CEL ZICM0868P0-1CU, ZICM0868P2-1CU, ZICM0900P, ZICM0868P0-1CS, ZICM0868P0-1C Preliminary Data Sheet

...

PRELIMINARY DATA SHEET

MeshConnect™ Sub-G Module Series

ZICM0868Px

ZICM0900Px

868 / 900 MHz Transceiver Based Modules

Development Kits Available:

ZICM0868P2-KIT1-1 and ZICM0900P2-KIT1-1

DESCRIPTION

CEL's MeshConnect™ Module Series provides high performance

and low cost Sub-G modules for a broad range of wireless net-

works. The MeshConnect certied and qualied modules enable

customers to accelerate time to market by greatly reducing design

and certication phases of development.

CEL's MeshConnect™ Sub-G modules (868/900MHz) are based

on the Silicon Labs SoC ICs (single-chip solutions). Each IC consists of an RF transceiver with baseband modem, a hard-wired

MAC and an embedded 8051 microcontroller with internal RAM

(4kB) and Flash (64kB) memory. The device provides numerous general-purpose I/O pins and peripheral functions such as

timers and UARTs.

The MeshConnect Sub-G modules have 2 different output powers

(+12dBm and +19dBm). They provide a reliable transmission, to

reduce the number of nodes in a network. They are especially

useful for open outdoor applications where the nodes are physically far apart. The higher power Modules have an outstanding

118dB link budget ensuring high quality connections even in

harsh environments.

APPLICATIONS

• Metering

• RFID

• RemoteKeylessEntry

• HomeAutomation

• Security

• Irrigation

• WeatherStations

• Andmore...

™

MeshConnect

ZICM0868Px ZICM0900Px

Sub-G Modules

Best Reliable Performance

• Good sensitivity providing longer range for Non-line-of-site

aplications

• Low operating (receive) current

FEATURES

•FrequencyRange:

902- 928 MHz

868 MHz

•Sensitivity:-99dBm

•MaxOutputPower:

+ 12 dBm @ 3.6 VDC (ZICM0xxxP0)

+ 19 dBm @ 3.6 VDC (ZICM0xxxP2)

•DataRate:0.123to150kbps

•Upto21GPIOPins

•HighSpeed8051MCU:

30 MHz

4kB RAM / 64 kB Flash

•10-BitADC:

300 ksps, 18-ch inputs

•SerialCommunication:

UARTs, SPI (Master/Slave)

SMBus, PCA

•Modulation:

FSK

•RFPowerConsumption

24 mA Receive

18 mA @ + 1 dBm transmit

30 mA @ + 12 dBm transmit

90 mA @ + 19 dBm transmit

•Auto-FrequencyCalibration(AFC)

•FrequencyHoppingCapability

•Upto12milesofrange

•OperatingTemperatureRange:

-40 to +85ºC

•SoftwareSupport:

Synapse SNAP Embedded Firmware

Wireless M-Bus (868MHz Only)

Silicon Labs EZMac

CEL Protocol

•FCC,CEandICcerticationsin

Progress

•ROHScompliant

The information in this document is subject to change without notice, please conrm data is current

Document No: 0009-00-07-00-000 (Issue ES)

