximum of 5 stages can be added.

The Dynamic Control option can be programmed for three (3) stages for multiple irradiation steps and is a general control

method for maintaining critical control points.

1. With the main menu displayed, press the DISCOVER key.

2. Using the ARROWS and “+/-” keys highlight “Dynamic”.

3. Press the ENTER key.

4. Press one of the hotkeys to modify any of the default parameters.

5. Use the ARROW keys to navigate between temperature, time, power, pressure, stirring, PreMix, PowerMAX and

number of Stages to enter the desired method parameters. Use the “+/-” keys to increase and decrease the

numeric value.

Temperature - 0 - 220 °C

Time - 1 second to 99 hours, 59 minutes and 59 seconds

Power - 0-300W (150W recommended)

Pressure - 0-400 PSI or 0-21Bar (250PSI recommended)

Stirring - “high”, “medium”, “low” and “off” (High recommended)

PreMix - fifteen-second increments up to 120 seconds

PowerMAX - “on” or “off”

Stage - 1-5 stages

17

Page 22

6. Press the DISCOVER key to activate and program parameters for the ActiVent option. If the ActiVent feature is

not being used, proceed to step 8.

CAUTION

If the reaction temperature exceeds the acid boiling point and too many venting actions are performed, the vial

could become dry and superheat.

NOTE: The ActiVent feature is not required for the Dynamic Control Option. It allows the Discover SP-D Clinical System

to release unwanted gaseous byproducts from the reaction to prevent over pressurization and vial failure from gaseous

buildup.

NOTE: If the ActiVent feature is not being used, the system will automatically release excess pressure above 400 Psi or

21 Bar.

7. Enter the desired vent parameters using the ARROW keys to navigate between Delta Pressure, Stage, PressureSp,

and Times @ SP. Use the “+/-” keys to increase and decrease the numeric value(s).

The “Delta Pressure” is the assigned amount of pressure to drop from the pressure set point. A delta of 50 PSI

(1.7 BAR) is recommended.

The “PressureSP” is the pressure set point at which the venting will begin. If the gaseous byproduct that is

generated is the only pressure in the reaction vial (the reaction temperature does NOT exceed the boiling point of

the solvent), the ActiVent pressure release can be set below the control point. If a gas is generated, but some of

the pressure is due to vapor pressure, then the release point for the ActiVent must be set at or above the

pressure control point.

The “Times at SP” is the maximum number of times a reaction will vent during the assigned ramp and hold time.

However, this parameter can be adjusted based on specific reaction conditions. For a typical reaction, 5 vents

are recommended.

The number of stages is the stage at which the PressureSP will be active for a multistage method. A maximum of

5 stages can be added.

8. Once all ActiVent parameters have been entered, press the ENTER key to return to the method parameters screen.

9. Press the ENTER key to accept all method parameters.

Ramp-to-Temperature

The Ramp to Temperature Control option is the RECOMMENDED control type for all digestion samples. The sample is

brought to temperature in an exact programmed time, and power is varied automatically to follow that time. The effects of

variations in sample absorbance characteristics are minimized as each sample runs the same temperature profile. The

user programs:

the ramp time to achieve the temperature

the hold time at that temperature

the input power level

a control temperature (the temperature at which the magnetron will turn off)

a maximum pressure (the maximum pressure the Discover SP-D Clinical will control at or below)

stirring speed (stirring is required for digestions). CEM Corporation recommends medium speed.

a premix time (time for stirring before the heating begins)

18

Page 23

1. With the main menu displayed, press the DISCOVER key.

2. Using the ARROWS and “+/-” keys highlight “Ramp to Temp”.

3. Press the ENTER key.

4. Press a ‘HOT KEY’ (T or P).

5. Enter the desired method parameters using the “arrow” keys to navigate between power, time, temperature, pressure

stirring and PreMix. Use the “+/-” keys to increase and decrease the numeric value.

• Ramp “Time”- 1 second to 99 hours, 59 minutes and 59 seconds

• Hold “Time”- 1 second to 99 hours, 59 minutes and 59 seconds

• Power “μλ”- 0-300W

• Temperature “To”- 15-260 ºC

19

Page 24

• Pressure ‘P’ – 0 – 500PSI

• Stirring Speed – Low, Medium, High (Medium is recommended). Stirring is required for digestions.

• PreMix Time – 0-120 seconds

6. Press the Discover key to activate and program parameters for the ActiVent® option and select the vessel type.

NOTE: The ActiVent feature is REQUIRED for the Ramp to Temperature Control Option. It allows the Discover to release

unwanted gaseous byproducts from the reaction to prevent over pressurization and vial failure from gaseous buildup.

NOTE: If the ActiVent feature is not set, the system will automatically release excess pressure above 500PSI or 35Bar.

Select or change the Vessel Type – Vessel or Vessel with Liner.

