User Manual

Innovation from

C Enterprise Ltd

THANK YOU

Thank you for investing in a CEL power tool. The POWER workshop has

been engineered and made to demanding high quality standards, ease of

operations and Proper care of

your POWER workshop will give you years of trouble-free use.

Normal wear and tear, including accessory wear, is not covered under

guarantee. The product is guaranteed for domestic use against manufacturing

faults for a period of 12 months (for additional guarantee period please

refer to the store or agent from which you purchased the product or contact the

nearest authorized dealer). This product is not guaranteed for HIRE purpose.

If you have any questions, please contact us at:

It is possible to download updated owner manuals, view demonstration video

and find information about new products at: www.POWER8workshop.com

Warning: User must read and understand the user manual before using this product to

reduce the risk of injury. Failure to follow all instructions may result in electric shook, fire

and/or serious personal injury. The tool must be used only for its prescribed purpose.

Any use other than those mentioned in this manual will be considered a case of misuse.

The manufacturer shall NOT be liable for any damage or injury resulting from such

cases of misuse.

8

8

safety have taken a major role in development.

(if any)

service@POWER8workshop.com

Tel: (UK) 08453 88 97 69 (US) 800 233 7592

For Repairs and Authorised Dealers please contact:

CEL-UK: Unit 60 Moravian Road Business Pack, Moravian Road, Bristol, BS15 8NF, UK

service@POWER8workshop.com

Tel: (UK) 08453 88 97 69 (US) 800 233 7592

3061583

Dectschland

Bauart

gepruft

Contents

Safety

1. Description of Symbols

2. Getting Started

2.1 General Safety Instructions

2.2 Tool Use and Care - Service

Power Management

3. POWERhandle

3.1 POWERhandle -

3.2 POWERhandle - Additional Safety Rules

3.3 POWERhandle - Operating Instructions

3.4 POWERhandle - Multi-Purpose Button (MPB)

3.5 POWERhandle - Maintenance

4. Charging

4.1 Charging - Specifications and Know Your Products

4.2 Charging - Additional Safety Rules

4.3 Charger Dock - Operating Instructions

4.4 Charger - Secondary Charging Point (SCP)

Handheld Power Tools

5. Drill/Driver

5.1 Drill/Driver - Specifications and Know Your Product

5.2 Drill/Driver - Additional Safety Rules

5.3 Drill/Driver - Operating Instructions

5.4 Drill/Driver - Maintenance

5.5 Drill/Driver - Notes

6. Circular Saw

6.1 Circular Saw - Specifications and Know Your Product

6.2 Circular Saw - Additional Safety Rules

6.3 Circular Saw - Operating Instructions

6.4 Circular Saw - Maintenance

Specifications and Know Your Products

Handheld Power Tools (continue)

7. Jigsaw

7.1 Jigsaw - Specifications and Know Your Product

7.2 Jigsaw - Additional Safety Rules

7.3 Jigsaw - Operating Instructions

7.4 Jigsaw - Maintenance

8. Halogen Light

8.1 Halogen Light - Specifications and Know Your Product

8.2 Halogen Light - Operating Instructions

8.3 Halogen Light - Maintenance

Bench top Functions

9. Case

9.1 Know Your Product

9.2 Post and Accessory Cases Storage and Release

10. Table Saw

10.1 Table Saw - Specifications and Know Your Product

10.2 Table Saw - Additional Safety Rules

10.3 Table Saw - Assembly

10.4 Table Saw - Operating Instructions

10.5 Table Saw - Maintenance

11. Drill Press

11.1 Drill Press - Specifications and Know Your Product

11.2 Drill Press - Additional Safety Rules

11.3 Drill Press - Assembly

11.4 Drill Press - Operating Instructions

11.5 Drill Press - Maintenance

Contents

Contents

Bench top Functions (continue)

12. Scroll Saw

12.1 Scroll Saw - Specifications and Know Your Product

12.2 Scroll Saw - Additional Safety Rules

12.3 Scroll Saw - Assembly

12.4 Scroll Saw - Operating Instructions

12.5 Scroll Saw - Maintenance

13. Table Light

13.1 Specifications and Know Your Product

13.2 Table Light Operating Instructions

Others

14. Spirit Level and Protractor

14.1 Post and Protractor Know Your Product

14.2 Post and Protractor Operating Instructions

15. Trouble Shooting

16. Additional Parts and Accessories

The safety and International symbols and pictographs that appear on this product, in the

owner’s manual and rating plate, represent important information about the product or

instructions on its use.

Wear hearing protection.

Wear eye protection.

Wear breathing protection.

Read the manual.

Warning.

Do not dispose of the batteries.

Return exhausted batteries to

your local collection or

recycling point.

Do not expose to water

Contains Nickel-cadmium

batteries. Battery must be

recycled or disposed of

properly

Always change the battery

pack between temperatures

0°C to 40°C (32°F to 104°F).

Do not burn.

Recycle unwanted materials

instead of disposing of them as

waste. All tools, hoses and

packaging should be sorted,

taken to the local recycling

center and disposed of in an

environmentally safe way.

For indoor use only.

Keep your hands away from

blade or working area.

Double insulation.

MAX 40°C

Description of Symbols

1.0

General Safety Instructions

2.1

Work area

a) Keep your work area clean and well lit.

Cluttered benches and dark areas can cause

accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power

tools create sparks which may ignite the dust or

fumes.

c) Keep bystanders, children, and visitors

away while operating a power tool.

Distractions can cause you to lose control.

Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do not use

any adaptor plugs with earthed (grounded)

power tools.

b) Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators.

c) Do not expose power tools to rain or wet

conditions.

d) Handle the cord carefully. Never use the

cord for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil, sharp

edges or moving parts.

e) When operating a power tool outdoors, use

an extension cord suitable for outdoor use. Use

of a cord suitable for outdoor use reduces the

risk of electric shook.

Personal safety

a) Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use tool when tired or under the

influence of drugs, alcohol or medication. A

moment of inattention while operating power

tools may result in serious personal injury.

b) Dress properly. Do not wear loose clothing

or jewellery. Contain long hair. Keep your hair,

clothing and gloves away from moving parts.

Loose clothes, jewellery, or long hair can be

caught in moving parts.

c) Remove adjusting keys or wrenches before

turning the tool on. A wrench or a key that is left

attached to a rotating part of the tool may result

in personal injury.

d) Do not overreach. Keep proper footing and

balance at all times. Proper footing and balance

enables better control of the tool in unexpected

situations.

e) Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for

appropriate conditions.

f) Avoid accidental starting. Ensure the switch

is in the off-position before plugging. Carrying

power tools with your finger on the switch or

plugging in power tools that have the switch on

invites accidents.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

that these are connected and properly used. Use

of these devices can reduce dust-related hazard.

Tool Use and Care - Service

2.2

h) Only use accessories that are

only

recommended by the manufacturer for your

model. Accessories that may be suitable for

one tool, may become hazardous when used on

another tool.

Service

a) Tool service must be performed only by

qualified repair personnel. Service or

maintenance performed by unqualified

personnel could result in a risk of injury.

b) When servicing a tool, use identical

replacement parts. Follow instructions in the

Maintenance section of this manual. Use of

unauthorized parts or failure to follow

Maintenance instructions may create a risk of

electric shook or injury.

Tool use and care

a) Use clamps or other practical ways to

secure and support the workpiece to a stable

platform. Holding the work by hand or against

your body is unstable and may lead to loss of

control.

b) Do not force tool. Use the correct tool for

your application. The correct tool will do the job

better and safer at the rate for which it is

designed.

c) Do not use the tool if switch does not

turn it on or off. Any tool that cannot be

controlled with the switch is dangerous and must

be repaired.

d) Disconnect the plug from the power

source before making any adjustments,

changing accessories, or storing power

tools. Such preventive safety measures reduce

the risk of starting the power tools accidentally.

e) Store idle tools out of reach of children

and other untrained persons. Tools are

dangerous in the hands of untrained users.

f) Maintain tools with care. Keep cutting

tools sharp and clean. Properly maintained

tools, with sharp cutting edges are less likely to

bind and are easier to control.

g) Check for misalignment or binding of

moving parts, breakage of parts, and any

other condition that may affect the tools

operation. If damaged, have the tool serviced

before using. Many accidents are caused by

poorly maintained tools.