Date Published: December 7, 2010

Page 1

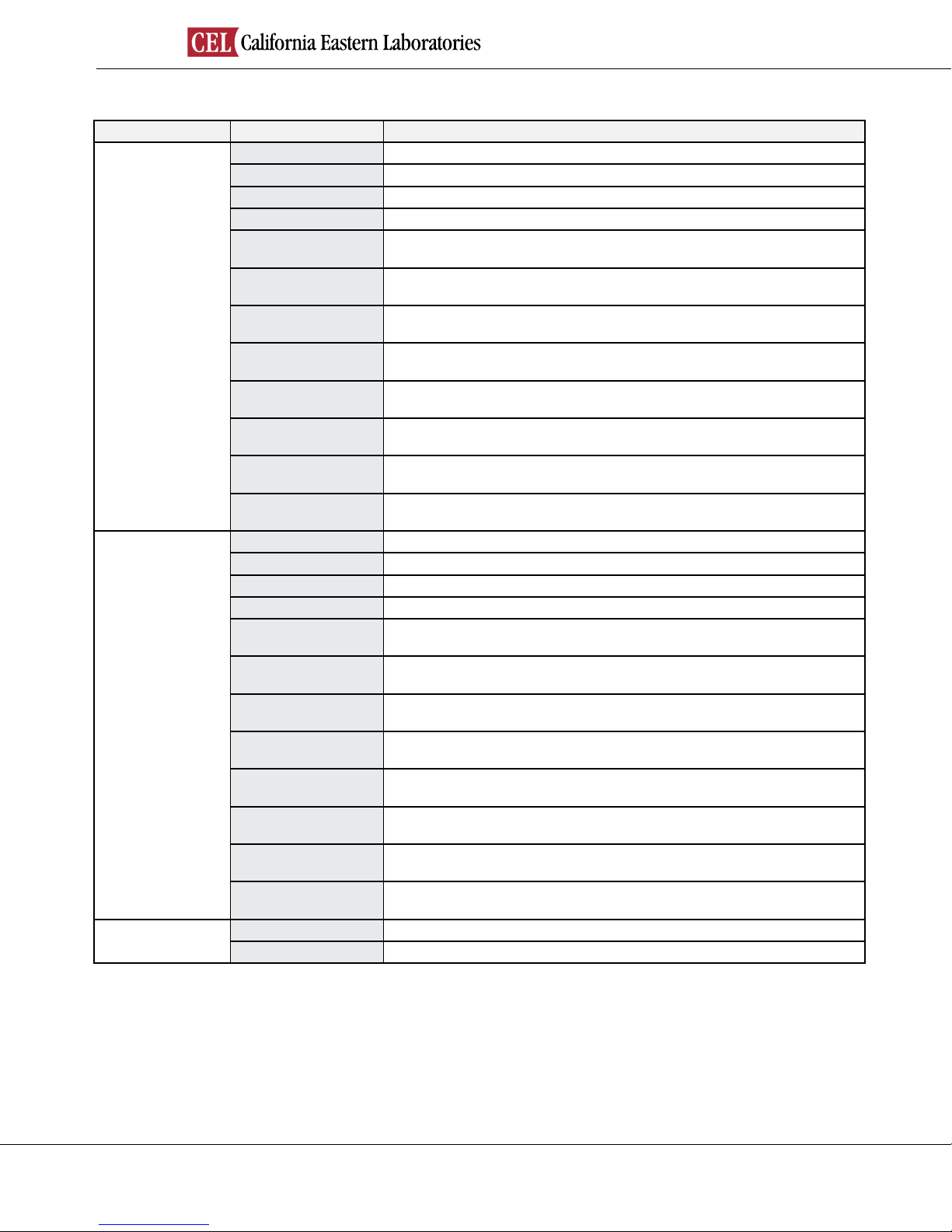

ORDERING INFORMATION

Part Number Order Number Description

ZICM0868P0-1CU 868 MHz Module, +12dBm output power with U.FL connector for external antenna

ZICM0868P2-1CU 868 MHz Module, +19dBm output power with U.FL connector for external antenna

ZICM0868P0-1CS 868 MHz Module, +12dBm output power with RP-SMA connector for external antenna

ZICM0868P2-1CS 868 MHz Module, +19dBm output power with RP-SMA connector for external antenna

ZICM0868P0-1C

ZICM0868P2-1C

MeshConnect™ Sub-G

(Eruope Only)

MeshConnect™ Sub-G

MeshConnect™ Sub-G

Development Kits

ZICM0868P0-1CU-SN

ZICM0868P2-1CU-SN

ZICM0868P0-1CS-SN

ZICM0868P2-1CS-SN

ZICM0868P0-1C-SN

ZICM0868P2-1C-SN

ZICM0900P0-1CU 900 MHz Module, +12dBm output power with U.FL connector for external antenna