7. Enter the desired vent parameters using the “arrow” keys to navigate between Delta pressure, Stage, PressureSP,

and Times @ SP. Use the “+/-” keys to increase and decrease the numeric value.

The “Delta Pressure” is the assigned amount of pressure to drop from the pressure set point before reclosing. A

minimum delta of 50 PSI (3.45 BAR) for 4 mL and 10 mL vessels is recommended.

• The “PressureSP” is the pressure set point at which the venting will begin. The pressure vent setpoint should be

set at a value appropriate for the sample type and size.

• The “Times at SP” is the maximum number of times a reaction will vent during the assigned ramp and hold time

at that vent point. This parameter should be adjusted based on specific reaction conditions.

• The number of stages is the stage at which the PressureSP will be active for a multistage method. A maximum of

5 stages can be added.

8. Once all parameters have been entered, press the ENTER key to return to the method parameters screen.

9. Press the ENTER key again to accept all method parameters.

Save a Method

Saving a method allows the user to save/store the method so it can be recalled later. There are two (2) options to save a

Method: (a) press the DISCOVER key, highlight “Save” and press the ENTER key or (b) press the start key after

programming a new method.

NOTE: A method can be created and used without being saved. If not saved, once the method has been used, but before

any modifications are made to the screen, the method can be saved using the (a) procedure outlined above.

NOTE: All of the current user’s methods can be saved to a USB device and transferred to another instrument or placed

on a personal computer. Refer to the section titled “Back Up Methods” for additional information.

After programming a new method, when the Start key is pressed, the user is given the option to save or not save the

method that is currently set to start. If “No” is selected, the method that was just created will be sent to the Discover and

the reaction will begin. If “Yes” is selected, the method will be saved and the reaction will start immediately after the

method has been saved.

1. Create a new method (refer to section “Create New Method”).

20

Page 25

2. Choose one option to save the method:

a. Press the DISCOVER key, highlight “Save” and press the ENTER key.

b. Press the Start key after a new method has been created.

3. A new screen will appear. Use the ARROW and “+/-” keys to highlight the first letter or number of the desired

method name.

NOTE: “Shift” changes the letters and/or symbols to lowercase.

4. Press the ENTER key to accept the first letter.

5. Continue highlighting the letters or numbers of the name and pressing the ENTER key for each letter/number until

the name is displayed on the screen.

6. Once the method name has been entered, use the ARROW and “+/-” keys to highlight “OK.” The method will be

saved to the current user’s database.

Load Method

The Load Method option gives the user the ability to recall a method previously saved under their user profile or that of

another user saved on the same Discover SP-D Clinical System. Methods can also be transferred from one system to

another using the USB flash drive supplied with the Discover SP.

1. With the main menu displayed, press the DISCOVER key.

2. Using the ARROWS and “+/-” keys, highlight “Load”.

3. Press the ENTER key.

4. The current user’s methods will be displayed. Use the “+/-” keys to highlight the desired method to load into the

system.

5. Press the ENTER key to load the method.

NOTE: To load a method stored for another user:

1. Use the “+/-” keys to highlight the user’s name.

2. Once the user name is highlighted, press the ENTER key.

3. Use the “+/-” keys to highlight the desired method.

4. Press the ENTER key to load the method.

NOTE: The method can be saved in the user’s folder by using the “Save” feature.

19

21

Page 26

NOTE: To load a method stored on the USB flash drive:

1. Insert a USB device with stored methods into the side of the system. Refer to the section titled “Backup Methods” for

information on how to save methods onto the USB device.

2. Press the DISCOVER key.

3. Press the “+/-” keys to highlight “Load.”

4. Press the ENTER key.

5. Use the “+/-” keys to scroll through the list until the desired user is highlighted.

6. Press the ENTER key to display the user’s methods.

7. Use the “+/-” keys to highlight the desired method.

8. Press the ENTER key to load the method.

9. The main menu is displayed with the loaded method’s name in the title bar.

Data Review

If the USB drive is in position on the side of the Discover during the reaction, the temperature data for each run will

automatically be stored. This data can be viewed on the Discover screen later as a graph or viewed as individual data

points on a computer.

NOTE: Only USB flash drives supplied by CEM Corporation are compatible with the Discover SP-D Clinical system.

1. Install the USB flash drive containing the desired method data for review.

2. With the main menu displayed, press the DISCOVER key.

3. Using the ARROW and “+/‐” keys, highlight “Data Review.”

4. Press the ENTER key.

5. Use the “+/-” keys to highlight the user for which the data is to be reviewed.

6. Press the ENTER key.

7. Use the “+/-” keys to highlight the data to be viewed.

8. Press the ENTER Key. A graph will appear on the screen with a temperature curve.

22

Page 27

NOTE: The Synergy Software provides a more detailed record of the reaction, including information such as

power and pressure data in addition to the temperature data.