3. POWERhandle

Know Your Product

Voltage:

18V

Batteries

Options:

Charging time: 1 Hour

Weight: 2.2 lbs (0.95 kg)

POWERhandle - Specifications and Know Your Product

3.1

1. Rails

2. Product release latch

3. Rear soft grip

4. Battery cooling vent

5. Electronic coupling

6. Mechanical coupling parts

7. MPB (Multi-Purpose-Button)

8. Power Trigger

9. Front soft grip

10. Loop handle socket

11. Battery cooling vent.

Specifications

1 Hour charge times are based on the 1.5Ah

POWERhandle, Larger Capacity batteries will have

longer charge times

PH01 15x1.2v 1.5Ah Ni-Cd

PH02 15x1.2v 1.5Ah Ni-MH

PH03 15x1.2v 1.7Ah Ni-Cd

PH04 15x1.2v 2.6Ah Ni-MH

POWERhandle - Know Your Product 3.1

1

2

3

4

5

8

9

10

11

6

7

Additional Safety Rules

Battery Packs

a) Ensure the switch is in the off position

before inserting the POWERhandle (battery).

Inserting the battery pack into power tools that

have the switch on invites accidents.

b) A battery operated tool with integral

batteries or a separate battery pack must be

recharged only with the specified charger for

the battery. A charger that may be suitable for

one type of battery may create a risk of fire when

used with another battery.

c) Use battery operated tool only with

specifically designated battery pack. Use of

any other batteries may create a risk of fire.

d) The battery pack for this tool has been

shipped in a low charge condition. You should

charge the battery pack fully before use.

e) Avoid conducting short charges. Make sure

that the battery is fully charged every time by

allowing the charger to complete its full charging

cycle.

f) Never allow the drill to come to a complete

standstill before recharging. The battery should

be placed on charge whenever it is noticeably

running down or the drill no longer performs a

task it previously performed.

g) To ensure the longest battery life and best

battery performance, always charge the battery

when the air temperature is between 18-24°C

(65-75°F). Do not charge or store the battery

pack below 4°C (40°F), or above 40°C (104°F).

This is important. Failure to observe this safety

rule could cause serious damage to the battery

pack.

h) Do not incinerate the battery pack even if it is

seriously damaged or can no longer hold a

charge. The battery pack can explode in a fire.

i) A small leakage of liquid from the battery

pack may occur under extreme usage or

temperature conditions. This does not

necessarily indicate a failure of the battery pack.

However, if the outer seal is broken and this

leakage comes into contact with your skin:

?Wash the affected area quickly with soap and

water

?Neutralise the liquid with a mild acid such as

lemon juice or vinegar

If the leakage gets into your eyes:

?Flush your eyes with clean water for a

minimum of 10 minutes and seek immediate

medical attention. Inform the medical staff

that the liquid is a 25-35% solution of

potassium hydroxide.5. Never attempt to

open the battery pack for any reason. If the

plastic housing of the battery pack breaks

open or cracks, immediately discontinue its

use and do not recharge it.

j) Do not store or carry a spare battery pack in

a pocket or toolbox or any other place where it

may come into contact with metal objects. The

battery pack may be short circuited causing

damage to the battery pack, burns or a fire.

I) If the battery of the POWERhandle (battery

pack) utilises nickel-cadmium cells, beware that

cadmium is considered to be a toxic material.

k) Use an environmentally safe disposal unit at

a municipal waste disposal centre to dispose of

a damaged or worn out battery, or return it to

your dealer.

POWERhandle - Additional Safety Rules

3.2

1. To fit the POWERhandle to a product, grip

one in each hand and align the rails. Push the

POWERhandle forward onto the product until it

‘clicks’ and will move no further. To ensure that it

is fully assembled, try to pull them apart; they

should be locked together.

2. To release a POWERhandle from a product,

first pull the release slider down with your thumb

whilst gripping the handle. Grip the product head

with the other hand and pull the POWERhandle

backwards. The handle should easily slide off

the product.

All POWER8 components are connected and

disconnected in this way; it is also necessary to

slide the product release slider down to remove

the POWERhandle from the charger dock.

POWERhandle - Operating Instructions

3.3

1

2

2

1

2

POWERhandle - Multi-Purpose Button (MBP)

3.4

The MPB (Multi-Purpose-Button) will adapt its

function to the requirements of the product

attached to the POWERhandle.

For example when the POWERhandle is

connected to;

The Drill/Driver:

direction control

The Halogen Light: .

on / off / flashes (press trigger)

The Jigsaw and Circular Saw:

safety button, pressed before the

trigger is released.

The MPB has 3 normal positions; fully left,

centred and fully right. It is not possible to move

the MPB when the trigger is pulled and when the

MPB is centred the trigger will be locked

forward.

The trigger will also perform differently when the

POWERhandle is attached to different products.

Some products may require variable power,

others a simple on/off. For example: the drill

spindle speed is controlled by the amount the

trigger is pulled, but the Circular Saw only

requires on/off.

4. Charging Dock and

Secondary Charger (SCP)

Charging - Additional Safety Rules

Know Your Product

Input:

120V~240V AC 50/60Hz 35W

Output:

18V DC 1.5A

Charging time: 1 Hour

Specifications

Charging - Specification and Know Your Product

4.1

1. Before using the charger (Handle Dock), read

all the instructions and cautionary markings on

the charger and battery pack (POWERhandle)

as well as the instructions on using the battery

pack.

2. This charger is designed for indoor use only.

Do not charge your batteries outdoors.

3. DANGER: Do not allow any liquid to come

into contact with the charger. There is a danger

of electric shook.

4. The charger is not intended for any use other

than charging the exact type of rechargeable

battery pack as supplied with the charger. Any

other use may result in the risk of fire, electric

shook or electrocution.

5. To reduce the risk of an electric shook, unplug

the charger from the power supply before

attempting to clean it.

6. Do not disassemble the charger. Take it to an

authorised service center when service or repair

is required. Incorrect re-assembly may result in

the risk of fire, electric shock or electrocution.

7. Do not pull on the lead of the charger to

disconnect it from the power source. Do not

carry the charger by the cable. Protect the cable

from sharp objects, heat and oil; have it replaced

if damaged.

4.2

Secondary

Charger

Point(SCP)

Charger Dock

POWERhandle

LED Display

1 Hour charge times are based on the

1.5Ah POWERhandle, Larger Capacity

batteries will have longer charge times

Charging Dock - Operating Instructions

4.3

The POWERhandle has been shipped in a low

charge condition. You should charge the battery

fully before use.

WARNING. Do not throw used POWERhandles

into a fire or water; it could cause an explosion!

NOTE. It is necessary to slide down the product

release latch in order to remove the

POWERhandle from the charger dock, or from

the tools.

To charge the POWERhandle slide it into the

charger dock; the rails of the POWERhandle

should be aligned with the rails of the charger

dock. Slide the battery down until it “clicks” into

position. Connect the mains plug to a suitable

mains outlet.

LED’s on the top of the charger dock

will display the battery’s condition.

When the red LED is on, the case is

correctly connected to the mains

power. A green flashing LED means

fast charging. When the green LED is

on, the POWERhandle is fully charged.

NOTE. The RED LIGHT may flash when a hot

battery is or

.

. The battery could take

up to an 1 hour to cool to the optimal charging

temperature.

attached for charging

The battery will not charge whilst the red light is

flashing; the Battery is undergoing a cooling off

period to protect their life

when you

press the stop button while using the product in

bench mode This is normal and you can

continue using your product while its

performance is still normal (DO NOT run the

battery completely flat).

Plugged

Charging

Full

Charging

Error

Battery

Hot

Charging - Secondary Charger Point (SCP) 4.4

As well as the main charger dock the

POWER8works is fitted with a secondary

charger point(SCP). This allows a

POWERhandle to be charged while a second

POWERhandle is powering the

POWER8workshop benchtop functions.

Note: T

hen the secondary charger

point is removed from its pocket. The secondary

charger point must be correctly replaced into the

side of the charger dock to start charging the

POWERhandle in the dock.