ZICM0900P2-1CU 900 MHz Module, +19dBm output power with U.FL connector for external antenna

ZICM0900P0-1CS 900 MHz Module, +12dBm output power with RP-SMA connector for external antenna

ZICM0900P2-1CS 900 MHz Module, +19dBm output power with RP-SMA connector for external antenna

ZICM0900P0-1C

ZICM0900P2-1C

ZICM0900P0-1CU-SN

ZICM0900P2-1CU-SN

ZICM0900P0-1CS-SN

ZICM0900P2-1CS-SN

ZICM0900P0-1C-SN

ZICM0900P2-1C-SN

ZICM0868P2-KIT1-1 868 MHz Evaluation board for +19 dBm module

ZICM0900P2-KIT1-1 900 MHz Evaluation board for +19 dBm module

MeshConnect™ Sub-G Module Series

868 MHz Module, +12dBm output power with a connection for 1/4 wave wire antenna

(in place of RP-SMA)

868 MHz Module, +19dBm output power with a connection for 1/4 wave wire antenna

(in place of RP-SMA)

868 MHz Module, +12dBm output power with U.FL connector for external antenna

with SNAP Operating System software and MAC address

868 MHz Module, +19dBm output power with U.FL connector for external antenna

with SNAP Operating System software and MAC address

868 MHz Module, +12dBm output power with RP-SMA connector for external antenna

with SNAP Operating System software and MAC address

868 MHz Module, +19dBm output power with RP-SMA connector for external antenna

with SNAP Operating System software and MAC address

868 MHz Module, +12dBm output power for 1/4 wave wire antenna (in place of

RP-SMA) with SNAP Operating System software and MAC address

868 MHz Module, +19dBm output power for 1/4 wave wire antenna(in place of

RP-SMA) with SNAP Operating System software and MAC address

900 MHz Module, +12dBm output power with a connection for 1/4 wave wire antenna

(in place of RP-SMA)

900 MHz Module, +19dBm output power with a connection for 1/4 wave wire antenna

(in place of RP-SMA)

900 MHz Module, +12dBm output power with U.FL connector for external antenna

with SNAP Operating System software and MAC address

900 MHz Module, +19dBm output power with U.FL connector for external antenna

with SNAP Operating System software and MAC address

900 MHz Module, +12dBm output power with RP-SMA connector for external antenna

with SNAP Operating System software and MAC address

900 MHz Module, +19dBm output power with RP-SMA connector for external antenna

with SNAP Operating System software and MAC address

900 MHz Module, +12dBm output power for 1/4 wave wire antenna (in place of

RP-SMA) with SNAP Operating System software and MAC address

900 MHz Module, +19dBm output power for 1/4 wave wire antenna (in place of

RP-SMA) with SNAP Operating System software and MAC address

Page 2

MODULE BLOCK DIAGRAM

ANT

SI100x

MeshConnect™ Sub-G Module Series

Sub-G

T/R

Switch

External

Memory

Optional

Low Pass

Filter

DEVELOPMENT KIT

CEL's Development Kit assist users in both evaluation and

development. As a stand-alone radio system, the kit allows

users to place the modules into the target environment

and evaluate performance on-site. The Development Kit

also serves as an invaluable aid in application development. Through the many interface headers on the board,

the user has access to all of the MeshConnect module

pins, enabling easy connection to target systems for application development.

The interface board features a serial communication

interface, a power management module, and peripherals

such as a buzzer, push-button switches, LEDs, and GPIO

headers.