9. Press the “Home” key twice to return to the Main Menu.

NOTE: The data file can be graphed on a computer as a CSV file.

1. Install the USB drive containing the reaction data into the computer.

2. Select the “CEM” folder.

3. Select the appropriate user’s folder.

4. Select the “data” folder.

5. Select the appropriate data file and open as a CSV or excel document.

Delete Method

The Delete Method function allows the user to delete methods that have been stored within the Discover SP-D Clinical

database.

1. With the main menu displayed, press the DISCOVER key.

2. Using the ARROWS and “+/-” keys, highlight “Load.”

3. Press the ENTER key. The current user’s methods will be displayed.

4. Use the “+/-” keys to highlight the desired method to be deleted.

5. Press the right ARROW key.

6. Use the ARROW keys to highlight “Delete”.

23

Page 28

7. Press the ENTER key.

8. Use the ARROW keys to highlight “Yes” or “No”.

9. Press the ENTER key. If “yes” was selected the method will be permanently deleted. If “No” is selected the

previous screen will appear.

Discover Home

The Discover home screen allows the users to set operations parameters within the Discover firmware. The Discover

firmware is designed to permit use by three types of users: Standard, Administrator and Guest. A Guest can perform

methods. A Standard User can perform methods and modify all system settings. An Administrator can add, modify, or

delete users; perform tasks related to the maintenance of the system; modify all system settings and perform methods.

The Discover includes three users when shipped:

Administrator (includes all administrator privileges and is password protected

USER (includes all administrator privileges and does not include a password)

Guest (includes Guest privileges)

If the Discover is not being installed by a CEM representative, contact CEM to obtain a password that will permit

administrative rights.

The Discover Home screen will appear differently for users according to their user type: Guest, Standard, and

Administrator.

Guest Standard Administrator

Rxn Programming

The Reaction Programming screen allows the user to return to the main menu screen. The user can also press the

HOME key to return to the main menu.

NOTE: “Rxn programming” can be viewed by all user types (guest, standard, and administrator).

1. To view the “Discover Home” screen press the HOME key.

2. Use the “+/-” keys to highlight “Rxn Programming.”

3. Press the ENTER key. The main menu screen will appear.

24

Page 29

Logout

Once system operation is complete, the user can log out of the system. If the system is idle for 20 minutes or longer, the

system will automatically go into an idle mode and the user will be required to login to continue operation.

NOTE: “Logout” can be viewed by all user types (guest, standard, and administrator).

1. To logout, press the HOME key until the “Discover Home” screen appears.

2. Use the “+/-” keys to highlight “XXXX-Logout.”

NOTE: The username will appear where the “XXXX” is located.

3. Press the ENTER key to log out.

ActiVent Home, ActiVent Moving, ActiVent Closed, APM Recovery

There are four (4) different messages that can appear in the 3rd line of the Discover Home screen. Each message

describes the position of the ActiVent (APM).

NOTE: “ActiVent Home, ActiVent Moving, ActiVent Closed, APM Recovery” can be viewed by all user types (guest,

standard, and administrator).

• ActiVent Home is displayed when the attenuator is exposed and the APM is near the back of the instrument.

When “ActiVent Home” is highlighted and the ENTER key is pressed, the ActiVent will move to the closed

position. If a vessel is not in place when the ENTER key is pressed, the Discover SP-D Clinical will display a

“Vessel Not Found” message.

• ActiVent Moving is displayed when the ActiVent is either going to the home or closed position.

• ActiVent Closed is displayed when the ActiVent is positioned over the attenuator and the vessel is sealed. If

“ActiVent Closed” is highlighted and the ENTER key is pressed, the ActiVent will move to the home position.

• APM Recovery is displayed if the ActiVent is unable to find the home position. If “APM Recovery” appears, first

try to home the ActiVent. To home the ActiVent:

1. Use the “+/-” keys to highlight “APM Recovery”.

2. Press the ENTER key. A new screen will appear with the current error message.

3. Use the ARROW keys to highlight “APM Recovery”.

25

Page 30

4. Press the ENTER key. A new screen will appear.

5. Use the ARROW and “+/-” keys to highlight the “HOME” button.

6. Press the ENTER key. The APM will return to the HOME position.

CAUTION

Improper use of the APM Recovery screen could result in destruction of the APM, making the warranty null and

void.

The pressure assembly needs to be in the highest position before the APM is moved to the back of the

instrument.

7. If the APM does not return to the home position:

a. Follow steps 3-5 above.

b. Use the ARROW and “+/-” keys to highlight “Z UP.” Press the ENTER key. If the motor can be

heard, continue to select “Z Up” until the motor no longer sounds like it is turning. This will raise

the ActiVent to the highest position.

c. Use the ARROW and “+/-” keys to highlight “APM Back.”

d. Press the ENTER key. If the APM appears to be moving backward, select “APM Back” until the

ActiVent no longer moves backward. The ActiVent should be all the way back, away from the attenuator.

e. Use the ARROW and “+/-” keys to highlight the “HOME” button.

f. Press the ENTER key. The APM should now return to the HOME position.