As soon as a POWERhandle is connected to the

SCP, and the mains plug is connected to a

suitable power source, it will start the charging

cycle.

he main dock will not charge a

POWERhandle, w

To obtain the best life for the battery:

Never allow the battery to completely discharge;

it should be placed on charge whenever it is

noticeably running down, or the tool no longer

performs a task it previously performed.

Avoid conducting short charges. Make sure that

the battery is fully charged every time by

allowing the charger to complete its full charging

cycle.

Avoid allowing loose items like screws or nails

etc. to be stored with battery packs as this may

cause a fire or explosion.

Always unplug the charger when not in use and

store in a dry, secure place. Avoid charging or

storing your battery in temperatures below 0°C

(32°F), and above 40°C

(104°F).

ambient temperature

5. Drill/Driver

Drill/Driver - Specifications and Know Your Product 5.1

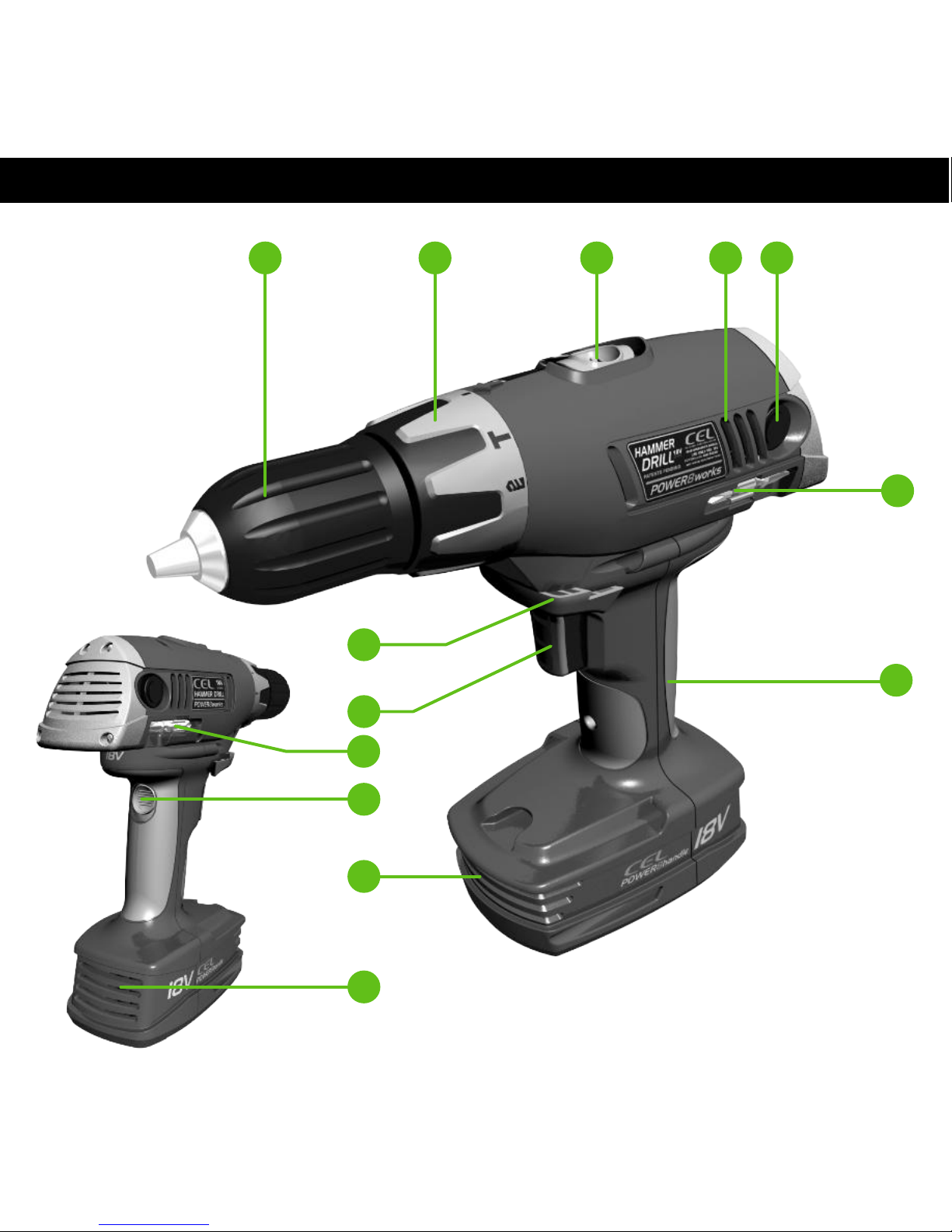

Know Your product

1. Variable power trigger/Stop

2. MPB(Direction selector/lock)

3. Soft grip

4. Motor cooling vents

5. Keyless chuck

6. 2 Speed gearbox selector

7. Torque/Hammer selector

8. Replaceable brush cover for

Hammer drill/driver

9. Battery cooling vents

10. Handle release latch

11. Driver bit

NOTE. Hammer Mode is not available on drill model WS1-LD01

Voltage: 18V

No load speed: 0-350, 0-950 RPM (LIGHT)

Torque settings:

21 Positions (LIGHT)

Max drilling capacity:

Steel 1/2” (13 mm)

Wood 1 1/10” (28 mm)

Concrete 1/2” (13 mm)

Hammer impact frequency:

0-5,600, 0-20,000 min

-1

Single Sleeve

Drill chuck capacity:

Weight: (WS1-HD01) 5.3lbs (2.4 kg)

Specifications

½” (13 mm) keyless

Weight: (WS1-LD01) 4.2lbs (1.9 kg)

Double Sleeve

Drill chuck capacity:

⅜” (10 mm) keyless

0-350, 0-1,250 RPM (HAMMER)

18+1+1 Positions (HAMMER)

67

2

8

1

9

3

11

5 4

9

10

11

Drill/Driver - Know Your Product

5.1

Additional Safety Rules

Cordless Drills & Drivers

a) Hold tool by insulated gripping surfaces when

performing an operation where the drill bits may

contact hidden wiring. Contact with a “live” wire

will make exposed metal parts of the tool “live”

and shock the operator.

b) Always wear safety goggles or eye protection

when using this tool. Use a dust mask or

respirator for applications which generate dust.

c) Secure the material being drilled. Never hold

it in your hand or across your legs. Unstable

support can cause the drill bit to bind causing

loss of control and injury.

d) Position yourself to avoid being caught

between the tool or side handle and walls or

posts. Should the bit become bound or jammed

in the work, the reaction torque of the tool could

crush your hand or leg.

e) If the bit becomes bound in the workpiece,

release the trigger immediately, reverse the

direction of rotation and slowly squeeze the

trigger to back out the bit. Be ready for a strong

reaction torque. The drill body will tend to twist

in the opposite direction as the drill bit is rotating.

f) Do not grasp the tool or place your hands too

close to the spinning chuck or drill bit. Your

hand may be injured.

g) When installing a drill bit, insert the shank of

the bit well within the jaws of the chuck. If the bit

is not inserted deep enough, the grip of the jaws

over the bit is reduced and the loss of control is

increased.

h) Do not use dull or damaged bits and

accessories. Dull or damaged bits have a

greater tendency to bind in the workpiece.

i) When removing the bit from the tool avoid

contact with skin and use proper protective

gloves when grasping the bit or accessory.

Accessories may be hot after prolonged use.

Check to see that keys and adjusting wrenches

are removed from the drill before switching the

tool on. Keys or wrenches can fly away at high

velocity striking you or a bystander.

j) Do not run the drill while carrying it at your

side. A spinning drill bit could become entangled

with clothing and injury may result.

WARNING! Some dust created by power

sanding, sawing, grinding, drilling and other

construction activities contains chemicals known

to cause cancer, birth defects or reproductive

harm. Some examples of these chemicals are:

a) Lead from lead-based paints

b) Crystalline silica from bricks and cement and

other masonry products, and

c) Arsenic and chromium from chemically

treated lumber.

Your risk from these exposures varies,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals work in a well ventilated area, and

work with approved safety equipment, such as

dust masks that are specifically designed to filter

out microscopic particles.