™

MeshConnect

Sub-G Module Development Kit

For more detail information regarding MeshConnect

Development Kits, refer to the respective development

kit user guides documents. (Available at CEL’s website

http://www.cel.com)

DEVELOPMENT KIT ORDERING INFORMATION

Part Number Order Number Description

MeshConnect™ Sub-G

Development Kits

ZICM0868P2-KIT1-1 868 MHz Evaluation board for +19dBm module

ZICM0900P2-KIT1-1 900 MHz Evaluation board for +19dBm module

Kit Contents:

• Evaluation Boards w/Module (2)

• USB Cables (1)

• AA Batteries (4)

• Software & Technical Information CD (1)

Page 3

TABLE OF CONTENTS

Introduction and Overview

MeshConnect™ Sub-G Module Series

Description..............................................................................................................................................................................................

Features..................................................................................................................................................................................................

Applications............................................................................................................................................................................................

Ordering Information.............................................................................................................................................................................

Module Block Diagram........................................................................................................................................................................... 3

Development Kit..................................................................................................................................................................................... 3

System Level Function

Transceiver IC.........................................................................................................................................................................................

Antenna.................................................................................................................................................................................... 5

Additional Flash Memory....................................................................................................................................................................... 5

Electrical Specication

Absolute Maximum Ratings...................................................................................................................................................................

Recommended (Operating Condition)..................................................................................................................................................

DC Characteristics..................................................................................................................................................................................

RF Characteristics..................................................................................................................................................................................

Pin Signal & Interfaces

Pin Signals I/O Conguration................................................................................................................................................................

I/O Pin Assignment.................................................................................................................................................................................

Software/Firmware..................................................................................................................................................................................

Module Dimensions................................................................................................................................................................................

Module Footprint....................................................................................................................................................................................

1

1

1

2

5

6

6

6

7

8

8

9

10

11

Processing.........................................................................................................................................................................................

Agency Certications...................................................................................................................................................................

Shipment, Storage & Handling.................................................................................................................................................

References & Revision History.................................................................................................................................................

12

13

14

15

Page 4

MeshConnect™ Sub-G Module Series

TRANSCEIVER IC

The MeshConnect Sub-G modules are based on the Silicon Labs Si1000 and Si1002 SOC transceiver ICs. These ICs

incorporate the RF transceiver with the baseband modem, a hardwired MAC, and an embedded 8051 microcontroller,

offering a high performance solution for all Sub-G applications.

For more information about the Silicon Labs ICs, visit http://www.silabs.com.

ANTENNA

The MeshConnect Sub-G modules include RF connectors for external antenna options only (There is no trace antenna

option). The following options are supported by CEL:

• U.FL connector

• RP-SMA connector

• A Connection for 1/4 wave wire antenna in place of RP-SMA

Here are some design guidelines to help ensure antenna performance:

• Never place the antenna close to metallic objects.

• In the overall design, ensure that wiring and other components are not placed near the antenna.

• Do not place the antenna in a metallic or metalized plastic enclosure.

• Keep plastic enclosures 1cm or more from the antenna in any direction.

ADDITIONAL FLASH MEMORY (Optional)

The Silicon Labs Transceiver ICs (Si1000 and Si1002) have an embedded 64kB of ash. Additional memory (1MB) can be

mounted on the module (as an option) to enable Over The Air (OTA) programming capability.

This is a custom solution as an option for all part numbers.

Page 5

ABSOLUTE MAXIMUM RATINGS

MeshConnect™ Sub-G Module Series

Description

Power Supply Voltage (VDD) -0.3 3.6 VDC

Voltage on any I/O Line -0.3 VDD + 0.3 VDC

RF Input Power –

Storage Temperature Range -40 125 °C

Reow Soldering Temperature – 260 °C

Note: Exceeding the maximum ratings may cause permanent damage to the module or devices.

RECOMMENDED (OPERATING CONDITIONS)

Description

Power Supply Voltage (VDD)

Input Frequency

Input Frequency 902 – 928 MHz

Ambient Temperature Range -40 25 85 °C

Note: * 2.7v is the min voltage if an additional memory IC was placed on the module.