System Setup

The “System Setup” function consists of five (5) “pages” that allow the user to calibrate system settings, set method

defaults, clean the ActiVent feature, and view system information.

NOTE: “System Setup” can only be viewed by Standard and Administrator users.

To enter the System Setup screen:

1. Press the HOME key until the “Discover Home” screen appears.

2. Use the “+/-” keys to highlight “System Setup”.

3. Press the ENTER key. A new screen will appear.

26

Page 31

User Setup

The “User Setup” page is the 1

st

page that appears after selecting “System Setup” from the Discover home screen. This

page allows the user to set up method defaults and general operating parameters for the Discover SP-D Clinical system.

Temperature Type

“Temperature Type” allows the user to switch between the Infrared and Fiber Optic temperature control.

1. Using the “+/-” keys, highlight “Temperature Type.”

2. Press the ENTER key.

3. Using the “+/-” keys, highlight the applicable temperature control to be utilized (infrared or fiber optic).

NOTE: To utilize the fiber optic control, the fiber optic temperature control option must be connected on the side of the

instrument. The part number for the fiber optic assembly is 541166.

4. Press the ENTER key. The “User Setup” screen will appear again.

Release limits

Temperature and pressure release limits are the temperature and pressure at which the ActiVent will

automatically open and release the vessel after cooling. The recommended default temperature is 60°C. The

recommended default pressure is 2.8 Bar (40 PSI).

NOTE: The default temperature should be lowered if a solvent with a low boiling point is used.

1. Using the “+/-” keys, highlight “Release Limits.”

2. Press the ENTER key.

3. Use the “+/-” keys to increase and decrease the release limits. Use the ARROW keys to toggle between

“Temperature” and “Pressure.”

4. Once the parameters have been entered, press the ENTER key. The “User Setup” screen will appear.

27

Page 32

User Profiles

The User Profiles option allows the user to set defaults when creating methods, edit/change the password and edit

system parameters. There are 4 pages within the “User Profiles” page.

1. From the “User Setup” screen, use the “+/-” keys to highlight “User Profiles.”

2. Press the ENTER key.

User Profiles

The “User Profiles” screen is the 1

st

page of the “User Profiles” menu. This page allows the user to clear or change

the password.

Clear Password

1. Use the “+/-” keys to highlight “Clear Password.” The user will be prompted to clear the password - yes or no.

2. Use the ARROW keys to highlight either “Yes” to clear the password or “No” to leave the password as is.

3. Press the ENTER key.

Change Password

1. Use the “+/-” keys to highlight “Change Password.” A new screen will appear.

2. Use the ARROW and “+/-” keys to highlight the first letter or number of the password.

NOTE: The “Shift” key changes the letters and/or symbols to lowercase.

3. Press the ENTER key to accept the first letter.

4. Continue highlighting the letters or numbers of the password and press the ENTER key for each letter/number until

the password has been entered.

5. Once the password is entered, use the ARROW and “+/-” keys to highlight “OK.”

User Profile Defaults -1

“User Profile Default” is the 2

nd

page of the “User Profile” menu. The “User Profile Defaults” page allows the user to

program a default Hold Time, Ramp Time, Temperature and Microwave Power.

Hold Time

“Hold Time” is the default amount of time defined by the user for the instrument to maintain the control temperature or

pressure. The instrument default hold time is five (5) minutes. When creating a new method, the hold time can be

changed from the default hold time programmed in the “User Profiles.”

1. Use the “+/-” keys to highlight hold time.

2. Press the ENTER key.

3. Use the ARROW keys to toggle between hours, minutes and seconds. Use the “+/-” keys to increase and decrease

the hold time (0 - 99 hours, 59 minutes, 59 seconds).

4. Press the ENTER key to accept the default hold time.

28

Page 33

Ramp Time

“Ramp Time” is the default amount of time defined by the user for the instrument to reach the temperature or pressure.

The instrument default ramp time is ten (10) minutes. The Discover System will achieve the set temperature as fast as

possible. The ramp time is a maximum amount of time that power will be applied before switching to the hold time. When

creating a new method, the ramp time can be changed from the default ramp time programmed in the “User Profiles.”

1. Use the “+/-” keys to highlight “Ramp Time.”

2. Press the ENTER key.

3. Use the ARROW keys to toggle between hours, minutes and seconds. Use the “+/-” keys to increase and decrease

the hold time (0 - 99 hours, 59 minutes, 59 seconds).

4. Press the ENTER key to accept the default ramp time.

Temperature