Drill/Driver - Additional Safety Rules

5.2

Use the MPB switch on the POWERhandle to

select the direction of rotation, then pull the

trigger. This trigger switch is an electronic

variable speed control which enables the user to

vary the speed continuously. The speed varies

according to how far the trigger switch is

depressed. The further it is depressed the faster

the chuck will rotate and the lighter it is

depressed, the slower it will rotate.

To stop the drill, release the trigger switch.

NOTE. You can only change the direction of the

rotation of the drill using the forward / reverse

switch when the trigger is NOT depressed.

Drilling uses the forward mode. The reverse

mode is intended for the removal of screws.

Drilling Positions

This symbol indicates the DRILLING MODE.

Used for all normal drilling (wood, aluminium,

and steel) in this mode the clutch is deactivated.

This symbol indicates the HAMMER MODE.

(some models of this product have hammer

function) This mode will activate the hammer

action while drilling. For best results in hammer

mode, set the gear selector to high gear.

NOTE. Hammer Mode is not available on the

drill model WS1-LD01

Torque Adjustment/Hammer Selection Collar

By rotating the torque adjustment / hammer

selection collar behind the chuck, it is possible to

adjust the torque to each of the 20 settings, or

select hammer action setting.

The range of 20 torque settings allows better

control when using the drill as a screwdriver as it

prevents over-tightening of the screws.

The symbols circling the collar are used to

indicate the level of torque. The larger the

symbol or number on the collar, the higher

torque and the larger the fastener which can be

driven. To select any of the symbols, rotate the

collar until the desired symbol aligns with the

arrow head indicator on the housing.

Speed Gearbox

The 2 Speed Gearbox allows you to select a

gear with the optimum speed and torque to suit

the application.

NOTE. When changing the gear selector ensure

the drill is not operating.

To select the LOW gear (low speed, high torque

setting), pull the gear selector back, always from

the chuck. The word LOW will be displayed.

To select the HIGH gear (high speed, low torque

setting), push the gear selector forward, towards

the chuck. The word HIGH will be displayed.

NOTE. Hammer Mode is not available on the

drill model WS1-LD01

Drill/Driver - Operating Instructions

5.3

Inserting and Removing Cutting tools

For Two Sleeve Chucks

Hold the rear sleeve of the chuck, turn the front

sleeve in a direction which releases the jaws.

For Single Sleeve Chucks

The drill is fitted with an auto spindle lock which

means if you try and rotate the chuck by hand

the spindle of the drill will automatically lock.

You only need to grasp the chuck and rotate the

chuck housing to remove or fit accessories.

This drill has a keyless chuck, hence the chuck

key is not needed to secure a bit in the drill.

Always set the MPB switch to the center, lock

'OFF' position, when installing and removing bits.

Open the chuck jaws by firmly holding the chuck

housing and rotating the housing in an anticlockwise direction. Open the jaws sufficiently to

fit the desired accessory.

Ensure the accessory is fully inserted, so that

the jaws of the chuck grip onto the flat section of

the accessory.

To firmly clamp the accessory in the chuck,

grasp the housing and rotate the chuck housing

in a clockwise direction. Ensure the bit is

retained firmly or the chuck jaws maybe

damaged.

To remove the accessory, open the chuck jaws

by firmly holding the housing and rotating the

chuck housing in an anti clockwise direction.

Open the jaws sufficiently to remove the

accessory.

Drilling Metals

1) For maximum performance, use high speed

steel bits for metal or steel drilling.

2) Ensure that the torque adjustment / hammer

selection collar is in normal drilling mode.

3) Begin drilling at a very low speed to prevent

the bit from slipping off the starting point.

4) Always clamp sheet metal.

5) Support thin metal with a block of wood to

avoid distorting it.

6) Use a punch to mark the centre of the hole.

7) Use a suitable lubricant for the material you

are working on.

Use: For:

Oil Steel

Turpentine or paraffin Aluminium

Do not lubricate Brass, copper or cast

iron

Drilling plastics and plastic coated chipboard

a. Use high-speed drill bits

b. See drilling wood

Drill/Driver - Operating Instructions

5.3

Drilling wood

1) For maximum performance, use high speed

steel bits for wood drilling.

2) Ensure that the mode selector is in normal

drilling mode.

3) Begin drilling at a very low speed to prevent

the bit from slipping off the starting point.

Increase the speed of the drill as soon as the

cutting tool is in the material.

4) When drilling through holes, place a block of

wood behind the workpiece to prevent

ragged or splintered edges on the back side

of the hole.

Drilling masonry

1) For maximum performance use carbidetipped masonry impact bits when drilling

holes in brick, tile, concrete etc.

2) Turn the torque collar to hammer mode, or

drill if unavailable.

3) Apply light pressure and medium speed for

best results in brick.

4) Apply additional pressure and high speed for

hard materials such as concrete.

5) When drilling holes in tile, practice on a scrap

piece to determine the best speed and

pressure.

WARNING. Never attempt to lock the trigger

switch in the on position, do not lock the trigger

on jobs where your hammer drill may need to be

stopped suddenly.

All drilling operations

1) Mark off the centre of the hole using a centre

punch or nail.

2) Don't force the drill, let it work at its own

pace.

3) Keep the drill bit sharp.

4) Reduce pressure as the drill is about to

break through the item being drilled.

Maintenance

1) Store the tool, instruction manual and

accessories in a secure place. This way you

will always have all the information and parts

on hand.

2) Keep the tool's air vents unclogged and

clean at all times.

3) Remove dust and dirt regularly. Cleaning is

best done with compressed air or a rag.

4) Never use caustic agents to clean plastic.

CAUTION. Do not use cleaning agents to clean

the plastic parts of the tool. A mild detergent on

a damp cloth is recommended. Water must

never come into contact with the tool.

General Inspection

Regularly check that all the fixing screws are

tight. They may vibrate loose over time.

Drill/Driver - Operating Instructions

5.3

Drill/Driver-Maintenance

5.4

Drill/Driver - Notes

5.5

6. Circular Saw

Know Your Product

1. Power trigger/Stop

2. MPB (Safety lock)

3. Motor cooling vent

4. Hex key

5. Soft grip

6. Handle release latch

7. Blade lock bolt

8. Auxiliary handle

9. Saw dust exhaust

10. Battery cooling vent

11. Depth adjustment lock

12. Lower blade guard lever

13. Spindle lock

14. Bevel angle lock knob

17. Fence locking knob

18. Fence angle lock knob

15. 45° Bevel cut guide noch

16. Straight cut guide noch

Voltage: 18V

No load speed:

Cutting depth @ 0º:

Weight: 7.3lbs (3.3 kg)

Specifications

3,500 RPM

1

9

/

16” (40mm)

Cutting depth @ 45º:

1 ” (28mm)

Saw Blade Options:

Blade bore:

3

/8” (10mm)

1

/16” (2mm)

Circular Saw - Specifications and Know Your Product

6.1 Circular Saw - Know Your Product

1

/

8

2

WS1-SB01 - 5 / " (136mm)

5

24 tooth TCT

kerf

5½” (140mm)

18 tooth TCT

0.06" (1.5mm) kerf

WS1-SB02 -

87 10

13

15

11

6 6

16

4

9

1

2

5

12

18

3

6.1

14

17

Circular Saws - Additional Safety Rules

6.2

Additional Safety Rules

Circular Saws

a) Keep hands away from cutting area and

blade. Keep your second hand on the auxiliary

handle, or motor housing. If both hands are

holding the saw, they cannot be cut by the blade.

b) Do not reach underneath the workpiece.

The guard cannot protect you from the blade

below the workpiece.

c) Adjust the cutting depth to the thickness of

the workpiece. Less than a full tooth of the

blade teeth should be visible below the

workpiece.

d) Never hold the piece being cut in your hands

or across your leg. Secure the workpiece to a

stable platform. It is important to support the

work properly to minimise body exposure, blade

binding, or loss of control.

e) Hold the power tool by the insulated grip

when performing an operation where the cutting

tool may contact hidden wiring or its own cord.

Contact with a “live” wire will also make exposed

metal parts of the power tool “live” and shock the

operator.

f) When ripping, always use a rip fence or

straight edge guide. This improves the accuracy

of cut and reduces the chance of the blade

binding.

g) Always use blades with the correct size and

shape (diamond versus round) or arbour holes.