MeshConnect™ Sub-G Module

Min Max

10

MeshConnect™ Sub-G Module

Min Typ Max

1.8/2.7*

863

3.3 3.6 V

–

Unit

dBm

870

DC CHARACTERISTICS (@ 25°C, VDD = 3.6V, ZICM0xxxP2 TX power max)

Unit

MHz

Description

Transmit Mode Current –

Receive Mode Current –

Sleep Mode Current –

MeshConnect™ Sub-G Module

Min Typ Max

90

24

TBD

– mA

– mA

– µA

DC CHARACTERISTICS (@ 25°C, VDD = 3.6V, ZICM0xxxP0 TX power max)

Description

Transmit Mode Current – 35 – mA

Receive Mode Current – 24 – mA

Sleep Mode Current – TBD – µA

MeshConnect™ Sub-G Module

Min Typ Max

Unit

Unit

Page 6

RF CHARACTERISTICS (@ 25°C, VDD = 3.6V, ZICM0xxxP2)

MeshConnect™ Sub-G Module Series

Description

General Characteristics

RF Frequency Range

Transmitter

Maximum Output Power –

Minimum Output Power –

FSK Error TBD – TBD

Carrier Offset TBD – TBD KHz

Deviation – 75 – KHz

Receiver

Sensitivity (1% PER, 156kbps)

Saturation (maximum input level)

MeshConnect™ Sub-G Module

Min Typ Max

863

–

–

–

19

-5

-99 TBD

–

928

– dBm

– dBm

10

RF CHARACTERISTICS (@ 25°C, VDD = 3.6V, ZICM0xxxP0)

Description

General Characteristics

RF Frequency Range 863 – 928 MHz

Transmitter

Maximum Output Power – 12 – dBm

Minimum Output Power – -12 – dBm

FSK Error TBD – TBD %

Carrier Offset TBD – TBD KHz

Deviation – 75 – KHz

Receiver

Sensitivity (1% PER, 156kbps) – -99 TBD dBm

Saturation (maximum input level) – – 10 dBm

MeshConnect™ Sub-G Module

Min Typ Max

Unit

MHz

%

dBm

dBm

Unit

Page 7

MeshConnect™ Sub-G Module Series

PIN SIGNALS I/O PORT CONFIGURATION

MeshConnect module has 56 edge I/O interfaces for connection to the user’s host board. The MeshConnect Module Dimensions

shows the layout of the 56 edge castellations.

MeshConnect I/O PIN ASSIGNMENTS

Number Name Notes

1 GND

2 GND

3 GND

4 GND

5 GND

6 GND

7 GND

8 NC

9 ANTA Available: Not used for any module funconality

10 GPIO0 Available: Not used for any module funconality

11 GPIO2 Available: Not used for any module funconality

12 P0.7/IREF Must be connected to SDN for SNAP rmware

P0.6/

13

14 P0.5/RXD UART TXD

15 P0.4/TXD UART RXD

16 WP Write Protect Pin of Memory Chip on Module

17 NC

18 GND

19 GND

20 NC

21 NC

22 NC

23 P0.3 Used as Chip Select for Memory IC on the CEL Module

24 P0.2 Memory IC MISO signal pin

25 P0.1 Must be connected to NIRQ for SNAP rmware

26 P0.0 Memory IC Clock Signal

27 GND

28 VCC

29 RST/C2CK Debug Clock

30 P2.7/C2D Debug Data

31 P2.6 GPIO connected to Buzzer on CEL Eval Board

32 P2.5 GPIO connected to Switch 3 on CEL Eval board

33 P2.4 GPIO connected to LED3 on CEL Eval board

34 P2.3 GPIO connected to Switch 2 on CEL Eval Board

CNVSTR Used as Chip Select for Memory on CEL Eval. Board

Page 8

MeshConnect I/O PIN ASSIGNMENTS (Continued)