Blades that do not match the mounting hardware

of the saw will run eccentrically, causing loss of

control.

h) Never use damaged or incorrect blade

washers or bolt. The blade washers and bolt

were specifically designed for your saw, for

optimum performance and safety of operation

I) Wear goggles, ear protection and breathing

mask for better protection yourself against

personal Injury.

Causes and operator prevention of kickback

?Kickback is a sudden reaction to a pinched,

bound or misaligned saw blade, causing an

uncontrolled saw to lift up and out of the

workpiece towards the operator.

?When the blade is pinched or bound tightly

by the kerf closing down, the blade stalls and

the motor reaction drives the unit rapidly

back towards the operator.

?If the blade becomes twisted or misaligned in

the cut, the teeth at the back edge of the

blade can dig into the top surface of the

wood causing the blade to climb out of the

kerf and jump back towards operator.

Kickback is the result of tool misuse and/or

incorrect operating procedures or conditions and

can be avoided by taking proper precautions as

given below.

a) Maintain a firm grip with both hands on the

saw and position your arms to resist kickback

forces. Position your body to either side of the

blade, but not in line with the blade. Kickback

could cause the saw to jump backwards – you

will be able to control its force by standing on the

side.

b) When the blade is binding, or when

interrupting a cut for any reason, release the

trigger and hold the saw motionless in the

material until the blade comes to a complete

stop. Never attempt to remove the saw from the

work or pull the saw backward while the blade is

in motion or kickback may occur. Check the

situation and take corrective actions to eliminate

the cause of blade binding.

c) When restarting a saw in the workpiece,

centre the saw blade in the kerf and check that

the saw teeth are not engaged into the material.

If saw blade is binding, it may kick back from the

workpiece as the saw is restarted.

d) Support large workpieces to minimize the

risk of blade pinching and kickback. Large

workpieces tend to sag under their own weight.

Supports must be placed under the panel on

both sides, near the line or cut and near the

edge of the piece.

e) Do not use dull or damaged blades.

Unsharpened or improperly set blades produce

a narrow kerf causing excessive friction, blade

binding and kickback.

f) Blade depth and bevel adjusting locking

levers must be tight and secure before making a

cut. If blade adjustment shifts while cutting, it

may cause binding and kickback.

g) Use extra caution when making a “plunge

cut” into existing walls or other blind areas. The

protruding blade may cut objects that can cause

kickback.

Circular Saws - Additional Safety Rules

6.2

Safety instructions regarding lower guard

a) Check lower guard for proper closing before

each use. Do not operate the saw if the lower

guard does not move freely and close instantly.

Never clamp or tie the lower guard in the open

position. If the saw is accidentally dropped,

lower guard may be bent. Raise the lower guard

with the blade guard lever and make sure it

moves freely and does not touch the blade or

any other part, in all angles and depths of cut.

b) Check the operation of the lower guard

spring. If the guard and the spring are not

operating properly, they must be serviced before

use. Lower guard may operate sluggishly due to

damaged parts, gummy deposits, or a build-up

of debris.

c) Lower guard should be retracted manually

only for special cuts such as “plunge cuts” and

“compound cuts”. Raise lower guard by blade

guard lever. As soon as blade enters the

material, the lower guard must be released. For

all other sawing tasks, the lower guard should

operate automatically.

d) Always ensure that the lower guard is

covering the blade before placing the saw down

on bench or floor. An unprotected, coasting

blade will cause the saw to move backward,

cutting whatever is in its path. Be aware of the

time it takes for the blade to stop after the switch

is released.

WARNING!

(POWERhandle) from the tool before making

any adjustments or maintenance, including

changing the blade.

Always remove the battery pack

Circular Saws - Additional Safety Rules

6.2

.

When operating the saw, use safety

equipment including safety goggles, ear

protection, dust mask and protective clothing

including safety gloves.

Do not use the saw to cut firewood.

Ensure that the lighting is adequate in the

work area.

? This appliance is not intended for use by

persons (including children) with reduced

physical sensory or mental capabilities, or

lack of experience and knowledge, unless

they have been given supervision or

instruction concerning use of the appliance

by a person responsible for their safety.

Always stand to one side when operating the

saw.

Never use a cracked or distorted saw blade.

Only use sharp blades.

When cutting round wood, use clamps that

prevent the workpiece from turning.

Never use your hands to remove sawdust,

chips or waste close to the blade.

use blades.

Do not use High Speed Steel (HSS) blades

with this saw.

Rags, cloths and string should never be left

around the work area.

Avoid cutting nails. Inspect the work piece

and remove all nails and other foreign

objects before beginning the cut.

Safety instructions regarding the saw

?

?

?

?

?

?

?

?Only recommended

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

Support the work properly.

Never reach over the blade to remove waste

or off-cuts.

Do not attempt to free a jammed blade

before first switching off the tool.

Do not slow or stop a blade with a piece of

wood. Let the blade come to rest naturally.

If you are interrupted when operating the

saw, complete the process and switch off the

tool before looking up.

Periodically check that all nuts, bolts and

other fixings are properly tightened.

Always hold the saw on parts that are

insulated. If you accidentally cut into hidden

wiring or the saw's own cable, the metal

parts of the saw will become “live”.

Never use the saw near flammable liquids or

gases.

Note the direction of rotation of the motor and

the blade.

Do not lock the movable guard in the open

position and always ensure that it is working

properly, freely rotating and returning to fully

cover the teeth of the blade.

This circular saw is installed with a riving

knife. The function of a riving knife is to

prevent the work piece from closing onto the

blades. It must be securely fitted clear of the

blade.

Always use the riving knife provided except

when plunging in the middle of work piece or

glove cut is required.

Switching On and Off

This product, when combined with the

POWERhandle, is fitted with a safety button

(MPB).

1. To start the machine, press MPB. Then

squeeze the trigger.

2. Release the safety button when the machine

starts. The machine will can now run

continuously.

3. To stop the machine, release the on/off trigger.

WARNING: The tool runs for approximately 2

seconds after it has been switched off. Let the

motor come to a complete standstill before

setting the tool down.

Adjusting the cutting depth

WARNING: Always ensure that the saw is

switched off and the POWERhandle is detached

from the tool before making any adjustments.

Refer to 6.1 “Know your product” about the

location of trigger, buttons and locks. Ensure that

the saw is facing away from you.

1. Loosen the depth adjustment lock by pulling

the lever up.

2. Hold the base plate flat against the edge of

the workpiece and lift the body of the saw until

the blade is at the required depth.

3. The correct depth is set when the blade does

not protrude more than ¼” (6.35mm) below the

material being cut. Tighten the depth adjustment

lock by pressing the lever down.

Adjusting the Bevel Angle (Mitre Cut)

WARNING: Always ensure that the saw is

switched off and the POWERhandle is detached

from the tool before making any adjustments.

1. Refer to “6.1 Know your product” about the

location of trigger, buttons and locks. Ensure that

the saw is facing away from you.

2. Loosen the bevel angle locking knob located

at the front of the base plate.

3. Tilt the body of the saw until the required

angle is reached.

4. Use the quadrant scale as a guide.

5. Tighten the locking knob to secure the base

plate.

NOTE: For accurate work it is necessary to

make a trial cut, measure the work and reset the

angle until the correct setting is achieved.

Making a Cut

1. Mark the line of cut on the workpiece. Adjust

the depth of cut and bevel angle as required.

Note: When making 90° cross or rip cuts, align

your line of cut with the outer blade guide notch

on the base of the saw.

Note: When making 45° bevel cuts, align your

line of cut with the inner blade guide notch on

the base of the saw.

2. Rest the front edge of the base on the

workpiece.

Circular Saw - Operating Instructions

6.3

3. Start the motor by depressing the MPB and

squeezing the trigger switch.

NOTE: Always let the blade reach full speed

(approximately 2 seconds) before you begin to

cut into the workpiece.

4. Slowly push the saw forward using both

hands.

NOTE: When making a cut always use steady,

even pressure. Forcing the saw causes rough

cuts and could shorten the life of the saw or

cause kickback. Allow the blade and the saw to

do the work.

5. After completing your cut, release the trigger

switch and allow the blade to come to a

complete stop.

NOTE: Do not remove the saw from the

workpiece while the blade is moving.

NOTE: Since blade thickness varies, always

make a trial cut in scrap wood along the

guideline to determine how much, if any, the

guideline must be offset to get an accurate cut.

Using the Parallel Fence (Cross Cut or Rip

Cut)

The parallel fence allows you to make parallel

cuts in a sheet of wood at a set width.

WARNING: Always ensure that the saw is

switched off and the POWERhandle is detached

from the tool before making any adjustments.

1. Adjust the fence angle to 90° and tighten the

Angle Lock knob (18).

2. Slide the fence (protractor) into the slot in the

sole plate.

3. Adjust the guide to the required width and

secure it into the position with the fence locking

Knob (17).

4. Ensure that the guide rests against the wood

along its entire length to give a consistent

parallel cut.

Making Pocket Cut

1. Set depth and bevel adjustment accordingly.

2. Tilt saw forward with cutting guide notch line

matched up with the line drawn.

3. Raise the Lower Guard by using lower blade

guard lever (12) and hold the saw.

4. With the blade clearing the material to be

cut, start the motor.

5. Gradually lower the back end of the saw

using the front end of the sole plate as the hinge

point.

WARNING: As block starts cutting the material,

release the lower guard immediately. When the

sole plate rests flat on the surface being cut,

proceed cutting in forward direction to end of cut.

Circular Saw - Operating Instructions

6.3

Changing the blade

WARNING. Always ensure that the saw is

switched off and the POWERhandle is detached

from the tool before making any adjustments.

1. Rotate the saw blade by hand while

depressing the spindle lock button until the blade

locks.

2. Turn the blade bolt clockwise using the hex

key provided.

3. Remove the outer blade flange and the

blade bolt.

4. Remove the saw blade from the inner flange

and pull it out.

NOTE: Clean the saw blade flanges thoroughly

before mounting the new saw blade.

5. Mount the new saw blade in reverse order

and tighten the blade bolt.

WARNING. The direction in which the blade

rotates has to be the same as the direction of

the arrow marked on the housing.

Ensure that the spindle lock button is released.

Before using the saw again, check that the

safety devices are in good working order.

IMPORTANT. After replacing the saw blade,

make sure that the blade runs freely by turning it

by hand.

Re-attach the POWERhandle and run the saw

under no load to check that it runs smoothly

before using it to cut any material.

General Inspection

Regularly check that all the fixing screws are

tight. They may vibrate loose over time.

Circular Saw - Maintenance

6.4

Circular Saw - Notes

6.5

7. Jigsaw

Know Your product

Voltage: 18V

0-2400 SPM

Max Cutting Capacity:

Metal ?” (13 mm)

Wood 2” (50 mm)

Weight: 4.5lbs (2.1 kg)

1. Handle release latch

2. Soft grip

3. Power trigger/Stop

4. MPB (Safety lock)

5. Motor cooling vents

6. Blade cover

7. Blade guide wheel

8. Hex screw

9. Blade

10. Sole plate

11. Hex key

12. Angle adjustment bolt

Specifications

No load speed:

Jigsaw Specifications and - Know Your Product 7.1

Jigsaw - Know Your Product

7.1

1

2

3

4

5

6

7

9

97

10

8

10

11

12

Jigsaw - Additional Safety Rules

7.2

Additional Safety Rules

?

When operating the saw, use safety

equipment including safety goggles, ear

protection, dust mask and protective clothing

including safety gloves.

The jigsaw is fitted with an adjustable blade

guide roller, ensure that this is correctly

adjusted.

Do not start the machine with the blade in

contact with the workpiece.

?Check the workpiece for any protruding nails,

screw heads or anything that could damage

the blade.

?Ensure that there are no obstructions

underneath the workpiece; it is easy to cut

into sawhorses and bench tops.

?Hold the machine correctly and adopt a

stable stance.

?Use the correct blade for the job and replace

the blade as soon as it becomes worn. This

will ensure ease of cutting and prolong the

life of the machine.

?Always ensure that the base plate is in firm

contact with the workpiece before starting

the cut.

?Do not force the jigsaw, let the jigsaw do the

work. Forcing the jigsaw will reduce the life

of the blade putting undue pressure on the

machine.

?Allow the jigsaw to stop completely before

removing it from the workpiece.

Cordless Jigsaws

?

?

?

?

?

?

?

?

?

?

?

?

?

?

Do not try and cut a curve that is too tight.

This will put undue pressure on the blade

causing it to snap.

Keep hands away from cutting area and

blade.

Do not reach the underneath the workpiece.

Never use your hands to remove sawdust,

chips or waste close to the blade.

Support the work properly.

Never reach over the blade to remove waste

or “off cuts”.

Do not attempt to free a jammed blade

before first switching off the tool.

If you are interrupted when operating the

saw, complete the process and switch off

before looking up.

Always hold the saw on parts that are

insulated. If you accidentally cut into hidden

wiring or the saw's own cable, the metal

parts of the saw will become “live”.

Never use the saw near flammable liquids or

gases.

The blade roller guide is used to support the

blade when cutting and must be in contact

with the back edge of the cutting blade at all

times and allowed to move freely.

Jigsaw - Operating Instructions

7.3

Switching the Jigsaw On and Off

NOTE: This product when combined with the

POWERhandle is fitted with a safety button

(MPB).

1. To start the machine, press MPB. Then

squeeze the trigger.

2. Release the safety button when the machine

starts. The machine will now run continuously.

3. To stop the machine, release the on/off

trigger.

Making a Cut

1. Start the motor by depressing the MPB and

squeezing the trigger switch .

2. Slowly push the saw forward.

3. After completing your cut, release the trigger

switch and allow the blade to come to a

complete stop.

NOTE: If the jigsaw base is not held firmly onto

the workpiece, the blade will snag and break.

Angle Cutting

CAUTION. Always ensure that the saw is

switched off and the POWERhandle is removed

before any adjustments.

Loosen the hexagonal screw on the underside of

the machine using the included hexagonal key

and tilt the base, using a protractor to achieve

the required angle 0°- 45°. Finally re-tighten the

hexagonal screw.

Blade Roller Guide

When setting the jigsaw for angle cutting or

replacing the blade, set the blade roller guide.

Loosen the hexagonal screw on the underside of

the machine using the included hexagonal key.

With the blade fitted, slide the blade roller guide

mounting plate until the blade is in the groove in

the blade roller guide and the guide is in contact

with the back edge of the blade.

Metal Cutting

When cutting metals, a suitable cooling/cutting

oil must be used. Simply squirt the lubricant onto

the blade or workpiece at regular intervals during

cutting to reduce blade wear.

WARNING: Do not immerse the jigsaw in water

or allow oil to enter the casing. A fatal electric

shock could occur.

Circle Cutting

When starting a cut from the center of the

workpiece, drill a 12 mm diameter hole to ensure

that there is enough clearance for the blade.

Tip

When cutting materials with a decorative or

polished finish, cover either the base of the

jigsaw or the surface of the material being cut

with masking tape or other suitable tape to

prevent scratching.

Jigsaw - Maintenance

7.4

Changing the blade

WARNING. Always ensure that the saw is

switched off and the POWERhandle is detached

from the tool before making any adjustments.

1. To fit the blade, loosen the 2 hexagonal

screws on the blade clamping block.

2. Slide the blade into the locating groove with

the teeth pointing forward.

3. Tighten the hexagonal screws with the

included hexagonal key.

WARNING. The teeth of the jigsaw blade

should be pointing forward away from the user.

IMPORTANT. After replacing the saw blade,

make sure that the hexagonal screws are firmly

tightened and the blade is running freely.

Re-attach the POWERhandle and run the saw

under no load to check that it runs smoothly

before using it to cut any material.

General Inspection

Regularly check that all the fixing screws are

tight. They may vibrate loose over time.