Number Name Notes

35 NC

36 NC

37 GND

38 GND

39 GND

40 GND

41 GND

42 P2.2 GPIO connected to LED2 on CEL Eval board

43 P2.1 GPIO connected to Switch 1 on CEL Eval Board

44 P2.0 GPIO connected to LED1 on CEL Eval board

45 P1.7 GPIO connected to Switch 0 on CEL Eval Board

46 P1.6 GPIO connected to LED0 on CEL Eval board

47 P1.5 Memory IC MOSI

48 NIRQ External Interrupt Request

49 SDN Radio Shutdown (Acve High)

50 GND

51 GND

52 GND

53 GND

54 GND

55 GND

56 GND

MeshConnect™ Sub-G Module Series

SOFTWARE/FIRMWARE

The Sub-G modules support the following software:

• SynapseSNAPEmbeddedFirmware

• WirelessM-Bus(868MHzOnly)

• SiliconLabsEZMac

• CELProtocol

The MeshConnect Sub-G Development Kit provides a guide on how to access the Si100x IC and utilize the Silicon Labs

software development environment. It also provides a set of demo applications to conduct several tests. Below is the list of

the demo software features:

Page 9

MeshConnect™ Sub-G Module Series

SOFTWARE/FIRMWARE (Continued)

• Self Healing (Orphan handling)

• Point-to-Point network formation

• Point-to-Multipoint (Star) network formation

• Self Healing (Orphan handling)

• Point-to-Point network formation

• Point-to-Multipoint (Star) network formation

• ACK

• Wakeup Modes (Si100X) – most likely software will just use one of the wakeup modes

• Frequency Hopping

• Unicast Addressing using 16-bit device IDs

• Broadcast Addressing

• Packet Forwarding (Master node only)

• Forwarding Table Aging (Master node only)

• Promiscuous Mode (TBD – later release)

• Listen Before Talk (LBT)

• RSSI

• Packet Filtering

• Pairing/Joining

• Network Synchronization through beacon messages to coordinate sleep/wake cycles

- Master node needs to send out beacon as well as gure out when to go to sleep and when to wake up

- End node wakes up and looks for beacon to gure out when to go to sleep and wake up

• Command line interface for debug/testing/conguration

• Push buttons for Range or PER packet test on a Eval board

• Save conguration to ash

• Save conguration to external ash

• Over-the-air programming of the image to another device (TBD – later release)

• Low Battery detection

MODULE DIMENSIONS

MeshConnect™ Sub-G Module with U.FL Connector for external antenna

MeshConnect™ Sub-G Module with RPSMA Connector for external Antenna

For layout recommendation for optimum antenna performance, refer to Antenna section in this document.

Page 10

MODULE LAND FOOTPRINT

Note: Unless otherwise specied. Dimensions are in Inches [mm].

MeshConnect™ Sub-G Module Series

EVALUATION BOARD

CEL provides an Evaluation board to allow easy testing of the Module. The Evaluation board provides power via:

• AA cell batteries

• USB

• AC Adapter regulated down to 3.3VDC

• External Lab Power Supply (A jumper is also provided for the purposes of monitoring the DC current of

the module under various modes of operation).

Also included on the evaluation board are four momentary push button switches and four LEDs, a piezo buzzer, a potenti-

ometer, and a SPI memory IC. The peripherals are connected to GPIO of the module (see notes in Pin denitions) through

slide switches. If the user would wants to connect user specic circuits to the GPIO, slide switches can be used to discon-

nect the evaluation board peripherals.

The purpose of the evaluation board is to demonstrate simple applications of using GPIO, communicating with the device

and also allow exibility for user specic needs.

Page 11

MeshConnect™ Sub-G Module Series

PROCESSING

Recommended Reow Prole

Parameters Values

Ramp up rate (from Tsoakmax to Tpeak) 3º/sec max

Minimum Soak Temperature 150ºC

Maximum Soak Temperature 200ºC

Soak Time 60-120 sec

TLiquidus 217ºC

Time above TL 60-150 sec

Tpeak 250ºC

Time within 5º of Tpeak 20-30 sec

Time from 25º to Tpeak 8 min max

Ramp down rate 6ºC/sec max

Achieve the brightest possible solder llets with a good shape and low contact angle.