Jigsaw blade fitment type:

(Universal Type)

8. Halogen Light

3

1 2

6

7

Know Your Product

Voltage:

18V

Bulb: 2 x 18v 0.6A Halogen

Bulb Life: Approx 300 hours

Weight: 2.9lbs (1.3 kg)

1. Lens

2. Lens bezel

3. Torch arm

4. Torch body

5. Air cooling vent

6. MPB (Multi-Purpose-Button)

7, Handle trigger (Flash Light)

Specifications

Halogen Light - Specifications and Know Your Product

8.1

4

5

Switching the Halogen Light on and off

NOTE: This product when combined with the

POWERhandle is fitted with Multi-Purpose

Button (MPB).

1. To turn the halogen light on, slide the MPB

to the right.

2. To turn the halogen light off, slide the MPB

to the left.

Flash Light

1. To flash the light, slide the MPB button to

right. Then press and release the handle trigger.

Rotate the halogen light head

1. To swivel the head of the halogen light, hold

the body firmly with one hand.

2. Move the head of the halogen light up and

down as required with the other hand.

button

button

Halogen Light - Operating Instructions

8.2

Replacing the Light Bulb

WARNING. The halogen light immediately

begins to heat up when it is being used. Please

handle the halogen light with care especially

around the light bulb and lens. Extra caution

should be taken when replacing the light bulb.

Allow the light to cool down before attempting to

change the light bulb.

To change the light bulb, hold the top of the light

with one hand and the rim of the halogen light

lens with the other. Start turning the rim of the

lens in a counter clockwise direction.

Continue to turn the rim until it separates from

the body of the halogen light. Handle with care

when doing this to avoid damaging the reflector

or the protective lens.

The burnt out bulb should be removed from the

spring and discarded appropriately.

This halogen light is shipped with a spare light

bulb. It is stored inside the light assembly. You

can see it when you remove the rim and light

assembly. Replace the new bulb in the spring.

Carefully align the rim and light assembly with

the halogen light body. Twist the lens rim in a

clockwise direction to reattach the lens cover.

Cleaning

1. Clean the halogen light regularly. Before

cleaning, remove the battery pack and any

accessories. To clean use ONLY a mild

soap and damp cloth on the housing. Never

immerse the halogen light in water or any

kind of liquid.

2. Remove dust and dirt regularly. Cleaning is

General Inspection

Regularly check that all the fixing screws are

tight. They may vibrate loose over time.

CAUTION. Do not use cleaning agents to clean

the plastic parts of the halogen light. A mild

detergent on a damp cloth is recommended.

Water must never come into contact with the

halogen light.

best done with compressed air or a rag.

3. Do not open the halogen light (other than to

change the light bulb as described above)

Halogen Light - Maintenance

8.3

9. Case

7

1. Vertical post hole

2. Vertical post release lever

3. Angle fence running slot

4. Parallel fence measurement guide

5. Battery power and charger indicators

6. Benchtop On/Off operation buttons

7. Secondary charger point(SCP)

8. Cable storage hooks

9. POWERhandle charger dock

10. Table saw blade slot

11. Scroll saw blade slot

12. Case latch (closed)

13. Case opening handle

14. Case latch (open)

15. Case carry handle

16. Case carry shoulder strap fixing

8

4

5

6

9

2

1

15

16

12

13

14

11

10

3

Case - Know Your Product

9.1

18. Parallel fence measurement guide

19. Future product mount

20. Post storage pocket

21. Rubber feet

22. Angle fence running slot

23. Steel armoured work surface

24. Accessory box storage area

25. Accessory box release button

26.

27. Optional

28. Post (in storage area)

Accessory box location hook

Accessory box

19

18

22

20

26

27

24

25

23

22

Case - Know Your Product 9.1

28

1. Product case lock

2. Internal power coupling

3. Circular saw sole plate pocket

4. Jigsaw sole plate pocket

5. Internal power coupling cable storage

6. User manual storage

6

3

4

5

2

1

Case - Know Your Product

9.1

8

11

7

12

10

13

9

Case - Know Your Product 9.1

7. Post handle

8. Protractor (Optional)

9. Table Clamp

Optional)

10. Drill head

11. Jigsaw head

12. Torch head

13. Circular saw head

14.Extra POWERhandle (

14

Case - Post and Accessory Box Storage and Release

9.2

Post Removal

To remove the post from its storage area, first

close the case lid and ensure that the latches are

both locked. Place the case onto its front face

(handle area) the post should be facing you.

1. Grip the moving part of the post head and pull

it away from the case. This will release the

latch and allow the head of the post to rotate

out.

Note: May use the post handle to slide the post

head away from the case easily.

2. When the latch is clear of the recess rotate out

the metal portion of the post to approx 20°.

3. Now slide the post along the bottom of the

case to allow the other post hook to come free

from the POWER8works.

Post Replacement

To replace the post, once again place the case

onto its front face.

Hook the green post hook into the post storage

pocket.

Rotate the post head and push the active post

hook until the latch “clicks” into recess inside the

case.

Accessory Case Release

4. Press the latch on the back of the case (with

the arrow pointing up) upward, then pull the

accessory case by thumb away from the case to

release it.

1

2

2

3

1

2

4

Accessory Case Release

1

10. Table Saw

Know Your Product

10.1

Table Saw - Specifications and Know Your Product

Voltage: 18V

No load speed:

Specifications

3,500 RPM

Blade bore:

3

/8” (10mm)

Cutting depth @ 0º:

(20mm) ~ (38mm)

Cutting depth @ 45º:

(14mm) ~ (24mm)

Fence

Cut scale

Table saw shield

Work surface

Protractor

Cut scale

Fence lock

3

/

4”

1

/

2”

~1

9

/

16”

15

/

16”

~

2

WS1-SB01 - 5 / " (136mm)

5

24 tooth TCT

kerf

5½” (140mm)

18 tooth TCT

0.06" (1.5mm) kerf

WS1-SB02 -

Saw Blade Options:

1

/16” (2mm)

Please also refer to 2.1 - General Safety

Instructions and 6.2 - Additional Safety Rules Circular Saw before using the table saw.

Do not install the post and/or drill to the bench

for drill Press function while using the table

saw.

Keep guards in place and in working order.

Never operate the tool with any guard or cover

removed. Make sure all guards are operating

properly before each use.

Never start table saw when any rotating

components are in contact with workpiece.

Always use a fence or straight edge guide

when ripping.

Always use a push stick for ripping narrow

stock. A push stick is a device used to push a

work piece through the blade instead of using

your hands. Size and sharp can vary but the

push stick must always be narrower than the

workpiece to prevent the push stick from

contacting the saw blade.

Support large panels to minimize risk of the

blade pinching and kickback.

Provide adequate support to the rear and sides

of the saw table for wide or long workpiece.

Use only correct blades, do not use blades with

incorrect size holes. Never use blade washers or

bolts that are defective or incorrect. The

maximum blade capacity of your saw is 140mm.

Avoid cutting nails. Inspect for and remove all

nails from lumber of workpiece before cutting.

Never touch blade or any moving parts during

use.

Keep hands away from cutting area. Keep hands

away from blades. Do not reach underneath

work or around or over the blade while it is

rotating.

Do not attempt to remove cut material when

blade is moving.

Never attempt to free a stalled saw blade without

first turning the saw OFF.

Guard against kickback. Kickback occurs when

the blade stalls rapidly and workpiece is driven

back resulting in serious personal injury. Stay

out of blade path and turn switch off immediately

if blade binds or stalls.

Never leave the table saw running unattended.

Turn power OFF by pressing the RED Button.

Don't leave tool until it comes to a complete

stop.

Table Saw - Additional Safety Rules

10.2

Table Saw - Assembly

10.3

How to mount the TABLE SAW GUARD:

Warning: Remove the battery handle from the

Circular Saw before assembling the TABLE SAW

GUARD.

If the TABLE SAW GUARD has not been installed,

then follow instructions below:

1. Turn the Circular saw head upside down as (1).

Retract the circular saw shield all the way and hold it

out of the way by using the lever on the side of the

product.

2. Align the protrusion on the metal support of TABLE

SAW GUARD and insert it to the hole on the sole

plate of the Circular saw. Then rotate the rear end of

TABLE SAW GUARD down over the riving blade as

fig.2.

3. Press the rear end of TABLE SAW GUARD down

until the latch hooks up with the sole plate. When it

fits flat with the sole plate of the circular saw. this

should now hold the Circular saw shield out of the

way.

4. The Circular saw is now ready to be installed into

the case.

Warning: Never operate the tool with any guard or

cover removed. Make sure all guards are operating

properly before each use.

NOTE. TABLE SAW GUARD is correctly mounted as

per fig 4 (mounted on when packed away)

NOTE. The Table Saw will NOT operate if the TABLE

SAW GUARD is not correctly mounted.

1

Hold it here

4

2

3

Table Saw - Assembly 10.3

5

6

5. Open the case and push the front of the sole plate

into the pocket on the underside of the case lid.

6. Pull back the green product lock slider and rotate

the rear of the circular saw into the case lid until the

sole plate is against the metal work surface, release

the product lock, check that it returns fully left. If it

doesn’t then the circular saw can’t be fully pushed in.

7. Remove the internal power coupling from its

storage pocket and slide it onto the top of the

circular saw until it will not go any further.

Warning: Never operate the tool with any guard or

cover removed. Make sure all guards are operating

properly before each use.

7

8

9

Table Saw - Assembly

10.3

8. Close the lid of the case and ensure that both latched

are closed.

WARNING the Table Saw will not work unless the lid

is closed.

TO INSTALL THE FENCE:

If required the POST can be used as a parallel fence.

The post can be assembled on to the case on both side

of the saw blade.

9. To install the fence, use the green hook, on the

bottom of the post, to latch under the case lid, pull the

fence tight towards the centre of the case. Then lower

the locking end until the fence lies parallel with the table

surface. Swing the head of the fence down and press it

down until it hooks into the groove on the charger dock.

10

Table Saw - Operating Instructions 10.4

On both edges of the case lid there are

dimension to give a guide to the cut width. When

fitting the post it is important to ensure that both

ends of the post are the same distance from the

blade (parallel to the blade), use the dimension

to check this.

Lifting the head of the Post will again release the

fence and allow it to be removed and the

position to be changed.

10. The depth and angle of the blade can be

adjusted by simply lifting the lid and using the

Adjustment knobs, the same as described in the

“Circular Saw Use” section of this user manual.

The angle plate can be used as a angle fence,

by placing it in one of the grooves on the case

work surface.

11. Insert the POWERhandle into the handle

dock, your table saw is now ready to use.

NOTE: When the table saw is configured in the

way you require it is time to add a

POWERhandle into the charger dock, this will

supply power to the case and you can start

cutting your work.

NOTE: Table saw is started and stopped by the

main case operation button above the charger

dock. The table saw will not work unless the

Table Saw Guard is correctly installed and the

case lid is shut. If the Case is connected to the

main then the POWER8handle will be charged

when the table saw is not in operation.

Different Type of Cutting

The Power8 Table Saw can be used for different

wood cutting operations ,as straight-line cutting

operations such as cross cutting, parallel cutting,

angle cutting, bevel cutting, and compound

cutting.

1. Cross cuts are straight 90’ cuts made across

the grain of the workpiece. The wood is fed into

the cut at a 9’ angle to the blade, and the blade

is vertical.

2. Parallel cuts are made with the grain of the

wood. To avoid kickback while making a parallel

cut, make sure the side of the wood rides firmly

against the fence.

3. Mitre cuts are made with the wood at any

angle to the blade other than 90’. The blade is

vertical.

4. Bevel cuts are made with an angled blade.

Bevel cross cuts are across the wood grain, and

bevel rip cuts are with the grain. The rip fence

must alwways be on the left side of the blade for

bevel rip cuts.

5. Compounds (or bevel) mitre cuts are made

with an angled blade and the wood is angled to

the blade.

Please refer to the page labeled"Table Saw

Different Cut Types" in 10.4.

Switching Table Saw On and Off

1. Setup the table saw to the your cutting

requirement with the use of the additional or

optional accessory provided (Parallel Fence,

Protractor or Push Stick).

2. Switch on the machine by pressing the green

operation button above the charger dock.

3. Hold the workpiece firmly with both hands and

feed into the saw blade slowly. For narrow work

which has the fence set closly to the blade use

the push stick end of the post lever to hold the

work down next to the blade.

1. To start the saw, press the green operation

button above the charger dock.

2. The machine will now run continuously.

3. To stop the machine, press the red operation

button above the charger dock.

NOTE: When the table saw is configured in the

way you require it is time to add a

POWERhandle into the charger dock, this will

supply power to the case.

NOTE: The table saw will not work unless the

table saw shield is correctly installed and the

case lid is shut. If the case is connected to the

main then the POWERhandle will be charged

when the table saw in not in operation.

Making a Cut

4. When the cut is made, turn the saw of

f by

pressing the red button.

5. W

ait for the blade to come to a complete stop

before removing the workpiece.

Adjusting the Table Saw

CAUTION. Always ensure that the table saw is

switched of

f and the POWERhandle is removed

before any adjustments are made.

1.

T

o adjust the blade depth, open the lid, and

release the depth adjustment lock then lower the

circular saw to expose the correct amount of

blade, then relock the adjustment lever

.

NOTE:

T

o give better cutting performance, the

blade depth should be set so that the upper

points of the blade is higher than the workpiece

by approximately 3mm (1/8 in) to 6mm (1/4 in).

2. T

o adjust the blade angle, open the lid, adjust

the bevel angle lock knob on the circular saw to

the desired cutting angle.

3.

T

o adjust the width of a cut when using the

fence loosen the fence by raising the post head

slider up. Release the green hook and reattach it

at your desired width. Push the post slider head

down to tighten the fence onto the table surface.

Table Saw - Operating Instructions

10.4

Cutting depth @ 0º:

Cutting depth @ 45º:

¾”(20mm) ~ 1 (38mm)

(14mm) ~ (24mm)

15

/

16”

9

/

16”

1

/

2”

Miter Cut

Rip Cut

1. Position the fence to

the desired distance

from the blade for the

cut. Securely lock the

fence on the table by

pressing the post slider

head down firmly.

3.

1. Remove the fence

2. Adjust the protractor

to the desired angle for

you to cut into the

workpiece.

3. Put the protractor

into the groove at the

front of the saw table.

4. Hold the workpiece

and protractor firmly

together and feed

slowly the workpiece

into the saw blade

Hold the workpiece

and protractor firmly

together and feed

them slowly into the

saw blade.

4. Use the provided

push stick or a push

block to move the

workpiece through the

cut and past the blade.

Cross Cut

1. Remove the fence

2. Adjust the protractor

angle to 90°.

3. Put the protractor into

the groove at the front of

the saw table.

4. Hold the workpiece

and protractor firmly

together and feed

slowly into the

saw blade.

the

workpiece

Table Saw - Operating Instructions 10.4

Table Saw Different Cut Types

Cross Cut

Rip Cut

Miter Cut

Bevel Cross Cut

Bevel Rip Cut

Cross Cut

Miter Cut

Rip Cut

Store the Table Saw Properly

WARNING. Always ensure that the saw is

switched off and the POWERhandle is detached

from the tool before disassemble the product

from the case.

General Inspection

Regularly check that all the fixing screws are

tight. They may vibrate loose over time.

1. Open Case lid, slide the internal plug away

from the Jigsaw.

2. Put internal plug back to its storage area.

3. Slide back the product lock, and remove the

Circular Saw Head from the bottom of the lid.

4. Replace the tools to the Lift Out Tray before

putting them back into the Case for storage.

NOTE: The Lift Out Tray is for easy storage and

protection of tools inside the Case.

5. Disconnect the product from the mains power.

Bevel Cut

1. Open the lid of the saw table, adjust the

circular saw bevel angle by releasing the lock

knob and re-tightening at the desired angle.

2. Position the fence at the desired distance

from the blade.

3. Use the provided push stick or a push block to

move the workpiece through the cut and past the

blade.

WARNING: Never push a small piece of wood

into the blade with your hand, always use the

provided push stick or a push block.

Table Saw-Maintenance

10.5

Table Saw - Operating Instructions

10.4

Bevel Cut

11. Drill Press

Know Your product

4.1

4.2

Please also refer to 2.1 - General Safety

Instructions and 5.2 - Additional Safety Rules Cordless Drill/Driver before using the Drill Press.

Ensure the circular saw or jigsaw are NOT

installed onto the lid of the case before starting

to assemble the drill press.