Pb-Free Soldering Paste

Use of “No Clean” soldering paste is strongly recommended, as it does not require cleaning after the soldering process.

Note: The quality of solder joints on the castellations (‘half vias’) where they contact the host board should meet the appropriate IPC Speci-

cation. See the latest IPC-A-610 "Acceptability of Electronic Assemblies, section 8.2.4 Castellated Terminations.”

Cleaning

In general, cleaning the populated modules is strongly discouraged. Residuals under the module cannot be easily removed

with any cleaning process.

• Cleaning with water can lead to capillary effects where water is absorbed into the gap between the host board and

the module. The combination of soldering ux residuals and encapsulated water could lead to short circuits between

neighboring pads. Water could also damage any stickers or labels.

• Cleaning with alcohol or a similar organic solvent will likely ood soldering ux residuals into the two housings, which

is not accessible for post-washing inspection. The solvent could also damage any stickers or labels.

• Ultrasonic cleaning could damage the module permanently.

The best approach is to consider using a “no clean” soldering paste and eliminate the post-soldering cleaning step.

Optical Inspection

After soldering the Module to the host board, consider optical inspection to check the following:

• Proper alignment and centering of the module over the pads.

• Proper solder joints on all pads.

• Excessive solder or contacts to neighboring pads, or vias.

Repeating Reow Soldering

Only a single reow soldering process is encouraged for host boards.

Wave Soldering

If a wave soldering process is required on the host boards due to the presence of leaded components, only a single wave

soldering process is encouraged.

Page 12

MeshConnect™ Sub-G Module Series

PROCESSING (Continued)

Hand Soldering

Hand soldering is possible. Use a soldering iron temperature setting equivalent to 350°C, follow IPC recommendations/

reference document IPC-7711.

Rework

The MeshConnect Module can be unsoldered from the host board. Use of a hot air rework tool and hot plate for pre-heating

from underneath is recommended. Avoid overheating.

Warning Never attempt a rework on the module itself, e.g. replacing individual components. Such actions will

terminate warranty coverage.

Additional Grounding

Attempts to improve module or system grounding by soldering braids, wires, or cables onto the module RF shield cover is

done at the customer's own risk. The numerous ground pins at the module perimeter should be sufcient for optimum

immunity to external RF interference.

AGENCY CERTIFICATIONS

FCC Compliance Statement (Part 15.19) Section 7.15 of RSS-GEN

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that may cause undesired operation.

Warning (Part 15.21)

Changes or modications not expressly approved by CEL could void the user's authority to operate the equipment.

20 cm Separation Distance

To comply with FCC/IC RF exposure limits for general population / uncontrolled exposure, the antenna(s) used for this

transmitter must be installed to provide a separation distance of at least 20 cm from all persons and must not be co-located

or operating in conjunction with any other antenna or transmitter.

OEM Responsibility to the FCC Rules and Regulations

The MeshConnect Module has been certied per FCC Part 15 rules for integration into products without further testing or

certication. To fulll the FCC certication requirements, the OEM of the MeshConnect Module must ensure that the

information provided on the MeshConnect Label is placed on the outside of the nal product. The MeshConnect Module is

labeled with its own FCC ID Number. If the FCC ID is not visible when the module is installed inside another device, then

the outside of the device into which the module is installed must also display a label referring to the enclosed module. This

exterior label can use wording such as the following: “Contains Transmitter Module FCC ID: W7Z-ICP0” or “Contains FCC

ID: W7Z-ICP0”

The OEM of the MeshConnect Module must only use the approved antenna, (PCB Trace Antenna) that has been certied

with this module. The OEM of the MeshConnect Module must test their nal product conguration to comply with Uninten-

tional Radiator Limits before declaring FCC compliance per Part 15 of the FCC rules.

Page 13

MeshConnect™ Sub-G Module Series

AGENCY CERTIFICATIONS (Continued)

IC Certication — Industry Canada Statement

The term "IC" before the certication / registration number only signies that the Industry Canada technical specications

were met.

Section 14 of RSS-210

The installer of this radio equipment must ensure that the antenna is located or pointed such that it does not emit RF eld in

excess of Health Canada limits for the general population. Consult Safety Code 6, obtainable from Health Canada's

website: http://www.hc-sc.gc.ca/ewh-semt/pubs/radiation/99ehd-dhm237/index-eng.php

CE Certication — Europe

The MeshConnect 868MHz RF modules has been tested and certied for use in the European Union.

OEM Responsibility to the European Union Compliance Rules

If the MeshConnect module is to be incorporated into a product, the OEM must verify compliance of the nal product to the

European Harmonized EMC and Low-Voltage / Safety Standards. A Declaration of Conformity must be issued for each of

these standards and kept on le as described in Annex II of the R&TTE Directive.

The manufacturer must maintain the user's guide and adhere to the settings described in the manual for maintaining

European Union Compliance. If any of the specications are exceeded in the nal product, the OEM is required to

make a submission to the notied body for compliance testing.

OEM Labeling Requirements

The `CE' mark must be placed on the OEM product in a visible location.

The CE mark shall consist of the initials “CE” with the following form:

· If the CE marking is reduced or enlarged, the proportions given in the above graduated

drawing must be adhered to.

· The CE mark must be a minimum of 5mm in height

· The CE marking must be afxed visibly, legibly, and indelibly. Since the 2400 - 2483.5 MHz

band is not harmonized by a few countries throughout Europe, the Restriction sign must be

placed to the right of the “CE” marking as shown in the picture

SHIPMENT, HANDLING, AND STORAGE

Shipment

The MeshConnect Modules are delivered in trays of 28.

Handling

The MeshConnect Modules are designed and packaged to be processed in an automated assembly line.

Warning The MeshConnect Modules contain highly sensitive electronic circuitry. Handling without proper ESD

protection may destroy or damage the module permanently.

Warning According to JEDEC ISP, the MeshConnect Modules are moisture-sensitive devices. Appropriate handling instruc-

tions and precautions are summarized in Section 2.1. Read carefully to prevent permanent damage due to moisture intake.

Moisture Sensitivity Level (MSL)

MSL 3, per J-STD-033

Storage

Storage/shelf life in sealed bags is 12 months at <40°C and <90% relative humidity.

Page 14

REFERENCES & REVISION HISTORY

MeshConnect™ Sub-G Module Series

Previous Versions Changes to Current Version

0008-00-07-00-000

(Issue ES) December 7, 2010

Initial preliminary datasheet.

Disclaimer

• The information in this document is current as of the published date. The information is subject to change without

notice. For actual design-in, refer to the latest publications of CEL data sheets or data books, etc., for the most

up-to-date specications of CEL products. Not all products and/or types are available in every country. Please

check with an CEL sales representative for availability and additional information.

• No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of CEL. CEL assumes no responsibility for any errors that may appear in this document.

• CEL does not assume any liability for infringement of patents, copyrights or other intellectual property rights of

third parties by or arising from the use of CEL products listed in this document or any other liability arising from the

use of such products. No license, express, implied or otherwise, is granted under any patents, copyrights or other

intellectual property rights of CEL or others.

• Descriptions of circuits, software and other related information in this document are provided for illustrative

purposes in semiconductor product operation and application examples. The incorporation of these circuits,

software and information in the design of a customer’s equipment shall be done under the full responsibility of the

customer. CEL assumes no responsibility for any losses incurred by customers or third parties arising from the use

of these circuits, software and information.

• While CEL endeavors to enhance the quality, reliability and safety of CEL products, customers agree and

acknowledge that the possibility of defects thereof cannot be eliminated entirely. To minimize risks of damage to

property or injury (including death) to persons arising from defects in CEL products, customers must incorporate

sufcient safety measures in their design, such as redundancy, re-containment and anti-failure features.

Page(s)

N/A

Page 15

Loading...

Loading...